Multiobjective Optimization of the Economic Efficiency of Biodegradable Plastic Products: Carbon Emissions and Analysis of Geographical Advantages for Production Capacity

Abstract

1. Introduction

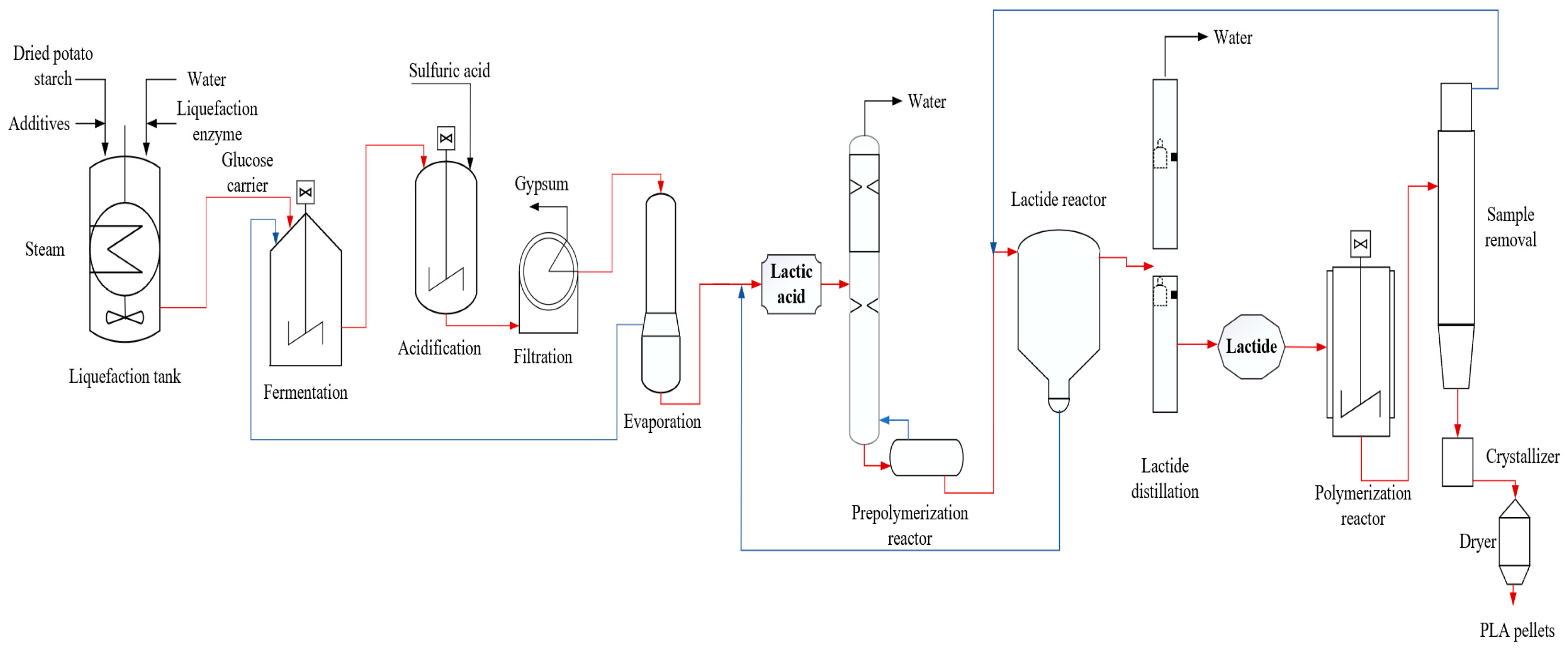

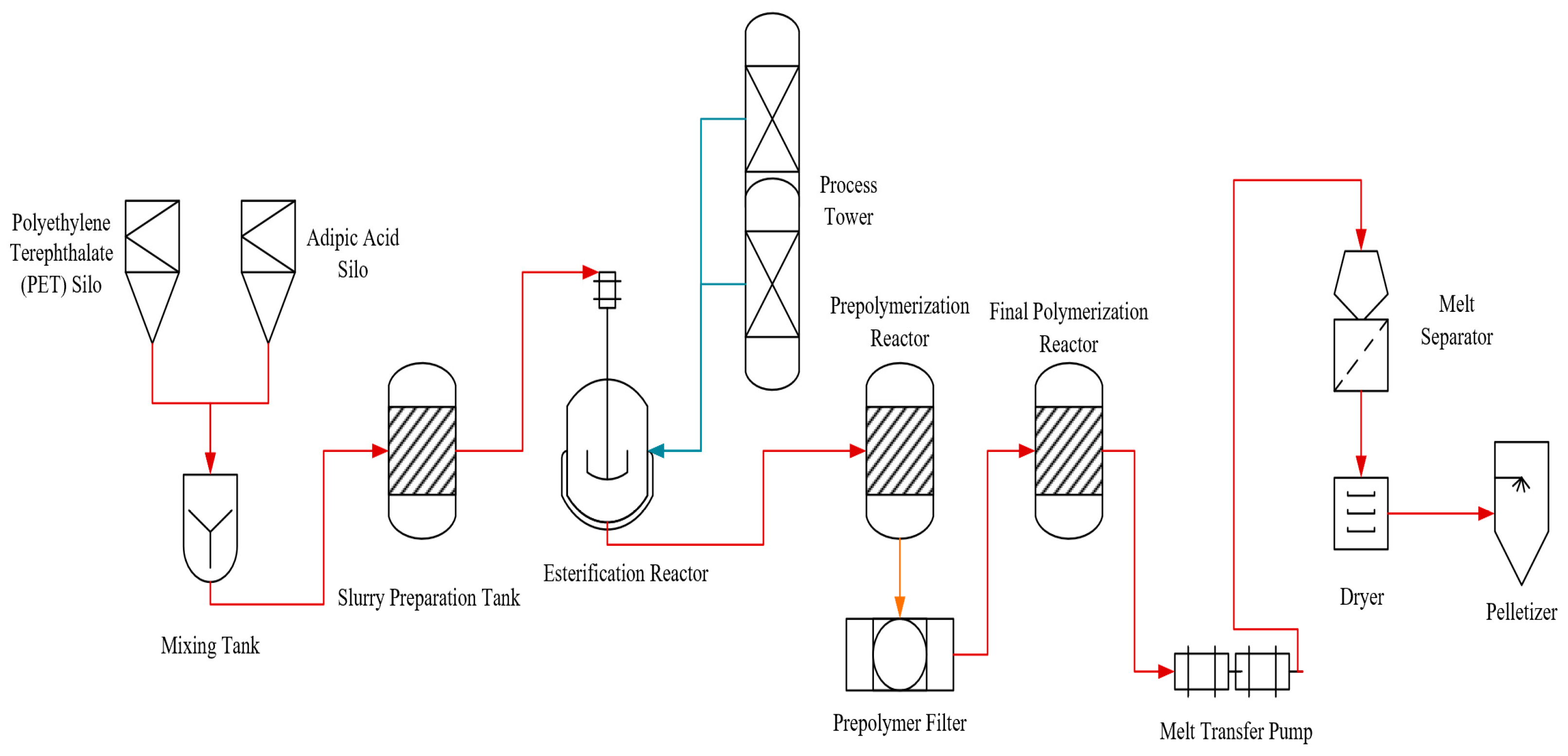

2. Analysis on the Production Process of Biodegradable Plastics

2.1. Decomposition of Processing Technology and Selection of Economic Indicators

