1. Introduction

The manufacturing industry is undergoing a significant transformation driven by the urgent need for sustainability and resource efficiency. In response to growing concerns about climate change, resource depletion, and environmental degradation, industries are shifting from traditional linear production models toward circular economy (CE) principles. This transition demands innovative digital solutions to optimize resource use, minimize waste, and ensure sustainability across product lifecycles. Among these technologies, digital twins (DTs) have gained considerable attention for their ability to create real-time virtual representations of physical assets, systems, and processes. By enabling continuous monitoring, predictive analytics, and AI-driven decision-making, DTs provide a data-rich foundation for optimizing operations, extending product lifespans, and achieving sustainability goals.

Despite their potential, the integration of DTs into CE frameworks remains underdeveloped and lacks sufficient empirical validation in real-world industrial settings. Existing research primarily highlights applications in predictive maintenance, production optimization, and supply chain visibility. However, few studies have addressed their direct contributions to CE strategies such as closed-loop production, waste reduction, and resource recirculation. Furthermore, large-scale DT adoption faces several barriers, including high implementation costs, data security concerns, and interoperability challenges. These limitations highlight the need for a structured approach to guide industries in effectively deploying DTs for sustainable, circular manufacturing. Unlike traditional lifecycle assessment (LCA) methods that offer static evaluations, DT-enabled lifecycle intelligence supports dynamic, real-time feedback that enhances circularity and responsiveness across the manufacturing value chain.

Meng et al. (2023) [

1] focus on the construction sector and identify DT applications in design and demolition phases but do not present a lifecycle-wide framework or cross-sector applicability. Preut et al. (2021) [

2] emphasize stakeholder-specific information flows in circular supply chains but stop short of proposing structured adoption pathways. Mügge et al. (2024) [

3] conduct a systematic review with TRL-based lifecycle classifications but lack an implementation roadmap. Chi et al. (2023) [

4] review multiple digital technologies in CE but offer limited depth on DT-specific frameworks. Rocca et al. (2020) [

5] present a lab-scale DT-VR use case without broader generalization. Similarly, Pehlken et al. (2024) [

6] focus on DTs for eco-design in the automotive sector, while Anwar et al. (2024) [

7] and Ali et al. (2025) [

8] explore sector-specific DT applications without offering a structured, cross-sectoral maturity model. In contrast, this study introduces the Sustainable Digital Twin Maturity Pathway (SDT-MP) and the DT Nexus Framework, which together support the scalable deployment of DTs across the full lifecycle—from design to monitoring, analytics, and decision-making. The SDT-MP maturity stages map closely to Industry 4.0 advancement levels, from data acquisition via IoT devices to autonomous decision-making supported by AI-driven analytics. This approach incorporates AI-enabled feedback and optimization mechanisms, thereby operationalizing DTs within CE strategies in a way that prior studies have not addressed.

To address this gap, this study proposes the Sustainable Digital Twin Maturity Path (SDT-MP), a systematic roadmap for DT adoption and implementation in sustainable manufacturing ecosystems. Specifically, the study aims to (1) identify the key phases and technological enablers for integrating DTs into CE strategies, (2) develop a structured maturity model to support industries at various stages of DT deployment, (3) evaluate the practical impact of DT-enabled CE strategies on resource efficiency, waste reduction, and lifecycle management.

In this review, the term “digital twin (DT)” refers to both real-time data-driven models and hybrid approaches that integrate physical simulation with sensor feedback. We consider DT applications that support feedback loops, monitoring, prediction, or optimization across the product lifecycle. The review excludes purely theoretical models or digital mockups lacking interaction with physical systems. The term “circular manufacturing” refers to manufacturing systems that aim to maximize resource efficiency and sustainability through circular economy (CE) strategies such as reuse, remanufacturing, recycling, and closed-loop production systems. This review focuses on industrial and manufacturing domains, including sectors such as electronics, automotives, process industries, and precision component manufacturing.

This review adopts a narrative approach to synthesize recent developments in digital twin applications for circular manufacturing. Literature was collected from Scopus, Web of Science, and Google Scholar using combinations of keywords such as “digital twin,” “circular manufacturing,” “Industry 4.0,” “lifecycle,” and “sustainability,” focusing on peer-reviewed publications. Studies were selected based on their relevance to DT integration across lifecycle stages (design, production, end-of-life) and their contribution to sustainability metrics or circular economy strategies.

This study employs a multi-methods approach, combining a comprehensive literature review with industrial case study analysis. This dual-validation strategy bridges theory and practice, offering both conceptual insights and empirical evidence to support the integration of DT technology into sustainable manufacturing systems. The contributions of this research are twofold. First, it introduces a structured DT adoption model that addresses the technological, operational, and economic challenges encountered in transitioning to DT-enabled CE frameworks. Second, it extends the discourse on Industry 4.0 and sustainability by positioning DTs as key enablers of responsible technological transformation. By offering a practical roadmap for digital adoption, this study supports both academia and industry in advancing sustainable, intelligent, and circular production systems. This work directly contributes to Sustainable Development Goal 9 (Industry, Innovation, and Infrastructure) by promoting digital infrastructure and sustainable industrialization. Through the structured integration of AI-driven DT technologies and CE principles, the proposed frameworks foster innovation, technological upgrading, and environmentally responsible industrial transformation.

To address the fragmented nature of DT integration in circular manufacturing, this review proposes two complementary frameworks: the Sustainable Digital Twin Maturity Path (SDT-MP), which outlines progressive stages of DT adoption aligned with circular economy outcomes, and the Digital Twin Nexus, which synthesizes the multi-dimensional nature of DT deployment across lifecycle phases. These frameworks serve as analytical structures to classify and evaluate prior work while guiding future DT-CE alignment. The proposed frameworks—SDT-MP and DT Nexus—not only guide digital twin adoption for circular economy goals but also serve as practical enablers for the Industry 4.0 transition by aligning DT implementation with real-time, intelligent manufacturing paradigms.

The remainder of this paper is structured as follows:

Section 2 examines the evolution of manufacturing. It discusses the industrial revolutions and transformations in manufacturing paradigms to highlight the shift toward sustainability and digitalization.

Section 3 discusses responsible technological transformation for sustainable and circular manufacturing, covering principles and metrics for sustainable manufacturing, CE strategies in manufacturing, and hyper-personalization, before concluding with an in-depth exploration of responsible technological transformation.

Section 4 explores the future of sustainable and intelligent manufacturing, introducing the concepts of connected micro and urban smart factories, followed by the DT Nexus, which examines how DTs facilitate CE integration and sustainable manufacturing practices.

Section 5 presents the real-world implementation of DT strategies in sustainable industries, providing case studies and empirical insights into their applications.

Section 6 introduces an SDT-MP and discusses real-world implementations of DT to guide industries through structured adoption pathways. Finally, the paper concludes with key insights, practical recommendations, and directions for future research, thereby offering a roadmap for advancing DT-enabled sustainability in modern manufacturing.

2. Evolution of Manufacturing

Manufacturing transformations have been shaped by technological revolutions that increased the efficiency, productivity, and adaptability of global production systems. Each industrial revolution has brought about new paradigms in manufacturing, from mechanized production in the 18th century to the current intelligent, data-driven ecosystems. However, as manufacturing systems evolve, their social, environmental, and ethical implications have also expanded.

Past revolutions primarily emphasized efficiency and scale; however, current digital transformation demands a more responsible approach to technological innovation. I4.0, which introduces unprecedented opportunities for autonomous decision-making and hyperefficient production, also raises pressing concerns about energy consumption, ethical AI deployment, and equitable access to digital manufacturing technologies. AI-driven automation, DTs, and blockchain are redefining manufacturing by optimizing operations, but their unchecked deployment can lead to sustainability challenges, such as increased energy consumption, resource depletion, and ethical concerns in human–AI collaboration. As industries transition toward circular and sustainable manufacturing, a pressing need to balance innovation with responsibility exists, ensuring that technology-driven transformations align with environmental goals, ethical AI practices, and resilient supply chains. The following section examines how manufacturing paradigms have evolved to incorporate sustainability, hyper-personalization, and CE principles.

2.1. The Industrial Revolutions: Transitions in Manufacturing

Manufacturing transformation has been shaped by four major industrial revolutions driven by technological advancements, economic demands, and evolving societal expectations [

9]. These revolutions have successively improved efficiency, productivity, and adaptability, leading to the development of intelligent, interconnected, and autonomous manufacturing ecosystems [

10].

Table 1 lists the key economic, societal, and technological drivers of each industrial revolution, highlighting their progressive impact on manufacturing systems and the enabling technologies that facilitated these transformations.

The first industrial revolution marked a significant shift from handcrafted goods to mechanized production. The emergence of steam engines and water-powered machinery revolutionized production processes, particularly in the textile industry, leading to higher efficiency and mass-production capabilities [

11]. However, this period also introduced labor-intensive factory systems, requiring a new workforce dynamic and creating urban migration trends as populations moved toward industrial centers [

10]. Although this revolution improved manufacturing output, it was constrained by manual labor requirements and limited automation [

12].

The second industrial revolution [late 19th to early 20th centuries] was characterized by electrification, standardization, and the expansion of global supply chains. The widespread adoption of electric power, assembly line production, and mechanized tools enabled manufacturers to achieve higher production speeds and lower costs through economies of scale [

11]. Innovations, such as Henry Ford’s assembly line, revolutionized industrial operations by introducing process standardization and modular production techniques [

9]. This period also saw the rise of mass consumer markets, prompting industries to optimize logistics, distribution networks, and global trade strategies [

10].

The third industrial revolution [mid-to-late 20th century] introduced automation, computer-integrated manufacturing, and robotics, transforming manufacturing into a highly efficient, programmable, and scalable system [

12]. Adopting computer numerical control (CNC) machines, industrial robotics, and enterprise computing systems enabled higher precision, repeatability, and efficiency, thereby reducing dependence on human labor [

9]. This era marked the beginning of digital transformation in manufacturing, as companies integrated information technology, cybernetics, and early AI to improve production planning, quality control, and supply chain management [

11]. However, automation increased efficiency, and it also led to workforce displacement, necessitating the development of new skills and labor policies [

10].

