Optimization of Biogas and Biomethane Yield from Anaerobic Conversion of Pepper Waste Using Response Surface Methodology

Abstract

1. Introduction

2. Materials and Methods

2.1. Inoculum and Substrate

2.2. Analytical Methods

2.3. Operating Procedure

3. Experimental Design Through CCD-RSM

4. Results and Discussion

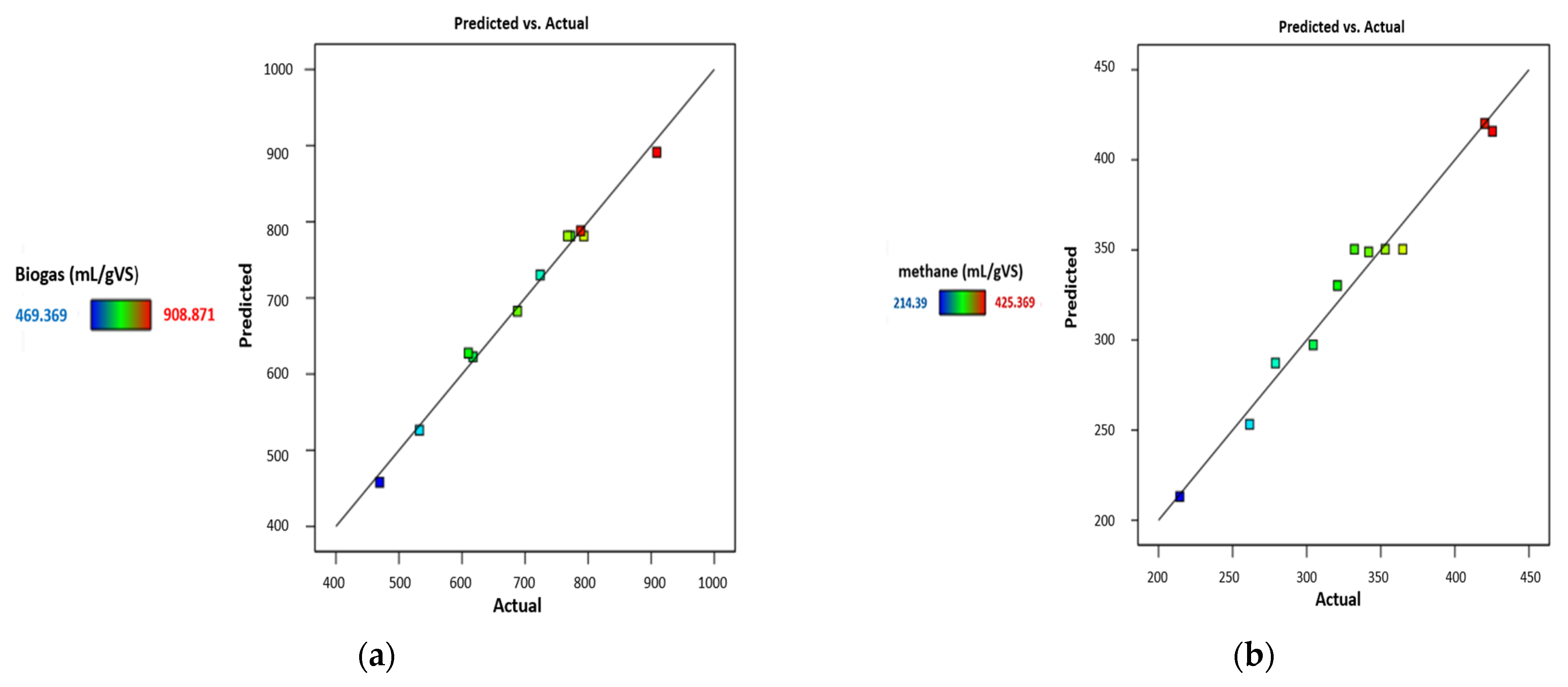

4.1. Statistical Analysis of Regression Model

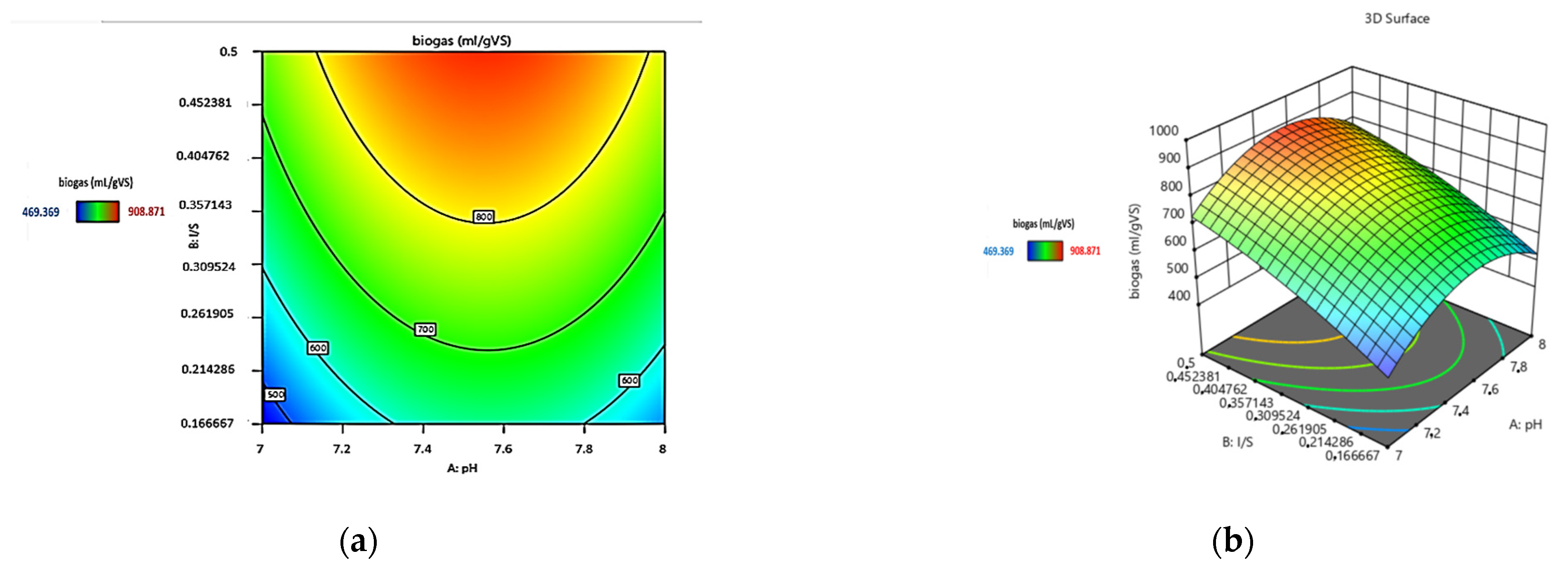

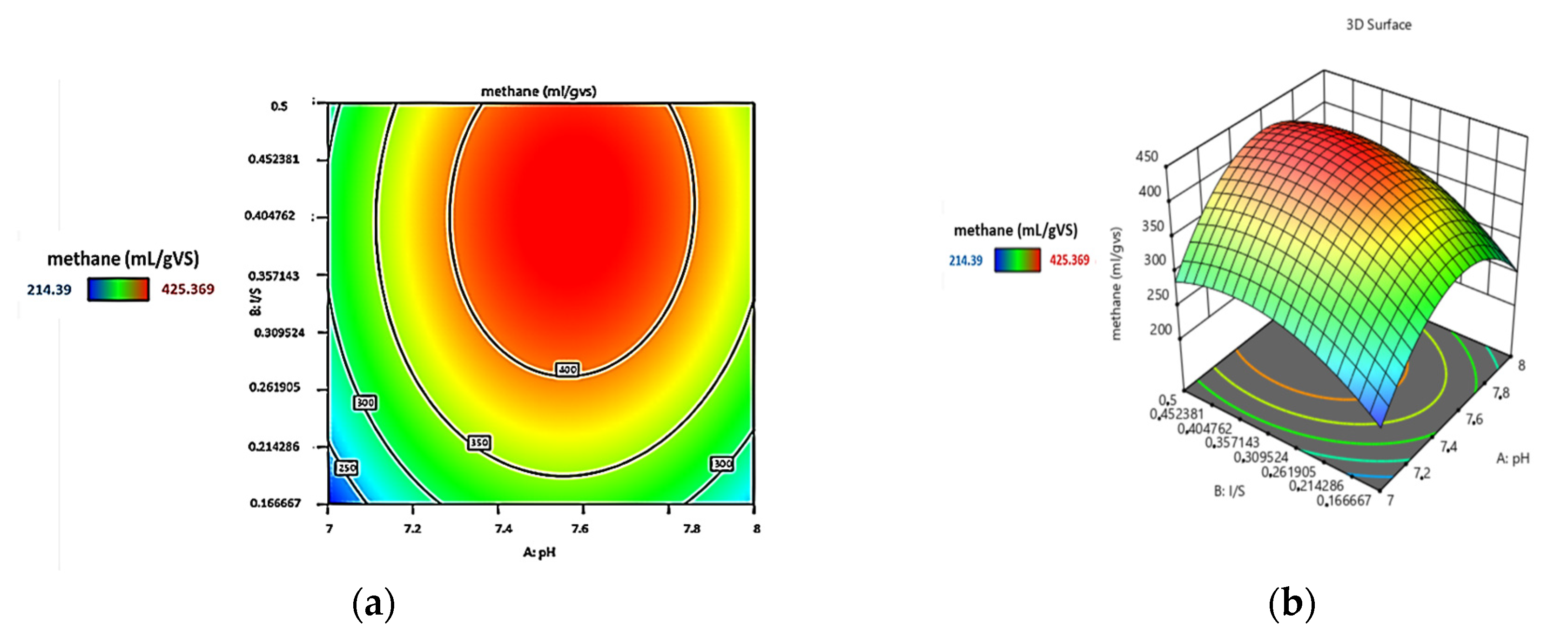

