Digitally-Enabled Carbon Reduction in Plastics Supply Chain Based on Literature Review Method

Abstract

1. Introduction

- (1)

- How has the research on carbon emission reduction in plastic supply chains evolved?

- (2)

- What are the research hotspots for digitally enabling carbon emission reduction in plastic supply chains?

- (3)

- How can digitalization enable carbon reduction in the plastics supply chain?

- (4)

- What are the trends of digital empowerment and carbon reduction research in the plastics supply chain?

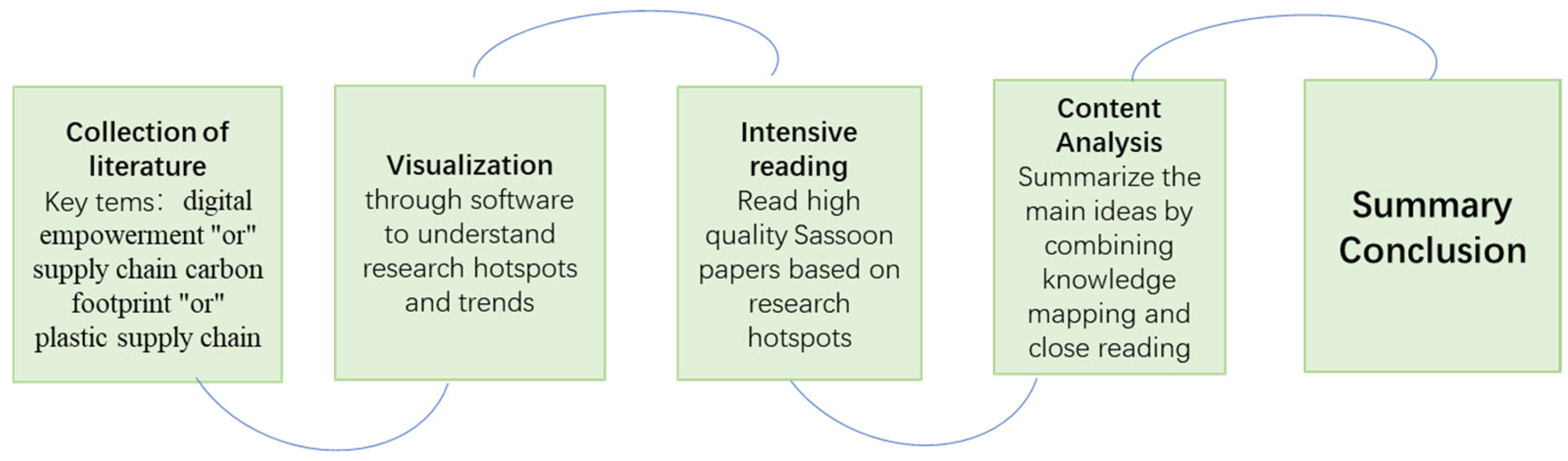

2. Research Methods