The fourth industrial revolution (I4.0) represents the convergence of advanced digital technologies, including artificial intelligence, the Internet of Things (IoT), DTs, cyber–physical systems, and edge computing [

12]. These technologies enable autonomous decision-making, real-time analytics, and interconnected smart factories, allowing for unprecedented flexibility and adaptability [

10]. The economic drivers of this revolution include the need for hyperefficient data-driven manufacturing systems, the rise of customized and on-demand production, and growing concerns over sustainability and resource optimization [

11]. Integrating AI-driven automation, edge computing, and DTs facilitates predictive maintenance, self-optimization of production lines, and decentralization of control systems, thereby enhancing productivity and resilience [

9]. However, these advancements also introduce challenges, including cybersecurity threats, workforce reskilling demands, and the high cost of technological infrastructure [

12]. I4.0 is increasingly being leveraged to address global manufacturing challenges, including supply chain disruptions, carbon footprint reduction, and energy efficiency, positioning smart factories as key enablers of sustainable industrial growth [

10].

As discussed, industrial revolutions have reshaped manufacturing processes, organizational structures, and workforce dynamics [

9]. Although each revolution introduced new technological enablers, their successful adoption required corresponding shifts in manufacturing paradigms, aligning strategic, operational, and digital frameworks with evolving industrial needs [

11]. The transition from handcrafted goods to automated data-driven production highlights the continuous efforts required to balance efficiency, scalability, and customization in response to market, technological, and environmental pressures [

9]. Furthermore, understanding this evolution requires examining the manufacturing paradigms that define how production systems have adapted to new technological landscapes. The following section explores the shift from craft-based production to intelligent digital manufacturing by analyzing key enablers, industry trends, and long-term implications in the I4.0 era [

12].

2.2. Transformations in Manufacturing Paradigms

Progress in manufacturing paradigms is driven by economic imperatives, technological advancements, and evolving societal and environmental needs. Each paradigm has shaped product development, business models, and production processes, reflecting the pursuit of efficiency, customization, and sustainability by the industries [

13].

Table 2 lists an overview of the key economic, societal, and technological drivers of each manufacturing paradigm, highlighting their impacts on product development, business models, and manufacturing processes.

Craft production, which was the earliest form of manufacturing, relied on artisanal expertise and localized production. This system was constrained by limited scalability and high production costs, as skilled artisans handcrafted products in small batches [

14]. The business model predominantly followed a made-to-order approach in which each product was uniquely tailored to customer needs [

15]. However, the absence of standardization and mass-production techniques limited craft production in niche markets [

16]. The introduction of mass production in the early 20th century transformed manufacturing by enabling high-volume and cost-effective production [

17]. Economic factors, such as growing consumer demand and cost reduction through economies of scale, were key drivers [

13]. The assembly line standardized production workflows, reduced variability, and increased efficiency [

14]. Despite its advantages, mass production prioritized efficiency over customization, leading to a lack of product variety [

15]. Lean manufacturing emerged in response to competitive pressures and waste reduction needs, particularly in the automotive and electronics industries [

17]. The adoption of Kaizen principles, just-in-time (JIT) methodologies, and continuous process optimization allowed manufacturers to eliminate waste, streamline operations, and improve resource efficiency [

13]. Societal concerns over environmental impacts and sustainability further reinforced lean principles, making them a standard in modern industrial operations [

14]. With advancements in flexible manufacturing systems, digital platforms, and modular design, mass customization has become the dominant paradigm [

18]. Economic factors, including the need to balance efficiency with product variety, drove the transition from standardized production to consumer-driven manufacturing models [

15]. Integrating digital tools, robotics, and AI-driven automation enabled real-time adaptation to customer preferences while maintaining production efficiency [

14]. The latest paradigm, personalized manufacturing, is characterized by AI-driven decision-making, cyber–physical systems, and DTs [

17]. This model emphasizes real-time adaptability, hyper-customization, and sustainability-driven production, leveraging IoT and advanced analytics to create demand-responsive systems [

16]. In this era, consumers are becoming increasingly involved in co-creation and product personalization, shifting from passive to active participation in the manufacturing process [

18]. The co-evolution of industrial revolutions and manufacturing paradigms underscores how technological advancements reshape production systems [

13]. Integrating autonomous systems, decentralized production, and CE principles defines the next phase of industrial transformation [

17]. However, the challenge lies in harmonizing these advancements with sustainability goals, ethical considerations, and long-term resilience to ensure that future manufacturing paradigms benefit businesses and society [

14].

As manufacturing paradigms continue to evolve in response to economic pressures, technological advancements, and societal expectations, the focus has increasingly shifted toward sustainability, customization, and CE principles. Although I4.0 has introduced intelligent, data-driven, and decentralized manufacturing systems, emerging challenges necessitate a more responsible approach to technological transformation. The next phase of industrial evolution will be shaped by the ability to integrate sustainable production models, hyper-personalization, and responsible innovation to ensure resilience and efficiency in global manufacturing. These drivers, along with the challenges they introduce, are explored in

Section 3, which defines the key concerns, values, parameters, and KPIs for sustainable and circular manufacturing and discusses the role of hyper-personalization in future production systems.

The evolution of industrial revolutions and manufacturing paradigms highlights the continuous drive for efficiency, adaptability, and customization. However, past transitions have often neglected environmental sustainability, ethical labor practices, and the long-term impact of industrial growth. As the manufacturing industry embraces AI, IoT, blockchain, and DTs, it must also address responsible technological transformation, ensuring that digital advancements do not exacerbate environmental or ethical challenges while enhancing sustainability. CE principles, energy-efficient AI algorithms, and blockchain-enabled transparency in supply chains are reshaping global manufacturing by minimizing waste, optimizing resource usage, and reducing the carbon footprint.

Section 3 explores the role of responsible technological innovation in fostering sustainable circular manufacturing models. As manufacturing enters a new phase defined by AI, hyper-personalization, and closed-loop production, the challenge lies in ensuring that these advancements serve economic and environmental objectives rather than merely accelerating production at the cost of sustainability.

3. Responsible Technological Transformation for Sustainable and Circular Manufacturing

The rapid advancement of I4.0 technology has brought manufacturing to a critical crossroads. Although AI, IoT, blockchain, and DTs have the potential to redefine efficiency, scalability, and automation, their unregulated adoption has accelerated environmental and ethical challenges. The prevailing linear production model, in which resources are extracted, used, and discarded, has severe ecological consequences, including resource depletion, excessive carbon emissions, and unsustainable waste generation. Without a shift toward responsible technological integration, these innovations risk deepening sustainability crises rather than mitigating them.

To reverse these unsustainable trends, the manufacturing sector must adopt circular and responsible production models prioritizing waste elimination, resource regeneration, and extended product lifecycles. Circular manufacturing moves beyond merely reducing waste and emphasizes remanufacturing, recycling, and material recovery to create closed-loop, sustainable production ecosystems. By integrating AI-driven automation, IoT-enabled resource tracking, and blockchain-based transparency, industries can optimize their resource efficiency, reduce emissions, and transition toward regenerative production models. However, achieving truly responsible technological transformation requires more than just technological adoption. It demands strong ethical governance, international regulatory alignment, and lifecycle-oriented design principles that ensure sustainability at every production stage.

A successful transition toward circular and responsible manufacturing requires a structured framework integrating sustainability, economic viability, and social responsibility. The triple bottom line (TBL) framework provides this foundation by ensuring that manufacturing strategies balance profitability, environmental stewardship, and equitable labor practices.

Additionally, the rise of hyper-personalization driven by AI, DTs, and I4.0 presents opportunities and challenges for sustainable production. Unlike traditional mass manufacturing, hyper-personalized production allows on-demand customer-specific product customization, which reduces overproduction, minimizes material waste, and enhances resource efficiency. However, if not responsibly implemented, hyper-personalization can increase energy demand and supply chain complexity, potentially undermining its sustainability benefits. This section explores how TBL principles, CE strategies, and hyper-personalization can be integrated to drive sustainable technology-enabled manufacturing transformation.

3.1. Principles and Metrics for Sustainable Manufacturing

Sustainability in manufacturing is a TBL-centered multi-dimensional concept. It integrates economic, environmental, and social considerations into industrial operations. The TBL framework ensures that manufacturing processes optimize resource efficiency, minimize environmental impacts, and maintain long-term economic viability while prioritizing social well-being [

19]. Driven by regulatory mandates, increasing consumer awareness, and the necessity of resource optimization, sustainable manufacturing has become a core strategic objective for industries [

20]. This aligns with global sustainability goals and encourages the transition from traditional manufacturing toward cleaner, circular, and technology-driven sustainable practices [

21].

The existing literature identifies two primary approaches to achieving sustainability in manufacturing: the cumulative and trade-off approaches. The cumulative approach posits that economic, environmental, and social goals can be pursued simultaneously, reinforcing one another, whereas the trade-off approach suggests that prioritizing one dimension may come at the expense of another [

19]. The cumulative approach is often associated with I4.0 technologies, such as AI, IoT, and DTs, which facilitate a balance between efficiency and sustainability. By contrast, firms adopting the trade-off approach may prioritize short-term financial gains, often at the expense of long-term environmental or social sustainability.

Based on the TBL framework, sustainable manufacturing is classified into three key disciplines: economic, environmental, and social. Economic sustainability ensures business profitability by minimizing waste, reducing production costs, and optimizing energy consumption. It emphasizes cost efficiency, resource optimization, and long-term profitability, enabling firms to remain competitive while reducing operational waste [

22,

23]. Environmental sustainability focuses on improving energy efficiency and conserving resources. It prioritizes reducing carbon footprint, enhancing resource utilization, and implementing closed-loop production systems to mitigate environmental impact [

21,

24]. Social sustainability promotes workforce safety, fair labor practices, and ethical supply chain management, ensuring long-term societal benefits. It encompasses workplace safety, ethical sourcing, and corporate social responsibility and contributes to employee well-being and sustainable business practices [

25,

26].