2.2. Waste Disposal

2.3. Screening of Technical and Economic Indicators

3. Model Construction

3.1. Objective Function Construction

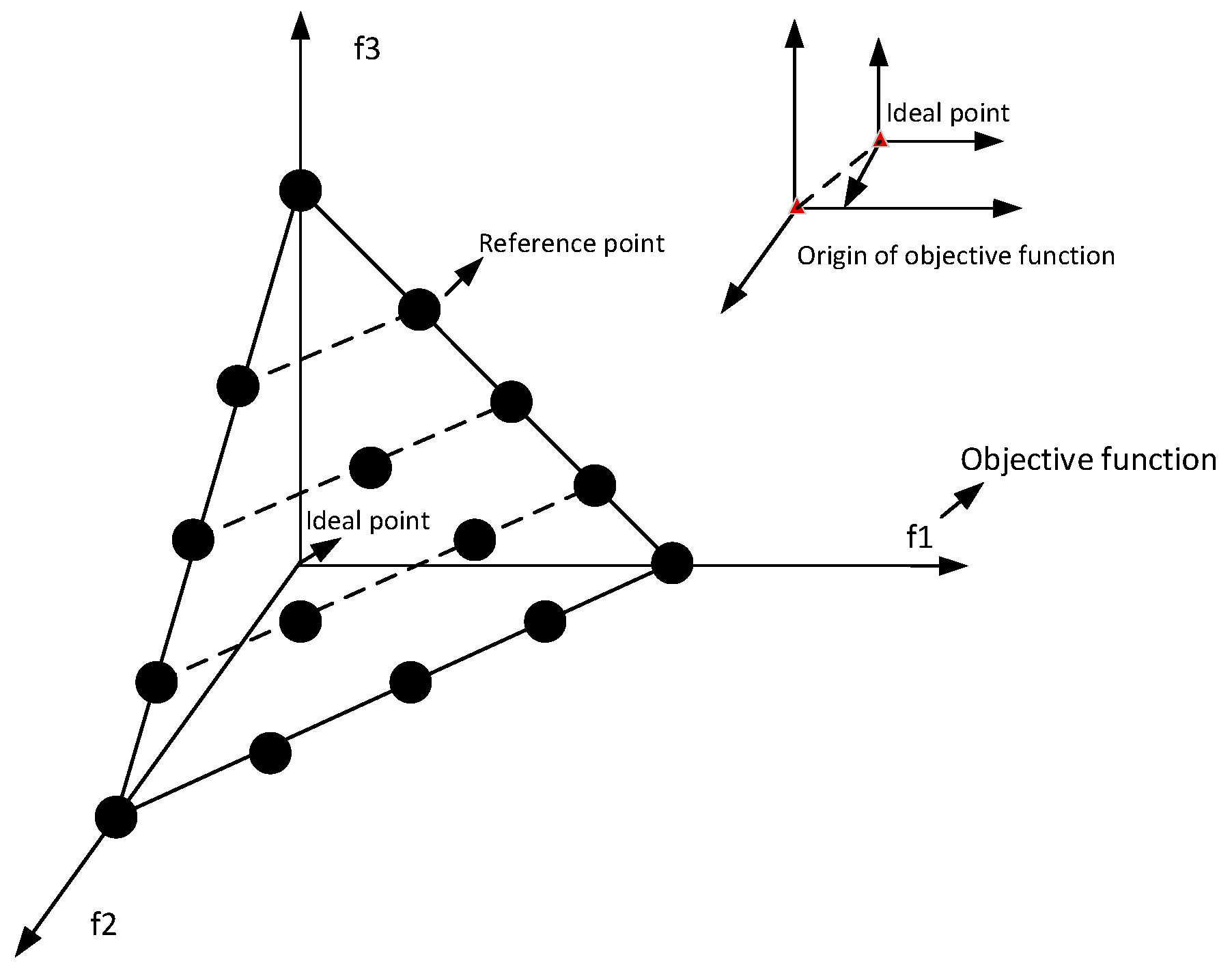

3.1.1. NSGA-III Algorithm

- Define the reference point. For a three-dimensional multiobjective optimization problem, the population’s minimum value in the three objective functions is obtained, and the set it constitutes is defined as reference point set .

