Enhancing Sustainability in Power Systems: A High-Capacity Testing System Based on a Power System

Abstract

1. Introduction

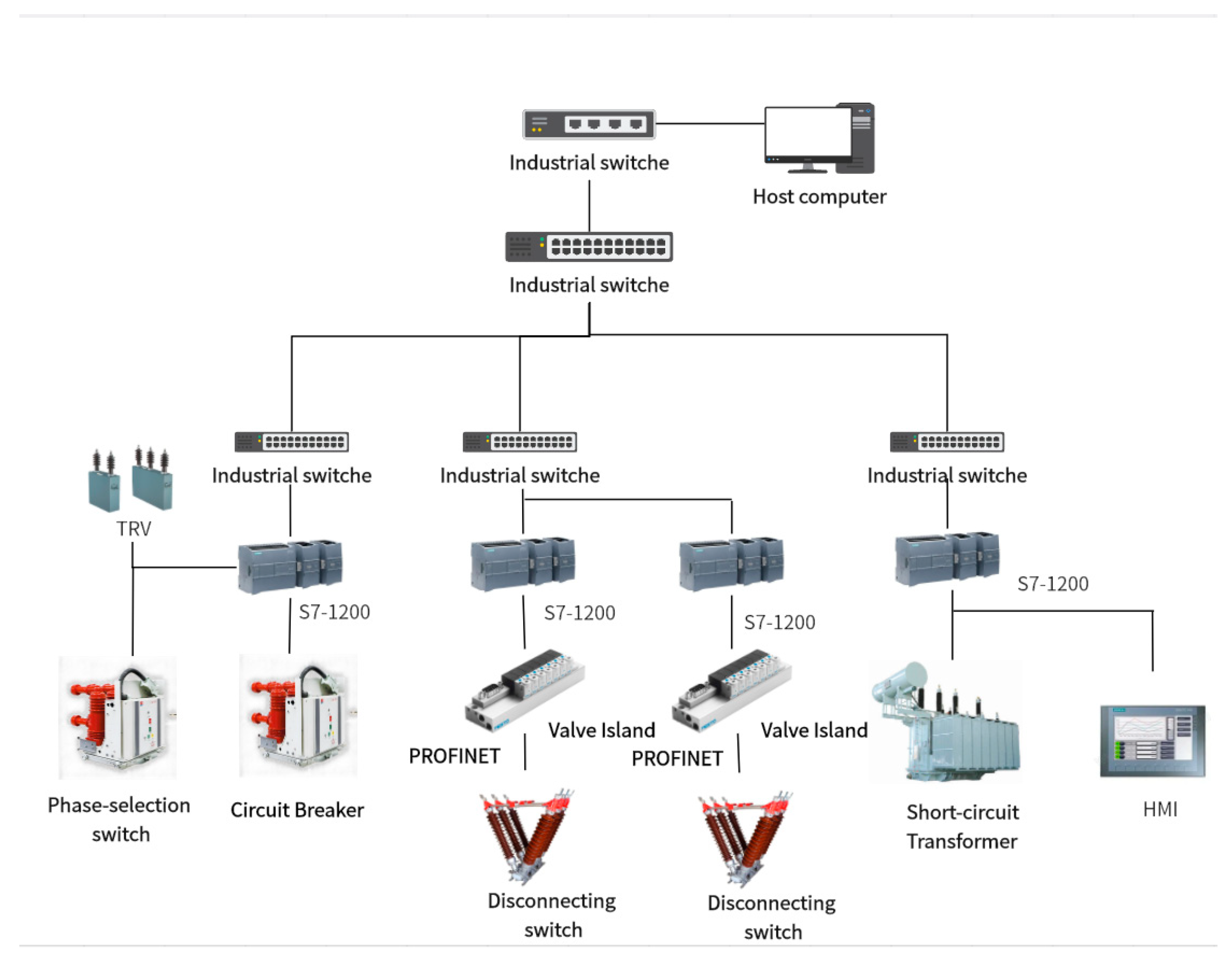

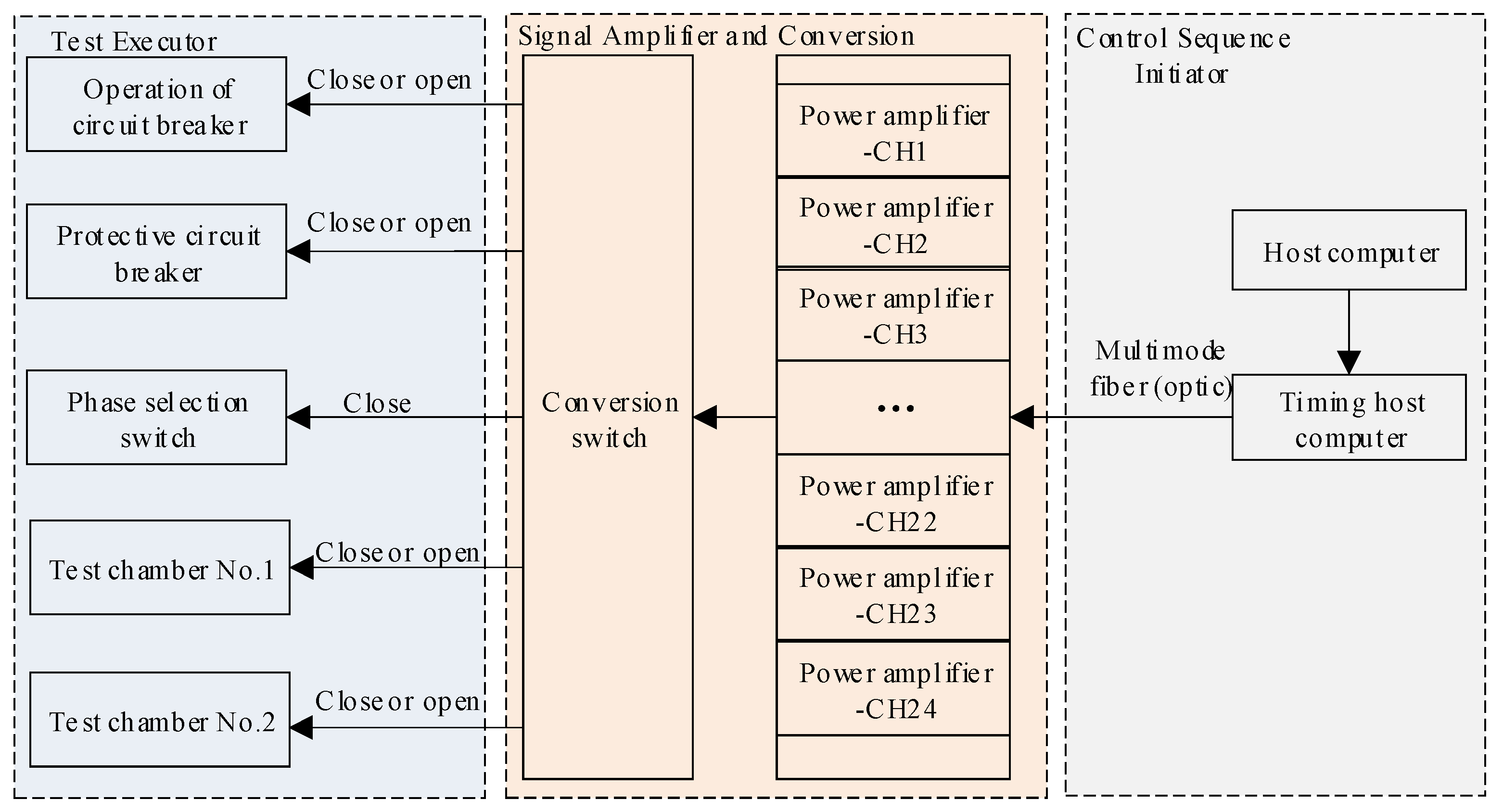

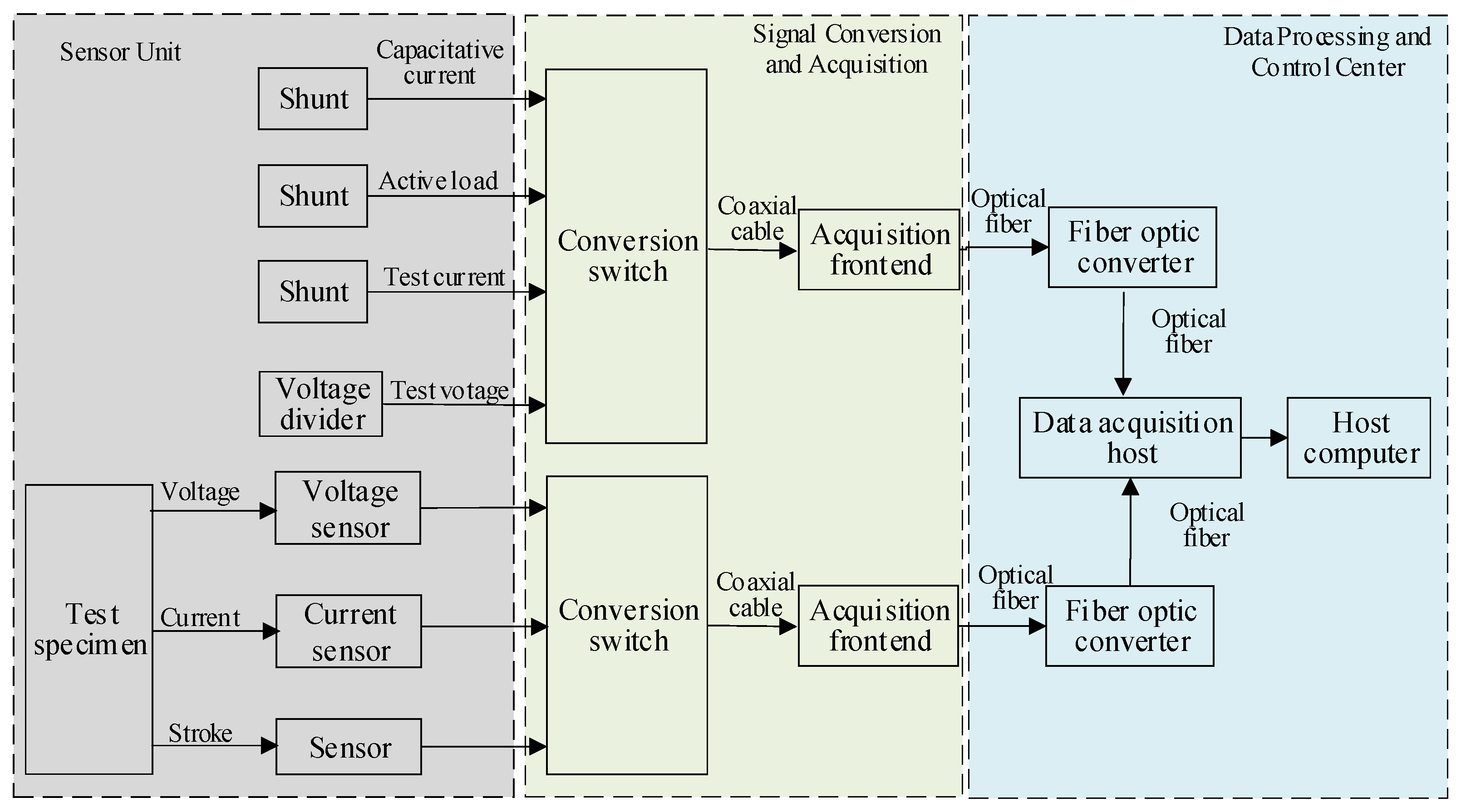

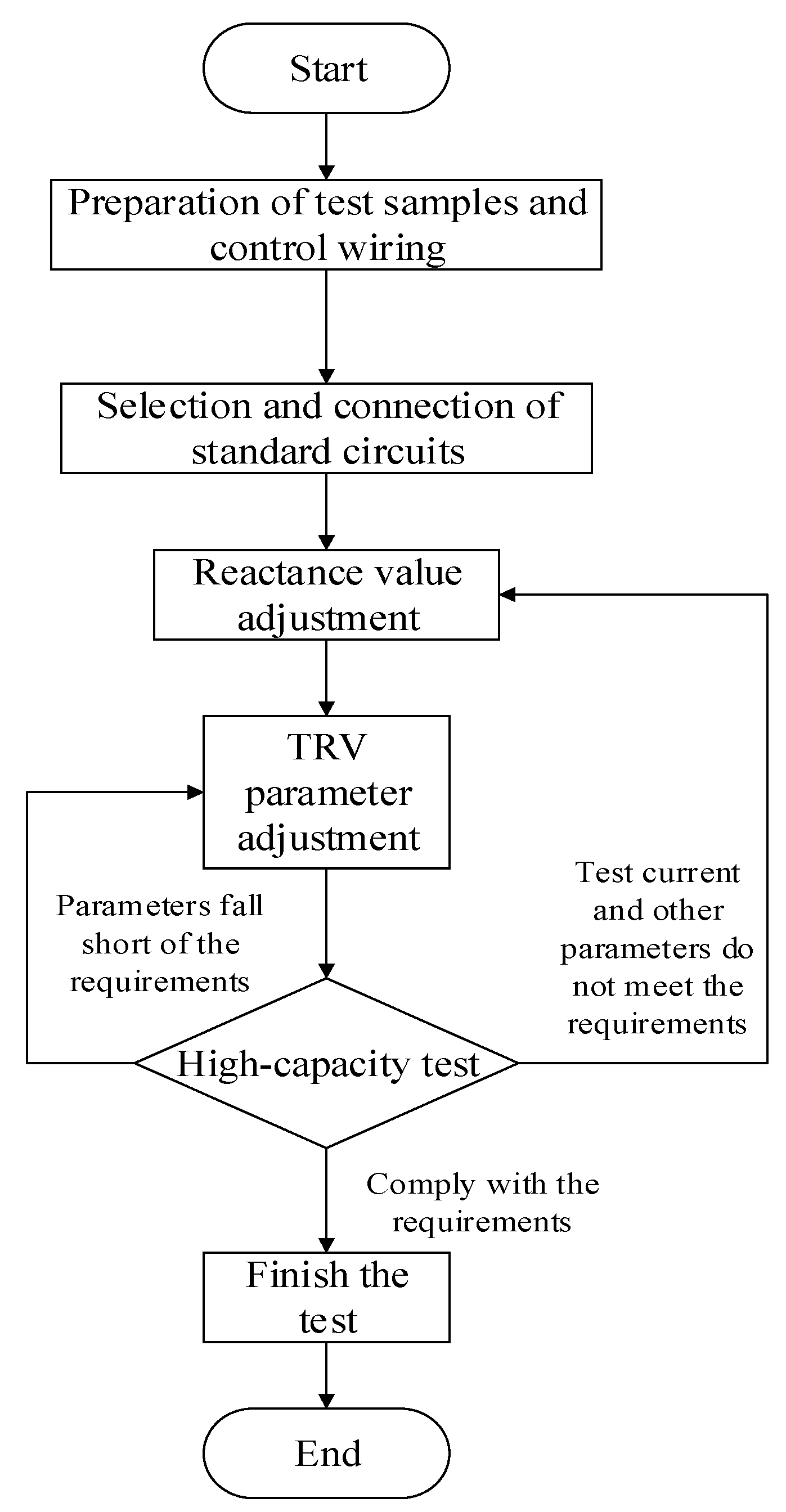

- Testing design and system optimization: It proposes standardized methods for high-capacity testing, ring-network monitoring topologies, and integrated automated workflow solutions to enhance testing efficiency and data reliability, resolving issues of low system integration and inadequate automation. This includes standardized test circuit design methods, ring-network topologies for testing monitoring and control, systematic solutions covering data acquisition, signal monitoring, and control schemes, as well as optimized high-capacity short-circuit testing procedures.

- Automated monitoring system construction: It designs an automated monitoring and control system based on a ring-shaped PROFINET network, achieving full-process automation for high-capacity testing. By integrating PLCs, valve islands, coaxial cables, and optical fibers, it effectively isolates interference from complex electromagnetic environments. Sequential control technology precisely manages equipment action sequences, reducing human intervention and enhancing test repeatability and consistency.

- Method validation and effects: It verifies the feasibility and accuracy of the standardized test circuit design method through MATLAB 2024a/Simulink simulations and physical experiments. The results show that short-circuit current and TRV parameter errors fall within the standard permissible range, proving that this automated design and standardized method significantly improve the efficiency and safety of high-capacity testing, ensuring the consistency and reliability of the test results.

