Integrating Circular Economy Principles in the New Product Development Process: A Systematic Literature Review and Classification of Available Circular Design Tools

Abstract

1. Introduction

- What circular design tools and methods are currently available, and how can they be classified to support the early stages of the NPD process?

- To what extent do these tools overlap, and what are the key gaps in their characteristics and applicability within the NPD process?

2. Methodology

2.1. Systematic Literature Review

2.2. Classification Criteria

2.3. Mapping Tools to the NPD Process

3. Results and Interpretations

3.1. Overview of Identified Tools

3.2. Classification of Circular Design Tools

3.2.1. Tool Format

3.2.2. Data Type

3.2.3. Industry Sector

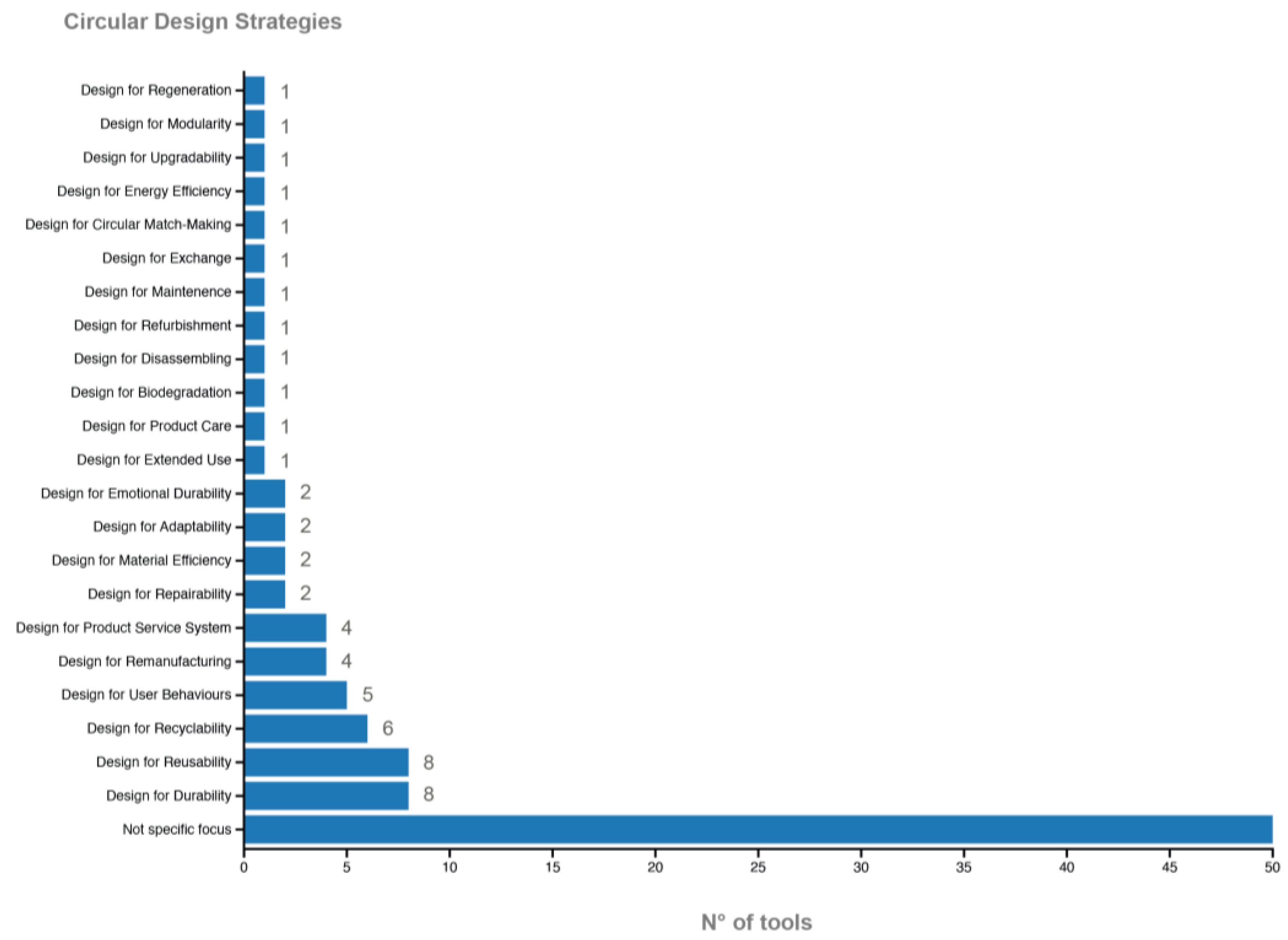

3.2.4. Circular Strategies Covered

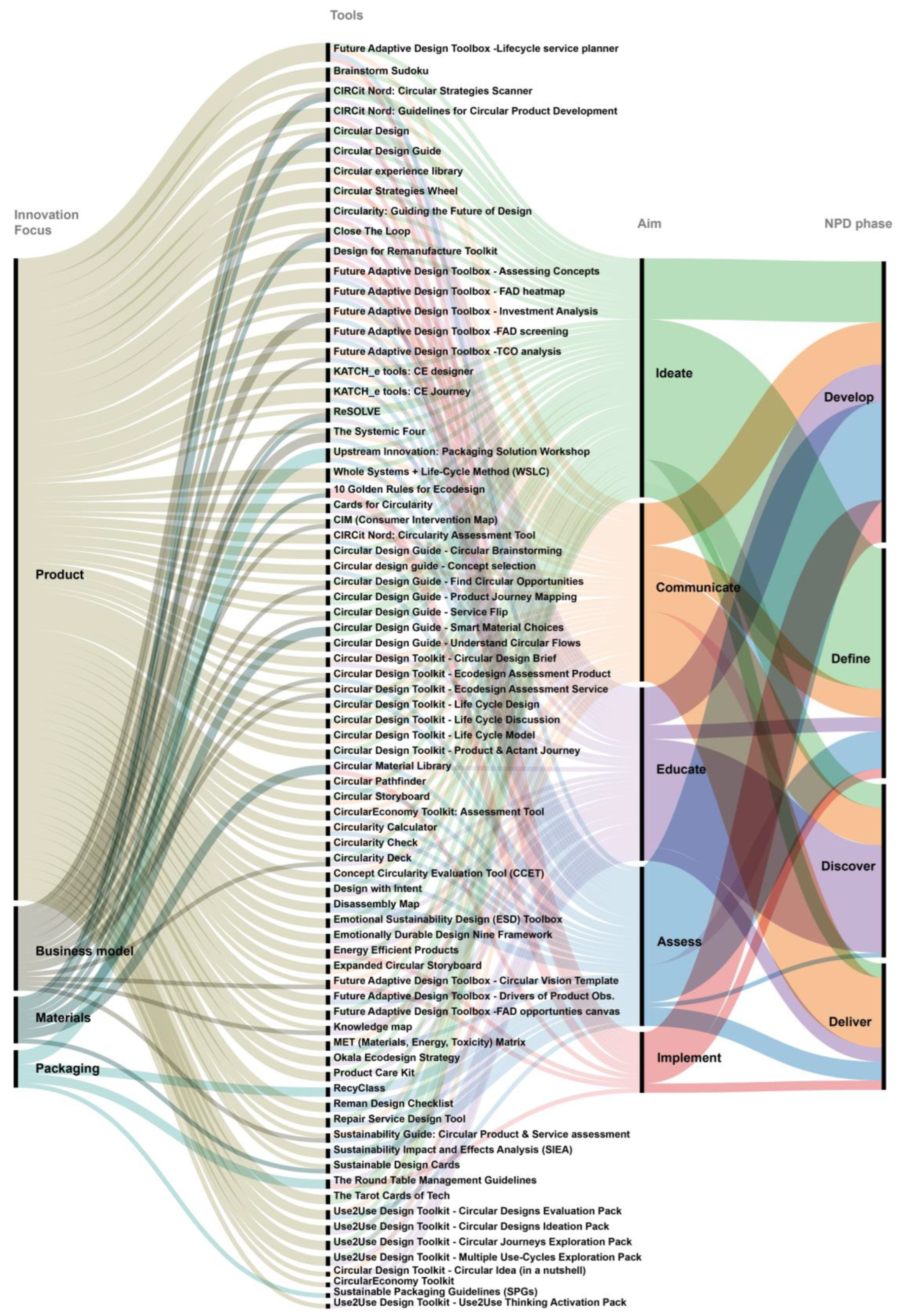

3.3. Tool Distribution Across NPD Phases

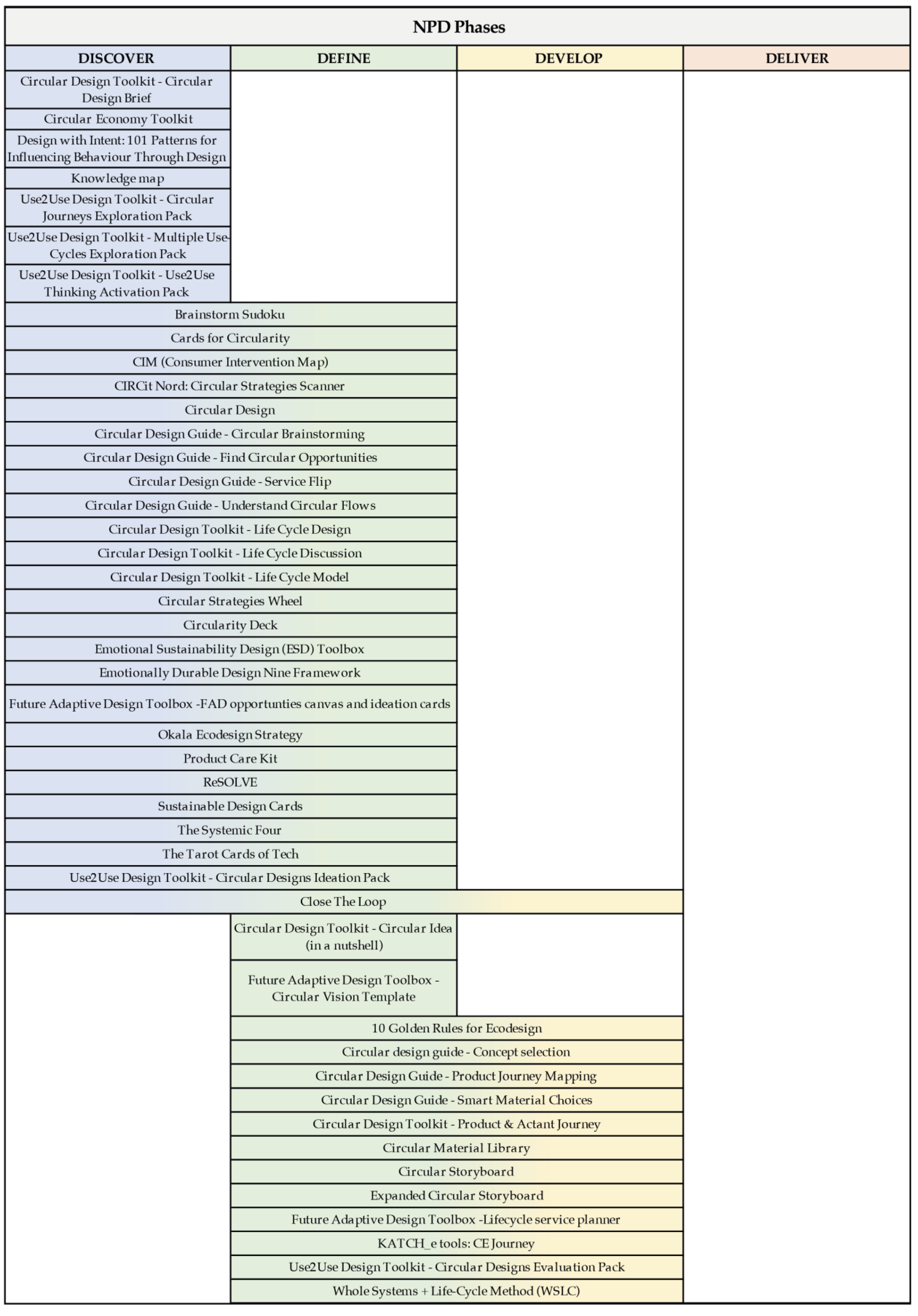

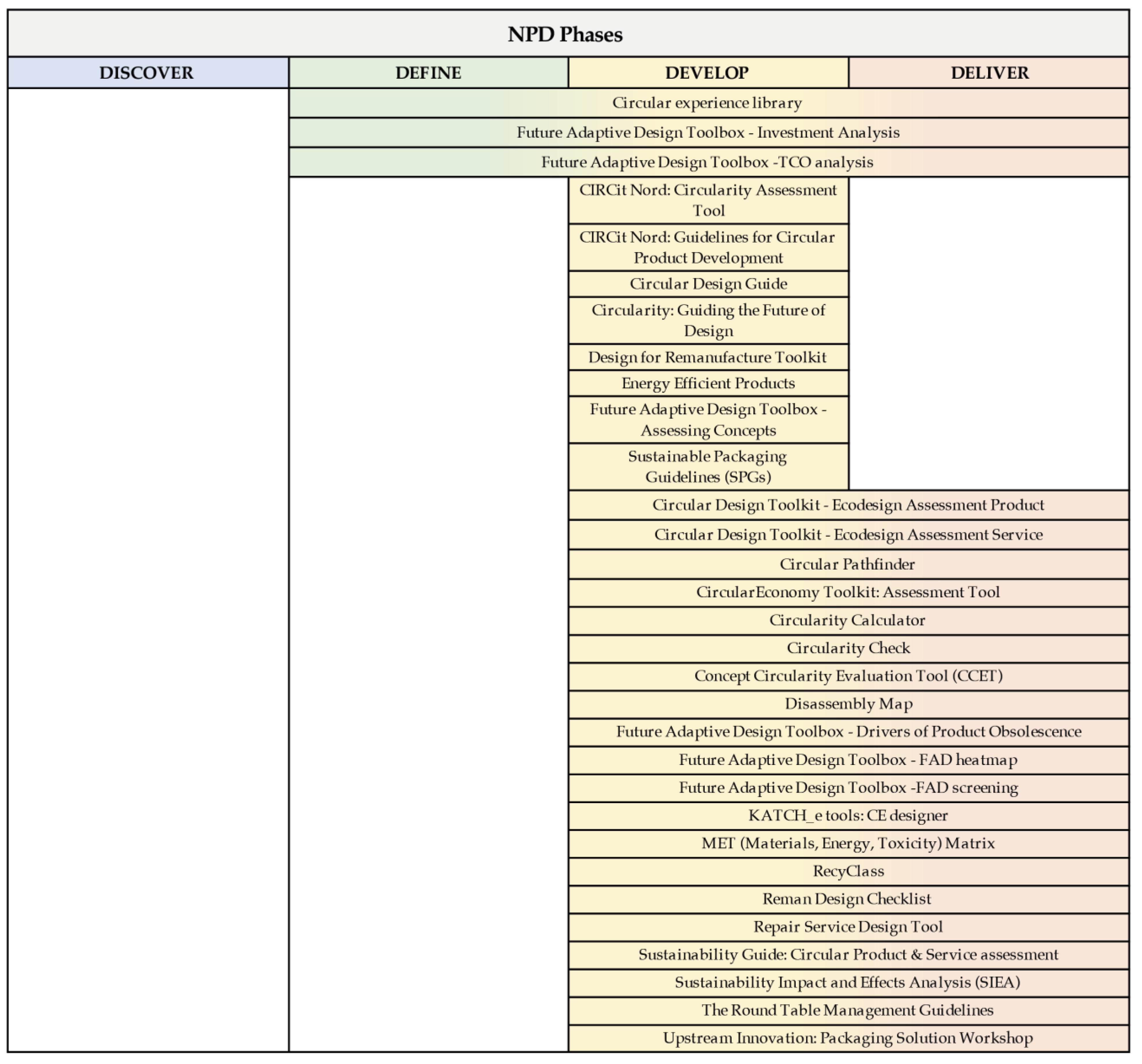

- The Discover phase includes the highest number of tools (32), primarily supporting early-stage market analysis and ideation.

- The Define phase follows closely, with 42 tools, which mainly aid in concept development, strategy selection, and preliminary feasibility analysis.

- The Develop phase has 44 tools, highlighting a strong presence of implementation and assessment tools that support refining, prototyping, and evaluating circular solutions.

- The Deliver phase, with 23 tools, primarily includes resources for finalising design specifications, preparing for production, verifying compliance, and facilitating communication. The limited availability of tools for the Deliver phase indicates a clear gap in post-market circularity tracking and consumer engagement strategies.