- Translate the target value . Translate all target values by subtracting the ideal point for each target from the target value of the population to obtain the translated target value.

- Calculate the extreme point for each target; the extreme value for each one-dimensional coordinate is taken as the minimum of the scalar function in Equation (3).

- 4.

- Construct a linear hyperplane and calculate the intercept to achieve normalization of the population’s individual target value. The purpose of normalization is to enable comparison between quantities with different dimensions or ranges, to select superior individuals, and to ensure the convergence of the population.

- 5.

- Normalize the population’s target value; the normalization formula for each individual target value is given in Equation (5).where .

3.1.2. Profit Objective

3.1.3. Carbon Emission Objective

3.1.4. Process Risk Objective

3.1.5. Constraints

- (1)

- Benefit constraint

- (2)

- Greenhouse gas constraints

- (3)

- Risk constraints

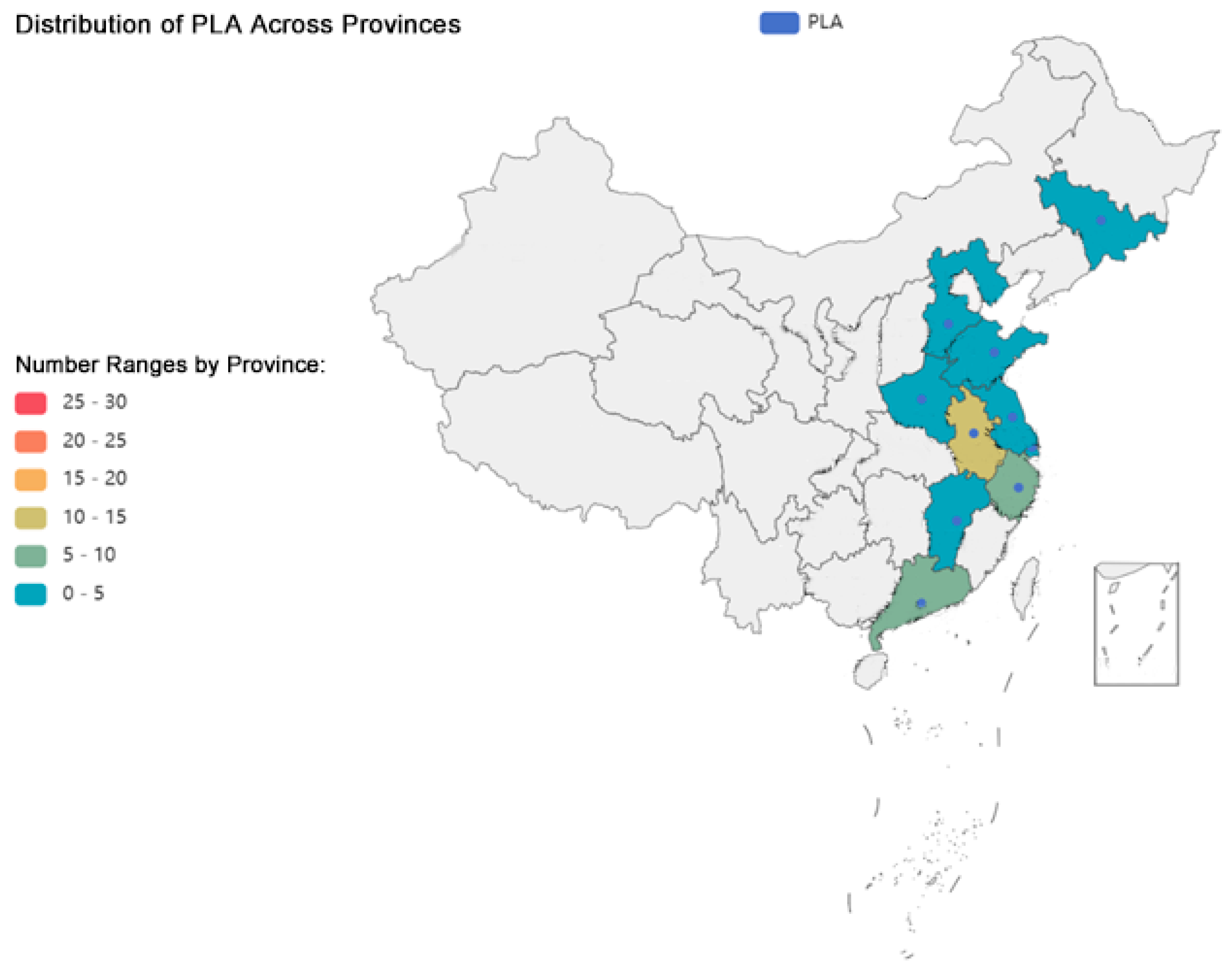

3.2. Analysis of the Economic Advantages of Geographical Transport

3.2.1. Road Advantage and Capacity Analysis

3.2.2. Entropy-Weighted Efficiency Index (EWEI)

4. Analysis of Experimental Results

4.1. Project Overview

4.1.1. Economic Data

4.1.2. Carbon Emission Data

4.1.3. Process Risk

4.2. Analysis of Results