2. Power-System-Based High-Capacity Testing Circuit

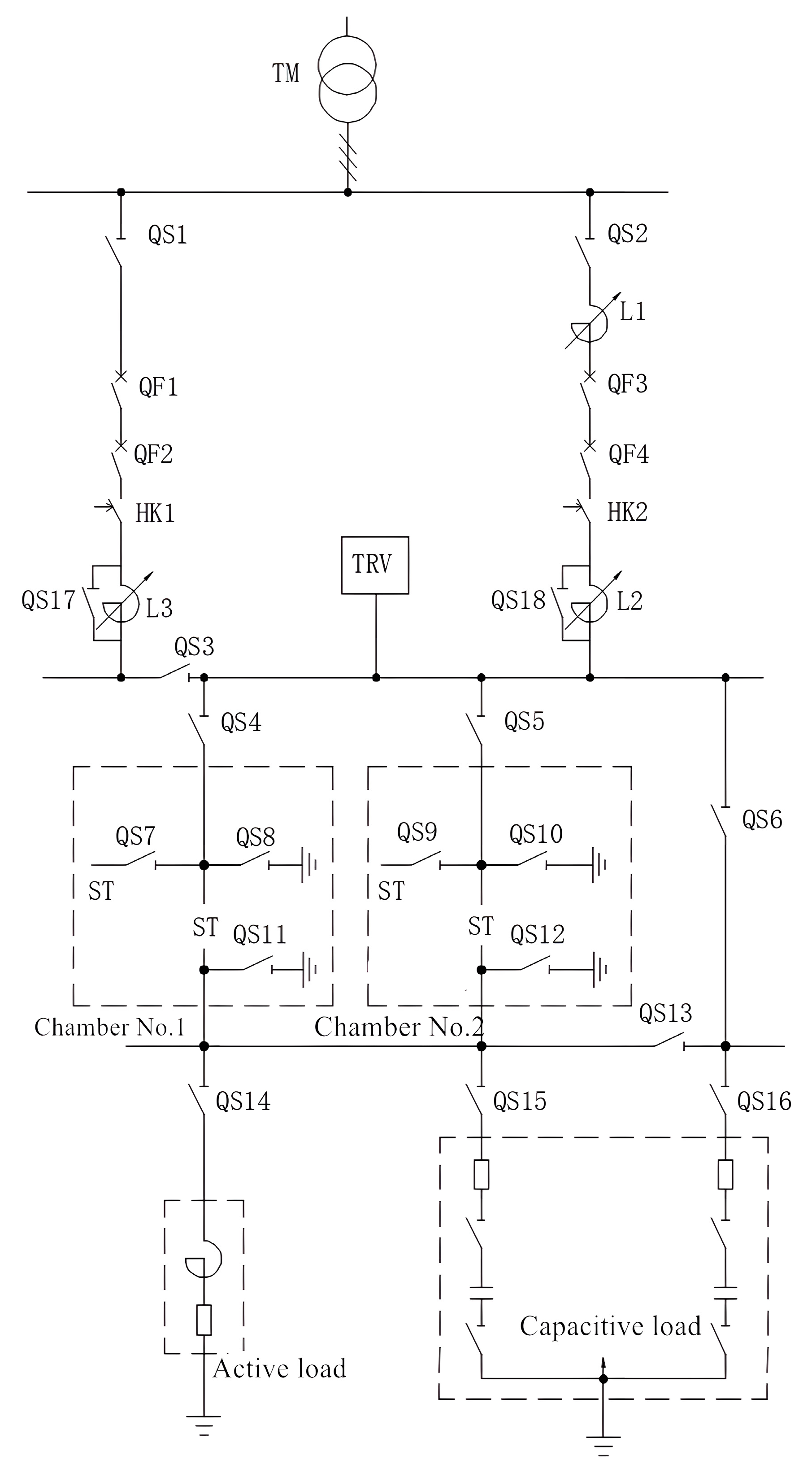

2.1. Main Test Circuit Architecture

2.1.1. Dual-Voltage Test Circuit Configuration (12 kV/40.5 kV)

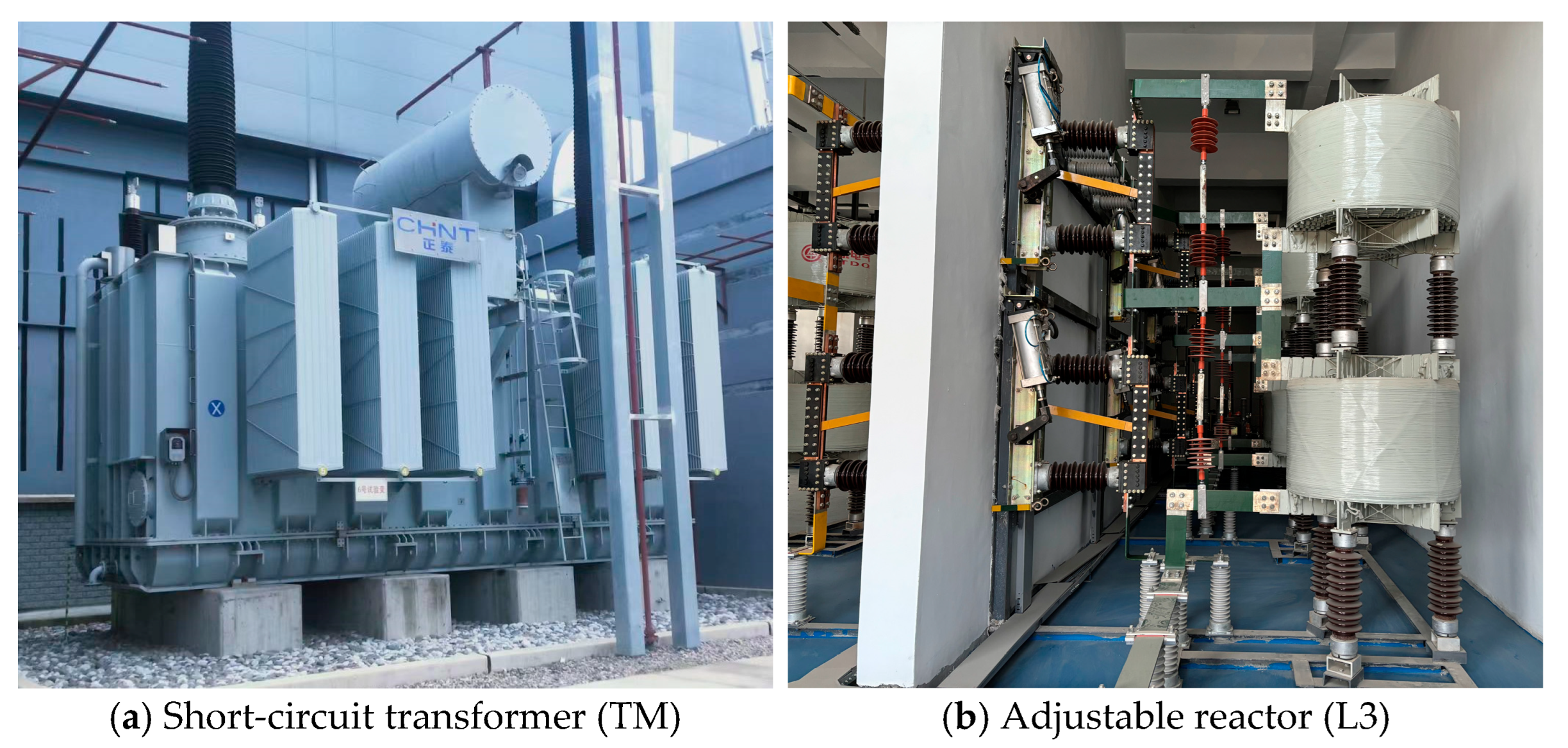

- Short-circuit transformer (TM) (see Figure 2a);