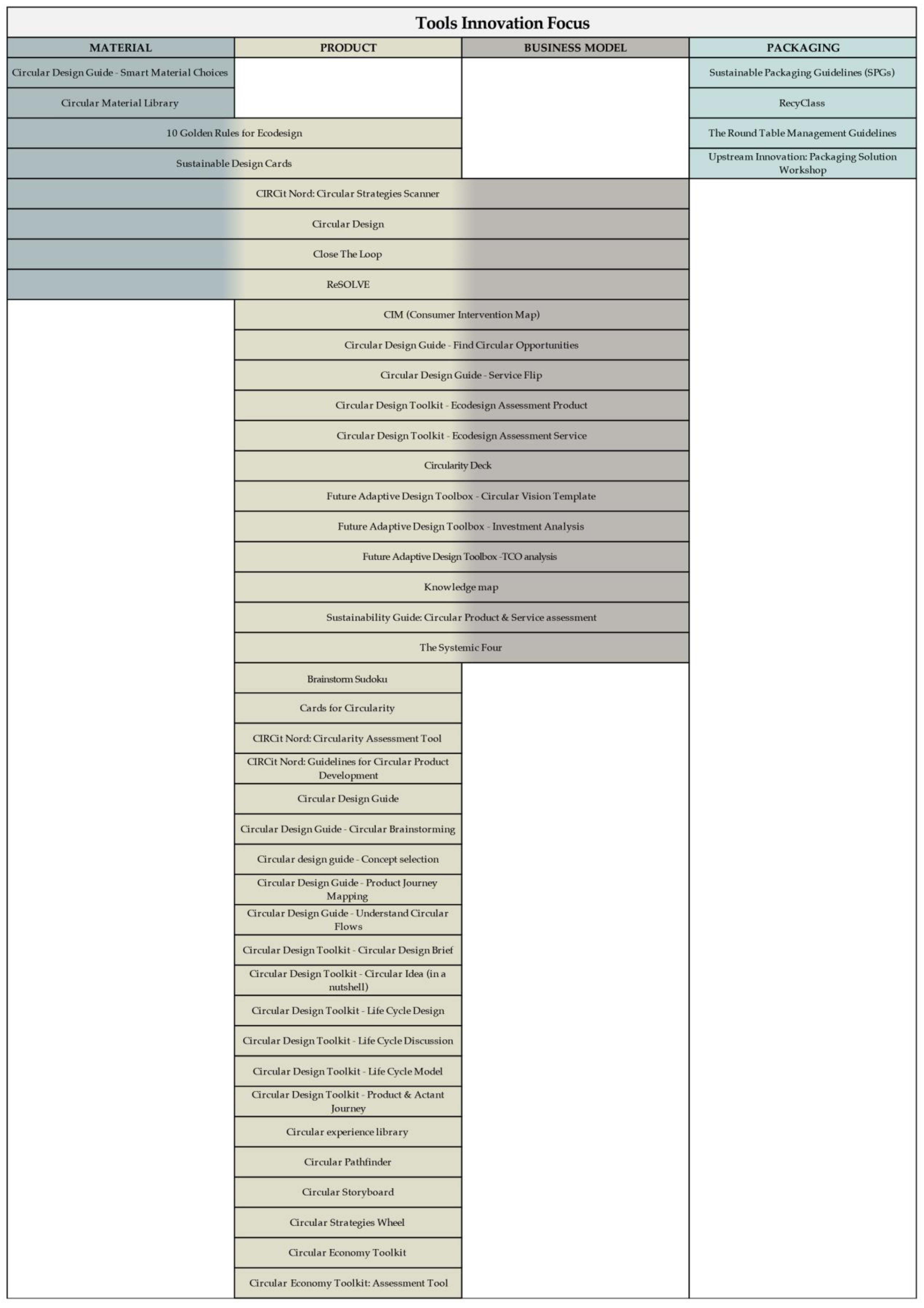

- Classifying the tools by innovation focus revealed the following:

- Product-focused tools are predominately available across the Discover, Define, and Develop phases.

- Business model-oriented tools are concentrated mainly in the Discover and Define phases, aiding strategic planning and revenue model development.

- Material-focused tools appear mainly in the Develop and Deliver phases, specifically supporting material selection and sustainable resource management.

- Packaging-related tools are underrepresented, primarily appearing in the Develop and Deliver phases, suggesting the need for additional resources focused explicitly on sustainable packaging design.

4. Discussion

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Heshmati, A. A Review of the Circular Economy and Its Implementation; IZA Discussion Paper No. 9611; IZA—Institute of Labor Economics: Bonn, Germany, 2016. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Towards a Circular Economy: Business Rationale for an Accelerated Transition. 2015. Available online: https://www.ellenmacarthurfoundation.org/towards-a-circular-economy-business-rationale-for-an-accelerated-transition (accessed on 3 March 2025).

- European Parliament. Circular Economy: Definition, Importance and Benefits. Available online: https://www.europarl.europa.eu/topics/en/article/20151201STO05603/circular-economy-definition-importance-and-benefits (accessed on 3 March 2025).

- European Commission. Circular Economy Action Plan. Available online: https://environment.ec.europa.eu/strategy/circular-economy-action-plan_en (accessed on 3 March 2025).

- European Commission. Ecodesign for Sustainable Products Regulation. Available online: https://commission.europa.eu/energy-climate-change-environment/standards-tools-and-labels/products-labelling-rules-and-requirements/ecodesign-sustainable-products-regulation_en (accessed on 3 March 2025).

- Suppipat, S.; Hu, A.H. A scoping review of design for circularity in the electrical and electronics industry. Resour. Conserv. Recycl. Adv. 2022, 13, 200064. [Google Scholar] [CrossRef]

- Rahee, S.P.; Sarker, M.R. Circular product design strategies in the apparel industry: Toward the circular economy. Discov. Sustain. 2024, 5, 437. [Google Scholar] [CrossRef]

- Cooper, R.G.; Edgett, S.J. Maximizing Productivity in Product Innovation. Res.-Technol. Manag. 2008, 51, 47–58. [Google Scholar] [CrossRef]

- Kahn, K.B. Understanding innovation. Bus. Horiz. 2018, 61, 453–460. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Wang, J.X.; Burke, H.; Zhang, A. Overcoming barriers to circular product design. Int. J. Prod. Econ. 2022, 243, 108346. [Google Scholar] [CrossRef]

- Jiao, R.; Commuri, S.; Panchal, J.; Milisavljevic-Syed, J.; Allen, J.K.; Mistree, F.; Schaefer, D. Design Engineering in the Age of Industry 4.0. J. Mech. Des. 2021, 143, 070801. [Google Scholar] [CrossRef]

- Moreno, M.; De los Rios, C.; Rowe, Z.; Charnley, F. A Conceptual Framework for Circular Design. Sustainability 2016, 8, 937. [Google Scholar] [CrossRef]

- Rotondo, B.; Arquilla, V. Exploring the role of design in the new product development process towards circular business innovation: Systematic literature review and future directions. In DRS2024: Boston; Design Research Society: London, UK, 2024. [Google Scholar] [CrossRef]

- McAloone, T.C.; Pigosso, D.C.A. Ecodesign implementation and LCA. In Life Cycle Assessment: Theory and Practice; Springer: Cham, Swizerland, 2017; pp. 545–576. [Google Scholar] [CrossRef]