4.2.1. Profitability Analysis

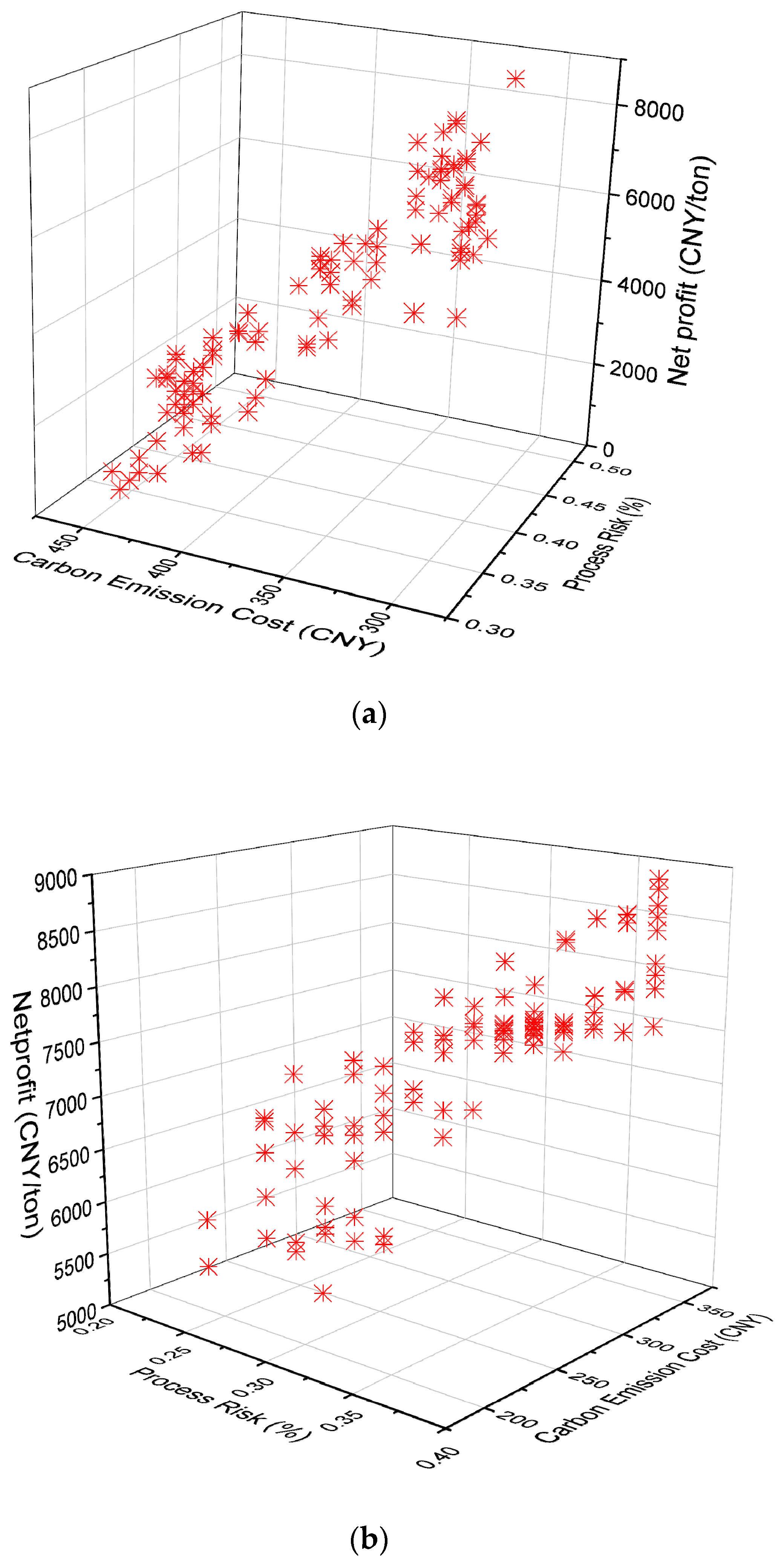

4.2.2. Multiobjective Optimization Analysis of the NSGA-III Algorithm

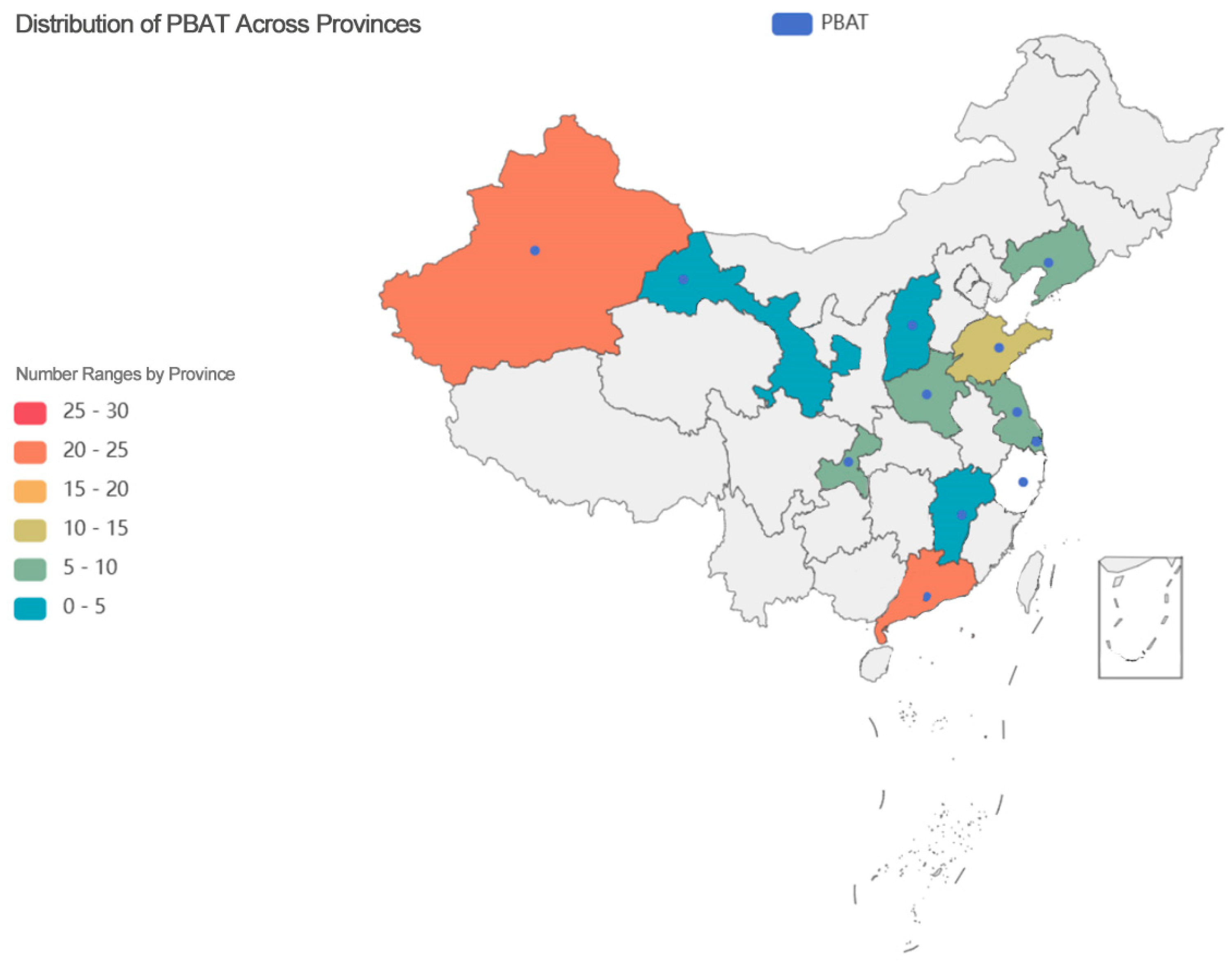

4.3. Analysis of Geographical Economic Advantages

5. Discussion and Conclusions

5.1. Economic Evaluation and Analysis of Road Transport Advantages

5.2. Practical Implications

5.3. Policy Implications

5.4. Limitations and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, G.; Li, J.; Sun, Y.; Wang, Z.; Leeke, G.A.; Moretti, C.; Cheng, Z.; Wang, Y.; Li, N.; Mu, L.; et al. Replacing Traditional Plastics with Biodegradable Plastics: Impact on Carbon Emissions. Engineering 2024, 32, 152–162. [Google Scholar] [CrossRef]

- Mishra, R.; Chavda, P.; Kumar, R.; Pandit, R.; Joshi, M.; Kumar, M.; Joshi, C. Exploring genetic landscape of low-density polyethylene degradation for sustainable troubleshooting of plastic pollution at landfills. Sci. Total Environ. 2024, 912, 168882. [Google Scholar] [CrossRef] [PubMed]

- Idris, S.N.; Amelia, T.S.M.; Bhubalan, K.; Lazim, A.M.M.; Zakwan, N.A.M.A.; Jamaluddin, M.I.; Santhanam, R.; Amirul, A.-A.A.; Vigneswari, S.; Ramakrishna, S. The degradation of single-use plastics and commercially viable bioplastics in the environment: A review. Environ. Res. 2023, 231, 115988. [Google Scholar]