Recent studies have emphasized the need for integrated sustainability frameworks that combine sustainability objectives with process-oriented models to systematically measure and improve performance [

27]. Sustainability-oriented innovation has played a pivotal role in this transition, with firms increasingly adopting green technologies, eco-design strategies, and digital solutions to embed sustainability into manufacturing [

28]. Effective implementation requires data-driven decision-making and leveraging of bibliometric and content analysis methodologies to track progress and identify gaps in current sustainability practices [

29].

A structured approach to sustainable manufacturing integrates economic, environmental, and social considerations into key performance metrics. Each discipline presents distinct challenges, values, and measurement parameters that collectively define sustainability assessments in industrial settings. The role of open-architecture products is gaining attention as modular design extends product lifecycles and reduces material waste [

16]. Additionally, barrier analysis methods, such as the best–worst method (BWM), have been employed to systematically identify key obstacles to sustainability adoption and to provide structured solutions [

30].

Table 3 lists the core TBL disciplines of sustainable manufacturing, highlighting key concerns, values, parameters, and associated KPIs.

Adopting I4.0 technologies—including AI-driven analytics, DT-enabled monitoring and optimization, and automation—transforms sustainability measurement, allowing firms to track and enhance sustainability metrics in real time [

31,

32,

33]. Organizations aiming to improve their sustainability performance must integrate these parameters into their strategic decision-making, investment planning, and operational frameworks [

27]. To effectively incorporate sustainability into manufacturing, companies must analyze the drivers, challenges, and opportunities associated with the economic, environmental, and social dimensions. A well-defined sustainability framework enhances organizational resilience, ensures compliance with global sustainability standards, and strengthens long-term competitiveness [

34]. This necessitates comprehensive sustainability assessments that leverage digital tools, circular economic strategies, and sustainable business models [

28].

Table 4 lists key sustainability dimensions and their associated strategic considerations.

Addressing these dimensions requires cross-functional collaboration, standardization across industries, and adopting next-generation sustainability frameworks. Companies implementing sustainability strategies often experience enhanced operational efficiency, stronger stakeholder relationships, and long-term competitive advantages [

35]. However, digitalizing sustainability initiatives presents opportunities and challenges, requiring firms to overcome technological, organizational, and regulatory barriers [

36,

37]. Integrating emerging technologies, such as blockchain, AI, and DTs, enables real-time sustainability tracking and predictive insights. These advancements have helped manufacturers proactively address supply chain risks, carbon emissions, and resource efficiency, thereby strengthening their sustainability strategies.

Furthermore, systematic reviews of sustainability frameworks indicate that incorporating open-product architectures, modular design, and CE principles is essential to ensuring that manufacturing systems remain flexible, resilient, and environmentally responsible over time [

38]. As industries move toward sustainable digital transformation, aligning industrial strategies with global sustainability objectives is critical for maintaining economic viability and environmental stewardship [

39]. By embedding sustainable development principles into industrial strategies and leveraging intelligent data-driven decision-making, manufacturers can establish resilient, adaptive, and responsible production models that support business growth and environmental sustainability [

40]. These sustainability principles are closely aligned with the objectives of Sustainable Development Goal 9, which emphasizes inclusive industrial development, sustainable infrastructure, and innovation-driven economic growth. The adoption of digital twins and AI technologies contributes to upgrading industrial capabilities and fostering resilient, ecoefficient production systems.

3.2. CE Strategies in Manufacturing

The CE has emerged as a strategic alternative to the conventional linear economy, which follows a “take–make–dispose” model. The CE fosters a regenerative industrial system that reduces resource consumption and waste generation while maximizing the utility of materials throughout their lifecycles. It integrates sustainability principles, resource efficiency, and closed-loop material flows to generate long-term economic and environmental benefits [

41]. In manufacturing, CE signifies a paradigm shift, emphasizing product and process designs that extend material longevity, optimize resource utilization, and reduce reliance on virgin raw materials [

42].

The 10R strategy is a foundational framework within the CE, outlining a hierarchical approach to resource efficiency: refusing, relinking, reducing, reusing, repairing, refurbishing, repurposing, recycling, and recovery. Each strategy plays a distinct role in minimizing waste and maximizing material value. For example, “Refuse” and “Rethink” promote alternative consumption models, such as product-as-a-service and modular design, whereas “Reduce” focuses on minimizing material use at the design stage [

43]. “Reuse” and “Repair” extend product life spans, whereas “Refurbish” and “Remanufacture” restore used products to near-original conditions, decreasing the need for new production [

44]. At lower levels of the hierarchy, “Repurpose” assigns new functions to used components, whereas “Recycle” and “Recover” extract valuable materials and energy from end-of-life products [

45]. Implementing the 10R principles in manufacturing requires advanced production strategies and innovative business models. I4.0, including smart sensors, additive manufacturing, and AI, enhances real-time material tracking and improves remanufacturing efficiency [

46]. Additionally, modular product design and DTs support predictive maintenance and lifecycle assessment, enabling manufacturers to extend product durability and optimize resource utilization [

47]. Transitioning to CE-driven manufacturing requires supply chain collaboration, particularly in reverse logistics systems, which streamline the collection, sorting, and reintegration of used products into production cycles [

48]. Although the 10R principles offer significant advantages, their implementation in manufacturing faces several challenges. Economic feasibility, regulatory barriers, and technological limitations often hinder their full-scale adoption. Companies must balance cost efficiency and sustainability, necessitating targeted incentives and policy support for CE practices [

49]. Furthermore, standardized assessment metrics and CE-specific KPIs are essential for tracking progress and ensuring effective integration into industrial operations [

50]. Overcoming these challenges requires continuous innovation and cross-sectoral collaboration to establish a fully circular production system.

The CE framework provides a structured approach for minimizing resource consumption, optimizing waste management, and promoting sustainable industrial practices. The shift from a linear to a circular model is guided by key principles, including resource recovery, sustainable supply chains, and waste reduction [

51]. Each 10R strategy is critical in enhancing material efficiency and mitigating the environmental impact of manufacturing operations [

52]. Industries have integrated the 10R framework to enhance production sustainability using diverse strategies. In the electronics sector, a modular design enables easier repair and upgrades, thereby reducing product obsolescence and waste generation [

49]. Similarly, the automotive industry has embraced remanufacturing, restoring used components to their original specifications and decreasing the reliance on virgin raw materials [

51]. Additionally, industrial symbiosis, in which waste outputs from one sector serve as inputs for another, has gained momentum, fostering cross-industry resource optimization [

52]. CE strategies fundamentally reshape supply chain management by emphasizing closed-loop production systems and reverse logistics. A well-designed circular supply chain ensures the efficient collection, sorting, and reintegration of end-of-life products into manufacturing cycles. Companies adopting circular principles benefit from reduced material consumption and improved resilience to resource scarcity [

51]. However, full implementation faces challenges, including the depletion of raw materials, which necessitates greater reliance on secondary resources [

49]. Additionally, regulatory compliance imposes hurdles as industries must navigate complex policies related to waste management and sustainability reporting [

53]. Overcoming these barriers requires robust regulatory frameworks and cross-sector collaboration [

51]. The effectiveness of CE practices is assessed using KPIs, such as recycling rates, waste reduction percentages, and secondary raw material utilization [

54]. These metrics provide valuable insights into sustainability performance and enable continuous improvements to circular production models [

51].

Table 5 lists a structured overview of the 10R strategies, outlining the major concerns, core values, key parameters, and KPIs. This illustrates how each strategy enhances resource efficiency, minimizes waste, and promotes sustainability in manufacturing and supply chain operations. By implementing these strategies, addressing concerns, and monitoring KPIs, industries can effectively transition toward the CE, balancing economic viability with environmental sustainability.

Upgradable product design is a key enabler of a CE that extends product lifecycles, reduces material consumption, and improves resource efficiency. By facilitating modular upgrades rather than full product replacements, manufacturers can lower production costs while minimizing their environmental impact [

55]. This approach is particularly beneficial in industries, such as consumer electronics and machinery, where rapid technological advancements often lead to obsolescence. Companies incorporating upgradability into their design strategies enhance sustainability and generate new revenue streams through after-sales services and component sales [

55]. Circular manufacturing requires a flexible contingency-based approach that aligns production processes with resource efficiency and waste reduction principles. Successful startups implementing circular manufacturing have adopted flexible production lines, modular design principles, and advanced digital tracking systems to optimize material flows [

56]. These adaptive strategies enhance supply chain resilience by minimizing reliance on virgin raw materials and maximizing the use of secondary resources [

56]. Additionally, circular manufacturing fosters industrial symbiosis, wherein waste from one process becomes an input for another, promoting cross-industry collaboration and resource efficiency [

56]. Economic incentives are instrumental in accelerating the adoption of CE practices. Dynamic pricing models and targeted investment strategies help businesses balance their cost-efficiency and sustainability goals. Companies that integrate recycling investments into their business models enhance their financial viability by leveraging material recovery and reprocessing [

57]. Additionally, government subsidies and tax incentives are pivotal in promoting circular initiatives by offsetting the initial costs of transitioning to sustainable production [

57].

Integrating upgradability, adaptive manufacturing, and economic incentives into CE strategies offers industries a pathway to sustainability while maintaining competitiveness. By prioritizing design innovation and financial models that support circular principles, businesses can establish resilient and resource-efficient operations that align with long-term environmental and economic objectives.