4.2. Analysis of Contour Plots and 3D Response Surfaces

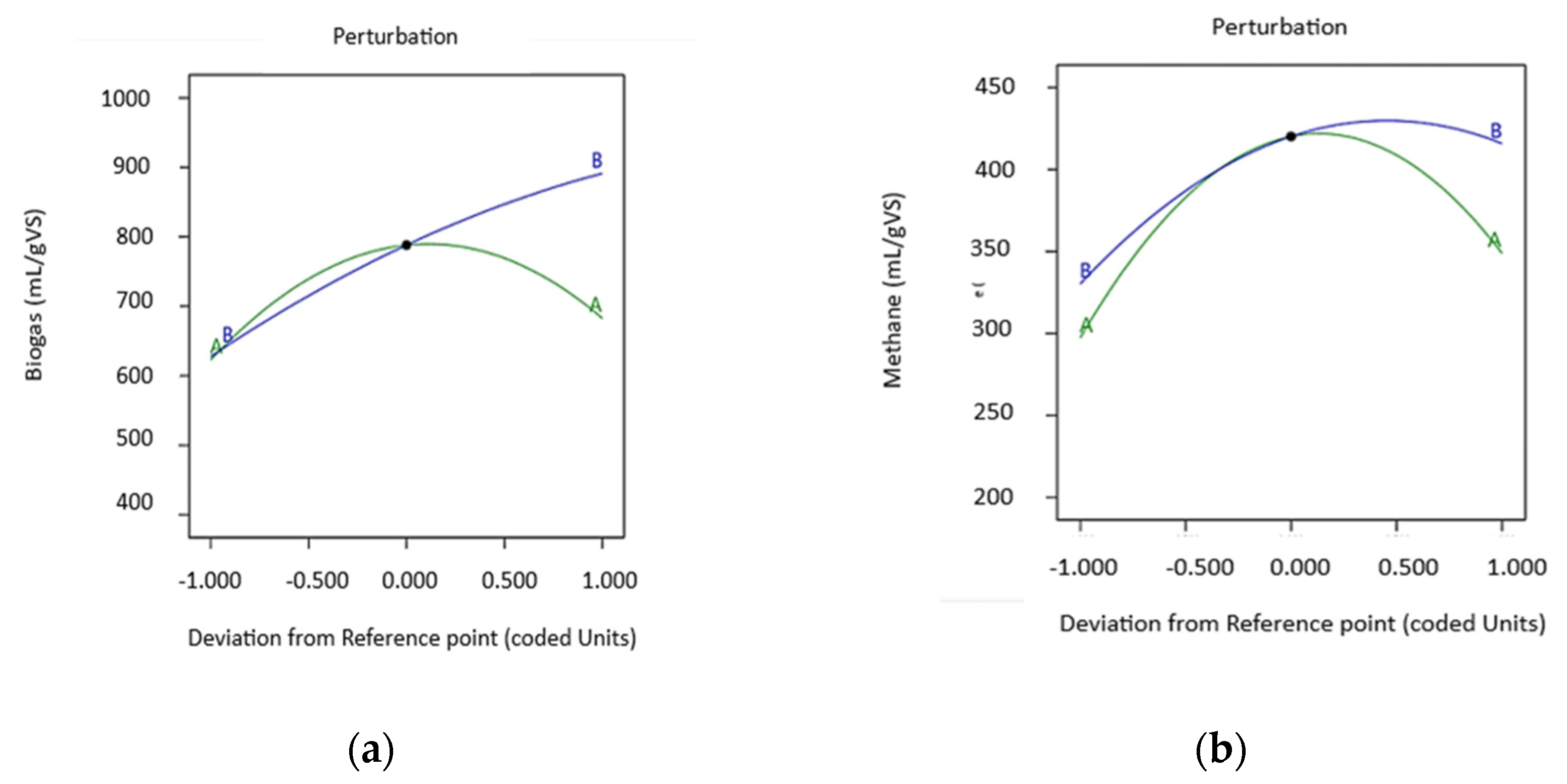

4.3. Evaluating the Effect of Independent Variables on Biogas and Methane Yield

- The effect of pH on the responses:

- The effect of the I/S ratio on the biogas and methane yield:

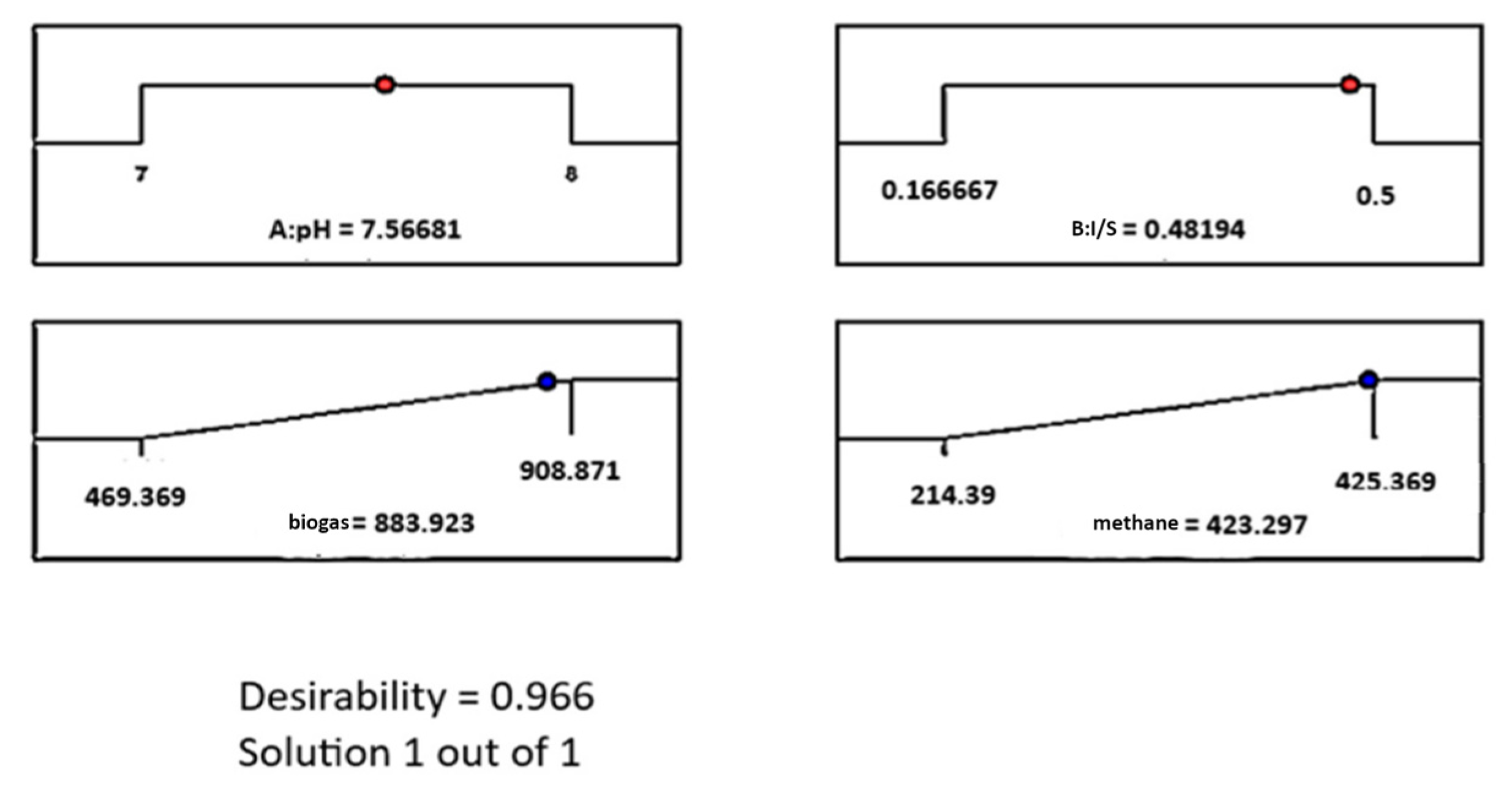

4.4. Process Optimization

5. Conclusions

- The research was conducted in batch mode, which does not simulate real conditions.

- The microbial composition involved in this study was not examined.

- The long-term stability of the system was not confirmed.

- Conducting a study in a semi-continuous or continuous reactor, to confirm the long-term stability of the system.

- Integrating CCD–response surface methodology with an AI tool to enhance the prediction of biogas and methane yield.

- Conducting research at the microscopic scale to understand the behavior of microorganisms during the degradation of the substrate.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rashwan, A.K.; Bai, H.; Osman, A.I.; Eltohamy, K.M.; Chen, Z.; Younis, H.A.; Al-Fatesh, A.; Rooney, D.W.; Yap, P.-S. Recycling Food and Agriculture By-Products to Mitigate Climate Change: A Review. Environ. Chem. Lett. 2023, 21, 3351–3375. [Google Scholar] [CrossRef]

- EPA. Food Waste Management in the United States, 2014; Environmental Protection Agency, Office of Resource Conservation and Recovery: Washington, DC, USA, 2016; pp. 2–18. [Google Scholar]

- Counsil Directive on Waste 442/1975/EEC. 1975. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=CONSLEG:1975L0442:20031120:EN:PDF (accessed on 30 November 2024).

- Cederberg, C.; Sonesson, U. Global Food Losses and Food Waste: Extent, Causes and Prevention. In Proceedings of the International Congress Save Food! At Interpack 2011, Düsseldorf, Germany, 16–17 May 2011; Gustavsson, J., Ed.; Food and Agriculture Organization of the United Nations: Rome, Italy, 2011. ISBN 978-92-5-107205-9. [Google Scholar]