- Haider, T.P.; Völker, C.; Kramm, J.; Landfester, K.; Wurm, F.R. Plastics of the future? The impact of biodegradable polymers on the environment and on society. Angew. Chem. Int. Ed. 2019, 58, 50–62. [Google Scholar] [CrossRef] [PubMed]

- Kim, P.; Park, H.; Rajendran, N.; Yu, J.; Min, J.; Kim, S.K.; Han, J. Economic and environmentally viable preparation of a biodegradable polymer composite from lignocellulose. J. Ind. Eng. Chem. 2023, 122, 221–230. [Google Scholar]

- Venschott, M.; Hoelderich, W.F.; Eisenacher, M. 2nd generation PLA; Lactide formation directly from aqueous lactic acid. Catal. Commun. 2023, 177, 106636. [Google Scholar] [CrossRef]

- Gamiz-Conde, A.K.; Burelo, M.; Franco-Urquiza, E.A.; Martínez-Franco, E.; Luna-Barcenas, G.; Bravo-Alfaro, D.A.; Treviño-Quintanilla, C.D. Development and Properties of Bio-Based Polymer Composites Using PLA and Untreated Agro-Industrial Residues. Polym. Test. 2024, 139, 108576. [Google Scholar]

- Kim, J.K.; Oh, S.H.; Song, M.O.; Jang, S.; Kang, S.J.; Kwak, S.K.; Jin, J. Wholly bio-based, ultra-tough, transparent PLA composites reinforced with nanocellulose and nanochitin. Compos. Part B Eng. 2024, 281, 111563. [Google Scholar]

- Wang, W.; Niu, B.; Liu, R.; Chen, H.; Fang, X.; Wu, W.; Wang, G.; Gao, H.; Mu, H. Development of bio-based PLA/cellulose antibacterial packaging and its application for the storage of shiitake mushroom. Food Chem. 2023, 429, 136905. [Google Scholar] [CrossRef]