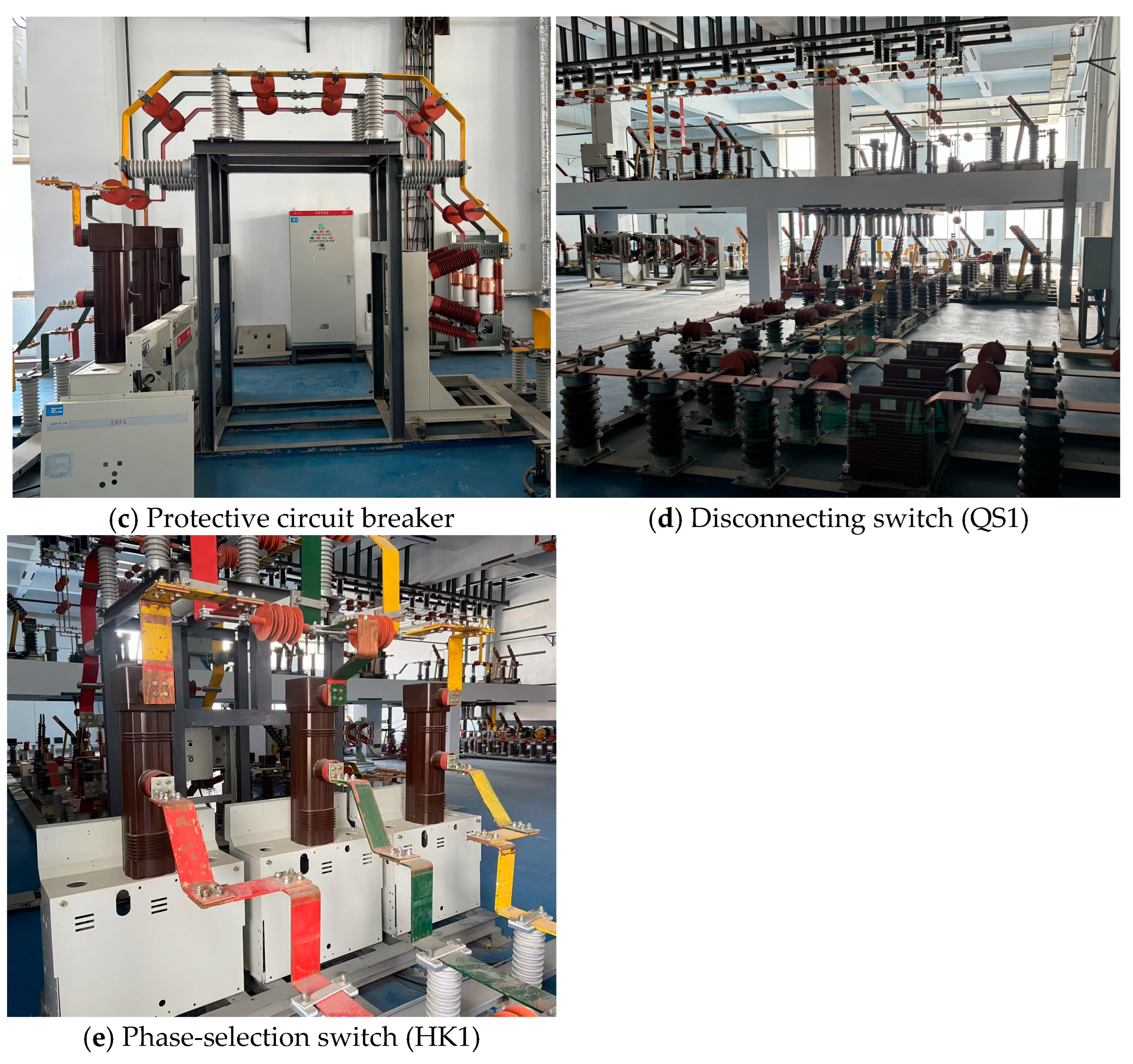

- Busbar system (see Figure 2c,d);

- Disconnecting switch (QS1) (see Figure 2b,d);

- Protective circuit breaker (QF1) (see Figure 2c);

- Operating circuit breaker (QF2) (see Figure 2c);

- Phase-selection switch (HK1) (see Figure 2e);

- Adjustable reactor (L3) (see Figure 2b).

- Three-phase short-circuit capacity of 330 kV busbar: 7111 MVA;

- Short-circuit transformer: Composed of three single-phase transformers, with specific parameters detailed in Table 1.

- Short-circuit transformer (TM);

- Busbar system;

- Disconnecting switch (QS2);

- Current-limiting reactor (L1);

- Protective circuit breaker (QF3);

- Operating circuit breaker (QF4);

- Phase-selection switch (HK2);

- Adjustable reactor (L2).

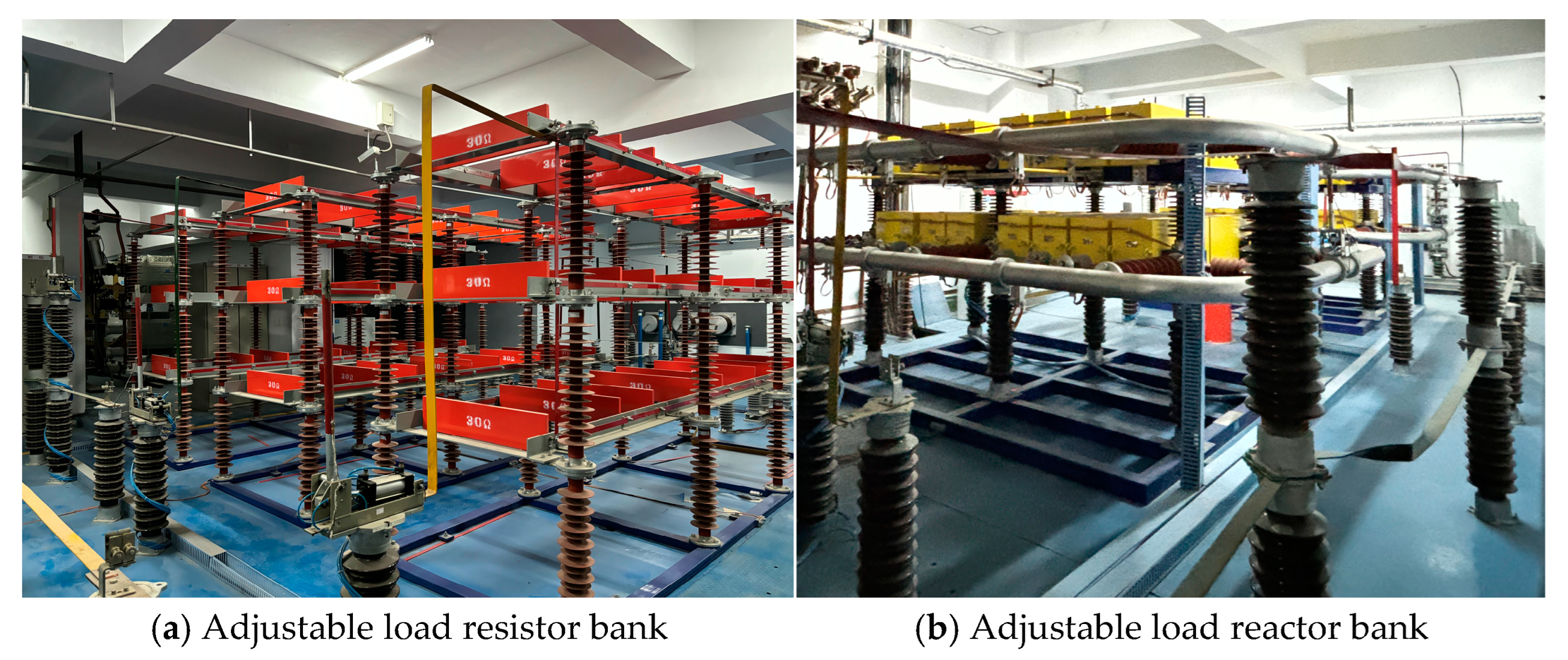

2.1.2. Active Load and Capacitive Load

- Load switches;

- Fuses;

- AC contactors.

- Two 40.5 kV back-to-back capacitor banks;

- Continuous current rating: 1–1000 A.

- High-voltage AC circuit breakers;

- High-voltage AC load switches.

- Rated voltage range: 3.6–40.5 kV;

- Capacitive current range: 1–1000 A.

