Waste Foundry Sand as an Alternative Material in Road Construction

Abstract

1. Introduction

2. Materials and Methods

2.1. Waste Foundry Sand

2.2. Soil

2.3. Additive

2.4. Methodology

3. Analysis of Results

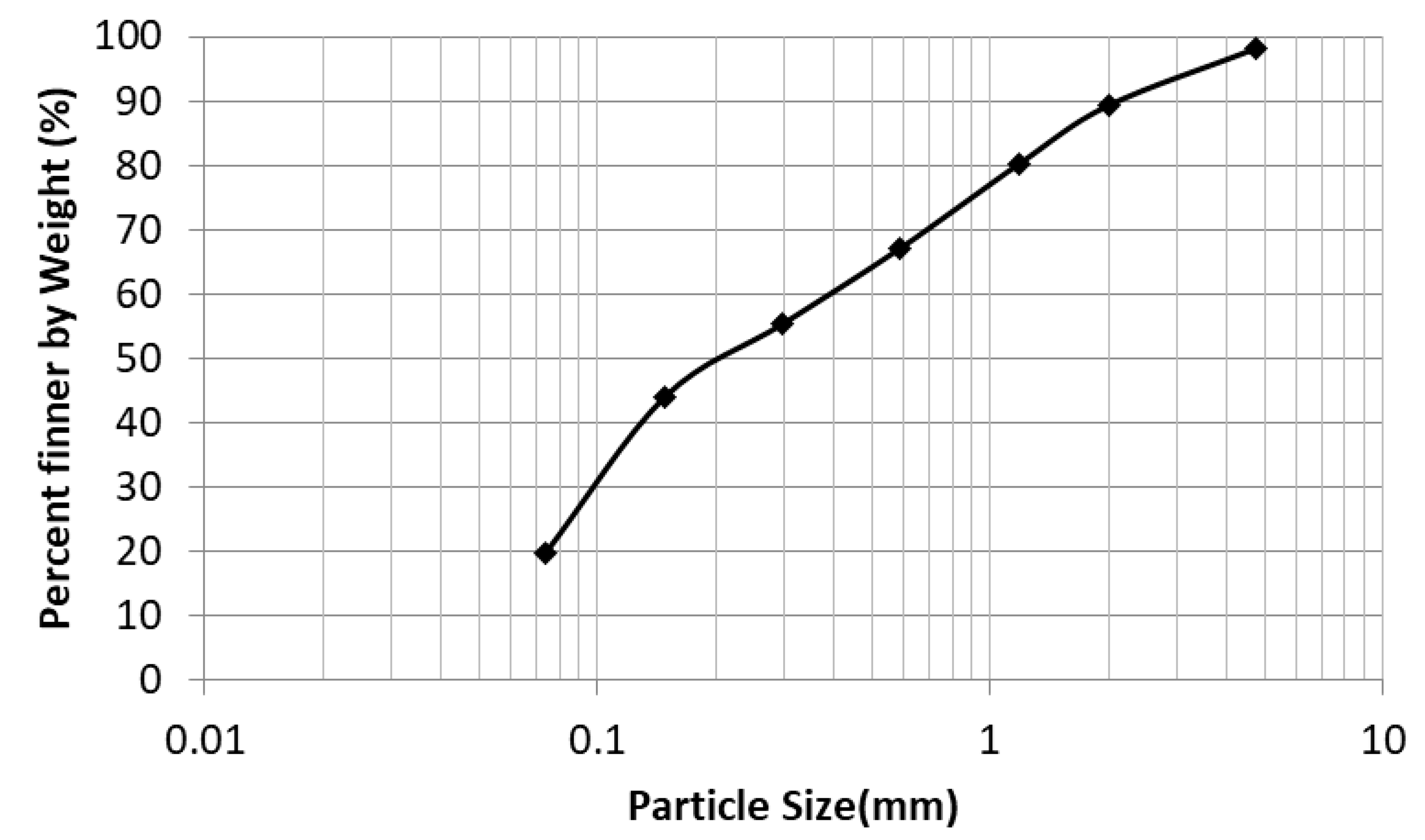

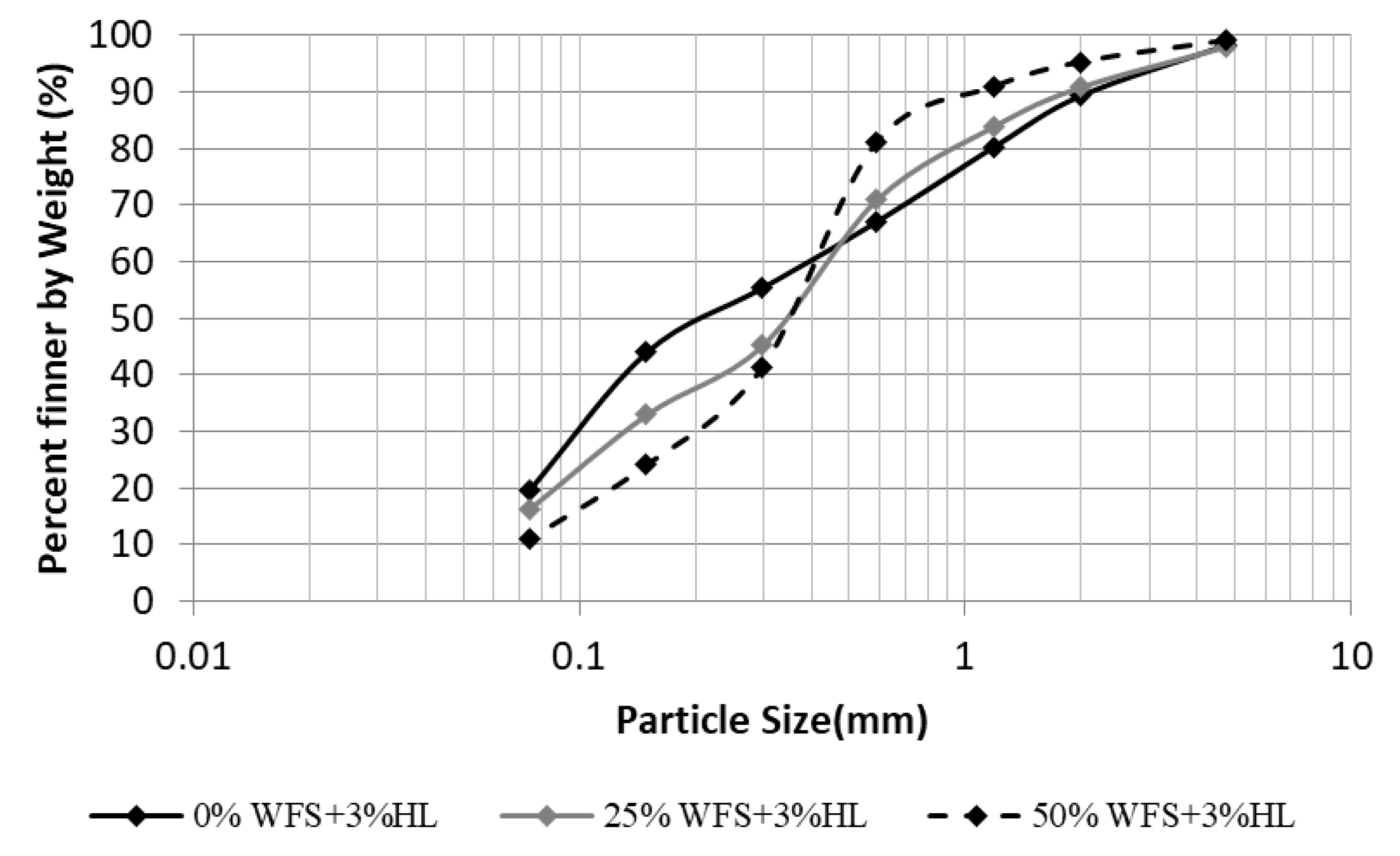

3.1. Characterization

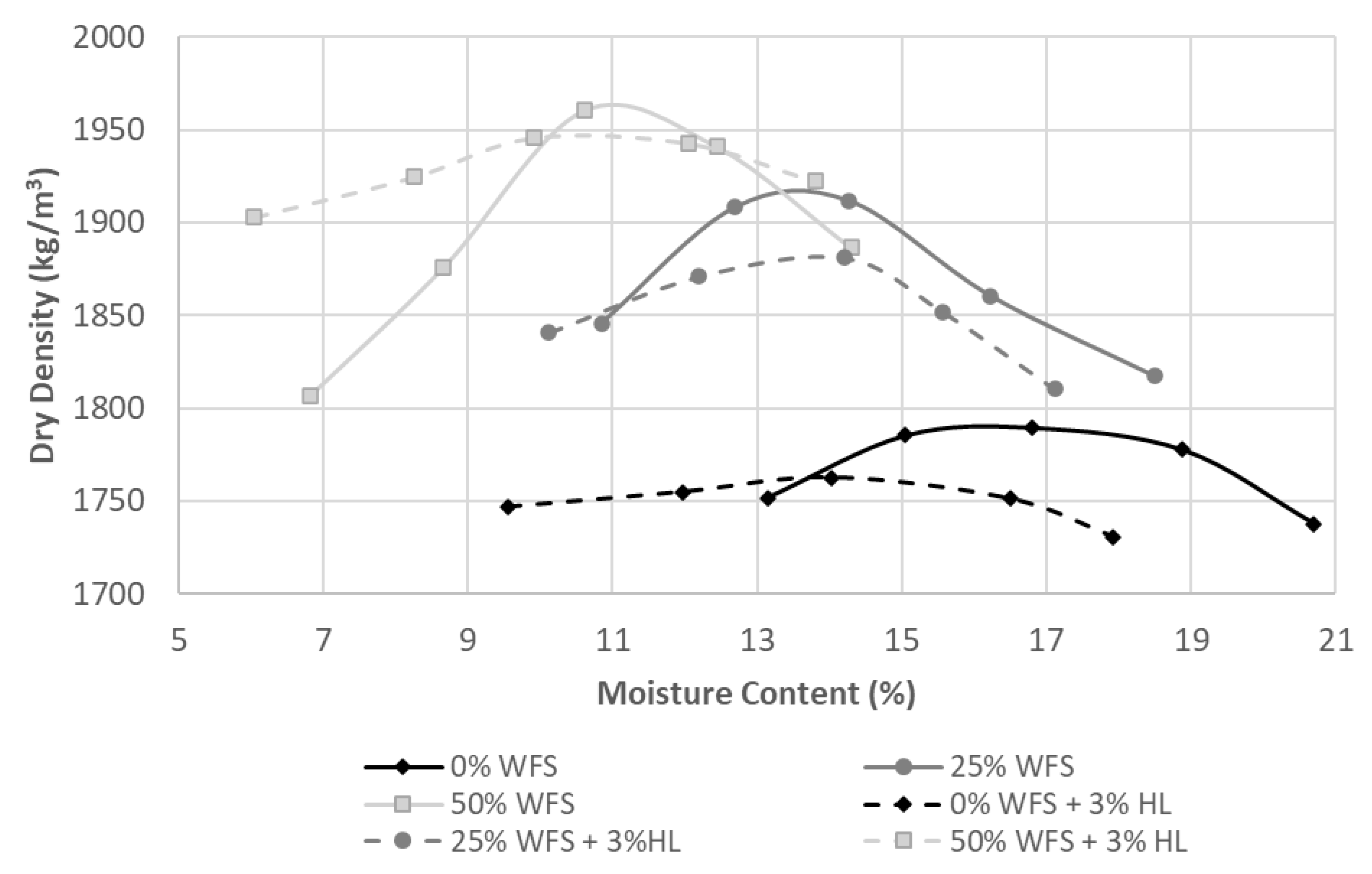

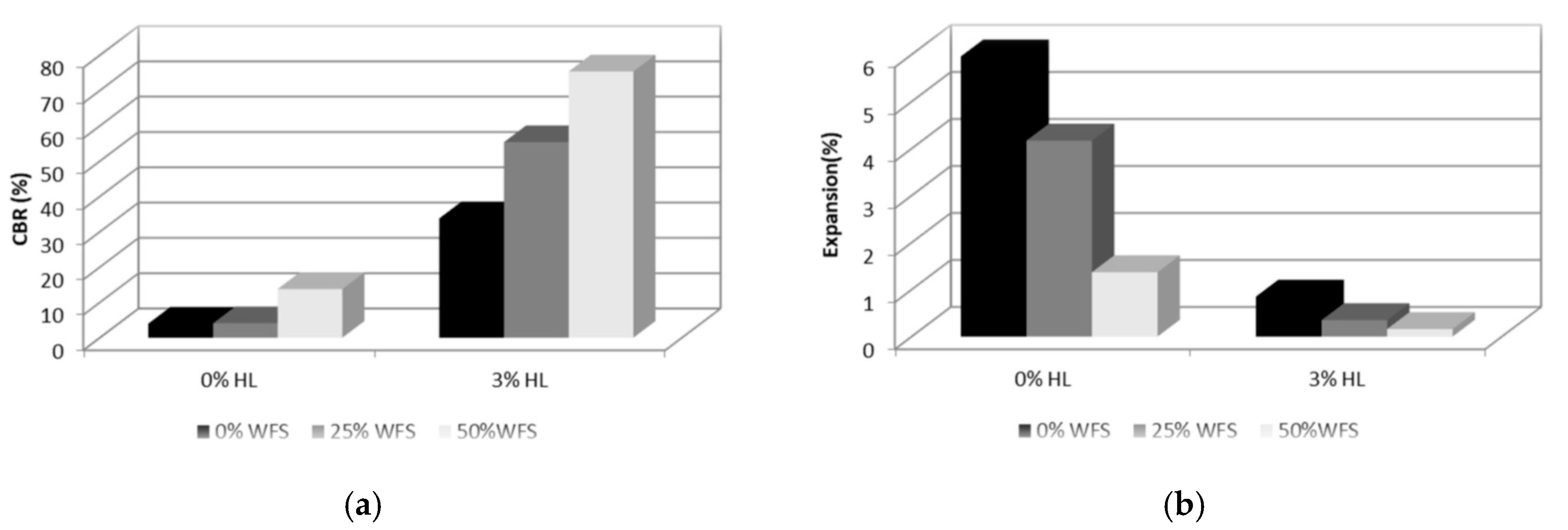

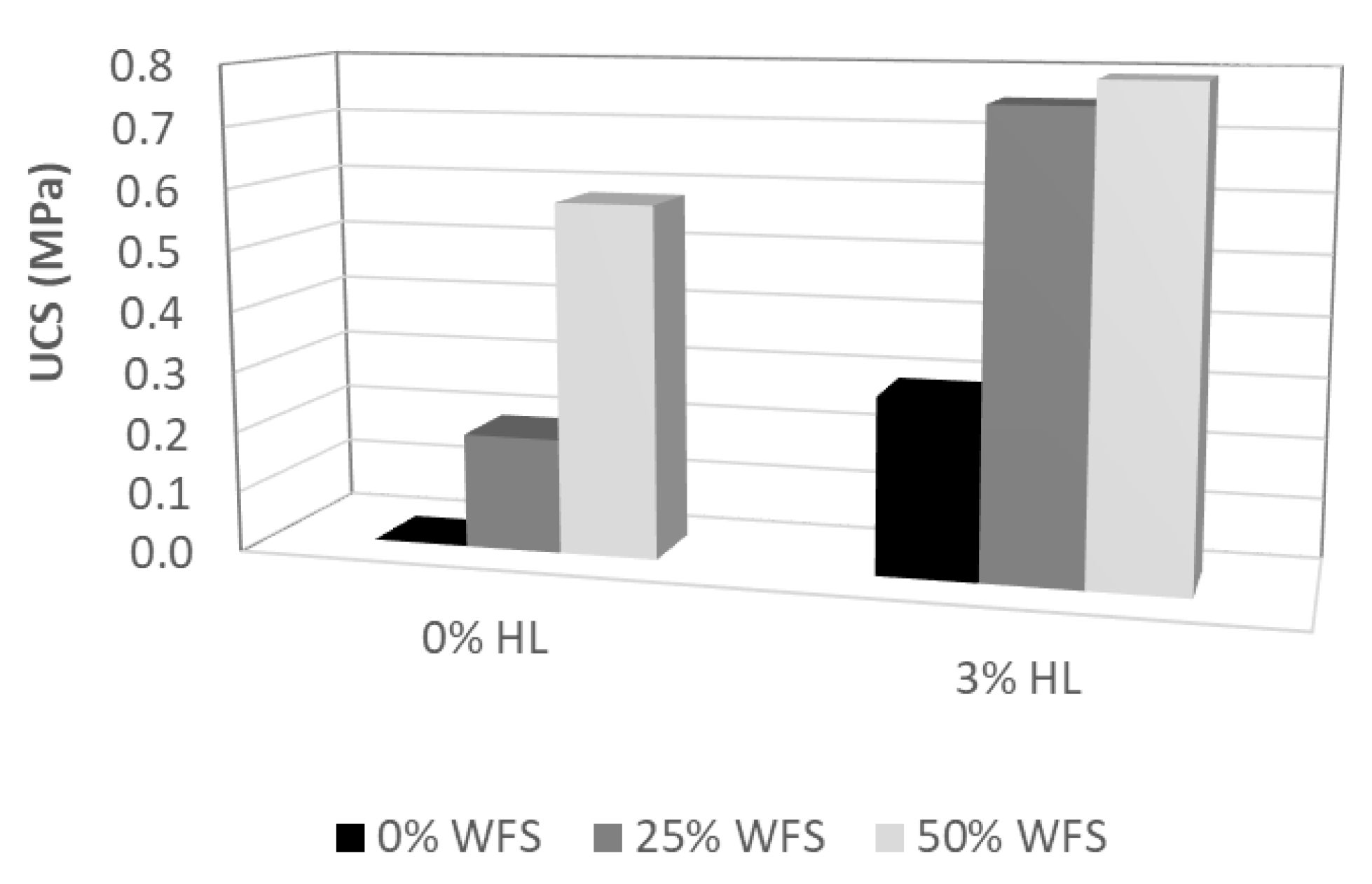

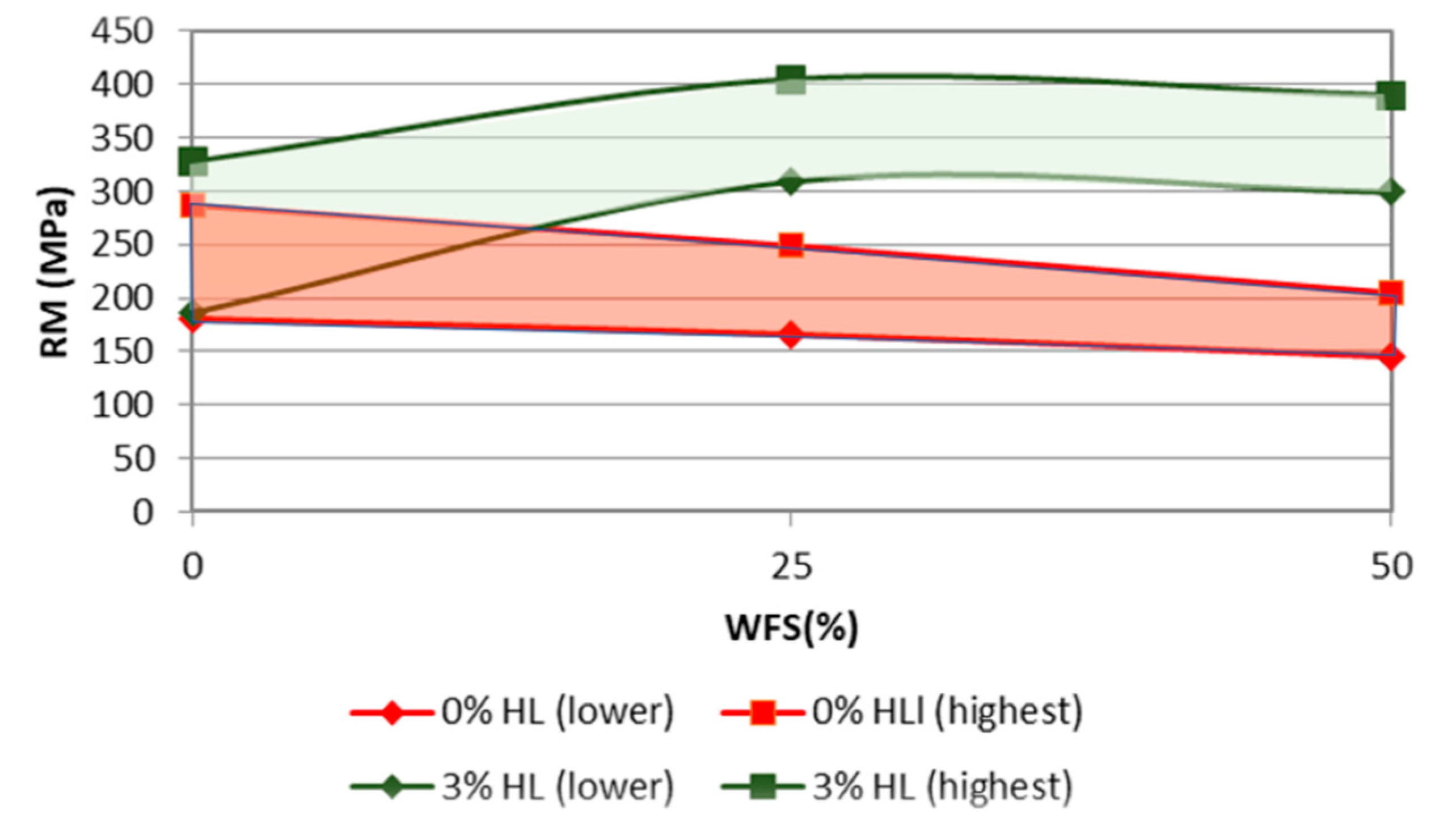

3.2. Mechanical Behavior

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| WFS | waste foundry sand |

| AASHTO | American Association of State Highway and Transportation Officials |

| USCS | Unified Soil Classification System |

| SC | clayed sand |

| OMC | optimum moisture content |

| MDD | maximum dry density |

| CBR | California Bearing Ratio |

