1. Introduction

Biomass conversion has become a crucial component in the transition toward sustainable energy systems. With the growing threat of climate change, resource scarcity, and energy insecurity, advanced biomass conversion technologies present a viable and efficient solution. Biomass, which includes agricultural residues, forest by-products, aquatic biomass, and organic waste, is a biological resource rich in carbon, hydrogen, and oxygen, making it an ideal candidate for producing biofuels, biogas, and biomaterials. Moreover, its renewable nature and versatility support its role as a key component in sustainable energy systems. However, the traditional direct combustion of biomass (

Figure 1) often results in low energy efficiency and generates pollutants, emphasizing the need for advanced conversion technologies and/or advance biomass management models [

1]. In response to these challenges, advanced biomass conversion methods have been developed to optimize the use of this resource. These methods are generally categorized into thermochemical and biochemical processes, each characterized by specific mechanisms, benefits, and limitations.

The performance and efficiency of biomass conversion technologies are strongly influenced by the physicochemical properties of the feedstock. Lignocellulosic biomass, such as wheat straw, corn stover, and forestry residues, is rich in cellulose, hemicellulose, and lignin, making it particularly suitable for thermochemical routes due to its high carbon content and low moisture. Conversely, wet organic waste streams, such as sewage sludge, animal manure, and food waste, are more amenable to biochemical processes, owing to their lower lignin content and higher biodegradability. Algal biomass, with low lignin and moderate ash content, is versatile and can be processed through either route, depending on the target product and operational conditions. Therefore, aligning biomass characteristics (e.g., moisture, ash, lignin, and volatile solids content) with the specific technical requirements of each process is essential to optimize yields, energy recovery, and environmental performance [

1].

1.1. Thermochemical Conversion Processes

Thermochemical conversion processes release the chemical energy stored in biomass by breaking covalent bonds such as C–C, C–H, and C–O present in carbohydrates, lignin, and other organic macromolecules formed during photosynthesis. These processes transform organic matter into solid, liquid, or gaseous products such as biochar, bio-oil, and syngas. Depending on the primary product, thermochemical pathways can be grouped into three categories: biomass-to-solid processes, biomass-to-liquid processes, and biomass-to-gas processes [

2]. Biomass-to-solid processes, such as torrefaction and hydrothermal carbonization (HTC), produce energy-dense solids like pyrochar and hydrochar. These methods improve the ease of particle size reduction (grindability), enhance storability by reducing moisture and biological degradation, and increase the energy density of biomass. Torrefaction, a mild pyrolysis process performed at 200–300 °C under inert conditions, enhances biomass handling properties by producing biochar with improved grindability and a higher calorific value [

3]. On the other hand, HTC is conducted at 180–230 °C and pressures of 2–10 MPa, converting wet biomass into hydrochar through dehydration and polymerization reactions. HTC is particularly advantageous for wet feedstocks as it eliminates the need for pre-drying. Hydrochars are known for their high porosity and oxygen functional groups, making them useful in adsorption applications [

4]. Despite these benefits, biomass-to-solid processes require significant energy inputs, and emissions must be controlled to mitigate environmental impacts. Future research focuses on integrating these processes into biorefineries to enhance efficiency and valorize waste streams.

In biomass-to-liquid processes, including hydrothermal liquefaction, slow pyrolysis, and fast pyrolysis, bio-oils or hydrocarbon-rich liquids are produced. Pyrolysis involves the thermal decomposition of biomass in the absence of oxygen, resulting in bio-oil, biochar, and gases. Fast pyrolysis, performed at temperatures of 450–600 °C with short vapor residence times (<2 s), is particularly effective for maximizing bio-oil yields [

5]. However, the resulting bio-oils have a high oxygen content, which lowers their energy density and stability, necessitating further upgrading through hydrodeoxygenation. Slow pyrolysis, conducted at 350–700 °C, produces a higher yield of biochar with a higher carbon content suitable as a coal substitute [

6]. Hydrothermal liquefaction (HTL), operating at 200–450 °C and pressures of 10–25 MPa, uses water or alcohol as the reaction medium to convert wet biomass into biocrude without pre-drying. Compared to pyrolysis oils, HTL biocrude has a higher hydrogen content, lower viscosity, and fewer oxygenated compounds, making it a superior fuel precursor. Recent studies have demonstrated that co-solvents, such as methanol and water, can improve biocrude yield and quality. However, HTL is energy-intensive, requiring efficient heat recovery systems to enhance economic viability [

7].

Biomass-to-gas processes like gasification and hydrothermal gasification (HTG) convert biomass into syngas—a versatile mixture of hydrogen, carbon monoxide, and carbon dioxide—that can be used for energy generation or as a precursor for biofuels and chemicals. Conventional gasification occurs at high temperatures (700–1000 °C) with limited oxygen, producing syngas that can be upgraded to fuels or used directly for power generation. Research has focused on optimizing reactor designs, feedstock particle size, and gasifying agents to improve efficiency [

8]. HTG, particularly supercritical water gasification (SCWG), operates at pressures above 22 MPa, utilizing supercritical water to convert wet biomass without drying. SCWG enhances hydrogen production through water–gas shift reactions but faces challenges related to high equipment costs and material corrosion. Recent advancements have introduced novel catalysts to improve gas yield and reaction efficiency [

9].

Key factors influencing thermochemical processes include temperature, residence time, heating rate, and pressure, as gathered in

Table 1. Additionally, feedstock composition, particle size, moisture content, and the type of reactor used significantly impact the efficiency and yield of these processes. The selection of catalysts and gasifying agents can further optimize reaction kinetics and product distribution, particularly in gasification and hydrothermal liquefaction. However, thermochemical methods have limitations, such as the need for costly gas purification systems to remove impurities like tars, hydrogen sulfide, and carbon dioxide, which can affect downstream applications. High-temperature processes, such as conventional gasification, often require advanced materials to withstand thermal stress and corrosion, increasing capital costs. Moreover, incomplete combustion or improper conditions can lead to the formation of polycyclic aromatic hydrocarbons and other pollutants, posing environmental concerns.

Despite these challenges, thermochemical processes play a significant role in waste biomass management and energy production by reducing dependence on fossil fuels and generating value-added by-products. For instance, biochar from pyrolysis can be used as a soil amendment or carbon sequestration agent, contributing to a sustainable bioeconomy. Hydrochar produced via HTC has also shown potential for nutrient retention and water filtration applications. Similarly, biocrude from HTL serves as a promising feedstock for renewable diesel production, while syngas from gasification can be upgraded into synthetic fuels, hydrogen, or methanol, further enhancing the versatility of these technologies [

10]. Moreover, advancements in reactor designs, such as fluidized beds and supercritical water reactors, have improved reaction efficiency and scalability [

11].

