Abstract

Greenhouse technologies provide controlled environmental conditions for crop growth, often incorporating automation to enhance productivity. Energy management, which involves monitoring, controlling, and conserving energy, is particularly crucial in northern climates, where greenhouses are among the most energy-intensive sectors of agriculture. This paper presents a comprehensive review of state-of-the-art greenhouse technologies from an energy management perspective, exploring their role in enhancing efficiency and sustainability. It examines the energy management framework, key technological advancements, benefits, challenges, and available solutions in the market. Furthermore, it discusses principles and methods of energy optimization, best practices for sustainable greenhouse operations, and emerging trends in smart grids, renewable integration, and automation. Unlike previous studies primarily focusing on agricultural and control perspectives, this review highlights new insights into integrating greenhouse energy management with smart grid participation, leveraging model predictive control (MPC) for energy optimization, multi-agent reinforcement learning (DRL) for adaptive control, and digital twin technology for real-time system modeling. By bridging greenhouse energy management with transactive energy platforms, this paper underscores the importance of intelligent, data-driven decision-making in enhancing efficiency, sustainability, and system resilience while minimizing environmental impact.

1. Introduction

The rise in the global urban population is anticipated to be substantial by 2050, reaching a staggering 9.7 billion [1]. This represents an increase of approximately 21.25%, signifying a remarkable growth, equivalent to an additional 1.7 billion people within the span of three decades. This urbanization trend intensifies the demand for food by almost 70% [2], creating pressure on existing food systems as cities grow. Consequently, urban communities find themselves increasingly reliant on food sourced from rural areas or imported from distant regions [3]. Furthermore, the expanding urban footprint contributes to a growing disparity between food production and consumption. When examining the entire life cycle, it becomes evident that emissions associated with current food systems constitute a significant portion, representing approximately one-third of total global greenhouse gas (GHG) emissions. However, this figure represents a global estimate and can vary by region due to differences in agricultural practices, energy sources, and transportation methods. For instance, emissions from food systems in industrialized nations may differ from those in developing regions due to variations in mechanization, fertilizer use, and supply chain efficiencies. Additionally, transportation related to food systems alone accounts for about one-fifth of total food system emissions. This highlights the need to reduce food imports and develop self-sufficient, sustainable food production strategies to address climate uncertainties and reduce emissions that contribute to global warming [4,5]. Importantly, self-sufficient sustainable food production is a challenging task for certain geographical realms, depending on the climate and weather conditions, limited arable land, soil quality, transportation and infrastructure, limited technological adoption, and many more [6]. In Canada, import dependence varies substantially across different fruits and vegetables. Mostly, Canada relies on international imports for over 80% of its national supply [7], and provincial dependencies rely on their personal supplies. For example, in Québec, only half of the wholesale food consumed is grown/processed locally; the rest is imported. This heavy import is due to low self-sufficiency and sustainability, which stems from the vulnerabilities to climate change [7].

In addition to traditional field methods, greenhouses are vital in enhancing crop production and achieving self-sufficient fruit and vegetable growth. Their structures protect plants from unfavorable climatic conditions and allow them to grow efficiently and sustainably at any time of the year [8,9]. The greenhouses’ controlled microclimate environment ensures desired levels of indoor vitals as well as protects against external factors [9], thus providing high-quality live stocks all year round [10]. Especially in northern climates, greenhouse production is of particular interest. Despite greenhouses evolving toward industrialization and scalability owing to the advancements in facility-based farming, one significant challenge faced is their substantial energy consumption [11]. Microclimate control activities, such as lighting, heating, ventilation, and air conditioning, contribute significantly to this energy demand. For instance, this high energy demand during winter peaks in northern climates can strain the electrical grid, leading to congestion and other potential issues [12]. Traditional rule-based control methods often fail to optimize energy usage and ensure constraint satisfaction [13]. That underscores the importance of the energy management perspective in greenhouse technologies. Figure 1 displays the terminologies of potential work and research in advancing greenhouse technologies towards the grids of the future.

Figure 1.

Terminologies surrounding the important aspects of greenhouse technologies.

Globally, there is a strong push towards renewable energy and smart grid technologies to create more resilient and sustainable energy systems. Specifically, in Québec, by 2035, 75% of the new electricity generation will be dedicated to decarbonizing the environment, out of which 35% will be dedicated to industrial decarbonization [14]. As a significant energy consumer, the agricultural sector has a crucial role in this transition. Improving grid performance and reducing grid stress in agricultural greenhouses involves a multifaceted approach integrating advanced mathematical modeling, sophisticated control strategies, energy optimization techniques, and demand response programs. Mathematical modeling involves creating mathematical representations of greenhouse energy systems to simulate and analyze their behavior under various conditions, including models for energy consumption, crop production, and storage [15]. That enables precise planning and dynamic response to energy demand fluctuations. Implementing automated control strategies [16], such as smart thermostats and HVAC systems, enables real-time adjustments that reduce energy consumption and shift demand away from peak grid periods. Energy optimization, through efficient lighting and insulation, coupled with adjusting energy use based on grid conditions and demand-side energy management strategy, ensures sustainable operations while maintaining crop quality [17]. Participating in flexibility markets and embedding renewable energy sources [18], like solar panels, further alleviates grid stress by providing additional flexibility and reducing reliance on fossil fuels. Design optimization of greenhouses enhances these benefits by integrating energy-efficient structures from the outset [19]. By adjusting energy use based on grid conditions, demand-side management further optimizes energy consumption patterns [20]. Collectively, these strategies contribute to significant energy savings, operational efficiency, and decarbonization, which are crucial in mitigating climate change and enhancing the sustainability of agricultural practices.

Energy management is a crucial aspect of greenhouse operations, affecting cost-effectiveness, profitability, and grid operations. In the greenhouse operations context, several reviews are available from the crop-production perspective [21,22,23]. Also, we can find several reviews describing ways to achieve energy efficiency, implementing different controls and modeling techniques, embedding renewables, and different design methods for cost-effectiveness. For instance, Qayyum et al. [24] discuss econometric models for sustainable agriculture, Zhang et al. [11] describe energy-saving designs and control for sustainable greenhouses, and Cuce et al. [25], Gorjian et al. [26] mention various renewable energy integration options towards sustainable energy saving. Energy efficiency in agricultural greenhouses has often been linked with control methods, modeling, and operations. Iddio et al. [27] discuss energy-efficient modeling and operations, whereas Paris et al. [18] describe energy efficiency measures in greenhouses, especially for the EU region. Zhang et al. [28] discuss various control strategies for improving energy efficiency in agricultural greenhouses. With the advent of the Internet of Things (IoT), various studies have been carried out for resource management towards automated agricultural greenhouses [29,30]. The decarbonization perspective on greenhouse gas mitigation has also been explored in agricultural greenhouses [31,32]. Badji et al. [19] discuss various design trends specifically related to the construction and management of the greenhouse environment.

While numerous studies have explored improvements in greenhouse technologies from agricultural and control perspectives, the integration of energy management strategies remains an evolving challenge. With the emergence of smart grids, there is a pressing need to enable greenhouse participation in energy markets, incorporate renewable energy sources, and harness demand-side flexibility for demand response (DR) programs. This review addresses this gap by providing new insights into energy management techniques tailored for agricultural greenhouses. It highlights the pivotal role of model predictive control (MPC) in optimizing energy usage, the growing adoption of multi-agent reinforcement learning (DRL) for adaptive control, and the potential of digital twin technology in developing accurate greenhouse models. By bridging greenhouse energy management with transactive energy platforms, this paper underscores the importance of intelligent, data-driven decision-making in enhancing efficiency, sustainability, and overall system resilience.

2. Greenhouse Energy Management in the Smart Grid Context

Energy management within the smart grid context involves the integration of advanced technologies and strategies to optimize energy consumption and production [33]. Smart grids utilize real-time data, automation, and communication technologies to enhance the efficiency and reliability of electricity distribution. This enables the grid to adapt to fluctuations in energy demand and supply, thereby improving overall grid stability and resilience. Smart grids also facilitate the integration of renewable energy sources, distributed energy resources, and energy storage systems, which are essential for achieving sustainability goals.

One of the key components of smart grid energy management is demand response (DR) [34], which involves adjusting energy demand to match supply conditions. DR mechanisms provide grid operators with the flexibility to manage load fluctuations, particularly during peak demand periods, by incentivizing consumers to reduce or shift their energy usage. This is especially critical in managing the challenges posed by increasing energy demand during winter peaks, as it helps to alleviate pressure on distribution system operators (DSOs).