- Čolović, D.; Rakita, S.; Banjac, V.; Đuragić, O.; Čabarkapa, I. Plant Food By-Products as Feed: Characteristics, Possibilities, Environmental Benefits, and Negative Sides. Food Rev. Int. 2019, 35, 363–389. [Google Scholar] [CrossRef]

- Vulić, J.; Šeregelj, V.; Kalušević, A.; Lević, S.; Nedović, V.; Tumbas Šaponjac, V.; Čanadanović-Brunet, J.; Ćetković, G. Bioavailability and Bioactivity of Encapsulated Phenolics and Carotenoids Isolated from Red Pepper Waste. Molecules 2019, 24, 2837. [Google Scholar] [CrossRef]

- Naveen, B.P.; Sumalatha, J.; Malik, R.K. A Study on Contamination of Ground and Surface Water Bodies by Leachate Leakage from a Landfill in Bangalore, India. Int. J. Geo-Eng. 2018, 9, 27. [Google Scholar] [CrossRef]

- Romero-Huelva, M.; Ramírez-Fenosa, M.A.; Planelles-González, R.; García-Casado, P.; Molina-Alcaide, E. Can By-Products Replace Conventional Ingredients in Concentrate of Dairy Goat Diet? J. Dairy Sci. 2017, 100, 4500–4512. [Google Scholar] [CrossRef]

- Hu, C.H.; Zuo, A.Y.; Wang, D.G.; Pan, H.Y.; Zheng, W.B.; Qian, Z.C.; Zou, X.T. Effects of Broccoli Stems and Leaves Meal on Production Performance and Egg Quality of Laying Hens. Anim. Feed Sci. Technol. 2011, 170, 117–121. [Google Scholar] [CrossRef]

- Scano, E.A.; Grosso, M.; Pistis, A.; Carboni, G.; Cocco, D. An In-Depth Analysis of Biogas Production from Locally Agro-Industrial by-Products and Residues. An Italian Case. Renew. Energy 2021, 179, 308–318. [Google Scholar] [CrossRef]