1.2. Biological Conversion Processes

Biochemical conversion processes, by contrast, use biological agents such as microorganisms and enzymes to decompose biomass under milder conditions. The main processes in this category are anaerobic digestion (AD) and syngas fermentation (SNF) [

4]. Although other biochemical pathways such as ethanol or butanol fermentation, biohydrogen production, and bioelectrochemical systems also fall within this category, this review focuses specifically on gas-generating routes, particularly those involving AD and its integration with thermochemical processes, due to their relevance in maximizing energy recovery from wet biomass. AD is a well-established process that converts organic biomass into biogas—a mixture primarily of methane (CH

4) and carbon dioxide (CO

2)—through the metabolic activities of different microbial communities [

12]. AD consists of four stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis. In hydrolysis, complex organic molecules such as carbohydrates, proteins, and lipids are broken down into simpler sugars, amino acids, and fatty acids. During acidogenesis, these molecules are further converted into volatile fatty acids (VFAs), hydrogen, and CO

2. The VFAs are subsequently transformed into acetate, hydrogen, and CO

2 in the acetogenesis stage. Finally, methanogenesis converts acetate and hydrogen into methane. AD is particularly valued for its ability to handle diverse feedstocks with high moisture content and for its capacity to reduce organic waste. However, challenges include the accumulation of intermediate metabolites, such as ammonia and VFAs, which can lower the reactor pH and inhibit microbial activity. Maintaining a balance between acidogenic and methanogenic microbial populations is crucial for stable reactor performance [

13]. Two-stage AD systems, which separate acetogenesis and methanogenesis from hydrolysis and acidogenesis, have been shown to improve process stability and increase biogas yields [

14]. Recent advancements have explored the synergy between thermochemical and biochemical processes, particularly the reuse of thermochemical by-products such as biochar to enhance AD performance. Biochar addition can help stabilize microbial communities, buffer pH, and improve electron transfer, leading to increased methane production [

10].

SNF is an emerging technology that uses microorganisms to convert syngas—a mixture of hydrogen (H

2), carbon monoxide (CO), and carbon dioxide (CO

2)—into biofuels such as ethanol, butanol, and methane. Acetogenic bacteria carry out this conversion through the Wood–Ljungdahl pathway, which involves acetogenesis (the formation of acetate) and solventogenesis (the conversion of acetate to alcohols) [

15]. Unlike conventional catalytic processes, SNF operates at lower temperatures and pressures (

Table 1), making it more energy-efficient. However, a significant challenge in SNF is the low solubility of CO and H

2 in the liquid phase, which limits gas–liquid mass transfer and reduces product yields. Strategies to improve mass transfer include the use of pressurized reactors and biofilm-based systems, such as hollow-fiber membrane reactors [

16]. Research has also focused on developing engineered microbial strains with enhanced metabolic capabilities and optimizing reactor designs to increase SNF efficiency and selectivity [

17]. In summary, biochemical conversion processes offer sustainable pathways for bioenergy production by utilizing biological systems to convert waste biomass into valuable products. However, improvements in pretreatment, microbial engineering, and reactor design are essential to address the current limitations and enhance the economic feasibility of these processes.

1.3. Challenges and Integration Opportunities

Both thermochemical and biochemical conversion processes face significant challenges related to operational costs, feedstock variability, and product upgrading. Thermochemical processes, such as pyrolysis and gasification, require high temperatures and pressures, resulting in increased energy demands and the need for robust materials to withstand harsh conditions. On the other hand, biological processes, such as AD and SNF, must address issues like microbial imbalances, long retention times, and sensitivity to inhibitory compounds [

18].

Despite these limitations, hybrid systems that integrate thermochemical and biochemical processes offer promising opportunities for maximizing resource recovery, improving energy output, and enhancing economic viability. Integrated systems capitalize on the strengths of both conversion routes, aligning with the goals of circular bioeconomy frameworks [

1,

2,

19]. For instance, syngas produced from biomass gasification can serve as a carbon-rich feedstock for SNF, allowing for the direct microbial conversion of syngas into bioethanol or other biofuels, thereby reducing the need for complex catalytic upgrading. Similarly, biochar generated from pyrolysis or HTC can act as a catalyst support in AD systems, enhancing microbial activity by improving pH buffering, electron transfer efficiency, and adsorption of inhibitory compounds. Additionally, the heat generated from thermochemical processes can be used to maintain optimal temperatures for biochemical reactions, such as thermophilic AD, improving overall energy efficiency and reducing external heating requirements. Bio-oil fractions from pyrolysis can also be explored as substrates for microbial upgrading, expanding the potential product portfolio of biorefineries.

To overcome the technical and economic challenges associated with hybrid systems, advancements in reactor design and computational modeling have played a critical role. The use of simulation frameworks, such as the ADM1 model, has improved the understanding of microbial kinetics and reactor dynamics, enabling better control and optimization of integrated systems. Furthermore, pressurized reactors and membrane-based systems have been developed to enhance gas–liquid mass transfer during syngas fermentation, addressing one of the primary limitations of this process [

20]. In this context, this review provides a comprehensive analysis of the latest advancements in integrated biomass conversion technologies. It highlights the synergies between thermochemical and biochemical processes, outlines key challenges and innovations, and offers a roadmap for scaling these technologies to industrial levels. By presenting a holistic overview that emphasizes both the technical feasibility and economic potential of hybrid systems, this work underscores the critical role of integrated approaches in advancing sustainable biofuel and bioproduct production.

2. Hybrid Thermochemical and Biochemical Systems

2.1. Integration of Anaerobic Digestion and Pyrolysis

AD produces digestate, a nutrient-rich by-product that, after being dehydrated, can be used as feedstock in pyrolysis processes to produce biochar. This integrated approach enhances energy efficiency and sustainability while reducing overall costs. Research has shown that combining AD and pyrolysis improves resource recovery from agricultural waste. When dried digestate is used as input for pyrolysis, energy output can increase by up to 42% compared to AD alone [

21]. The additional electricity generated can be sold to the grid, resulting in supplementary revenue. Moreover, the integrated system produces biogas and bio-oil at 11% and 15% lower costs, respectively, compared to their standalone counterparts [

22]. Pretreatment of biomass before pyrolysis has been explored to improve bio-oil quality and selectivity, demonstrating that pretreatment can enhance the stability of bio-oil by reducing the formation of unwanted by-products. Compared to the solid digestate produced by AD, biochar obtained from digestate pyrolysis shows superior performance as a soil conditioner due to its higher potassium and phosphorus content, larger surface area, and improved water retention capacity. These properties make it particularly effective for soil nutrient enrichment and structure improvement [

23].

