Abstract

This study examines the environmental consequences of implementing textile-to-textile recycling at scale in the EU by 2035, as this is viewed as a key solution in the sustainable development of the European textile sector. Three research questions are addressed: (i) How likely is it that increased textile-to-textile recycling reduces climate and water deprivation impacts, (ii) What is the extent of these reductions (if any), and (iii) What are the most influential parameters affecting the results? The method used is a consequential life cycle assessment (LCA), coupled with a Monte Carlo analysis to systematically address uncertainties. Results show a 92% probability that increasing textile-to-textile recycling to 10% in the EU will reduce climate impact and an almost 100% probability that it will lower water deprivation impact. Sensitivity analyses indicate climate-impact reduction probabilities ranging from 62% to 98%, and water deprivation impact reduction probabilities consistently above 99%. While recycling is likely to reduce climate impact, there is a notable risk of an increase. On average, climate impact would be reduced by about 0.5%, and water deprivation impact by slightly more than 3%, relative to the estimated impact of current textile consumption in the EU. These reductions increase if the textile recycling sector focuses on producing fibers with low climate and water impact or high replacement rates are ensured. Still, additional measures beyond recycling are needed to cut the textile industry’s environmental impact substantially.

1. Introduction

Recycling rates for textiles are low compared to many other materials, and existing recycling routes seldom quality-assured textile-to-textile recycling, but various forms of downcycling into industrial wipers or insulation [1,2] (henceforth, “quality-assured” is omitted when referring to “textile-to-textile recycling”, with the understanding that the term does not refer to downcycling into low-grade textile products like industrial wipers or insulation; in addition, the shorter term “textile recycling” is occasionally used.). Also, recycled content in textiles is seldom of textile origin, but from PET bottles, which also is a case of downcycling [2,3]. Textile-to-textile recycling is considered a key solution for reducing textiles’ environmental impact and thereby contributing to sustainable development in the textile sector. For example, it is highlighted in the EU strategy for sustainable and circular textiles [4]. As a result, policies are being implemented and proposed, and investments are being made to boost efforts for increased textile-to-textile recycling [5,6,7,8,9]. For example, EU member states are required to set up separate collections for textiles, with the aim to increase recycling rates [10].

Meanwhile, plenty of research highlights potential pitfalls of circular business models (including recycling) in terms of their environmental viability [11,12,13,14,15]. While research has found that textile recycling may reduce environmental impact compared to not recycling [16,17,18,19], we have identified a specific lack of research on the environmental impact consequences of implementing textile recycling at scale across an entire region, such as the EU, and the associated uncertainties.

We have identified one study [20] on the environmental impacts of large-scale textile recycling in a region larger than a country, which uses a material flow analysis (MFA) to map the textile waste streams in Europe and the associated greenhouse gas emissions. However, it only considers climate impact and lacks a life cycle perspective in the sense that it disregards the effects on reduced primary fiber production or the need to compensate for decreased energy production. Also, it does not systematically map the influence of uncertainties. Another study by Dahlbo et al. [21] is more similar to ours in terms of the methodological approach, as it accounts for the effects of avoiding primary fiber production. However, their study assessed the consequences of a two-fold increase in textile recycling in Finland, and, therefore, has a country-level scope. Also, it does not systematically track and quantify the influence of uncertainties, as in the present study. Nevertheless, the study is compared to our study in the discussion of results in Section 3.

There is a risk that this scarcity of research on the environmental consequences of implementing textile-to-textile recycling at scale in the EU—research based on a life cycle perspective and a systematic consideration of uncertainties—indicates a lack of knowledge. Without sufficient knowledge on the matter, resources may be misdirected toward ineffective solutions, hampering sustainable development in the textile sector.

This study aims to expand the knowledge of potential climate and water deprivation impacts of implementing large-scale textile-to-textile recycling in the EU until 2035. This is achieved by addressing the following research questions:

- How likely is it that implementing textile-to-textile recycling at scale in the EU will reduce climate and water deprivation impacts?

- What is the extent of climate and water deprivation impact reductions (if any) from textile-to-textile recycling at scale in the EU?

- What are the most influential parameters affecting the results?

Specifically, we studied an increase of discarded textiles entering textile-to-textile recycling in the EU, from an estimated 1% today to an assumed 10% in the year 2035.

The 1% estimate of the current rate of textile-to-textile recycling is derived from the Ellen MacArthur Foundation’s global estimate for the rate of textile-to-textile recycling [22]. The fact that the rate is not more than 1% is confirmed by more recent data [3]. Furthermore, a rate of 1%, or below 1%, of textile-to-textile recycling globally is commonly assumed in research, e.g., see [23,24,25].

The 10% scenario for 2035 is conservative compared to available projections, such as one performed by [26], which in two scenarios projects textile-to-textile recycling rates of 18% and 26% by 2030. In an earlier version of the present study [27], we assumed a 26% recycling rate by 2035, i.e., a 25% percentage points increase compared to the estimated current rate. Based on feedback, we opted for a more conservative future scenario in the present article while acknowledging that a 10% rate of textile-to-textile recycling still represents a sharp increase compared to the estimated current rate. Whether such a recycling rate is realistic or feasible for 2035—considering the challenges and limitations of textile recycling, e.g., see [23,25,28,29,30]—is not a question we explore further in this article, as our research questions rather focus on the potential consequences if a 10% recycling rate becomes reality. The study remains applicable even if the rate of recycling would increase with less, or more, than nine percentage points, although the answer to research question two depends on the rate achieved (as is discussed in Section 3).

Furthermore, we assumed the amount of discarded textile in the EU is 6.5 million tonnes and will remain stable until 2035, with increased recycling diverting waste from landfills or incineration. This means we assumed (i) reuse will not decrease (it will likely increase due to EU strategies [4]), and (ii) downcycling will stay at current levels. See the Supplementary Materials (SM) for data and reasoning behind these assumptions.

We used a consequential LCA (CLCA) to address the research questions. This offers a different perspective from most LCA studies of textile recycling, which rely on attributional LCA (ALCA). CLCAs have been used to study changes in solid waste management systems in general [31], but not large-scale changes in textile recycling. By employing CLCA, this research complements and extends previous research.

Since the study assesses the consequences of future changes, it involves inherent uncertainties and relies on various assumptions, e.g., in relation to the environmental impact of affected processes (marginal technologies). These uncertainties and assumptions were systematically explored using Monte Carlo analysis, a method that employs random sampling and statistical modelling to assess the likelihood of different results.

The study is aimed at stakeholders shaping, or participating in, the textile recycling industry, especially in the EU, including policy developers, business leaders, investors, and researchers. These stakeholders were considered when outlining recommendations for actions and further research in Section 4.

2. Method

2.1. Consequential LCA

Various definitions of CLCA exist in the literature [32,33,34]. In brief, a CLCA assesses the impacts of a change, while ALCA assesses a product system “as it is”. Key differences include: (i) system boundaries, where ALCA considers processes physically linked to the product life cycle, from raw material extraction to end-of-life processes, while CLCA considers processes influenced by the change, even beyond the product life cycle; and (ii) ALCA uses average data, while CLCA often uses marginal data.

