Short-Wave Infrared Spectroscopy for On-Site Discrimination of Hazardous Mineral Fibers Using Machine Learning Techniques

Abstract

1. Introduction

2. Materials and Methods

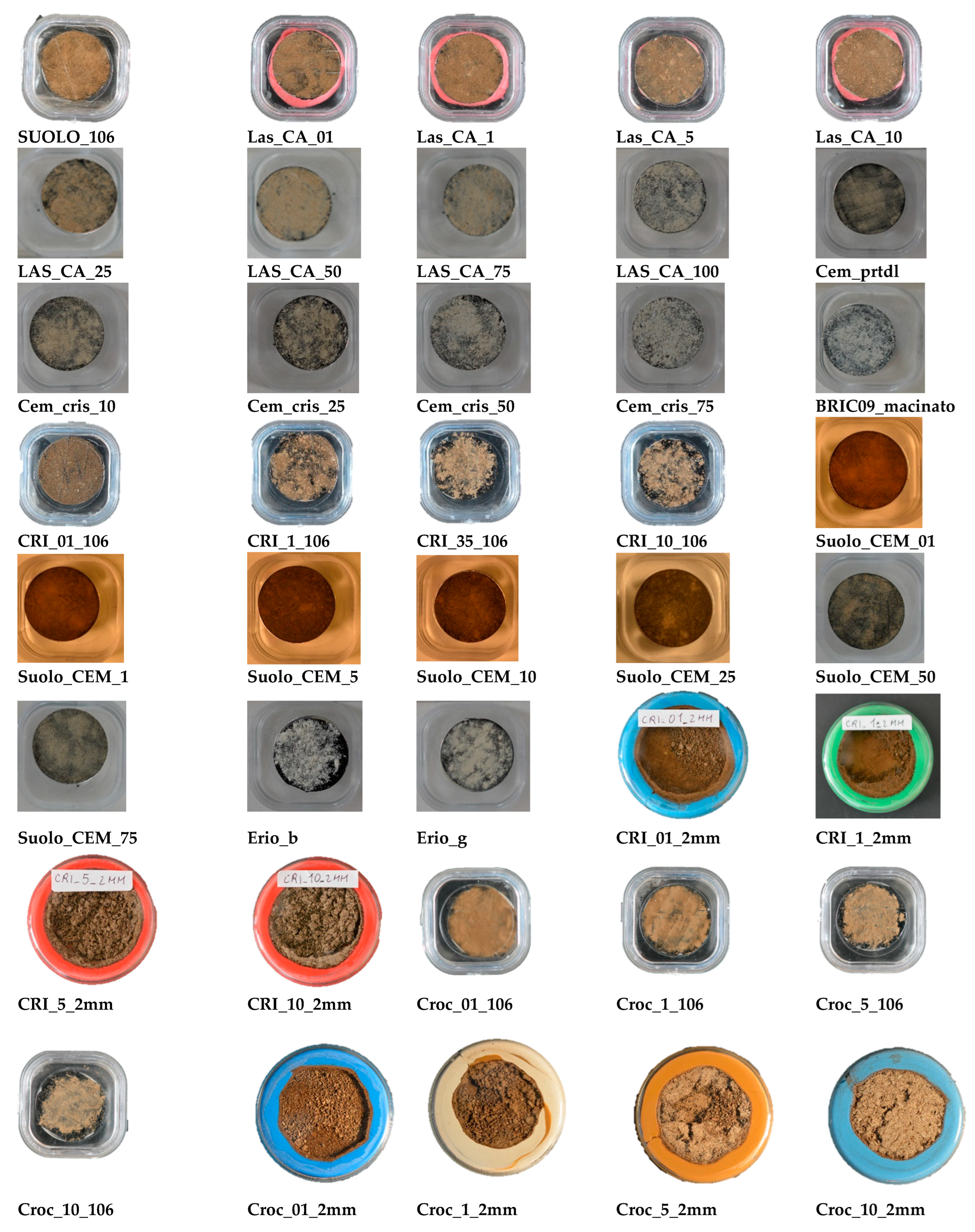

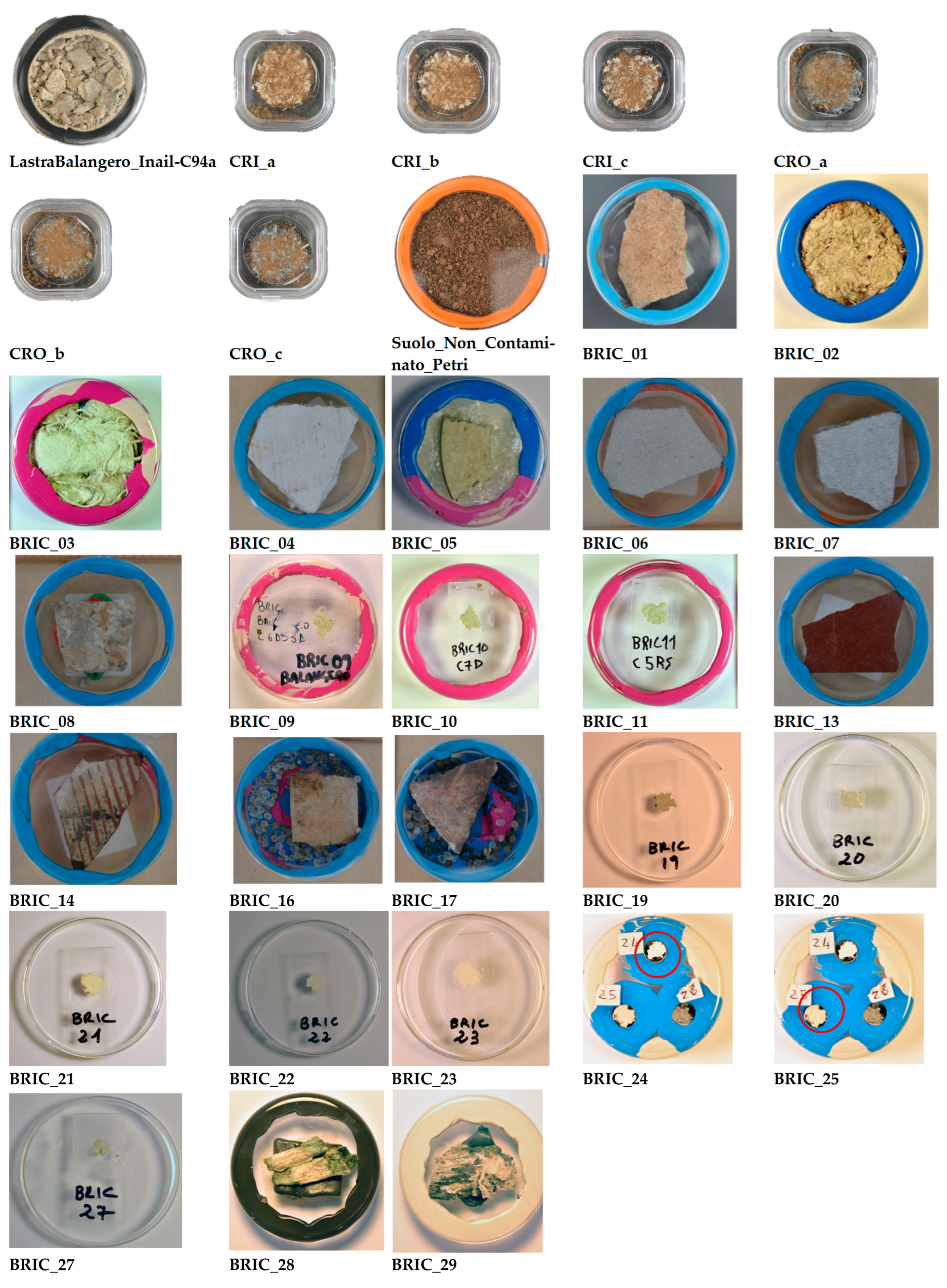

2.1. Analyzed Samples

2.2. Spectra Acquisition and Data Preparation

2.3. Spectra Preprocessing and Exploratory Analysis

- All samples (all the analyzed samples labelled according to ‘Category’).

- Pure mineral samples (‘ERIONITE’, ‘CHRYSOTILE’, ‘AMOSITE’, ‘CROCIDOLITE’, and ‘TREMOLITE’ classes).

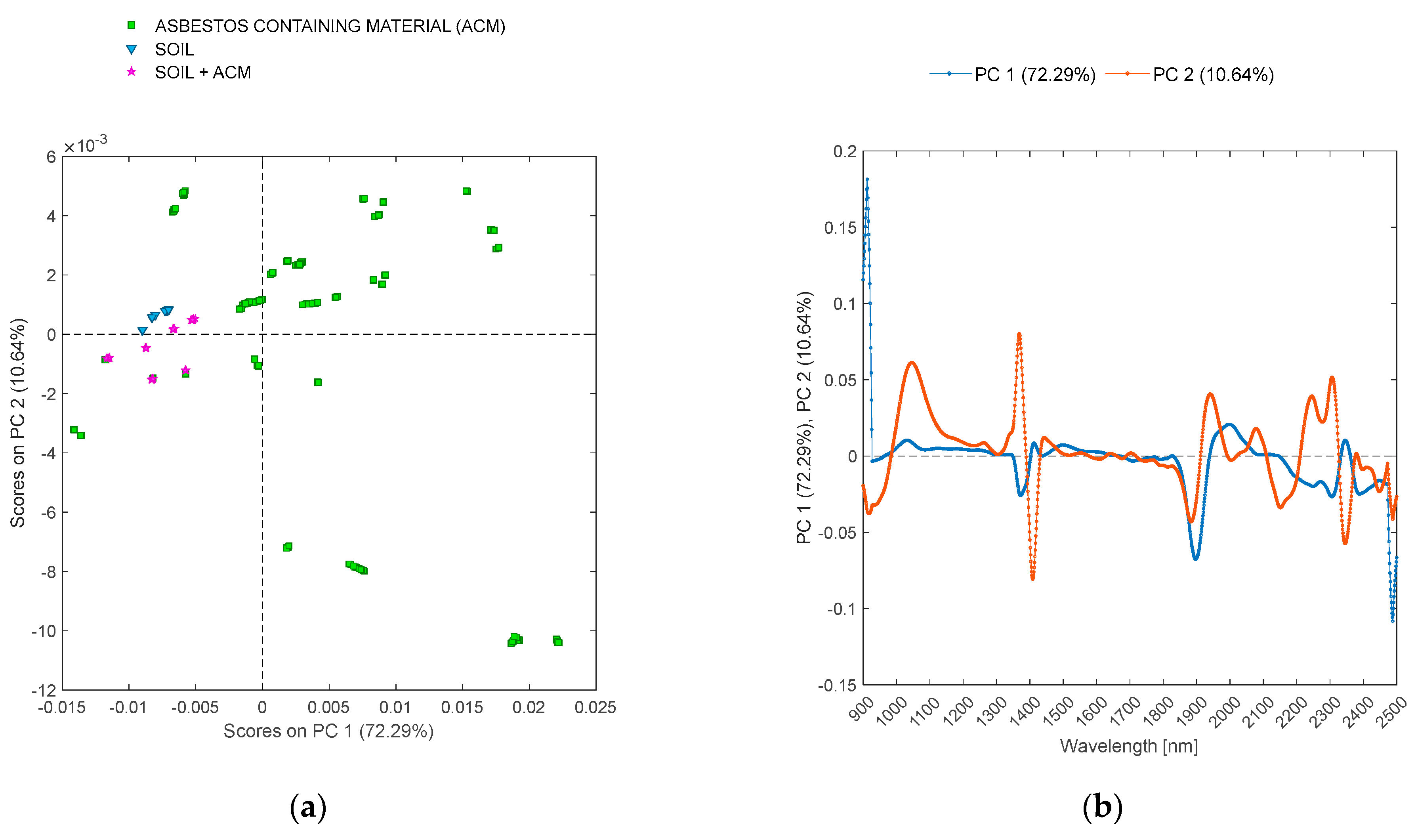

- Soil, ACM and soil mixed with ACM (‘ACM’, ‘SOIL’, and ‘SOIL + ACM’ classes).