Several studies have investigated hybrid AD–pyrolysis systems using different feedstocks, including food waste digestate. Studies have shown that pyrolyzing raw food waste results in higher gas and bio-oil yields compared to pyrolyzing digestate. However, the bio-oil obtained from digestate contains fewer hydrocarbons, phenols, and esters, making it more suitable for biofuel applications [

24]. A recent study [

25] demonstrated that bio-oil from digestate pyrolysis using 20 wt% K

3PO

4 at 500 °C contained a high fraction of aromatic hydrocarbons and reduced acidity, indicating improved fuel properties and suitability for biofuel applications. The integration of AD and pyrolysis can also include the reuse of pyrolysis liquids (pyro-liquid) and gases (pyrogas). Pyro-liquid can be reintroduced into the system, forming a triple-loop process (AD–pyrolysis–AD), which further enhances resource recovery [

26]. However, pyro-liquids contain inhibitory compounds, such as phenols, furans, and aldehydes, which can negatively impact microbial activity in AD. Detoxification and pretreatment methods are essential to mitigate these effects. Additionally, blending pyrogas with biogas reduces the need for extensive gas cleaning while meeting stringent emissions regulations during combustion [

27]. However, pyrogas conversion in AD is often limited by gas–liquid mass transfer constraints, which researchers suggest can be improved by using gas-permeable membranes. In summary, the integration of AD and pyrolysis offers a highly effective approach to enhance energy recovery, produce bio-oil with biofuel-like properties, and generate biochar for agricultural use. By addressing the challenges associated with pyro-liquid toxicity and improving gas–liquid mass transfer, hybrid AD–pyrolysis systems can significantly contribute to circular bioeconomy strategies.

2.2. Integration of Anaerobic Digestion and Hydrothermal Liquefaction

The combination of AD and HTL represents a powerful approach for maximizing energy recovery from organic waste streams. HTL is particularly effective for processing feedstocks with high moisture content, such as digestate, since it bypasses the need for energy-intensive drying. This feature makes it a highly efficient option for converting digestate into biocrude, a valuable liquid fuel that can be further upgraded into sustainable transportation fuels. A key challenge in managing anaerobic digestate is its high organic content, which can contribute to environmental issues such as odor, pollution, and the presence of pathogens. Using HTL can mitigate these concerns by converting the organic-rich material into biofuel and simultaneously reducing the environmental footprint associated with digestate disposal. In addition to producing biocrude, HTL generates an aqueous by-product containing up to 40% of the original organic content and 80% of the nutrients from the feedstock, making it a promising resource for biological processes [

28]. The integration of AD and HTL can further enhance overall resource recovery by recycling the aqueous phase into the AD process to generate biogas. However, this by-product contains inhibitory compounds, such as furfurals and phenols, which can limit microbial activity [

29]. Frugoli et al. [

30] investigated the use of biochar derived from spent coffee grounds in the AD of post-HTL wastewater. Their findings indicated that incorporating biochar improved phenol removal efficiency and increased methane yield by 62%, demonstrating biochar’s potential to mitigate inhibitory effects and promote microbial activity in AD systems.

The potential of integrating HTL with AD is further amplified by its compatibility with algae cultivation systems. Post-HTL wastewater, rich in nitrogen and phosphorus, can serve as a nutrient source for algal growth, providing a sustainable method for nutrient recycling. However, certain compounds present in post-HTL wastewater, such as chloride salts and pyrrolidines, can inhibit algal growth. To address this, detoxification methods combining granular activated carbon and ozone treatment can improve water quality for algae cultivation. In addition to serving as a detoxification step, AD can act as a pretreatment process to remove inhibitory organics before the wastewater is used for algae cultivation. Research by Fernandez et al. [

31] showed that methane yields from the AD of wastewater produced from algae HTL could reach up to 327 mL/g vs. for Tetraselmis and 263 mL/g vs. for Chlorella at lower dilution ratios. However, higher concentrations of post-HTL wastewater (40%

v/

v) significantly reduced methane production due to the accumulation of inhibitory compounds. The use of biochar or hydrochar from HTL as an additive in AD systems has also been explored to enhance methane yields and improve nutrient retention. By increasing the carbon-to-nitrogen ratio and acting as an electron transfer agent, hydrochar can stabilize microbial populations and improve the overall process efficiency. Integrating AD and HTL offers a comprehensive approach to organic waste valorization, combining bioenergy production with effective resource recovery. The development of advanced detoxification and nutrient recycling strategies, such as the use of granular activated carbon and algae cultivation, underscores the potential of this integrated system to contribute to circular bioeconomy frameworks.

2.3. Integration of Anaerobic Digestion and Hydrothermal Carbonization

The combination of AD and HTC offers a promising approach for maximizing resource recovery from organic waste. HTC is particularly effective for processing digestate due to its high moisture content, eliminating the need for energy-intensive drying steps. During this process, the digestate is converted into hydrochar, a carbon-rich material that can be used as fuel or as a valuable input in various industrial processes. In addition to hydrochar, the process yields an aqueous phase rich in dissolved organics and nutrients, facilitating chemical recovery and nutrient recycling. Unlike pyrochar, which forms at high temperatures and has a stable carbon structure resistant to microbial degradation, hydrochar retains a significant portion of the nutrients present in the feedstock and is more prone to decomposition. This makes hydrochar particularly suitable for applications such as soil improvement and nutrient enrichment [

32]. Despite the advantages of combining HTC and AD, challenges remain, particularly regarding the stability of the AD process when the aqueous phase from HTC is reintroduced into the reactor. The composition of the aqueous liquid can vary significantly and may introduce organic compounds, such as acetic acids, phenols, and furans, that inhibit microbial activity and destabilize the process. To address this issue, researchers have proposed a two-stage AD system that separates the acidification and hydrolysis phases from the methanation phase, allowing each stage to operate under optimal conditions for microbial growth and activity [

33].

In a two-stage system, the first phase breaks down complex organic materials into simpler compounds, while the second phase focuses on methane production. After the initial digestion, the hydrolysate and aqueous liquid from HTC, which are rich in soluble carbon and organic acids, can be used in the second stage to enhance biogas production. Recent studies have demonstrated that this integration can significantly enhance energy recovery. For instance, coupling HTC with AD has been shown to improve energy recovery from biomass waste, with energy efficiencies reaching up to 84.1% [

34]. Additionally, the use of hydrochar as an additive in AD processes has been reported to increase methane yields, with improvements of up to 36%, attributed to its ability to stabilize microbial communities and enhance volatile fatty acid conversion to methane [

35]. Moreover, the aqueous phase from HTC has potential as a nutrient source for microalgae cultivation due to its nitrogen and phosphorus content. However, it often requires additional treatment to remove inhibitory compounds that could hinder algal growth. Detoxification methods such as ozone treatment and the addition of granular activated carbon have been effective in reducing these inhibitory effects and improving the quality of the effluent for biological processes. In conclusion, the integration of AD and HTC presents a highly efficient strategy for organic waste valorization, enhancing energy recovery and nutrient recycling. The implementation of optimized two-stage AD systems and advanced detoxification methods can further improve the performance and stability of this integrated process, contributing to a sustainable circular bioeconomy.