As we move towards more sophisticated energy management frameworks, the concept of transactive energy (TE) emerges as a promising approach. TE frameworks extend the capabilities of smart grids by integrating economic signals and market mechanisms to optimize energy use and production. This involves integrating advanced technologies and market mechanisms to optimize energy use and production within greenhouses. That includes dynamic pricing [35] and economic incentives [36,37], embedding renewable, energy storage elements [18,38], and distributed energy resources [39], among others. From a broader perspective of the TE framework, DR can be viewed as a mechanism adjusting demand to balance supply, which can be a part of a broader range of mechanisms, including automated energy trading, comprehensive grid management, and real-time pricing. Mainly, DR provides promising solutions for load management from the consumer side when the increasing load demand causes significant problems for the DSOs, especially during winter peaks [40].

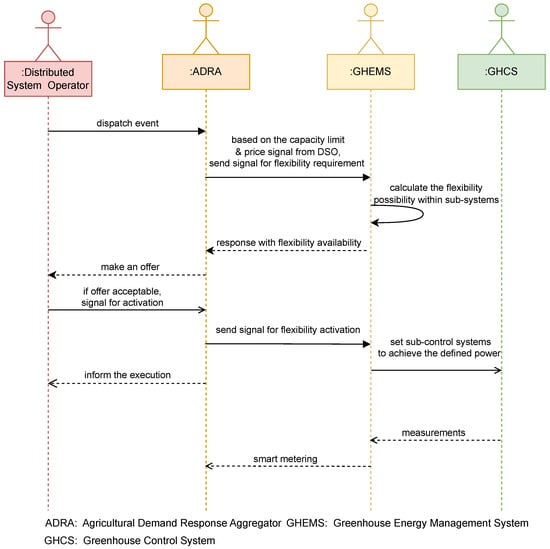

Figure 2 represents a typical DR mechanism, where various sub-systems within agricultural greenhouses can interact to respond to the demand response events. That contributes to grid stability through an optimized energy consumption strategy that aligns with external grid requirements while maintaining greenhouse microclimate conditions. The process starts with a dispatch event from the distributed system operator (DSO) sending a price signal or request for flexibility to the aggregator based on capacity limits and grid distance. Then, the requirement is evaluated with flexible availability, which is further activated if accepted by the DSO. The role of a greenhouse energy management system (GHEMS) is to calculate the flexibility possibility within its sub-systems. Once the offer is activated, GHEMS commands its sub-system (greenhouse control system (GHCS)) to achieve defined consumption objectives according to the received flexibility instructions based on the price policy.

Figure 2.

Sequence diagram of a DR mechanism for a greenhouse.

The DR mechanism illustrated in Figure 2 adapts the conventional demand response framework to the unique requirements of agricultural greenhouses, where energy consumption directly influences crop growth and environmental stability. Unlike traditional home energy management systems that primarily regulate household loads, greenhouse energy management must balance demand-side flexibility with precise microclimate control to prevent disruptions in plant growth. The greenhouse energy management system (GHEMS) plays a crucial role in ensuring this balance by assessing the flexibility potential across sub-systems such as heating, cooling, lighting, and CO2 enrichment. By dynamically responding to price signals and grid constraints while preserving optimal growing conditions, this mechanism not only enhances grid stability but also optimizes energy efficiency in agricultural operations, reducing costs and enabling greater integration of renewable energy sources.

Note that Figure 2 is a scenario of a grid operated by automated agents; there are mainly three bifurcations from the perspective of automation: (i) manual DR, (ii) semi-automated DR, and (iii) automated DR [41]. Many sources are available for energy management strategies in the TE framework.

However, in the context of smart grids, agricultural greenhouses participating in the energy markets or specific DR programs have been scarcely available until recently. For instance, Rezaei et al. [42] considered a network of greenhouses participating in demand response to reduce power consumption during peak hours, thereby managing power exchange with the primary grid. Table 1 shows a high-level comparison of different demand-side energy management strategies for grid-connected agricultural greenhouses to participate in DR programs. From the survey, it can be found that multi-agent DRL and MPC are the most popular methodologies for specific tasks. Moreover, only a few research works have considered uncertainties and maximum demand limit constraints from the aggregator side. Most of the work encapsulated the PV generation for trading with the grid aggregator, whereas only a few considered the model of the crop. That is one of the important aspects of agricultural greenhouse microclimate. The importance of crop models brings the mathematical intricacies for the overall energy optimization problem, which will be further discussed in Section 3.2. To solve the demand-side and aggregator-side problems, the interaction between entities is crucial, and it has become a point of interest for many researchers in recent years [43].

Substantially, game-theoretic approaches in collaboration with a multi-agent system perspective are widely used in energy optimization for greenhouses, particularly for managing energy consumption. They provide a structured way to analyze and design energy management strategies, considering participants’ interactions. These methods often involve strategic decision-making among multiple participants, such as energy prosumers, utility companies, and consumers, to achieve an optimal balance between energy supply and demand [44]. Naz et al. [45] proposed a two-stage non-cooperative Stackelberg game to capture the interconnection between the consumers and the micro-grid.

One of the principal uses of non-cooperative games has been in strategic bidding in electricity markets. Moreover, cooperative games have also found a place in energy management to improve the collective playoffs, including sharing distributed resources or coordinating energy consumption. Dynamics and static games are also often utilized for energy trading systems for demand-side management [46]. Apart from individual research articles, Ji et al. [47] provide a systematic review of the game-theoretic approach for decision-making on demand-side energy management. Wang et al. [48] comprehensively review the evolutionary game approach for sustainable energy development, encompassing energy savings, carbon emission reduction, energy vehicles, electric power market, DERs, micro-grids, smart grids, and energy storage. Similarly, He et al. [49] focused on reviewing the application of game theory in integrated energy systems.

Table 1.

Comparison of demand-side management methods for DR programs of agricultural greenhouse.

Table 1.

Comparison of demand-side management methods for DR programs of agricultural greenhouse.

| References | Method | Objective | Pricing | Renewable Energy Integration | Maximum Demand Limit | Mathematical Model | Unc. | Reliability/Scalability | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PV | WT | HVAC | TESS | PV | BESS | WP | AL | Crop | |||||||

| [50] | Multi-agent DRL | Load reduction | Dynamic pricing | ✓ | - | - | ✓ | - | ✓ | ✓ | - | ✓ | - | - | It can be adapted to include other renewable sources, such as wind and geothermal energy |

| [42] | ADMM-based MPC for a multi-greenhouse system | Aggregator water reservoir pumping system | Dynamic pricing | ✓ | - | ✓ | ✓ | - | ✓ | ✓ | - | ✓ | - | - | Applicable for multi greenhouse system, limited to the use of water reservoir |

| [51] | Prosumer-based PSO problem-solving | Maximizes power income and time-shifting power usage | Day-ahead dynamic pricing (peak and valley) | ✓ | - | - | ✓ | - | ✓ | ✓ | - | - | - | - | Limited to prosumer-based models |

| [52] | Bi-level MILP Stackelberg game theory | Minimize HVAC consumption | Hourly load curve-based pricing | - | - | ✓ | ✓ | - | - | - | - | - | - | - | 20% HVAC flexibility demonstrated, which can be extended to stochastic formulations |

| [53] | Coordinated optimization embedded MPC | Optimal dispatch of renewables, water storage, and HVAC | - | ✓ | ✓ | - | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | - | - | Balanced use of renewables and power loads |

| [54] | Supervisory Centralized MPC | Operating setpoints of microclimate | - | ✓ | ✓ | - | ✓ | - | ✓ | ✓ | ✓ | - | - | ✓ | Applicable to Smart Multi-floor Vertical Greenhouses |

| [55] | Agent-based implicit DR | Optimal overall consumption | Time-varying spot market pricing | - | - | - | ✓ | - | - | - | - | ✓ | ✓ | - | Commercial software dependencies |

| [56] | Robust optimization (grid-connected and islanded mode) | Balancing power buying and selling to grid | Time-of-use (ToU) market pricing | ✓ | ✓ | - | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | - | ✓ | Applicable for trading in different operational modes |

| [57] | Multi-agent system with modified contract protocol | Minimizing operational cost of building micro-grid (energy transactions with grid) | ToU day-ahead market pricing | ✓ | - | - | ✓ | ✓ | ✓ | ✓ | - | ✓ | - | - | Applicable to rooftop type greenhouses |

| [58] | Time-based DR | Optimal energy consumption of artificial lighting | Spot market pricing | - | - | - | ✓ | - | - | - | - | ✓ | - | - | Commercial software dependencies, limited modeling ability |

| [59] | Monte Carlo Simulation and MILP | Minimizing total energy cost and demand charges | Real-time pricing + demand charges + flat rate price | - | - | - | ✓ | - | - | - | - | ✓ | - | ✓ | Applicable to hierarchical control approach for greenhouses |

Unc.: uncertainty, PV: photovoltaics, WT: wind turbine, BESS: battery energy storage system, TESS: thermal energy storage system, WP: water pump, AL: artificial lighting, DRL: deep

reinforcement learning, MPC: model predictive control, DR: demand response, MILP: mixed integer linear programming, PSO: particle swarm optimization, and ToU: time of use.

