Life Cycle Assessment-Based Analysis of Environmental and Economic Benefits in Construction Solid Waste Recycling

Abstract

1. Introduction

2. Recycling of Construction Solid Waste

3. Life Cycle Assessment

4. Goal and Scope Definition

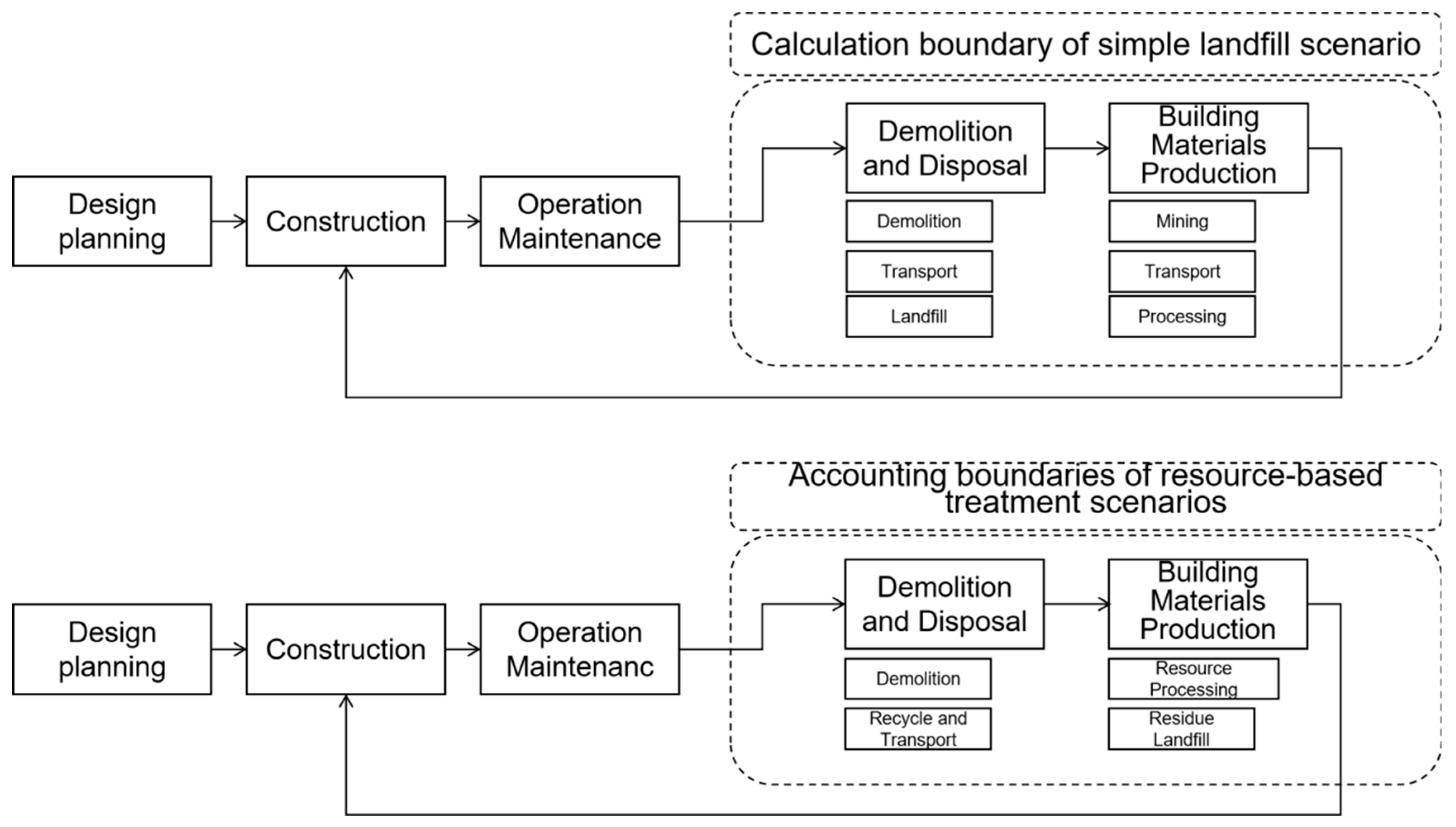

4.1. Scenario Construction

- Scenario 1: Simple Landfill

- Scenario 2: Recycling Treatment

- (1)

- Same origin of construction solid waste: The construction solid waste in two scenarios comes from the same demolition project and has the same composition.

- (2)

- Equivalent substitution of recycled aggregate and natural aggregate: The produced recycled aggregate can replace natural aggregate in a certain proportion and be used to produce finished concrete, concrete blocks, or other building materials. Under this setting, the proportion and quality of other auxiliary materials such as cement, water, and additives required for the production stage after substitution are the same as those in the natural aggregate scenario, and the production process remains consistent.

- (3)

- Consistency in the construction and usage processes of building material products: The conditions during the construction and usage processes of the building material products produced under the two scenarios are identical.

- (4)

- Mixed treatment of construction waste: It is stipulated that construction solid waste after building demolition is not subjected to on-site manual or mechanical sorting but undergoes entirely mixed treatment. Under the two scenarios, the quantity of transported construction solid waste is identical.