- Albæk, J.K.; Shahbazi, S.; McAloone, T.C.; Pigosso, D.C.A. Circularity Evaluation of Alternative Concepts During Early Product Design and Development. Sustainability 2020, 12, 9353. [Google Scholar] [CrossRef]

- Diaz, A.; Schöggl, J.P.; Reyes, T.; Baumgartner, R.J. Sustainable product development in a circular economy: Implications for products, actors, decision-making support and lifecycle information management. Sustain. Prod. Consum. 2021, 26, 1031–1045. [Google Scholar] [CrossRef]

- Faludi, J.; Hoffenson, S.; Kwok, S.Y.; Saidani, M.; Hallstedt, S.I.; Telenko, C.; Martinez, V. A Research Roadmap for Sustainable Design Methods and Tools. Sustainability 2020, 12, 8174. [Google Scholar] [CrossRef]

- Faludi, J. Recommending sustainable design practices by characterising activities and mindsets. Int. J. Sustain. Des. 2017, 3, 100. [Google Scholar] [CrossRef]

- Vicente, J.; Camocho, D. Design for Sustainability Tools: Categories of classification towards practical use. In Human-Centered Design and User Experience; AHFE Open Access: New York, NY, USA, 2023; Volume 114. [Google Scholar] [CrossRef]

- Saidani, M.; Kim, H. Design for Product Circularity: Circular Economy Indicators with Tools Mapped Along the Engineering Design Process. In Proceedings of the ASME Design Engineering Technical Conference, Virtual, 17–19 August 2021; Volume 5. [Google Scholar] [CrossRef]

- Shahbazi, S.; Jönbrink, A.K. Design Guidelines to Develop Circular Products: Action Research on Nordic Industry. Sustainability 2020, 12, 3679. [Google Scholar] [CrossRef]

- Aguiar, M.F.; Jugend, D. Circular product design maturity matrix: A guideline to evaluate new product development in light of the circular economy transition. J. Clean. Prod. 2022, 365, 132732. [Google Scholar] [CrossRef]

- Ahmad, S.; Wong, K.Y.; Tseng, M.L.; Wong, W.P. Sustainable product design and development: A review of tools, applications and research prospects. Resour. Conserv. Recycl. 2018, 132, 49–61. [Google Scholar] [CrossRef]

- Rexfelt, O.; Selvefors, A. Mapping the landscape of circular design tools. Resour. Conserv. Recycl. 2024, 209, 107783. [Google Scholar] [CrossRef]

- Royo, M.; Chulvi, V.; Mulet, E.; Ruiz-Pastor, L. Analysis of parameters about useful life extension in 70 tools and methods related to eco-design and circular economy. J. Ind. Ecol. 2023, 27, 562–586. [Google Scholar] [CrossRef]

- Rexfelt, O.; Selvefors, A. The Use2Use Design Toolkit—Tools for User-Centred Circular Design. Sustainability 2021, 13, 5397. [Google Scholar] [CrossRef]

- Schöggl, J.P.; Baumgartner, R.J.; Hofer, D. Improving sustainability performance in early phases of product design: A checklist for sustainable product development tested in the automotive industry. J. Clean. Prod. 2017, 140, 1602–1617. [Google Scholar] [CrossRef]

- Mauri, M.; Elli, T.; Caviglia, G.; Uboldi, G.; Azzi, M. RAWGraphs: A visualisation platform to create open outputs. In Proceedings of the CHItaly’17: 12th Biannual Conference of the Italian SIGCHI Chapter, Cagliari, Italy, 18–20 September 2017. ACM International Conference Proceeding Series. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Baas, J.; Schotten, M.; Plume, A.; Côté, G.; Karimi, R. Scopus as a curated, high-quality bibliometric data source for academic research in quantitative science studies. Quant. Sci. Stud. 2020, 1, 377–386. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Circular Design Guide—Methods. Available online: https://www.ellenmacarthurfoundation.org/circular-design-guide/methods (accessed on 7 March 2025).

- Chrispim, M.C.; Mattsson, M.; Ulvenblad, P. The underrepresented key elements of Circular Economy: A critical review of assessment tools and a guide for action. Sustain. Prod. Consum. 2023, 35, 539–558. [Google Scholar] [CrossRef]

- Cooper, R.G. The Stage-Gate Idea to Launch System. In Wiley International Encyclopedia of Marketing; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2010. [Google Scholar] [CrossRef]

- Design Council. The Double Diamond. Available online: https://www.designcouncil.org.uk/our-resources/the-double-diamond/ (accessed on 24 March 2025).

- Ulrich, K.T.; Eppinger, S.D. Product Design and Development, 6th ed.; McGraw-Hill Education: New York, NY, USA, 2016. [Google Scholar]

- Pahl, G.; Beitz, W.; Feldhusen, J.; Grote, K.-H. Engineering Design A Systematic Approach; Springer: London, UK, 2007. [Google Scholar]

- Cross, N. Engineering Design Methods, 5th ed.; Wiley: Hoboken, NJ, USA, 2021; Available online: https://www.wiley.com/en-nl/Engineering+Design+Methods%3A+Strategies+for+Product+Design%2C+5th+Edition-p-9781119724407 (accessed on 22 April 2025).

- Cooper, R.G. Stage-gate systems: A new tool for managing new products. Bus. Horiz. 1990, 33, 44–54. [Google Scholar] [CrossRef]

- DDC—Dansk Design Center. Designing Your Circular Transition. Available online: https://ddc.dk/tools/designing-your-circular-transition/ (accessed on 7 March 2025).

- RISE Research Institutes of Sweden. Future Adaptive Design for a Circular Economy. Available online: https://www.ri.se/en/expertise-areas/expertises/future-adaptive-design-for-a-circular-ec (accessed on 7 March 2025).

- EcoDesign Circle. Home—EcoDesign Circle. Available online: https://www.ecodesigncircle.eu/ (accessed on 10 February 2025).