3. Greenhouse Microclimate

The GHEMS is critical to address grid challenges and participate in DR programs. Figure 3 depicts the stages involved in greenhouse microclimate environment management.

Figure 3.

Stages of the greenhouse energy management system (GHEMS).

3.1. Sensors and Data Acquisition

The first stage in greenhouse energy management is data acquisition and monitoring, which has gained significant attention with the rise of Industry 4.0 [30]. This stage is critical as it involves collecting high-frequency data from multiple sources, ensuring robust and efficient handling of large datasets while maintaining data quality. Over recent decades, sensor technology has evolved significantly, becoming increasingly industrialized and technology-driven [60]. With the integration of IoT-based smart agricultural tools, growers now have enhanced control over crop growth, improved predictability, and increased operational efficiency.

However, the challenge comes in handling the heterogeneity and fast pace of data generation, particularly with smart grids that introduce numerous data points and require high-frequency monitoring [61]. Additionally, sensor calibration and data accuracy remain critical concerns. Over time, factors such as temperature fluctuations, humidity, and sensor drift can lead to measurement errors, affecting real-time decision-making in greenhouse operations. Studies have shown that insufficient ventilation around sensors can cause temperature over-estimations by up to 1–2 °C and relative humidity underestimations by 10–20%, highlighting the need for regular calibration and validation protocols [62]. Implementing self-calibrating sensors or periodic recalibration procedures is essential to maintaining data reliability.

Beyond calibration, sensor failures can severely disrupt greenhouse management. Failures may occur due to power supply issues, hardware malfunctions, or long-term wear, leading to either complete data loss (hard failures) or gradual inaccuracies (soft faults) that persist undetected [63]. The latter can be particularly problematic, as slow sensor drift can result in incorrect climate control adjustments, ultimately impacting crop health and energy efficiency. Deploying redundancy strategies, such as multi-sensor networks for critical parameters, and integrating fault detection algorithms can mitigate these risks and enhance system reliability.

Furthermore, high capital expenditures remain a challenge for small and medium-sized growers, as advanced sensing technologies often come with significant costs. To address this, a three-s (sensing, smart, and sustainable) strategy was proposed by Miranda et al. [64], advocating for cost-effective, scalable sensor solutions that balance affordability with technological advancement [65].

In Table 2, we summarize the key measurement variables for greenhouse microclimates that are essential from both a crop growth and energy management perspective. The table categorizes variables based on their relevance to different irrigation systems, acknowledging that their communication protocols, environmental adaptability, and economic feasibility vary widely, posing unique challenges that remain beyond the scope of this paper.

Table 2.

Measurement variables for comprehensive agricultural greenhouse management.

3.2. Modeling and Simulation

This stage involves creating mathematical models to simulate the system’s behavior under different conditions. The challenge is ensuring that the models accurately represent the real-world system and predict its behavior under various scenarios. As mentioned earlier, agricultural greenhouses provide a controlled environment to optimize the indoor microclimate, mitigating the variability caused by weather, diseases, and soil conditions. However, external factors, such as freezing weather, still present challenges, necessitating continuous reassessment and adjustment of cultivation strategies. For that purpose, digital twins can be considered an ideal choice to test the algorithms based on real-time data or near real-time data [66]. Digital twins are virtual representations of physical systems, processes, or assets. They mirror the real-world behavior of their counterparts and allow real-time monitoring, analysis, and prediction [67].

Implementing digital twins in greenhouse environments involves integrating various Industry 4.0 technologies, including the Internet of Things (IoT), artificial intelligence (AI), big data analytics, and cloud computing. These technologies collectively enable the creation of a virtual replica of the greenhouse, facilitating real-time monitoring and control. The process begins with deploying IoT sensors throughout the greenhouse to collect data on critical parameters such as temperature, humidity, CO2 levels, and light intensity. These data are then transmitted to the cloud, where AI algorithms process them to simulate the greenhouse’s behavior under different conditions. The digital twin is validated by comparing its outputs with actual greenhouse performance, ensuring accuracy in modeling and simulation [68]. Incorporating digital twins into greenhouse management represents a significant advancement in precision agriculture, enabling more sustainable and efficient production systems, see [69] for a comprehensive review on the implementation of DTs for smart agriculture.

A notable example of digital twin implementation is the Greenhouse Industry 4.0 (GHI4.0) project in Denmark [67]. This initiative developed a digital twin software platform that integrates IoT, AI, big data, and cloud computing to optimize greenhouse production processes. The digital twin allows for the co-optimization of production schedules, energy consumption, and labor costs by considering factors such as production deadlines, quality grading, heating, artificial lighting, energy prices, and weather forecasts. By simulating various operational scenarios, the digital twin aids in decision-making, enhancing energy efficiency and productivity without compromising product quality or sustainability. The technical implementation of digital twins in greenhouses involves several key components:

- IoT sensors collect real-time data on environmental conditions and plant health.

- Data analytics process large datasets to identify patterns and predict outcomes.

- AI algorithms enable predictive modeling and optimization of greenhouse operations.

- Cloud computing provides scalable storage and computational power for data processing.

By integrating these components, digital twins offer several benefits:

- Enhanced decision-making simulates different scenarios to inform strategies.

- Energy efficiency optimizes resource usage, reducing energy consumption.

- Improved productivity streamlines operations for higher yields and better quality.

Given the benefits of DTs with smart grids, the complexity increases due to the need to model and simulate various components like renewable energy sources, storage devices, and consumer loads. It is argued that DTs can be crucial in cyber-physical system-based DR programs [70]. Van Der Veen et al. [71] discuss the importance of DTs in the interaction between the cyber and physical systems for the coordination between various stakeholders, such as prosumers, consumers, DSOs, and DRAs. With the advent of Industry 4.0, digital twins in power systems (DTiPS) have been coined with a focus on real-time or near real-time energy management systems for better decision-making [72]. DTs can have essential characteristics to be addressed, such as timeliness, fidelity, integration, intelligence, and complexity. Broadly, DTs can be based on three modeling paradigms [73]: black box, gray box, and white box.

3.2.1. White Box

These models are derived from the energy and mass balance equations and are capable of describing physics-based dynamics. These models are considered the most detailed and closest-to-reality models, which are ideal for DTs. However, their parameters carry physical meaning and hence must be obtained from technical documentation, orientation, geometry, properties, and specifications. Here are the principal benefits and drawbacks mentioned for white box models.

Benefits:

- Detailed Process Insight: Provides a comprehensive insight into the dynamics, enhancing our understanding of every aspect of the system.

- Predictive Precision: Considers that all the details are rightfully mentioned and understood. It can provide extremely precise predictions of the system under study, making it ideal for DTs.

- Customizability: It can be customized to specific systems and conditions, allowing tailored solutions.

- Reliability: Complimentary to the precision, they provide reliable results under perfect details.

- Controllability: Higher controllability at a granular level.

Drawbacks:

- Complexity: As the number of variables grows, model complexity increases, demanding greater domain-specific knowledge and expertise.

- Sensitivity to Parameter Change: Model accuracy and stability can be questionable due to the model sensitivity to parameter changes.

- Time Expense: Describing the system’s aspects is tedious and time-consuming, making it computationally expensive.

- Adaptation Difficulty: Challenging to adapt quickly to new or significantly changing conditions without extensive recalibration or redevelopment.

For the brevity of the presentation, a foundational generalized greenhouse model for energy management is presented. Contributions from diverse sources [74,75,76,77] are considered to comprehensively describe the model with a particular focus on aligning them with the GHEMS, including both the climatic and agronomic axes.

Indoor Temperature: Maintaining an appropriate indoor temperature is vital for plant health and productivity. The temperature inside the greenhouse influences several physiological processes in plants, including photosynthesis, respiration, and transpiration. From the first law of thermodynamics, we have

where , and is the latent heat loss due to crop transpiration, which is proportional to , i.e., (latent heat of vaporization ). represents the heat generated by artificial lighting, i.e., . and .