- Li, J.; Wang, Y.; Xu, C.; Liu, S.; Dai, J.; Lan, K. Bioplastic derived from corn stover: Life cycle assessment and artificial intelligence-based analysis of uncertainty and variability. Sci. Total Environ. 2024, 946, 174349. [Google Scholar] [CrossRef]

- Cheroennet, N.; Pongpinyopap, S.; Leejarkpai, T.; Suwanmanee, U. A trade-off between carbon and water impacts in bio-based box production chains in Thailand: A case study of PS, PLAS, PLAS/starch, and PBS. J. Clean. Prod. 2017, 167, 987–1001. [Google Scholar]

- Zheng, Y.; Xu, M.; Tian, J.; Yu, M.; Tan, B.; Zhao, H.; Tang, Y. Study on the properties of esterified corn starch/Polylactide biodegradable blends. J. Renew. Mater. 2022, 10, 2949–2959. [Google Scholar]

- Ratshoshi, B.K.; Farzad, S.; Görgens, J.F. A techno-economic study of Polybutylene adipate terephthalate (PBAT) production from molasses in an integrated sugarcane biorefinery. Food Bioprod. Process. 2024, 145, 11–20. [Google Scholar]

- National Bureau of Statistics. Statistical data [EB/OL]. Available online: https://www.stats.gov.cn/sj/ (accessed on 7 December 2024).

- Mehta, J.; Dilbaghi, N.; Deep, A.; Hai, F.I.; Hassan, A.A.; Kaushik, A.; Kumar, S. Plastic waste upcycling into carbon nanomaterials in circular economy: Synthesis, applications, and environmental aspects. Carbon 2024, 234, 119969. [Google Scholar] [CrossRef]

- Yıldız, N.Ç.; Avunduk, Z.B.; Erdiaw-Kwasie, M.O. Circular economy in Turkish manufacturing sector: The roles of green manufacturing and innovation. In Circular Economy Strategies and the UN Sustainable Development Goals; Springer Nature: Singapore, 2023; pp. 381–415. [Google Scholar]

- Ramesh; Kumar, S.; Shaiju, P.; O’Connor, K.E. Bio-based and biodegradable polymers-State-of-the-art, challenges and emerging trends. Curr. Opin. Green Sustain. Chem. 2020, 21, 75–81. [Google Scholar] [CrossRef]

- Lima, L.R.; Gutierrez, R.F.; Cruz, S.A. Challenges in the context of single-use plastics and bioplastics in Brazil: A legislative review. Waste Manag. Res. 2022, 40, 998–1006. [Google Scholar] [PubMed]

- Barone, A.S.; Maragoni-Santos, C.; de Farias, P.M.; Cortat CM, G.; Maniglia, B.C.; Ongaratto RS Ferreira, S.; Fai, A.E.C. Rethinking single-use plastics: Innovations, polices, consumer awareness and market shaping biodegradable solutions in the food packaging industry. Trends Food Sci. Technol. 2025, 158, 104906. [Google Scholar]

- Rajendran, N.; Han, J. Integrated polylactic acid and biodiesel production from food waste: Process synthesis and economics. Bioresour. Technol. 2022, 343, 126119. [Google Scholar]

- Bilo, F.; Pandini, S.; Sartore, L.; Depero, L.E.; Gargiulo, G.; Bonassi, A.; Federici, S.; Bontempi, E. A sustainable bioplastic obtained from rice straw. J. Clean. Prod. 2018, 200, 357–368. [Google Scholar]

- Swetha, T.A.; Ananthi, V.; Bora, A.; Sengottuvelan, N.; Ponnuchamy, K.; Muthusamy, G.; Arun, A. A review on biodegradable polylactic acid (PLA) production from fermentative food waste-Its applications and degradation. Int. J. Biol. Macromol. 2023, 234, 123703. [Google Scholar]

- Liu, L.; Xu, M.; Ye, Y.; Zhang, B. On the degradation of (micro) plastics: Degradation methods, influencing factors, environmental impacts. Sci. Total Environ. 2022, 806, 151312. [Google Scholar] [PubMed]

- Sun, J.; Wang, X.; Zheng, H.; Xiang, H.; Jiang, X.; Fan, J. Characterization of the degradation products of biodegradable and traditional plastics on UV irradiation and mechanical abrasion. Sci. Total Environ. 2024, 909, 168618. [Google Scholar]

- Wang, F.; Wu, N.; Wang, M.; Deng, S.; Jia, H. Synthesis of phenylphosphorylated microcrystal cellulose biobased flame retardants and its flame-retardant modification on PLA biomaterials. Polym. Degrad. Stab. 2024, 227, 110843. [Google Scholar]

- Fu, Y.; Zhu, L.; Liu, B.; Zhang, X.; Weng, Y. Biodegradation behavior of poly (glycolic acid) (PGA) and poly (butylene adipate-co-terephthalate) (PBAT) blend films in simulation marine environment. Polymer 2024, 307, 127295. [Google Scholar]

- Cheung, C.K.H.; Not, C. Degradation efficiency of biodegradable plastics in subtropical open-air and marine environments: Implications for plastic pollution. Sci. Total Environ. 2024, 938, 173397. [Google Scholar] [PubMed]

- Zhao, Y.; Ming, J.; Cai, S.; Wang, X.; Ning, X. One-step fabrication of polylactic acid (PLA) nanofibrous membranes with spider-web-like structure for high-efficiency PM0. 3 capture. J. Hazard. Mater. 2024, 465, 133232. [Google Scholar]