- de Pauw, I.; van der Grinter, B.; Flipsen, B.; Alvarez Mendez, L. The Circularity Calculator: A Tool for Circular Product Development with Circularity and Potential Value Capture Indicators. 2022. Available online: https://research.tudelft.nl/en/publications/the-circularity-calculator-a-tool-for-circular-product-developmen (accessed on 9 February 2025).

- Giliam Dokter. Cards for Circularity. Available online: https://giliam.shinyapps.io/10_CircularityCards/ (accessed on 8 March 2025).

- Konietzko, J.; Bocken, N.; Hultink, E.J. A tool to analyze, ideate and develop circular innovation ecosystems. Sustainability 2020, 12, 417. [Google Scholar] [CrossRef]

- Hasling, K.M.; Ræbild, U. Sustainable Design Cards: A Learning Tool for Supporting Sustainable Design Strategies. 2018. Available online: https://www.researchgate.net/publication/334041972_Sustainable_Design_Cards_A_Learning_Tool_for_Supporting_Sustainable_Design_Strategies (accessed on 8 March 2025).

- Nike. Nike Circular Design Guide. Available online: https://circulardesign.nike.com/ (accessed on 7 March 2025).

- Flanders DC and Vlaanderen Circulair. Close The Loop—A Guide Towards a Circular Fashion Industry. Available online: https://www.close-the-loop.be/en (accessed on 7 March 2025).

- European Union. KATCH_e: Knowledge Alliance on Product-Service Development Towards Circular Economy and Sustainability in Higher Education. Available online: https://circulareconomy.europa.eu/platform/en/knowledge/katche-knowledge-alliance-product-service-development-towards-circular-economy-and-sustainability-higher-education (accessed on 7 March 2025).

- European Commission. Product List. Available online: https://energy-efficient-products.ec.europa.eu/product-list_en (accessed on 7 March 2025).

- Franconi, A.; Ceschin, F.; Peck, D. Structuring Circular Objectives and Design Strategies for the Circular Economy: A Multi-Hierarchical Theoretical Framework. Sustainability 2022, 14, 9298. [Google Scholar] [CrossRef]

- Evans, J.; Bocken, N. A Tool for Manufacturers to Find Opportunity in the Circular Economy. InImpact J. Innov. Impact 2016. Available online: https://www.semanticscholar.org/paper/A-tool-for-manufacturers-to-find-opportunity-in-the-Evans-Bocken/7889ba6e1fbaef7503d2644f72670a6a28105f25 (accessed on 9 March 2025).

- Het Groene Brein. Knowledge Maps. Available online: https://kenniskaarten.hetgroenebrein.nl/ (accessed on 9 March 2025).

- Ellen MacArthur Foundation. Circular Brainstorming. Available online: https://www.ellenmacarthurfoundation.org/circular-brainstorming (accessed on 9 March 2025).

- DDC—Dansk Design Center. Tool 01: Circular Strategies Wheel. Available online: https://ddc.dk/tools/tool-01-circular-strategies-wheel/ (accessed on 9 March 2025).

- Fedosov, A.; Kitazaki, M.; Odom, W.; Langheinrich, M. Sharing economy design cards. In Proceedings of the Conference on Human Factors in Computing Systems, Glasgow, UK, 4–9 May 2019. [Google Scholar] [CrossRef]

- Haines-Gadd, M.; Chapman, J.; Lloyd, P.; Mason, J.; Aliakseyeu, D. Emotional Durability Design Nine—A Tool for Product Longevity. Sustainability 2018, 10, 1948. [Google Scholar] [CrossRef]

- Artefact. The Tarot Cards of Tech. Available online: https://www.artefactgroup.com/resources/the-tarot-cards-of-tech/ (accessed on 9 March 2025).

- CIRCit Nord. Guidelines for Circular Product Development. Available online: https://circitnord.com/tools/guidelines-for-circular-product-development/ (accessed on 9 March 2025).

- Post, P. Circular Experience Design. Available online: https://www.circular-experience-library.org/ (accessed on 9 March 2025).

- Gibson, L.; Gujar, D.; Keller Aviram, D. Circular Material Library. Available online: https://circularmateriallibrary.org/ (accessed on 9 March 2025).

- CIRCit Nord. Circularity Assessment Tool. Available online: https://circitnord.com/tools/circularity-assessment-tool/ (accessed on 9 March 2025).

- PermissionToPlay. Work out Environmental Impacts of Innovations with the MET Matrix. Available online: https://www.permissiontoplay.co/fieldnotes/work-out-environmental-impacts-of-innovations-with-the-met-matrix/ (accessed on 9 March 2025).

- De Fazio, F.; Bakker, C.; Flipsen, B.; Balkenende, R. The Disassembly Map: A new method to enhance design for product repairability. J. Clean. Prod. 2021, 320, 128552. [Google Scholar] [CrossRef]

- Bakker, C.A.; van Dam, S.S.; de Pauw, I.; van der Grinten, B.; Asif, F. ResCoM Design Methodology for Multiple Lifecycle Products. 2017. Available online: https://www.researchgate.net/publication/333747851_ResCoM_Design_Methodology_for_Multiple_Lifecycle_Products (accessed on 9 March 2025).

- EcoDesign Circle. Ecodesign Toolkit—Tools. Available online: https://circulardesign.tools/ (accessed on 7 March 2025).