4.2. Determining the Scope

5. Life Cycle Inventory Analysis (LCI)

5.1. Life Cycle Inventory Analysis

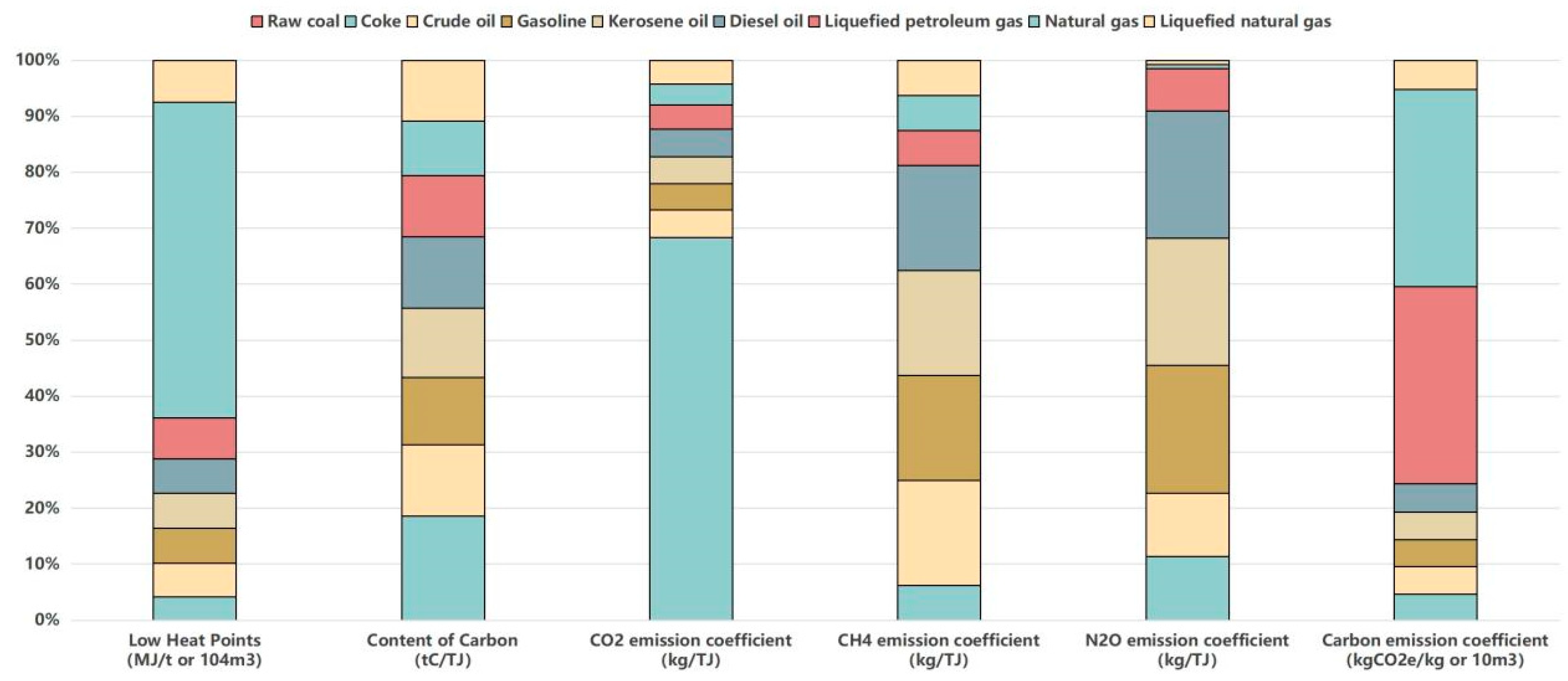

5.1.1. Greenhouse Gases

5.1.2. Carbon Emission Factors for Fossil Fuels