I4.0 technologies serve as key enablers of CE by enhancing resource efficiency, sustainable production, and supply chain optimization. Integrating AI, big data analytics, blockchain, and IoT improves transparency, traceability, and operational efficiency in circular supply chains [

58]. These advancements have enabled real-time material tracking, predictive maintenance, and optimized resource flows, thereby reducing waste generation and extending product lifespan [

59]. I4.0 facilitates sustainable production through smart manufacturing systems that leverage CPSs, automated decision-making, and DTs. These technologies enhance the precision of material usage, reduce energy consumption, and optimize product remanufacturing processes [

60]. For instance, additive manufacturing (3D printing) supports on-demand production with minimal waste, whereas blockchain ensures the secure and transparent tracking of recycled materials and reused components [

58]. I4.0 technologies drive the adoption of circular business models, including servitization, PaaS models, and reverse logistics. Smart sensors and IoT devices enable the real-time monitoring of product conditions, facilitate predictive maintenance, and extend product lifespans [

59]. Additionally, digital connectivity strengthens collaboration among suppliers, manufacturers, and consumers, ensuring seamless reintegration of recovered and repurposed materials within circular supply chains [

60]. Despite its advantages, integrating I4.0 with the CE presents challenges, including high implementation costs, data security risks, and the need for specialized digital infrastructure [

59]. Additionally, although automation and smart technologies improve sustainability, effective adoption requires workforce upskilling and expertise in digital solutions [

58].

I4.0 technologies are pivotal for advancing CE strategies, enabling sustainable production, resource optimization, and closed-loop supply chains. By leveraging digital innovation, businesses can enhance environmental sustainability while maintaining economic viability. However, to fully realize the potential of I4.0 in CE, addressing implementation challenges through policy support, targeted investments, and workforce upskilling is essential.

3.3. Hyper-Personalization

Hyper-personalization, powered by AI-driven predictive analytics and real-time data insights, has emerged as a transformative force in customer engagement, enabling businesses to create individualized experiences tailored to specific consumer behaviors and preferences [

61]. Unlike traditional personalization approaches that rely on broad demographic segmentation, hyper-personalization employs advanced machine learning algorithms to analyze consumer interactions across multiple touchpoints, delivering context-aware and need-based recommendations [

62]. This level of customization fosters greater customer satisfaction and loyalty while aligning with broader sustainability goals by reducing excess production and minimizing resource wastage [

63]. As industries transition toward circular business models, hyper-personalization is crucial in demand-driven manufacturing, shifting from mass production to dynamic on-demand solutions that optimize resource use while enhancing consumer experience [

64].

Hyper-personalization is crucial in sustainable and circular manufacturing by optimizing resource efficiency and minimizing waste using tailored production and consumption strategies [

65]. By leveraging AI-driven demand forecasting, businesses can reduce excess inventory and overproduction, which are the primary sources of material and energy waste in traditional manufacturing models [

66]. Furthermore, hyper-personalization enables localized production, which lowers the carbon footprint associated with global supply chains by shifting towards on-demand customer-centric manufacturing processes [

63]. This shift aligns with the CE principles by promoting shorter supply chains, reducing transportation emissions, and enhancing supply chain resilience [

66]. Additionally, modular product designs and upgradable components enhance sustainability by extending product lifecycles, reducing the need for frequent replacements, and enabling users to customize or repair their products rather than discard them [

65]. This approach benefits the environment and supports the transition from traditional ownership-based models to service-oriented business models, such as PaaS, which encourage resource efficiency and circularity by ensuring that products remain in use for longer periods [

66].

The convergence of hyper-personalization with Industry 5.0 principles facilitates the development of sustainable manufacturing ecosystems that prioritize human–machine collaboration, flexibility, and circular resource utilization [

67]. Industry 5.0, emphasizing mass customization and consumer-centric production, leverages real-time data analytics and AI-driven decision-making to enhance product personalization while minimizing environmental impact [

68]. By integrating hyper-personalization with advanced manufacturing technologies, such as additive manufacturing and DTs, companies can streamline production processes, reduce waste, and align product design with evolving consumer demands while incorporating the 4Cs of mass customization—co-creation, configuration, customer involvement, and choice navigation—to enhance product adaptability and user engagement [

69]. This dynamic approach allows businesses to create highly individualized products without compromising sustainability, reinforcing CE principles by fostering resource-efficient production and extending product lifespans [

67].

Integrating hyper-personalization within CE frameworks fosters a paradigm shift from conventional production models to adaptive demand-driven approaches. By leveraging DT technology, AI-driven analytics, and real-time data insights, businesses can enhance material efficiency and reduce waste through predictive maintenance and performance optimization [

63]. Unlike traditional customization strategies, which rely on predefined product modules, hyper-personalization integrates real-time consumer data and AI-driven insights to dynamically tailor products and services to unique customer preferences [

70]. This approach enhances resource efficiency by aligning production output more precisely with actual demand, minimizing excess inventory, and supporting sustainable consumption patterns [

71]. Furthermore, DT technology facilitates hyper-personalization in circular manufacturing by simulating product performance and enabling the predictive optimization of materials, ensuring that products meet customer expectations while maximizing resource efficiency [

72].

Hyper-personalization in circular business models is further strengthened by integrating mass customization principles with resource-sharing and remanufacturing strategies. The convergence of mass customization and CE principles enables businesses to design products with modularity and extended lifecycles, supporting refurbishment, remanufacturing, and repurposing initiatives [

73]. By embedding digital intelligence into production systems, manufacturers can adjust product features and configurations in real time based on consumer preferences, ensuring efficient material utilization and reducing production waste [

74]. Additionally, smart manufacturing environments enable companies to create flexible and responsive production lines that adapt to evolving customer needs without increasing environmental burden [

75]. This approach fosters a closed-loop manufacturing system in which products are designed for reusability and repair, extending their lifespan and reducing material depletion [

73].

Despite its potential to enhance sustainability, hyper-personalization within CE frameworks presents several challenges, particularly concerning data privacy, computational demand, and supply chain integration. The extensive collection and processing of consumer data required for hyper-personalized production raises significant concerns regarding privacy regulations, such as GDPR and CCPA, necessitating transparent consent management and robust data security measures [

61]. Additionally, the real-time processing of vast datasets for personalized manufacturing relies on an AI-driven infrastructure that demands high computational power, which may increase energy consumption and offset sustainability benefits if not effectively managed [

65]. Integrating hyper-personalization into circular supply chains also requires seamless coordination among manufacturers, suppliers, and logistics providers to optimize production efficiency and minimize resource waste and transportation emissions [

63]. Emerging technologies, such as blockchain and decentralized digital ledgers, are being explored to enhance transparency in product lifecycle tracking, ensuring ethical sourcing, material recovery, and waste minimization in CE applications. Overcoming these challenges will require cross-industry collaboration; adaptive regulatory frameworks that balance innovation with ethical considerations; and continuous advancements in AI, smart manufacturing, and sustainability-driven digital transformation strategies.

Sustainability and circularity have become the defining pillars of modern manufacturing, and the role of advanced technologies in enabling these strategies has become increasingly significant.

Section 3.4 explores the key enablers of future manufacturing, such as microconnected factories and USFs, and their synergistic integration with DT technologies to enhance sustainability, efficiency, and flexibility.

3.4. Responsible Technological Transformation

The rapid evolution of I4.0 and the emerging Industry 5.0 have catalyzed unprecedented advancements in manufacturing through AI, DTs, CPSs, and IoT. Although these technologies contribute significantly to operational efficiency, product customization, and resource optimization, their implementation also raises concerns regarding ethical responsibility, environmental sustainability, and socioeconomic impacts. Previous studies have established the critical role of these technologies in fostering sustainable manufacturing practices. However, achieving a truly responsible technological transformation requires a strategic balance between efficiency and ethical considerations. This section explores the key challenges and strategies to ensuring that responsible AI integration, secure DT deployment, sustainable CE strategies, and ethical hyper-personalization models are at the forefront of the next phase of industrial transformation.

As previously highlighted, AI-driven automation has enabled demand-driven production systems, material waste reduction, and supply chain optimization. However, unregulated AI adoption may lead to unintended consequences, such as workforce displacement, algorithmic bias, and safety risks in human–machine collaborations. Hyper-automated production lines risk replacing human workers without adequate reskilling initiatives. AI models trained on historical data may unintentionally reinforce biased decision-making, affecting product personalization and quality control. Additionally, if improperly integrated, AI-powered robotics can introduce workplace hazards and ergonomic issues.

To address these challenges, manufacturers must implement human–AI collaboration models that enhance worker efficiency without eliminating human roles. Developing explainable AI frameworks ensures accountability in smart manufacturing decisions, whereas workforce reskilling initiatives focused on AI governance, robotics maintenance, and human-in-the-loop decision-making can facilitate ethical workforce transitions.

DTs are a cornerstone of circular and sustainable manufacturing as they enable real-time tracking of material flows, predictive maintenance, and lifecycle optimization. In addition to improving the resource efficiency in smart factories, DTs facilitate remanufacturing, waste reduction, and closed-loop production by providing data-driven insights into product longevity, reusability, and recycling pathways. However, as DTs become increasingly integrated with cloud-based infrastructures and decentralized networks, their deployment introduces cybersecurity and data privacy challenges. DTs store highly sensitive operational data, making them prime targets for cyberattacks, industrial espionage, and unauthorized access. Additionally, unclear data governance policies complicate how manufacturing firms share, store, and utilize DT insights.

To ensure responsible technological transformation, manufacturers must implement secure-by-design architectures that leverage end-to-end encryption, zero-trust security frameworks, and blockchain-based transparency to protect data integrity and prevent tampering. Furthermore, compliance with global data sovereignty laws ensures that DT applications adhere to privacy, security, and ethical standards. By combining sustainability-driven innovations with robust cybersecurity measures, manufacturers can fully realize the potential of DTs in creating a resilient, transparent, and environmentally responsible production ecosystem. However, digital transformation extends beyond cybersecurity and operational efficiency and introduces new challenges in sustainability. CE strategies emphasize the urgent need to transition from linear production models to closed-loop regenerative manufacturing systems.