Crop Canopy Temperature: The temperature of the crop canopy is a critical component of the greenhouse microclimate. The crop canopy temperature affects both the indoor temperature and humidity balance. It is influenced by solar radiation, ambient air temperature, and the transpiration process. The energy balance equation for the crop canopy temperature can be written as follows:

where with k as the extinction coefficient varying with the type of vegetation, leaf orientation, and solar angle. represents the heat exchange between the crop canopy and the indoor air. Note that and refer to the same physical process of latent heat loss due to transpiration. However, their perspective is different: for (1), it is the heat loss from the air due to the latent heat of transpiration by the crop, and in (2), it is the latent heat loss from the crop canopy due to transpiration.

Leaf Area Index (LAI) Growth Model: LAI affects both the light interception and transpiration rates, influencing the greenhouse’s energy and humidity balance. LAI can be described as a function of the node development rate, which is itself influenced by temperature and other environmental conditions. The LAI dynamics can be modeled using a growth equation, such as the logistic growth model, where the rate of change in LAI depends on the node development rate and the current temperature.

where represents the node development rate (NDR) influenced by temperature. Generally, can take the form of a polynomial or an exponential function that accounts for the optimal temperature range for crop growth. Golzar et al. [15] can be referred to for a more detailed model of LAI.

Indoor Humidity: Moisture balance within a greenhouse is a crucial aspect of maintaining optimal growing conditions for crops. This balance is influenced by both the ventilation system, which exchanges air with the outside environment, and the transpiration process, where plants release moisture into the air.

where denotes crop transpiration, which can be modeled by the Penman–Monteith method as follows:

or empirically as . Equation (5) uses radiative, aerodynamic, and resistive factors to estimate transpiration, whereas the simple empirical model uses a coefficient and a function of environment factors to estimate transpiration [78].

Soil Temperature and Humidity: Soil environment is the backbone of promoting crop nutrient uptake. The temperature and humidity of the soil can be provided by the following:

Concentration: in a greenhouse can enhance photosynthesis rates and improve crop yields. Importantly, ventilation and plant respiration can mainly influence concentration.

where with as a coefficient that scales the uptake rate with LAI.

Ventilation System: Ventilation systems play a pivotal role in regulating temperature and humidity within the greenhouse. By exchanging air with the external environment, ventilation helps to remove excess heat and moisture, introducing fresh air and maintaining optimal growing conditions. Effective ventilation management is crucial for preventing overheating, reducing humidity to acceptable levels, and ensuring a constant supply of for photosynthesis.

Equation (9) consists of sensible and latent heat components. The first term represents the energy due to the temperature difference between the inside and outside air. The second term represents the energy associated with moisture content change, including both sensible heat of water vapor and the latent heat of vaporization. This formulation ensures that both temperature and moisture dynamics are accurately captured in the ventilation system model.

Note that although the above mathematical model (1) to (10b) aims to provide a comprehensive understanding of the greenhouse system dynamics, it is essential to acknowledge that specific components, such as empirical coefficients, may require more profound expertise in thermodynamics or agricultural science for precise determination. These aspects represent areas where further refinement and specialized knowledge could enhance the model’s accuracy and applicability. Additionally, the dynamics change as we add other components and distributed/renewable energy sources, such as water pumps, wind turbines, photovoltaic (PV) systems, battery energy storage systems (BESS), and thermal energy storage systems (TESS).

3.2.2. Gray Box

Gray box models have always found a sweet spot between black and white, as they offer a more practical and flexible approach to modeling. For real-world applications, if the data from the greenhouse are accessible, then gray box models are a practical solution as they can be effectively calibrated and validated using experimental data. Gray box models balance physical principles and empirical relationships to capture the essential dynamics [79]. Below are some of the benefits and drawbacks of a typical gray box model.

Benefits:

- Development Time: Compared to white box models, gray box models take less time owing to the partial dependence on empirical data.

- Robustness: They are more robust to the stochasticity of variables, such as climate conditions, compared to black box models, enhancing crop yield predictions.

- Management: Combined simplified plant growth models and data can improve environmental management.

Drawbacks:

- Calibration Complexity: Robust parameter estimation methods are required to improve accuracy, which is one of the major challenges of gray box models.

- Computational Demand: The complexity of the model’s physical part and the objective function’s complexity can make them computationally expensive.

- Re-calibration: Periodic re-calibration is required with more recent data.

- Moderate Data and Knowledge Requirement: Though better than the black box model, it might be challenging to fit sometimes if the training period is too long. Additionally, appropriate knowledge is necessary as some of the sub-processes can have an analogy or be empirical.

Traditionally, the RC analogy is the most widely used method to achieve a well-suited gray box model for control applications. Equations (11a)–(11f) covers a simplified RC model for the greenhouse system. The RC model analogy allows us to represent the CO2 transfers, temperature, humidity, crop, and soil dynamics in terms of capacitive and resistive elements, capturing the system’s transient response to changes in environmental conditions.

In the indoor temperature balance (11a), thermal capacitance represents the thermal inertia of the air inside the greenhouse, while the resistances (R) correspond to heat transfer rates between different components of the system, such as heating, cooling, ventilation, and crop canopy exchange. Similarly, Equations (11b)–(11f) represent moisture content, CO2 concentration, the thermal mass of the soil, and crop canopy temperature. Notice that heat gain from solar radiation is often treated separately due to its direct dependence on light interception efficiency and LAI. This term remains empirical and based on the specific characteristics of the crop and glazing, capturing the direct impact of solar radiation on the greenhouse temperature.

Various optimization techniques can be utilized to obtain the parameters of a gray box model, namely, convex optimization [79], PSO [80], genetic algorithm [75] evolutionary algorithms [81], etc. There are two stages of this parameter estimation: batch and online. Batch estimation includes minimization of the model error over a specific period of time, which can be performed offline. On the other hand, an online estimation can be argued as a filtering technique such as Kalman filtering [82], non-linear Kushner filtering [83], sequential Monte Carlo, and many others.

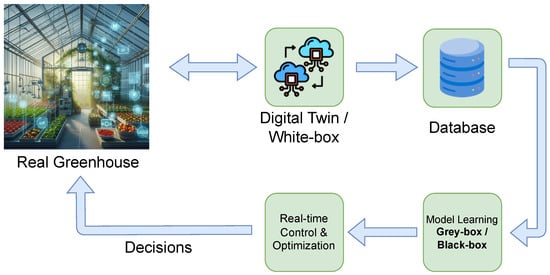

Figure 4 displays a potential application of integrated modeling, which can be adapted to manage the microclimate of greenhouses effectively. Notably, the DT/white box can virtually represent an actual greenhouse that creates a database by simulating various scenarios [67,84]. It could contain a detailed greenhouse simulation, including all the components in this context. Subsequently, a gray box or a black box model can be learned to capture the dynamics essential for a particular control/optimization technique, for instance, MPC. That can also take decisions and apply the changes to the real greenhouse or digital twin. Consequently, this decision-making mechanism can be of great use to interact and test various algorithms and management schemes.

Figure 4.

Schematic representation of integrated modeling approaches in greenhouse technologies.

Table 3 compares various simulators available based on their offerings. Altes-Buch et al. [85] provide a detailed simulator compared to others by leveraging Modelica libraries. However, the control scheme is limited to PID only. On the other hand, Szalai [86] provide a complete open-source Python-based library for greenhouse simulations. It provides predominately vertical farming simulations, where the crop models are limited to just two, and the control solution is only a proportional controller. Nevertheless, owing to its open-source nature, the framework can be further extended to improve the controller, add types of crops, and use other optimization techniques from an energy management perspective.

3.2.3. Black Box

Purely data-driven black box models rely on historical data and machine learning algorithms to predict system behavior without prior knowledge of the underlying physics-based dynamics. Broadly, black box models can be classified into parametric and non-parametric models. Parametric linear models are argued to be the simplest of all, mainly covering the offspring of regressive and auto-regressive models [87,88]. Recently, parametric nonlinear models such as NN, ANN, LSTM, etc., have become the most popular, demonstrating improved microclimate predictions [89,90]. LSTMs are flexible as they do not make strong assumptions about the form of the mapping function from inputs to outputs. Instead, they are designed to learn the patterns from the data, regardless of the underlying distribution. Gharghory [91] can be consulted for detailed time series prediction of microclimate data inside the greenhouse. On the other hand, Zhou et al. [92] claimed to improve the prediction accuracy of the process-based greenhouse with a combination of particle filtering and DNN. Also, a multi-model DL approach has recently surfaced [93], addressing the prediction imbalances in smart greenhouses arising from a single-model approach.

Benefits:

- Rapid Deployment: Quick to implement for real-time monitoring and control based on historical data.