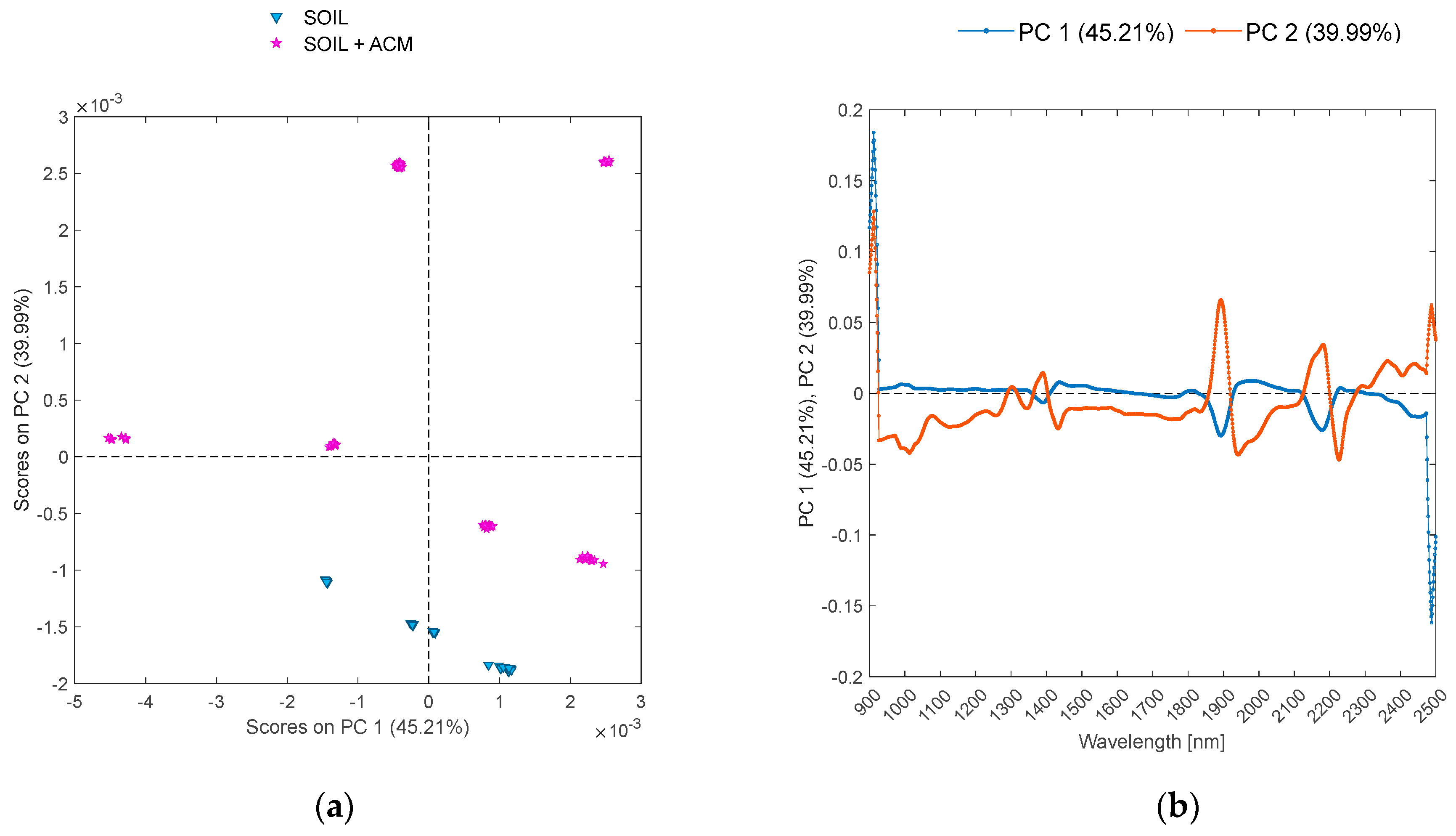

- Soil and soil mixed with ACM (‘SOIL’ and ‘SOIL + ACM’ classes).

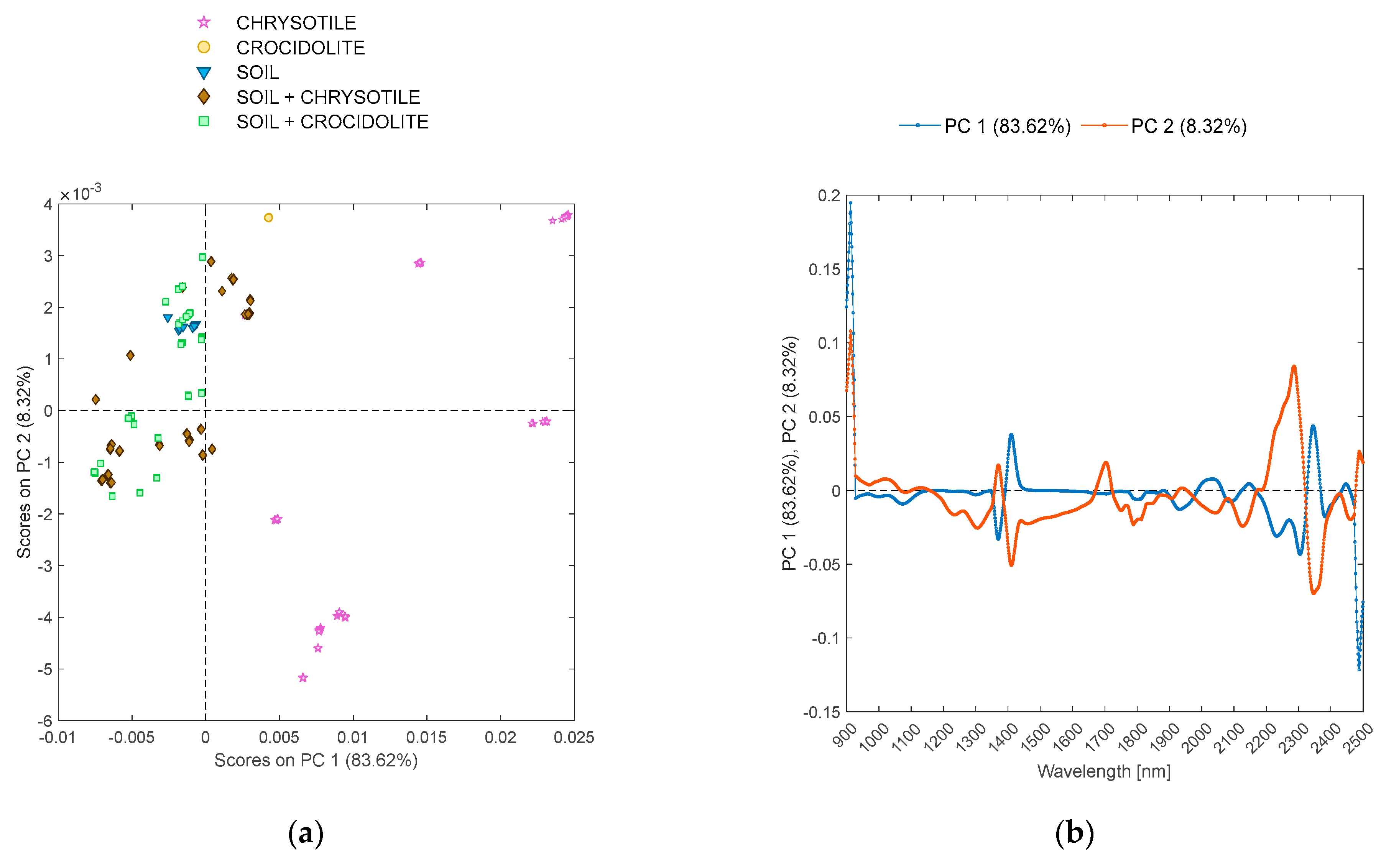

- Soil, chrysotile, crocidolite, and soil–chrysotile/soil–crocidolite mixtures (‘SOIL’, ‘CHRYSOTILE’, ‘CROCIDOLITE’, ‘SOIL + CHRYSOTILE’, and ‘SOIL + CROCIDOLITE’ classes).