2.1.3. TRV Equipment

2.2. Standardization of Test Circuits

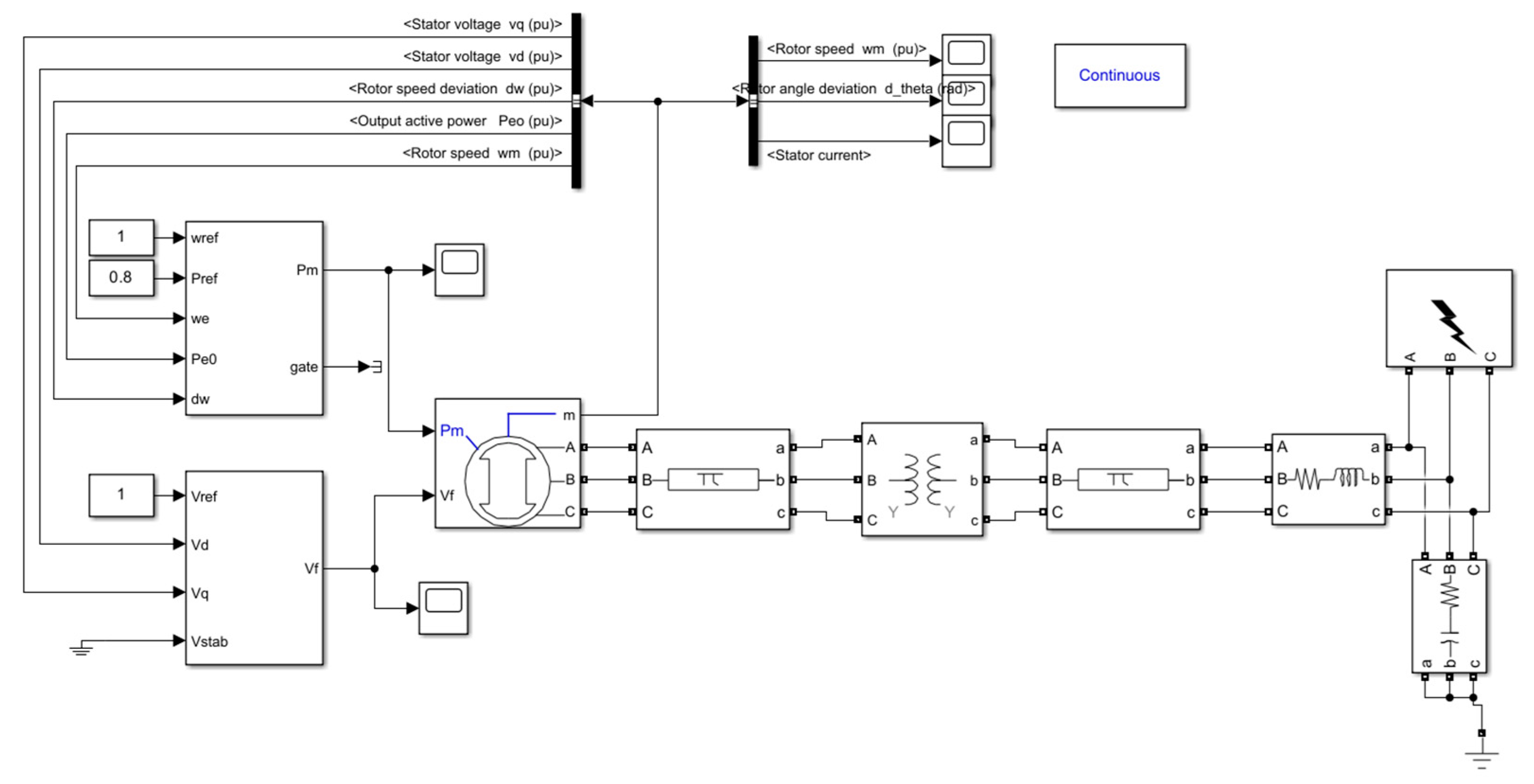

2.2.1. Simulation

- (1)

- High-capacity testing circuit and short-circuit current simulation

- (2)