2.4. Integration of Gasification and Syngas Fermentation/Biomethanation

The integration of gasification and SNF presents a robust pathway for converting lignocellulosic biomass, such as softwood and wheat straw, into second-generation biofuels [

36]. SNF operates under relatively mild conditions compared to other conversion methods, making it more stable and less prone to operational disruptions. The biocatalysts used in SNF provide several advantages, including high resistance to sulfur-based contaminants in the syngas, flexibility in terms of the CO/H

2 molar ratio, and high selectivity for the desired end products with minimal by-products. Additionally, hybrid gasification-SNF processes can improve cost efficiency by optimizing syngas conditioning and minimizing unnecessary cleaning steps, which significantly reduces operational costs.

Research has demonstrated that the combination of gasification technologies with SNF can significantly influence syngas composition and biofuel yields [

37]. For instance, a comparative study of bubbling fluidized bed, updraft fixed bed, and indirect gasification technologies identified indirect gasification as the most effective option for wheat straw due to its lower tar content (34 g/Nm

3) and favorable hydrogen-to-carbon monoxide molar ratio. This configuration enhanced carbon fixation by up to 55% when

Clostridium species, such as

Clostridium ljungdahlii, were used as inoculum after downstream processing steps to remove methane and saturated hydrocarbons (C

2–C

4) from the syngas [

38]. In addition to syngas fermentation, syngas biomethanation has emerged as a complementary approach for enhancing biofuel recovery by converting carbon dioxide, hydrogen, and carbon monoxide into methane using anaerobic microorganisms. This process provides an efficient route for producing renewable methane, which can be used as a direct fuel or as a precursor for further biofuel synthesis.

Syngas biomethanation is particularly advantageous due to its flexibility in handling diverse gas compositions without strict CO/H

2 ratios. The deployment of hydrochar, a carbon-rich material derived from HTG, has also been proposed to improve SNF performance. Hydrochar serves as a porous support material that enhances mass transfer rates by immobilizing microbial cells at the liquid–solid interface. Furthermore, hydrochar’s macronutrient-rich composition—including nitrogen (N), phosphorus (P), potassium (K), and other essential elements—makes it an effective soil amendment, contributing to circular economy objectives [

39].

Recent studies have also highlighted the potential of using the aqueous phase generated during HTG as a medium supplement for syngas fermentation. This phase is rich in biogenic carbon, phosphorus, and nitrogen, which can stimulate microbial growth and enhance fermentation yields. Additionally, process simulation studies have demonstrated that hybrid gasification–SNF plants can achieve energy self-sufficiency. While conventional gasification–SNF systems have been extensively studied, fewer studies have focused on integrating HTG with SNF. Nevertheless, this emerging technology shows significant potential for sustainable waste management and alternative fuel production. For instance, commercial-scale HTG-SNF plants, such as those developed by LanzaTech Inc., have successfully demonstrated the valorization of agricultural and municipal solid wastes into biofuels.

2.5. Integration of Hydrothermal Liquefaction and Syngas Fermentation/Biomethanation

Hydrothermal liquefaction is a promising thermochemical conversion method capable of producing biocrude oils from biomass with high moisture content, eliminating the need for energy-intensive drying steps. One of the by-products of this process is a significant volume of an aqueous phase known as hydrothermal liquefaction aqueous phase (HTL-AP). While often considered a waste liquid, HTL-AP contains a rich mixture of organic and inorganic components, including carbon, nitrogen, and trace amounts of heavy metals. These components, transported through various chemical pathways, make HTL-AP a potential energy source for biological conversion. Anaerobic fermentation presents an effective method for valorizing HTL-AP by converting it into environmentally friendly chemicals and biofuels [

40]. However, the chemical complexity of HTL-AP, including the presence of inhibitory compounds, can hinder the efficiency of biological processes. To overcome this challenge, pretreatment methods such as solvent extraction, partial oxidation, and adsorption are employed to convert inhibitory substances into more metabolizable compounds [

41]. These steps improve the bioavailability of the organic content, making it suitable for further microbial conversion.

SNF and biomethanation can also be integrated with HTL to enhance resource recovery. Syngas, which is rich in carbon monoxide, hydrogen, and carbon dioxide, can be used as a substrate for biological conversion to produce bioethanol or biomethane. This integration supports circular resource flows, as the HTL-AP provides essential nutrients for microbial growth in fermentation systems, and the syngas generated from hydrothermal biocrude processing can further be utilized in biofuel production [

42]. Although anaerobic fermentation is widely used for HTL-APL, aerobic fermentation can also be a viable alternative for producing value-added products. The presence of oxygen accelerates the conversion process, reducing reaction times and increasing the overall yield of bio-based chemicals and fuels.

3. Economic and Environmental Impact Analysis

Hybrid biomass conversion systems that integrate thermochemical and biochemical processes represent a transformative solution to the challenges of sustainable energy production and resource management. These technologies aim to make full use of biomass, minimizing waste while generating valuable products and energy. Evaluating their economic viability and environmental impacts is critical to understanding their potential role in advancing global sustainability goals. From an economic perspective, the diversification of outputs in hybrid systems is a key advantage.

Recent techno-economic evaluations provide a more precise basis for comparing biomass treatment technologies. According to Ochieng et al. [

43], the unit treatment cost of sewage sludge via AD is estimated at USD 252 per ton of dry sludge, which can be reduced to USD 131 per ton when revenues from energy and digestate valorization are considered. In contrast, the same authors report that SCWG shows a higher cost of USD 269 per ton, decreasing to USD 200 per ton with by-product recovery. Similarly, Gerner et al. [

44] estimate that HTC treatment costs range between USD 91 and USD 183 per ton, depending on the feedstock’s moisture content, while the production of pelletized hydrochar costs approximately EUR 157 per ton, with a break-even point of EUR 200 per ton, making it economically feasible as a CO

2-neutral solid biofuel. Furthermore, thermal plasma gasification has been reported by Ramos et al. [

45] to cost between EUR 88.50 and EUR 99.77 per ton, depending on the gasification medium. These figures reinforce the economic potential of hybrid systems, especially when combining AD and thermochemical treatments to improve energy output and product diversification.

Unlike standalone processes, hybrid technologies generate multiple value-added products, including biochar, syngas, bio-oil, and biogas. For example, biochar derived from digestate pyrolysis has high market value due to its enhanced nutrient content and utility as a soil amendment. Similarly, hydrochar from HTC can be tailored for specific applications, such as adsorbents in industrial processes or precursors for activated carbon. These diversified revenue streams make hybrid systems particularly appealing for industries seeking circular economy solutions. The energy self-sufficiency potential of hybrid systems is another critical factor. Integrating processes such as HTL with AD allows for the internal reuse of energy and water. For instance, biogas produced in AD can supply the energy required for HTL operations, creating a closed-loop system that minimizes external energy dependencies. Recent techno-economic analyses indicate that such configurations can achieve operational cost reductions of up to 30% compared to standalone technologies [

46]. Additionally, modular designs are emerging as a cost-effective solution for small- to medium-scale applications, enabling the adoption of hybrid systems in decentralized contexts.