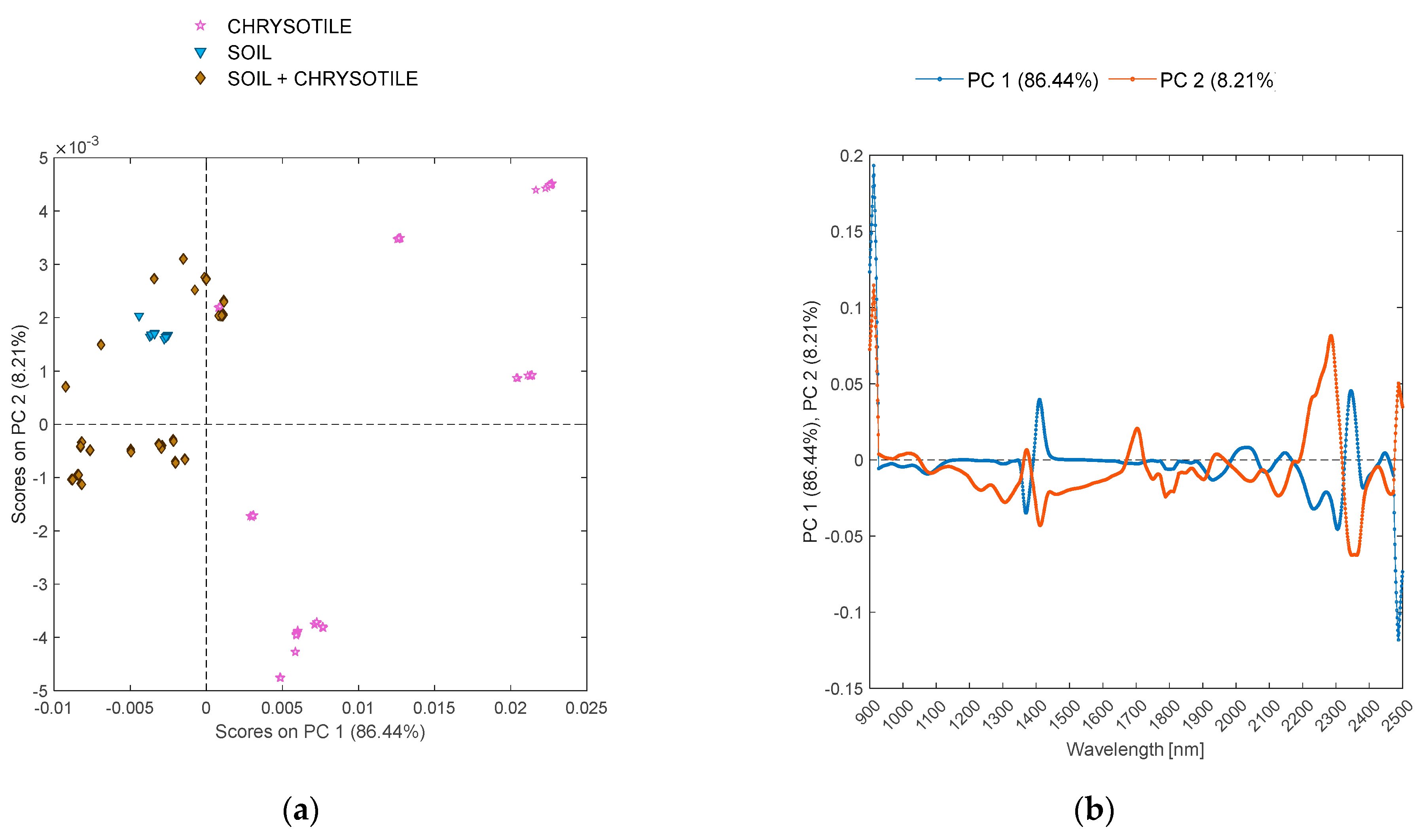

- Soil, chrysotile, and soil–chrysotile mixtures (‘SOIL’, ‘CHRYSOTILE’, and ‘SOIL + CHRYSOTILE’ classes).

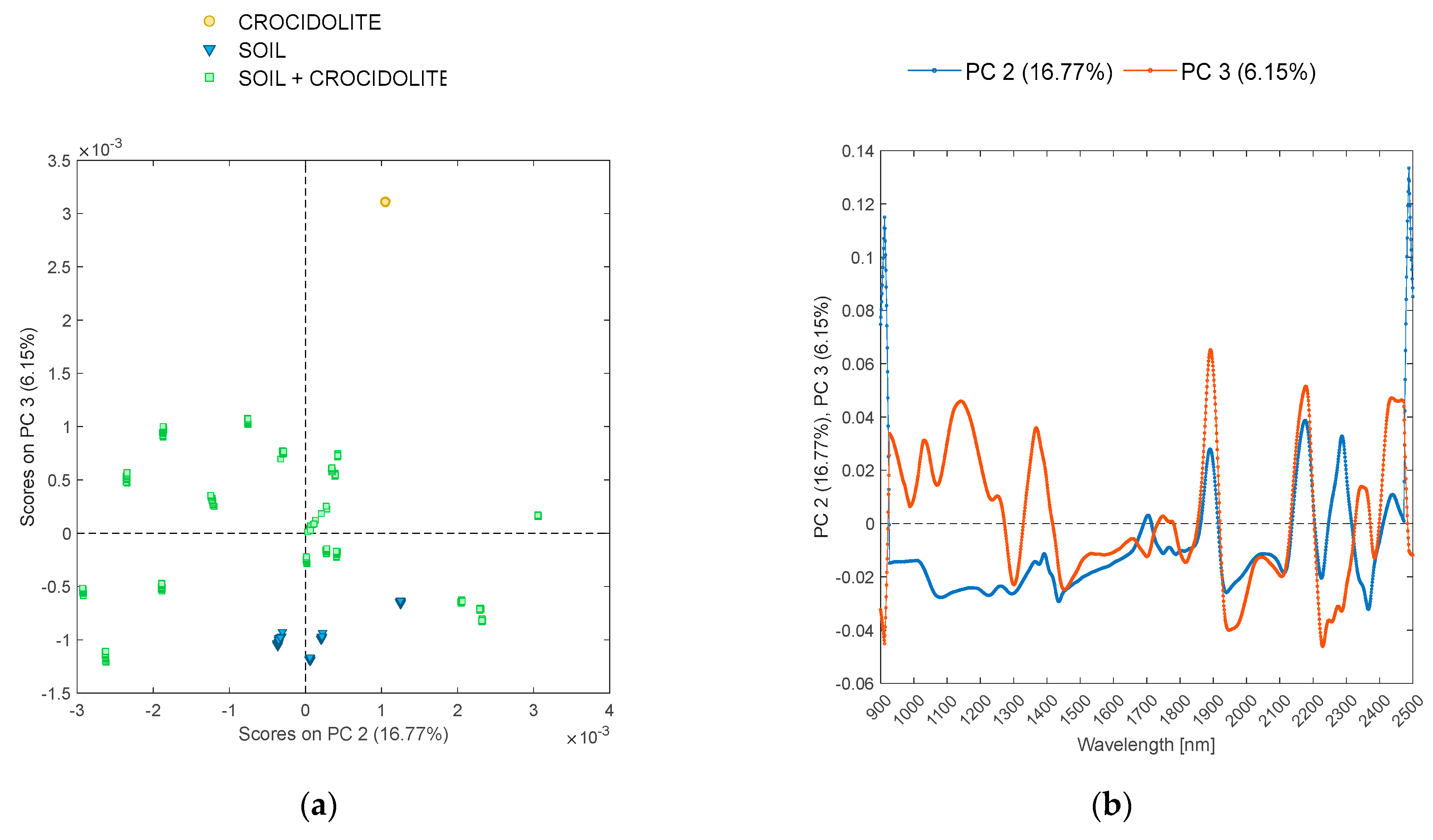

- Soil, crocidolite, and soil–crocidolite mixtures (‘SOIL’, ‘CROCIDOLITE’, and ‘SOIL + CROCIDOLITE’ classes).

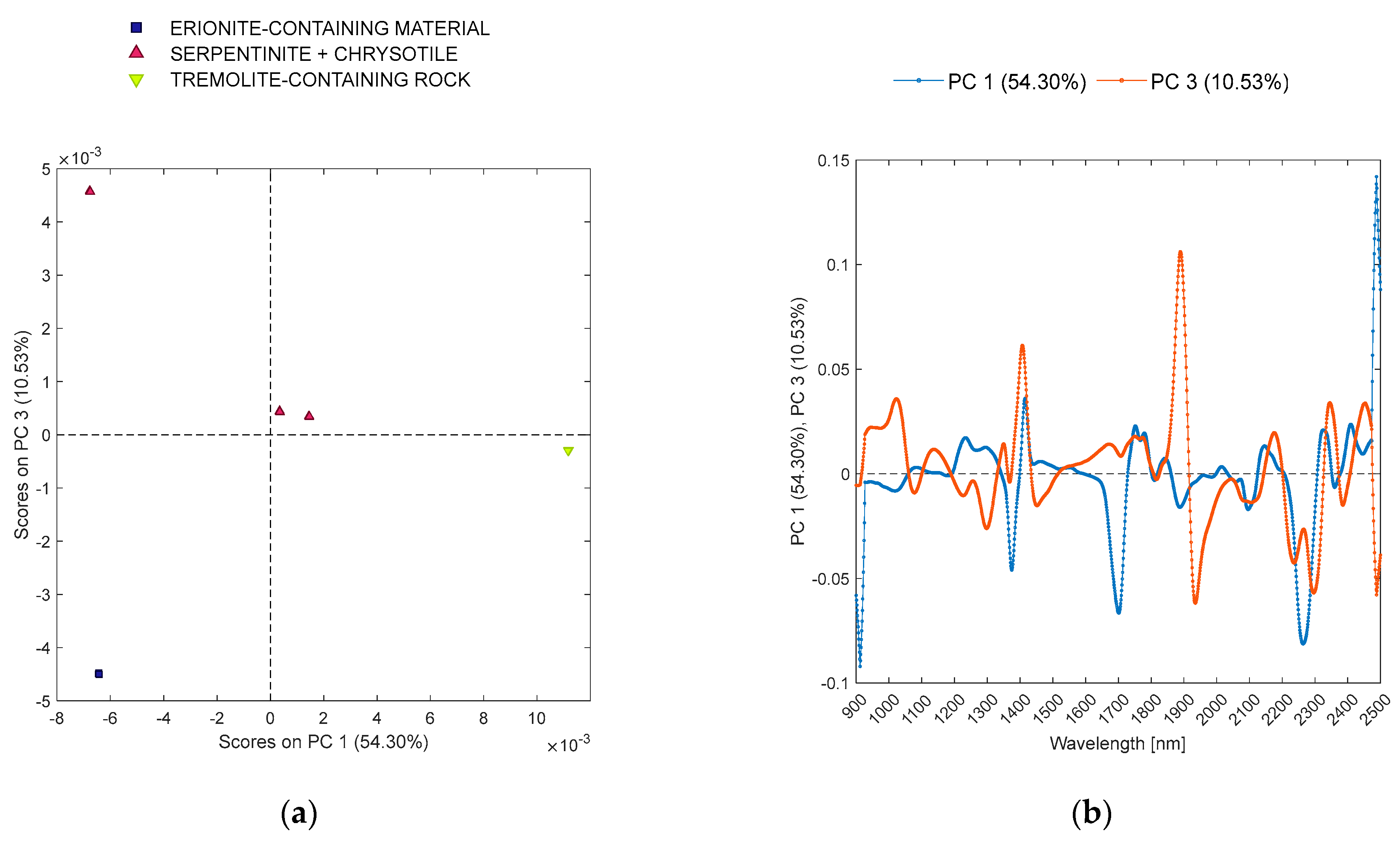

- Naturally occurring asbestos and erionite-containing material samples (‘SERPENTINE+CHRYSOTILE’, ‘TREMOLITE-CONTAINING ROCK’, and ‘ERIONITE-CONTAINING MATERIAL’).