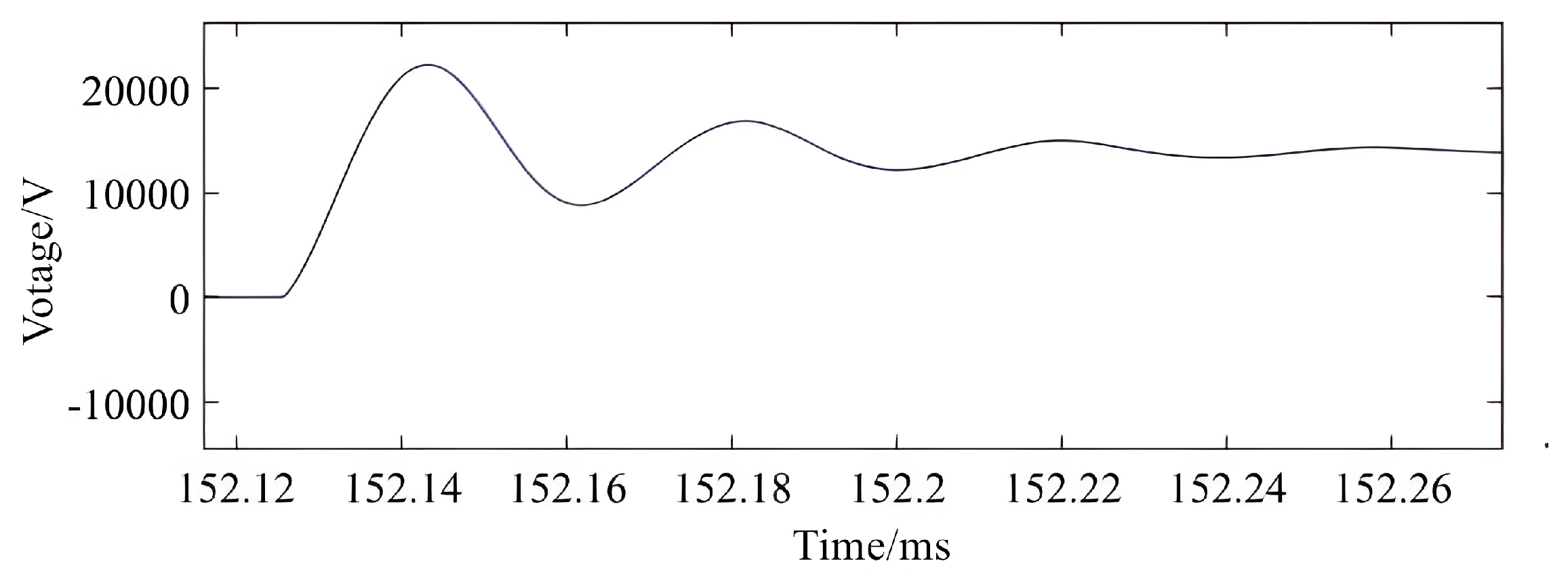

- TRV characteristic simulation

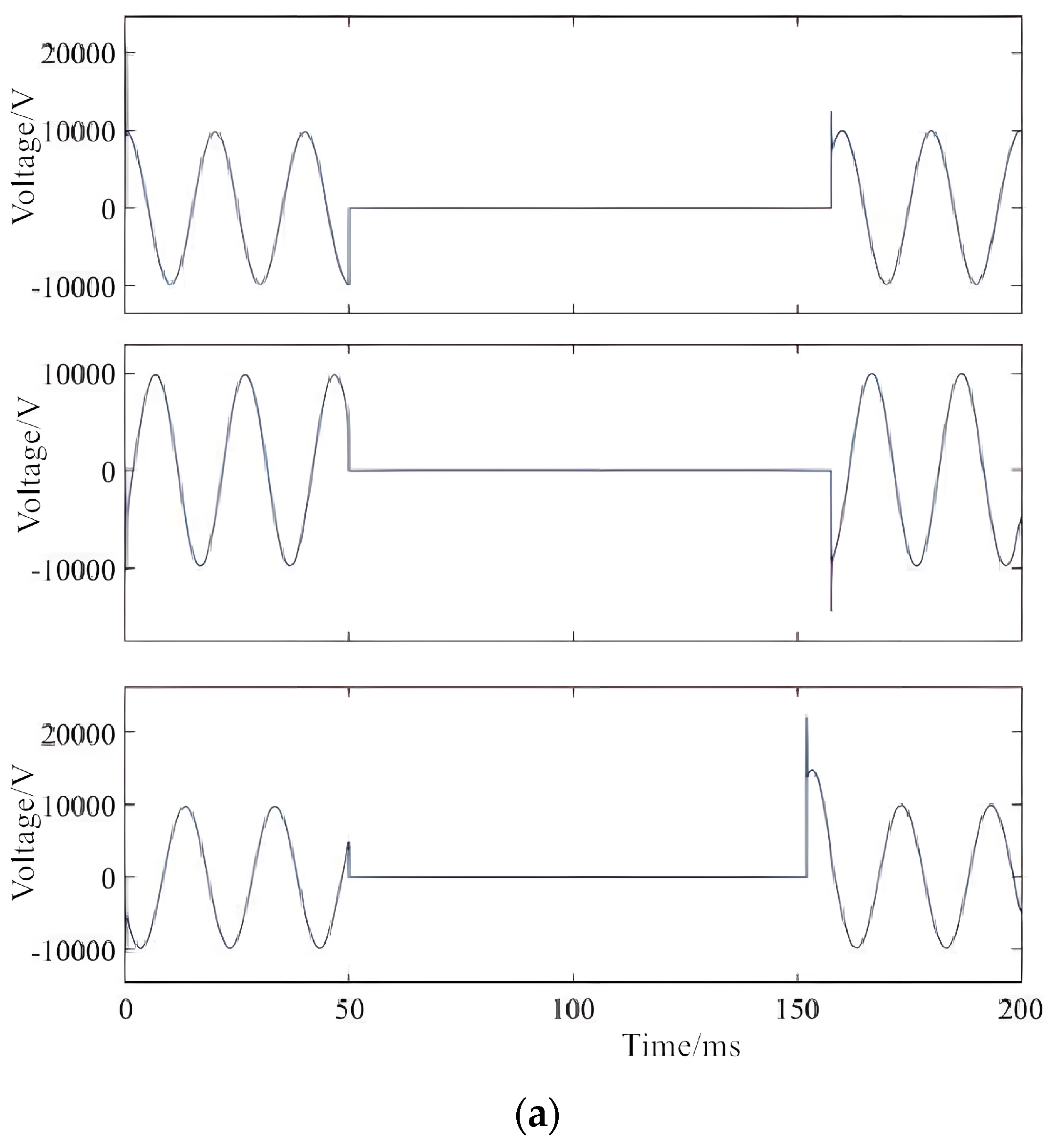

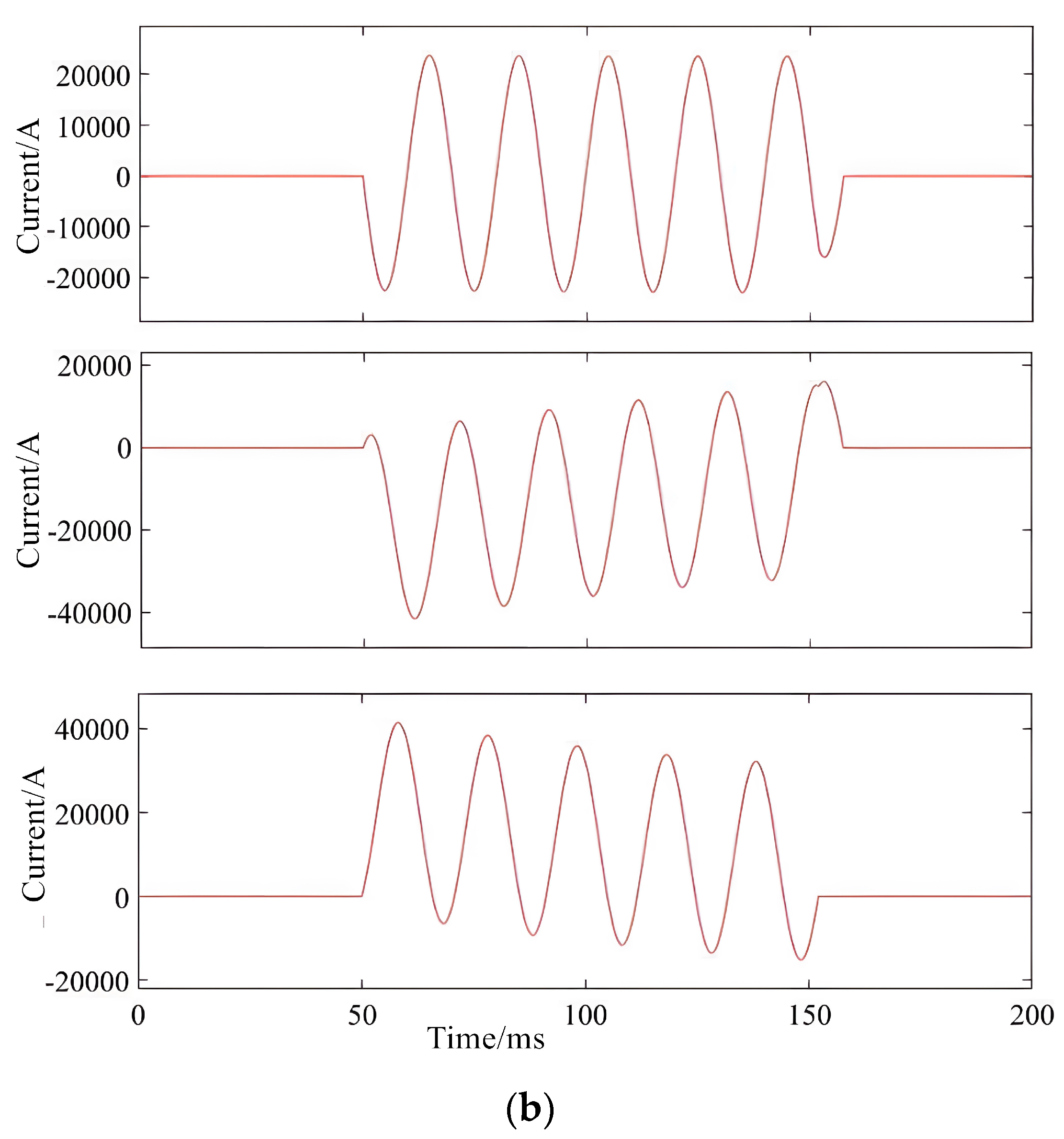

2.2.2. Experimental Validation

- (1)

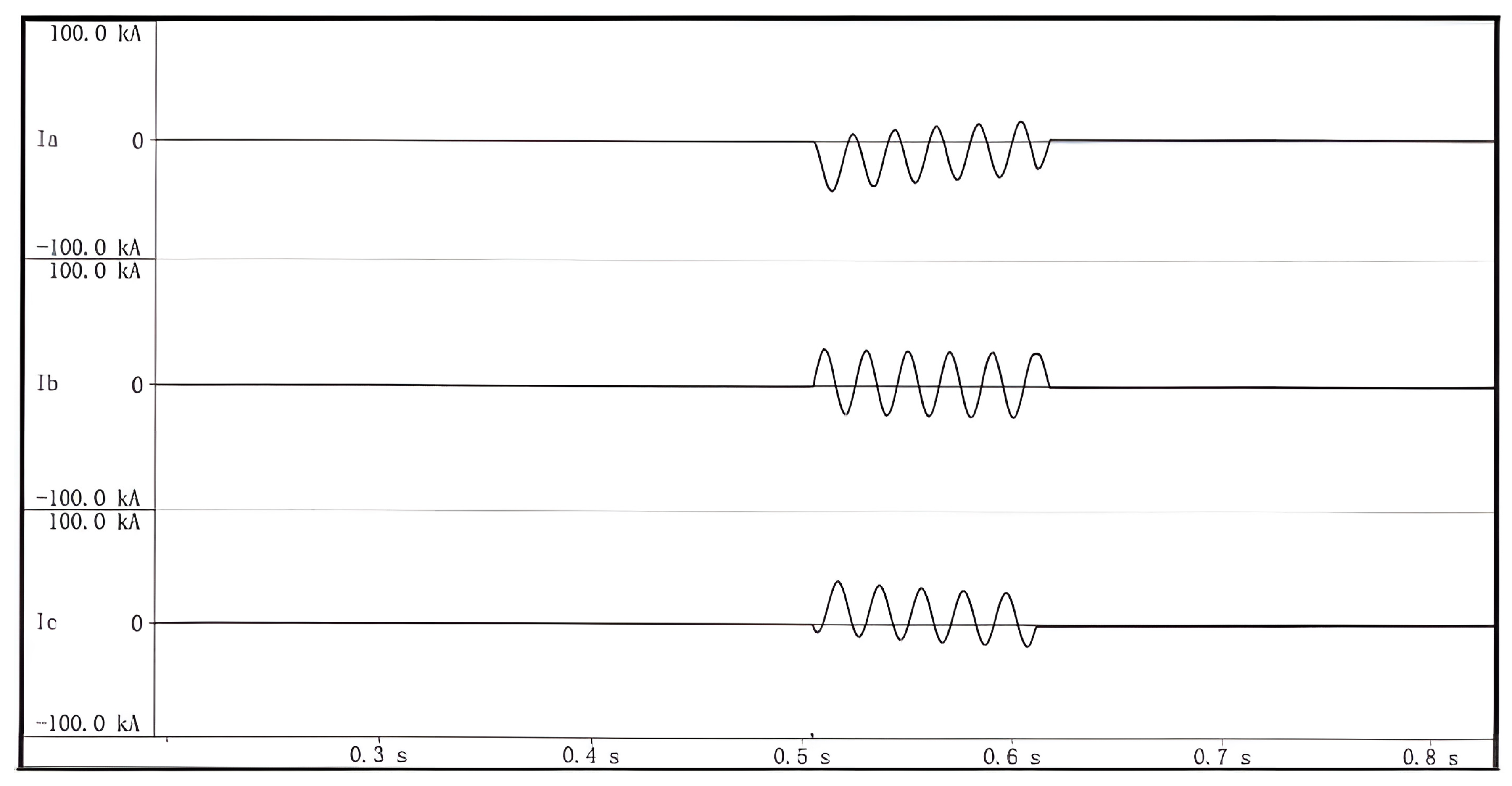

- Verification of short-circuit current simulation

- (2)