| RM | resilient modulus |

| HL | hydrated lime |

| LL | liquid limit |

| PI | plasticity index |

| NLA | National Lime Association |

| UCS | unconfined compression strength |

| TRB | Transportation Research Board |

References

- Gunka, V.; Hidei, V.; Sidun, I.; Demchuk, Y.; Stadnik, V.; Shapoval, P.; Bratychak, M. Wastepaper Sludge Ash and Acid Tar as Activated Filler Aggregates for Stone Mastic Asphalt. Coatings 2023, 13, 1183. [Google Scholar] [CrossRef]

- American Foundry Society—AFS. Foundry Sand Recycling Starts Today. 2011. Available online: https://www.afsinc.org/sustainability-metalcasting (accessed on 2 June 2022).

- American Foundry Society—AFS. Recycling and Beneficial Use of Foundry Byproducts. 2020. Available online: https://www.afsinc.org/all-you-ever-wanted-know-about-foundry-sand (accessed on 12 June 2024).

- ABIFA, Associação Brasileira de Fundição. 2020. Available online: http://www.abifa.com.br (accessed on 12 June 2024).

- Dantas, J.M. Montagem, Comissionamento e Operação de um Sistema de Recuperação de Areia de Fundição: Regenerador Térmico—Plano de Trabalho da Fase II; Instituto de Pesquisas Energéticas e Nucleares: São Paulo, Brazil, 2003. [Google Scholar]

- U.S. Environmental Protection Agency—EPA. Foundry Sands Recycling; EPA: Washington, DC, USA, 2007. [Google Scholar]

- NBR 10004; Resíduos Sólidos, Classificação, Rio de Janeiro. ABNT—Associação Brasileira de Normas Técnicas: São Paulo, Brazil, 2004.

- U.S. Environmental Protection Agency—EPA. Reuse of Foundry Sand: A Review of State Practices and Regulations; EPA: Washington, DC, USA, 2002. Available online: https://archive.epa.gov/sectors/web/pdf/reuse.pdf (accessed on 24 November 2024).