- Cost-effective: Lower initial cost is one of the major benefits of black box models as they do not require domain-specific knowledge.

- Flexible and Scalable: Large dataset handling capacity and swiftly transformable to state space formulation for control applications.

Drawbacks:

- Generalization: Cannot be generalized as they are vulnerable to uncertain conditions previously not encountered.

- Data Dependent: As no physics-based knowledge is involved, they are highly dependent on data and can lead to inaccuracies for certain processes where knowledge is paramount, for instance, plant growth patterns or anomalies.

- Trust Issues: Lack of insights can limit the understanding of predictions.

Table 3.

Comparison of simulators for agricultural greenhouses.

Table 3.

Comparison of simulators for agricultural greenhouses.

| References | Platform | Method | Open Source | Modular Design | Microclimate Model | Crop Model | Crops Grown | Supplementary Lighting | Validated/ Location | Sub-Systems Measurements | Data Acquisition | Control |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [85] | Modelica | Sub-process oriented | ✓ (3-clause BSD License) | ✓ | ✓ | ✓ | Tomato | ✓ | ✓ (Beglium) | HVAC, Window Aperture, Lighting, Energy Consumption | ✓ | ✓ (PID) |

| [94] | MATLAB + EnergyPlus | ODEs | ✗ (Apache 2.0) | ✗ | ✓ | Yes, Detailed Crop Model | Tomato | ✓ (Configurable HPS/LED) | ✓ (The Netherlands and USA) | Microclimate, Lighting, Energy Consumption | ✓ | ✗ |

| [95] | Sketchup + TRNSYS | CFD | ✗ | ✓ (Requires new 3D design) | ✓ (20 Thermal Zones) | ✓ | Flowering Crops | ✓ (HPS) | ✓ (Italy) | Crop Thermal Condition, Energy Consumption | ✓ (Hourly) | ✗ |

| [77] | Undisclosed | Undisclosed | ✗ | ✓ (Semi-closed and Closed) | ✓ | ✓ | Multiple vegetables and fruits | ✓ | ✓ (Weather File Required) | HVAC, Lighting, Energy Consumption | ✓ (Hourly) | ✓ |

| [86] | Python | ODEs | ✓ | ✗ (Changeable characteristics of the structure) | ✓ | ✓ | Basil, Tomato | ✓ (LEDs) | ✓ (Spain) | Microclimate, Ventilation, CO2, Humidity, Lighting, Energy Consumption | ✓ (Custom) | ✓ (only P) |

| [96] | Web-based Application, ActionScript 2.0 | Energy and Mass Balance | ✗ | ✓ (Three different structure) | ✓ | ✓ (Plant Transpiration) | Tomato | ✗ | ✓ (Arizona, USA) | Microclimate | ✓ (15 min time step) | ✓ (ON/OFF) |

3.3. Control and Optimization

In this stage, an objective function is defined, and the system parameters are tuned to optimize this function. The challenge in this stage is to ensure that the optimization process leads to a solution that is not only optimal but also feasible in the real world. In the context of smart grids, the optimization process becomes complex due to the need to balance various factors like energy efficiency, cost, reliability, and sustainability.

A critical challenge in optimizing smart grid operations is the intermittency of renewable energy sources, such as solar and wind power, which can cause fluctuations in energy availability [97]. These fluctuations necessitate advanced predictive control strategies and real-time optimization algorithms to ensure a stable power supply. Studies have shown that high penetration of non-synchronous renewable energy sources can impact grid stability due to a lack of rotational inertia, making efficient energy management crucial [98]. The integration of hybrid energy storage systems (HESS), combining battery storage, thermal energy storage, and pumped hydro storage, has been explored as a solution to mitigate these challenges [99]. Proper storage sizing and optimal charging-discharging schedules are essential for maximizing efficiency while ensuring cost-effectiveness [100].

Subsequently, the final stage involves executing the optimized strategies through control decisions. The challenge is to ensure that control strategies are robust, adaptive, and capable of responding to real-time grid conditions and renewable energy variations [101]. With smart grids, control implementation becomes particularly complex due to the need to manage a large number of interconnected devices and ensure coordinated operation. AI-driven optimization techniques have been widely studied to address this complexity, providing predictive modeling capabilities for energy demand and renewable generation [102].

The onset of smart grid technologies has indeed brought about numerous challenges, including security and privacy concerns, information management issues, grid imbalance problems, and the integration of renewable and distributed energy resources. However, these challenges also present opportunities for innovation. Predictive optimization, AI-driven demand-side management, and multi-agent control frameworks are promising solutions that help balance grid operations while ensuring optimal energy utilization, storage integration, and real-time adaptability [101]. Leveraging these advanced methodologies allows for a more resilient and flexible energy system, enabling greenhouses and other smart grid participants to efficiently integrate renewables while maintaining stability and reliability.

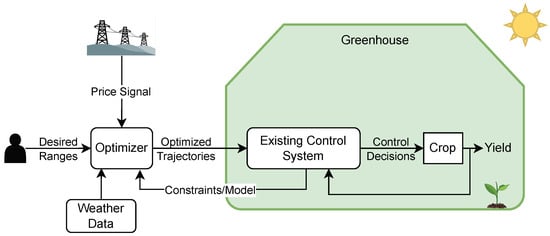

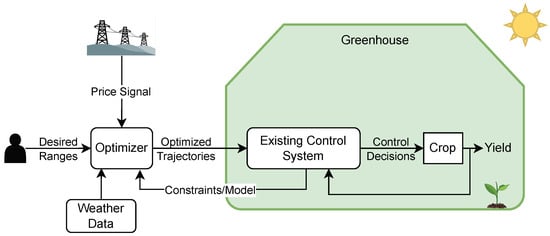

Figure 5 depicts a schematic of an existing greenhouse system with its control system for controlling the microclimate. Here, an entity responsible for energy management is established that evaluates the greenhouse model, utility price signal, weather, and the constraints to generate optimal power profiles for optimizing energy usage with respect to the price signal as well as plant comfort. In flexibility/energy markets, this manager can respond to the ADRA in the hierarchy (Figure 2). This optimizer is essentially for demand-side problem solving; similarly, the ADRA also solves an optimization problem. As discussed in Section 2, various game-theoretic strategies can be employed for energy management, encompassing case-specific optimization algorithms. Table 4 shows the comparison of control and optimization algorithms employed for greenhouse systems. Also, a bifurcation of the roles of various variables of the greenhouse control system is devised. The objective of each methodology has to be divided into either a setpoint or energy cost perspective. Moreover, comments on the results of the study, convergence/stability criteria undertaken, sensitivity, platform, and crops grown are also considered. Here, we present the most commonly used optimization problems in the literature for greenhouse control and optimization. From the energy management perspective participating in DR scenarios, the common modes of operation adopted are the grid-connected and islanded modes. The optimization problem adopted for grid-connected mode is as follows [103].

Figure 5.

Control and optimization framework: greenhouse energy usage and crop yield with price adaptation.

In (12), denotes the cost of the generation of power and startup, which can be sourced from various renewable energy resources. depicts the operational cost. is for the difference in the cost of buying the power from the grid to maintain the microclimate conditions and selling the generated power to the grid. Based on the number of units for power production and the type of renewables used, (12) can be modified to accommodate the changes. Importantly, the objective function in (12) is subject to certain constraints. Specifically, microclimate bounds are the indoor environmental conditions that need to be maintained within the greenhouse, such as temperature, humidity, light intensity, CO2 concentration, etc. The energy management system should ensure these conditions are kept within certain ranges for optimal plant growth. Moreover, power generation bounds could be the limits on the amount of power that can be generated or used. For instance, there might be a maximum limit on the power that can be drawn from the grid or a minimum amount of power that needs to be generated by the greenhouse’s own energy sources (like solar panels or wind turbines). On the contrary, in the islanded mode, the following objective function could be adopted:

Here, in (13), a total penalty cost is added to the objective function. That covers the cost of violating the microclimate bounds, which may cover the basic penalty factor as well as an additional penalty for consecutive interval violations. This penalty term is important as the violation of not maintaining the microclimate parameters at the desired levels can adversely affect the growth of plants. Lin et al. [104] proposed an optimization to reduce the consumption of not only energy but water and CO2 as well, i.e.,

In (14), , , and are the prices for energy , water , and CO2. is the total energy consumed by heating/cooling, ventilation, irrigation pump, and artificial lighting. is the water consumption, and is the CO2 consumption. Importantly, water requirements have no constraints as they depend on the crop. Ref. [103] proposed a more growers-oriented objective function, i.e.,

where is the gross economic return of the production process by selling the harvested crops at the harvest auction, and represents the overall operating cost for maintaining the microclimatic conditions. Moreover, another instance of a grower-oriented objective function can be found in [105], i.e.,

The aim of this objective function (16) is to maximize the crop yield and minimize the energy usage at the same time. Ref. [50] utilized the most commonly used objective function comprising of all microclimate-controlled variables (from i to N) and energy consumption (17). This helped to minimize the energy consumption and maximize the plant comfort.

