Experimental Investigation of the Hydraulic Performance of a Permeable Block Pavement System Using a Multi-Scale Testing Apparatus

Abstract

1. Introduction

2. Literature Review

2.1. Review of Permeable Pavement Standards

2.2. Characteristics and Permeability Evaluation Methods of Aggregates for Permeable Bases

2.3. Research Distinctiveness and Summary

3. Materials and Methods

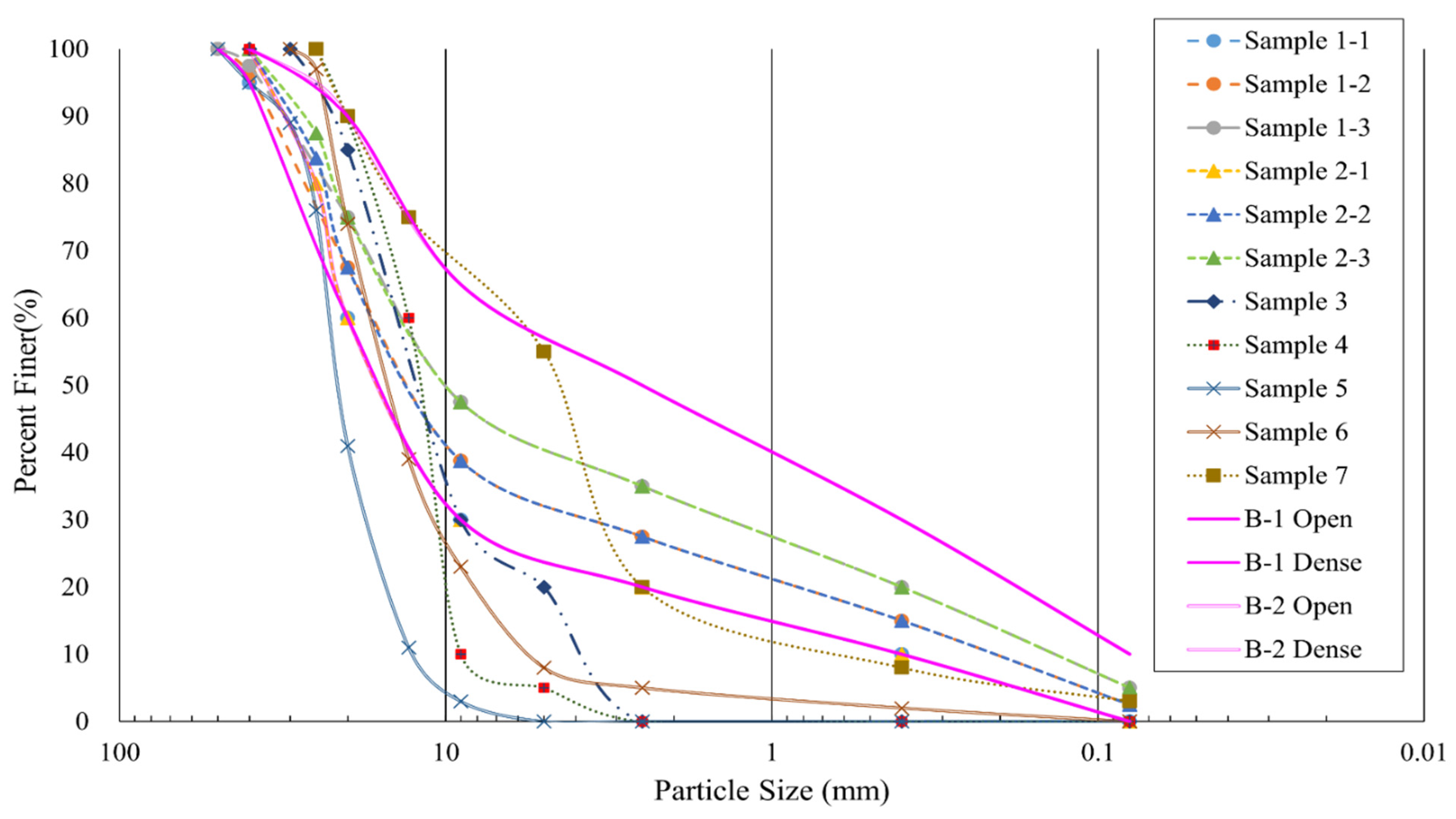

3.1. Test Material

3.2. Permeability Evaluation Equipment

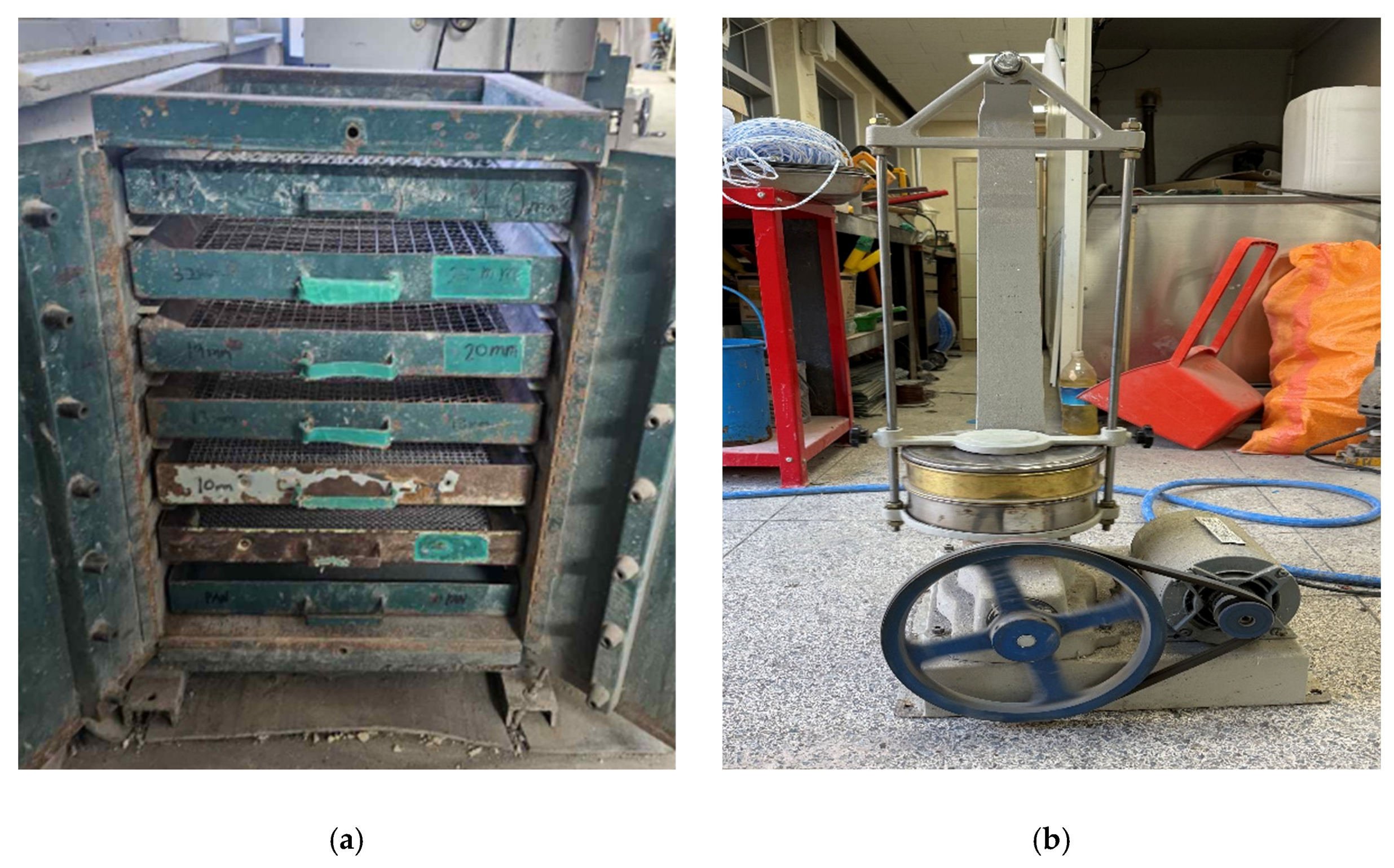