- Meng, X.; Yu, L.; Cao, Y.; Zhang, X.; Zhang, Y. Progresses in synthetic technology development for the production of l-lactide. Org. Biomol. Chem. 2021, 19, 10288–10295. [Google Scholar]

- Pan, X.; Yang, X.; Li, X. Evaluation of maleic anhydride-modified chitosan as filler reinforced PBAT composite film. Int. J. Polym. Anal. Charact. 2024, 29, 64–74. [Google Scholar]

- Colucci, G.; Lupone, F.; Bondioli, F.; Messori, M. 3D printing of PBAT-based composites filled with agro-wastes via selective laser sintering. Eur. Polym. J. 2024, 215, 113197. [Google Scholar] [CrossRef]

- Arzumanova, N.B. Polymer biocomposites based on agro waste: Part iii. shells of various nuts as natural filler for polymer composites. New Mater. Comp. Appl. 2021, 5, 19–44. [Google Scholar]

- Aljabhan, B. Economic strategic plans with supply chain risk management (SCRM) for organizational growth and development. Alex. Eng. J. 2023, 79, 411–426. [Google Scholar]

- Bhatti, U.A.; Marjan, S.; Wahid, A.; Syam, M.; Huang, M.; Tang, H.; Hasnain, A. The effects of socioeconomic factors on particulate matter concentration in China’s: New evidence from spatial econometric model. J. Clean. Prod. 2023, 417, 137969. [Google Scholar]

- Wang, Z.; Duan, L.; Zhang, Z. Multi-objective optimization of gas turbine combined cycle system considering environmental damage cost of pollution emissions. Energy 2022, 261, 125279. [Google Scholar]

- Liu, H.; Shao, L.; Min, J.; Ji, X. Regional differences and determinants of environmental efficiency in China’s road transportation industry. Econ. Anal. Policy 2024, 81, 931–946. [Google Scholar]

- Ignatov, A. European highway networks, transportation costs, and regional income. Reg. Sci. Urban Econ. 2024, 104, 103969. [Google Scholar]

- Wu, P.; Zou, D.; Yu, N.; Zhang, G.; Kong, L. An improved NSGA-III for the dynamic economic emission dispatch considering reliability. Energy Rep. 2022, 8, 14304–14317. [Google Scholar]

- Ahmad, A.; Banat, F.; Taher, H. A review on the lactic acid fermentation from low-cost renewable materials: Recent developments and challenges. Environ. Technol. Innov. 2020, 20, 101138. [Google Scholar]

- Wang, J.; Xu, M.; Yan, J.; Guo, G.; Wang, Y.; Zhang, J.; Wu, J. Biodegradable poly (butylene adipate-co-terephthalate) (PBAT) modified by 1, 4 cyclohexanedimethanol. Polymer 2024, 308, 127348. [Google Scholar]

- Luo, C.; Zhou, Y.; Chen, Z.; Bian, X.; Chen, N.; Li, J.; Wu, Y.; Yang, Z. Comparative life cycle assessment of PBAT from fossil-based and second-generation generation bio-based feedstocks. Sci. Total Environ. 2024, 954, 176421. [Google Scholar]

- Dong, X.; Chen, N.; Zhang, X.; Wang, C.; Qiao, N.; Long, H. Research on the environment & economic indicators for electricity trading. Energy Rep. 2023, 9, 1774–1783. [Google Scholar]

- Zhu, S.; Tian, H.; Wang, C. Economic Indicator Accuracy and Corporate ESG Performance. Econ. Lett. 2024, 243, 111907. [Google Scholar]

- Ranjan, S.; Gupta, R.; Nanda, S.J. Threshold based constrained θ-NSGA-III algorithm to solve many-objective optimization problems. Inf. Sci. 2025, 697, 121751. [Google Scholar]

- Jung, S.; Jung, H.; Ahn, Y. Plastic-to-energy: Process and economic–environmental assessment of a recycling technology. Process Saf. Environ. Prot. 2024, 183, 1051–1058. [Google Scholar]

- Žižlavský, O. Net present value approach: Method for economic assessment of innovation projects. Procedia-Soc. Behav. Sci. 2014, 156, 506–512. [Google Scholar]

- Cao, Y.; Salem, M.; Nasr, S.; Sadon, S.H.; Singh, P.K.; Abed, A.M.; Dahari, M.; Almoneef, M.M.; Wae-Hayee, M.; Galal, A.M. A novel heat recovery for a marine diesel engine with power and cooling outputs; exergetic, economic, and net present value investigation and multi-criteria NSGA-II optimization. Ain Shams Eng. J. 2023, 14, 102067. [Google Scholar]

- Sun, B.; Zhang, Q.; Mao, H.; Li, K. Road energy capacity model for sustainable Transportation: Assessing energy consumption under road attributes and traffic condition. Sustain. Energy Technol. Assess. 2024, 70, 103930. [Google Scholar]

- National Bureau of Statistics. China Energy Statistical Yearbook [EB/OL]. Available online: https://www.stats.gov.cn/sj/ndsj/2022/indexch.htm (accessed on 9 December 2024).

- Qianzhan Database [EB/OL]. Available online: https://x.qianzhan.com/xdata/ (accessed on 20 December 2024).