Table 4.

Comparison of control and optimization algorithms for agricultural greenhouses.

Table 4.

Comparison of control and optimization algorithms for agricultural greenhouses.

| Reference | Control Framework | Optimization Algorithm | Linear/ Nonlinear | Controlled Variables | Maniplulated Variables | Disturbance Variables | Objective | Convergence/ Stability | Sensitivity | Results of the Study | Platform | Climate | Crop | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SP | EC | |||||||||||||

| [17] | NMPC | IPOPT | N | T, H, CO2, AL | Fan flow rate, heating, CO2 injection, fogging rate, shade curtain coverage | Ext. T, H, SR, CO2 | Min. control cost CO2, Nat. Gas and Elec. | Jacobian linearization for stability | On penalty weights and energy costs | A 20% reduction in control costs and 40% increase in nominal\ sensitivity analysis | do-MPC/ Python | Winter, Spring, Summer | Tomato | |

| [103] | Two-stage optimal PI control | Maximum Principle of Pontryagin | L | CDW, T, H, CO2 | Ventilation, heating, CO2 injection | Ext. T, H, SR, CO2, WS | Max. the diff. B/W gross income and operating cost | Necessary conditions to achieve optimality | N/A | Cascade control loop with slower crop growth and faster microclimate dynamics | N/A | Winter | Lettuce | |

| [81] | MIMO PID | Multi-objective EA | L | T, H | Ventilation, fogging rate | Ext. T, H, SR, CO2, WS | Static-dynamic ref. tracking | ISE convergence | N/A | Time-consuming method not suitable for real-time control requirement | MATLAB | N/A | ||

| [106] | Nonlinear control | N/A | N | T, H | Heating, fogging rate | Ext. T, H, SR, CO2 | Ref. tracking with fixed rules | N/A | N/A | Improved transient time response in comparison to SMC | MATLAB | Summer | N/A | |

| [104] | MPC— two layer strategy | IPOPT | N | T, H, CO2 | Heating/cooling, ventilation, CO2 injection, solar radiation-based shading rate | Ext. T, H, SR, CO2 | Min. energy, water and CO2 consumption | N/A | Energy, water and CO2 costs | Cannot work in sub-zero exterior climates, 67% of total cost reduction | MATLAB | Winter (above 10C) | N/A | |

| [105] | Receding Horizon MPC | IPOPT | N | CDW, T, H, CO2 | Heating/cooling, ventilation, CO2 injection | Ext. T, H, SR, CO2 | Max. crop yield Min. energy | N/A | N/A | MPC achieves a higher economic return but slow due to an opt. problem | CasADi + MATLAB | Winter (2 to 8.5 C) | Lettuce | |

| RL agent-based control | DDPG | N | CDW, T, H, CO2 | Heating/cooling, ventilation, CO2 injection | Ext. T, H, SR, CO2 | Max. crop yield Min. energy | 500 epochs agent training, each epoch is one day of crop growth | White noise data to avoid overfitting | RL is faster after learning but permissive with humidity constraints. A health problem for the crops | N/A | N/A | N/A | ||

| [107] | DRL agent-based control | -greedy strategy with SGA for max. Q-learning | N | T | Heating power | Ext. T | Maintaining T | N/A | Stochastic transient dyanmics | 61% more energy savings in Q-learning than DDPG | MATLAB | Winter, Spring | Tomato | |

| [16] | AI-based model-free control | Robust Opt. with L-BFGS/ Adam | N | T, H, CO2, Carbohydrates per unit area in fruit, leaves and stem | Heating/cooling, humidification, CO2 injection, AL | Ext. T, RH, SR, CO2, ST | Max. comfort | Improve energy efficiency | N/A | Weather unc. | 26.8% improvement in ref. tracking and 57% in energy consumption over traditional MPC | MATLAB | Winter | Tomato |

| [108] | Multivariate Robust control | LMI formalism | L | T, H | Heating, Moistening, Roofing, Shadiness | Ext. T, H, SR, CO2 | Min. norm | Check of robust stability performed | Model unc. | 12% and 33 % improvement in the ref. tracking for T and H | MATLAB | Spring | N/A | |

| [109] | Optimal control | PROPT algorithm | N | T, H, CO2 | Heating/cooling, ventilation, CO2 injection | Ext. T, H, SR, CO2, WS | Min. energy | N/A | N/A | Heating and cooling energy were potentially reduced by 47% and 15% | MATLAB | Year around | Tomato, Cucumber, Sweet Pepper, and Rose | |

| [110] | Robust MPC | ADF policy | L | T, H, CO2 | Heating/cooling, dehumidifcation, CO2 injection | Ext. T, H, SR, CO2 | Min. power of actuators and constraint violation penalty | Bounded I/Os and COV for stability | Weather unc. | PCA and KDE-based data-driven robust MPC needs lower total control cost than rule-based control | MATLAB | Summer | Tomato | |

T: temperature, H: humidity, AL: artificial lighting, CDW: crop dry weight, ST: sky temperature, WS: wind speed, EA: evolutionary algorithm, RL: reinforcement learning, IPOPT: interior

point optimizer, ADF: affine disturbance feedback, Nat. Gas: natural gas, DDPG: deep deterministic policy gradient, DRL: deep reinforcement learning, MPC: model predictive control,

SMC: sliding mode control, Unc.: uncertainty, and Ref.: reference.

4. Discussions and Future Research

According to the literature, the scarcity of an energy management perspective for agricultural greenhouse systems is evident due to a lack of awareness of the inherent intricacies of multi-variable greenhouse systems and the diversity of available optimization algorithms. Energy management within the transactive energy (TE) framework for agricultural greenhouses integrates advanced technologies and market mechanisms to optimize energy use and production. Key strategies include dynamic pricing, economic incentives, renewable energy integration, and distributed energy resource (DER) deployment. Demand response (DR) plays a crucial role in this framework, adjusting demand to match supply and offering load management solutions during peak periods, particularly in winter. DR mechanisms involve the interaction between distributed system operators (DSOs) and greenhouse energy management systems (GHEMS), which evaluate and implement flexible energy consumption strategies to maintain grid stability while meeting greenhouse microclimate requirements. The literature highlights the importance of multi-agent systems (MAS), game-theoretic approaches, and machine learning techniques such as deep reinforcement learning (DRL) and model predictive control (MPC) in optimizing these processes. Studies reveal that while many efforts focus on integrating photovoltaic generation and energy trading, fewer address crop modeling and its direct impact on energy management.

Despite these advancements, financial and technological barriers remain significant obstacles to the widespread adoption of smart grid technologies in greenhouse operations. High initial investment costs for sensor networks, automation, and renewable energy systems can be prohibitive for small and medium-sized greenhouse operators. Additionally, the complexity of managing and analyzing real-time data from heterogeneous sources requires specialized expertise, posing another challenge to effective implementation. Cybersecurity risks further complicate adoption, as interconnected greenhouse systems are vulnerable to potential cyber threats, necessitating robust security frameworks to ensure operational resilience. Clausen et al. [58] implemented a novel software for integrating supplemental lighting control for greenhouse cultivation in Northern Europe. In Northern Europe, light is a limiting factor for greenhouse cultivation from late autumn to early spring. This dynamic control of supplemental lighting, utilizing weather forecasts and dynamic electricity prices, led to approximately 25% electricity savings without noticeable reductions in plant flowering and production time. Quebec’s weather has a similar challenge, as mentioned earlier, underscoring how financial incentives, regulatory support, and technological innovation can facilitate the integration of smart grid principles into greenhouse energy management.

On the other hand, in GHEMS, data acquisition and monitoring play a crucial role but also pose challenges, including handling heterogeneous and fast-paced data generation and the high costs of new technologies, especially for small and medium-sized growers. Key greenhouse monitoring variables, crucial for crop growth and energy management, require specialized sensors tailored to different irrigation systems. While white-box modeling offers a robust foundation for digital twins and virtual greenhouse simulations, it is often time-consuming and resource-intensive. As a result, gray-box and black-box approaches are frequently adopted for faster control implementation and real-time energy management schemes. Additionally, while various control and optimization algorithms have been proposed, selecting the most suitable one remains context-dependent, requiring a balance between precision, adaptability, and computational efficiency.