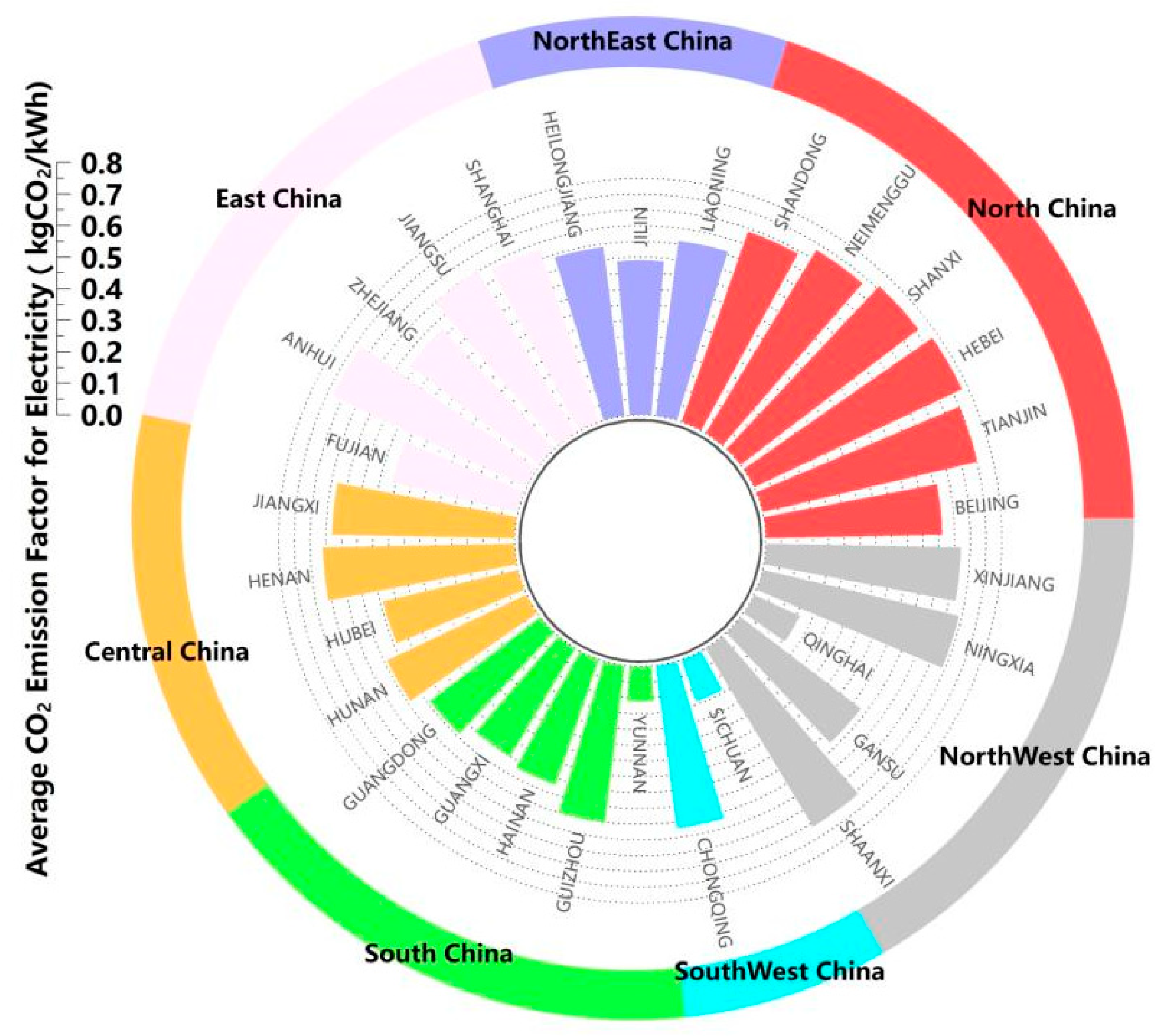

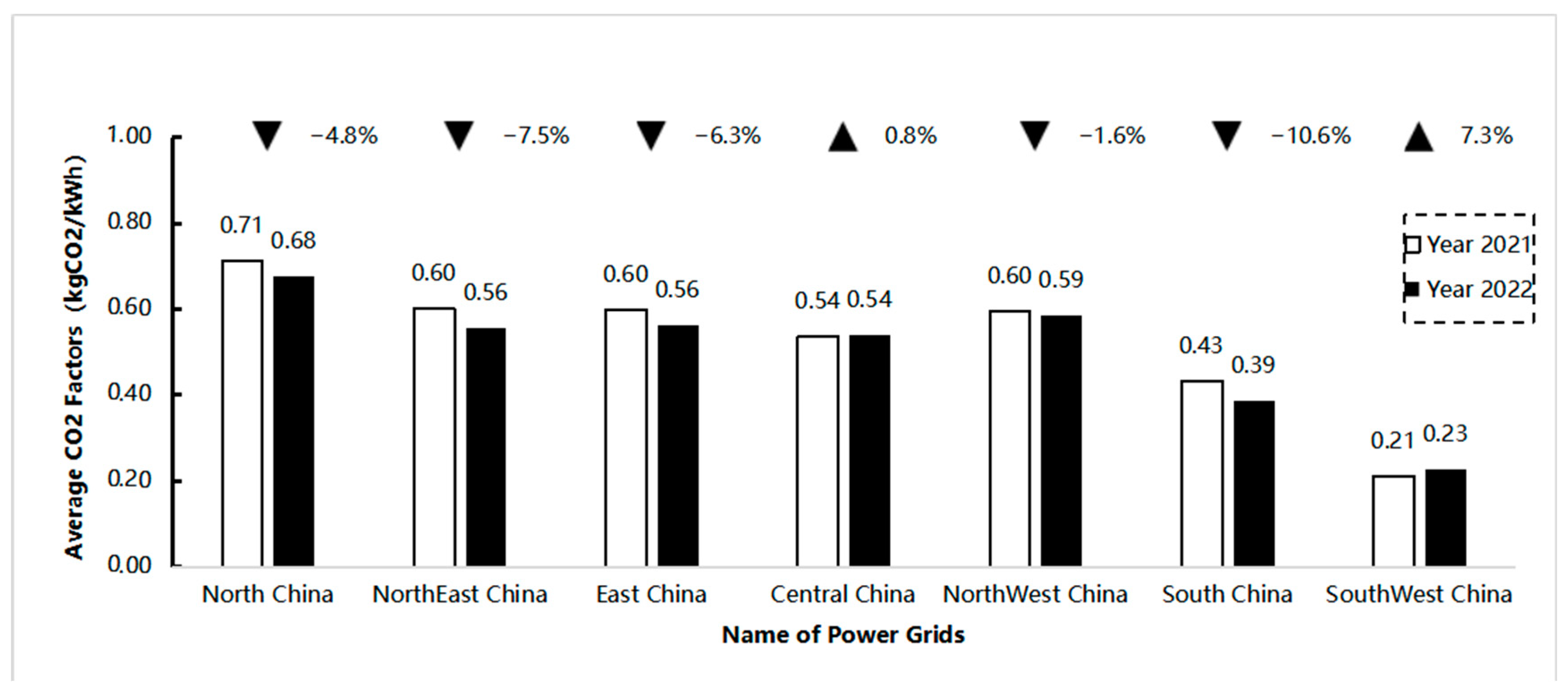

5.1.3. Electricity Carbon Emission Factors

5.2. Functional Unit

5.2.1. Carbon Emissions in the Building Material Production Stage

- (1)

- Simple Landfill Scenario

- (2)