ALCAs often incorporate elements of consequential modelling, such as scenario analysis (e.g., exploring how results change if a system is modified) or using allocation methods that account for impacts outside the processes directly involved in the product life cycle. Therefore, some view the attributional-consequential distinction as a spectrum, where many LCAs are a blend of both [35].

While this study is primarily a CLCA, it includes some attributional elements, such as the use of average data in certain instances to estimate the climate impacts of affected processes (see justification in the Supplementary Materials).

2.2. Functional Unit and System Boundaries

We defined the functional unit as an increase in the discarded textiles entering textile-to-textile in the EU, from 1% to 10% by 2035. This increase corresponds to a reference flow of 585,000 tonnes of textiles entering textile-to-textile recycling.

This increase in textiles entering recycling is thus the change studied in the CLCA. We identified five key processes affected by this change that contribute to environmental impact. As such, these are the processes within the system boundaries of the study. In the following, we list these processes and how they are assumed to be affected:

- Increased collection and sorting for recycling;

- Increased recycling;

- Reduced incineration and landfilling;

- Reduced primary fiber production;

- Compensation for the loss of recovered energy.

Section 2.3 outlines these five changes and details how we modelled the associated consequences on environmental impact.

Other potential downstream consequences on textile manufacturing were assumed to have negligible influence on the studied impact categories and were thus excluded from the system boundaries. An example of a potential such consequence is changed dyeing processes due to increased mechanical recycling, e.g., see [36]. As we assumed the increase in textile recycling is primarily due to increased chemical recycling (as explained below), we assumed the relevance of this consequence to be low compared to the five consequences listed above. However, in studies of specific textile value chains that employ a certain recycling technology, it may be important to account for downstream consequences on textile manufacturing.

2.3. Assessing the Consequences

The consequences on climate impact (CI) and water deprivation impact (WDI) of each of the five changes were combined to estimate the total consequences, as detailed in the following equations:

The following subsections detail each change and its associated consequences, corresponding to the components of the equations above. In these descriptions, tonnes refer to tonnes of textiles, except if indicated otherwise. Climate impact has been assessed using the Global Warming Potential method with a 100-year perspective (GWP100), with results given in tonnes CO2 equivalents (eq.). The impact of water deprivation has been assessed using the AWARE method [37], with results given in cubic meters (m3) of world eq.

Some parameters in the equations have fixed values, while others are represented as probability distributions, with specific values randomized in the Monte Carlo analysis (see Section 2.4). The fixed values, probability distributions, and supporting references and assumptions are outlined in the Supplementary Materials.

2.3.1. Increased Collection and Sorting for Recycling

An increase of nine percentage points of discarded textiles entering textile-to-textile recycling will require substantially more collection and sorting of textiles. While some sorting may occur outside the EU, we simplified our calculations by assuming that all sorting take place in the EU. The environmental impact of increased collection and sorting arises mainly from transportation associated with collection and energy used at sorting facilities.

The impacts of this additional collection and sorting are expressed in the following equations:

2.3.2. Increased Recycling

Once sorted, textiles enter recycling. This may involve mechanical processes that use energy to shred fabrics, preserving fibers for new yarn or nonwoven production. Alternatively, more advanced chemical recycling disassembles the fibers using chemicals and energy before generating new fibers [24]. We assumed that the increase in recycling is made possible by a mix of recycling technologies, with an estimated 80–90% being chemical recycling (see reasoning in the Supplementary Materials). Furthermore, when assessing the impact of recycling processes, we assumed that “recycling processes” here include all the transports from sorting to recycling as well as processes up to the production of fibers, which enabled us to integrate the impacts of mechanical recycling (which preserves fibers) and chemical recycling (which does not preserve fibers) in the same equations. For the research questions addressed, we did not have to define the recycling technologies in more detail; the uncertainties of which specific recycling technologies could enable a nine-percentage points increase in textiles entering recycling are assumed to be reflected in the uncertainty distributions of the climate and water deprivation impacts of recycling processes (see more in the Supplementary Materials).

Recycling processes were assumed to take place either within the EU or outside, more specifically in Asia.

The impacts of additional recycling processes are expressed in the following equations:

where:

and

where:

and

2.3.3. Reduced Incineration and Landfilling

Another consequence of more recycling is a reduction in the incineration and landfilling of textiles. While many recycled textiles will ultimately be incinerated or landfilled, if they replace primary fibers, incineration and landfilling of textiles will still experience a net reduction (hence the calculation of this consequence accounts for the replacement rate). The environmental impact avoided by reduced incineration is, for example, because of the CO2 emissions from burning fossil-based textiles like polyester.

As a simplification, we assumed the that reduced incineration includes energy recovery—incineration without energy recovery is unusual in the EU [38]—while reduced landfilling does not (as this would be a negligible contribution compared to the energy recovered from incineration). Additionally, we assumed the locations of reduced incineration and landfilling processes to be irrelevant, as their climate impact primarily depends on the proportion of fossil-based fibers, and their water deprivation impact is negligible (see Section 3).

The impacts of reduced incineration and landfilling are expressed in the following equations:

where:

and

where:

and

2.3.4. Reduced Primary Fiber Production

Increased textile recycling also leads to a decrease in primary fiber production. The scale of this reduction relies on the replacement rate, with a 100% rate meaning that recycled fibers fully substitute the same quantity of primary fibers. Factors such as fiber quality and price elasticity of fiber demand influence the replacement rate. We assumed the reduced fiber production occurs in Asia, where most fibers supplied to the European market are currently produced [8].

The impact of reduced fiber production is expressed in the following equations:

2.3.5. Compensation for the Decrease in Recovered Energy

The fifth change associated with increased textile-to-textile recycling relates to one of the previously listed changes: a reduction in incineration with energy recovery leads to less energy production. Assuming steady energy demand, this will necessitate more energy production elsewhere.

The impacts of compensating for the lost recovered energy from reduced incineration are expressed in the following equations (where CHP refers to combined heat and power):

2.4. Monte Carlo Analysis

The equations above incorporate uncertain parameters, which were randomized in the Monte Carlo analysis (see Table 1).

Table 1.

Parameters randomized in the Monte Carlo analysis and their assumed mean values.

A Monte Carlo analysis relies on an assumption that each randomized parameter is independent and does not correlate with any of the other parameters. In the present study, this may not be entirely true, which is listed as a limitation of the study (see Section 2.5) and an area that can be further explored in future research (see Section 3.3). In particular, it is uncertain whether parameters A and B are completely independent, which, therefore, is discussed in relation to the results in Section 3.2.1.

A normal distribution was assumed for each parameter to represent the probability of obtaining specific values. A random number generator in Microsoft Excel was used to create 50,000 random samples from each of these distributions, which were combined in the equation to produce 50,000 sets of results.