- Goodarzi, F.; Sanei, H. Characterization of trace elements in waste foundry sands. Waste Manag. 2009, 29, 2532–2537. [Google Scholar]

- Klinsky, L.M.G.; Fabbri, G.T.P.; Furlan, A.P. Efeito da adição de areia de fundição e cal em algumas propriedades de solos argilosos. Rev. Transp. 2012, 20, 22–30. [Google Scholar] [CrossRef][Green Version]

- Bonin, A.L.; Rossini, A.J. Reuse of black foundry sand in civil construction. In Proceedings of the 95 Foundry Congress (CONAF) & 95 Foundry Equipment and Supplies Fair (FENAF), São Paulo, Brazil; 1995. [Google Scholar]

- NBR 13896; Aterros de Resíduos Não Perigosos—Critérios Para Projeto, Implantação e Operação. ABNT—Associação Brasileira de Normas Técnicas: São Paulo, Brazil, 1997.

- European Parliament. European Council Directive (EU) 2018/851 of the European Parliament—Waste Framework Directive 2.0 (WFD 2.0). Off. J. Eur. Union 2018, 150, 109–140. [Google Scholar]

- Javed, S.; Lovell, C.W. Uses of Waste Foundry Sands in Civil Engineering. Transp. Res. Board 1995, 1417, 109–116. [Google Scholar]

- Abdulsattar, Z.A. Effect of waste foundry sand on indirect tensile strength of asphalt mixture. J. Eng. Sustain. Dev. 2018, 22, 116–123. [Google Scholar] [CrossRef]

- Naik, T.R.; Patel, V.; Parikh, D.; Tharaniyil, M. Utilization of Used Foundry Sand: Characterization and Product Testing; Report No. CBU-1992-20; University of Wisconsin-Milwaukee: Milwaukee, WI, USA, 1992. [Google Scholar]

- Guney, Y.; Sari, Y.D.; Yalcin, M.; Tuncan, A.; Donmez, S. Re-usage of waste foundry sand in high-strength concrete. Waste Manag. 2010, 30, 1705–1713. [Google Scholar] [CrossRef]