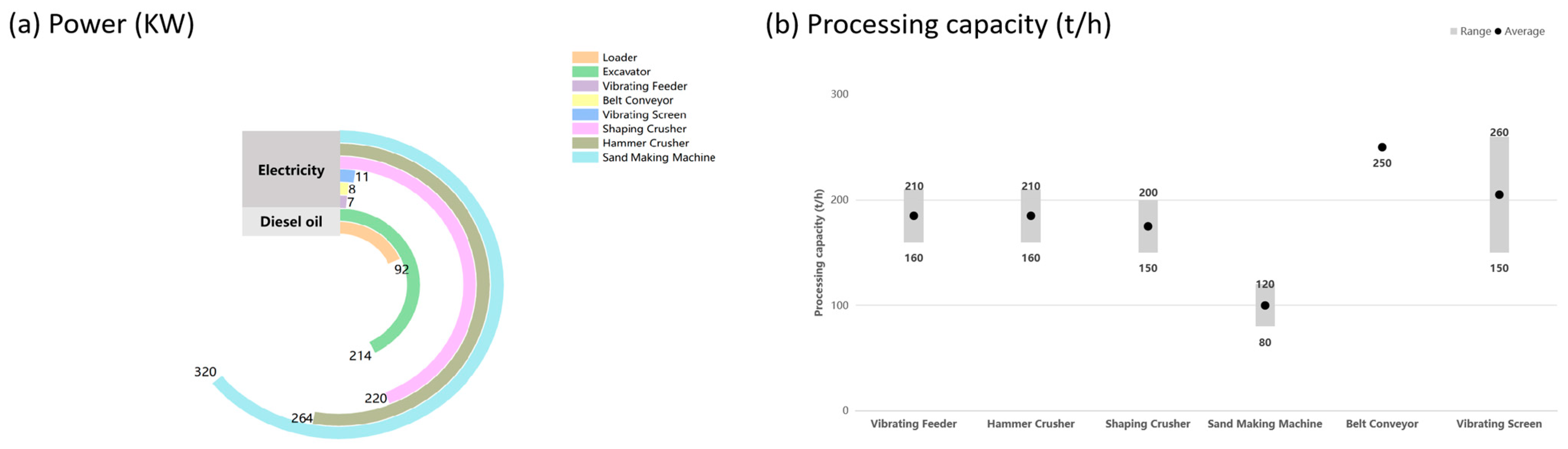

- Production of recycled aggregates from construction waste

5.2.2. Carbon Emissions During the Transportation, Construction, and Use Stages of Building Materials

5.2.3. Carbon Emissions During the Demolition Phase of Buildings

5.2.4. Carbon Emissions During the Construction Waste Treatment and Recycling Stage

- (1)

- Simple landfill of construction waste

- (2)

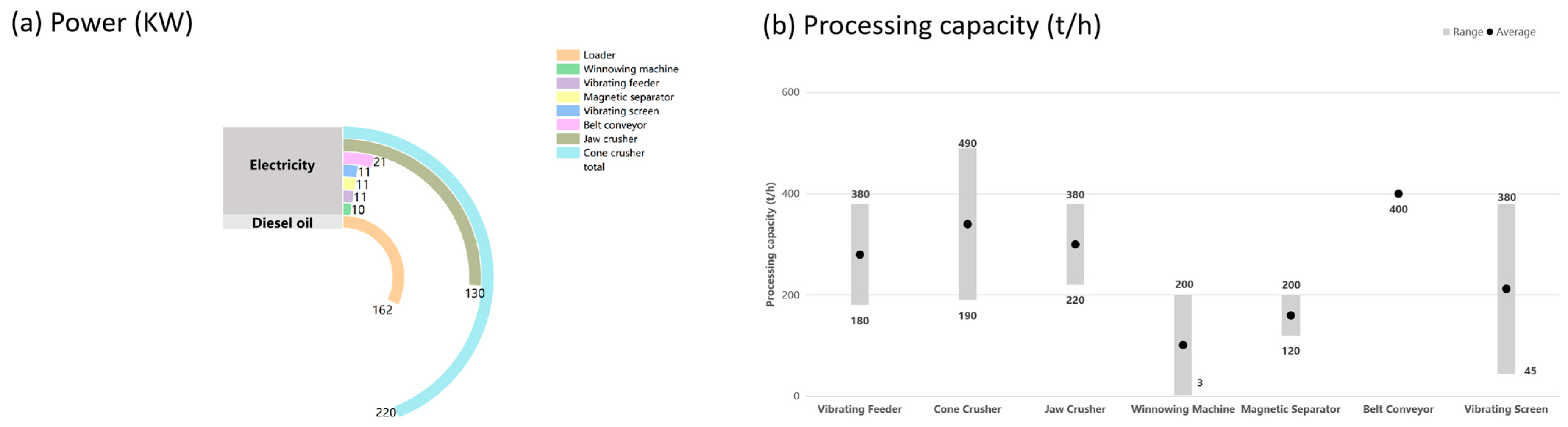

- Production of recycled aggregates from construction waste

5.3. Accounting Model for Carbon Emission Reduction Benefits of Construction Waste Resource Utilization

6. Life Cycle Impact Assessment

6.1. Building Material Production Stage

6.2. Processing and Recycling Stage

- (1)

- Simple landfill

- (2)

- Resource-based production of recycled aggregates

6.3. Interpretation of Data Sources and Error Values

7. Life Cycle Interpretation

7.1. Calculation Results

7.2. Result Analysis

7.3. Parameter Sensitivity Analysis

8. Discussion on Economic Benefits

8.1. Cost Comparative

8.1.1. Comparison of Production Costs

8.1.2. Comparison of Service Life and Maintenance Costs

8.2. Market Demand Comparison

8.2.1. Consumer Preferences

8.2.2. Industrial Chain

8.2.3. Policy Impact

8.2.4. Product Acceptance

8.3. Long-Term Benefit Comparison

- (1)

- From the perspective of resource scarcity, natural aggregates rely on limited natural resources, and the market supply–demand imbalance caused by resource scarcity will lead to price fluctuations. In the long run, this upward trend in costs will pose a serious challenge to the economic sustainability of enterprises and industries that rely on natural aggregates. In contrast, the raw materials for recycled aggregates mainly come from construction waste, and their supply is relatively stable and renewable, which can reduce the cost risks caused by resource scarcity in the long run.