In the absence of data on uncertainties, we considered normal distributions to be a the most plausible choice (e.g., uniform distributions were deemed less plausible for all studied parameters). The Supplementary Materials details the parameters and their normal distribution, including sources and rationales for estimating the means and standard deviations. The estimated means are presented in Table 1. Note that parameters A and B are not used in the calculations for water deprivation consequences.

2.5. Summary of Main Assumptions

The assumptions outlined above and in the Supplementary Materials are summarized in the following, together with reasonings of how we expect them to influence the study’s conclusions.

- The five consequences of implementing large-scale textile-to-textile recycling in the EU, as outlined in Section 2.3, were assumed to be environmentally important consequences. We do not anticipate any other consequences that would substantially change the study’s conclusions.

- The volume of discarded textiles in the EU was assumed to remain constant until 2035. We do not anticipate a change in volume to affect any conclusions on the likelihood of reduced impact (research question 1) or parameters influencing this likelihood (research question 3). However, if the volume increases (for example), a nine percentage points increase in discarded textiles entering recycling translates to a higher increase in absolute numbers, thus influencing the magnitude of impact reductions (research question 2).

- It was assumed that the increased volume of discarded textiles entering textile-to-textile recycling would come from items that would otherwise have been sent to landfills or incineration, meaning reuse and downcycling levels are expected to remain steady. If substantial quantities of textiles were diverted from reuse or downcycling, it could result in different consequences than those presented in this study.

- When discarded textiles are redirected from incineration with energy recovery to recycling, we assumed that all energy recovery losses will be compensated. This is a simplification of reality, as a reduced energy supply could increase energy prices, leading to lower demand and uncompensated energy losses. The simplification is expected to have a minimal effect on the results since the impact from compensating lost recovered energy is comparatively low (see Section 3.1).

- We assumed that fiber production and recycling processes outside of Europe take place in Asia. The potential differences between climate and water deprivation impacts of processes in Asia and elsewhere outside Europe were assumed to be adequately accounted for by the assumed uncertainty distributions of the associated parameters (impacts of recycling processes and primary fiber production as well as the decarbonization rates).

- The following assumptions are related to the parameters randomized in the Monte Carlo analysis as outlined in Section 2.4:

- ○

- The parameters’ uncertainties follow normal distributions.

- ○

- The parameters are independent of one another. This might not be fully accurate for the decarbonization rates of the EU and Asia (parameters A and B), as is further discussed in Section 3.2.1.

- ○

- The parameters possess the means outlined in Table S1 and the standard deviations outlined in the Supplementary Materials. A sensitivity analysis exploring other means is presented in Section 3.2.

3. Results and Discussion

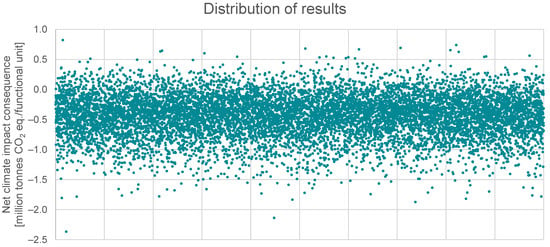

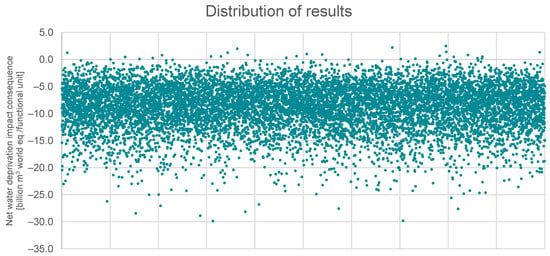

Figure 1 and Figure 2 present the results of the 50,000 Monte Carlo simulations. Negative values indicate reduced impacts due to the nine percentage points rise in discarded textiles entering textile-to-textile recycling by 2035, while positive values indicate increased impacts.

Figure 1.

Climate impact results of 50,000 Monte Carlo simulations.

Figure 2.

Water deprivation results of 50,000 Monte Carlo simulations.

For climate impact, results range from approximately −2.8 to +0.9 million tonnes CO2 eq., with a mean of −0.45 million tonnes CO2 eq. About 92% of the results are below zero, meaning it is more likely that implementing textile-to-textile recycling at scale will reduce rather than increase climate impact. However, the risk for an increase is notable, about 8%.

For water deprivation, results range from approximately −32 billion to +5.0 billion m3 world eq., with a mean of minus 8.8 billion m3 world eq. The probability of reduced water deprivation impact is almost 100%, with a 0.24% risk of an increase.

The above numbers could not be validated by comparing with other research, as we have not found any studies using a sufficiently similar method and scope to enable comparisons (see discussion in Section 1). Amicarelli and Bux (2022) studied a scenario with high separate collection rates in Europe, including a substantially increased textile recycling rate, and found it to have about 0.4 million tonnes CO2 eq. lower climate impact compared to a baseline scenario [20]. This is notably close to our mean estimate of reduced climate impact (0.45 million tonnes CO2 eq.), but we deem this to be a mere coincidence as they have assumed a much higher recycling rate (but it seems this includes downcycling) and narrower system boundaries, for example not including the effect of reduced primary fiber production.

Strategies to minimize the risk of increased impact and maximize the potential reductions are discussed in later sections.

Since the 2035 scenario represents 585,000 tonnes of textiles entering textile-to-textile recycling, a mean reduction of 0.44 million tonnes CO2 eq. translates to about 0.75 kg CO2 eq. per kg of textiles entering textile-to-textile recycling. To interpret this figure, we relate it to the total climate impact of textile products bought in the EU, encompassing emissions from production, use, and end-of-life management.

Peters et al. estimate that the global apparel and footwear sectors caused emissions corresponding to approximately 1.3 billion tonnes CO2 eq. in 2015, about 2.4% of global greenhouse gas emissions [39]. They conclude that this is in the range of other estimates: 0.3–4 billion tonnes CO2 eq. Another study found that the climate impact of clothing consumption is about 3% of the consumption-based climate impact of Swedes, which corresponds to about 330 kg CO2 eq. per capita annually [40].

With the EU’s annual consumption-based climate impact at 7 tonnes CO2 eq. per capita [41] and a population of 448.4 million [42], the total climate impact is approximately 3.2 billion tonnes CO2 eq. Assuming textiles account for 3% of this (based on the previous paragraph, and the facts that (textiles is a broader category than clothing, e.g., including home textiles and technical textiles, and that clothing consumption is Sweden can be assumed to be relatively high due to the cold climate and distinct seasons), the EU’s textile-related climate impact is about 94 million tonnes CO2 eq. Then, a mean reduction of 0.44 million tonnes of CO2 eq. due to increased textile recycling, represents a 0.5% decrease in the climate impact of textile products bought in the EU. If we instead would assume textiles account for 4% of EU’s consumption-based climate impact, the contribution from the studied increase in textile recycling would be 0.35%.