- Li, G.; Deng, H.; Yang, H. A multi-factor combined traffic flow prediction model with secondary decomposition and improved entropy weight method. Expert Syst. Appl. 2024, 255, 124424. [Google Scholar]

- Biakhmetov, B.; Li, Y.; Zhao, Q.; Dostiyarov, A.; Flynn, D.; You, S. Transportation and process modelling-assisted techno-economic assessment of resource recovery from non-recycled municipal plastic waste. Energy Convers. Manag. 2025, 324, 119273. [Google Scholar]

- Bressanin, J.M.; Sampaio, I.L.d.M.; Geraldo, V.C.; Klein, B.C.; Chagas, M.F.; Bonomi, A.; Filho, R.M.; Cavalett, O. Techno-economic and environmental assessment of polylactic acid production integrated with the sugarcane value chain. Sustain. Prod. Consum. 2022, 34, 244–256. [Google Scholar]

- Boschi, A.; Scieuzo, C.; Salvia, R.; Arias, C.F.; Perez, R.P.; Bertocchini, F.; Falabella, P. Beyond microbial biodegradation: Plastic degradation by Galleria mellonella. J. Polym. Environ. 2024, 32, 2158–2177. [Google Scholar]

- Kapoor, R.T.; Rafatullah, M. Leveraging biotechnological approaches for the degradation of plastics: A sustainable tool for plastic waste management and environment protection. J. Water Process Eng. 2025, 69, 106736. [Google Scholar] [CrossRef]

- Samak, N.A.; Jia, Y.; Sharshar, M.M.; Mu, T.; Yang, M.; Peh, S.; Xing, J. Recent advances in biocatalysts engineering for polyethylene terephthalate plastic waste green recycling. Environ. Int. 2020, 145, 106144. [Google Scholar] [CrossRef] [PubMed]

| Attributes | Type | Indicators |

|---|---|---|

| Economic indicators | Fixed costs | Facilities costs |

| Maintenance costs | ||

| Management costs | ||

| Construction costs | ||

| Depreciation of fixed assets | ||

| Insurance costs | ||

| Variable costs | Raw materials | |

| Chemical substances | ||

| Energy substances | ||

| Transport costs | ||

| Waste disposal | ||

| Research and development costs | ||

| Marketing costs | ||

| Taxes | ||

| Carbon emission indicators | Cost of carbon oxide emissions control | |

| Cost of nitrogen oxide emissions control | ||

| Cost of sulfur oxide emissions control |

| Region | Road Density km/km2 | Biodegradable Plastics Production (per 10,000 Tons) | |

|---|---|---|---|

| PLA | PBAT | ||

| East China | 0.19 | 32 | 61.6 |

| South China | 0.11 | 8 | 21.2 |

| Southwest China | 0.04 | 0 | 10 |

| Northwest China | 0.02 | 0 | 29 |

| North China | 0.06 | 5 | 2 |

| Northeast China | 0.05 | 3 | 8.3 |

| Central China | 0.12 | 4 | 9 |

| Cost Elements | PLA | PBAT |

|---|---|---|

| Raw material I | 5750 | 5153.04 |

| Chemical substance C | 3380.46 | 1760 |

| Energy E | 1336.10 | 712 |

| Transport costs T | 159.25 | 165.75 |

| Waste disposal W | 800 | 1500 |

| Fixed costs G | 3060 | 2817 |

| Energy Source | Standard Coal Conversion (kg) | CO2 Emissions (kg) | Carbon (C) Emissions (kg) | Cost (Yuan) |

|---|---|---|---|---|

| 1 kg standard coal | — | 2.493 | 0.680 | 0.042 |

| 1 kWh electricity | 0.4 | 0.997 | 0.272 | |

| 1 kg steam (1 MPa grade) | 0.108571 | 0.271 | 0.074 | |

| 1 t fresh water | 0.2429 | 0.606 | 0.165 | |

| 1 t recycled water | 0.1429 | 0.356 | 0.097 | |

| 1 L petrol | 0.923 | 2.301 | 0.628 | |

| 1 L diesel | 1.055 | 2.630 | 0.717 |

| Risk Category | Weight | Percentage | Correlation |

|---|---|---|---|

| Safety risk | 0.35 | 0.433 | 0.312 |

| Quality risk | 0.30 | 0.127 | 0.269 |

| Financial risk | 0.10 | 0.211 | 0.174 |

| Supply risk | 0.15 | 0.106 | 0.148 |

| Schedule risk | 0.10 | 0.123 | 0.097 |

| Type | Objective I (Profit/Yuan) | Objective II (Carbon Emissions/Yuan) | Objective III (Process Risk/%) |

|---|---|---|---|

| PBAT product | 8178.64 | 316.22 | 0.44 |

| PLA product | 7689.72 | 300.63 | 0.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Zhong, W.; Chen, N.; Weng, Y. Multiobjective Optimization of the Economic Efficiency of Biodegradable Plastic Products: Carbon Emissions and Analysis of Geographical Advantages for Production Capacity. Sustainability 2025, 17, 2874. https://doi.org/10.3390/su17072874

Zhang J, Zhong W, Chen N, Weng Y. Multiobjective Optimization of the Economic Efficiency of Biodegradable Plastic Products: Carbon Emissions and Analysis of Geographical Advantages for Production Capacity. Sustainability. 2025; 17(7):2874. https://doi.org/10.3390/su17072874

Chicago/Turabian StyleZhang, Junpeng, Wei Zhong, Ning Chen, and Yingbo Weng. 2025. "Multiobjective Optimization of the Economic Efficiency of Biodegradable Plastic Products: Carbon Emissions and Analysis of Geographical Advantages for Production Capacity" Sustainability 17, no. 7: 2874. https://doi.org/10.3390/su17072874

APA StyleZhang, J., Zhong, W., Chen, N., & Weng, Y. (2025). Multiobjective Optimization of the Economic Efficiency of Biodegradable Plastic Products: Carbon Emissions and Analysis of Geographical Advantages for Production Capacity. Sustainability, 17(7), 2874. https://doi.org/10.3390/su17072874