- (2)

- From an external perspective, the production process of natural aggregates often comes with high energy consumption, carbon emissions, and environmental pollution. These negative externalities not only cause damage to the environment, but may also lead to an increase in social costs, such as natural disaster losses caused by climate change and health problems caused by environmental pollution. In the long run, these externalities will be transformed into economic costs for enterprises through policies, regulations, tax adjustments, and social responsibility requirements. The production process of recycled aggregates has significant positive externalities, and its resource recycling mode can reduce waste landfill and carbon emissions, making positive contributions to environmental protection and sustainable development. This positive externality will be transformed into an increase in social value in the long run, which will then bring additional economic benefits to recycled aggregate enterprises through policy incentives, market recognition, and other means.

- (3)

- From the perspective of technology and long-term competitiveness, the recycled aggregate industry is in a rapid development stage, and the continuous progress of technology has gradually brought its performance and quality closer to or even surpassing that of native building materials. In the long run, technological innovation in recycled aggregates will continuously reduce their production costs, improve production efficiency, and expand their application scope. Therefore, in terms of long-term competitiveness, technological advancements in recycled aggregates will give them a more advantageous position in the market.

- (4)

- From the perspective of market dynamics, as the global emphasis on sustainable development continues to increase, consumers’ demand for environmentally friendly building materials will continue to grow. In the long run, the market potential of recycled aggregates is enormous, and its market share will continue to expand with the improvement in consumer awareness and technological progress. In addition, the support of policies and regulations will also provide strong guarantees for the development of recycled aggregates. This will further promote the market penetration rate of recycled building materials and reduce the operational risks of enterprises. In terms of long-term returns, recycled aggregate enterprises will benefit from the growth in market demand and the cost reduction brought about by technological progress, achieving a higher return on investment.

9. Countermeasures and Suggestions

9.1. Improve Laws and Regulations, Management Policies, and Technical Specifications, and Optimize the Governance Framework of the Entire Industry Chain

9.2. Diversified Policy Coordination Promotes Path Optimization of Construction Waste Resource Utilization Treatment

9.3. Conduct Reasonable Site Selection Planning to Reduce Traffic Volume

9.4. Research and Develop Advanced Equipment and Processes to Reduce Energy Consumption

9.5. Improve Data Collection and Management

10. Conclusions and Future Research Directions

- (1)

- This article adopts a comparative analysis of resource utilization and non-resource utilization, assuming that the transportation stage of building materials, the construction and use stage, and the demolition stage, which have similar processes in the scenario, are no longer included in the accounting scope. Therefore, it is not possible to account for all carbon emissions throughout the entire life cycle and compare them with carbon emission reductions. In future research, it should be improved, and long-term environmental impact tracking assessments of resource utilization should be carried out to enhance the time dimension of the LCA model.

- (2)

- In actual construction waste treatment, the composition is complex and there are various methods for resource utilization. This article only focuses on the component with the largest proportion for the purpose of simplifying calculations, and only studies the production of recycled aggregates, which is the most widely used resource utilization method. It is difficult to accurately measure the carbon emissions in actual situations.

- (3)

- This study focuses on the impact of greenhouse gases that cause global warming without addressing environmental impact types such as photochemical smog, acidification, eutrophication, and ecological toxicity, as well as the differential emission characteristics of pollutants such as SO2, NOx, CXHY, and dust. In the future, a multi-factor environmental impact assessment framework needs to be constructed to supplement the comparative analysis of emission inventories of multiple pollutants under different disposal methods.

- (4)

- This study did not consider the spatial heterogeneity of regional economic levels, environmental standards, and policy tools, and lacked an in-depth deconstruction of localized practical experience. In the future, an evaluation index system that includes regional characteristics can be established to compare resource utilization models in different economic gradient regions. By analyzing successful experiences and key obstacles through typical cases, empirical support can be provided for differentiated policy design and technical route selection.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| LCA | life cycle assessment |

| CDW | construction and demolition waste |

| CEAM | Carbon Emission Accounting Model |

| RA | recycled aggregate |

| OSPW | ornamental stone processing waste |

| R-HDCC | recycled high-ductility cementitious composite |

| RAC | recycled aggregate concrete |

| NAC | natural aggregate concrete |

| C&D | construction and demolition |

| MCDA | multi-criteria decision analysis |

| LCCA | life cycle cost assessment |

| GWP | global warming potential |

| UNEP | United Nations Environment Programme |

| IPCC | The Intergovernmental Panel on Climate Change |

| ISO | the International Organization for Standardization |

| LEED | Leadership in Energy and Environmental Design |

References

- United Nations Environment Programme. Global Status Report for Buildings and Construction. 2024. Available online: https://wedocs.unep.org/bitstream/handle/20.500.11822/45095/global_status_report_buildings_construction_2023.pdf?sequence=3&isAllowed=y (accessed on 10 January 2025).

- China Government Network. China Has Promoted the Treatment and Resource Utilization of Construction Waste. Available online: https://www.gov.cn/xinwen/2021-12/09/content_5659650.htm (accessed on 18 January 2025).

- Ministry of Housing and Urban-Rural Development of China: CJJ/T134-2019[S/OL]. Available online: https://english.www.gov.cn/state_council/2014/09/09/content_281474986284089.htm (accessed on 10 September 2024).