Sandin et al. estimated that the water deprivation impact of annual clothing consumption in Sweden is about 610 m3 world eq. per capita [40]. Applying this figure for all textile products in the EU results in a water deprivation impact of about 270 billion m3 world eq. for textile product consumption in the EU. The estimated mean reduction of 8.8 billion m3 world eq. annually then represents a 3.3% decrease in the water deprivation impact of textile products bought in the EU. To assume the number covers all textiles is an underestimating of the impact. On the other hand, the proportion of fossil fibers is expected to increase while the proportion of cotton decreases (see reasoning in the Supplementary Materials), which would reduce water deprivation impacts. Our estimate is that these two effects roughly neutralize each other.

The findings suggest that the climate and water deprivation benefits of substantially increased textile recycling in the EU are small compared to the reductions needed for the textile industry’s overall carbon and water footprints. This highlights the need for additional actions to address the climate and water footprints of textile products, which aligns with previous research [18,40,43]. However, textile-to-textile recycling could play a larger role in reducing the industry’s environmental footprint than what is indicated in this and previous research, if the textile recycling sector focusses on producing high-quality fibers (that facilitates achieving high replacement rates) with relatively low climate impact, e.g., by energy-efficient processes powered by renewable or nuclear energy. These opportunities for achieving greater benefits of textile recycling are supported by the results and discussion in the below subsections.

It is worth mentioning that our estimated mean reductions scale linearly with recycling rates (see equations in Section 2.3.1–Section 2.3.5). If the increase in recycling rate doubles compared to our scenario, to a rate of 19% in 2035, the estimated reductions would double to about 1% and 6.6% of the annual climate and water deprivation impacts of textile products, respectively. Similarly, with a 50% lower increase (i.e., a rate of 5.5%), the reductions would decrease by 50%.

3.1. Contribution Analysis

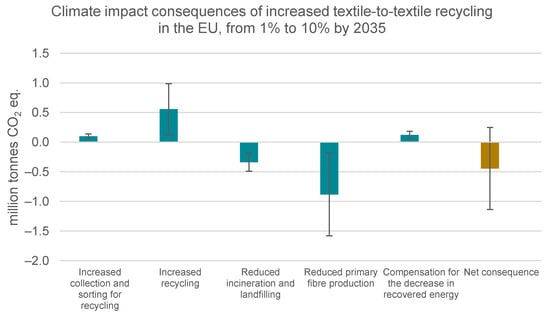

3.1.1. Climate Impact

Figure 3 presents the mean climate impact of each consequence and the mean net climate impact of all consequences. The error bars represent two standard deviations from the mean, covering 95% of Monte Carlo simulation outcomes. For climate impact, the most important consequences of substantially more textile-to-textile recycling in the EU appear to be the increase in recycling processes and the reduction in primary fiber production, with reduced incineration and landfilling also being relatively important (particularly reduced incineration). Increased collection and sorting have a minor impact, as does the additional energy production that compensates for the decrease in recovered energy. Notably, we have assumed that increased collection does not lead to an increase in household transport. If it would, the collection’s contribution could become more important, as previous studies [18,40,44] show that household transport, especially by cars, is a key factor in the life-cycle impact of textile products.

Figure 3.

Contribution of each consequence to the mean net climate-impact result. The error bars represent two standard deviations from the mean.

We compare the findings in Figure 3 with those of Dahlbo et al. [21], who studied the climate-impact consequences of increased collection for reuse and recycling, respectively, in Finland [21]. They have a different methodological approach and other system boundaries, but their results confirm our finding that it is the reduced primary fiber production (“avoided virgin textile production” in their terms) that has the greatest influence on the climate-impact consequences of increased recycling, and that there is a non-negligible contribution from recycling processes (they assumed 90% chemical recycling). Noteworthy, they assumed a 100% replacement rate in the base case, but an alternative case with a 50% replacement rate still translates to a net benefit of recycling. This rate is one of the parameters we randomized in the Monte Carlo analysis, with the mean assumed to be 75%. However, with the alternative means tested in the sensitivity analysis, we concluded that the mean replacement rate must be at least 44% for textile-to-textile recycling to be more likely to reduce rather than increase climate impact (see Section 3.2.1). This means that if we had assumed a mean replacement rate of 50%, our results would not have contradicted Dahlbo and colleagues’ conclusion. However, by adding a Monte Carlo analysis to the CLCA, we have also been able to demonstrate a notable risk of increased climate impact due to implementing large-scale textile recycling, also with a replacement rate of 50% or higher.

Due to the lack of further CLCAs on textile recycling, we compared our results with CLCAs of recycling of other materials, which confirms that the additional recycling processes and the reduced (or avoided) primary production often contribute most to the results; for example, see [45] for a study on waste paper and [46] for a study on metallurgic slag.

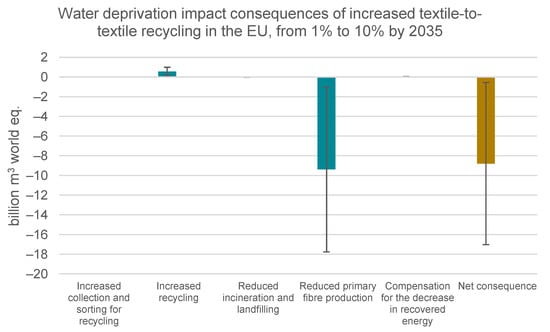

3.1.2. Water Deprivation

Figure 4 presents the mean water deprivation results of each consequence and the mean net water deprivation impact of all consequences. Again, 95% of the Monte Carlo simulation outcomes are within the error bars. For water deprivation, the most important consequence of more textile-to-textile recycling appears to be reduced primary fiber production. Other consequences seem to be relatively unimportant. These findings are expected given the high water use in fiber production, particularly for natural fibers like cotton, compared to the water use in recycling, collection, sorting, and textile waste management.

Figure 4.

Contribution of each consequence to the mean net water deprivation result. The error bars represent two standard deviations from the mean.

In contrast to the results of the climate impact, it has not been possible to compare these results to those of other studies on textile recycling, as the identified relevant studies neither cover water deprivation nor any related indicator (e.g., freshwater use). However, a CLCA on recycling of metallurgic slag [46] shows that reduced primary production is very important for the water deprivation results, although this is highly dependent on the type of production assumed to be reduced.

3.2. Sensitivity Analysis

We conducted two sensitivity analyses to test how sensitive the results are to small changes in the assumed means of all parameters (A–J), as well as for larger changes in some of the assumed means. The results for climate impact and water deprivation are presented separately.

3.2.1. Climate Impact

Table 2 presents the climate impact results under alternative assumptions for the means of parameters A–J. The blue columns show how results change when the assumed mean values are half a standard deviation higher, while the yellow columns show changes when they are half a standard deviation lower.

Table 2.

Sensitivity analysis on the influence of the means of parameters A–J on climate impact results.