4.1. Future Research Opportunities

4.1.1. Crop Model

Crop models are essential for accurately predicting the growth and yield of crops under varying environmental conditions, which directly impact energy management in greenhouses. Integrating these models with energy models is crucial for creating a comprehensive management system that optimizes both crop production and energy usage. However, current literature often overlooks the detailed integration of crop models with energy models in the context of smart grids. Future research should focus on developing comprehensive crop-energy models that dynamically link plant physiological processes with greenhouse energy consumption patterns. A promising approach involves hybrid modeling frameworks, which combine white-box mechanistic models (capturing crop physiology and energy flows) with data-driven gray-box models (leveraging real-time sensor data and machine learning for adaptive control). Additionally, further work is needed to refine real-time calibration techniques for crop-energy models, incorporating feedback from IoT-based sensor networks to enhance model accuracy. Future studies should explore multi-objective optimization techniques that co-optimize crop growth rates, energy efficiency, and cost-effectiveness. By integrating predictive analytics, reinforcement learning, and data assimilation techniques, these models can facilitate more adaptive and self-learning control strategies for greenhouse energy management. Collaboration across agricultural science, control engineering, and computational modeling will be key to achieving these advancements. Developing open-source crop-energy modeling platforms can further accelerate research and provide practical tools for greenhouse operators seeking to implement intelligent, energy-efficient, and climate-resilient cultivation strategies.

4.1.2. Integrated Modeling Approach

An integrated modeling approach that leverages virtual greenhouses can significantly enhance energy management strategies. Virtual greenhouses can simulate different scenarios and control strategies without impacting real-world operations, allowing for the testing and optimization of various energy management techniques. Despite the potential benefits, the inclusion of virtual greenhouses in energy management research is still limited. Future research should explore how virtual greenhouses can be used to develop and validate integrated models that combine environmental control, energy consumption, and crop production. This approach can provide a robust framework for testing new energy management technologies and strategies, ultimately leading to more efficient and sustainable greenhouse operations.

4.1.3. Smart Grid-Inclined Management

Integrating multi-agent systems (MAS) into greenhouse energy management presents unique challenges and opportunities. One significant challenge is ensuring effective coordination among diverse agents, such as heating, ventilation, and lighting systems, to maintain optimal microclimate conditions while responding to energy demands. Security concerns also arise, as the interconnected nature of MAS can expose systems to cyber threats, potentially compromising both energy management and crop health. Additionally, balancing workloads among agents to prevent resource contention and inefficiencies is crucial for seamless operation [111].

Beyond these technical challenges, barriers to adoption also limit the widespread implementation of smart grid technologies in greenhouse operations. High initial costs for deploying MAS frameworks, including advanced sensors, controllers, and communication infrastructures, can be prohibitive for small and medium-sized greenhouse operators. Furthermore, the successful implementation of MAS and game-theoretic approaches requires specialized expertise in control engineering, artificial intelligence, and data analytics, which may not be readily available to all growers. Cybersecurity risks further complicate adoption, as increasing interconnectivity exposes greenhouse systems to potential cyber threats, necessitating robust security measures.

Game theory offers valuable tools to address these challenges within MAS frameworks. By modeling the interactions among self-interested agents, game theory facilitates the design of strategies where each agent’s decisions lead to a Nash equilibrium, optimizing overall system performance. For instance, in a greenhouse setting, game-theoretic approaches can be employed to allocate energy resources efficiently among various subsystems, ensuring that the collective energy consumption aligns with both operational requirements and external grid demands [112].

Future research should focus on developing MAS frameworks that incorporate game-theoretic models to enhance decision-making processes in greenhouse energy management while addressing key adoption barriers. This includes creating cost-effective deployment strategies, developing user-friendly automation tools that require minimal specialized expertise, and implementing adaptive cybersecurity protocols to protect greenhouse networks. By overcoming these hurdles, smart grid technologies can be more accessible and practical for real-world greenhouse operations, leading to improved energy efficiency, reduced operational costs, and enhanced sustainability.

While the advancement of energy management technologies and methodologies for greenhouses is promising, these findings can be applied in real-world scenarios to improve energy efficiency, reduce costs, and ensure sustainable operations. A critical step is to adapt these findings to specific regional conditions, such as Quebec’s seasonal challenges, by incorporating climate-specific energy strategies, including dynamic lighting controls, and leveraging renewable energy integration in greenhouse systems. The development of hybrid crop-energy models combining physiological processes with real-time energy usage data will allow greenhouse operators to optimize both crop yield and energy consumption. Moreover, policies promoting the adoption of these technologies, including financial incentives for small and medium-sized growers, can facilitate their transition toward smarter, more energy-efficient operations. Policy recommendations should focus on providing subsidies for sensor networks, renewable energy systems, and smart grid technologies, along with support for cybersecurity infrastructure to address potential risks in interconnected systems. These improvements, alongside industrial applications like virtual greenhouse simulations, will enhance real-time decision-making and foster more efficient, cost-effective greenhouse operations, ensuring that smart grid principles are widely adopted.

5. Concluding Remarks

This review provides a comprehensive analysis of recent advancements in greenhouse energy management, emphasizing the integration of smart grid participation, transactive energy frameworks, and advanced control strategies. Model predictive control (MPC) remains a cornerstone of energy optimization, while multi-agent reinforcement learning (DRL) is gaining prominence for its adaptability to dynamic energy conditions. The incorporation of crop growth models into greenhouse energy management systems (GHEMS) is essential for achieving precise environmental control and optimizing energy efficiency. However, balancing sensor accuracy and cost remains a challenge, particularly for small to medium-sized growers. The use of digital twins and virtual greenhouse simulations is recommended to enhance predictive modeling, with white-box approaches offering high-fidelity representations and open-source simulators providing scalable alternatives, albeit with limitations in crop diversity. Furthermore, integrating data-driven decision-making and real-time adaptive control can significantly enhance greenhouse sustainability, improve demand-side flexibility, and enable participation in transactive energy platforms. Ultimately, selecting the appropriate control and optimization methods is highly context-dependent, requiring a balance between computational efficiency, adaptability, and precision to ensure cost-effective and resilient greenhouse operations.

Author Contributions

Conceptualization, S.N. and K.A.; methodology, S.N. and N.H.; validation, K.A., N.H. and M.B.; resources, K.A. and M.B.; data curation, S.N. and N.H.; writing—original draft preparation, S.N.; writing—review and editing, S.N., M.B., K.A. and N.H.; visualization, S.N.; supervision, K.A. funding acquisition, K.A. and M.B.; project administration, K.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

This work was supported in part by the Laboratoire des technologies de l’energie (LTE) d’Hydro-Québec, the Natural Science and Engineering Research Council of Canada, the UQTR Foundation, Ministry of Agriculture, Fisheries and Food Quebec MAPAQ, and La Chaire de Leadership en Enseignement (CLE) sur l’optimisation et la gestion de l’énergie et du climat des serres au Québec.

Conflicts of Interest

The authors declare no conflicts of interest.