To ensure responsible technological transformation, manufacturers must proactively address these challenges by leveraging DT technology for sustainability, efficiency, and CE integration.

Optimizing resource efficiency with digital twins enables real-time simulations and predictive analytics, allowing manufacturers to optimize production processes, reduce energy waste, and enhance material efficiency. By integrating edge computing and AI-powered DTs, companies can minimize the carbon footprint of manufacturing operations while ensuring energy-efficient production.

Unlike traditional IoT-based tracking systems, enhancing closed-loop material tracking with DTs provides a dynamic virtual representation of the entire supply chain, ensuring accurate resource utilization, predictive remanufacturing, and lifecycle tracking. By monitoring the material flow and product durability in real time, DTs support remanufacturing strategies, material recovery, and waste reduction, which are key enablers of CE.

Extending product lifecycles with modular design DTs to facilitate virtual prototyping and lifecycle assessment, enabling manufacturers to design modular upgradable components that reduce premature obsolescence. By continuously analyzing product performance and degradation, DTs can assist in adaptive maintenance planning, material reuse, and extending the functional life of industrial assets.

By embedding DT technology at the core of circular manufacturing strategies, industries can achieve higher operational resilience, lower waste generation, and enhanced sustainability while ensuring a transparent, secure, and responsible transformation toward Industry 5.0.

4. The Future of Sustainable and Intelligent Manufacturing: DTs and Decentralized Smart Factories

4.1. Connected Micro Smart Factory

Modular manufacturing systems have emerged as a transformative production approach, enabling manufacturers to build highly flexible and reconfigurable production environments. These systems rely on standardized, interoperable modules that can be dynamically reconfigured to accommodate varying product designs and requirements, thereby facilitating agile and scalable manufacturing processes [

76]. At the core of modular manufacturing lies the Micro Smart Factory (MSF), which is a compact, intelligent production system that integrates advanced automation, robotics, and CPSs to enable high-efficiency, small-scale manufacturing [

77]. The MSF concept aligns with I4.0 and Industry 5.0 paradigms by emphasizing decentralized production, real-time data analytics, and human–machine collaboration to enhance customization and operational efficiency [

78]. Unlike conventional large-scale factories, MSFs enable localized demand-driven production, reducing logistical costs and environmental impact while improving responsiveness to consumer preferences [

79].

A Connected MSF (CMSF) extends the MSF concept by integrating the Industrial IoT (IIoT), cloud computing, AI, big data analytics, and DTs to create an interconnected and highly autonomous manufacturing ecosystem [

80]. This approach enables real-time monitoring, predictive maintenance, and autonomous decision-making, significantly improving production efficiency, sustainability, and adaptability [

81]. A highly significant advancement in CMSFs is the integration of factory-as-a-service (FaaS), a paradigm in which production capabilities are offered as a service rather than as fixed, capital-intensive assets. FaaS leverages cloud-based platforms and DTs to enable businesses to achieve on-demand manufacturing, allowing small and medium enterprises to access high-end production capabilities without heavy upfront investments [

82]. This enhances resource utilization and CE integration and supports mass customization and personalized production, driving greater sustainability and efficiency [

83].

The CMSF model contributes significantly to sustainable manufacturing by reducing waste, optimizing resource utilization, and facilitating closed-loop production systems. By leveraging DT technology, manufacturers can simulate production processes, optimize energy consumption, and predict system failures, thereby minimizing downtime and reducing material waste [

84]. Additionally, IoT-enabled real-time monitoring ensures continuous performance optimization, further enhancing operational sustainability [

85]. From a CE perspective, CMSFs enable remanufacturing, component reuse, and material recovery through data-driven decision-making and predictive analysis. The modular and decentralized nature of CMSFs supports local production hubs that minimize transportation emissions while ensuring efficient material circulation within production cycles [

78]. The FaaS model further enhances circularity by sharing manufacturing resources among multiple users, reducing idle capacity, and promoting a more sustainable production ecosystem [

82]. Additionally, CMSFs enhance personalization by integrating AI-driven design automation with real-time consumer feedback mechanisms. This allows manufacturers to deliver hyper-personalized products while maintaining cost efficiency and sustainability. By leveraging DTs and cloud-based design platforms, manufacturers can dynamically adjust product specifications based on customer preferences, thereby reducing the need for excessive prototyping and minimizing raw material consumption [

83].

The realization of connected micro smart factories heavily depends on technological advancements in IoT, AI, cloud computing, big data analytics, and DTs.

IoT and cloud computing: IoT sensors collect real-time data from machines, materials, and production lines, thereby enabling predictive analytics and performance optimization. Cloud computing ensures seamless data exchange between factory components and enhances flexibility and scalability [

85].

AI and big data analytics: AI-driven algorithms analyze vast datasets to identify production inefficiencies, forecast demand, and automate decision-making, leading to smarter resource allocation and reduced production waste [

79].

DTs: DTs provide a virtual representation of the physical factory environment, enabling real-time monitoring, simulation, and predictive optimization of manufacturing processes. This improves maintenance efficiency, energy management, and adaptive production strategies, ensuring sustainability and cost-effectiveness [

80].

Reinforcement learning and CPSs: AI-powered reinforcement learning enables adaptive and resilient production control, allowing CMSFs to autonomously adjust operations in response to changing market demands and environmental conditions [

83].

A CMSF represents a paradigm shift in modern manufacturing, bridging modular production, real-time data integration, and hyper-personalization with sustainability and CE principles. By leveraging FAAS, IoT, AI, and DTs, CMSFs can enhance manufacturing agility, reduce waste, support personalized production, and align industrial processes with next-generation, sustainable, and customer-centric manufacturing models. Future advancements in AI-driven automation, edge computing, and decentralized manufacturing networks will further strengthen CMSFs as critical enablers of the next industrial revolution, paving the way for self-optimizing, hyper-flexible, and resilient production ecosystems [

83].

4.2. Urban Smart Factory

The urban smart factory (USF) represents an innovative manufacturing paradigm that integrates I4.0 technologies within urban environments to enhance sustainability, resilience, and human-centric production. Unlike traditional factories that are often located in peripheral industrial zones, USFs leverage urban infrastructure to provide localized, flexible, and highly automated production capabilities [

86]. The rise in urbanization, mass personalization, and resource scarcity has driven the need for smart manufacturing solutions that optimize production processes while minimizing environmental and social impacts [

87].

USFs are crucial for achieving Sustainable Development Goals (SDGs) by reducing transportation emissions, optimizing energy consumption, and integrating CE principles into production [

88]. By utilizing local supply chains and minimizing waste generation, these factories contribute to resource-efficient production systems that align with modern sustainability imperatives [

89]. Additionally, USFs facilitate local employment and enhance the resilience of urban economies by decentralizing production networks [

90].

The successful implementation of USFs relies on various I4.0 technologies, including the IoT, DTs, big data analytics, AI, and cloud computing [

91]. IoT-enabled devices facilitate real-time monitoring and control of manufacturing operations, ensuring seamless integration with urban logistics and smart city infrastructures [

92]. DTs create virtual representations of production processes, enabling predictive maintenance, process optimization, and enhanced decision-making capabilities [

93]. Furthermore, AI-driven analytics support adaptive production strategies that respond dynamically to market demand and urban conditions [

94].

USFs employ a transformative manufacturing approach integrating sustainability, advanced technology, and urban infrastructure to create efficient and resilient production ecosystems. As these factories continue to evolve, the synergy between DTs, AI, and CPSs plays a pivotal role in enhancing their capabilities.

Section 4.3 explores how these advanced technologies, particularly DTs, contribute to shaping the future of manufacturing through enhanced interoperability, process optimization, and real-time decision-making.

4.3. The DT Nexus: Enabling CE and Sustainable Manufacturing

The increasing complexity of global supply chains and the growing demand for sustainable production practices have driven the integration of DT technologies into CE frameworks. DTs offer real-time data exchange, predictive analytics, and system optimization, which are essential for achieving sustainability goals in manufacturing. The role of DTs in facilitating CE is expanding beyond process monitoring to support material reuse, resource efficiency, and lifecycle assessment [

5].