- Valenti, F.; Porto, S.M.C. Net Electricity and Heat Generated by Reusing Mediterranean Agro-Industrial By-Products. Energies 2019, 12, 470. [Google Scholar] [CrossRef]

- Gürsan, C.; de Gooyert, V. The Systemic Impact of a Transition Fuel: Does Natural Gas Help or Hinder the Energy Transition? Renew. Sustain. Energy Rev. 2021, 138, 110552. [Google Scholar] [CrossRef]

- Ryckebosch, E.; Drouillon, M.; Vervaeren, H. Techniques for Transformation of Biogas to Biomethane. Biomass Bioenergy 2011, 35, 1633–1645. [Google Scholar] [CrossRef]

- Angelidaki, I.; Treu, L.; Tsapekos, P.; Luo, G.; Campanaro, S.; Wenzel, H.; Kougias, P.G. Biogas Upgrading and Utilization: Current Status and Perspectives. Biotechnol. Adv. 2018, 36, 452–466. [Google Scholar] [CrossRef] [PubMed]

- Jeppu, G.P.; Janardhan, J.; Kaup, S.; Janardhanan, A.; Mohammed, S.; Acharya, S. Effect of Feed Slurry Dilution and Total Solids on Specific Biogas Production by Anaerobic Digestion in Batch and Semi-Batch Reactors. J. Mater. Cycles Waste Manag. 2022, 24, 97–110. [Google Scholar] [CrossRef]

- Harissa: The Story Behind North Africa’s Favorite Hot Sauce: The Salt: NPR. Available online: https://www.npr.org/sections/thesalt/2012/06/04/154293245/harissa-the-story-behind-north-africas-favorite-hot-sauce (accessed on 25 December 2024).

- Akman, H.E.; Akman, E.; Ciggin, A.S.; Perendeci, N.A.; Yaldız, O. Effects of Mixture Ratio of Cow Manure and Greenhouse Wastes on Anaerobic Co-Digestion Process. Agric. Eng. Int. CIGR J. Spec. 2015, 2015, 160–167. [Google Scholar]

- Ferrer, P.; Cambra-López, M.; Cerisuelo, A.; Peñaranda, D.S.; Moset, V. The Use of Agricultural Substrates to Improve Methane Yield in Anaerobic Co-Digestion with Pig Slurry: Effect of Substrate Type and Inclusion Level. Waste Manag. 2014, 34, 196–203. [Google Scholar] [CrossRef]

- Riaño, B.; Molinuevo-Salces, B.; Parralejo, A.; Royano, L.; González-Cortés, J.; García-González, M.C. Techno-Economic Evaluation of Anaerobic Co-Digestion of Pepper Waste and Swine Manure. Biomass Convers. Biorefin. 2023, 13, 7763–7774. [Google Scholar] [CrossRef]

- Sidi Habib, S.; Torii, S.; S, K.M.; Charivuparampil Achuthan Nair, A. Optimization of the Factors Affecting Biogas Production Using the Taguchi Design of Experiment Method. Biomass 2024, 4, 687–703. [Google Scholar] [CrossRef]

- Walter, W.G. Standard Methods for the Examination of Water and Wastewater (11th Ed.). Am. J. Public Health Nations Health 1961, 51, 940. [Google Scholar] [CrossRef]

- Cicco, N.; Lanorte, M.T.; Paraggio, M.; Viggiano, M.; Lattanzio, V. A Reproducible, Rapid and Inexpensive Folin–Ciocalteu Micro-Method in Determining Phenolics of Plant Methanol Extracts. Microchem. J. 2009, 91, 107–110. [Google Scholar] [CrossRef]

- Ghaleb, A.A.S.; Kutty, S.R.M.; Ho, Y.-C.; Jagaba, A.H.; Noor, A.; Al-Sabaeei, A.M.; Almahbashi, N.M.Y. Response Surface Methodology to Optimize Methane Production from Mesophilic Anaerobic Co-Digestion of Oily-Biological Sludge and Sugarcane Bagasse. Sustainability 2020, 12, 2116. [Google Scholar] [CrossRef]

- Mahanta, P.; Saha, U.K.; Dewan, A.; Kalita, P.; Buragohain, B. Biogas Digester: A Discussion on Factors Affecting Biogas Production and Field Investigation of a Novel Duplex Digester. J. Sol. Energy Soc. India 2005, 15, 1–12. [Google Scholar]

