Pistachio Shell Ash in Agro-Waste Cement Composites: A Pathway to Low-Carbon Binders

Abstract

1. Introduction

2. Materials and Methods

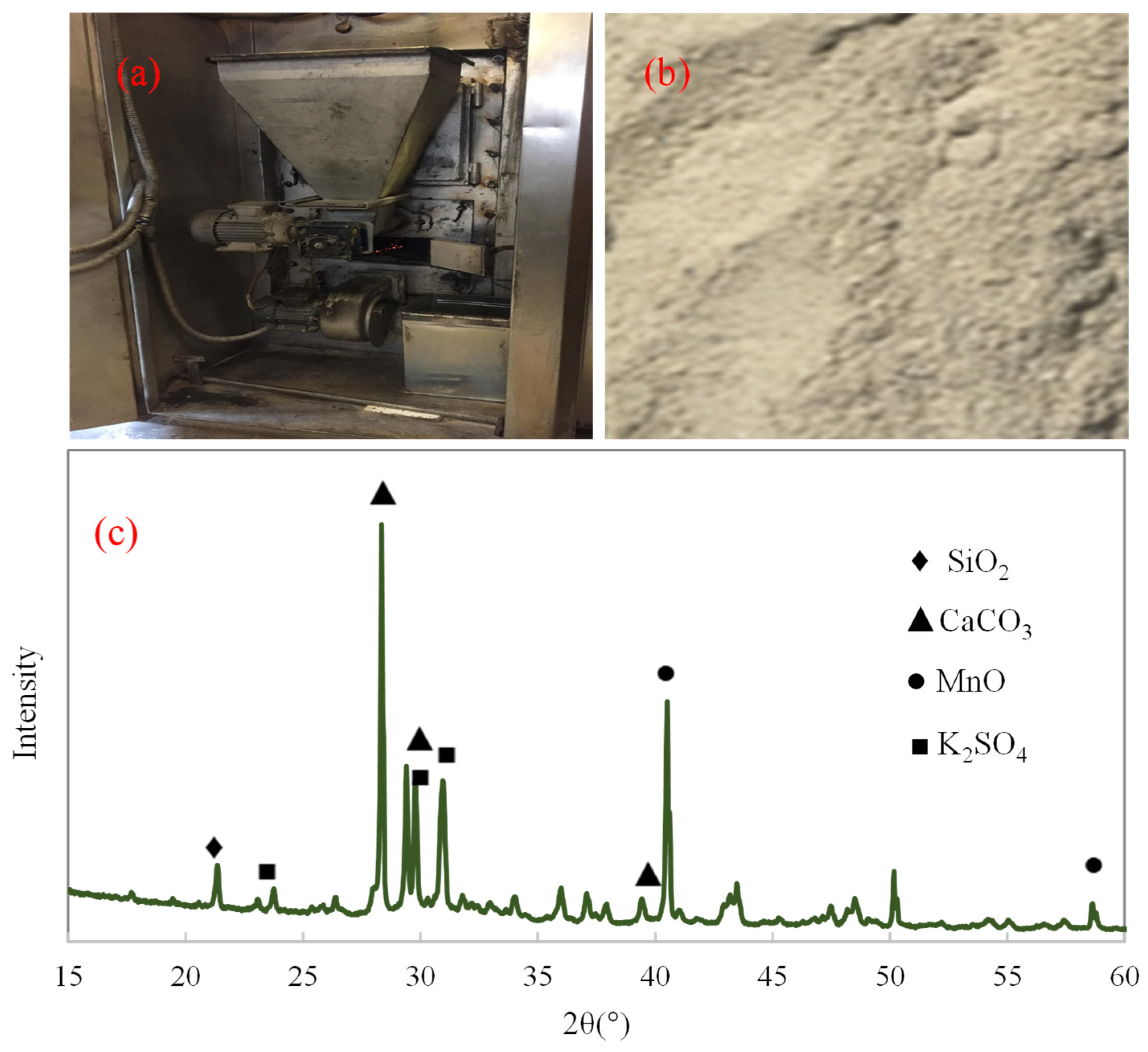

2.1. Material

2.2. Methods

3. Results

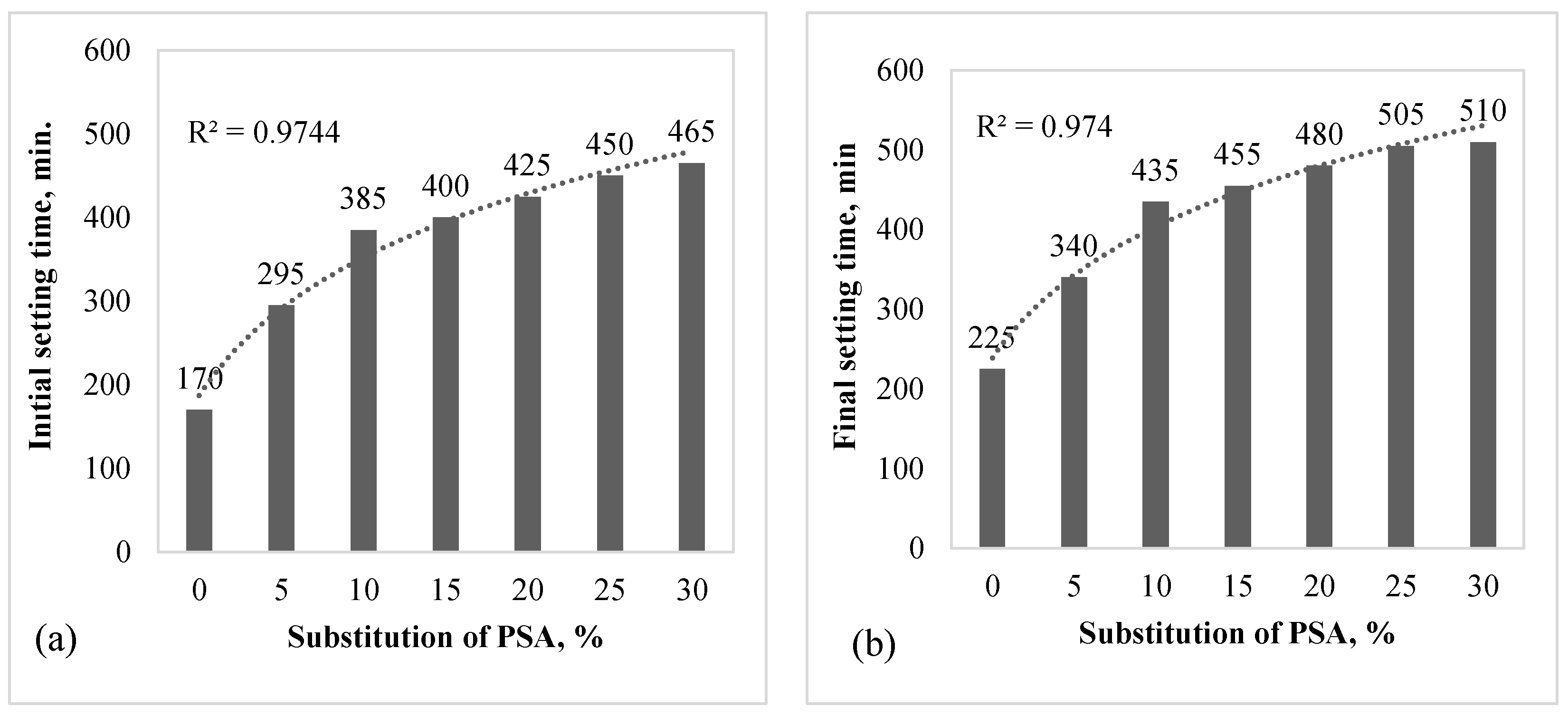

3.1. Amount of Water and Setting Time of Blended Cement

3.2. Oxide Composition of Blended Cement

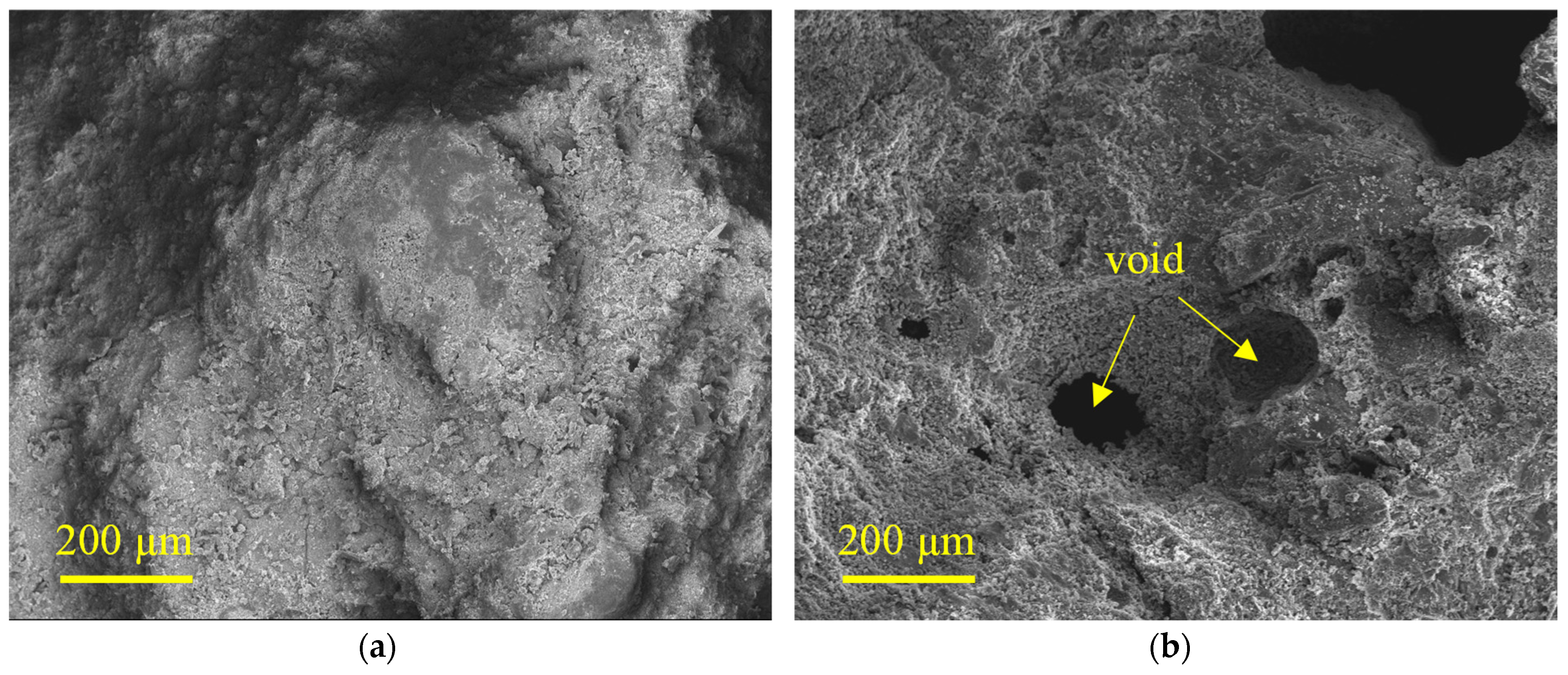