Techno-economic assessments and life cycle assessments (LCAs) are invaluable tools for evaluating the viability of hybrid biomass systems. A comprehensive review conducted by Okolie et al. [

46] consolidates findings from various studies to provide a detailed overview of their benefits and challenges (

Table 2). For instance, an LCA on an algae biodiesel system, integrating subcritical water extraction and conventional transesterification, demonstrated that approximately 0.6 kg of CO

2 is sequestered for every kilogram of biodiesel produced, especially when combined with AD of HTL aqueous phase (HTL-AP). Furthermore, comparative analyses of HTL-AP integration explored methods like direct recycling, catalytic HTG, and AD. Among these, direct recycling emerged as the most cost-effective solution, requiring only minimal infrastructure, while HTG and AD increased the minimum fuel selling price by 11% and 2.9%, respectively. However, financial barriers remain significant.

High capital investments, particularly for advanced reactors and pretreatment technologies, often limit the scalability of these hybrid systems. For example, studies integrating AD, HTL, and biomethanation for dairy waste valorization revealed an annual production potential of 22 million MJ of renewable natural gas but highlighted the critical role of renewable gas pricing in determining economic feasibility. Similarly, comparisons between standalone AD and HTC-AD combinations for sewage sludge treatment illustrated trade-offs. While the integrated approach improved energy efficiency by 14% and reduced environmental impacts via hydrochar recovery, its treatment cost (EUR 94.3 per ton) was notably higher than standalone AD (EUR 66.2 per ton). From an environmental perspective, the review by Okolie et al. [

46] highlights the significant potential of hybrid systems to reduce greenhouse gas (GHG) emissions and enhance waste valorization. Integrated HTL-AD systems have been shown to lower GHG emissions by up to 70% compared to fossil fuel-based systems, primarily due to efficient carbon capture and the utilization of by-products like digestate and HTL-AP. Additionally, these systems promote circular economy principles by recycling process water and recovering nutrients, thus reducing landfill dependency and mitigating pollution. The transformation of agricultural residues, municipal solid waste, and industrial by-products into energy and valuable materials aligns with global sustainability goals.

Innovative processes, such as gasification coupled with SNF for 2,3-butanediol production, demonstrate both environmental and economic advantages. These systems not only reduce carbon emissions but also require lower investments compared to standalone biological or fossil-based technologies. However, challenges in managing process by-products persist. For instance, aqueous streams from HTL and HTG often contain inhibitory compounds, including furans, phenols, and acetic acids, which necessitate detoxification before reuse. Advanced treatments like granular activated carbon filtration and catalytic oxidation have shown promise but add operational complexity. Okolie et al. [

46] also underscores the potential of integrating solar-driven hydrothermal pretreatment with AD for biogas production. This approach not only reduces GHG emissions but also lowers energy costs compared to conventional hydrothermal methods. Moreover, the combination of HTC with AD demonstrates opportunities for nutrient recovery and soil enhancement. However, the risks posed by inhibitory compounds in hydrochar remain a critical area for further investigation.

Looking ahead, the integration of hybrid systems with carbon capture and utilization (CCU) technologies offers good opportunities for achieving carbon-negative outcomes. For example, CO2 captured during SNF can be redirected for methanol synthesis or algae cultivation, creating additional value streams while reducing emissions. Advances in artificial intelligence and digital process optimization are enabling more precise control over energy flows and material use, enhancing the overall efficiency of hybrid systems. With supportive policies and increased investment in R&D, hybrid systems could play a pivotal role in transforming energy landscapes and advancing the circular bioeconomy.

Despite the promising performance indicators described above, the industrial upscaling of hybrid biomass conversion systems still faces considerable technical and economic challenges. The integration of multiple unit operations, each with distinct temperature, pressure, and residence time requirements, demands sophisticated control strategies and robust system-level synchronization. Moreover, variability in feedstock composition, especially in decentralized settings, can significantly affect process stability and conversion efficiency. From an economic standpoint, the lack of standardized designs and limited commercial-scale demonstrations continue to hinder investor confidence. Additionally, regulatory frameworks and market incentives for hybrid valorization routes (e.g., carbon credits, renewable gas certificates) remain underdeveloped in many regions. Addressing these barriers will be essential to move from pilot-scale success to widespread industrial deployment.

To further explore the economic viability of hybrid systems, system-level evaluations have shed light on capital investment, operational expenditures, treatment unit costs, and potential revenue streams associated with various technology combinations. The following comparative overview summarizes key metrics for three integrated configurations: AD + HTC, AD + HTL, and SCWG + biomethanation, benchmarked against their conventional counterparts. These quantitative analyses reveal the trade-offs between financial inputs, conversion efficiency, and economic performance, offering a more refined understanding of the conditions under which hybrid valorization routes can achieve commercial feasibility.

3.1. AD + HTC vs. Standalone AD or Incineration

From a capital investment standpoint, hybridization with HTC increases the initial expenditure. AD + HTC configurations have been reported to require capital costs of approximately EUR 25.7 million, in contrast to EUR 18.9 million for AD alone [

47]. However, techno-economic assessments indicate that the additional investment can be recovered in less than six years, with a projected internal rate of return close to 12% and a net present value of around EUR 10 million [

48]. In contrast, conventional sludge incineration for equivalent capacities (e.g., 250,000 t/year) may involve capital costs in the range of EUR 169 million, reflecting a much higher economic barrier [

49]. Operating costs are also increased in hybrid systems. Over a 20-year plant life, AD + HTC has been estimated to accumulate ~EUR 68.5 million in operating expenditures, compared to EUR 47.3 million for standalone AD [

50]. This translates into a unit treatment cost of EUR 94.3 per ton for AD + HTC versus EUR 66.2/t for AD alone, a ~42% increase. However, avoided sludge disposal costs (typically EUR 150–200/t) and revenues from hydrochar (market value EUR 60–80/t, production ~26 kg/t sludge) can partially or fully compensate these additional costs [

51]. In fact, scenarios that include integration of process water from HTC back into AD report positive cash flows, highlighting the importance of system-level optimization. Energy-wise, coupling HTC with AD can increase total energy recovery by approximately 14%. While standalone AD typically recovers ~50–60% of the feedstock energy in the form of biogas, the hybrid process captures additional energy via the solid hydrochar [

51]. Although the heat available for external use may be reduced due to HTC operation demands, total system efficiency improves, supporting its environmental attractiveness.