- Deng, A.; Tikalsky, P.J. Experimental study on the utilization of waste foundry sand as embankment and structural fill. Waste Manag. 2008, 28, 2161–2170. [Google Scholar] [CrossRef]

- Kleven, J.; Edil, T.; Benson, C. Evaluation of excess foundry system sands for use as subbase material. Transp. Res. Rec. J. Transp. Res. Board 2000, 1714, 40–48. [Google Scholar] [CrossRef]

- Dyer, P.O.L.; Coppio, G.J.L.; Silva, S.A.; Cividanes, L.S.; Klinsky, L.M.G.; De Lima, M.G. Mechanical and microstructural assessments of waste foundry sand in hot mix asphalt. Constr. Build. Mater. 2021, 311, 125329. [Google Scholar] [CrossRef]

- Mishra, B. A study on characteristics of subgrade soil by use of foundry sand and iron turnings. Int. J. Sci. Res. 2015, 4, 1262–1266. [Google Scholar]

- Yazoghli-Marzouk, O.; Vulcano-Greullet, N.; Cantegrit, L.; Friteyre, L.; Jullien, A. Recycling foundry sand in road construction–field assessment. J. Constr. Build. Mater. 2014, 2014, 69–78. [Google Scholar] [CrossRef]

- Heidemann, M.; Hastenpflug, D. Experimental study on the resilient and permanent deformation of a compacted waste foundry sand. Transp. Geotech. 2024, 48, 101319. [Google Scholar] [CrossRef]

- Yaghoubi, E.; Arul, A.; Yaghoubi, M.; Horpibulsuk, S. Shear strength properties and stress–strain behavior of waste foundry sand. Constr. Build. Mater. 2020, 249, 118761. [Google Scholar] [CrossRef]

- Heidemann, M.; Nierwinski, H.P.; Hastenpflug, D.; Barra, B.S.; Perez, Y.G. Geotechnical behavior of a compacted waste foundry sand. Constr. Build. Mater. 2021, 277, 122267. [Google Scholar] [CrossRef]

- Bhardwaj, A.; Sharma, R.K. Effect of industrial wastes and lime on strength characteristics of clayey soil. J. Eng. Des. Technol. 2020, 18, 1749–1772. [Google Scholar] [CrossRef]

- Pompermaier, C.L.; Ferrazzo, S.T.; Levandoski, W.M.K.; Bruschi, G.J.; Prietto, P.D.M.; Korf, E.P. Stabilization of waste foundry sand with alkali-activated binder: Mechanical behavior, microstructure and leaching. Constr. Build. Mater. 2024, 444, 137772. [Google Scholar] [CrossRef]

- Zhang, Y.; Sappinen, T.; Korkiala-Tanttu, L.; Vilenius, M.; Juuti, E. Investigations into stabilized waste foundry sand for applications in pavement structures. Resour. Conserv. Recycl. 2021, 170, 105585. [Google Scholar] [CrossRef]

- Morais, M.; Levandoski, W.M.K.; Reis, J.B.; Rosa, F.D.; Korf, E.V. Environmental and technical feasibility of a waste foundry sand applied to pavement granular layers. Soil Rocks 2022, 46, e2023001722. [Google Scholar] [CrossRef]

- Naik, P.A.; Marathe, S.; Akhila, S.; Megha Mayuri, B.G. Properties of WFS Incorporated Cement Stabilized Lateritic Soil Subgrades for Rural Pavement Applications. Int. J. Geosynth. Ground Eng. 2023, 9, 38. [Google Scholar] [CrossRef]

- Ham, R.K.; Boyle, W.C.; Kunes, T.P. Leachability of foundry process solid waste. J. Environ. Eng. Div. 1981, 107, 155–170. [Google Scholar] [CrossRef]

- Lovejoy, M.A.; Ham, R.K.; Traeger, P.A.; Wellander, D.; Hippe, J.; Boyle, W.C. Evaluation of selected foundry wastes for use in highway construction. In Proceedings of the 19th International Madison Waste Conference, Madison, WI, USA, 25–26 September 1996; pp. 19–31. [Google Scholar]

- Naik, T.R.; Singh, S.S.; Ramme, B.W. Performance and leaching assessment of flowable slurry. J. Environ. Eng. 2001, 127, 359–368. [Google Scholar] [CrossRef]

- Freber, B. Beneficial reuse of selected foundry waste material. In Proceedings of the 19th International Madison Waste Conference, Madison, WI, USA, 25–26 September 1996; pp. 246–257. [Google Scholar]

- Guney, Y.; Aydilek, A.H.; Demirkan, M.M. Geoenvironmental behavior of foundry sand amended mixtures for highway subbases. Waste Manag. 2006, 26, 932–945. [Google Scholar] [CrossRef] [PubMed]

- Pstrowska, K.; Gunka, V.; Prysiazhnyi, Y.; Demchuk, Y.; Hrynchuk, Y.; Sidun, I.; Kułażyński, M.; Bratychak, M. Obtaining of Formaldehyde Modified Tars and Road Materials on Their Basis. Materials 2022, 15, 5693. [Google Scholar] [CrossRef]

- United Nations. Sustainable Development Goals. 2015. Available online: https://sdgs.un.org/goals (accessed on 12 June 2024).