2.1. Data Collection

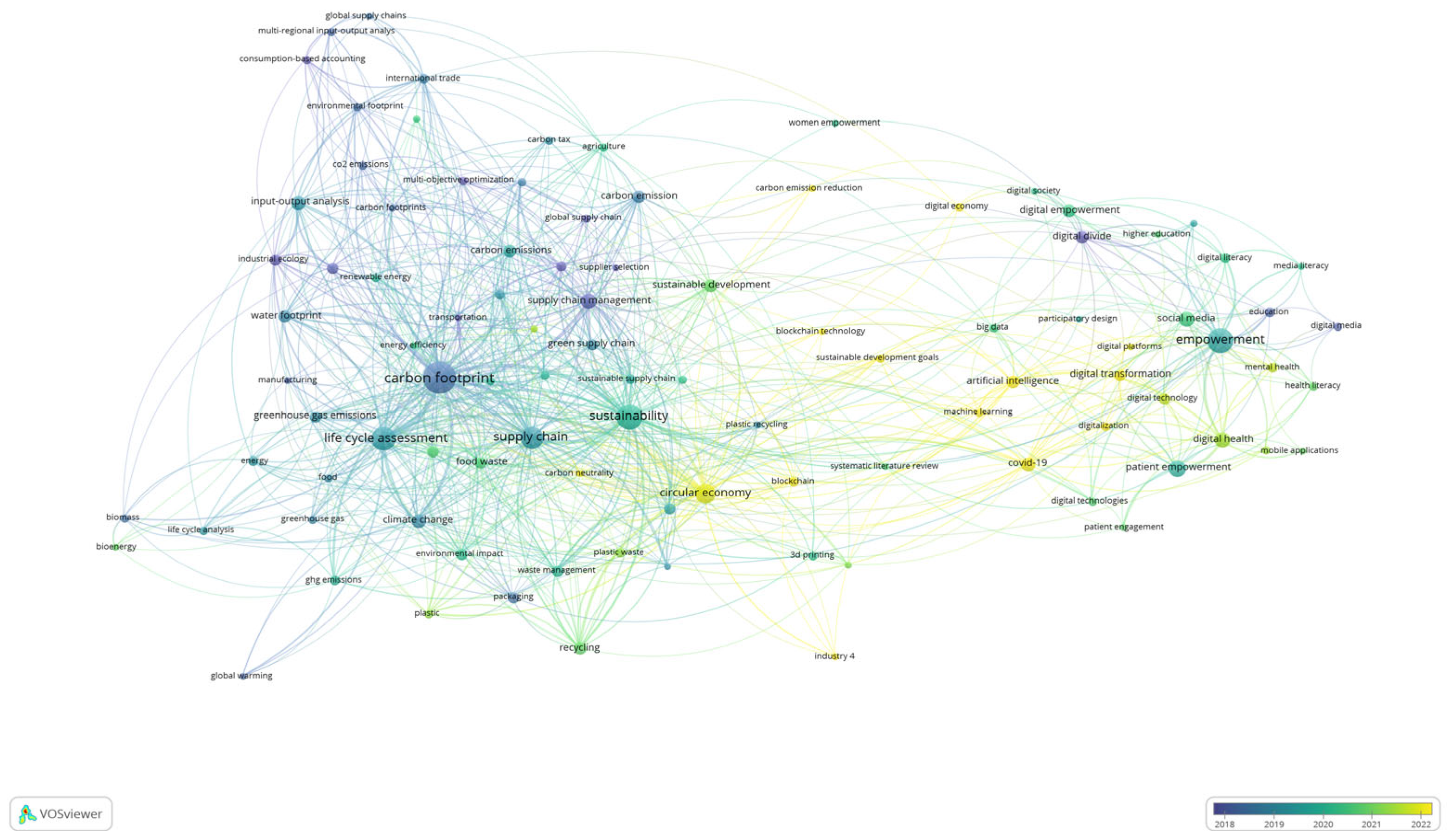

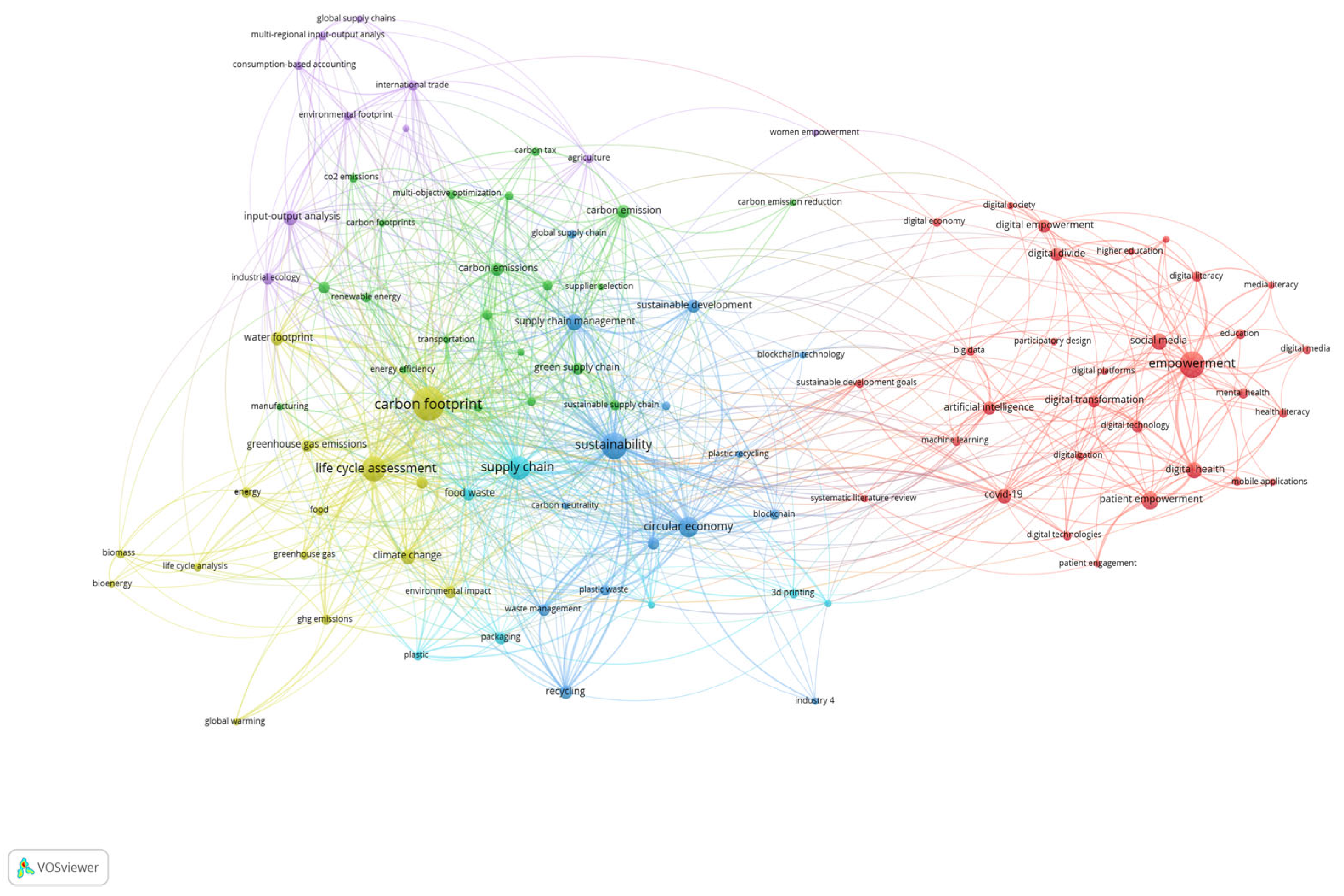

2.2. Bibliometrics Analysis

2.3. Content Analysis

3. Bibliometric Analysis

3.1. Research Trend of Carbon Emission Reduction in Plastic Supply Chain

3.2. Analysis of Research Hotspots Based on Keyword Clustering

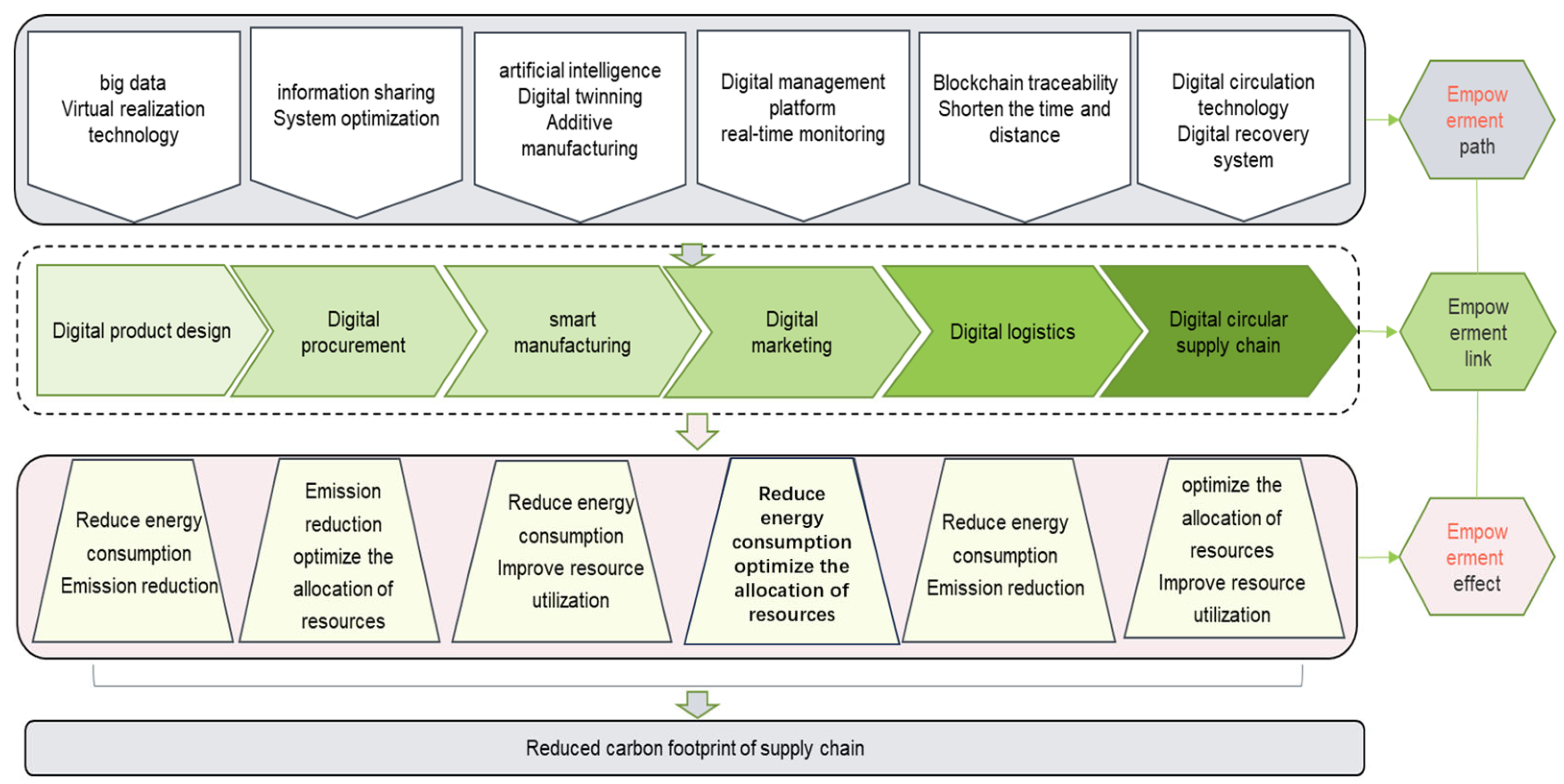

4. The Mechanism of Digitally Empowered Plastic Supply Chain Carbon Emission Reduction

4.1. Carbon Reduction in Plastic Supply Chain

4.2. Mechanistic Model of Digitally Enabled Plastic Supply Chain Carbon Emission Reduction