3.2. AD + HTL vs. Conventional Processing

HTL systems, particularly when integrated with AD, target the production of liquid biofuels from wet biomass. However, they are considerably more capital-intensive, with biocrude production steps estimated at EUR 1550–1900 per kW of throughput [

52]. Small-scale plants (~3 t/day) report a minimum fuel selling price (MFSP) of ~EUR 2.4/L, which is significantly reduced to ~EUR 0.8/L when scaling up to 30 t/day. This range corresponds to ~21.5–64.7 EUR/GJ, notably higher than conventional AD-derived biogas (~6–12 EUR/GJ) [

53]. Operating costs for HTL include high consumption of hydrogen and catalysts, and handling of aqueous by-products. Despite this, hybrid configurations may allow recovery of up to 60% of the feed energy as biocrude, with an additional 10–15% recovered via methane from AD of the HTL aqueous phase. Revenues can thus be derived from both upgraded fuels (~EUR 150–300/t sludge at 19% fuel yield) and biomethane, enhancing the system’s economic viability if integration is optimized and energy markets accessible [

52]. However, profitability is highly sensitive to scale, process efficiency, and access to upgrading infrastructure (e.g., refinery hydroprocessing units), which can reduce MFSP by ~7% [

53]. While the AD + HTL route shows long-term potential to compete with fossil fuels in cost per liter or per GJ, it remains less favorable in the short term compared to AD unless strong policy incentives or negative-cost feedstocks are available.

3.3. SCWG + Biomethanation vs. AD or Incineration

Supercritical water gasification, when combined with biological methanation of syngas, represents one of the most promising (but capital-intensive) hybrid approaches for complete conversion of wet biomass to biomethane. Annualized costs for SCWG have been estimated at ~USD 10.86 million/year versus ~USD 6.22 million/year for AD. Capital annuities alone may double, and operating costs are proportionally higher due to pressure, corrosion-resistant materials, and complex process control. As such, SCWG has been reported to be ~75% more expensive than AD for equivalent throughput [

50]. Nevertheless, SCWG + biomethanation can achieve energy efficiencies of 70–84%, significantly surpassing those of AD (typically 50–60%). The hybrid route also enables higher biomethane yields per ton of feedstock, due to the near-complete carbon conversion, thus offering greater product output, provided markets can absorb it at parity prices. From a profitability standpoint, however, SCWG remains uncompetitive without subsidies. Levelized biomethane costs have been estimated around USD 82/GJ, far exceeding the USD 10–30/GJ typical for AD-based methane production [

54]. As such, SCWG + biomethanation is not yet financially viable at commercial scale, though it may hold promise in niche contexts with high sludge disposal costs or where hydrogen valorization is prioritized.

3.4. Environmental Indicators

Among the most relevant environmental benefits, hybrid systems, such as AD + HTC, AD + HTL, and AD + SCWG with biomethanation, demonstrate substantial GHG emission reductions. In the case of AD + HTC, integrating HTC into sludge treatment has been shown to reduce the global warming potential from 72 kg CO

2-eq/t to 18 kg CO

2-eq/t of sludge, equivalent to a 75% reduction. Depending on the use of hydrochar (as fuel or soil amendment), net GHG credits can range from –71.4 to +7.7 g CO

2-eq per kg of sludge processed [

50]. For AD + HTL configurations, GHG emissions from biofuel production can range from 0.3 to 2.5 kg CO

2-eq/kg of biocrude, which corresponds to 35–90% fewer emissions compared to conventional diesel [

55]. AD + SCWG + biomethanation systems can convert nearly 100% of biomass carbon into methane, achieving energy efficiencies of 70–84% and potentially doubling methane yield per ton of input versus AD alone [

56]. Regarding energy recovery, AD + HTC integration has been shown to increase the total usable energy from ~14% (AD) to ~28% of the feedstock’s higher heating value [

50], while HTL-based hybrids recover 60% of the feed energy as biocrude and another 10–15% as biogas from the aqueous phase [

55]. In terms of nutrient recovery, phosphorus retention in hydrochar allows valorization pathways via combustion ash or soil application, though toxicity trade-offs must be considered. Pollution indicators also show improvement: SCWG produces sulfur- and nitrogen-free syngas with negligible particulate emissions, while hybrid configurations consistently reduce acidification, eutrophication, and human toxicity impacts compared to AD alone or incineration. Furthermore, integrated systems reduce fugitive methane and nitrous oxide emissions from digestate spreading and can eliminate the need for landfill disposal, thus strengthening their environmental sustainability [

57]. These quantitative results support the environmental relevance of hybrid technologies for achieving carbon neutrality, maximizing renewable energy output, and closing nutrient loops.