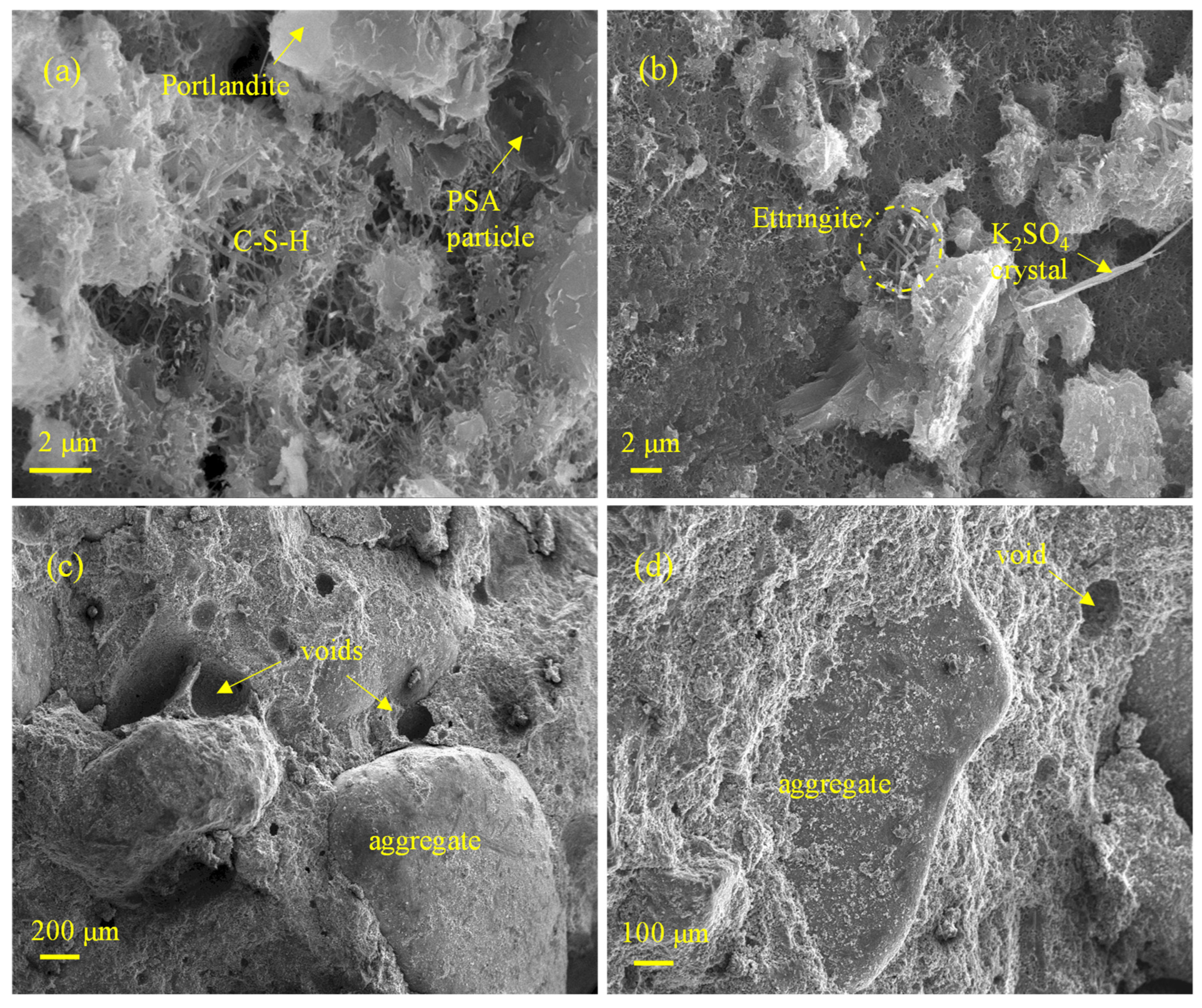

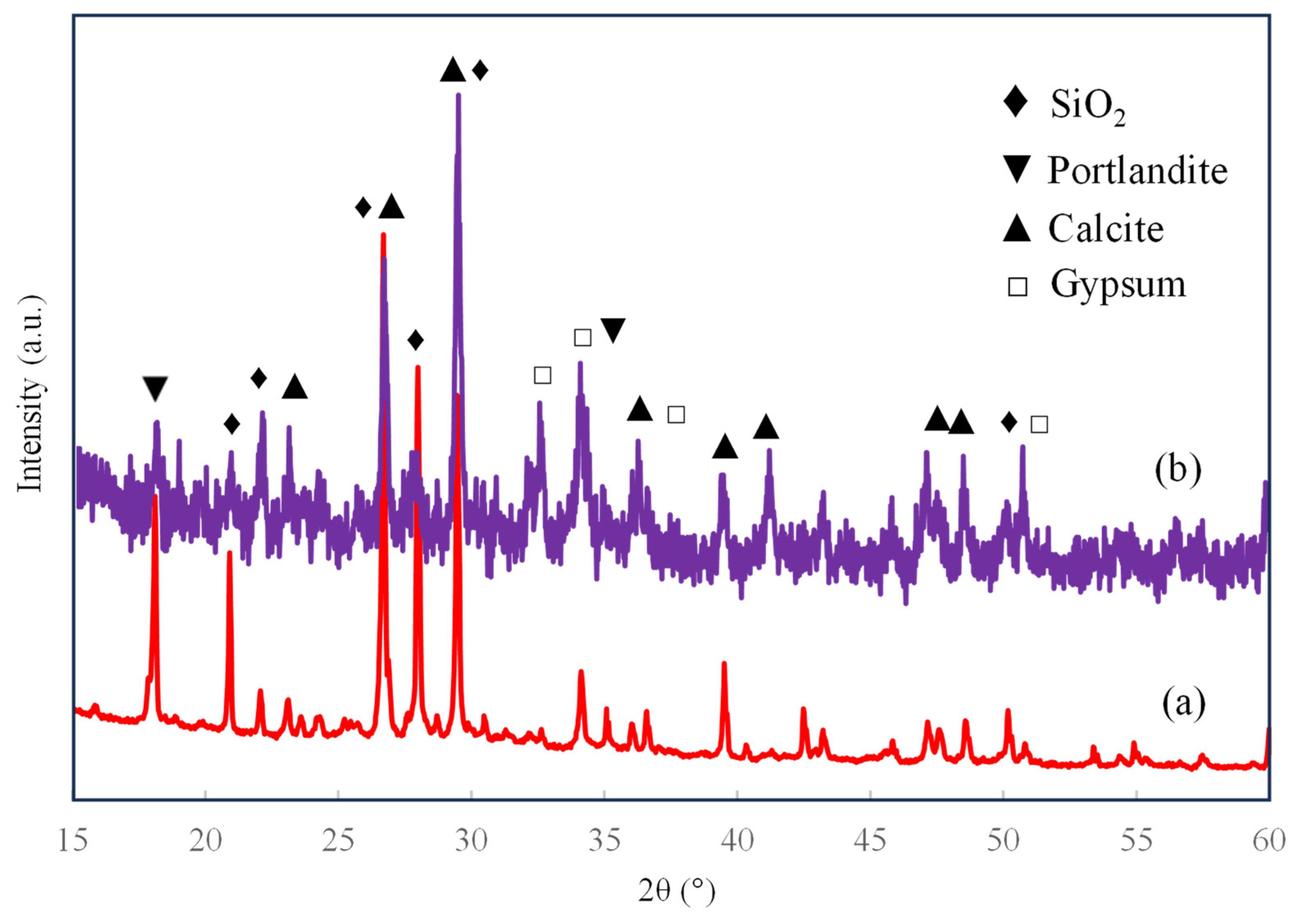

3.3. Microstructural Analyses

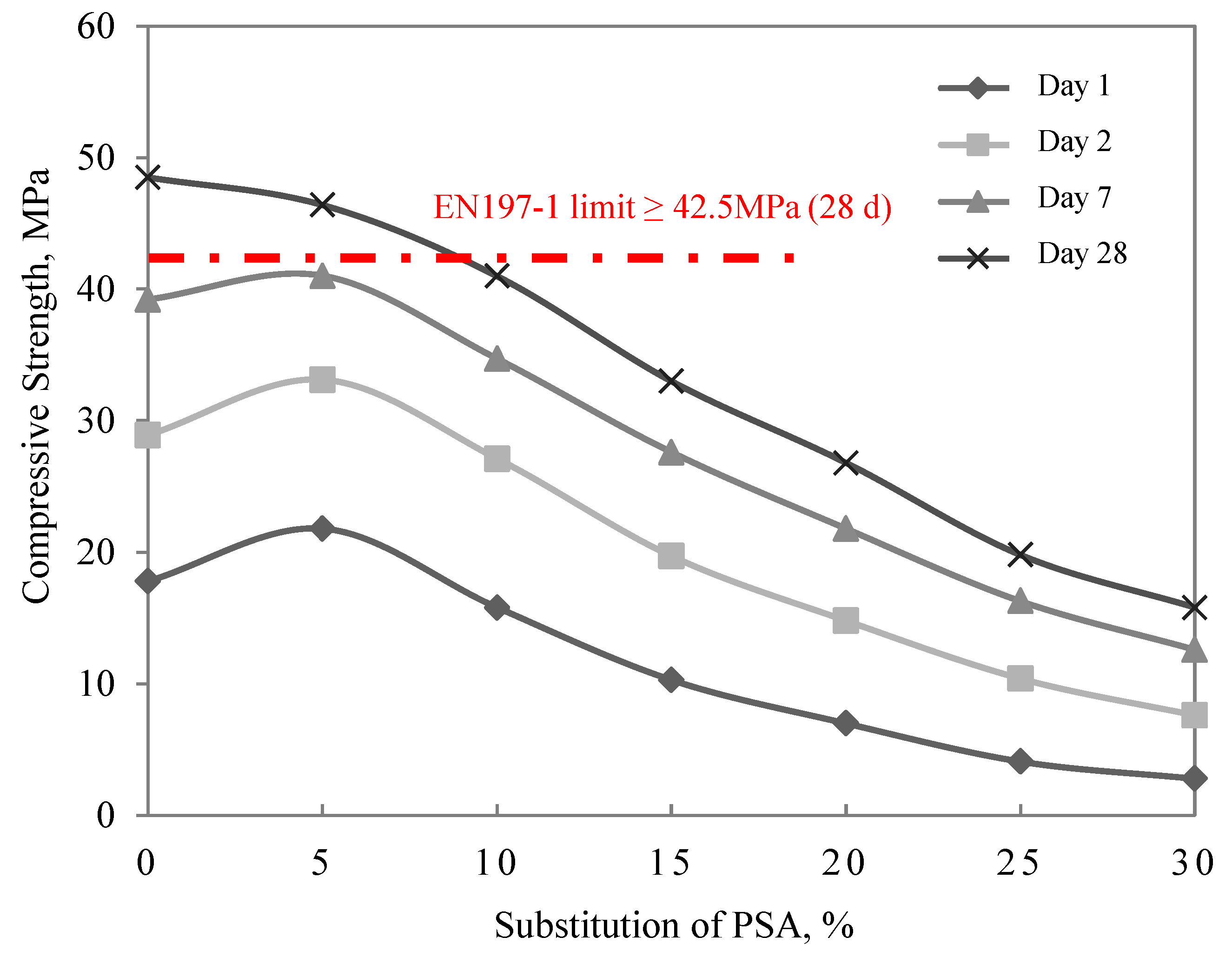

3.4. Strength of Blended Cement

4. Conclusions

- The experimental results demonstrate that PSA substitution significantly influences the compressive strength development of cement mortars. At early curing stages (1, 7, and 28 days), mortars containing 5% PSA exhibited enhanced strength characteristics compared to the control mixture, with measured values of 21.8 MPa, 33.1 MPa, and 41.0 MPa, respectively, versus 17.8 MPa, 28.9 MPa, and 39.2 MPa for the plain mortar. This improvement in early-age strength can be attributed to the accelerated hydration kinetics facilitated by PSA’s high alkali content (Na2O + K2O = 11.9%) and sulfate (SO3 = 12.96%) components. However, at 28 days of curing, the 5% PSA mixture showed a marginal reduction in ultimate compressive strength (46.4 MPa) compared to the control (48.5 MPa), though it still complied with the EN 197-1 standard requirements. This slight decrease may be associated with PSA’s limited pozzolanic activity (S+A+F = 3.82%) and its interference with long-term C-S-H gel formation.