2.4. Classification Models and Performance Metrics

2.4.1. Partial Least Squares Discriminant Analysis (PLS-DA)

2.4.2. Principal Component Analysis-Based Discriminant Analysis (PCA-DA)

2.4.3. Principal Component Analysis-Based K-Nearest Neighbors Classification (PCA-KNN)

2.4.4. Classification and Regression Trees (CART)

2.4.5. Error-Correcting Output-Coding Support Vector Machine (ECOC SVM)

2.4.6. Metrics to Measure Classification Performance

3. Results and Discussion

3.1. Reflectance Spectra

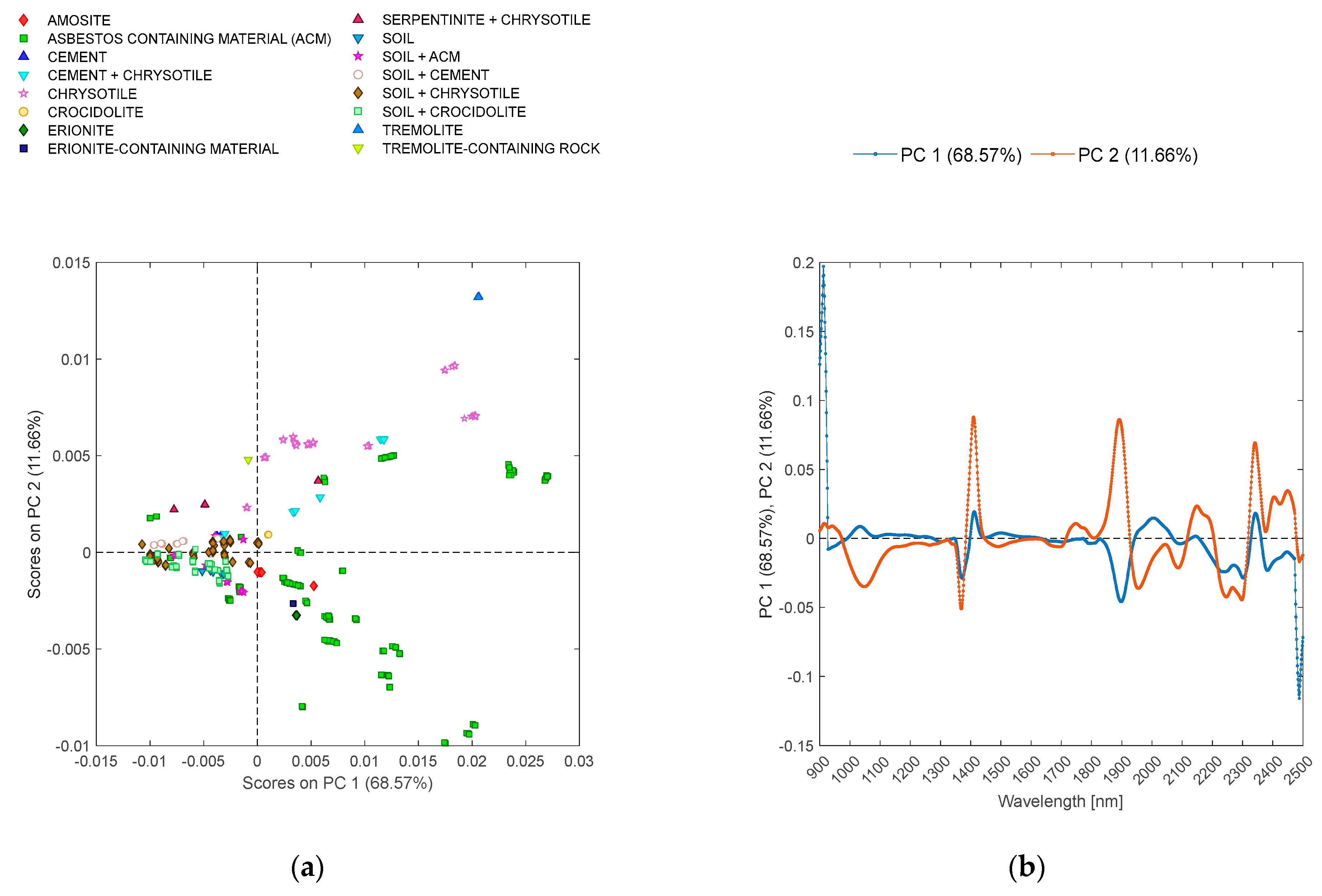

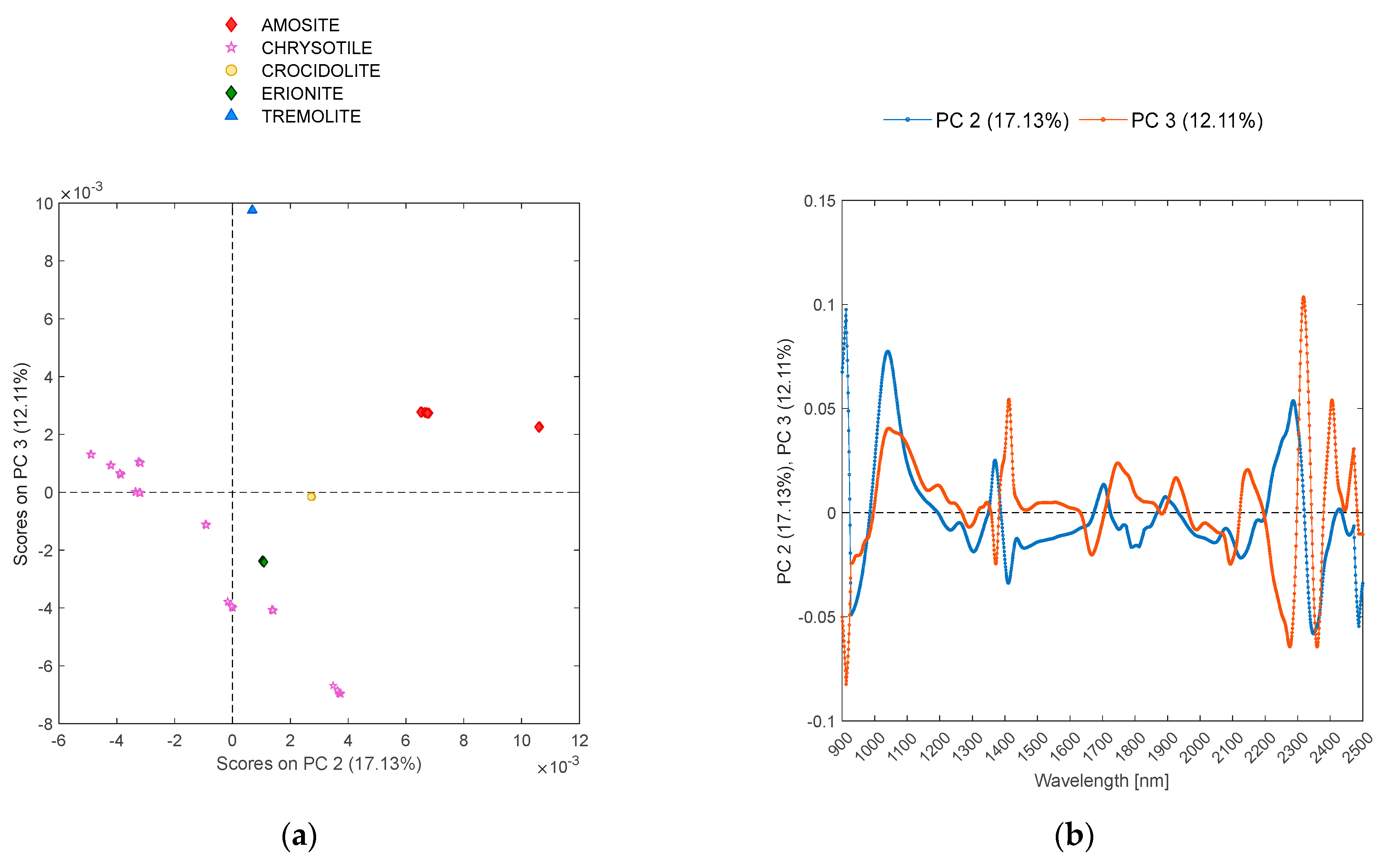

3.2. Principal Component Analysis

4. Classification Performances

4.1. PLS-DA

4.2. PCA-DA

4.3. PCA-KNN

4.4. CART

4.5. ECOC SVM

4.6. Classifiers Comparison

5. Conclusions and Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Analyzed Samples

| Sample’s ID | Sample Description | Casing | Category |

|---|---|---|---|

| Erio_b | Erionite at 98% (Bric 39) | SEM Specimen Stub (25 mm diameter) | ERIONITE |

| Erio_g | Erionite at 40% (Bric 40) | SEM Specimen Stub (25 mm diameter) | ERIONITE-CONTAINING MATERIAL |

| Cem_prtdl | Milled Portland Cement | SEM Specimen Stub (25 mm diameter) | CEMENT |

| LAS_100 | Hand-ground asbestos–cement slab from Balangero’s industrial site (Piedmont, Italy) | SEM Specimen Stub (25 mm diameter) | ASBESTOS-CONTAINING MATERIAL (ACM) |

| BRIC09_macinato | Milled chrysotile from Balangero’s mining site | SEM Specimen Stub (25 mm diameter) | CHRYSOTILE |

| SUOLO_106 | Monte Porzio Catone (MPC)’s (Roma, Italy) topsoil, hand-ground with granulometry < 106 μm | SEM Specimen Stub (25 mm diameter) | SOIL |

| Cem_cris_10 | Portland cement + Balangero’s chrysotile (10 wt%) | SEM Specimen Stub (25mm diameter) | CEMENT + CHRYSOTILE |

| Cem_cris_25 | Portland cement + Balangero’s chrysotile (25 wt%) | SEM Specimen Stub (25mm diameter) | CEMENT + CHRYSOTILE |

| Cem_cris_50 | Portland cement + Balangero’s chrysotile (50 wt%) | SEM Specimen Stub (25mm diameter) | CEMENT + CHRYSOTILE |

| Cem_cris_75 | Portland cement + Balangero’s chrysotile (75 wt%) | SEM Specimen Stub (25mm diameter) | CEMENT + CHRYSOTILE |

| Las CA 01 | MPC’s soil < 106 μm + hand-ground asbestos–cement slab from Balangero’s mining site (0.1 wt%) | SEM Specimen Stub (25mm diameter) | SOIL + ACM |

| Las CA 1 | MPC’s soil < 106 μm + hand-ground asbestos–cement slab from Balangero’s mining site (1 wt%) | SEM Specimen Stub (25mm diameter) | SOIL + ACM |

| Las CA 5 | MPC’s soil <1 06 μm + hand-ground asbestos–cement slab from Balangero’s mining site (5 wt%) | SEM Specimen Stub (25mm diameter) | SOIL + ACM |