5. Future Research Directions

- (1)

- Carbon emission reduction in the consumer side of the plastics supply chain

- (2)

- The development of digital industrialization of carbon emission reduction

- (3)

- Digital finance for the carbon footprint

- (4)

- Digital Value Creation of Carbon Neutralization

- (5)

- Carbon Neutralization Innovation

- (6)

- Mechanism of metaverse-enabled plastic supply chain

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Prata, J.C.; Silva, A.L.P.; da Costa, J.P.; Mouneyrac, C.; Walker, T.R.; Duarte, A.C.; Rocha-Santos, T. Solutions and Integrated Strategies for the Control and Mitigation of Plastic and Microplastic Pollution. Int. J. Environ. Res. Public Health 2019, 16, 2411. [Google Scholar] [CrossRef] [PubMed]

- Law, K.L.; Morét-Ferguson, S.; Maximenko, N.A.; Proskurowski, G.; Peacock, E.E.; Hafner, J.; Reddy, C.M. Plastic accumulation in the North Atlantic subtropical gyre. Science 2010, 329, 1185–1188. [Google Scholar] [CrossRef] [PubMed]

- Clark, J.H. From waste to wealth using green chemistry: The way to long term stability. Curr. Opin. Green Sustain. Chem. 2017, 8, 10–13. [Google Scholar] [CrossRef]