The outcomes in Table 2 reveal that the probability of increased climate impact, due to the studied increase in recycling, falls within a range of 6.0% to 12%, compared to 8% in the baseline scenario. The estimated reduction varies from 340,000 to 560,000 tonnes CO2 eq. (baseline scenario: 440,000 tonnes CO2 eq.). Since these intervals come from adjusting a single parameter by half of a standard deviation, the analysis underscores the strong sensitivity of the Monte Carlo results to parameter assumptions. Particularly influential parameters include the EU energy system decarbonization rate, the replacement rate, and the climate impacts of reduced fiber production and recycling processes.

Certain elements of specific recycling systems are linked to the randomized parameters (A–J). For instance, the energy source used in a recycling process is linked to parameters A and B (the decarbonization rate of energy systems in the region where the process takes place) and has an influence on parameters I and J (the climate impact of recycling processes). Since these parameters greatly affect the results, the energy source used in recycling becomes critical in designing future recycling systems. This applies to energy used at recycling facilities as well as in transports for collecting discarded textiles.

Table 3 presents the results of our next sensitivity analysis, testing substantially changed assumptions for the means of a selection of the more uncertain parameters. These parameters are heavily influenced by future policy and investments and/or their assumed means, and standard deviations are supported by limited or unreliable data.

Table 3.

Sensitivity analysis on the influence of larger changes in the means of selected parameters on climate impact results.

For the decarbonization and replacement rates, substantially lower and higher means were tested. A higher mean for the decarbonization rate reflects more effective climate-impact mitigation efforts than currently expected or represents a scenario projected further into the future. A lower mean reflects slower progress toward reducing impact.

A higher mean is tested for parameter C, which represents a scenario where future recycling facilities are located closer to current textile production plants, even if the feedstock originates in the EU. A higher mean was also tested for parameter D, representing a scenario where fossil fibers continue to grow in importance and/or the EU market in 2035 aligns more closely with the global market, which has a higher proportion of fossil fibers [47].

Table 3 shows that increased decarbonization of the EU’s energy systems (parameter A) increases the probability of large-scale textile recycling reducing climate impact, while lower decarbonization reduces the probability. The reverse effect is observed for the Asian decarbonization (parameter B). However, there is probably a degree of correlation between these parameters; if decarbonization progresses quicker in the EU due to technological advancements, similar progress may occur in Asia. This connection implies that the net effect of a substantially lower or higher decarbonization rate will likely be smaller than shown here. Importantly, across all tested decarbonization rates, climate-impact reduction remains the most likely outcome. Furthermore, the fact that two parameters randomized in the Monte Carlo analysis may not be fully independent constitutes a potential limitation of the study (recognized in Section 2.5) that is worthy of further analysis in future studies (see discussion in Section 3.3).

Additionally, the proportion of recycling taking place outside the EU (parameter C) substantially influences outcomes. However, with a larger proportion (70%) taking place in Asia, where energy used generally has a higher climate impact than in the EU, implementing textile-to-textile recycling at scale is still expected to reduce climate impact.

The proportion of fossil fibers among recycled fibers (parameter D) also substantially influence the results. The higher the proportion of fossil fibers being recycled, the higher the probability that textile recycling at scale will reduce climate impact due to avoiding CO2 emissions from burning fossil fibers.

Large adjustments of the replacement rate (parameter H) greatly affect the results as well. A replacement rate as high as 95% makes it highly likely (97.5%) that implementing textile recycling at scale will reduce climate impact. With a low replacement rate of 50%, this probability drops to 62%. Assuming an extremely low replacement rate of 0%—meaning recycled textile fibers merely expand the market of textile fibers—it is guaranteed (100%) that recycling will increase climate impact. Our model indicates that a replacement rate of at least 44% is required for textile-to-textile at scale in the EU to more likely lead to a decrease rather than a rise in climate impact, assuming other parameters do not change. This stresses the critical need for a high replacement rate by producing high-quality fibers from recycled feedstock and implementing policies that not only encourage recycling but phase out primary fiber production (e.g., through taxes on extraction of virgin resources). Without such measures, the expanding fiber market may outweigh the benefits of increased textile-to-textile recycling. As a low replacement rate implies significant rebound effects, the criticality of the replacement rate for our results reflects the criticality of rebound effects, identified by others, for the environmental viability of circular business models [11,14,22] and raw material efficiency [48].

Substantially different assumptions on several parameters could create a scenario in which implementing textile-to-textile recycling at scale in the EU is more likely to cause a rise in climate impact rather than a decrease. For instance, with a mean replacement rate of 50% and a mean proportion of recycling taking place in Asia of 70%, there is a 63% risk that climate impact will rise, with an estimated mean of 110,000 tonnes CO2 eq. per year, assuming other parameters stay the same as in the baseline scenario. This stresses the need to monitor and manage these key parameters when developing future textile recycling systems in the EU.

3.2.2. Water Deprivation

Table 4 shows the water deprivation impact results assuming alternative means for parameters C–J. The blue columns show how results change when the assumed mean values are half a standard deviation higher, while the yellow columns show changes when they are half a standard deviation lower.

Table 4.

Sensitivity analysis on the influence of the mean of each parameter C-J on water deprivation results.

The outcomes in Table 4 show a probability range of 0.21% to 0.30% for textile recycling at scale to reduce water deprivation impact, compared to 0.24% in the baseline scenario. The mean reduction spans from 7.3 to 10 billion m3 world eq. (baseline scenario: 5.1 billion m3 world eq.). This sensitivity analysis reaffirms that increased textile-to-textile recycling in the EU is highly likely to reduce the impact of water deprivation. Moreover, it highlights the water deprivation impact of the reduced fiber production (parameter D2) as one of the most important parameters for the results.

Table 5 presents the results of the second sensitivity analysis for water deprivation impact, which tests substantially different assumptions for the means of certain parameters. These parameters are influential as well as uncertain, as they are heavily affected by future policy decisions and investments, and there were limited or unreliable data to support the assumptions of their mean values.

Table 5.

Sensitivity analysis on the influence of larger changes in means of selected parameters on water deprivation results.

For the water deprivation impact of reduced fiber production (parameter D2), the sensitivity analysis tests a mean that is one-third of the baseline scenario. This represents a scenario where fibers associated with high water deprivation impact, particularly cotton, are less likely to be replaced by recycled fibers than other fibers, such as polyester or man-made cellulose fibers. This could occur if polyester recycling expands faster than other types of recycling, as could happen if a company such as Syre succeeds in its polyester recycling goals and captures a substantial percentage of the global textile recycling market [49]. Defining a process affected by a change (the marginal technology) and its environmental impact is a critical assumption in CLCA [31] that is particularly difficult to make and uncertain when the affected processes occur (or are avoided) more than 10 years into the future. Therefore, the above sensitivity analysis of the WDI of primary fiber production replaced in 2035 is a way to capture that uncertainty as well.

For the replacement rate (parameter H), we tested both substantially lower and higher means, as we did for climate impact. A higher mean could be achieved through policies aimed at phasing out primary fiber production, while a lower could occur if primary fiber production continues to expand alongside textile recycling due to a lack of policy or industry-driven efforts to phase out primary fiber production.