- Plati, C. Sustainability factors in pavement materials, design, and preservation strategies: A literature review. Constr. Build. Mater. 2019, 211, 539–555. [Google Scholar] [CrossRef]

- AASHTO M 145-91; Classification of Soil-Aggregate Mixtures for Highway Construction Purposes. American Association of State Highways Officials: Washington, DC, USA, 2021.

- Dyer, P.P.O.L.; Klinsky, L.M.G.; Silva, S.A.; de Lima, M.G. Mechanical and structural assessment of hot mix bituminous mixtures containing waste foundry sand. Int. J. Pavement Eng. 2021, 22, 1801–1812. [Google Scholar] [CrossRef]

- Dyer, P.P.O.L.; Klinsky, L.M.G.; Silva, S.A.; Silva, R.A.E.; de Lima, M.G. Macro and microstructural characterization of waste foundry sand reused as aggregate. Road Mater. Pavement Des. 2021, 22, 464–477. [Google Scholar] [CrossRef]

- ASTM D422; Standard Test Method for Particle-Size Analysis of Soils. ASTM: West Conshohocken, PA, USA, 2007.

- ASTM D4318; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM: West Conshohocken, PA, USA, 2018.

- ASTM D2487; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM: West Conshohocken, PA, USA, 2020.

- ASTM D698; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort. ASTM: West Conshohocken, PA, USA, 2021.

- ASTM D1883; Standard Test Method for California Bearing Ratio (CBR) of Laboratory-Compacted Soils. ASTM: West Conshohocken, PA, USA, 2021.

- ASTM D2166; Standard Test Method for Unconfined Compressive Strength of Cohesive Soil. ASTM: West Conshohocken, PA, USA, 2016.

- AASHTO T 307-99; Standard Method of Test for Determining the Resilient Modulus of Soils and Aggregate Materials. American Association of State Highways Officials: Washington, DC, USA, 1999.

- Dunlap, W.S. A Report on a Mathematical Model Describing the Deformation Characteristics of Granular Materials; Technical Report 1, Project 2-8-62-27, TTI; Texas A & M University: College Station, TX, USA, 1963. [Google Scholar]

- Moosazadeh, J.M.; Witczak, W. Prediction of subgrade moduli for soil that exhibits nonlinear behavior. Transp. Res. Rec. 1981, 810, 9–17. [Google Scholar]

- National Cooperative Highway Research Program—NCHRP. Laboratory Determination of Resilient Modulus for Flexible Pavement Design; NCHRP Web Document 14 for Project 1–28; Transportation Research Board: Washington, DC, USA, 1997. [Google Scholar]

- Solanki, P.; Zaman, M.M.; Dean, J. Resilient Modulus of Clay Subgrades Stabilized with Lime, Class C Fly Ash and Cement Kiln Dust for Pavement Design. Transp. Res. Rec. J. Transp. Res. Board 2010, 2186, 101–110. [Google Scholar] [CrossRef]

- Klinsky, L.M.G.; Bardini, V.S.S.; Fabbri, G.T.P. Efeito da adição de areia de fundição residual e cal a solos argilosos no módulo de resiliência. Rev. Transp. 2014, 22, 1–10. [Google Scholar] [CrossRef]

- National Lime Association—NLA. Lime-Treated Soil, Construction Manual. Lime Stabilization and Lime Modification. USA. 2004. Available online: www.lime.org (accessed on 13 February 2009).

- Thompson, M.R. Lime-Reactivity of Illinois Soils. J. Soil Mech. Found. Division. 1966, 92, 67–92. [Google Scholar] [CrossRef]

- Yunus, N.Z.M.; Yung, Y.C.; Wei, N.T.; Abdullah, N.; Mashros, N.; Kadir, M.A.A. Shear strength behaviour of canlite-treated laterite soil. J. Teknol. 2015, 72, 91–97. [Google Scholar] [CrossRef][Green Version]

- Abichou, T.; Edil, T.B.; Benson, C.H.; Bahia, H. Beneficial use of foundry byproducts in highway construction. In Geotechnical Engineering for Transportation Projects; ASCE Press: Reston, VA, USA, 2004; pp. 715–722. [Google Scholar]

- Centro de Pesquisas Rodoviárias—CPR. Estudo do Comportamento Mecânico de Solos Estabilizados com Cal Hidratada; Concessionária NovaDutra s.l.: São José dos Campos, Brazil, 2014. [Google Scholar]

- AFS-FIRST. American Society of Foundry. 2001. Available online: https://www.afsinc.org/afs-first (accessed on 8 July 2024).

- Sharma, R.K.; Gupta, C. Influence of Waste Materials on Geotechnical Characteristics of Expansive Soil. Int. J. Eng. Res. Technol. 2013, 2, 2536–2542. [Google Scholar]

- Behak, L. Soil Stabilization with Rice Husk Ash. In Rice—Technology and Production; IntechOpen: London, UK, 2017; Available online: https://www.intechopen.com/chapters/53281 (accessed on 8 July 2024). [CrossRef]

- Garber, N.J.; Hoel, L.A. Ingeniería de Tránsito y de Carreteras; Thomson: Mexico City, Mexico, 2005. [Google Scholar]

- Spagnoli, G.; Shimobe, S. An overview on the compaction characteristics of soils by laboratory tests. Eng. Geol. 2020, 278, 105830. [Google Scholar] [CrossRef]

- Transportation Research Board—TRB. State of the Art Report 5—Lime Stabilization; Transportation Research Board: Washington, DC, USA, 1987; Available online: https://onlinepubs.trb.org/Onlinepubs/state-of-the-art/5/5.pdf (accessed on 12 June 2024).