- PSA substitution significantly extended the setting times of the cement. A 30% PSA substitution increased the initial setting time by 174% and the final setting time by 126%. This effect is due to the high SO3 content and low pozzolanic activity of PSA.

- As the PSA substitution rate increased, the water requirement of mortars also increased. This was attributed to the high surface area and fine-grained structure of PSA particles.

- SEM-EDS and XRD analyses showed that calcite and gypsum phases dominated in the PSA-substituted samples. These phases increased the early age strength but limited the C-S-H gel formation in the long term.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rudnicki, T. The influence of the type of cement on the properties of surface cement concrete. Materials 2022, 15, 4998. [Google Scholar] [CrossRef] [PubMed]

- Belaïd, F. How does concrete and cement industry transformation contribute to mitigating climate change challenges? Resour. Conserv. Recycl. Adv. 2022, 15, 200084. [Google Scholar] [CrossRef]

- Poudyal, L.; Adhikari, K. Environmental sustainability in cement industry: An integrated approach for green and economical cement production. Resour. Environ. Sustain. 2021, 4, 100024. [Google Scholar] [CrossRef]

- Andrew, R.M. Global CO2 emissions from cement production. Earth Syst. Sci. Data 2018, 10, 195–217. [Google Scholar] [CrossRef]

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global strategies and potentials to curb CO2 emissions in cement industry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Le, Q.C.; Andrew, R.M.; Friedlingstein, P.; Sitch, S.; Hauck, J.; Pongratz, J.; Pickers, P.A.; Korsbakken, J.I.; Peters, G.P.; Canadell, J.G. Global carbon budget 2017. Earth Syst. Sci. Data 2018, 10, 2141–2194. [Google Scholar]

- Isberto, C.D.; Labra, K.L.; Landicho, J.M.B.; De Jesus, R. Optimized preparation of rice husk ash (RHA) as a supplementary cementitious material. GEOMATE J. 2019, 16, 56–61. [Google Scholar] [CrossRef]

- Karaşin, A.; Doğruyol, M. An experimental study on strength and durability for utilization of fly ash in concrete mix. Adv. Mater. Sci. Eng. 2014, 2014, 417514. [Google Scholar] [CrossRef]

- Karasin, A.; Hadzima-Nyarko, M.; Işık, E.; Doğruyol, M.; Karasin, I.B.; Czarnecki, S. The Effect of Basalt Aggregates and Mineral Admixtures on the Mechanical Properties of Concrete Exposed to Sulphate Attacks. Materials 2022, 15, 1581. [Google Scholar] [CrossRef]

- Chen, J.J.; Ng, P.L.; Kwan, A.K.H.; Li, L.G. Lowering cement content in mortar by adding superfine zeolite as cement replacement and optimizing mixture proportions. J. Clean. Prod. 2019, 210, 66–76. [Google Scholar] [CrossRef]

- Gökçe, H.S.; Şimşek, O.; Korkmaz, S. Reduction of alkali—Silica reaction expansion of mortars by utilisation of pozzolans. Mag. Concr. Res. 2013, 65, 441–447. [Google Scholar] [CrossRef]

- Doğruyol, M. Determination of ASR in Concrete Using Characterization Methods. Buildings 2024, 14, 657. [Google Scholar] [CrossRef]

- Bolte, G.; Zajac, M.; Skocek, J.; Haha, M.B. Development of composite cements characterized by low environmental footprint. J. Clean. Prod. 2019, 226, 503–514. [Google Scholar] [CrossRef]

- Tekin, İ.; Dirikolu, İ.; Gökçe, H.S. A regional supplementary cementitious material for the cement industry: Pistachio shell ash. J. Clean. Prod. 2021, 285, 124810. [Google Scholar] [CrossRef]

- Tosti, L.; van Zomeren, A.; Pels, J.R.; Dijkstra, J.J.; Comans, R.N.J. Assessment of biomass ash applications in soil and cement mortars. Chemosphere 2019, 223, 425–437. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Siddique, R. Recent advances in understanding the role of supplementary cementitious materials in concrete. Cem. Concr. Res. 2015, 78, 71–80. [Google Scholar] [CrossRef]

- Doğruyol, M.; Ayhan, E.; Karaşin, A. Effect of waste steel fiber use on concrete behavior at high temperature. Case Stud. Constr. Mater. 2024, 20, e03051. [Google Scholar] [CrossRef]

- Ikumapayi, C.M.; Arum, C.; Alaneme, K.K. Reactivity and hydration behavior in groundnut shell ash based pozzolanic concrete. Mater. Today Proc. 2021, 38, 508–513. [Google Scholar] [CrossRef]

- Utsev, J.T.; Taku, J.K. Coconut shell ash as partial replacement of ordinary Portland cement in concrete production. Int. J. Sci. Technol. Res. 2012, 1, 86–89. [Google Scholar]

- Baran, Y.; Gökçe, H.S.; Durmaz, M. Physical and mechanical properties of cement containing regional hazelnut shell ash wastes. J. Clean. Prod. 2020, 259, 120965. [Google Scholar] [CrossRef]

- Doğruyol, M.; Durmaz, M. The Effect of Pistachio Vera Shell Ash (PSA) on Concrete Performance. Bitlis Eren Üniversitesi Fen Bilim. Derg. 2025, 14, 513–528. [Google Scholar] [CrossRef]

- Taghizadeh-Alisaraei, A.; Assar, H.A.; Ghobadian, B.; Motevali, A. Potential of biofuel production from pistachio waste in Iran. Renew. Sustain. Energy Rev. 2017, 72, 510–522. [Google Scholar] [CrossRef]

- Sabuncu, Y.; Mamay, M.; Özgen, İ. Overwintering insect (Arthropoda: Insecta) biodiversity in pistachio orchards of the Middle Euphrates Valley, Turkey. Harran Tarım Ve Gıda Bilim. Derg. 2021, 25, 185–192. [Google Scholar] [CrossRef]