Lastly, we tested substantially lower water deprivation impact from textile recycling processes: half of the mean of the baseline scenario. This represents (i) the possibility that the limited data we based the baseline scenario on are not representative of textile recycling processes in general, or (ii) a future scenario where mechanical recycling, which uses less water than chemical recycling, constitutes a larger percentage of textile recycling than assumed in the baseline scenario.

Table 5 reveals that a replacement rate as high as 95% makes it even more certain (99.8%) that textile recycling at scale will reduce water deprivation impact. Even with a substantially lower replacement rate (50%), the likelihood remains very high (99.6%). The replacement rate needs to be as low as 4–5% for textile-to-textile recycling at scale to be more likely to reduce rather than increase water deprivation impact, assuming other parameters remain as in the baseline scenario. While ensuring a high replacement rate is important for maximizing the water deprivation benefits of textile recycling, this factor is less critical than it is for the climate-impact results.

Table 5 also shows that a substantially lower mean of the impact of reduced fiber production (parameter D2) greatly influences the estimated net water deprivation impact, but there is still a more than 99% chance of textile recycling reducing water deprivation impact.

3.3. Limitations and Research Needs

We identified three main areas of limitations of the study, which translate to needs for further studies and data on the environmental viability of large-scale textile-to-textile recycling:

- For a more comprehensive assessment and to avoid burden-shifting, a broader range of impact categories should be covered. For instance, it would be relevant to assess toxicity, a major issue in the textile industry.

- More robust data are needed, particularly for parameters identified as influential in the sensitivity analysis. This includes more data on replacement rates (parameter H), preferably considering rebound effects [14,50], and climate and water deprivation impacts of primary fiber production and recycling processes (parameters D2, I2, J2). Related to this, it would be valuable to conduct more research on identifying the processes affected (marginal technologies) by large-scale changes in textile recycling and a further analysis of the independence of parameters randomized in the Monte Carlo analysis.

- Accurate statistics on textile flows are essential for effectively tracking the progress and implementation of textile recycling, along with its environmental impact. Uniform methods for gathering and presenting data in and outside Europe would help in this. Additionally, accurate statistics would help in building more knowledge on other dimensions of the textile sector, such as the environmental viability of the second-hand market, exports of discarded textiles, and similar.

4. Conclusions

In the following section, we list the main conclusions of the study, divided into answers to the research questions defined in Section 1, and recommendations for actions and further research based on these answers.

- How likely is it that implementing textile-to-textile recycling at scale in the EU will reduce climate and water deprivation impacts?

- Climate impact: The baseline scenario estimates a 92% probability that textile-to-textile recycling at scale in the EU will reduce climate impact. Two sensitivity analyses show this probability ranges from 87% to 95% with minor parameter changes and from 62% to 98% with major changes. While a reduction in climate impact is likely, the risk of an increased impact is notable, highlighting the need to focus on influential parameters (see below) when implementing large-scale textile recycling.

- Water deprivation: The baseline scenario estimates an almost 100% probability that recycling reduces the impact of water deprivation. Sensitivity analyses suggest this probability is always above 99%. Therefore, it is almost certain that textile recycling at scale in the EU will result in water deprivation benefits.

- What is the extent of climate and water deprivation impact reductions (if any) of textile-to-textile recycling at scale in the EU?

- Climate impact: The baseline scenario estimates a mean reduction of 440,000 tonnes CO2 eq. per year, representing about 0.5% of the climate impact of textile products bought in the EU.

- Water deprivation: The baseline scenario estimates an average reduction of 8.8 billion m³ world eq., representing about 3.3% of the water deprivation impact of textile products bought in the EU.

- What are the most influential parameters for the results?

The consequences of increased textile recycling with the highest influence on climate and water deprivation impacts are:

• Increased recycling processes

• Reduced primary fiber production

Additionally, reduced incineration is a relatively important contributor to the reduced impact of climate change. In contrast, increased collection or sorting has little influence on either impact category unless it leads to a rise in household transports, which could then become important for climate impact (this has not been assessed in the present study). Similarly, the energy production required to compensate for the decrease in recovered energy has little influence on either impact category.

The sensitivity analyses highlight that the following underlying parameters substantially influence the results:

• Replacement rate

• Climate and water deprivation impact of reduced fiber production

• Climate impact of recycling processes

For climate impact, the decarbonization rate of the EU’s energy systems until 2035 is also an important factor.

- Recommended actions

The following measures are crucial for ensuring and enhancing the potential environmental benefits of textile-to-textile recycling at scale:

• Develop energy-efficient recycling powered by energy sources with comparably low climate impact.

• Safeguard high replacement rates so that fibers produced from recycled feedstocks substitute primary fibers to a large degree. This can be achieved by producing high-quality recycled fibers and implementing policies aimed at reducing primary fiber production, such as imposing taxes on the extraction of virgin resources.

If high replacement rates are not achieved, increased textile-to-textile recycling may merely expand the overall fiber market, potentially escalating the textile sector’s climate impact. For water deprivation impact, this risk is negligible.

The results also show that actions other than increased material recycling are necessary to substantially decrease the climate and water deprivation impacts of the textile sector and thereby contribute to the sector’s journey to increased sustainability. However, by following the recommended actions, the achieved environmental impact reductions can be considerably higher than the estimated mean reductions presented above.

- Recommended further research

Based on the limitations of the study (see Section 3.3), we recommend further research on large-scale textile recycling to focus on:

• Including more impact categories of relevance for the textile industry, such as toxicity.

• Developing and using more robust data for influential parameters, such as data on replacement rates and climate and water deprivation impacts of primary fiber production and recycling processes.

• Identify marginal technologies affected by large-scale changes in textile recycling and further analyze the independence of parameters randomized in the Monte Carlo analysis.

• Developing methods for gathering and presenting data on textile flows in the EU.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/su17051931/s1, Table S1. Climate and water-deprivation impact of landfilling and incineration of fossil fibres and landfilling of non-fossil fibres. Table S2. Assumed quantities of heat and electricity generated from incinerating textile waste, and assumed climate impact (CI) and water deprivation impact (WDI) of electricity and heat production in the EU. Figure S1. Probability distribution of parameter A, the decarbonisation rate of the EU energy system until 2035. Figure S2. Probability distribution of parameter B, the decarbonisation rate of the Asian energy system until 2035. Figure S3. Probability distribution of parameter C, the proportion of textile recycling occurring outside the EU in 2035. Figure S4. Probability distribution of parameter D1, climate impact of reduced primary fibre production. Figure S5. Probability distribution of parameter D2, water-deprivation impact of reduced primary fibre production. Figure S6. Probability distribution of parameter E, recycling yield. Figure S7. Probability distribution of parameter F, proportion of fossil fibres among the recycled fibres. Figure S8. Probability distribution of parameter G, proportion of landfilled textiles, among landfilled or incinerated textiles. Figure S9. Probability distribution of parameter H, replacement rate. Figure S10. Probability distribution of parameter I1, climate impact of textile recycling processes today in the EU. Figure S11. Probability distribution of parameter J1, climate impact of textile recycling processes today in Asia. Figure S12. Probability distribution of parameters I2 and J2, water-deprivation impact of textile recycling processes in the EU or Asia, respectively.