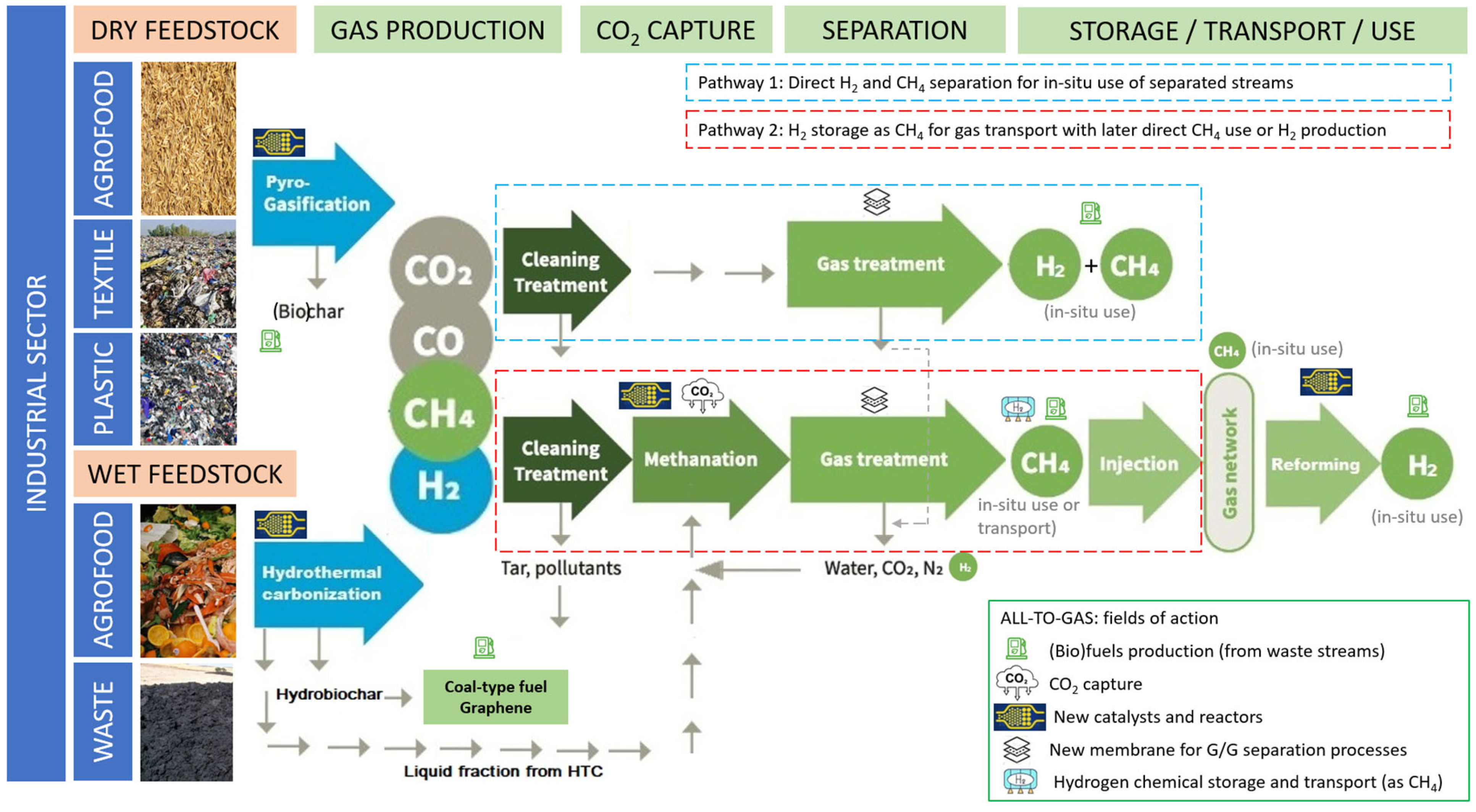

4. Practical Case Study: The ALL-to-GAS Project

The ALL-to-GAS project [

58] (

Figure 2) exemplifies an innovative approach to biomass conversion, combining thermochemical and biochemical processes to optimize resource utilization and energy generation. This initiative addresses key challenges in the renewable energy sector by demonstrating how integrated systems can maximize the value derived from diverse biomass streams, including both wet and dry residues. By employing a sequential process design, the project strategically aligns thermochemical and biochemical reactions to enhance conversion efficiency and minimize waste, offering a practical pathway toward sustainable bioenergy production.

The project integrates HTC and catalytic reforming as thermochemical processes with dark fermentation and methanation as complementary biochemical stages. HTC is utilized to convert wet biomass into hydrochar, which acts as a precursor for biohydrogen production via catalytic reforming. This step also produces an aqueous phase rich in nutrients, which is directed into the biochemical processes, ensuring a closed-loop system that minimizes environmental impact. Dark fermentation leverages this aqueous phase and additional biomass to generate biohydrogen and volatile fatty acids, which are subsequently converted into biogas through methanation, resulting in methane-rich outputs suitable for energy applications. This carefully orchestrated integration of technologies enables the recovery of valuable energy carriers while addressing the inefficiencies commonly observed in standalone systems.

The ALL-to-GAS project’s approach to combining thermochemical and biochemical pathways not only demonstrates technical feasibility but also highlights the potential for significant environmental and economic benefits. By coupling these processes, the project ensures efficient heat and mass transfer between stages, reducing energy requirements and enhancing overall sustainability. Moreover, the development of tailored catalysts for reforming and methanation has been a crucial innovation, enabling higher conversion efficiencies and improved product quality. This integration showcases the synergies that can be achieved when complementary technologies are strategically aligned.

The results of the ALL-to-GAS project have been highly satisfactory, confirming the viability of this integrated approach to biomass conversion. The process has successfully achieved high yields of biohydrogen and methane, surpassing the performance of conventional methods. Furthermore, the project has demonstrated the scalability of this approach, providing a foundation for industrial applications. By focusing on a diverse range of feedstocks, including agricultural residues and organic waste, the project offers a replicable model that aligns with the principles of the circular economy. This case study illustrates how the integration of thermochemical and biochemical processes can bridge the gap between technological potential and practical implementation. The success of the ALL-to-GAS project not only validates this approach but also establishes a precedent for future advancements in biomass conversion systems, reinforcing the role of integrated solutions in addressing global energy and sustainability challenges.

5. Strategies for Industrial Implementation

The successful industrial implementation of hybrid biomass conversion systems necessitates a comprehensive understanding of the technological, economic, and infrastructural challenges that arise during scaling up. While these systems promise substantial environmental and economic benefits, their integration into existing energy frameworks requires addressing key barriers, optimizing system design, and creating supportive policy and infrastructure frameworks. One of the most significant challenges in scaling up hybrid biomass conversion systems is the high capital investment required for advanced technologies. Processes such as HTL, AD, and gasification rely on high-pressure and/or high-temperature reactors, which demand robust materials and intricate designs to handle extreme operating conditions. For instance, SCWG requires reactors capable of withstanding pressures above 22 MPa, significantly increasing costs. Additionally, the economic feasibility of these systems depends on reliable access to feedstocks, which can be hindered by seasonal variations, logistics challenges, and market competition for biomass. The complex nature of biomass feedstock and productivity challenges during initial deployment stages further complicate scaling up these technologies [

59]. Another critical barrier is the management of by-products and process residues. For example, aqueous streams generated from HTL and HTG often contain inhibitory compounds such as phenols, furans, and organic acids. These require additional detoxification processes, such as advanced oxidation or adsorption, which add operational complexity and cost. Similarly, hydrochar from HTC can contain heavy metals or other contaminants, limiting its application in agriculture or soil amendment. Addressing these by-product challenges is essential to ensure the environmental sustainability and economic viability of hybrid systems.

The design and optimization of reactors and gasifiers play a critical role in improving the efficiency, scalability, and cost-effectiveness of hybrid systems. Innovations in reactor materials, heat recovery systems, and flow dynamics can significantly enhance process efficiency. For instance, advanced gasifiers equipped with modular designs and multi-stage configurations allow for precise control of reaction parameters, enabling higher conversion efficiencies and reduced tar formation. Fluidized bed reactors, known for their high heat transfer rates and uniform temperature distribution, have been widely adopted in biomass gasification to overcome challenges related to feedstock heterogeneity and ash formation [

60].

For HTL processes, the integration of heat exchangers and energy recovery systems can offset the high energy demands of the process. Solar-driven hydrothermal systems represent an emerging innovation, using renewable energy to power reactor heating, thereby reducing greenhouse gas emissions and operational costs. Additionally, advancements in catalysis, such as the development of heterogeneous catalysts with improved activity and durability, have shown promise in enhancing bio-oil quality and yield while minimizing secondary processing requirements. In AD systems, biochar has emerged as a valuable additive to enhance microbial activity and stability. The porous structure of biochar provides a habitat for microbial consortia, improving methane yield and mitigating the effects of inhibitory compounds such as ammonia or volatile fatty acids. Furthermore, the design of two-stage digesters, which separate hydrolysis and acidogenesis from acetogenesis and methanogenesis, has been shown to improve process stability and biogas production.

The large-scale adoption of hybrid biomass conversion systems requires supportive policy frameworks and substantial infrastructure development. Policy measures, such as feed-in tariffs, carbon credits, and renewable energy subsidies, can incentivize investment in biomass conversion technologies. Governments must establish clear regulatory standards for biofuel quality, waste management, and GHG emissions to provide certainty to investors and stakeholders. Understanding the drivers and barriers aids in addressing financial challenges, creating supportive policies, promoting market acceptance, optimizing material flows, addressing transportation costs, and enhancing stakeholder engagement [

61].