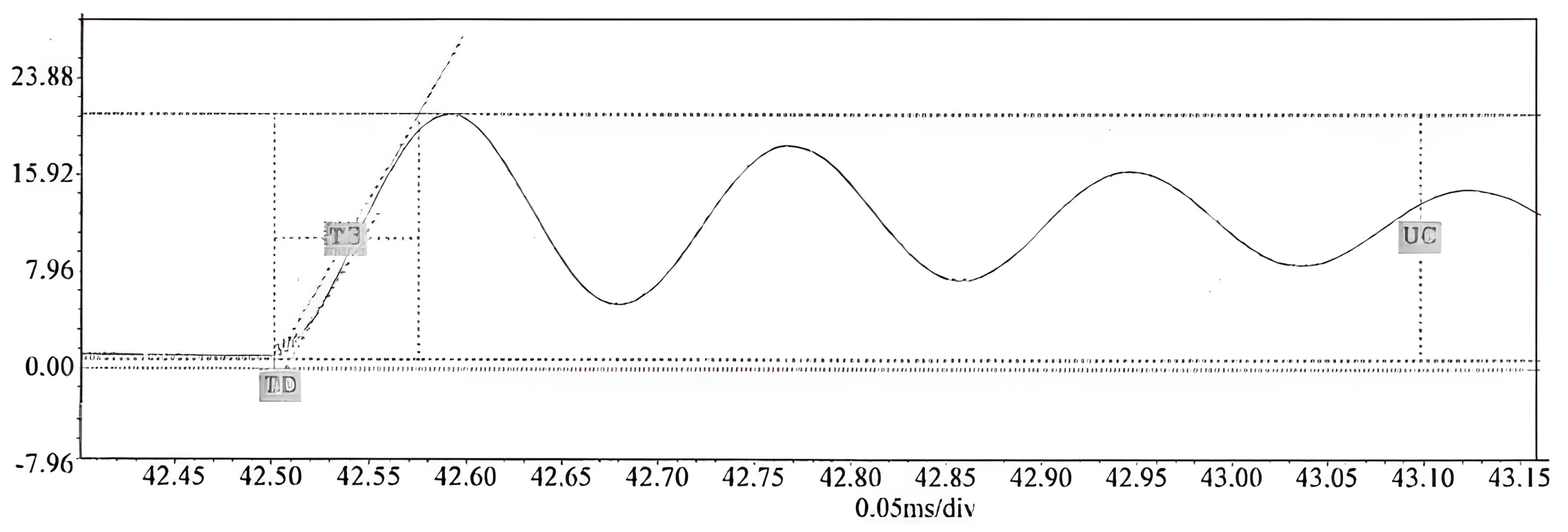

- Verification of TRV characteristics

2.2.3. Comparison and Discussion

3. Test Monitoring Control System

3.1. Secondary Monitoring and Control

3.1.1. Secondary Signal Monitoring and Control

- PLCs handle digital signal processing (e.g., door status, transformer measurements, breaker operations) and execute control commands (alarms, indicators, switching sequences).

- HMIs provide an intuitive visualization of analog/digital parameters (e.g., transformer oil temperature) for field personnel.

3.1.2. TRV Device Monitoring and Control

3.1.3. Sequential Control

3.2. Test Data Acquisition System

3.2.1. System Composition

3.2.2. System Functions

3.2.3. System Advantages

3.2.4. System Integration

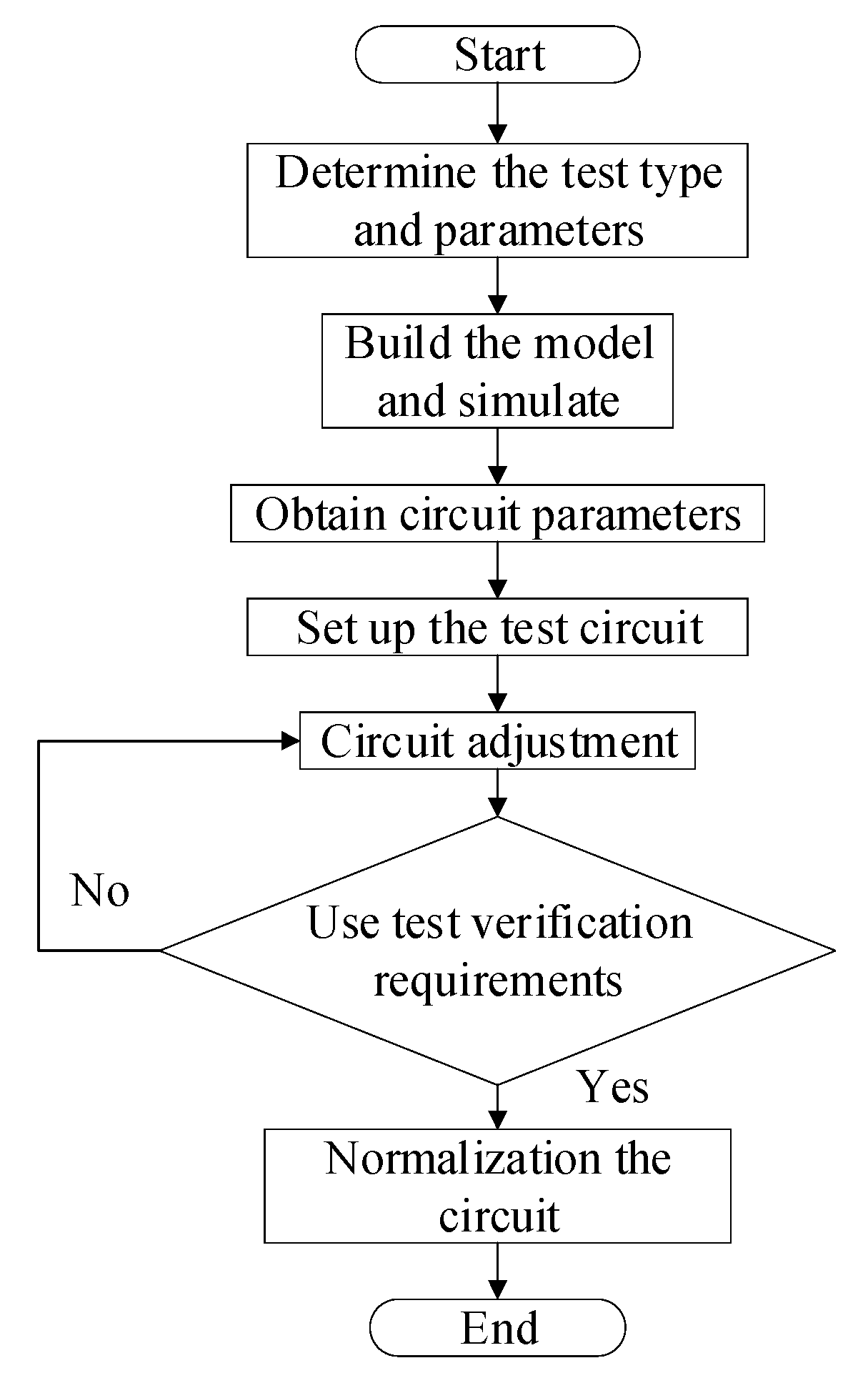

4. High-Capacity Testing Process Control

5. Conclusions

- (1).

- Standardization of test circuits

- (2).

- Automation of test monitoring and control systems

- (3).