- Zeng, S.; Yuan, X.; Shi, X.; Qiu, Y. Effect of Inoculum/Substrate Ratio on Methane Yield and Orthophosphate Release from Anaerobic Digestion of Microcystis spp. J. Hazard. Mater. 2010, 178, 89–93. [Google Scholar] [CrossRef] [PubMed]

- Mata-Alvarez, J.; Macé, S.; Llabrés, P. Anaerobic Digestion of Organic Solid Wastes. An Overview of Research Achievements and Perspectives. Bioresour. Technol. 2000, 74, 3–16. [Google Scholar] [CrossRef]

- Khadka, A.; Parajuli, A.; Dangol, S.; Thapa, B.; Sapkota, L.; Carmona-Martínez, A.A.; Ghimire, A. Effect of the Substrate to Inoculum Ratios on the Kinetics of Biogas Production during the Mesophilic Anaerobic Digestion of Food Waste. Energies 2022, 15, 834. [Google Scholar] [CrossRef]

- Sri Bala Kameswari, K.; Kalyanaraman, C.; Porselvam, S.; Thanasekaran, K. Optimization of Inoculum to Substrate Ratio for Bio-Energy Generation in Co-Digestion of Tannery Solid Wastes. Clean Technol. Environ. Policy 2012, 14, 241–250. [Google Scholar] [CrossRef]

- Song, X.; Kong, F.; Liu, B.-F.; Song, Q.; Ren, N.-Q.; Ren, H.-Y. Antioxidants alleviated low-temperature stress in microalgae by modulating reactive oxygen species to improve lipid production and antioxidant defense. Bioresour. Technol. 2024, 413, 131451. [Google Scholar] [CrossRef]

| Characteristics | PW | SS |

|---|---|---|

| pH | 6.42 | 7.5 |

| TS (g/Kg) | 948.4 | 68.73 |

| TVS (g/Kg) | 919.8 | 30.85 |

| Total COD | 480 (mg/g) | 14,400 (mg/L) |

| Total carbon | 74.05 (mg/g) | 1401 (mg/L) |

| Polyphenols | 539.35 (mg/g) | 586.39 (mg/L) |

| Independent Variable | Unit | Variable Level | ||

|---|---|---|---|---|

| −1 (Min) | 0 | +1 (Max) | ||

| I/S ratio (X1) | g VS/g VS | 0.167 | 0.334 | 0.5 |

| pH (X2) | - | 7 | 7.5 | 8 |

| Runs Order | Real Values | Coded Values | Responses | |||||

|---|---|---|---|---|---|---|---|---|

| pH | I/S | X1 | X2 | Biogas (mL/gVS) (Y1) | Methane (mL/gVS) (Y2) | |||

| Experimental Biogas Yield (mL/g VS) | Predicted Biogas Yield (mL/g VS) | Experimental Methane Yield (mL CH4/g VS) | Predicted Methane Yield (mL CH4/g VS | |||||

| 1 | 8.0 | 0.500 | +1 | +1 | 793.145 | 781.38 | 364.846 | 350.41 |

| 2 | 8.0 | 0.500 | +1 | +1 | 767.339 | 781.38 | 352.975 | 350.41 |

| 3 | 8.0 | 0.500 | +1 | +1 | 772.177 | 781.38 | 332.201 | 350.41 |

| 4 | 8.0 | 0.167 | +1 | −1 | 532.477 | 526.34 | 261.526 | 253.23 |

| 5 | 7.0 | 0.167 | −1 | −1 | 469.369 | 457.89 | 214.39 | 213.19 |

| 6 | 7.0 | 0.334 | −1 | 0 | 617.384 | 622.72 | 304.407 | 297.31 |

| 7 | 7.5 | 0.500 | 0 | +1 | 908.871 | 891.26 | 425.369 | 415.87 |

| 8 | 7.5 | 0.167 | 0 | −1 | 610 | 627.62 | 320.774 | 330.27 |

| 9 | 8.0 | 0.334 | +1 | 0 | 687.903 | 682.57 | 341.835 | 348.93 |

| 10 | 7.0 | 0.500 | −1 | +1 | 723.994 | 730.13 | 278.932 | 287.23 |

| 11 | 7.5 | 0.334 | 0 | 0 | 788.144 | 788.14 | 420.179 | 420.18 |

| Source | Sum of Squares | DF | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 1.655 × 105 | 5 | 33,103.51 | 126.80 | <0.0001 | significant |