| Las CA 10 | MPC’s soil < 106 μm + hand-ground asbestos–cement slab from Balangero’s mining site (10 wt%) | SEM Specimen Stub (25mm diameter) | SOIL + ACM |

| LAS_CA_25 | MPC’s soil < 106 μm + hand-ground asbestos–cement slab from Balangero’s mining site (25 wt%) | SEM Specimen Stub (25mm diameter) | SOIL + ACM |

| LAS_CA_50 | MPC’s soil < 106 μm + hand-ground asbestos–cement slab from Balangero’s mining site (50 wt%) | SEM Specimen Stub (25mm diameter) | SOIL + ACM |

| LAS_CA_75 | MPC’s soil < 106 μm + hand-ground asbestos–cement slab from Balangero’s mining site (75 wt%) | SEM Specimen Stub (25mm diameter) | SOIL + ACM |

| Suolo_CEM_01 | MPC’s soil < 106 μm + Portland cement (0.1 wt%) | SEM Specimen Stub (25mm diameter) | SOIL + CEMENT |

| Suolo_CEM_1 | MPC’s soil < 106 μm + Portland cement (1 wt%) | SEM Specimen Stub (25mm diameter) | SOIL + CEMENT |

| Suolo_CEM_5 | MPC’s soil < 106 μm + Portland cement (5 wt%) | SEM Specimen Stub (25mm diameter) | SOIL + CEMENT |

| Suolo_CEM_10 | MPC’s soil < 106 μm + Portland cement (10 wt%) | SEM Specimen Stub (25mm diameter) | SOIL + CEMENT |

| Suolo_CEM_25 | MPC’s soil < 106 μm + Portland cement (25 wt%) | SEM Specimen Stub (25mm diameter) | SOIL + CEMENT |

| Suolo_CEM_50 | MPC’s soil < 106 μm + Portland cement (50 wt%) | SEM Specimen Stub (25mm diameter) | SOIL + CEMENT |

| Suolo_CEM_75 | MPC’s soil < 106 μm + Portland cement (75 wt%) | SEM Specimen Stub (25mm diameter) | SOIL + CEMENT |

| CRI_01_106 | MPC’s soil < 106 μm + Balangero’s chrysotile (0.1 wt%) | SEM Specimen Stub (25mm diameter) | SOIL + CHRYSOTILE |

| CRI_1_106 | MPC’s soil < 106 μm + Balangero’s chrysotile (1 wt%) | SEM Specimen Stub (25mm diameter) | SOIL + CHRYSOTILE |

| CRI_35_106 | MPC’s soil < 106 μm + Balangero’s chrysotile (3.5 wt%) | SEM Specimen Stub (25mm diameter) | SOIL + CHRYSOTILE |

| CRI_10_106 | MPC’s soil < 106 μm + Balangero’s chrysotile (10 wt%) | SEM Specimen Stub (25mm diameter) | SOIL + CHRYSOTILE |

| CRI_01_2mm | MPC’s soil < 2 mm + Balangero chrysotile (0.1 wt%) | Borosilicate petri dish (60 mm diameter) | SOIL + CHRYSOTILE |

| CRI_1_2mm | MPCs’ soil < 2 mm + Balangero chrysotile (1 wt%) | Borosilicate petri dish (60 mm diameter) | SOIL + CHRYSOTILE |

| CRI_5_2mm | MPC’s soil < 2 mm + Balangero chrysotile (5 wt%) | Borosilicate petri dish (60 mm diameter) | SOIL + CHRYSOTILE |

| CRI_10_2mm | MPC’s soil < 2 mm + Balangero’s chrysotile (10 wt%) | Borosilicate petri dish (60 mm diameter) | SOIL + CHRYSOTILE |

| Croc_01_106 | MPC’s soil < 106 μm + crocidolite (0.1 wt%) | SEM Specimen Stub (25mm diameter) | SOIL + CROCIDOLITE |

| Croc_1_106 | MPC’s soil < 106 μm + crocidolite (1 wt%) | SEM Specimen Stub (25mm diameter) | SOIL + CROCIDOLITE |

| Croc_5_106 | MPC’s soil < 106 μm + crocidolite (5 wt%) | SEM Specimen Stub (25mm diameter) | SOIL + CROCIDOLITE |

| Croc_10_106 | MPC’s soil < 106 μm + crocidolite (10 wt%) | SEM Specimen Stub (25mm diameter) | SOIL + CROCIDOLITE |

| Croc_01_2mm | MPC’s soil < 2 mm + crocidolite (0.1 wt%) | Borosilicate petri dish (60 mm diameter) | SOIL + CROCIDOLITE |

| Croc_1_2mm | MPC’s soil < 2 mm + crocidolite (1 wt%) | Borosilicate petri dish (60 mm diameter) | SOIL + CROCIDOLITE |

| Croc_5_2mm | MPC’s soil < 2 mm + crocidolite (5 wt%) | Borosilicate petri dish (60 mm diameter) | SOIL + CROCIDOLITE |

| Croc_10_2mm | MPC’s soil < 2 mm + crocidolite (10 wt%) | Borosilicate petri dish (60 mm diameter) | SOIL + CROCIDOLITE |

| LastraBalangero_Inail-C94a | Hand-ground asbestos–cement slab from Balangero’s mining site | Borosilicate petri dish (60 mm diameter) | ASBESTOS-CONTAINING MATERIAL (ACM) |

| CRI_a | Chrysotile massively deposited all over the stub and MPC’s soil deposited in the empty spaces | SEM Specimen Stub (25mm diameter) | SOIL + CHRYSOTILE |

| CRI_b | Chrysotile massively deposited all over the stub and MPC’s soil deposited in the empty spaces | SEM Specimen Stub (25mm diameter) | SOIL + CHRYSOTILE |

| CRI_c | Chrysotile massively deposited all over the stub and MPC’s soil deposited in the empty spaces | SEM Specimen Stub (25mm diameter) | SOIL + CHRYSOTILE |

| CRO_a | Crocidolite massively deposited all over the stub and MPC’s soil deposited in the empty spaces | SEM Specimen Stub (25mm diameter) | SOIL + CROCIDOLITE |

| CRO_b | Crocidolite massively deposited all over the stub and MPC’s soil deposited in the empty spaces | SEM Specimen Stub (25mm diameter) | SOIL + CROCIDOLITE |

| CRO_c | Crocidolite massively deposited all over the stub and MPC’s soil deposited in the empty spaces | SEM Specimen Stub (25mm diameter) | SOIL + CROCIDOLITE |

| Suolo_Non_Contaminato_Petri | MPC’s soil, hand-ground with granulometry < 2 mm | Borosilicate petri dish (60 mm diameter) | SOIL |

| BRIC_01 | Wet corrugated asbestos–cement sheet | Borosilicate petri dish (60 mm diameter) | ASBESTOS-CONTAINING MATERIAL (ACM) |

| BRIC_02 | Insulating asbestos-containing felt | Borosilicate petri dish (60 mm diameter) | ASBESTOS-CONTAINING MATERIAL (ACM) |

| BRIC_03 | Asbestos-containing cord (diameter~5cm) | Borosilicate petri dish (60 mm diameter) | ASBESTOS-CONTAINING MATERIAL (ACM) |

| BRIC_04 | Flat asbestos–cement sheet (thickness~1.5cm) | Borosilicate petri dish (60 mm diameter) | ASBESTOS-CONTAINING MATERIAL (ACM) |

| BRIC_05 | Asbestos-containing gasket | Borosilicate petri dish (60 mm diameter) | ASBESTOS-CONTAINING MATERIAL (ACM) |

| BRIC_06 | Asbestos-containing panel (thickness~0.5cm) | Borosilicate petri dish (60 mm diameter) | ASBESTOS-CONTAINING MATERIAL (ACM) |

| BRIC_07 | Asbestos-containing panel (thickness~0.8cm) | Borosilicate petri dish (60 mm diameter) | ASBESTOS-CONTAINING MATERIAL (ACM) |

| BRIC_08 | Asbestos–cement piping (diameter~20cm, thickness~2cm) | Borosilicate petri dish (60 mm diameter) | ASBESTOS-CONTAINING MATERIAL (ACM) |

| BRIC_09 | Balangero’s chrysotile | Borosilicate petri dish (60 mm diameter) | CHRYSOTILE |

| BRIC_10 | Balangero’s chrysotile | Borosilicate petri dish (60 mm diameter) | CHRYSOTILE |

| BRIC_11 | Balangero’s chrysotile | Borosilicate petri dish (60 mm diameter) | CHRYSOTILE |

| BRIC_13 | Vinyl–asbestos tile | Borosilicate petri dish (60 mm diameter) | ASBESTOS-CONTAINING MATERIAL (ACM) |

| BRIC_14 | Vinyl–asbestos tile | Borosilicate petri dish (60 mm diameter) | ASBESTOS-CONTAINING MATERIAL (ACM) |

| BRIC_16 | Piping with amosite | Borosilicate petri dish (60 mm diameter) | ASBESTOS-CONTAINING MATERIAL (ACM) |

| BRIC_17 | Asbestos–cement slab | Borosilicate petri dish (60 mm diameter) | ASBESTOS-CONTAINING MATERIAL (ACM) |

| BRIC_19 | Crocidolite (standard 5174) | Concave microscope slide in borosilicate petri dish | CROCIDOLITE |

| BRIC_20 | Amosite (standard 312M) | Concave microscope slide in borosilicate petri dish | AMOSITE |

| BRIC_21 | Chrysotile (standard intermediate 031G) | Concave microscope slide in borosilicate petri dish | CHRYSOTILE |

| BRIC_22 | Chrysotile (standard intermediate 127H) | Concave microscope slide in borosilicate petri dish | CHRYSOTILE |

| BRIC_23 | Tremolite fibers (standard NIEHS) | Concave microscope slide in borosilicate petri dish | TREMOLITE |

| BRIC_24 | Chrysotile (standard NIEHS plastibest 20) | SEM Specimen Stub (12.5 mm diameter) in borosilicate petri dish | CHRYSOTILE |

| BRIC_25 | Amosite (standard NIEHS) | SEM Specimen Stub (12.5 mm diameter) in borosilicate petri dish | AMOSITE |

| BRIC_27 | Cement + chrysotile | SEM Specimen Stub (12.5 mm diameter) in borosilicate petri dish | CEMENT + CHRYSOTILE |

| BRIC_28 | Rock with fibrous tremolite (Castelluccio Superiore, Italy) | SEM Specimen Stub (12.5 mm diameter) in borosilicate petri dish | TREMOLITE-CONTAINING ROCK |

| BRIC_29 | Serpentinite with chrysotile (Balangero, Italy) | SEM Specimen Stub (12.5 mm diameter) in borosilicate petri dish | SERPENTINITE + CHRYSOTILE |