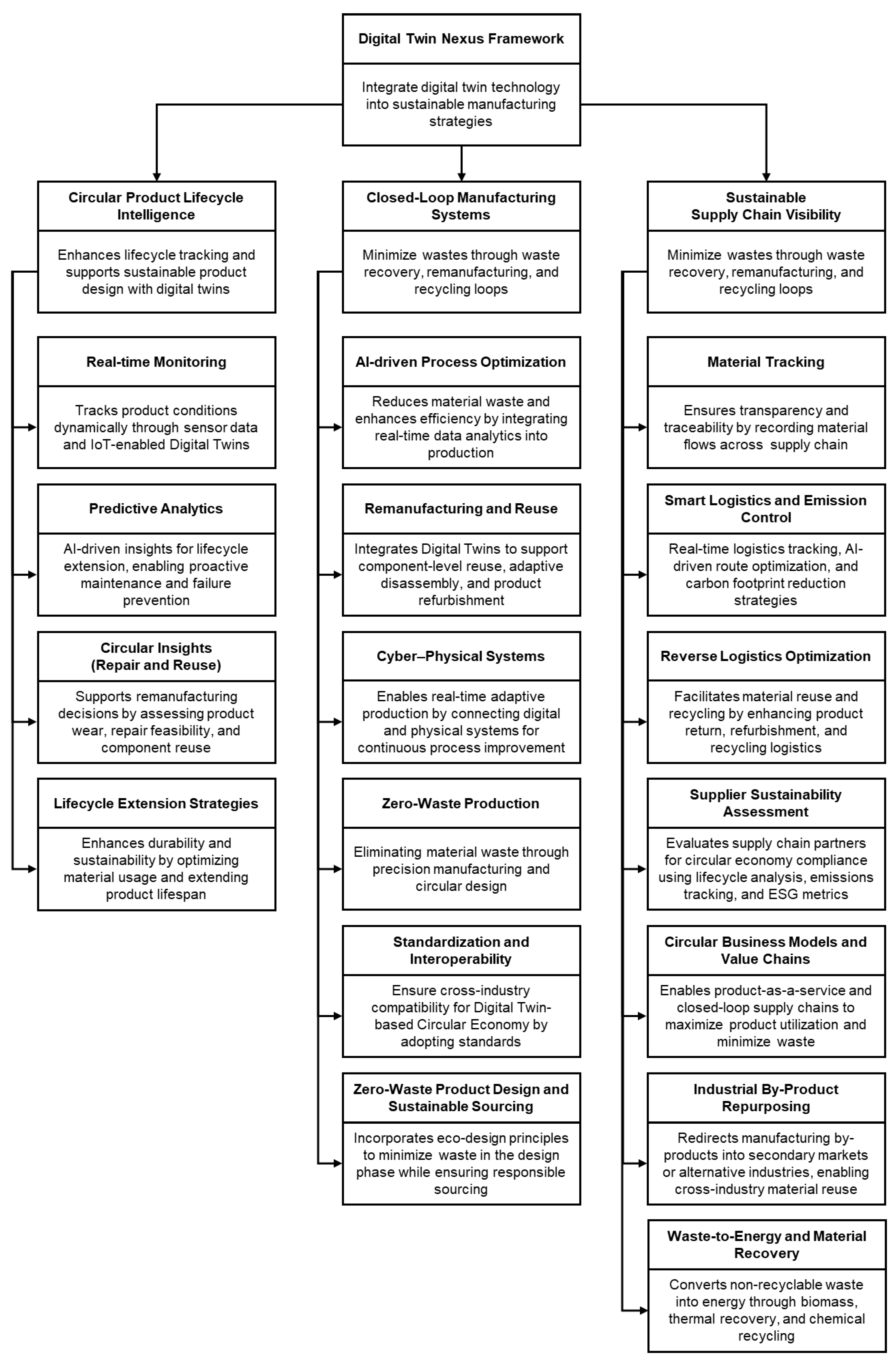

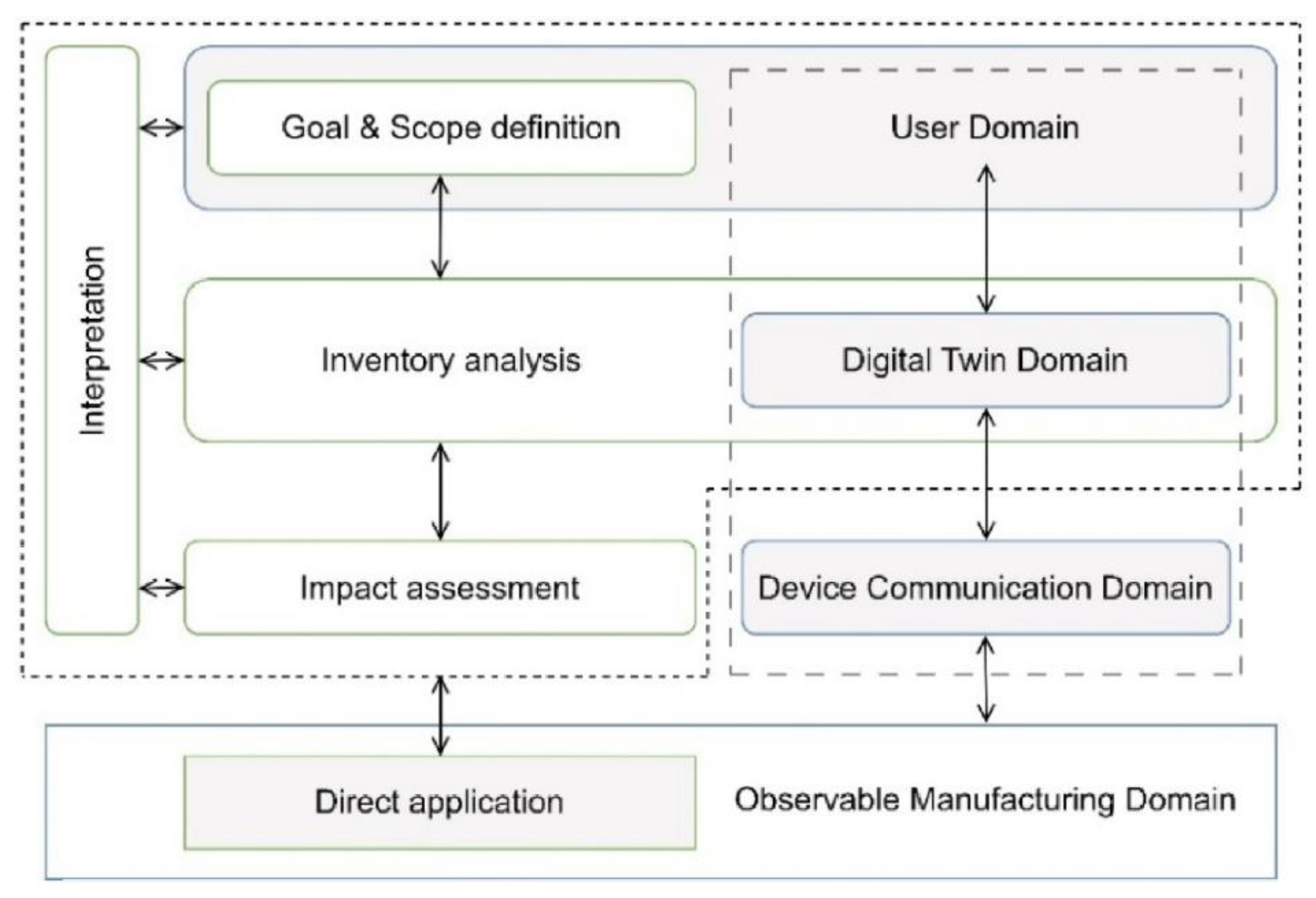

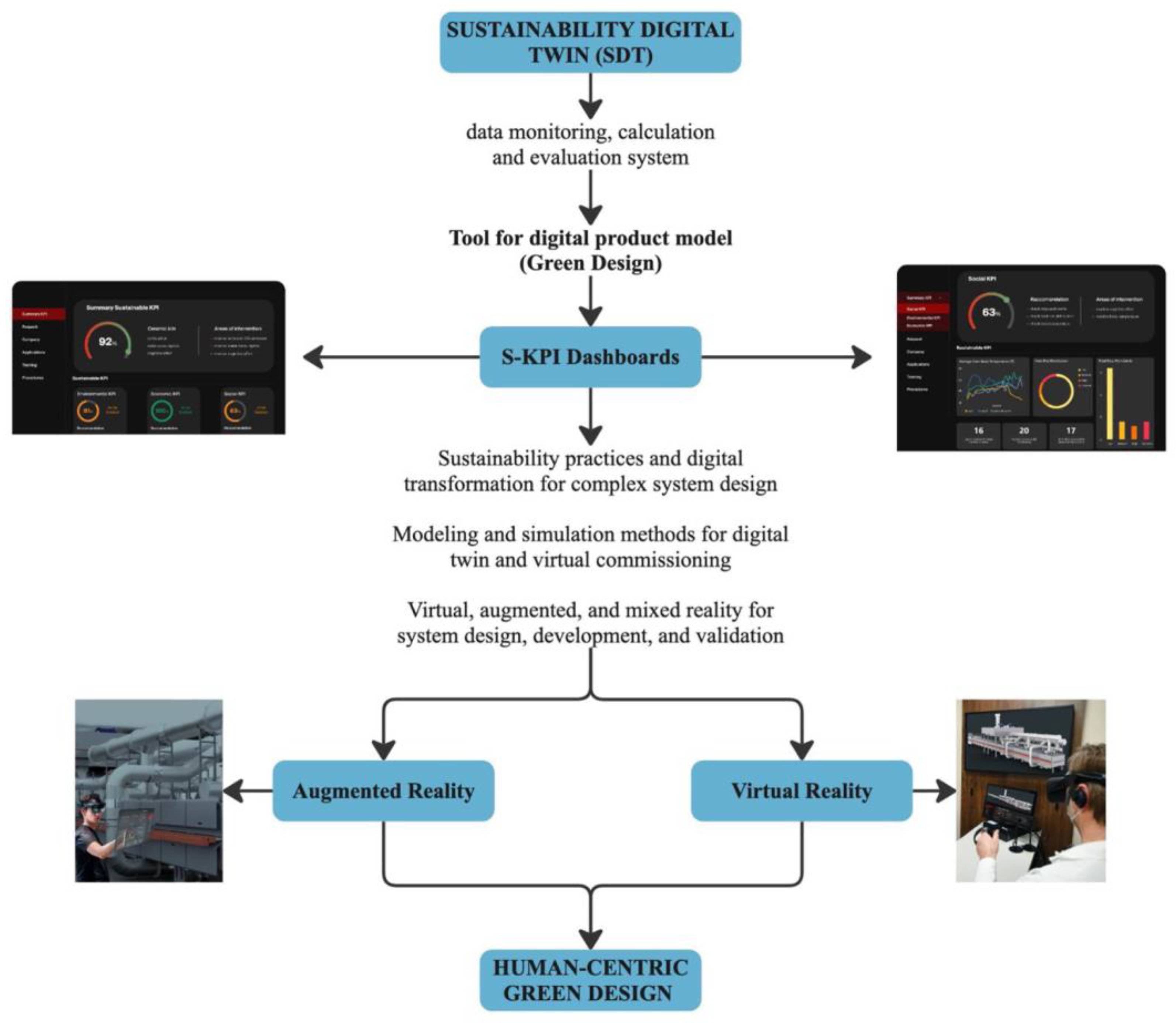

The DT Nexus Framework (DTNF) illustrated in

Figure 1 provides a structured approach for integrating DT technology into sustainable manufacturing and CE strategies. The framework comprises three interdependent dimensions, each of which is crucial in enhancing lifecycle efficiency, optimizing resource utilization, and increasing supply chain transparency.