Author Contributions

G.S.: Writing—original draft, Conceptualization, Methodology, Investigation, Validation, Formal analysis, Visualization, Supervision, Project administration. M.L.: Writing—review & editing, Conceptualization, Methodology, Formal analysis, Investigation, Data curation. M.N.: Writing—review & editing, Conceptualization, Methodology, Investigation. All authors have read and agreed to the published version of the manuscript.

Funding

The research was funded by Formas, a Swedish government research council for sustainable development.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- European Environment Agency. Progress Towards Preventing Waste in Europe—The Case of Textile Waste Prevention. Publications Office of the European Union 2021, EEA Report 15/2021. Available online: https://www.eea.europa.eu/en/analysis/publications/progressing-towards-waste-prevention-in (accessed on 21 January 2024).

- Köhler, A.; Watson, D.; Trzepacz, S.; Löw, C.; Liu, R.; Danneck, J.; Konstantas, A.; Donatello, S.; Faraca, G. Circular Economy Perspectives in the EU Textile Sector, EUR 30734 EN; Publications Office of the European Union: Luxembourg, 2021; Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC125110 (accessed on 22 January 2025).

- Textile Exchange. Materials Market Report. Available online: https://textileexchange.org/app/uploads/2024/09/Materials-Market-Report-2024.pdf (accessed on 26 January 2025).

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions—EU Strategy for Sustainable and Circular Textiles, Document 52022DC0141. Available online: https://www.wrap.ngo/resources/report/driving-circular-fashion-and-textiles-ecap-summary-report#download-file (accessed on 26 January 2024).

- WRAP. Driving Circular Fashion and Textiles: ECAP Summary Report 2019. Available online: https://wrap.org.uk/resources/report/driving-circular-fashion-and-textiles-ecap-summary-report (accessed on 7 September 2023).

- Constantinou, G.; Holmgaard, I. Research and Identification of Textile Plants in the Nordic Countries & Europe—Focusing on Fiber-to-Fiber Recycling for the Fashion & Textile Industry. Available online: https://telaketju.turkuamk.fi/uploads/2020/11/e26547b8-telaketju_4resweb_lifestyledesigncluster-gabriellac_small.pdf (accessed on 10 September 2023).

- Dahlbom, M.; Aguilar Johansson, I.; Billstein, T. Sustainable Clothing Futures—Mapping of Textile Actors in Sorting and Recycling of Textiles in Europe; Report Number C736; IVL Swedish Environmental Research Institute: Stockholm, Sweden, 2023. [Google Scholar]

- European Environment Agency. Textiles in Europe’s Circular Economy. 2023. Available online: https://www.eea.europa.eu/publications/textiles-in-europes-circular-economy/textiles-in-europe-s-circular-economy (accessed on 14 September 2023).

- Thomas, K.; Durrani, H.; Brady, J.; Ludwig, K.; Yatvitskiy, M.; Clarke-Sather, A.R.; Cao, H.; Cobb, K. Fundamental challenges and opportunities for textile circularity. Sustainability 2024, 16, 11117. [Google Scholar] [CrossRef]

- European Commission. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives (Text with EEA Relevance). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:02008L0098-20180705&from=EN#page=19 (accessed on 23 January 2025).

- Zink, T.; Geyer, R. Circular economy rebound. J. Ind. Ecol. 2017, 21, 593–602. [Google Scholar] [CrossRef]

- Aguilar-Hernandez, G.A.; Rodrigues, J.F.D.; Tukker, A. Macroeconomic, social and environmental impacts of a circular economy up to 2050: A meta-analysis of prospective studies. J. Clean. Prod. 2021, 278, 123421. [Google Scholar] [CrossRef]

- Castro, C.G.; Trevisan, A.H.; Pigosso, D.C.A.; Mascarenhas, J. The rebound effect of circular economic: Definitions, mechanisms and a research agenda. J. Clean. Prod. 2022, 345, 131136. [Google Scholar] [CrossRef]

- Bączyk, M.; Tunn, V.; Worrell, E.; Corona, B. Consumer behaviour in circular business models: Unveiling conservation and rebound effects. Sustain. Prod. Conum. 2024, 52, 283–298. [Google Scholar]

- Arpin, M.-L.; Leclerc, S.H.; Lonca, G. The circular economy (CE) rebound as a paradox of knowledge: Forecasting the future of the CE-IoT nexus through the global E-waste crisis. Sustainability 2024, 16, 6364. [Google Scholar] [CrossRef]

- Sandin, G.; Peters, G.M. Environmental impact of textile reuse and recycling—A review. J. Clean. Prod. 2018, 184, 353–365. [Google Scholar] [CrossRef]

- Braun, G.; Som, C.; Schmutz, M.; Hischier, R. Environmental consequences of closing the textile loop—Life cycle assessment of a circular polyester jacket. Appl. Sci. 2023, 11, 2964. [Google Scholar] [CrossRef]

- Lidfeldt, M.; Nellström, M.; Sandin Albertsson, G.; Hallberg, L. Siptex WP5 Report: Life Cycle Assessment of Textile Recycling Products; Report Number C718; IVL Swedish Environmental Research Institute: Stockholm, Sweden, 2022. [Google Scholar]

- Hidalgo-Crespo, J.; Rivas-Garcia, P.; Garcia-Balandran, E.E.; Albalate-Ramírez, A.; Quintero-Herrera, S.; Velastegui-Montoya, A.; Amaya Rivas, J.L.; Soto, M. Validating circular end-of-life strategies for domestic post-consumer materials in the Latin-American region: A life cycle assessment approach. Environments 2024, 11, 228. [Google Scholar] [CrossRef]

- Amicarelli, V.; Bux, C. Quantifying textile streams and recycling prospects in Europe by material flow analysis. Environ. Impact Assess. Rev. 2022, 97, 106878. [Google Scholar] [CrossRef]

- Dahlbo, H.; Aalto, K.; Eskelinen, H.; Salmenperä, H. Increasing textile circulation—Consequences and requirements. Sustain. Prod. Consum. 2017, 9, 44–57. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. A New Textiles Economy: Redesigning Fashion’s Future. Available online: https://ellenmacarthurfoundation.org/a-new-textiles-economy (accessed on 26 January 2025).