- Avcioglu, Ü.; Aksoy, A. Analysis of correlation of pistachio production and income with the Koyck models in Turkey. Alinteri J. Agric. Sci. 2021, 36, 71–76. [Google Scholar] [CrossRef]

- Givi, A.N.; Rashid, S.A.; Aziz, F.N.A.; Salleh, M.A.M. Contribution of rice husk ash to the properties of mortar and concrete: A review. J. Am. Sci. 2010, 6, 157–165. [Google Scholar]

- Nassiri, O.; Mahboub, I.; Ibnoussina, M.; Moukmir, O.; El Amrani, A.; Mazirh, K.; Ammari, A.; El Cheickine, I. Physico-mechanical, structural, and mineralogical analysis of composite concrete incorporating hydraulic lime and pozzolan. Constr. Build. Mater. 2024, 437, 136804. [Google Scholar] [CrossRef]

- Doğruyol, M. Characterization of historic mortars and the effect of rice husk ash (RHA) on quicklime. Case Stud. Constr. Mater. 2024, 21, e03542. [Google Scholar] [CrossRef]

- Subramaniam, D.N.; Sathiparan, N. Comparative study of fly ash and rice husk ash as cement replacement in pervious concrete: Mechanical characteristics and sustainability analysis. Int. J. Pavement Eng. 2023, 24, 2075867. [Google Scholar] [CrossRef]

- MSandanayake; Bouras, Y.; Haigh, R.; Vrcelj, Z. Current sustainable trends of using waste materials in concrete—A decade review. Sustainability 2020, 12, 9622. [Google Scholar] [CrossRef]

- Al-Alwan, A.A.K.; Al-Bazoon, M.; Mussa, F.I.; Alalwan, H.A.; Shadhar, M.H.; Mohammed, M.M.; Mohammed, M.F. The impact of using rice husk ash as a replacement material in concrete: An experimental study. J. King Saud Univ.-Eng. Sci. 2024, 36, 249–255. [Google Scholar] [CrossRef]

- I.S. EN 196-1:2016; Methods of Testing Cement-Part 1: Determination of Strength. Turkish Standards Institute: Ankara, Turkey, 2009.

- Anuar, M.F.; Fen, Y.W.; Zaid, M.H.M.; Matori, K.A.; Khaidir, R.E.M. The Physical and Optical Studies of Crystalline Silica Derived from the Green Synthesis of Coconut Husk Ash. Appl. Sci. 2020, 10, 2128. [Google Scholar] [CrossRef]

- Shakouri, M.; Exstrom, C.L.; Ramanathan, S.; Suraneni, P. Hydration, strength, and durability of cementitious materials incorporating untreated corn cob ash. Constr. Build. Mater. 2020, 243, 118171. [Google Scholar] [CrossRef]

- Kamau, J.; Ahmed, A.; Hirst, P.; Kangwa, J. Suitability of Corncob Ash as a Supplementary Cementitious Material. Int. J. Mater. Sci. Eng. 2016, 4, 215–228. [Google Scholar]

- Doğruyol, M.; Karaşin, A. Sülfatın beton ve betonarme elemanlara olumsuz etkisi. Dicle Üniversitesi Mühendislik Fakültesi Mühendislik Derg. 2011, 2, 79–85. [Google Scholar]

- Papadakis, V.G.; Tsimas, S. Supplementary cementing materials in concrete Part I: Efficiency and design. Cem. Concr. Res. 2002, 32, 1525–1532. [Google Scholar] [CrossRef]

- Wang, B.; Yao, W.; Stephan, D. Preparation of calcium silicate hydrate seeds by means of mechanochemical method and its effect on the early hydration of cement. Adv. Mech. Eng. 2019, 11, 1687814019840586. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 4th ed.; McGraw-Hill Education: New York, NY, USA, 2006. [Google Scholar]

- Ke, X.; Wu, Z.; Lin, J.; Wang, F.; Li, P.; Xu, R.; Yang, M.; Han, L.; Zhang, D. A rapid analytical method for the specific surface area of amorphous sio2 based on X-Ray diffraction. J. Non-Cryst. Solids 2020, 531, 119841. [Google Scholar] [CrossRef]

- Islam, K.N.; Bakar, M.Z.B.A.; Ali, M.E.; Hussein, M.Z.B.; Noordin, M.M.; Loqman, M.Y.; Miah, G.; Wahid, H.; Hashim, U. A novel method for the synthesis of calcium carbonate (aragonite) nanoparticles from cockle shells. Powder Technol. 2013, 235, 70–75. [Google Scholar] [CrossRef]

- Haastrup, S.; Bødker, M.S.; Hansen, S.R.; Yu, D.; Yue, Y. Impact of amorphous micro silica on the C-S-H phase formation in porous calcium silicates. J. Non-Cryst. Solids 2018, 481, 556–561. [Google Scholar] [CrossRef]

- Arvaniti, E.C.; Juenger, M.C.G.; Bernal, S.A.; Duchesne, J.; Courard, L.; Leroy, S.; Provis, J.L.; Klemm, A.; De Belie, N. Physical characterization methods for supplementary cementitious materials. Mater. Struct./Mater. Constr. 2015, 48, 3675–3686. [Google Scholar] [CrossRef]

- BS EN 196-3:2016; Methods of Testing Cement. Determination of Setting Times and Soundness. European Standards Institution: Brussels, Belgium, 2016.

- Zunino, F.; Bentz, D.P.; Castro, J. Reducing setting time of blended cement paste containing high-SO3 fly ash (HSFA) using chemical/physical accelerators and by fly ash pre-washing. Cem. Concr. Compos. 2018, 90, 14–26. [Google Scholar] [CrossRef] [PubMed]

- BS EN 197-1:2011; Cement-Part 1: Composition, Specifications and Conformity Criteria for Common Cements. European Committee for Standardisation: London, UK, 2011.