Nomenclature

| Abbreviations | |

| ADF | Affine Disturbance Feedback |

| ADRA | Agricultural Demand Response Aggregator |

| AL | Artificial Lighting |

| ANN | Artificial Neural Network |

| BESS | Battery Energy Storage System |

| CDW | Crop Dry Weight |

| DER | Distributed Energy Resources |

| DNN | Deep Neural Network |

| DDPG | Deep Deterministic Policy Gradient |

| DT | Digital Twin |

| DTiPS | Digital Twins in Power Systems |

| DR | Demand Response |

| DRL | Deep Reinforcement Learning |

| DSO | Demand Side Operator |

| EC | Energy Cost |

| EA | Evolutionary Algorithm |

| GHCS | Greenhouse Control System |

| GHEMS | Greenhouse Energy Management System |

| GHG | Greenhouse Gas |

| HVAC | Heating, Ventilation, Air Conditioning |

| IoT | Internet of Things |

| IPOPT | Internal-point Optimizer |

| LSTM | Long Short Term Memory |

| MPC | Model Predictive Control |

| MILP | Mixed-integer Programming |

| NDR | Node Development Rate |

| NN | Neural Network |

| PSO | Particle Swarm Optimization |

| PV | Photovoltaic |

| SMC | Sliding Mode Control |

| SP | Set Point |

| TE | Transactive Energy |

| TESS | Thermal Energy Storage System |

| WT | Wind Turbine |

| WP | Water Pump |

| Greek Symbols | |

| Air density | |

| Efficiency of solar radiation conversion | |

| Efficiency of crop light interception | |

| Psychrometric constant | |

| Slope of the saturation vapor pressure curve | |

| Coefficient for transpiration rate | |

| Laplacian operator | |

| Growth coefficient for LAI | |

| Coefficient for uptake rate | |

| Latent heat of vaporization | |

| Variables | |

| Mass flow rate of water vapor entering | |

| Mass flow rate of water vapor leaving | |

| Mass flow rate of water vapor due to evaporation | |

| Mass flow rate of water vapor due to condensation | |

| Mass flow rate of water vapor due to transpiration | |

| Mass flow rate of water drainage | |

| Mass flow rate of water uptake by plants | |

| Mass flow rate of uptake by plants | |

| Mass flow rate of air | |

| Mass flow rate of entering the greenhouse | |

| Mass flow rate of exiting the greenhouse | |

| Mass flow rate of water vapor due to ventilation | |

| Effective area of the crop canopy | |

| Area of the greenhouse glazing | |

| Specific heat of air | |

| Thermal capacitance of indoor air | |

| Thermal capacitance of the crop canopy | |

| Thermal capacitance of the soil | |

| Indoor concentration | |

| External concentration | |

| Vapor pressure deficit | |

| G | Soil heat flux density |

| External humidity | |

| Indoor humidity | |

| Soil humidity | |

| Incident solar radiation | |

| k | Extinction coefficient for light interception |

| Thermal conductivity of the soil | |

| L | Leaf area index (LAI) |

| Maximum LAI | |

| Power of the artificial lighting system | |

| Heat removal by the cooling system | |

| Heat exchange with the soil and plants | |

| Heating input from the heating system | |

| Heat generated by artificial lighting | |

| Heat loss to deeper soil layers or surroundings | |

| Solar heat gain | |

| Solar heat absorbed by the crop canopy | |

| Latent heat loss due to transpiration | |

| Net radiation at the crop surface | |

| Crop canopy temperature | |

| Indoor temperature | |

| Temperature of artificial lighting | |

| Soil Temperature | |

| Indoor air volume | |

| Volume of soil | |

| Aerodynamic resistance | |

| Stomatal resistance | |

| Duration of artificial lighting |

References

- United Nations. Global Issues: Population; United Nations: New York, NY, USA, 2023. [Google Scholar]

- Doering, O.; Sorensen, A. The land that shapes and sustains us. In How to Feed the World; Springer: Berlin/Heidelberg, Germany, 2018; pp. 46–58. [Google Scholar] [CrossRef]

- Drottberger, A.; Zhang, Y.; Yong, J.W.H.; Dubois, M.C. Urban farming with rooftop greenhouses: A systematic literature review. Renew. Sustain. Energy Rev. 2023, 188, 113884. [Google Scholar] [CrossRef]

- Li, M.; Jia, N.; Lenzen, M.; Malik, A.; Wei, L.; Jin, Y.; Raubenheimer, D. Global food-miles account for nearly 20% of total food-systems emissions. Nat. Food 2022, 3, 445–453. [Google Scholar] [CrossRef] [PubMed]

- Clark, M.A.; Domingo, N.G.; Colgan, K.; Thakrar, S.K.; Tilman, D.; Lynch, J.; Azevedo, I.L.; Hill, J.D. Global food system emissions could preclude achieving the 1.5° and 2 °C climate change targets. Science 2020, 370, 705–708. [Google Scholar] [CrossRef] [PubMed]

- Baer-Nawrocka, A.; Sadowski, A. Food security and food self-sufficiency around the world: A typology of countries. PLoS ONE 2019, 14, e0213448. [Google Scholar] [CrossRef]

- Bajaj, K. Canada’s Fruit & Vegetable Supply at Sub-National Scale: A First Step to Understanding Vulnerabilities to Climate Change; The Canadian Agri-Food Policy Institute: Ottawa, ON, Canada, 2023. [Google Scholar]

- Tawalbeh, M.; Aljaghoub, H.; Alami, A.H.; Olabi, A.G. Selection criteria of cooling technologies for sustainable greenhouses: A comprehensive review. Therm. Sci. Eng. Prog. 2023, 38, 101666. [Google Scholar] [CrossRef]

- Sahdev, R.K.; Kumar, M.; Dhingra, A.K. A comprehensive review of greenhouse shapes and its applications. Front. Energy 2019, 13, 427–438. [Google Scholar] [CrossRef]

- Ghani, S.; Bakochristou, F.; ElBialy, E.M.A.A.; Gamaledin, S.M.A.; Rashwan, M.M.; Abdelhalim, A.M.; Ismail, S.M. Design challenges of agricultural greenhouses in hot and arid environments. Eng. Agric. Environ. Food 2019, 12, 48–70. [Google Scholar] [CrossRef]

- Zhang, M.; Yan, T.; Wang, W.; Jia, X.; Wang, J.; Klemeš, J.J. Energy-saving design and control strategy towards modern sustainable greenhouse: A review. Renew. Sustain. Energy Rev. 2022, 164, 112602. [Google Scholar] [CrossRef]

- Hydro-Québec. What Happens When Electricity Use Exceeds the Grid’s Capacity? Hydro-Québec: Quebec, QC, Canada, 2024. [Google Scholar]

- Decardi-Nelson, B.; You, F. Optimal energy management in greenhouses using distributed hybrid DRL-MPC framework. Comput. Aided Chem. Eng. 2023, 52, 1661–1666. [Google Scholar] [CrossRef]

- Hydro-Québec. Action Plan 2035—Towards a Decarbonized and Prosperous Québec; Technical Report; Hydro-Québec: Quebec, QC, Canada, 2023. [Google Scholar]

- Golzar, F.; Heeren, N.; Hellweg, S.; Roshandel, R. A novel integrated framework to evaluate greenhouse energy demand and crop yield production. Renew. Sustain. Energy Rev. 2018, 96, 487–501. [Google Scholar] [CrossRef]

- Ajagekar, A.; Mattson, N.S.; You, F. Energy-efficient AI-based Control of Semi-closed Greenhouses Leveraging Robust Optimization in Deep Reinforcement Learning. Adv. Appl. Energy 2023, 9, 100119. [Google Scholar] [CrossRef]

- Chen, W.H.; Mattson, N.S.; You, F. Intelligent control and energy optimization in controlled environment agriculture via nonlinear model predictive control of semi-closed greenhouse. Appl. Energy 2022, 320, 119334. [Google Scholar] [CrossRef]

- Paris, B.; Vandorou, F.; Balafoutis, A.T.; Vaiopoulos, K.; Kyriakarakos, G.; Manolakos, D.; Papadakis, G. Energy Use in Greenhouses in the EU: A Review Recommending Energy Efficiency Measures and Renewable Energy Sources Adoption. Appl. Sci. 2022, 12, 5150. [Google Scholar] [CrossRef]

- Badji, A.; Benseddik, A.; Bensaha, H.; Boukhelifa, A.; Hasrane, I. Design, technology, and management of greenhouse: A review. J. Clean. Prod. 2022, 373, 133753. [Google Scholar] [CrossRef]

- Nebey, A.H. Recent advancement in demand side energy management system for optimal energy utilization. Energy Rep. 2024, 11, 5422–5435. [Google Scholar] [CrossRef]

- Bouadila, S.; Baddadi, S.; Ben Ali, R.; Ayed, R.; Skouri, S. Deploying low-carbon energy technologies in soilless vertical agricultural greenhouses in Tunisia. Therm. Sci. Eng. Prog. 2023, 42, 101896. [Google Scholar] [CrossRef]

- Forkuor, G.; Amponsah, W.; Oteng-Darko, P.; Osei, G. Safeguarding food security through large-scale adoption of agricultural production technologies: The case of greenhouse farming in Ghana. Clean. Eng. Technol. 2022, 6, 100384. [Google Scholar] [CrossRef]

- Smolka, G.; Kosatica, E.; Berger, M.; Kissinger, M.; Fridman, D.; Koellner, T. Domestic water versus imported virtual blue water for agricultural production: A comparison based on energy consumption and related greenhouse gas emissions. J. Ind. Ecol. 2023, 27, 1123–1136. [Google Scholar] [CrossRef]

- Qayyum, M.; Zhang, Y.; Wang, M.; Yu, Y.; Li, S.; Ahmad, W.; Maodaa, S.N.; Sayed, S.R.; Gan, J. Advancements in technology and innovation for sustainable agriculture: Understanding and mitigating greenhouse gas emissions from agricultural soils. J. Environ. Manag. 2023, 347, 119147. [Google Scholar] [CrossRef]