Infrastructure development is equally critical, particularly in regions with limited access to biomass supply chains or renewable energy infrastructure. Efficient biomass logistics, including collection, transportation, and storage systems, are fundamental to ensuring a steady feedstock supply. Establishing centralized biorefineries capable of handling diverse feedstocks can optimize resource utilization and reduce costs through economies of scale. Furthermore, integrating biomass conversion facilities with existing industrial ecosystems, such as chemical plants or power stations, can leverage waste heat and by-products, improving overall system efficiency. The role of public–private partnerships (PPPs) cannot be overstated in fostering innovation and accelerating deployment. Collaborative efforts between governments, research institutions, and private industry can drive advancements in technology development, workforce training, and market expansion. For instance, pilot projects funded through PPPs can demonstrate the technical and economic feasibility of hybrid systems, paving the way for commercial-scale implementation [

62].

Aligning hybrid biomass systems with circular economy principles offers a pathway to improve resource efficiency and reduce environmental impact. By converting agricultural residues, municipal solid waste, and industrial by-products into biofuels, chemicals, and energy, these systems not only minimize waste but also create value-added products. The recovery of nutrients from process residues, such as digestate in anaerobic digestion or aqueous phases from HTL, can further enhance the economic viability of these systems. For example, integrating HTC with anaerobic digestion enables the recovery of hydrochar, which can be used as a soil amendment or a precursor for activated carbon. Similarly, the recycling of process water in HTL systems reduces water consumption and waste generation. Ensuring the safe and efficient reuse of these by-products requires advancements in analytical methods to monitor contaminants and the development of treatment technologies to detoxify residues. The adoption of hybrid biomass systems varies across regions, influenced by local policies, market conditions, and resource availability. In Europe, stringent emission reduction targets and robust policy frameworks have driven the development of biomass conversion technologies. Programs like Horizon Europe and the Renewable Energy Directive (RED II) provide funding and regulatory support for biomass-based innovations. In contrast, regions with abundant agricultural residues, such as Southeast Asia and South America, are leveraging hybrid systems to address waste management challenges and generate renewable energy [

63].

6. Future Trends and Innovations

Advancements in biomass conversion technologies are critical to addressing global sustainability challenges, and future trends point toward transformative innovations in process efficiency, integration, and scalability. These advancements aim to enhance the environmental and economic viability of hybrid systems, ensuring their adoption on an industrial scale, and many of them align with the measures taken to promote their industrial implementation (previous section). One of the most promising trends is the development of next-generation reactors tailored to hybrid systems. Modular and scalable reactor designs, such as fluidized bed reactors and supercritical water reactors, are gaining traction due to their flexibility and ability to handle diverse feedstocks. These reactors improve heat and mass transfer, reduce energy consumption, and enable the integration of multiple conversion steps within a single system. For example, compact modular reactors are particularly advantageous for decentralized applications, allowing smaller communities or industries to process biomass locally without the need for extensive infrastructure. The incorporation of advanced materials, such as corrosion-resistant alloys and ceramic coatings, further enhances reactor durability, particularly for high-pressure and high-temperature processes like HTL and gasification.

The integration of CCU technologies represents a significant step toward achieving carbon neutrality in biomass conversion systems. Emerging processes, such as CO2 reforming of methane and microbial electrosynthesis, allow for the transformation of captured CO2 into value-added products, including methanol, formic acid, and bioplastics. These innovations align with circular economy principles, creating closed-loop systems where waste streams are converted into valuable resources. For instance, CO2 captured from syngas fermentation can be utilized to cultivate algae or produce synthetic fuels, enhancing the overall carbon efficiency of the process

Artificial intelligence (AI) and machine learning (ML) are increasingly being applied to optimize biomass conversion processes. These technologies enable real-time monitoring and predictive control of complex systems, ensuring optimal operating conditions and maximizing resource efficiency. For example, AI-driven process modelling can predict the behaviour of reactors under varying conditions, reducing downtime and improving yield consistency. Additionally, ML algorithms can analyze large datasets to identify patterns and correlations, guiding the design of more efficient catalysts and optimizing feedstock blends. Integrating hybrid biomass systems with renewable energy sources, such as solar and wind power, offers a pathway to further reduce greenhouse gas emissions and improve system sustainability. Solar-driven hydrothermal systems, for instance, utilize concentrated solar energy to achieve the high temperatures required for biomass conversion, eliminating the need for fossil fuel-derived energy inputs. Similarly, the coupling of AD systems with wind power can stabilize grid energy supply by converting excess electricity into hydrogen, which can then be utilized in fuel cells or as a precursor for biofuel production

Expanding the range of feedstocks used in biomass conversion systems is another critical trend. Research is increasingly focusing on utilizing unconventional biomass sources, such as invasive plant species, marine algae, and industrial by-products, to reduce competition with food crops and enhance feedstock availability. Advances in pretreatment technologies, such as steam explosion and enzymatic hydrolysis, enable the efficient processing of lignocellulosic materials and other recalcitrant feedstocks, broadening the scope of viable inputs for hybrid systems. Efforts to improve nutrient recovery from biomass conversion processes are gaining momentum. By-products such as digestate, hydrochar, and aqueous streams from hydrothermal processes are being explored for their potential to recover nutrients like nitrogen, phosphorus, and potassium. These nutrients can be recycled into agricultural systems as fertilizers, closing the nutrient loop and minimizing environmental pollution. For example, the integration of HTL with algae cultivation systems allows for the reuse of nutrient-rich wastewater to grow biomass, which can then be reprocessed, creating a self-sustaining cycle.

Catalysts play a pivotal role in enhancing the efficiency and selectivity of biomass conversion processes. Future research is focusing on the development of sustainable catalysts that are cost-effective, non-toxic, and easily recyclable. Bimetallic and nanostructured catalysts are being explored for their superior activity and stability, particularly in high-temperature and high-pressure environments. Additionally, biochar-derived catalysts are emerging as a promising alternative due to their low cost, renewable nature, and ability to support electron transfer reactions in processes like SNF and AD.

The shift toward decentralized biomass conversion systems is another significant trend. Small-scale biorefineries are being designed to process biomass locally, reducing transportation costs and emissions. These systems are particularly well suited for rural or remote areas where centralized infrastructure is limited. Decentralized systems also facilitate community-level waste management and energy generation, contributing to regional sustainability goals. Finally, the alignment of biomass conversion technologies with circular economy frameworks is driving innovation across the sector. By prioritizing waste minimization, resource efficiency, and product diversification, hybrid systems are being designed to maximize value extraction from biomass. This includes the co-production of biofuels, biochemicals, and biomaterials, as well as the integration of waste-to-energy processes that utilize by-products like pyrolysis gases and hydrothermal aqueous phases. In conclusion, the future of biomass conversion lies in the integration of advanced technologies, diversified feedstocks, and sustainable practices. By addressing current limitations and leveraging emerging innovations, hybrid biomass systems have the potential to play a transformative role in global efforts to achieve a sustainable and circular bioeconomy.