- Zhang, J. Recent advance of MgO expansive agent in cement and concrete. J. Build. Eng. 2022, 45, 103633. [Google Scholar] [CrossRef]

- Lighty, J.S.; Veranth, J.M.; Sarofim, A.F. Combustion Aerosols: Factors Governing Their Size and Composition and Implications to Human Health. J. Air Waste Manag. Assoc. 2000, 50, 1565–1618. [Google Scholar] [CrossRef] [PubMed]

- Sánchez-Mendieta, C.; Galán-Díaz, J.J.; Martinez-Lage, I. Relationships between density, porosity, compressive strength and permeability in porous concretes: Optimization of properties through control of the water-cement ratio and aggregate type. J. Build. Eng. 2024, 97, 110858. [Google Scholar] [CrossRef]

- Wang, J.; Hu, Z.; Chen, Y.; Huang, J.; Ma, Y.; Zhu, W.; Liu, J. Effect of Ca/Si and Al/Si on micromechanical properties of C (-A)-SH. Cem. Concr. Res. 2022, 157, 106811. [Google Scholar] [CrossRef]

- Zheng, T.; Qian, C. Influencing factors and formation mechanism of CaCO3 precipitation induced by microbial carbonic anhydrase. Process Biochem. 2020, 91, 271–281. [Google Scholar] [CrossRef]

- Dorn, T.; Blask, O.; Stephan, D. Acceleration of cement hydration—A review of the working mechanisms, effects on setting time, and compressive strength development of accelerating admixtures. Constr. Build. Mater. 2022, 323, 126554. [Google Scholar] [CrossRef]

- Neto, J.S.A. Hydration and interactions between C3S and C3A polymorphs in the presence of different calcium sulfates. Cem. Concr. Res. 2021, 159, 106893. [Google Scholar] [CrossRef]

- Szudek, W.; Szydłowski, J.; Buchała, I.; Kapeluszna, E. Synthesis and Characterization of Calcium Sulfoaluminate Hydrates—Ettringite (AFt) and Monosulfate (AFm). Materials 2024, 17, 5216. [Google Scholar] [CrossRef]

- Krivoborodov, Y.R.; Samchenko, S.V.; Korshunov, A.V.; Kozlova, I.V.; Alpacky, D.G. Increasing the hydration activity of tricalcium silicate by adding microdispersed ettringite as a nucleating agent. Materials 2023, 16, 7078. [Google Scholar] [CrossRef]

- Zheng, Y. Size-Independent Nucleation and Growth Model of Potassium Sulfate from Supersaturated Solution Produced by Stirred Crystallization. Molecules 2023, 29, 141. [Google Scholar] [CrossRef] [PubMed]

- Briard, M.; Brandel, C.; Morin-Grognet, S.; Coquerel, G.; Dupray, V. Potassium Sulfate: A New Candidate to Explore Non-Photochemical Laser-Induced Nucleation Mechanisms. Crystals 2021, 11, 1571. [Google Scholar] [CrossRef]

- Sanytsky, M.; Kropyvnytska, T.; Shyiko, O. Effect of Potassium Sulfate on the Portland Cement Pastes Setting Behavior. Chem. Chem. Technol. 2023, 17, 170–178. [Google Scholar] [CrossRef]

- Faqe, H. Effect of Chemical Activators on the Compressive Strength of Cement-Slag Mortar. IOP Conf. Ser. Mater. Sci. Eng. 2020, 978, 012004. [Google Scholar] [CrossRef]

- Demir, I. Effect of organic residues addition on the technological properties of clay bricks. Waste Manag. 2008, 28, 622–627. [Google Scholar] [CrossRef] [PubMed]

- Erdoğan, Y.T. Materials of Construction; M.E.T.U. Press: Ankara, Turkey, 2002. [Google Scholar]

- Kara, İ.B. Kalsitin Çimento İkame Malzemesi Olarak Kullanımının Basınç Dayanımına Etkisi Effect of the Use of Calcite as a Substitute for Cement on Compressive Strength Keywords Concrete Cement Strenght Calcite. J. Investig. Eng. Technol. 2020, 3, 10–16. [Google Scholar]

- Akkaya, Y.; Kesler, Y.E. Mikrokalsit katkısının betonun işlenebilirliğine, mekanik özelliklerine ve dayanıklılığına etkisi. Tek. Dergi 2012, 23, 6051–6061. [Google Scholar]

- Winnefeld, F.; Läng, F.; Leemann, A. Pozzolanic Reaction of Carbonated Wollastonite Clinker. J. Adv. Concr. Technol. 2023, 21, 631–642. [Google Scholar] [CrossRef]

- Lu, B.; Huo, Z.; Xu, Q.; Hou, G.; Wang, X.; Liu, J.; Hu, X. Characteristics of CSH under carbonation and its effects on the hydration and microstructure of cement paste. Constr. Build. Mater. 2023, 364, 129952. [Google Scholar] [CrossRef]

- Wu, J.; Liao, H.; Ma, Z.; Song, H.; Cheng, F. Effect of different initial CaO/SiO2 molar ratios and curing times on the preparation and formation mechanism of calcium silicate hydrate. Materials 2023, 16, 717. [Google Scholar] [CrossRef]

- Al-saffar, F.Y.; Wong, L.S.; Paul, S.C. An Elucidative Review of the Nanomaterial Effect on the Durability and Calcium-Silicate-Hydrate (C-S-H) Gel Development of Concrete. Gels 2023, 9, 613. [Google Scholar] [CrossRef] [PubMed]

- Andrew, O.T.; Omotayo, O.O.; Arum, C.; Ikumapayi, C.M. Effects of sodium carbonate admixture and mix design ratios on the compressive strength of concrete. Niger. J. Technol. 2023, 42, 185–190. [Google Scholar] [CrossRef]

- Liu, C.; Li, Z.; Nie, S.; Skibsted, J.; Ye, G. Structural evolution of calcium sodium aluminosilicate hydrate (C-(N-) ASH) gels induced by water exposure: The impact of Na leaching. Cem. Concr. Res. 2024, 178, 107432. [Google Scholar] [CrossRef]

- Liao, W.; Lu, C.; Xu, Z. The Deterioration of CSH Gel in a Severe Sulfate Environment. Symmetry 2024, 16, 703. [Google Scholar] [CrossRef]