- Dong, H.; Geng, Y.; Xi, F.; Fujita, T. Carbon footprint evaluation at industrial park level: A hybrid life cycle assessment approach. Energy Policy 2013, 57, 298–307. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2007, 3, e1700782. [Google Scholar] [CrossRef]

- Wu, C.H. Green Low-Carbon Materials Bring New Growth Points to the Industry—Strategy of Petroleum and Petrochemical Industry in 2022; Guolian Securities: Wuxi, China, 2021; pp. 1–34. [Google Scholar]

- Xu, S.; Yang, C.; Huang, Z.; Failler, P. Interaction between Digital Economy and Environmental Pollution: New Evidence from a Spatial Perspective. Int. J. Environ. Res. Public Health 2022, 19, 5074. [Google Scholar] [CrossRef] [PubMed]

- Tsolakis, N.; Schumacher, R.; Dora, M.; Kumar, M. Artificial intelligence and blockchain implementation in supply chains: A pathway to sustainability and data monetisation? Ann. Oper. Res. 2023, 327, 157–210. [Google Scholar] [CrossRef]

- Chin, T.; Shi, Y.; Singh, S.K.; Agbanyo, G.K.; Ferraris, A. Leveraging blockchain technology for green innovation in ecosystem based business models: A dynamic capability of values appropriation. Technol. Forecast. Soc. Change 2022, 183, 121908. [Google Scholar] [CrossRef]

- Rachinger, M.; Rauter, R.; Müller, C.; Vorraber, W.; Schirgi, E. Digitalization and its Influence on Business Model Innovation. J. Manuf. Technol. Manag. 2019, 30, 1143–1160. [Google Scholar] [CrossRef]

- Meys, R.; Frick, F.; Westhues, S.; Sternberg, A.; Klankermayer, J.; Bardow, A. Towards a circular economy for plastic packaging wastes—The environmental potential of chemical recycling. Resour. Conserv. Recycl. 2020, 162, 105010. [Google Scholar] [CrossRef]

- Chang, L.; Zhang, Q.; Liu, H. Digital finance innovation in green manufacturing: A bibliometric approach. Env. Sci. Pollut. Res. 2023, 30, 61340–61368. [Google Scholar] [CrossRef] [PubMed]

- Law, K.L.; Narayan, R. Reducing environmental plastic pollution by designing polymer materials for managed end-of-life. Nat. Rev. Mater. 2021, 7, 104–116. [Google Scholar] [CrossRef]

- Fraga, L.P.; Lopes, S.I.; Fernández Caramés, T.M. Green IoT and Edge AI as Key Technological Enablers for a Sustainable Digital Transition towards a Smart Circular Economy: An Industry 5.0 Use Case. Sensors 2021, 21, 5745. [Google Scholar] [CrossRef] [PubMed]

- Beitzen-Heineke, E.F.; Balta-Ozkan, N.; Reefke, H. The prospects of zero-packaging grocery stores to improve the social and environmental impacts of the food supply chain. J. Clean. Prod. 2017, 140, 1528–1541. [Google Scholar] [CrossRef]

- Mohammadi, M.; Jämsä-Jounela, S.-L.; Harjunkoski, I. Optimal planning of municipal solid waste management systems in an integrated supply chain network. Comput. Chem. Eng. 2019, 123, 155–169. [Google Scholar] [CrossRef]

- De Vargas Mores, G.; Finocchio, C.P.S.; Barichello, R.; Pedrozo, E.A. Sustainability and innovation in the Brazilian supply chain of green plastic. J. Clean. Prod. 2018, 177, 12–18. [Google Scholar] [CrossRef]

- Gong, Y.; Wang, Y.; Frei, R.; Wang, B.; Zhao, C. Blockchain application in circular marine plastic debris management. Ind. Mark. Manag. 2022, 102, 164–176. [Google Scholar] [CrossRef]

- Gong, Y.; Xie, S.; Arunachalam, D.; Duan, J.; Luo, J. Blockchain-based recycling and its impact on recycling performance: A network theory perspective. Bus. Strategy Environ. 2022, 31, 3717–3741. [Google Scholar] [CrossRef]