- Practitioners implement standard frameworks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bing, J. Building a new power system for 30·60 goals: Thoughts on China’s power 4.0. Glob. Energy Interconnect. 2021, 4, 534–541. [Google Scholar]

- Voropai, N.; Podkovalnikov, S.; Chudinova, L. The evolution of interstate power grid formation. Glob. Energy Interconnect. 2021, 4, 335–353. [Google Scholar] [CrossRef]

- Sheng, G.H.; Qian, Y.; Luo, L.G.; Song, H.; Liu, Y.; Jiang, X. Key technologies and application prospects for operation and maintenance of power equipment in new power systems. High Volt. Eng. 2021, 47, 3072–3084. [Google Scholar]

- Chen, J.; Wang, Y.; Huang, H.; Liu, J. Application research on live detection of partial discharge in 10kV switchgear based on multi-dimensional diagnosis technology. Distrib. Util. 2016, 33, 64–68. [Google Scholar]

- Li, L. Application of intelligent monitoring and automation technology in power systems. Electron. Technol. 2024, 53, 328–329. [Google Scholar]

- Falcone, P.M. Sustainable energy policies in developing countries: A review of challenges and opportunities. Energies 2023, 16, 6682. [Google Scholar] [CrossRef]

- Zhang, Q.; Wei, L.; Su, W.; Li, H.; Wang, L. Commissioning of intelligent switchgear based on IEC61850 message simulation and analysis technology. High Volt. Appar. 2014, 50, 91–95, 101. [Google Scholar]

- Li, G.; Yao, S.L.; Du, W.; Sun, M.; Cheng, Y.; Wang, P.R.; Wang, C.J. Research on the capacity test circuit of uhv circuit breakers. High Volt. Appar. 2013, 49, 6–11. [Google Scholar]

- Dai, Q.; Ma, S.Q.; Ye, H.P.; Li, S.; Sun, S.H.; Wang, W. Current status and development trends of on-line insulation monitoring technology for high-voltage switchgear. High Volt. Appar. 2023, 59, 1–11. [Google Scholar]

- Zhen, J.Y.; Ding, Z.D.; Teng, C.L.; Gong, R.F.; Sun, P.H.; Zhang, Y. Caculation and analysis of influence of impact load from low voltage apparatus test station with large-capacity on power system. Low Volt. Appar. 2011, 19, 6–9. [Google Scholar]

- Kang, Z. Design of control system for high-voltage high-capacity laboratory. Electr. Eng. Electron. 2017, 11, 74–76. [Google Scholar]

- Dai, J.Z.; Zhang, S.C.; Shen, J.M.; Tao, C.C.; Tao, J.G.; Chen, Y.T.; Wu, X.; Wu, Y.F. Research on modeling method and one-click sequential control scheme for high-capacity test system. Glob. Energy Interconnect. 2023, 6, 660–669. [Google Scholar]

- Chen, H.; Lin, J.; Luo, Y. Research on synchronous control system for synthetic testing. Electr. Drive Autom. 2017, 39, 56–58. [Google Scholar]

- Li, G.; Gao, X.X.; Liu, H.J.; Huang, S.; Zhang, J.B.; Dong, W. High power short-circuit breaking and making tests technique of the high voltage AC circuit breakers. High Volt. Appar. 2018, 54, 69–75. [Google Scholar]

- Wang, Y.; Zhang, J.; Pan, C.; Yuan, X.; Wu, X.; Zhu, Y.; Jing, R.; Wang, Z.; Kang, L. Review of research on multi-dimensional performance evaluation indexes for integrated smart energy. Glob. Energy Interconnect. 2021, 4, 207–225. [Google Scholar]

- Chen, G.P.; Guo, W.K. Application of valve island technology in high-voltage high-capacity laboratory. Autom. Instrum. 2015, 36, 33–36. [Google Scholar]

- Wu, Z.Y.; Hu, J.T.; Zhou, Z.F.; Xing, W.T. Operational Impacts and Accident Analysis of High-Capacity High-Current Switch Test Stations. Electr. Appl. 2017, 36, 74–79. [Google Scholar]

- Gao, X.X.; Ji, X.Z.; Ma, J.; Liu, H.J.; Huang, S.; Dong, W.; Wang, W. Analysis and discussion on short-circuit test procedures for high-capacity generator circuit breakers. High Volt. Appar. 2017, 53, 172–177. [Google Scholar]

- Bai, Y.; Li, P.; Guan, Y.; Fang, C.; Guo, J.; Wang, Z.; Quan, H. Research on TRV breaking characteristics and suppression measures of high-capacity generator circuit breakers. High Volt. Appar. 2024, 60, 92–100. [Google Scholar]

- Liu, Z.; Zhao, Q.B.; Huang, S.; Yuan, J. Brief overview of the control system in high power laboratories. High Volt. Appar. 2018, 54, 237–241. [Google Scholar]

- Cao, L.; Zhu, X.; Wang, S. Research of computer aided analysis system in high power Lab. High Volt. Appar. 2002, 2, 32–34. [Google Scholar]

- Chen, G.P.; Guo, W.K. Development of control system for impulse generator set based on s7-300. Electr. Autom. 2015, 37, 87–89. [Google Scholar]

- Jiang, Z.Y.; Yan, D.F.; Wang, P.R.; Liu, P.; Zhe, Y.X. Research on High power test circuit for 550 kV/80 kA circuit-breaker. High Volt. Appar. 2023, 59, 200–206. [Google Scholar]

- IEC 62271-103:2011; High-Voltage Switchgear and Controlgear—Part 103: Switches for Rated Voltages Above 1 kV up to and Including 52 kV. International Electrotechnical Commission: Geneva, Switzerland, 2011.

- IEC 62271-100:2021; High-Voltage Switchgear and Controlgear—Part 100: Alternating-Current Circuit-Breakers. International Electrotechnical Commission: Geneva, Switzerland, 2021.

- Huang, S.; Gao, X.X.; Liu, H.J.; Yao, S.L.; Dong, W.; Li, G.; Hu, X. Calculation of current zero di/dt and trv peak uc for asymmetric current interruption test t100a. High Volt. Appar. 2015, 51, 163–167. [Google Scholar]

- Zhou, X.M.; Lin, Z.L.; Liu, C.X.; Miao, B.J.; He, D.S. Calculation of the envelope of transient recovery voltage waveform using the successive approximation method. High Volt. Appar. 2018, 54, 159–163. [Google Scholar]

| No. | Technical Parameter | Numerical Value |

|---|---|---|

| 1 | Voltage ratio | 330/(2 × 60 + 2 × 12.5) kV |

| 2 | Rated capacity | 8000 kVA |

| 3 | Impedance voltage (Uk) | 0.4% |

| 4 | Rated primary-side voltage | 330 kV |

| 5 | Rated secondary-side voltage | 12 kV; 24 kV; 40.5 kV |

| 6 | Maximum short-circuit capacity | 1828 MVA |

| No. | Comparison Item | Traditional Method | Standardized Method |

|---|---|---|---|

| 1 | Parameter Configuration | Manual configuration of circuit parameters leads to inconsistent results. | Automated configuration using predefined parameter libraries ensures uniformity and consistent results. |

| 2 | Process Optimization | Complex testing processes with multiple steps result in low efficiency. | Optimized processes through simulation and experimentation improve efficiency and consistency. |

| 3 | Testing Efficiency | Low testing efficiency with poor repeatability and significant human intervention. | Automated processes significantly enhance testing efficiency and repeatability. |

| 4 | Data Reliability | Low data reliability due to manual operation errors. | Automated data acquisition and analysis ensure high accuracy and reliability. |

| 5 | Resource Consumption | High resource consumption requiring significant human and material inputs. | Reduced resource consumption through automated processes. |

| 6 | Environmental Adaptability | Unstable performance in complex electromagnetic environments. | Stable performance and strong anti-interference capabilities in complex electromagnetic environments. |

| Uc | t3 | td | |

|---|---|---|---|

| Simulation results | 20.2 kV | 23 μs | 3 μs |

| Test results | 20.6 kV | 26 μs | 4 μs |

| Phase A Current | Phase B Current | Phase C Current | Proportion of DC Component in Phase A Current | Proportion of DC Component in Phase B Current | Proportion of DC Component in Phase C Current |

|---|---|---|---|---|---|

| 19.0 kA | 18.9 kA | 19.1 kA | 3.1% | 8.3% | 5.2% |

| 19.0 kA | 18.9 kA | 19.1 kA | 7.3% | 2.6% | 6.9% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, G.; Li, Y.; Wang, J.; Chen, H.; Luo, Y. Enhancing Sustainability in Power Systems: A High-Capacity Testing System Based on a Power System. Sustainability 2025, 17, 3679. https://doi.org/10.3390/su17083679

Chen G, Li Y, Wang J, Chen H, Luo Y. Enhancing Sustainability in Power Systems: A High-Capacity Testing System Based on a Power System. Sustainability. 2025; 17(8):3679. https://doi.org/10.3390/su17083679

Chicago/Turabian StyleChen, Guoping, Yong Li, Jian Wang, Huixin Chen, and Yuan Luo. 2025. "Enhancing Sustainability in Power Systems: A High-Capacity Testing System Based on a Power System" Sustainability 17, no. 8: 3679. https://doi.org/10.3390/su17083679

APA StyleChen, G., Li, Y., Wang, J., Chen, H., & Luo, Y. (2025). Enhancing Sustainability in Power Systems: A High-Capacity Testing System Based on a Power System. Sustainability, 17(8), 3679. https://doi.org/10.3390/su17083679