- Li, Y.; Ding, Z.; Wang, X.; Wang, X.; Han, B. Molecular dynamics study on structural characteristics of amorphous C-S-H with different Ca/Si ratios. J. Am. Ceram. Soc. 2025, 108, e20134. [Google Scholar] [CrossRef]

- Hou, G.; Chen, J.; Lu, B.; Chen, S.; Cui, E.; Naguib, H.M.; Guo, M.-Z.; Zhang, Q. Composition design and pilot study of an advanced energy-saving and low-carbon rankinite clinker. Cem. Concr. Res. 2020, 127, 105926. [Google Scholar] [CrossRef]

- Hou, G.; Yan, Z.; Sun, J.; Naguib, H.M.; Lu, B.; Zhang, Z. Microstructure and mechanical properties of CO2-cured steel slag brick in pilot-scale. Constr. Build. Mater. 2021, 271, 121581. [Google Scholar] [CrossRef]

- de Oliveira, C.C.N.; Szklo, A.; Rochedo, P.R.R. Evaluation of Carbon Capture Potential in the Brazilian Cement Sector. Appl. Mech. Mater. 2016, 830, 46–53. [Google Scholar] [CrossRef]

- Hejazi, B.; Montagnaro, F. A Modeling and Simulation Study to Accommodate Sorbent Sintering in a Ca-Looping System Coupled with a Cement Plant. Ind. Eng. Chem. Res. 2024, 63, 11069–11081. [Google Scholar] [CrossRef]

- Huntzinger, D.N.; Eatmon, T.D. A life-cycle assessment of Portland cement manufacturing: Comparing the traditional process with alternative technologies. J. Clean. Prod. 2009, 17, 668–675. [Google Scholar] [CrossRef]

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | K2O | Na2O | Na2Oeq 1 | LOI 2 | S+A+F | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| OPC | 19.61 | 4.92 | 3.15 | 63.66 | 2.19 | 2.54 | 0.75 | 0.29 | 0.78 | 2.89 | 27.68 |

| PSA | 2.4 | 0.65 | 0.77 | 17.07 | 5.92 | 12.96 | 33.77 | 8.13 | 30.35 | 18.33 | 3.82 |

| PSA (850 °C) 3 [14] | 18.11 | 4.60 | 2.96 | 64.49 | 2.34 | 2.95 | 0.66 | 0.13 | 0.79 | 3.31 | 25.67 |

| CHA [32] | 8.09 | 0.76 | 1.09 | 27.93 | - | 3.12 | 19.85 | - | - | 1.61 | 9.94 |

| HA [20] | 4.89 | 0.77 | 1.83 | 50.48 | 1.67 | 3.20 | 27.73 | 2.98 | 21.23 | - | 7.49 |

| Mix ID | OPC | PSA | Sand | Water |

|---|---|---|---|---|

| Plain | 450.0 | 0.0 | 1350 | 225 |

| 5 | 427.5 | 22.5 | ||

| 10 | 405.0 | 45.0 | ||

| 15 | 382.5 | 67.5 | ||

| 20 | 360.0 | 90.0 | ||

| 25 | 337.5 | 112.5 | ||

| 30 | 315.0 | 135.0 |

| Component | 0 (100% OPC) | 5 | 10 | 15 | 20 | 25 | 30 | EN197-1 [45] |

|---|---|---|---|---|---|---|---|---|

| SiO2 | 19.61 | 18.63 | 17.92 | 16.97 | 16.33 | 15.61 | 14.78 | |

| Al2O3 | 4.92 | 4.72 | 4.56 | 4.3 | 4.09 | 3.96 | 3.79 | |

| Fe2O3 | 3.15 | 3.03 | 2.9 | 2.78 | 2.74 | 2.55 | 2.46 | |

| CaO | 63.66 | 60.36 | 57.71 | 54.54 | 52.17 | 49.55 | 46.67 | |

| MgO | 2.19 | 2.37 | 2.46 | 2.63 | 2.7 | 2.96 | 3.1 | ≤5.0 |

| SO3 | 2.54 | 3.07 | 3.41 | 4.04 | 4.49 | 5.02 | 5.62 | ≤4.0 |

| K2O | 0.75 | 2.12 | 3.25 | 4.93 | 6.21 | 7.92 | 9.72 | |

| Na2O | 0.29 | 0.62 | 0.86 | 1.31 | 1.53 | 1.98 | 2.28 | |

| LOI | 2.89 | 5.08 | 6.93 | 8.5 | 9.74 | 10.45 | 11.58 |

| Parameter | Value (per Ton Cement) | Notes/Source |

|---|---|---|

| CO2 Reduction | 42.5 kg | 0.85 tCO2/t [4,73] |

| Cost Savings | $2.85 | Clinker cost: $60/tonne [74] |

| Clinker Replacement | 47.5 kg | 5% of standard 950 kg clinker/ton cement [75] |

| Compressive Strength Impact | 4.5% reduction | Test result (28-day curing) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Durmaz, M.; Doğruyol, M. Pistachio Shell Ash in Agro-Waste Cement Composites: A Pathway to Low-Carbon Binders. Sustainability 2025, 17, 4003. https://doi.org/10.3390/su17094003

Durmaz M, Doğruyol M. Pistachio Shell Ash in Agro-Waste Cement Composites: A Pathway to Low-Carbon Binders. Sustainability. 2025; 17(9):4003. https://doi.org/10.3390/su17094003

Chicago/Turabian StyleDurmaz, Mahmut, and Murat Doğruyol. 2025. "Pistachio Shell Ash in Agro-Waste Cement Composites: A Pathway to Low-Carbon Binders" Sustainability 17, no. 9: 4003. https://doi.org/10.3390/su17094003

APA StyleDurmaz, M., & Doğruyol, M. (2025). Pistachio Shell Ash in Agro-Waste Cement Composites: A Pathway to Low-Carbon Binders. Sustainability, 17(9), 4003. https://doi.org/10.3390/su17094003