| A-pH | 6164.19 | 1 | 6164.19 | 23.61 | 0.0046 | |

| B-I/S | 1.195 × 105 | 1 | 1.195 × | 457.91 | <0.0001 | |

| AB | 90.57 | 1 | 90.57 | 0.3469 | 0.5815 | |

| A2 | 38,532.60 | 1 | 38,532.60 | 147.60 | <0.0001 | |

| B2 | 1759.88 | 1 | 1759.88 | 6.74 | 0.0485 | |

| Residual | 1305.32 | 5 | 261.06 | |||

| Lack of Fit | 928.98 | 3 | 309.66 | 1.65 | 0.3996 | not significant |

| Pure Error | 376.34 | 2 | 188.17 | |||

| Cor Total | 1.668 × 105 | 10 |

| Source | Sum of Squares | DF | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 39,292.38 | 5 | 7858.48 | 40.62 | 0.0005 | significant |

| A-pH | 4573.85 | 1 | 4573.85 | 23.64 | 0.0046 | |

| B-I/S | 12,590.04 | 1 | 12,590.04 | 65.08 | 0.0005 | |

| AB | 163.92 | 1 | 163.92 | 0.8474 | 0.3995 | |

| A2 | 19,504.91 | 1 | 19,504.91 | 100.83 | 0.0002 | |

| B2 | 4551.74 | 1 | 4551.74 | 23.53 | 0.0047 | |

| Residual | 967.26 | 5 | 193.45 | |||

| Lack of Fit | 421.20 | 3 | 140.40 | 0.5142 | 0.7126 | not significant |

| Pure Error | 546.06 | 2 | 273.03 | |||

| Cor Total | 40,259.64 | 10 |

| Statistical Result | Y1 | Y2 |

|---|---|---|

| Model F-Value | 126.71 | 40.91 |

| Model p-Value | <0.0001 | 0.0005 |

| Lack of Fit F-Value | 1.64 | 0.5132 |

| Lack of Fit p-Value | 0.3997 | 0.7131 |

| R-Squared | 0.9922 | 0.9761 |

| Adj R-Squared | 0.9843 | 0.9523 |

| Pred R-Squared | 0.9462 | 0.8499 |

| Adeq Precision | 36.3225 | 20.1590 |

| Independent Variables | Optimal Level | Target | Responses | Target | Predicted Value | Desirability |

|---|---|---|---|---|---|---|

| pH | 7.567 | In range | Biogas yield (mL/g VS) (Y1) | Maximize | 884.350 | 0.966 |

| I/S ratio | 0.482 | In range | Methane yield (mL/g VS) (Y2) | Maximize | 422.827 |

| Responses | Predicted Value | Experimental Value | % Deviation |

|---|---|---|---|

| Biogas yield | 884.350 | 908.871 | 2.69 |

| Methane yield | 422.827 | 425.369 | 0.59 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bensegueni, C.; Kheireddine, B.; Khalfaoui, A.; Amrouci, Z.; Bouznada, M.O.; Derbal, K. Optimization of Biogas and Biomethane Yield from Anaerobic Conversion of Pepper Waste Using Response Surface Methodology. Sustainability 2025, 17, 2688. https://doi.org/10.3390/su17062688

Bensegueni C, Kheireddine B, Khalfaoui A, Amrouci Z, Bouznada MO, Derbal K. Optimization of Biogas and Biomethane Yield from Anaerobic Conversion of Pepper Waste Using Response Surface Methodology. Sustainability. 2025; 17(6):2688. https://doi.org/10.3390/su17062688

Chicago/Turabian StyleBensegueni, Chaima, Bani Kheireddine, Amel Khalfaoui, Zahra Amrouci, Maya Ouissem Bouznada, and Kerroum Derbal. 2025. "Optimization of Biogas and Biomethane Yield from Anaerobic Conversion of Pepper Waste Using Response Surface Methodology" Sustainability 17, no. 6: 2688. https://doi.org/10.3390/su17062688

APA StyleBensegueni, C., Kheireddine, B., Khalfaoui, A., Amrouci, Z., Bouznada, M. O., & Derbal, K. (2025). Optimization of Biogas and Biomethane Yield from Anaerobic Conversion of Pepper Waste Using Response Surface Methodology. Sustainability, 17(6), 2688. https://doi.org/10.3390/su17062688