- Little, D.N. Evaluation of Structural Properties of Lime Stabilized Soils and Aggregates. In Mixture Design and Testing Protocol for Lime Stabilized Soils; National Lime Association: Arlington, VA, USA, 2000; Volume 3. [Google Scholar]

- American Association of State Highway and Transportation Officials. AASHTO Guide for Mechanistic-Empirical Design of New and Rehabilitated Pavement Structures. 2002. Available online: http://onlinepubs.trb.org (accessed on 12 June 2024).

- Tanyu, B.F.; Kim, W.H.; Edil, T.B.; Benson, C.H. Development of Methodology to Include Structural Contribution of Alternative Working Platforms in Pavement Structure. J. Transp. Res. Board 2005, 1936, 70–77. [Google Scholar] [CrossRef]

| Characteristics | |

|---|---|

| Bulk Density (kg/m3) | 1398 |

| Specific Gravity (g/cm3) | 2.2 |

| Absorption (%) | 1.6 |

| Equivalent Sand (%) | 38 |

| pH | 7.5 |

| Lightweight particles (%) | 2.9 |

| Organic impurity (ppm) | <300 |

| Petrographic analysis | inoculant |

| Sphericity | High |

| Rounding | Rounded |

| Surface | Polished |

| Classification | inert |

| Element Composition | % |

|---|---|

| O | 36.5 |

| C | 15.0 |

| Fe | 19.8 |

| Si | 24.3 |

| Al | 4.1 |

| N | 0.0 |

| Mg | 0.3 |

| Na | 0.0 |

| K | 0.0 |

| Probable Oxides Content | % |

| SiO2 | 51.77 |

| Fe(OH)2 | 31.75 |

| Al2 | 2.1 |

| Al2O3 | 0.0 |

| Na2SiO3 | 0.0 |

| Na2O | 0.0 |

| NO3 | 0.0 |

| MgO | 0.0 |

| Organic impurity | 10.0 |

| Trace elements | 4.38 |

| Liquid Limit | Plastic Limit | Plastic Index |

|---|---|---|

| (%) | (%) | (%) |

| 42 | 17 | 25 |

| Constituents | (%) |

|---|---|

| Calcium Hidroxide [Ca(OH)2] | 85 |

| Magnesium Oxide (MgO) | 5 |

| Carbon Dioxide (CO2) | 5 |

| Silicon Oxide (SiO2) | 1 |

| Property | Result |

|---|---|

| Specific Gravity | 0.5 g/cm3 |

| Accumulated retained #30 (0.60 mm) | ≤0.5% |

| Accumulated retained #200 (0.075 mm | ≤10.00% |

| Model | Name | Equation |

|---|---|---|

| 1 | Model as a function of deviation stress | |

| 2 | Model as a function of confining stress | |

| 3 | Composed model |

| WFS | HL | LL | PL | PI |

|---|---|---|---|---|

| (%) | (%) | (%) | (%) | (%) |

| 0 | 0 | 42 | 17 | 25 |

| 25 | 31 | 23 | 8 | |

| 50 | 21 | NP | NP | |

| 0 | 3 | 42 | 19 | 23 |

| 25 | 30 | 23 | 7 | |

| 50 | 20 | NP | NP |

| WFS (%) | HL (%) | MDD (kg/m3) | OMC (%) |

|---|---|---|---|

| 0 | 0 | 1795 | 16.0 |

| 25 | 1921 | 13.5 | |

| 50 | 1969 | 11.0 | |

| 0 | 3 | 1766 | 15.1 |

| 25 | 1893 | 13.5 | |

| 50 | 1952 | 10.8 |

| Waste Foundry Sand (%) | Hydrated Lime (%) | Cyclic Triaxial Test at OMC | ||

|---|---|---|---|---|

| Min RM (MPa) | Max RM (MPa) | RM (MPa) | ||

| 0 | 0 | 180 | 287 | 216 |

| 25 | 166 | 249 | 149 | |

| 50 | 146 | 205 | 138 | |

| 0 | 3 | 187 | 327 | 178 |

| 25 | 309 | 404 | 316 | |

| 50 | 299 | 389 | 306 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bardini, V.S.d.S.; Klinsky, L.M.; Albuquerque, A.; Andrade Pais, L.; Fiore, F.A. Waste Foundry Sand as an Alternative Material in Road Construction. Sustainability 2025, 17, 2370. https://doi.org/10.3390/su17062370

Bardini VSdS, Klinsky LM, Albuquerque A, Andrade Pais L, Fiore FA. Waste Foundry Sand as an Alternative Material in Road Construction. Sustainability. 2025; 17(6):2370. https://doi.org/10.3390/su17062370

Chicago/Turabian StyleBardini, Vivian Silveira dos Santos, Luis Miguel Klinsky, Antonio Albuquerque, Luís Andrade Pais, and Fabiana Alves Fiore. 2025. "Waste Foundry Sand as an Alternative Material in Road Construction" Sustainability 17, no. 6: 2370. https://doi.org/10.3390/su17062370

APA StyleBardini, V. S. d. S., Klinsky, L. M., Albuquerque, A., Andrade Pais, L., & Fiore, F. A. (2025). Waste Foundry Sand as an Alternative Material in Road Construction. Sustainability, 17(6), 2370. https://doi.org/10.3390/su17062370