The circular product lifecycle intelligence dimension focuses on enhancing lifecycle tracking and supporting sustainable product design using DTs. As shown in the figure, real-time monitoring allows manufacturers to track product conditions dynamically using sensor data and IoT-enabled DTs, thereby ensuring continuous data-driven insights. Predictive analytics leverage AI-driven insights to extend product lifespan, enabling proactive maintenance and failure prevention before significant breakdowns occur. Additionally, circular insights (repair and reuse) assist businesses in evaluating product wear, repair feasibility, and component reuse, reducing unnecessary production and supporting remanufacturing efforts. Finally, lifecycle extension strategies contribute to durability and sustainability by optimizing material usage and extending the product lifespan, which are crucial for long-term resource efficiency.

As illustrated in

Figure 1, the CLMS dimension highlights the role of DTs in optimizing waste recovery, remanufacturing, and recycling loops, ensuring that manufacturing processes are aligned with sustainability goals. AI-driven process optimization enhances material efficiency by integrating real-time analytics into production systems and reduces material waste through data-driven insights. Remanufacturing and reuse allow for component-level reuse, adaptive disassembly, and product refurbishment, ensuring that products remain in circulation for longer periods. CPSs enable real-time adaptive production, improve process optimization, and facilitate automated reconfiguration of manufacturing networks. Another key component, zero-waste production, eliminates material waste through precision manufacturing and circular design principles, thereby ensuring the efficient use of resources. Additionally, standardization and interoperability play vital roles in ensuring cross-industry compatibility for DT-based CE applications by adopting standardized protocols that enable seamless integration. Finally, zero-waste product design and sustainable sourcing incorporate eco-design principles to minimize waste during the design phase while ensuring responsible material sourcing, thus contributing to the development of sustainable products.

The sustainable supply chain visibility dimension emphasizes digital twin-enabled supply chain tracking, logistics optimization, and sustainable sourcing. Material tracking ensures transparency and traceability by recording material flows across the supply chain, thereby allowing manufacturers to track the impact of a product’s lifecycle. Smart logistics and emission controls facilitate real-time logistics tracking, AI-driven route optimization, and carbon footprint reduction strategies, ensuring efficient and sustainable supply chain operations. Reverse logistics optimization enhances reuse, refurbishment, and recycling logistics, ensuring that products and materials are reintegrated into the economy rather than being disposed of prematurely. Furthermore, the supplier sustainability assessment evaluates supply chain partners for CE compliance using lifecycle analysis, emissions tracking, and environmental, social, and governance (ESG) metrics, ensuring that companies adhere to sustainable procurement practices. Additionally, circular business models and value chains promote PaaS, leasing, and closed-loop supply chains that maximize product utilization while minimizing waste. Industrial by-product repurposing redirects manufacturing by-products into secondary markets or alternative industries, enabling cross-industry material reuse and reducing landfill waste. Finally, waste-to-energy and material recovery utilize biomass, thermal recovery, and chemical recycling to convert non-recyclable waste into energy, maximizing material recovery efficiency while ensuring that waste is processed responsibly.

Through its three-dimensional structure, the DTNF creates a synergistic approach to sustainability, bridging the gap between technology-driven efficiency and environmental responsibility.

Table 6 lists a structured view of how DTs contribute to CE and sustainable manufacturing. It categorizes key functional areas, associated technologies, practical applications, and challenges industries face in implementing these solutions. Additionally, ethical and regulatory concerns are highlighted to ensure that DT deployment aligns with responsible technological transformation principles. This framework helps bridge the gap between digital innovation and sustainable practices, thereby promoting long-term economic and environmental benefits.

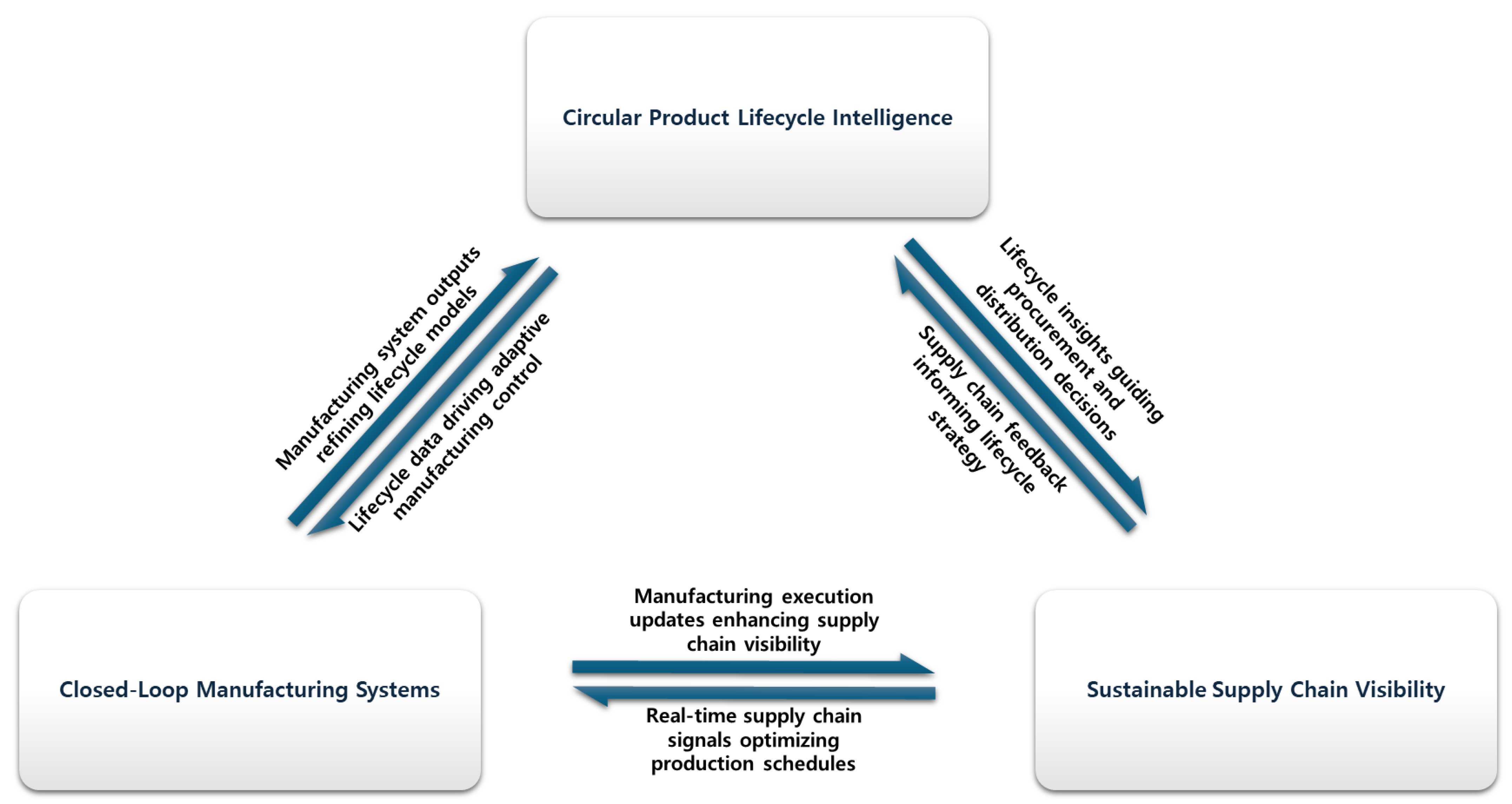

The three dimensions of the Digital Twin Nexus—circular product lifecycle intelligence, closed-loop manufacturing systems, and sustainable supply chain visibility—form an integrated framework that enables intelligent, closed-loop control and resource optimization across the manufacturing ecosystem. Circular product lifecycle intelligence delivers real-time insights into product condition, usage, and end-of-life potential, facilitating proactive decisions regarding reuse, repair, and re-design. These insights inform closed-loop manufacturing systems, which employ adaptive DT intelligence to autonomously manage remanufacturing, recycling, and zero-waste operations. In parallel, sustainable supply chain visibility ensures transparency, traceability, and predictive optimization across logistics networks. By interlinking suppliers, production systems, and recovery pathways through AI-driven analytics and digital product passports, it supports efficient resource circulation and waste minimization. Together, these dimensions reinforce one another: lifecycle intelligence drives manufacturing actions; manufacturing outputs influence supply chain flows; and supply chain feedback enhances lifecycle management. This synergistic interaction enables a resilient, self-optimizing, and circular industrial ecosystem.

Figure 2 visualizes the three core dimensions of the Digital Twin Nexus as an interconnected system supporting real-time data exchange, predictive analytics, and autonomous control. Collectively, they enable end-to-end optimization across the product lifecycle—from design to recovery—while dynamically aligning manufacturing processes with circular economy principles.

DTs facilitate the monitoring and tracking of product lifecycles from inception to end-of-life (EoL). DTs support decision-making in product design, refurbishment, and recycling by capturing data related to material composition, product usage, and maintenance history [

95]. Integrating behavioral modeling techniques within DTs enables manufacturers to predict material degradation and determine optimal reuse strategies. For example, predictive analytics embedded within DTs can inform remanufacturing decisions by assessing the structural integrity of components before reuse [

96].

A key CE principle is transitioning from a linear “take–make–dispose” model to a regenerative system where materials and components are continuously repurposed. DTs enable this transformation by creating virtual representations of physical assets, allowing for real-time monitoring and simulation of closed-loop production processes [

97]. These systems facilitate automated reverse logistics, waste minimization models, and decentralized remanufacturing networks. AI-driven DTs optimize the collection, sorting, and reintegration of post-consumer materials. DTs identify inefficiencies in manufacturing workflows and propose real-time adjustments to reduce waste generation [

5]. Moreover, DTs enable decentralized remanufacturing networks, which allow the coordination of manufacturing operations across multiple facilities to improve resource allocation and minimize transportation emissions [

98].