- Smit, D.; Hengeveld, B.; Murer, M.; Tscheligi, M. Hybrid Design Tools for Participatory, Embodied Sensemaking: An Applied Framework. In Proceedings of the TEI ‘22: Sixteenth International Conference on Tangible, Embedded, and Embodied Interaction, Daejeon, Republic of Korea, 13–16 February 2022; ACM International Conference Proceeding Series. Volume 10. [Google Scholar] [CrossRef]

- Marion, T.J.; Fixson, S.K. The Transformation of the Innovation Process: How Digital Tools are Changing Work, Collaboration, and Organizations in New Product Development. J. Prod. Innov. Manag. 2021, 38, 192–215. [Google Scholar] [CrossRef]

- Rodriguez, E.; Boks, C. How design of products affects user behaviour and vice versa: The environmental implications. In Proceedings of the Fourth International Symposium on Environmentally Conscious Design and Inverse Manufacturing, Eco Design, Tokyo, Japan, 12–14 December 2005; pp. 54–61. [Google Scholar] [CrossRef]

- Bai, C.; Dallasega, P.; Orzes, G.; Sarkis, J. Industry 4.0 technologies assessment: A sustainability perspective. Int. J. Prod. Econ. 2020, 229, 107776. [Google Scholar] [CrossRef]

- Shabur, M.A. A comprehensive review on the impact of Industry 4.0 on the development of a sustainable environment. Discov. Sustain. 2024, 5, 97. [Google Scholar] [CrossRef]

- Fassoula, E.D.; Rogerson, J.H. Management tools for SMEs. Total Qual. Manag. Bus. Excell. 2003, 14, 1143–1158. [Google Scholar] [CrossRef]

- Schweitzer, F.M.; Handrich, M.; Heidenreich, S. Digital Transformation in the New Product Development Process: The Role of It-Enabled Plm Systems for Relational, Structural, and Npd Performance. Int. J. Innov. Manag. 2019, 23, 1–34. [Google Scholar] [CrossRef]

- Attaran, M.; Celik, B.G. Digital Twin: Benefits, use cases, challenges, and opportunities. Decis. Anal. J. 2023, 6, 100165. [Google Scholar] [CrossRef]

| Classification Identifier | Sub-Classification Identifiers | Criteria Description |

|---|---|---|

| General Information | Name, Reference Link, Authorship, Year, Language, Access Conditions | Basic details regarding each tool, including its origin, language availability, and accessibility (e.g., free or free demo). |

| Format | Physical, Digital, Hybrid | Tools classified as physical (e.g., guidelines, worksheets, strategy cards, or canvases used in workshops), digital (e.g., databases, Miro/Mural boards, spreadsheets, dashboards, and checklists available online), or hybrid, combining both physical and digital formats. |

| Data Type | Qualitative, Quantitative, Hybrid | Categorisation based on whether the tool provides descriptive insights, numerical data analysis, or a combination of both. |

| Industry Sector | All or Specific (e.g., Fashion, Electronics, Construction, Furniture, etc.) | Identifies whether the tool is designed for general use across industries or tailored to specific sectors. |

| Circular Strategies | Not Specific Focus, Specific Strategies | Differentiates tools that provide a broad perspective on circular strategies from those focused on specific aspects (e.g., design for durability, remanufacturing, disassembly, product-service systems). |

| Innovation Focus | Materials | Includes material libraries and databases that help design teams explore and select sustainable and circular materials, as well as guidelines on the use of recycled or recyclable resources. |

| Product | Focuses on product design and its components, including associated services from a circular perspective. This category covers, for instance, information cards, case study databases, design guidelines, ideation canvases, and concept evaluation tools. | |

| Packaging | Encompasses tools aimed at developing more sustainable and resource-efficient packaging solutions, such as design guidelines and checklists for assessing packaging circularity. | |

| Business Model | Covers tools that support circular product design and address related business model adaptations aligned with circular strategies, such as product-service systems. Tools focused exclusively on circular business model innovation were excluded, as they fall outside the scope of this review. | |