- Li, J.; Liang, J.; Zuo, J.; Guo, H. Environmental impact assessment of mobile recycling of demolition waste in Shenzhen, China. J. Clean. Prod. 2020, 263, 121371. [Google Scholar] [CrossRef]

- Jiang, B.; Huang, H.; Ge, F.; Huang, B.; Ullah, H. Carbon Emission Assessment During the Recycling Phase of Building Meltable Materials from Construction and Demolition Waste: A Case Study in China. Buildings 2025, 15, 456. [Google Scholar] [CrossRef]

- Niekurzak, M.; Lewicki, W.; Wróbel, J. Efficiency Assessment of the Production of Alternative Fuels of High Usable Quality within the Circular Economy: An Example from the Cement Sector. Sustainability 2024, 16, 8762. [Google Scholar] [CrossRef]

- Marinković, S.; Radonjanin, V.; Malešev, M.; Ignjatović, I. Comparative environmental assessment of natural and recycled aggregate concrete. Waste Manag. 2010, 30, 2255–2264. [Google Scholar] [CrossRef]

- Hossain Md, U.; Poon, C.S.; Lo, I.M.C.; Cheng, J.C.P. Comparative environmental evaluation of aggregate production from recycled waste materials and virgin sources by LCA. Resour. Conserv. Recycl. 2016, 109, 67–77. [Google Scholar] [CrossRef]

- Dias, A.B.; Pacheco, J.N.; Silvestre, J.D.; Martins, I.M.; de Brito, J. Environmental and economic life cycle assessment of recycled coarse aggregates: A Portuguese case study. Materials 2021, 14, 5452. [Google Scholar] [CrossRef]

- Ortiz, O.; Pasqualino, J.C.; Castells, F. Environmental performance of construction waste: Comparing three scenarios from a case study in Catalonia, Spain. Waste Manag. 2010, 30, 646–654. [Google Scholar] [CrossRef]

- Yu, Y.; Yazan, D.M.; Bhochhibhoya, S.; Volker, L. Towards Circular Economy through Industrial Symbiosis in the Dutch construction industry: A case of recycled concrete aggregates. J. Clean. Prod. 2021, 293, 126083. [Google Scholar] [CrossRef]

- Jain, S.; Singhal, S.; Jain, N.K.; Bhaskar, K. Construction and demolition waste recycling: Investigating the role of theory of planned behavior, institutional pressures and environmental consciousness. J. Clean. Prod. 2020, 263, 121405. [Google Scholar] [CrossRef]

- Brandão, R.; Edwards, D.J.; Hosseini, M.R.; Silva Melo, A.C.; Macêdo, A.N. Reverse supply chain conceptual model for construction and demolition waste. Waste Manag. Res. 2021, 39, 1341–1355. [Google Scholar] [CrossRef]

- Badraddin, A.K.; Radzi, A.R.; Almutairi, S.; Rahman, R.A. Critical Success Factors for Concrete Recycling in Construction Projects. Sustainability 2022, 14, 3102. [Google Scholar] [CrossRef]

- Teixeira, R.F.M.; De Souza, D.M.; Curran, M.P.; Antón, A.; Michelsen, O.; i Canals, L.M. Towards consensus on land use impacts on biodiversity in LCA: UNEP/SETAC Life Cycle Initiative preliminary recommendations based on expert contributions. J. Clean. Prod. 2016, 112, 4283–4287. [Google Scholar] [CrossRef]

- ISO 14044; ‘Environmental Management-Life Cycle Assessment-Requirements and Guidelines’. International Organization for Standardization: Geneva, Switzerland, 2006.

- Liu, X.Y.; Ye, Z.N.; Lu, J.X. Comparative LCA-MCDA of high-strength eco-pervious concrete by using recycled waste glass materials. J. Clean. Prod. 2024, 479, 144048. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, X.; Kong, L. Evaluation of carbon and economic benefits of producing recycled aggregates from construction and demolition waste. J. Clean. Prod. 2023, 425, 138946. [Google Scholar] [CrossRef]

- Liu, Y.H.; Li, A.J.; Guo, G.Z.; Zhang, J.W.; Ren, Y.; Dong, L.; Gong, L.F.; Hu, H.Y.; Yao, H.; Naruse, I. Comparative life cycle assessment of organic industrial solid waste co-disposal in a MSW incineration plant. Energy 2024, 305, 11. [Google Scholar] [CrossRef]

- Huang, B.; Gao, X.; Xu, X.; Song, J.; Geng, Y.; Sarkis, J.; Fishman, T.; Kua, H.W.; Nakatani, J. A Life Cycle Thinking Framework to Mitigate the Environmental Impact of Building Materials. One Earth 2020, 3, 564–573. [Google Scholar] [CrossRef]

- Li, X.; Jiang, M.; Lin, C.; Chen, R.; Weng, M.; Jim, C.Y. Integrated BIM-IoT platform for carbon emission assessment and tracking in prefabricated building materialization. Resour. Conserv. Recycl. 2025, 215, 108122. [Google Scholar] [CrossRef]

- Zhang, B.; Pan, L.; Chang, X.; Wang, Y.; Liu, Y.; Jie, Z.; Ma, H.; Shi, C.; Guo, X.; Xue, S.; et al. Sustainable mix design and carbon emission analysis of recycled aggregate concrete based on machine learning and big data methods. J. Clean. Prod. 2025, 489, 144734. [Google Scholar] [CrossRef]

- Jasim, A.F.; Ali, Z.K.; Al-Saadi, I.F. A Comprehensive Review of Life Cycle Cost Assessment of Recycled Materials in Asphalt Pavements Rehabilitation. Adv. Civ. Eng. 2024, 19, 2004803. [Google Scholar] [CrossRef]

- Hasheminezhad, A.; King, D.; Ceylan, H.; Kim, S. Comparative life cycle assessment of natural and recycled aggregate concrete: A review. Sci. Total Environ. 2024, 950, 175310. [Google Scholar] [CrossRef]