Sustainability in global manufacturing requires enhanced visibility and traceability across supply chains. DTs provide data-driven infrastructure that supports transparency in sourcing, production, and distribution [

3]. The deployment of digital product passports ensures that every stakeholder in the supply chain has access to essential product lifecycle data, enabling informed decisions regarding material provenance, recyclability, and compliance with sustainability standards [

96]. Additionally, DTs enhance carbon footprint tracking, allowing manufacturers to measure and mitigate greenhouse gas emissions across production networks. AI-powered models integrated into DTs can optimize supply chain logistics to reduce energy consumption and improve resource utilization [

98].

Thus, the DTNF presents a transformative approach to CE integration by leveraging real-time data, predictive analytics, and intelligent automation. However, several challenges remain, including the need for standardized data-sharing protocols, interoperability between DT platforms, and alignment with regulatory policies [

3]. Future research should explore the development of federated DT ecosystems that connect stakeholders across industries, thereby enabling collaborative sustainability efforts. Moreover, advancements in edge computing and AI further enhance the efficiency and scalability of DT applications in circular manufacturing [

99]. By embedding DTs within the core CE principles, manufacturers can achieve a paradigm shift toward sustainable, data-driven, and resilient production systems. This transition is essential for environmental sustainability, enhancing economic viability, and fostering long-term competitive advantages in global manufacturing.

5. Real-World Implementation of DT Strategies for Sustainable Industry

The DTNF aims to integrate real-time data, AI, and sustainable manufacturing principles to enhance operational efficiency and CE adoption. To validate the applicability of DTNF in real-world industrial scenarios, this section presents case studies demonstrating its implementation across diverse domains, including supply chain optimization, smart manufacturing, sustainability assessment, human-centric DT applications, and AI-driven factory evolution. These case studies provide empirical insights into how DTs contribute to responsible and sustainable manufacturing by optimizing production processes, reducing waste, and improving decision-making.

5.1. Case Study 1: Digital Twins for Supply Chain Optimization and Circular Economy

Supply chains play a vital role in the sustainability of manufacturing operations and have significant implications for waste reduction, resource efficiency, and carbon emissions. Traditional supply chains often suffer from inefficiencies owing to a lack of real-time visibility, poor demand forecasting, and linear production–consumption models, which result in excessive waste. Adopting DTs in supply chain management offers a transformative approach to achieving sustainability and CE objectives by enabling predictive analytics, intelligent decision-making, and closed-loop logistics.

Kim et al. (2025) [

100] investigated the role of DT-based prediction and optimization in enhancing the operational efficiency and resilience of dynamic supply chains. Their study introduced a supply chain DT (SCDT) methodology (

Figure 3) that integrates real-time monitoring, predictive analysis, and optimization to mitigate logistics disruptions and improve resource allocation. By employing a DT system architecture, the study outlines key components, such as a real-time simulation model and an optimization module, enabling manufacturers to anticipate supply chain disruptions, streamline logistics operations, and reduce inefficiencies. This section presents a case study of the supply chain of an automobile body production company, demonstrating the effectiveness of DT-enabled predictive optimization. Traditional supply chains often face challenges, such as inventory shortages, delayed deliveries, and inefficient demand forecasting. By contrast, the SCDT system dynamically synchronizes supplier, manufacturer, and logistics information, ensuring real-time visibility across supply chain nodes. Through IoT-enabled data aggregation and AI-driven decision-making, the DT model continuously evaluates factory performance, transportation networks, and production schedules to minimize inventory fluctuations and enhance supply chain responsiveness.

A key feature of this study is its demonstration of metaheuristics-based supply chain optimization. Using a tabu search algorithm, the SCDT system determines optimal production locations and transportation routes based on real-time inventory and cost fluctuations. This approach reduces logistics costs, improves material tracking, and enhances coordination between supply chain entities. The simulation-based framework validated these findings by showing an 8.97%, 1.3%, and 8.82% reduction in inventory costs, logistics costs, and total supply chain expenses, respectively. In addition to economic efficiency, Kim et al. (2025) [

100] highlighted the sustainability benefits of DT-enabled supply chain management. By dynamically adjusting production and delivery schedules, the system reduces overproduction and transportation emissions, thereby addressing key environmental concerns in industrial manufacturing. Additionally, by optimizing logistics networks in response to real-time disruptions, this study demonstrates how DTs facilitate energy-efficient, low-carbon supply chain operations.

These findings align with the DTNF by validating the logistics and sustainability layers. The DTNF emphasizes the integration of AI-driven DT technologies to create data-driven, sustainable manufacturing ecosystems. This case study provides empirical evidence that DTs enable responsible and intelligent supply chain transformation, reduce waste, improve efficiency, and foster circular economic initiatives.

5.2. Case Study 2: Real-Time AI and Edge Computing for Smart Manufacturing

Manufacturing operations require constant monitoring and optimization to ensure efficiency, minimize energy consumption, and reduce waste. Traditional manufacturing systems often rely on centralized data processing models, which can create bottlenecks in decision-making owing to latency and network dependency. Conversely, edge computing combined with DT technology allows for real-time data processing at the source, improving operational efficiency and sustainability. By integrating AI-driven DTs with edge-computing architectures, manufacturers can optimize energy usage, enhance predictive maintenance, and achieve higher levels of automation.

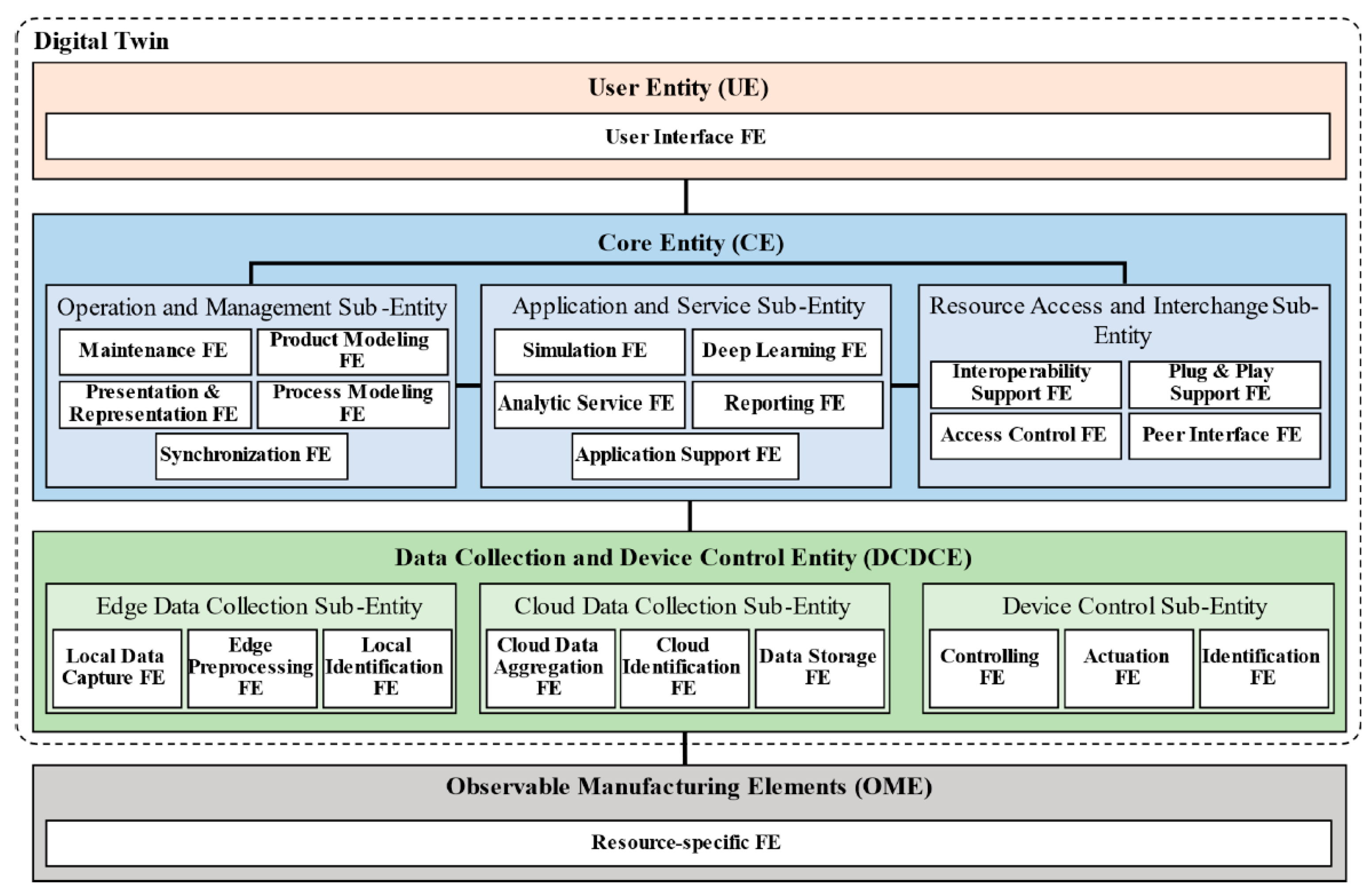

Kang et al. (2024) [

101] proposed an edge computing-based DT (E-DT) framework designed to enhance real-time data processing capabilities in smart manufacturing. Their study addresses the limitations of conventional DT architectures, which rely heavily on cloud-based processing, resulting in high latency and data transmission bottlenecks. By integrating edge computing into DT operations, the proposed framework enables faster data analysis, reduced network congestion, and enhanced real-time decision-making. Their research is based on ISO 23247 [

102], which is a reference architecture for DTs in manufacturing.

The E-DT framework is shown in