- Wen, Z.; Xie, Y.; Chen, M.; Dinga, C.D. China’s plastic import ban increases prospects of environmental impact mitigation of plastic waste trade flow worldwide. Nat. Commun. 2021, 12, 425. [Google Scholar] [CrossRef]

- Xie, S.; Gong, Y.; Kunc, M.; Wen, Z.; Brown, S. The application of blockchain technology in the recycling chain: A state-of-the-art literature review and conceptual framework. Int. J. Prod. Res. 2022, 61, 8692–8718. [Google Scholar] [CrossRef]

- Zheng, J.J.; Suh, S.W. Strategies to reduce the global carbon footprint of plastics. Nat. Clim. Change 2019, 9, 374–378. [Google Scholar] [CrossRef]

- Xu, J.P.; Jiang, X.L.; Wu, Z.B. A Sustainable Performance Assessment Framework for Plastic Film Supply Chain Management from a Chinese Perspective. Sustainability 2016, 8, 1042. [Google Scholar] [CrossRef]

- Simon, F.; Mélanie, D. Additive manufacturing and sustainability: An exploratory study of the advantages and challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar]

- Kshetri, N. Blockchain’s roles in meeting key supply chain management objectives. Int. J. Inf. Manag. 2018, 39, 80–89. [Google Scholar] [CrossRef]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain technology and its relationships to sustainable supply chain management. Int. J. Prod. Res. 2019, 57, 2117–2135. [Google Scholar] [CrossRef]

- Zhong, T.Y.; Ma, F.Q. Carbon emission reduction effect of digital transformation of enterprises: Theoretical mechanism and empirical test. J. Jianghai. 2022, 4, 99–105. [Google Scholar]

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The expected contribution of Industry 4.0 technologies for industrial performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Borrelle, S.B.; Ringma, J.; Law, K.L.; Monnahan, C.C.; Lebreton, L.; Mcgivern, A.; Murphy, E.; Jambeck, J.; Leonard, G.H.; Hilleary, M.A.; et al. Predicted growth in plastic waste exceeds efforts to mitigate plastic pollution. Science 2020, 369, 1515–1518. [Google Scholar] [CrossRef]

- Lau, W.W.Y.; Shiran, Y.; Bailey, R.M.; Cook, E.; Stuchtey, M.R.; Koskella, J.; Velis, C.A.; Godfrey, L.; Boucher, J.; Murphy, M.B.; et al. Evaluating scenarios toward zero plastic pollution. Science 2020, 369, 1455–1461. [Google Scholar] [CrossRef]

- Ohnishi, S.; Fujii, M.; Ohata, M.; Rokuta, I.; Fujita, T. Efficient energy recovery through a combination of waste-to-energy systems for a low-carbon city. Resour. Conserv. Recycl. 2018, 128, 394–405. [Google Scholar] [CrossRef]

- Hahladakis, J.N.; Iacovidou, E. Closing the loop on plastic packaging materials: What is quality and how does it affect their circularity? Sci. Total Environ. 2018, 630, 1394–1400. [Google Scholar] [CrossRef] [PubMed]

- Scavarda, A.; Daú, G.L.; Scavarda, L.F.; Korzenowski, A.L. A proposed healthcare supply chain management framework in the emerging economies with the sustainable lenses: The theory, the practice, and the policy. Resour. Conserv. Recycl. 2019, 141, 418–430. [Google Scholar] [CrossRef]

- Dong, L.; Liang, H.; Zhang, L.; Liu, Z.; Gao, Z.; Hu, M. Highlighting regional eco-industrial development: Life cycle benefits of an urban industrial symbiosis and implications in China. Ecol. Model. 2017, 361, 164–176. [Google Scholar] [CrossRef]

- Feitó-Cespón, M.; Sarache, W.; Piedra-Jimenez, F.; Cespón-Castro, R. Redesign of a sustainable reverse supply chain under uncertainty: A case study. J. Clean. Prod. 2017, 151, 206–217. [Google Scholar] [CrossRef]