Appendix B. Comparison of Spectra Within USGS Spectral Library

References

- IARC Working Group on the Evaluation of Carcinogenic Risks to Humans. Arsenic, metals, fibres, and dusts. In IARC Monographs on the Evaluation of Carcinogenic Risks to Humans; International Agency for Research on Cancer: Lyon, France, 2012; Volume 100, p. 11. [Google Scholar]

- IARC Working Group on the Evaluation of Carcinogenic Risks to Humans. Overall evaluations of carcinogenicity: And updating of IARC monographs. In IARC Monographs on the Evaluation of Carcinogenic Risks to Humans; No. Supplement 7; International Agency for Research on Cancer: Lyon, France, 1987; Volume 1–42, 440p. [Google Scholar]

- IARC Working Group on the Evaluation of Carcinogenic Risks to Humans. Some Nanomaterials and Some Fibres. In IARC Monographs on the Evaluation of Carcinogenic Risks to Humans; International Agency for Research on Cancer: Lyon, France, 2017. [Google Scholar]

- Lee, R.J.; Strohmeier, B.R.; Bunker, K.; Van Orden, D. Naturally occurring asbestos—A recurring public policy challenge. J. Hazard. Mater. 2008, 153, 1–21. [Google Scholar] [CrossRef]

- National Minerals Information Center. Mineral Commodity Summaries 2022; USGS: Reston, VA, USA, 2022; p. 202. [Google Scholar]

- Agency for Toxic Substances and Disease Registry. Toxicological Profile for Asbestos; Technical Report 1332-21-4; Department of Health and Human Services, Public Health Service: Atlanta, GA, USA, 2001. [Google Scholar]

- Bowes, D.; Langer, A.; Rohl, A. Nature and range of mineral dusts in the environment. Philos. Trans. R. Soc. London. Ser. A Math. Phys. Sci. 1977, 286, 593–610. [Google Scholar]

- Ricchiuti, C.; Bloise, A.; Punturo, R. Occurrence of asbestos in soils: State of the art. Epis. J. Int. Geosci. 2020, 43, 881–891. [Google Scholar] [CrossRef]

- HSE. Asbestos: The Analysts’ Guide for Sampling, Analysis and Clearance Procedures (HSG 248); TSO: London, UK, 2006. [Google Scholar]

- Malinconico, S.; Paglietti, F.; Serranti, S.; Bonifazi, G.; Lonigro, I. Asbestos in soil and water: A review of analytical techniques and methods. J. Hazard. Mater. 2022, 436, 129083. [Google Scholar] [CrossRef] [PubMed]

- Stark, E.; Luchter, K. NIR instrumentation technology. NIR News 2005, 16, 13–16. [Google Scholar] [CrossRef]

- Cen, H.; He, Y. Theory and application of near infrared reflectance spectroscopy in determination of food quality. Trends Food Sci. Technol. 2007, 18, 72–83. [Google Scholar] [CrossRef]

- Davies, A.; Grant, A. Near infra-red analysis of food. Int. J. Food Sci. Technol. 1987, 22, 191–207. [Google Scholar] [CrossRef]

- Cortés, V.; Blasco, J.; Aleixos, N.; Cubero, S.; Talens, P. Monitoring strategies for quality control of agricultural products using visible and near-infrared spectroscopy: A review. Trends Food Sci. Technol. 2019, 85, 138–148. [Google Scholar] [CrossRef]

- Ozaki, Y. Near-infrared spectroscopy—Its versatility in analytical chemistry. Anal. Sci. 2012, 28, 545–563. [Google Scholar] [CrossRef]

- Tekin, Y.; Kuang, B.; Mouazen, A.M. Potential of on-line visible and near infrared spectroscopy for measurement of pH for deriving variable rate lime recommendations. Sensors 2013, 13, 10177–10190. [Google Scholar] [CrossRef] [PubMed]

- Luypaert, J.; Massart, D.; Vander Heyden, Y. Near-infrared spectroscopy applications in pharmaceutical analysis. Talanta 2007, 72, 865–883. [Google Scholar] [CrossRef] [PubMed]

- Macho, S.; Larrechi, M.S. Near-infrared spectroscopy and multivariate calibration for the quantitative determination of certain properties in the petrochemical industry. TrAC Trends Anal. Chem. 2002, 21, 799–806. [Google Scholar] [CrossRef]

- Heise, H.M. Medical applications of NIR spectroscopy. In Near-Infrared Spectroscopy; Springer: Berlin/Heidelberg, Germany, 2021; pp. 437–473. [Google Scholar]

- Currà, A.; Gasbarrone, R.; Cardillo, A.; Fattapposta, F.; Missori, P.; Marinelli, L.; Bonifazi, G.; Serranti, S.; Trompetto, C. In vivo non-invasive near-infrared spectroscopy distinguishes normal, post-stroke, and botulinum toxin treated human muscles. Sci. Rep. 2021, 11, 17631. [Google Scholar] [CrossRef] [PubMed]

- Bonifazi, G.; Capobianco, G.; Palmieri, R.; Serranti, S. Hyperspectral imaging applied to the waste recycling sector. Spectrosc. Eur. 2019, 31, 8–11. [Google Scholar] [CrossRef]

- Bonifazi, G.; Fiore, L.; Gasbarrone, R.; Hennebert, P.; Serranti, S. Detection of Brominated Plastics from E-Waste by Short-Wave Infrared Spectroscopy. Recycling 2021, 6, 54. [Google Scholar] [CrossRef]

- Turner, D.J.; Rivard, B.; Groat, L.A. Visible and short-wave infrared reflectance spectroscopy of REE phosphate minerals. Am. Mineral. 2016, 101, 2264–2278. [Google Scholar] [CrossRef]

- Turner, D.J.; Rivard, B.; Groat, L.A. Visible and short-wave infrared reflectance spectroscopy of selected REE-bearing silicate minerals. Am. Mineral. J. Earth Planet. Mater. 2018, 103, 927–943. [Google Scholar] [CrossRef]

- Catelli, E.; Sciutto, G.; Prati, S.; Chavez Lozano, M.V.; Gatti, L.; Lugli, F.; Silvestrini, S.; Benazzi, S.; Genorini, E.; Mazzeo, R. A new miniaturised short-wave infrared (SWIR) spectrometer for on-site cultural heritage investigations. Talanta 2020, 218, 121112. [Google Scholar] [CrossRef]

- Rossel, R.V.; Cattle, S.R.; Ortega, A.; Fouad, Y. In situ measurements of soil colour, mineral composition and clay content by vis–NIR spectroscopy. Geoderma 2009, 150, 253–266. [Google Scholar] [CrossRef]

- Shi, T.; Chen, Y.; Liu, Y.; Wu, G. Visible and near-infrared reflectance spectroscopy—An alternative for monitoring soil contamination by heavy metals. J. Hazard. Mater. 2014, 265, 166–176. [Google Scholar] [CrossRef] [PubMed]

- Askari, M.S.; Cui, J.; O’Rourke, S.M.; Holden, N.M. Evaluation of soil structural quality using VIS–NIR spectra. Soil Tillage Res. 2015, 146, 108–117. [Google Scholar] [CrossRef]

- Corradini, F.; Bartholomeus, H.; Lwanga, E.H.; Gertsen, H.; Geissen, V. Predicting soil microplastic concentration using vis-NIR spectroscopy. Sci. Total Environ. 2019, 650, 922–932. [Google Scholar] [CrossRef] [PubMed]

- Wan, M.; Qu, M.; Hu, W.; Li, W.; Zhang, C.; Cheng, H.; Huang, B. Estimation of soil pH using PXRF spectrometry and Vis-NIR spectroscopy for rapid environmental risk assessment of soil heavy metals. Process Saf. Environ. Prot. 2019, 132, 73–81. [Google Scholar] [CrossRef]

- Bonifazi, G.; Capobianco, G.; Serranti, S. Hyperspectral imaging applied to the identification and classification of asbestos fibers. In Proceedings of the 2015 IEEE SENSORS, Busan, Republic of Korea, 1–4 November 2015; pp. 1–4. [Google Scholar]

- Zholobenko, V.; Rutten, F.; Zholobenko, A.; Holmes, A. In situ spectroscopic identification of the six types of asbestos. J. Hazard. Mater. 2021, 403, 123951. [Google Scholar] [CrossRef] [PubMed]

- Bonifazi, G.; Capobianco, G.; Serranti, S. Asbestos containing materials detection and classification by the use of hyperspectral imaging. J. Hazard. Mater. 2018, 344, 981–993. [Google Scholar] [CrossRef]

- Bonifazi, G.; Capobianco, G.; Serranti, S. Hyperspectral imaging and hierarchical PLS-DA applied to asbestos recognition in construction and demolition waste. Appl. Sci. 2019, 9, 4587. [Google Scholar] [CrossRef]

- EN 197-1; Cement: Composition, Specifications and Conformity Criteria, Part 1: Common Cements. European Committee for Standardization: Brussels, Belgium, 2011.

- ASD Inc. FieldSpec® 4 User Manual, ASD Document 600979; ASD Inc.: Boulder, CO, USA, 2015. [Google Scholar]

- ASD Inc. RS3™ User Manual, ASD Document 600545; ASD Inc.: Boulder, CO, USA, 2008.