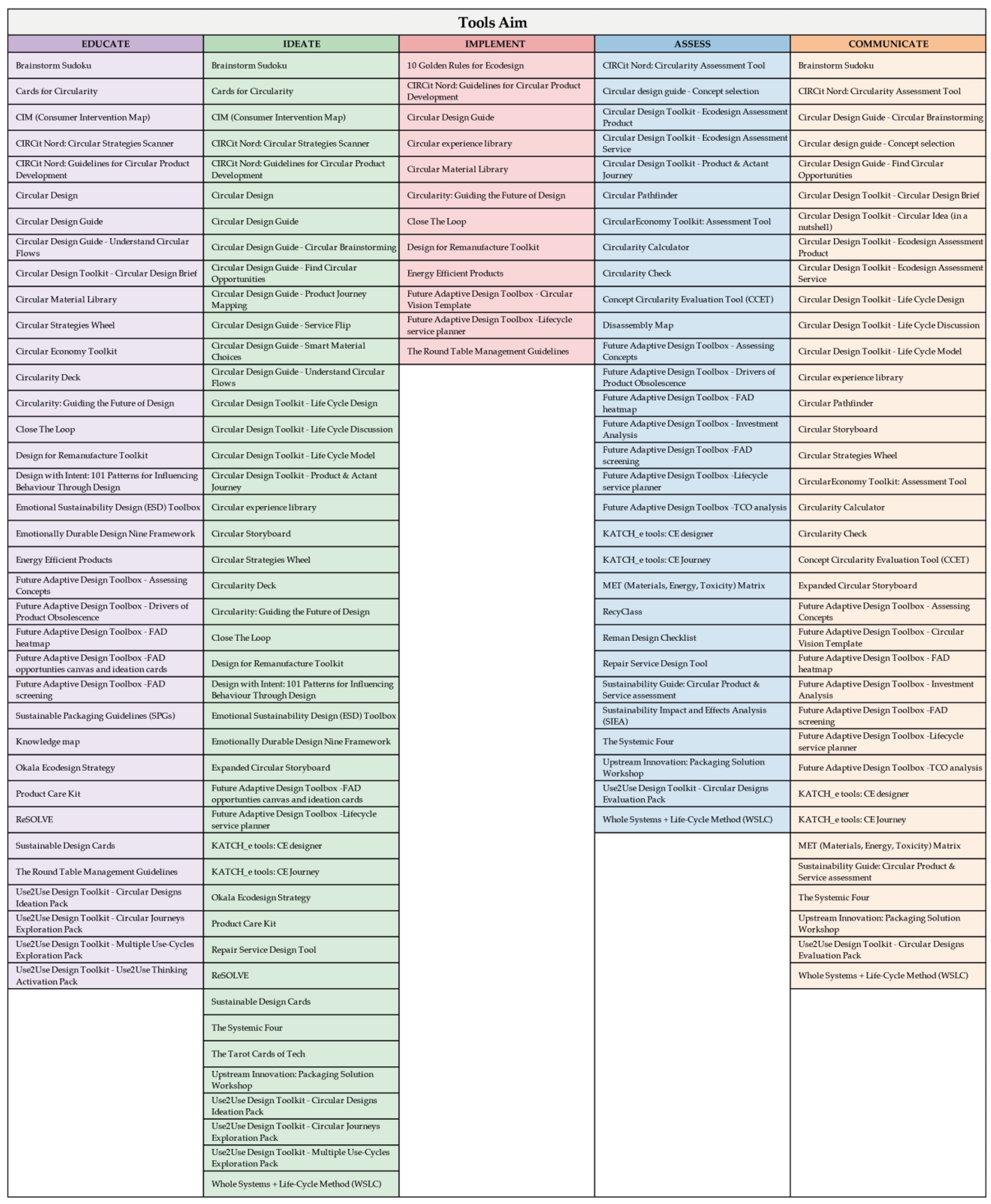

| Aim | Educate | Tools designed to raise awareness and provide fundamental knowledge on sustainability and circular economy strategies. This category includes educational tools that help organisations define circular strategic directions. |

| Ideate | Resources that facilitate brainstorming and the creation of circular product concepts. Examples include decks of case study cards showcasing successful circular strategies and guided canvases with key questions to stimulate creative thinking. | |

| Implement | Tools focused on the practical implementation of circular concepts, aiding in prototyping and refining ideas. | |

| Assess | Tools aimed at supporting the assessment of circular solutions, specifically focusing on the evaluation of circularity performance, potential value retention, and associated costs. | |

| Communicate | Tools that support internal dissemination of circular economy concepts across different company teams, ensuring organisational alignment. This category also includes tools designed for external communication between companies and end users. |

| Stage-Gate NPD Phase | Description of the NPD Phase [34] | Double Diamond Phase | Circular Tool Characteristics |

|---|---|---|---|

| Idea Generation | An initial phase focused on generating a wide range of potential ideas for exploring new opportunities. Activities may include technical research to identify emerging technologies, user research, competitive analysis, internal idea-gathering systems, strategic foresight exercises, and open innovation practices involving external collaborators. | Discover | Tools that support early exploration and opportunity identification for circular innovation. These include educative tools that raise awareness about circular economy principles and inspire initial engagement; contextual tools aimed at understanding the broader market, user needs, and sustainability-related challenges; idea generation tools for stimulating early-stage circular design concepts; and assessment tools for analyzing existing products and identifying preliminary circular strategies or interventions. |

| Scoping | An initial, low-cost exploratory phase aimed at assessing the technical and market feasibility of the project through secondary research. The main activities include a preliminary market analysis (to assess its size, potential, and user acceptance) and a technical evaluation (to assess feasibility, risks, and resource implications). The goal is to make early-stage business decisions with minimal effort and time. | ||

| Build Business Case | A detailed investigation phase to refine the product concept and assess its feasibility before committing significant resources. Key activities include Voice-of-Customer research to understand user needs, competitive analysis, and concept testing to evaluate market reactions. The technical evaluation focuses on feasibility, including preliminary designs and cost assessments, while an operations review evaluates manufacturability and supply chain issues. A comprehensive business and financial analysis, including risk assessments, is conducted to justify the project and create a detailed project plan. | Define | Tools that help refine and validate the strategic direction of the project. They include tools for defining circular design strategies, supporting teams in aligning product development with circularity principles; tools for selecting circular business models, guiding decisions on how value will be created, delivered, and retained in a circular context; and prioritisation tools that assist in evaluating and ranking solution concepts based on environmental, economic, and technical feasibility criteria. |

| Development | At this stage, the product is physically developed according to plan, with laboratory, alpha, or internal testing to ensure compliance with the required specifications. The focus is on technical development, but marketing and operational activities proceed in parallel, with continuous market analysis and customer feedback. Detailed test plans, production strategies, and financial analyses are prepared, and legal or regulatory issues are resolved. The result is a proven prototype, ready for further evaluation and refinement. | Develop | Tools that support the transition from concept to detailed design. These include tools for detailed design and prototyping that help translate circular strategies into tangible product features; material selection tools that assist in choosing sustainable, recyclable, or bio-based materials; tools for packaging development to minimise environmental impact; and assessment tools to evaluate the circularity and sustainability of design decisions, ensuring alignment with both performance and environmental goals. |

| Testing and Validation | This phase ensures the project’s viability by assessing the product, production process, customer acceptance, and economics. It involves in-house tests to check product performance, user trials to evaluate functionality in real-world conditions, and pilot operations to refine the production process. Pretest market trials are conducted to gauge customer reactions and estimate market potential. This phase confirms the product’s readiness for launch. | Deliver | Tools that support design refinement through insights gained from testing activities and help ensure production readiness. Additionally, mature circularity assessment tools are employed to evaluate the product’s circularity potential in a comprehensive manner before launch. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rotondo, B.; Bakker, C.; Balkenende, R.; Arquilla, V. Integrating Circular Economy Principles in the New Product Development Process: A Systematic Literature Review and Classification of Available Circular Design Tools. Sustainability 2025, 17, 4155. https://doi.org/10.3390/su17094155

Rotondo B, Bakker C, Balkenende R, Arquilla V. Integrating Circular Economy Principles in the New Product Development Process: A Systematic Literature Review and Classification of Available Circular Design Tools. Sustainability. 2025; 17(9):4155. https://doi.org/10.3390/su17094155

Chicago/Turabian StyleRotondo, Benedetta, Conny Bakker, Ruud Balkenende, and Venanzio Arquilla. 2025. "Integrating Circular Economy Principles in the New Product Development Process: A Systematic Literature Review and Classification of Available Circular Design Tools" Sustainability 17, no. 9: 4155. https://doi.org/10.3390/su17094155

APA StyleRotondo, B., Bakker, C., Balkenende, R., & Arquilla, V. (2025). Integrating Circular Economy Principles in the New Product Development Process: A Systematic Literature Review and Classification of Available Circular Design Tools. Sustainability, 17(9), 4155. https://doi.org/10.3390/su17094155