- Silvestre, J.D.; De Brito, J.; Pinheiro, M.D. Environmental impacts and benefits of the end-of-life of building materials—Calculation rules, results and contribution to a “cradle to cradle” life cycle. J. Clean. Prod. 2014, 66, 37–45. [Google Scholar] [CrossRef]

- Hossain Md, U.; Thomas Ng, S. Influence of waste materials on buildings’ life cycle environmental impacts: Adopting resource recovery principle. Resour. Conserv. Recycl. 2019, 142, 10–23. [Google Scholar] [CrossRef]

- Zulcão, R.; Calmon, J.L.; Rebello, T.A.; Vieira, D.R. Life cycle assessment of the ornamental stone processing waste use in cement-based building materials. Constr. Build. Mater. 2020, 257, 119523. [Google Scholar] [CrossRef]

- Piccardo, C.; Dodoo, A.; Gustavsson, L.; Tettey, U.Y.A. Retrofitting with different building materials: Life-cycle primary energy implications. Energy 2020, 192, 116648. [Google Scholar] [CrossRef]

- Honic, M.; Kovacic, I.; Sibenik, G.; Rechberger, H. Data-and stakeholder management framework for theimplementation of BIM-based Material Passports. J. Build. Eng. 2019, 23, 341–350. [Google Scholar] [CrossRef]

- Heidari, M.R.; Heravi, G.; Esmaeeli, A.N. Integrating life-cycle assessment and life-cycle cost analysis to select sustainable pavement: A probabilistic model using managerial flexibilities. J. Clean. Prod. 2020, 254, 120046. [Google Scholar] [CrossRef]

- Hussain, M.; Zheng, B.; Chi, H.-L.; Hsu, S.-C. Automated and continuous BIM-based life cycle carbon assessment for infrastructure design projects. Resour. Conserv. Recycl. 2023, 190, 106848. [Google Scholar] [CrossRef]

- Al-Najjar, A.; Malmqvist, T.; Stenberg, E.; Höjer, M. Stock, flow and reuse potential of precast concrete in Swedish residential buildings: Embodied carbon assessment. Resour. Conserv. Recycl. 2025, 218, 108229. [Google Scholar] [CrossRef]

- Hoang, N.H.; Ishigaki, T.; Kubota, R.; Tong, T.K.; Nguyen, T.T.; Nguyen, H.G.; Yamada, M.; Kawamoto, K. Financial and economic evaluation of construction and demolition waste recycling in Hanoi, Vietnam. Waste Manag. 2021, 131, 294–304. [Google Scholar] [CrossRef]

- IPCC. Safeguarding the Ozone Layer and the Global Climate System; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar]

- Zhang, X. Research on the Quantitative Analysis of Building Carbon Emissions and Assessment Methods for Low-Carbon Buildings and Structures; Harbin Institute of Technology: Harbin, China, 2018. [Google Scholar]

- Zhang, Y.R. Integrated Life Cycle Environmental Impact Assessment of Fly Ash Concrete; Beijing Jiaotong University: Beijing, China, 2016. [Google Scholar]

- Huiwen, W.; Zhonghe, S.; Zhongshou, L.; Kaitao, X. Environmental assessment for regenerated concrete. J. Wuhan Univ. Technol. 2003, 25, 17–20. [Google Scholar]

- Wang, X.; Yang, J.; Wu, Y.; Zhu, P.; Yan, X.; Liu, H. Tailoring high ductility cementitious composite incorporating recycled fine aggregate based on shrinkage and mechanical properties. J. Build. Eng. 2024, 93, 109868. [Google Scholar] [CrossRef]

- Aghamohammadi, O.; Jafari, Z.; Bahmani, H.; Mostofinejad, D. Novel eco-friendly high-strength concrete based on slag activated with calcium oxide: Environmental, thermal, and mechanical performance. Constr. Build. Mater. 2024, 449, 138334. [Google Scholar] [CrossRef]

- Ling, H.M.; Yew, M.C.; Yew, M.K.; Saw, L.H. Analyzing recent active and passive cool roofing technology in buildings, including challenges and optimization approaches. J. Build. Eng. 2024, 89, 109326. [Google Scholar] [CrossRef]

- Oberender, A.; Fruergaard Astrup, T.; Frydkjær Witte, S.; Camboni, M.; Chiabrando, F.; Hayleck, M.; Akelyte, R. EU Construction & Demolition Waste Management Protocol Including Guidelines for Pre-Demolition and Pre-Renovation Audits of Construction Works, Updated Edition 2024; Publications Office of the European Union: Copenhagen, Denmark, 2024. [Google Scholar]

- He, W.; Zhang, Y.; Kong, D.; Li, S.; Wu, Z.; Zhang, L.; Liu, P. Promoting green-building development in sustainable development strategy: A multi-player quantum game approach. Expert Syst. Appl. 2024, 240, 122218. [Google Scholar] [CrossRef]

- Bains, M.E.; Hongyi, Y.; Jialong, C. International policy perspectives on construction waste minimisation and recycling. Proc. Inst. Civ. Eng.-Waste Resour. Manag. 2019, 172, 76–85. [Google Scholar] [CrossRef]

- Tangtinthai, N.; Heidrich, O.; Manning, D.A.C. Role of policy in managing mined resources for construction in Europe and emerging economies. J. Environ. Manag. 2019, 236, 613–621. [Google Scholar] [CrossRef]

- Fang, S.; Zou, G.; Wang, H.; Yan, R. Investigation and inspiration on the recycling of foreign construction waste. Highw. Eng. 2017, 42, 154–167. [Google Scholar]

- Sun, G.; Jiang, D.; Feng, J.; Chen, X. Mechanism on Driving Factors of Green Construction Technology Under Carbon Peak Target in China: Based on System Dynamics Simulation Analysis. Sci. Technol. Manag. Res. 2022, 42, 194–201. [Google Scholar]

- GB/T 50378-2024; Green Building Evaluation Standards. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2024.