- Benitez Nara, E.O.; Becker da Costa, M.; Baierle, I.C.; Schaefer, J.L.; Benitez, G.B.; do Santos, L.M.A.L.; Benitez, L.B. Expected impact of industry 4.0 technologies on sustainable development: A study in the context of Brazil’s plastic industry. Sustain. Prod. Consum. 2021, 25, 102–122. [Google Scholar] [CrossRef]

- Shemesh, R.; Krepker, M.; Nitzan, N.; Vaxman, A.; Segal, E. Active Packaging Containing Encapsulated Carvacrol for Control of Postharvest Decay. Postharvest Biol. Technol. 2016, 118, 175–182. [Google Scholar] [CrossRef]

- Heyer, C. Human-robot Interaction and Future Industrial Robotics Applications. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Taipei, Taiwan, 18–22 October 2010; pp. 4749–4754. [Google Scholar]

- Gong, Y.; Zhang, T.; Dong, P.; Chen, X.; Shi, Y. Innovation adoption of blockchain technology in supply chain finance. Prod. Plan. Control 2022, 35, 992–1008. [Google Scholar] [CrossRef]

- Gong, Y.; Zhang, Y.; Alharithi, M. Supply Chain Finance and Blockchain in Operations Management: A Literature Review. Sustainability 2022, 14, 13450. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, S.; Liu, Y.; Yang, H.; Li, M.; Huisingh, D.; Wang, L. The “Internet of Things” enabled real time scheduling for remanufacturing of automobile engines. J. Clean. Prod. 2018, 185, 562–575. [Google Scholar] [CrossRef]

- Khanna, T.M.; Baiocchi, G.; Callaghan, M.; Creutzig, F.; Guias, H.; Haddaway, N.R.; Hirth, L.; Javaid, A.; Koch, N.; Laukemper, S.; et al. A multi-country meta-analysis on the role of behavioural change in reducing energy consumption and CO2 emissions in residential buildings. Nat. Energy 2021, 6, 925–932. [Google Scholar] [CrossRef]

| Authors | Emission Reduction Measures |

|---|---|

| Zheng and Suh (2019) [22] | Integrate energy, materials, recycling and demand management strategies |

| Law et al. (2010) [2] | Design principles must include a viable recycling and disposal program based on existing systems |

| Borrelle et al. (2020) [29] | Reduce plastic production, improve waste management, and increase recycling |

| Lau et al. (2020) [30] | Reduce plastic consumption, increase reuse rates, and expand safe waste disposal systems |

| Beitzen-Heineke et al. (2017) [15] | Plastic waste to resource |

| Ohnishi et al. (2018) [31] | Improve recycling waste utilization, incinerate for electricity |

| Hahladakis and Iacovidou (2018) [32] | Increase the value of recycling, increase investment in recycling technology |

| Scavarda et al. (2019) [33] | Improve corporate social responsibility and increase the proportion of recycling |

| Borrelle et al. (2020) [29] | Chemical and mechanical recycling, biomass utilization, and carbon capture and utilization |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, C.; Wang, B.; Saidula, M.; Gong, Y.; Alharithi, M. Digitally-Enabled Carbon Reduction in Plastics Supply Chain Based on Literature Review Method. Sustainability 2025, 17, 2472. https://doi.org/10.3390/su17062472

Zhao C, Wang B, Saidula M, Gong Y, Alharithi M. Digitally-Enabled Carbon Reduction in Plastics Supply Chain Based on Literature Review Method. Sustainability. 2025; 17(6):2472. https://doi.org/10.3390/su17062472

Chicago/Turabian StyleZhao, Changping, Bill Wang, Maliyamu Saidula, Yu Gong, and Mohammed Alharithi. 2025. "Digitally-Enabled Carbon Reduction in Plastics Supply Chain Based on Literature Review Method" Sustainability 17, no. 6: 2472. https://doi.org/10.3390/su17062472

APA StyleZhao, C., Wang, B., Saidula, M., Gong, Y., & Alharithi, M. (2025). Digitally-Enabled Carbon Reduction in Plastics Supply Chain Based on Literature Review Method. Sustainability, 17(6), 2472. https://doi.org/10.3390/su17062472