- Bianchi, S.; Bartoli, F.; Bruni, C.; Fernandez-Aliva, C.; Rodriquez-Turienzo, L.; Carretero-Mellado, J.; Spinelli, D.; Coltelli, M.-B. Opportunities and limitations in recycling fossil polymers from textiles. Macromol 2023, 3, 120–148. [Google Scholar] [CrossRef]

- Damayanti, D.; Wulandari, L.A.; Bagaskoro, A.; Rianjanu, A.; Wu, H.-S. Possibility routes for textile recycling technology. Polymers 2021, 12, 3834. [Google Scholar] [CrossRef] [PubMed]

- Juanga-Labayen, J.P.; Labayen, I.V.; Yuan, Q. A review on textile recycling practices and challenges. Textiles 2022, 2, 174–188. [Google Scholar] [CrossRef]

- McKinsey & Company. Scaling Textile Recycling in Europe—Turning Waste into Value. Available online: https://www.mckinsey.com/industries/retail/our-insights/scaling-textile-recycling-in-europe-turning-waste-into-value (accessed on 26 January 2025).

- Sandin, G.; Lidfeldt, M.; Nellström, M. Does Large Large-Scale Textile Recycling in Europe Reduce Climate Impact?—A Consequential Life Cycle Assessment; Report Number C803; IVL Swedish Environmental Research Institute: Stockholm, Sweden, 2023. [Google Scholar]

- Celep, G.; Tetik, G.D.; Yilmaz, F. Limitations of Textile Recycling: The Reason behind the Development of Alternative Sustainable Fibers. In Next-Generation Textiles; Ibrahim, H., Ed.; IntechOpen: Rijeka, Croatia, 2023; Available online: https://www.intechopen.com/chapters/82044 (accessed on 26 January 2025).

- Harmsen, P.; Scheffer, M.; Bos, H. Textiles for Circular Fashion: The Logic behind Recycling Options. Sustainability 2021, 13, 9714. [Google Scholar] [CrossRef]

- Riemens, J.; Lemieux, A.-A.; Lamouri, S.; Garnier, J. A Delphi-Régnier Study Addressing the Challenges of Textile Recycling in Europe for the Fashion and Apparel Industry. Sustainability 2021, 13, 11700. [Google Scholar] [CrossRef]

- Saraiva, A.B.; Souza, R.G.; Mahler, C.F.; Valle, R.A.B. Consequential lifecycle modelling of solid waste management systems—Reviewing choices and exploring their consequences. J. Clean. Prod. 2018, 202, 488–496. [Google Scholar] [CrossRef]

- Brandão, M.; Weidema, B.P.; Martin, M.; Cowie, A.; Hamelin, L.; Zamagni, A. Consequential life cycle assessment: What, why and how? In Encyclopedia of Sustainable Technologies, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Ekvall, T. Attributional and consequential life cycle assessment. In Sustainability Assessment at the 21st Century; Bastane-Ceca, M.J., Fuentes-Bargues, J.L., Hufnagel, L., Mihai, F.-C., Iatu, C., Eds.; IntechOpen: Rijeka, Croatia, 2019; Available online: https://www.intechopen.com/chapters/69212 (accessed on 10 September 2023).

- UNEP. Global Guidance Principles for Life Cycle Assessment Databases—A Basis for Greener Processes and Products. 2011. Available online: https://www.lifecycleinitiative.org/wp-content/uploads/2012/12/2011%20-%20Global%20Guidance%20Principles.pdf (accessed on 10 September 2023).

- Suh, S.; Yang, Y. On the uncanny capabilities of consequential LCA. Int. J. Life Cycle Assess. 2014, 19, 1179–1184. [Google Scholar] [CrossRef]

- Esteve-Turrillas, F.A.; de la Guardia, M. Environmental impact of Recover cotton in textile industry. Resour. Conserv. Recycl. 2017, 116, 107–115. [Google Scholar] [CrossRef]

- Boulay, A.-M.; Bare, J.; Benini, L.; Berger, M.; Lathuillière, M.J.; Manzardo, A.; Margni, M.; Motoshita, M.; Núñez, M.; Pastor, A.V.; et al. The WULCA consensus characterization model for water scarcity footprints: Assessing impacts of water consumption based on available water remaining (AWARE). Int. J. Life Cycle Assess. 2018, 23, 368–378. [Google Scholar] [CrossRef]

- Eurostat. Waste Management Indicators. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Waste_management_indicators&oldid=461870 (accessed on 18 September 2024).

- Peters, G.; Li, M.; Lenzen, M. The need to decelerate fast fashion in a hot climate—A global sustainability perspective on the garment industry. J. Clean. Prod. 2021, 295, 126390. [Google Scholar] [CrossRef]

- Sandin, G.; Roos, S.; Spak, B.; Zamani, B.; Peters, G. Environmental assessment of Swedish clothing consumption—Six garments, sustainable futures. In Mistra Future Fashion; Report Number 2019:05; RISE Research Institutes of Sweden: Gothenburg, Sweden, 2019. [Google Scholar]

- Our World in Data. Per Capita Consumption-Based CO2 Emissions. Available online: https://ourworldindata.org/grapher/consumption-co2-per-capita?tab=table®ion=Europe (accessed on 11 October 2023).

- Eurostat. EU Population Increases Again After Two Years Decrease. Available online: https://ec.europa.eu/eurostat/web/products-eurostat-news/w/EDN-20230711-1 (accessed on 7 September 2023).

- Roos, S.; Zamani, B.; Sandin, G.; Peters, G.M.; Svanström, M. A life cycle assessment (LCA)-based approach to guiding an industry sector towards sustainability: The case of the Swedish apparel sector. J. Clean. Prod. 2016, 133, 691–700. [Google Scholar] [CrossRef]

- Zamani, B.; Sandin, G.; Peters, G.M. Life cycle assessment of clothing libraries: Can collaborative consumption reduce the environmental impact of fast fashion? J. Clean. Prod. 2017, 162, 1368–1375. [Google Scholar] [CrossRef]

- Sevigné-Itoiz, E.; Gasol, C.M.; Rieradevall, J.; Gabarrell, X. Methodology of supporting decision-making of waste management with material flow analysis (MFA) and consequential life cycle assessment (CLCA): Case study of waste paper recycling. J. Clean. Prod. 2015, 105, 253–262. [Google Scholar] [CrossRef]

- Di Maria, A.; Van Acker, K. Chapter 13—Consequential life cycle assessment to promote the recycling of metallurgic slag as new construction material. In Environmental Sustainability and Economy; Singh, P., Verma, P., Perrotti, D., Srivastava, K.K., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 361–366. [Google Scholar]

- Textile Exchange. Preferred Fiber and Materials Market Report. Available online: https://textileexchange.org/knowledge-center/reports/preferred-fiber-and-materials/ (accessed on 11 September 2023).

- Meyer, M.; Hirschnitz-Garbers, M.; Distelkamp, M. Contemporary resource policy and decoupling trends—Lessons learnt from integrated model-based assessments. Sustainability 2018, 10, 1858. [Google Scholar] [CrossRef]

- Syre. Available online: https://www.syre.com (accessed on 26 January 2025).

- Siderius, T.; Poldner, K. Reconsidering the circular economy rebound effect: Propositions from a case study of the Dutch circular textile valley. J. Clean. Prod. 2021, 293, 125996. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).