- GB/T 25177; Recycled Coarse Aggregates for Concrete. National Standardization Administration: Beijing, China, 2010.

- GB 50010; Code for Design of Concrete Structures. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2010.

- Cao, X.; Zhao, T.; Xing, Z. How Do Government Policies Promote Green Housing Diffusion in China? A Complex Network Game Context. Int. J. Environ. Res. Public Health 2022, 19, 2238. [Google Scholar] [CrossRef]

- He, L.; Chen, L. The incentive effects of different government subsidy policies on green buildings. Renew. Sustain. Energy Rev. 2021, 135, 110123. [Google Scholar] [CrossRef]

- Yi, Y.; Fei, X.; Fedele, A.; Lavagnolo, M.C.; Manzardo, A. Decision support model for selecting construction and demolition waste management alternatives: A life cycle-based approach. Sci. Total Environ. 2024, 951, 175408. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Wang, C.; Kassem, M.A.; Liu, Y.; Ali, K.N. Study on Green Building Promotion Incentive Strategy Based on Evolutionary Game between Government and Construction Unit. Sustainability 2022, 14, 10155. [Google Scholar] [CrossRef]

- Ning, X.; Ye, X.; Wang, W. Research on the evolution path of high-quality innovative development of green housing under the background of “peak carbon emissions and carbon neutrality”. Syst. Eng.-Theory Pract. 2023, 43, 2653–2668. [Google Scholar] [CrossRef]

- Wand, Y.; Zhang, L. A Simulation Analysis of Optimized Incentive Policies in Green Housing Market—A Case Study of Xi’an. Syst. Eng. 2018, 36, 37–46. [Google Scholar]

- Patil, Y.R.; Dakwale, V.A.; Ralegaonkar, R.V. Recycling Construction and Demolition Waste in the Sector of Construction. Adv. Civ. Eng. 2024, 13, 6234010. [Google Scholar] [CrossRef]

| CO2 | CH4 | N2O | HFCS | PFCS | SF6 | |

|---|---|---|---|---|---|---|

| 20 Years | 1 | 62 | 275 | 9400 | 3900 | 15,100 |

| 100 Years | 1 | 21 | 310 | 11,700 | 5700 | 22,200 |

| Equipment | Data Acquisition Form | Sampling Time Span | Type of Measuring Instrument | Data Validation Method |

|---|---|---|---|---|

| Dump Truck | Semi-auto | Single | Fuel level gauges | Diesel oil consumption Fuel level gauges check |

| Excavator | Semi-auto | Single | Loader electronic scale Fuel level gauges | |

| Loader | Semi-auto | Single | ||

| Vibrating Feeder | Auto | Real-time | Ordinary precision electric meter Electronic scale Power analyzer Sensor | Power consumption Demand billing |

| Hammer Crusher (Cone Crusher) | Auto | Real-time | ||

| Shaping Crusher (Jaw Crusher) | Auto | Real-time | ||

| Sand Making Machine | Auto | Real-time | ||

| Winnowing Machine | Auto | Real-time | ||

| Magnetic Separator | Auto | Real-time | ||

| Belt Conveyor | Auto | Real-time | ||

| Vibrating Screen | Auto | Real-time |

| Equipment | Natural Aggregate Production Processing Capacity (t/h) | Recycled Aggregate Production Processing Capacity (t/h) |

|---|---|---|

| Vibrating Feeder | ±13.51% | ±35.71% |

| Hammer Crusher (Cone Crusher) | ±13.51% | (±44.12%) |

| Shaping Crusher (Jaw Crusher) | ±14.29% | (±26.67%) |

| Sand Making Machine | ±20% | —— |

| Winnowing Machine | —— | ±97.04% |

| Magnetic Separator | —— | ±25% |

| Belt Conveyor | ±0% | ±0% |

| Vibrating Screen | ±26.83% | ±21.18% |

| Stage | Natural Aggregate (kgCO2e) | Recycled Aggregate (kgCO2e) |

|---|---|---|

| Production Stage | 695.77 | 226.06 |

| Treatment and Recycling Stage | 233.33 | 173.85 |

| Total | 979.10 | 399.91 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Mu, X.; Hu, G.; Wang, L.; Zhu, X. Life Cycle Assessment-Based Analysis of Environmental and Economic Benefits in Construction Solid Waste Recycling. Sustainability 2025, 17, 3872. https://doi.org/10.3390/su17093872

Wang Y, Mu X, Hu G, Wang L, Zhu X. Life Cycle Assessment-Based Analysis of Environmental and Economic Benefits in Construction Solid Waste Recycling. Sustainability. 2025; 17(9):3872. https://doi.org/10.3390/su17093872

Chicago/Turabian StyleWang, Yulin, Xianzhong Mu, Guangwen Hu, Liyuchen Wang, and Xueting Zhu. 2025. "Life Cycle Assessment-Based Analysis of Environmental and Economic Benefits in Construction Solid Waste Recycling" Sustainability 17, no. 9: 3872. https://doi.org/10.3390/su17093872

APA StyleWang, Y., Mu, X., Hu, G., Wang, L., & Zhu, X. (2025). Life Cycle Assessment-Based Analysis of Environmental and Economic Benefits in Construction Solid Waste Recycling. Sustainability, 17(9), 3872. https://doi.org/10.3390/su17093872