- Rinnan, Å.; Van Den Berg, F.; Engelsen, S.B. Review of the most common pre-processing techniques for near-infrared spectra. TrAC Trends Anal. Chem. 2009, 28, 1201–1222. [Google Scholar] [CrossRef]

- Danner, M.; Locherer, M.; Hank, T.; Richter, K. Spectral Sampling with the ASD FIELDSPEC 4; GFZ Data Services: Potsdam, Germany, 2015. [Google Scholar]

- Wise, B.M.; Gallagher, N.; Bro, R.; Shaver, J.; Windig, W.; Koch, R.S. PLS Toolbox 4.0; Eigenvector Research Inc.: Manson, WA, USA, 2007. [Google Scholar]

- Van den Berg, R.A.; Hoefsloot, H.C.; Westerhuis, J.A.; Smilde, A.K.; Van der Werf, M.J. Centering, scaling, and transformations: Improving the biological information content of metabolomics data. BMC Genom. 2006, 7, 1–15. [Google Scholar] [CrossRef]

- Wold, S.; Esbensen, K.; Geladi, P. Principal component analysis. Chemom. Intell. Lab. Syst. 1987, 2, 37–52. [Google Scholar] [CrossRef]

- Bro, R.; Smilde, A.K. Principal component analysis. Anal. Methods 2014, 6, 2812–2831. [Google Scholar] [CrossRef]

- Kennard, R.W.; Stone, L.A. Computer aided design of experiments. Technometrics 1969, 11, 137–148. [Google Scholar] [CrossRef]

- Barker, M.; Rayens, W. Partial least squares for discrimination. J. Chemom. A J. Chemom. Soc. 2003, 17, 166–173. [Google Scholar] [CrossRef]

- Ballabio, D.; Consonni, V. Classification tools in chemistry. Part 1: Linear models. PLS-DA. Anal. Methods 2013, 5, 3790–3798. [Google Scholar] [CrossRef]

- Fisher, R.A. The use of multiple measurements in taxonomic problems. Ann. Eugen. 1936, 7, 179–188. [Google Scholar] [CrossRef]

- Bruns, R.; Faigle, J. Quimiometria. Química Nova 1985, 8, 84–99. [Google Scholar]

- Kemsley, E.K. Discriminant analysis of high-dimensional data: A comparison of principal components analysis and partial least squares data reduction methods. Chemom. Intell. Lab. Syst. 1996, 33, 47–61. [Google Scholar] [CrossRef]

- Parvin, H.; Alizadeh, H.; Minaei-Bidgoli, B. MKNN: Modified k-nearest neighbor. In Proceedings of the World Congress on Engineering and Computer Science, San Francisco, CA, USA, 22–24 October 2008. [Google Scholar]

- Guo, G.; Wang, H.; Bell, D.; Bi, Y.; Greer, K. KNN model-based approach in classification. In Proceedings of the OTM Confederated International Conferences “On the Move to Meaningful Internet Systems”, Catania, Sicily, Italy, 3–7 November 2003; pp. 986–996. [Google Scholar]

- Chitari, A.; Bag, V. Detection of brain tumor using classification algorithm. Int. J. Invent. Comput. Sci. Eng 2014, 1, 2348–3539. [Google Scholar]

- Imandoust, S.B.; Bolandraftar, M. Application of k-nearest neighbor (knn) approach for predicting economic events: Theoretical background. Int. J. Eng. Res. Appl. 2013, 3, 605–610. [Google Scholar]

- Breiman, L.; Friedman, J.H.; Olshen, R.A.; Stone, C.J. Classification and Regression Trees; Routledge: London, UK, 2017. [Google Scholar]

- Lewis, R.J. An introduction to classification and regression tree (CART) analysis. In Proceedings of the Annual Meeting of the Society for Academic Emergency Medicine, San Francisco, CA, USA, 22–25 May 2000. [Google Scholar]

- Timofeev, R. Classification and Regression Trees (CART) Theory and Applications; Humboldt University: Berlin, Germany, 2004; Volume 54. [Google Scholar]

- Xiao-Feng, L.; Xue-ying, Z.; Ji-Kang, D. Speech recognition based on support vector machine and error correcting output codes. In Proceedings of the 2010 First International Conference on Pervasive Computing, Signal Processing and Applications, Harbin, China, 17–19 September 2010; pp. 336–339. [Google Scholar]

- Hatami, N. Thinned-ECOC ensemble based on sequential code shrinking. Expert Syst. Appl. 2012, 39, 936–947. [Google Scholar] [CrossRef]

- He, X.; Wang, Z.; Jin, C.; Zheng, Y.; Xue, X. A simplified multi-class support vector machine with reduced dual optimization. Pattern Recognit. Lett. 2012, 33, 71–82. [Google Scholar] [CrossRef]

- Zhou, Y.; Fang, K.; Yang, M.; Ma, P. An Intelligent Model Validation Method Based on ECOC SVM. In Proceedings of the 10th International Conference on Computer Modeling and Simulation, Sydney, Australia, 8–10 January 2018; pp. 67–71. [Google Scholar]

- Ballabio, D.; Grisoni, F.; Todeschini, R. Multivariate comparison of classification performance measures. Chemom. Intell. Lab. Syst. 2018, 174, 33–44. [Google Scholar] [CrossRef]

- Fawcett, T. An introduction to ROC analysis. Pattern Recognit. Lett. 2006, 27, 861–874. [Google Scholar] [CrossRef]

- Grandini, M.; Bagli, E.; Visani, G. Metrics for multi-class classification: An overview. arXiv 2020, arXiv:2008.05756. [Google Scholar]

- Rainio, O.; Teuho, J.; Klén, R. Evaluation metrics and statistical tests for machine learning. Sci. Rep. 2024, 14, 6086. [Google Scholar] [CrossRef] [PubMed]

- Lewis, I.R.; Chaffin, N.C.; Gunter, M.E.; Griffiths, P.R. Vibrational spectroscopic studies of asbestos and comparison of suitability for remote analysis. Spectrochim. Acta—Part A Mol. Spectrosc. 1996, 52, 315–328. [Google Scholar] [CrossRef]

- Clark, R.N.; King, T.V.V.; Klejwa, M.; Swayze, G.A.; Vergo, N. High spectral resolution reflectance spectroscopy of minerals. J. Geophys. Res. Solid Earth 1990, 95, 12653–12680. [Google Scholar] [CrossRef]

- USGS Spectral Library Version 7. 2017. Available online: https://pubs.usgs.gov/publication/ds1035 (accessed on 15 December 2024).

| Model Phase | Modelled Class | Sens. | Spec. | Err. | Prec. | Acc. |

|---|---|---|---|---|---|---|

| C | AMOSITE | 1.00 | 0.99 | 0.01 | 0.56 | 0.99 |

| ASBESTOS-CONTAINING MATERIAL (ACM) | 0.71 | 1.00 | 0.08 | 1.00 | 0.92 | |

| CEMENT | 0.00 | 1.00 | 0.01 | - | 0.99 | |

| CEMENT + CHRYSOTILE | 0.41 | 0.99 | 0.03 | 0.67 | 0.97 | |

| CHRYSOTILE | 0.90 | 0.99 | 0.02 | 0.93 | 0.98 | |

| CROCIDOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| ERIONITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| ERIONITE-CONTAINING MATERIAL | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SERPENTINITE + CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL | 0.82 | 0.96 | 0.04 | 0.42 | 0.96 | |

| SOIL + ACM | 0.27 | 0.86 | 0.18 | 0.11 | 0.82 | |

| SOIL + CEMENT | 0.89 | 0.93 | 0.07 | 0.44 | 0.93 | |

| SOIL + CHRYSOTILE | 0.20 | 0.96 | 0.17 | 0.48 | 0.83 | |

| SOIL + CROCIDOLITE | 0.60 | 0.90 | 0.15 | 0.54 | 0.85 | |

| TREMOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| TREMOLITE-CONTAINING ROCK | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CV | AMOSITE | 1.00 | 0.99 | 0.01 | 0.56 | 0.99 |

| ASBESTOS-CONTAINING MATERIAL (ACM) | 0.71 | 1.00 | 0.08 | 1.00 | 0.92 | |

| CEMENT | 0.00 | 1.00 | 0.01 | - | 0.99 | |

| CEMENT + CHRYSOTILE | 0.41 | 0.99 | 0.04 | 0.58 | 0.96 | |

| CHRYSOTILE | 0.90 | 0.99 | 0.02 | 0.93 | 0.98 | |

| CROCIDOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| ERIONITE | 0.57 | 1.00 | 0.01 | 0.57 | 0.99 | |

| ERIONITE-CONTAINING MATERIAL | 0.57 | 1.00 | 0.01 | 0.57 | 0.99 | |

| SERPENTINITE + CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL | 0.82 | 0.96 | 0.05 | 0.40 | 0.95 | |

| SOIL + ACM | 0.23 | 0.86 | 0.18 | 0.10 | 0.82 | |

| SOIL + CEMENT | 0.89 | 0.93 | 0.07 | 0.45 | 0.93 | |

| SOIL + CHRYSOTILE | 0.19 | 0.96 | 0.17 | 0.48 | 0.83 | |

| SOIL + CROCIDOLITE | 0.60 | 0.90 | 0.15 | 0.54 | 0.85 | |

| TREMOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| TREMOLITE-CONTAINING ROCK | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| V | AMOSITE | 1.00 | 0.97 | 0.03 | 0.40 | 0.97 |

| ASBESTOS-CONTAINING MATERIAL (ACM) | 0.69 | 1.00 | 0.09 | 1.00 | 0.91 | |

| CEMENT | 0.00 | 1.00 | 0.01 | - | 0.99 | |

| CEMENT + CHRYSOTILE | 0.37 | 0.99 | 0.04 | 0.65 | 0.96 | |

| CHRYSOTILE | 0.94 | 0.99 | 0.02 | 0.87 | 0.98 | |

| CROCIDOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| ERIONITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| ERIONITE-CONTAINING MATERIAL | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SERPENTINITE + CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL | 0.58 | 0.97 | 0.04 | 0.41 | 0.96 | |

| SOIL + ACM | 0.26 | 0.87 | 0.17 | 0.11 | 0.83 | |

| SOIL + CEMENT | 0.79 | 0.93 | 0.08 | 0.42 | 0.92 | |

| SOIL + CHRYSOTILE | 0.20 | 0.97 | 0.16 | 0.55 | 0.84 | |

| SOIL + CROCIDOLITE | 0.70 | 0.89 | 0.14 | 0.55 | 0.86 | |

| TREMOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| TREMOLITE-CONTAINING ROCK | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 |

| Model Phase | Modelled Class | Sens. | Spec. | Err. | Prec. | Acc. |

|---|---|---|---|---|---|---|

| C | AMOSITE | 1.00 | 0.99 | 0.01 | 0.56 | 0.99 |

| ASBESTOS-CONTAINING MATERIAL (ACM) | 0.68 | 1.00 | 0.09 | 1.00 | 0.91 | |

| CEMENT | 0.29 | 1.00 | 0.01 | 0.57 | 0.99 | |

| CEMENT + CHRYSOTILE | 0.41 | 0.98 | 0.04 | 0.49 | 0.96 | |

| CHRYSOTILE | 0.80 | 0.99 | 0.03 | 0.92 | 0.97 | |

| CROCIDOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| ERIONITE | 1.00 | 0.99 | 0.01 | 0.48 | 0.99 | |

| ERIONITE-CONTAINING MATERIAL | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SERPENTINITE + CHRYSOTILE | 0.29 | 0.99 | 0.03 | 0.46 | 0.97 | |

| SOIL | 0.00 | 1.00 | 0.03 | - | 0.97 | |

| SOIL + ACM | 0.00 | 0.94 | 0.12 | 0.00 | 0.88 | |

| SOIL + CEMENT | 0.89 | 0.94 | 0.07 | 0.47 | 0.93 | |

| SOIL + CHRYSOTILE | 0.73 | 0.87 | 0.16 | 0.52 | 0.84 | |

| SOIL + CROCIDOLITE | 0.52 | 0.89 | 0.17 | 0.46 | 0.83 | |

| TREMOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| TREMOLITE-CONTAINING ROCK | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CV | AMOSITE | 1.00 | 0.99 | 0.01 | 0.56 | 0.99 |

| ASBESTOS-CONTAINING MATERIAL (ACM) | 0.69 | 1.00 | 0.09 | 1.00 | 0.91 | |

| CEMENT | 0.29 | 1.00 | 0.01 | 0.44 | 0.99 | |

| CEMENT + CHRYSOTILE | 0.40 | 0.98 | 0.05 | 0.45 | 0.95 | |

| CHRYSOTILE | 0.77 | 0.99 | 0.03 | 0.91 | 0.97 | |

| CROCIDOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| ERIONITE | 1.00 | 0.99 | 0.01 | 0.56 | 0.99 | |

| ERIONITE-CONTAINING MATERIAL | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SERPENTINITE + CHRYSOTILE | 0.29 | 0.99 | 0.03 | 0.46 | 0.97 | |

| SOIL | 0.00 | 1.00 | 0.03 | - | 0.97 | |

| SOIL + ACM | 0.00 | 0.92 | 0.13 | 0.00 | 0.87 | |

| SOIL + CEMENT | 0.89 | 0.93 | 0.07 | 0.46 | 0.93 | |

| SOIL + CHRYSOTILE | 0.71 | 0.87 | 0.16 | 0.52 | 0.84 | |

| SOIL + CROCIDOLITE | 0.49 | 0.89 | 0.17 | 0.47 | 0.83 | |

| TREMOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| TREMOLITE-CONTAINING ROCK | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| V | AMOSITE | 1.00 | 0.97 | 0.03 | 0.40 | 0.97 |

| ASBESTOS-CONTAINING MATERIAL (ACM) | 0.67 | 1.00 | 0.10 | 1.00 | 0.90 | |

| CEMENT | 0.67 | 1.00 | 0.01 | 0.57 | 0.99 | |

| CEMENT + CHRYSOTILE | 0.37 | 0.99 | 0.04 | 0.58 | 0.96 | |

| CHRYSOTILE | 0.85 | 0.99 | 0.03 | 0.86 | 0.97 | |

| CROCIDOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| ERIONITE | 1.00 | 0.99 | 0.01 | 0.55 | 0.99 | |

| ERIONITE-CONTAINING MATERIAL | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SERPENTINITE + CHRYSOTILE | 0.44 | 0.99 | 0.02 | 0.57 | 0.98 | |

| SOIL | 0.00 | 1.00 | 0.03 | - | 0.97 | |

| SOIL + ACM | 0.02 | 0.94 | 0.12 | 0.02 | 0.88 | |

| SOIL + CEMENT | 0.79 | 0.95 | 0.06 | 0.48 | 0.94 | |

| SOIL + CHRYSOTILE | 0.78 | 0.87 | 0.14 | 0.56 | 0.86 | |

| SOIL + CROCIDOLITE | 0.56 | 0.90 | 0.15 | 0.52 | 0.85 | |

| TREMOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| TREMOLITE-CONTAINING ROCK | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 |

| Model Phase | Modelled Class | Sens. | Spec. | Err. | Prec. | Acc. |

|---|---|---|---|---|---|---|

| C | AMOSITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 |

| ASBESTOS-CONTAINING MATERIAL (ACM) | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CEMENT | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CEMENT + CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CROCIDOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| ERIONITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| ERIONITE-CONTAINING MATERIAL | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SERPENTINITE + CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL + ACM | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL + CEMENT | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL + CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL + CROCIDOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| TREMOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| TREMOLITE-CONTAINING ROCK | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CV | AMOSITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 |

| ASBESTOS-CONTAINING MATERIAL (ACM) | 1.00 | 1.00 | 0.00 | 0.99 | 1.00 | |

| CEMENT | 0.86 | 1.00 | 0.00 | 0.86 | 1.00 | |

| CEMENT + CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CHRYSOTILE | 0.99 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CROCIDOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| ERIONITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| ERIONITE-CONTAINING MATERIAL | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SERPENTINITE + CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL + ACM | 0.99 | 1.00 | 0.00 | 0.99 | 1.00 | |

| SOIL + CEMENT | 0.99 | 1.00 | 0.00 | 0.99 | 1.00 | |

| SOIL + CHRYSOTILE | 0.98 | 1.00 | 0.01 | 0.99 | 0.99 | |

| SOIL + CROCIDOLITE | 0.98 | 1.00 | 0.01 | 0.98 | 0.99 | |

| TREMOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| TREMOLITE-CONTAINING ROCK | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| V | AMOSITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 |

| ASBESTOS-CONTAINING MATERIAL (ACM) | 0.99 | 1.00 | 0.01 | 1.00 | 0.99 | |

| CEMENT | 0.83 | 1.00 | 0.00 | 0.83 | 1.00 | |

| CEMENT + CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CROCIDOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| ERIONITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| ERIONITE-CONTAINING MATERIAL | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SERPENTINITE + CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL | 0.96 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL + ACM | 0.98 | 1.00 | 0.00 | 0.98 | 1.00 | |

| SOIL + CEMENT | 0.98 | 0.99 | 0.01 | 0.91 | 0.99 | |

| SOIL + CHRYSOTILE | 0.93 | 1.00 | 0.01 | 0.98 | 0.99 | |

| SOIL + CROCIDOLITE | 0.98 | 0.99 | 0.01 | 0.93 | 0.99 | |

| TREMOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| TREMOLITE-CONTAINING ROCK | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 |

| Model Phase | Modelled Class | Sens. | Spec. | Err. | Prec. | Acc. |

|---|---|---|---|---|---|---|

| C | AMOSITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 |

| ASBESTOS-CONTAINING MATERIAL (ACM) | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CEMENT | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CEMENT + CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CROCIDOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| ERIONITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| ERIONITE-CONTAINING MATERIAL | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SERPENTINITE + CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL + ACM | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL + CEMENT | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL + CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL + CROCIDOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| TREMOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| TREMOLITE-CONTAINING ROCK | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CV | AMOSITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 |

| ASBESTOS-CONTAINING MATERIAL (ACM) | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CEMENT | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CEMENT + CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CROCIDOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| ERIONITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| ERIONITE-CONTAINING MATERIAL | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SERPENTINITE + CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL | 1.00 | 1.00 | 0.00 | 0.98 | 1.00 | |

| SOIL + ACM | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL + CEMENT | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL + CHRYSOTILE | 1.00 | 1.00 | 0.00 | 0.99 | 1.00 | |

| SOIL + CROCIDOLITE | 0.99 | 1.00 | 0.00 | 1.00 | 1.00 | |

| TREMOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| TREMOLITE-CONTAINING ROCK | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| V | AMOSITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 |

| ASBESTOS-CONTAINING MATERIAL (ACM) | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CEMENT | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CEMENT + CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CROCIDOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| ERIONITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| ERIONITE-CONTAINING MATERIAL | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SERPENTINITE + CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL + ACM | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL + CEMENT | 0.98 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL + CHRYSOTILE | 0.98 | 1.00 | 0.00 | 0.99 | 1.00 | |

| SOIL + CROCIDOLITE | 1.00 | 1.00 | 0.00 | 0.98 | 1.00 | |

| TREMOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| TREMOLITE-CONTAINING ROCK | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 |

| Model Phase | Modelled Class | Sens. | Spec. | Err. | Prec. | Acc. |

|---|---|---|---|---|---|---|

| C | AMOSITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 |

| ASBESTOS-CONTAINING MATERIAL (ACM) | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CEMENT | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CEMENT + CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CROCIDOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| ERIONITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| ERIONITE-CONTAINING MATERIAL | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SERPENTINITE + CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL + ACM | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL + CEMENT | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL + CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL + CROCIDOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| TREMOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| TREMOLITE-CONTAINING ROCK | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CV | AMOSITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 |

| ASBESTOS-CONTAINING MATERIAL (ACM) | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CEMENT | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CEMENT + CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CROCIDOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| ERIONITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| ERIONITE-CONTAINING MATERIAL | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SERPENTINITE + CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL + ACM | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL + CEMENT | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL + CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL + CROCIDOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| TREMOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| TREMOLITE-CONTAINING ROCK | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| V | AMOSITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 |

| ASBESTOS-CONTAINING MATERIAL (ACM) | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CEMENT | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CEMENT + CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| CROCIDOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| ERIONITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| ERIONITE-CONTAINING MATERIAL | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SERPENTINITE + CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL + ACM | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL + CEMENT | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL + CHRYSOTILE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| SOIL + CROCIDOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| TREMOLITE | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 | |

| TREMOLITE-CONTAINING ROCK | 1.00 | 1.00 | 0.00 | 1.00 | 1.00 |

| Classification Model | Model Phase | (%) | (%) |

|---|---|---|---|

| PLS-DA | C | 74 | 95 |

| CV | 68 | 95 | |

| V | 72 | 95 | |

| PCA-DA | C | 66 | 95 |

| CV | 66 | 95 | |

| V | 70 | 95 | |

| PCA-KNN | C | 100 | 100 |

| CV | 99 | 100 | |

| V | 98 | 100 | |

| ECOC SVM | C | 100 | 100 |

| CV | 100 | 100 | |

| V | 100 | 100 | |

| CART | C | 100 | 100 |

| CV | 100 | 100 | |

| V | 100 | 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bonifazi, G.; Bellagamba, S.; Capobianco, G.; Gasbarrone, R.; Lonigro, I.; Malinconico, S.; Paglietti, F.; Serranti, S. Short-Wave Infrared Spectroscopy for On-Site Discrimination of Hazardous Mineral Fibers Using Machine Learning Techniques. Sustainability 2025, 17, 972. https://doi.org/10.3390/su17030972

Bonifazi G, Bellagamba S, Capobianco G, Gasbarrone R, Lonigro I, Malinconico S, Paglietti F, Serranti S. Short-Wave Infrared Spectroscopy for On-Site Discrimination of Hazardous Mineral Fibers Using Machine Learning Techniques. Sustainability. 2025; 17(3):972. https://doi.org/10.3390/su17030972

Chicago/Turabian StyleBonifazi, Giuseppe, Sergio Bellagamba, Giuseppe Capobianco, Riccardo Gasbarrone, Ivano Lonigro, Sergio Malinconico, Federica Paglietti, and Silvia Serranti. 2025. "Short-Wave Infrared Spectroscopy for On-Site Discrimination of Hazardous Mineral Fibers Using Machine Learning Techniques" Sustainability 17, no. 3: 972. https://doi.org/10.3390/su17030972

APA StyleBonifazi, G., Bellagamba, S., Capobianco, G., Gasbarrone, R., Lonigro, I., Malinconico, S., Paglietti, F., & Serranti, S. (2025). Short-Wave Infrared Spectroscopy for On-Site Discrimination of Hazardous Mineral Fibers Using Machine Learning Techniques. Sustainability, 17(3), 972. https://doi.org/10.3390/su17030972