3.2.1. Small-Scale Measurement Equipment and Methods

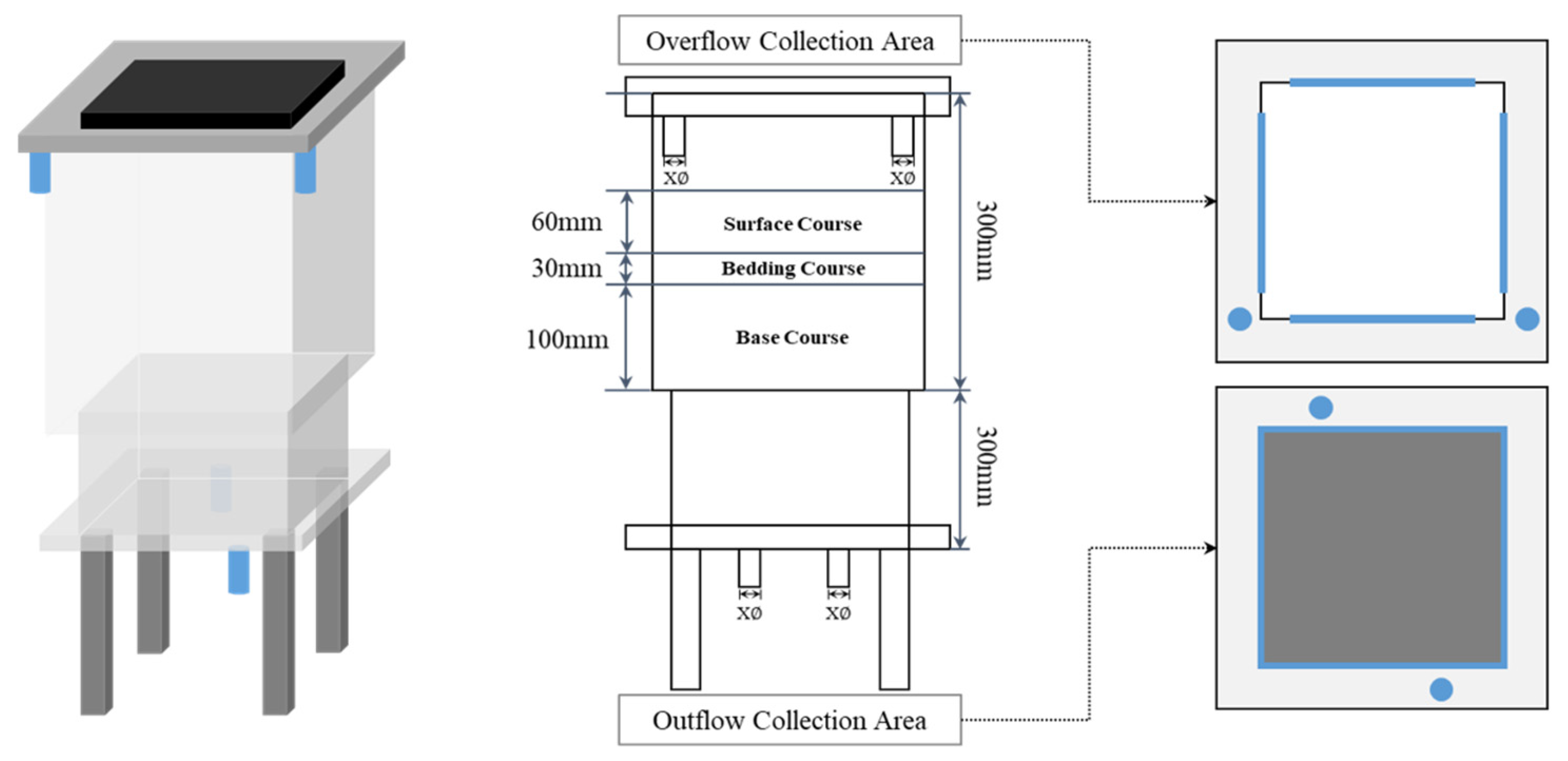

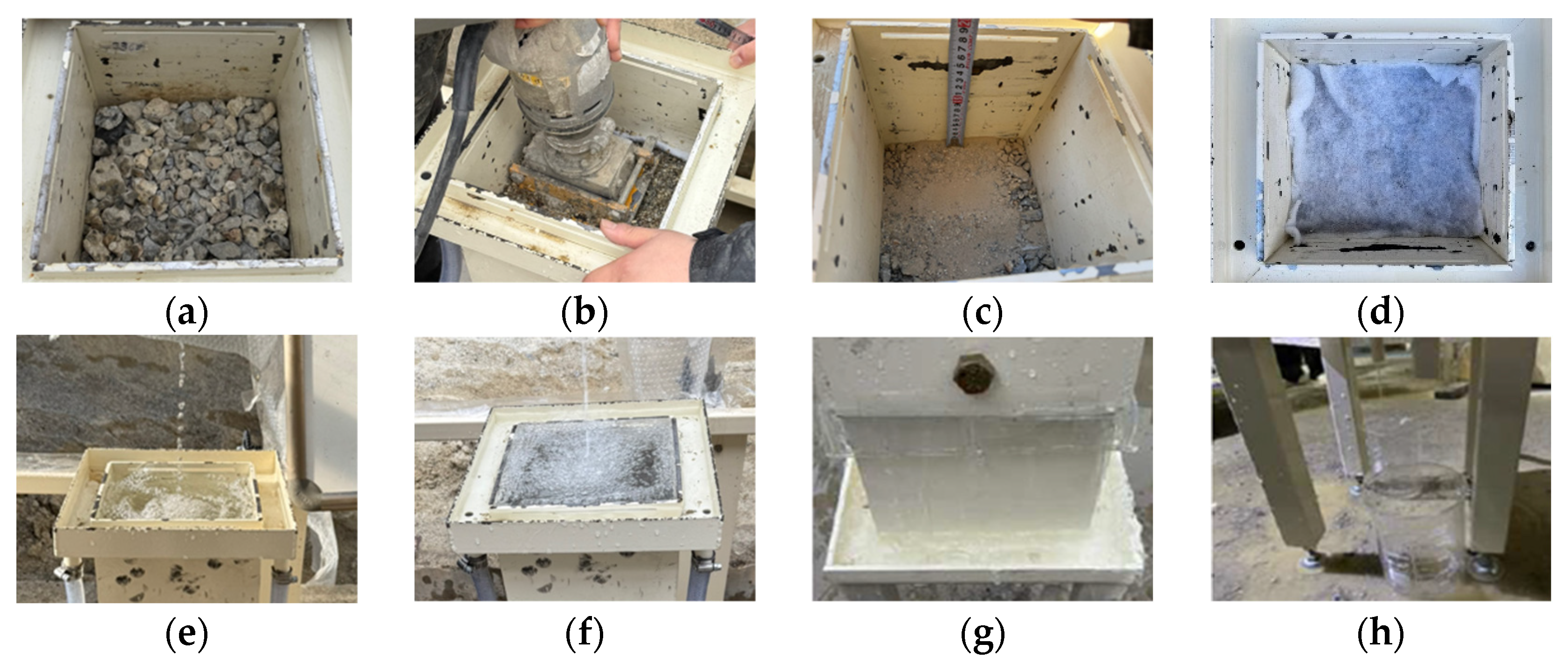

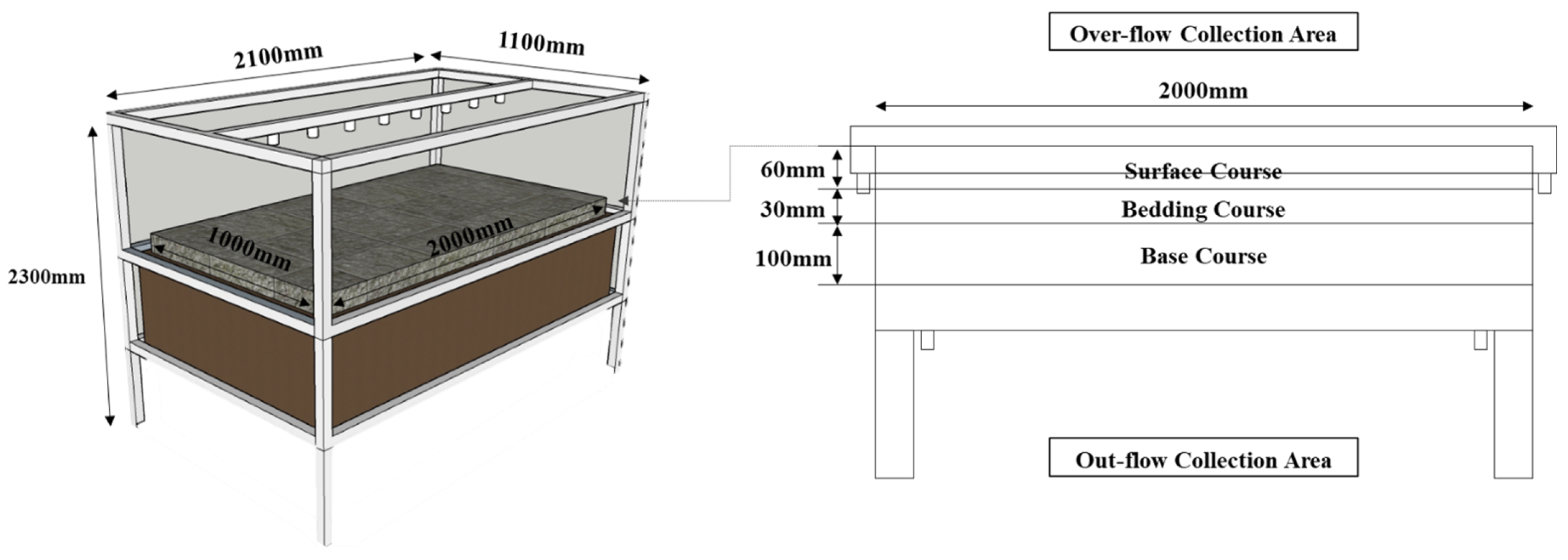

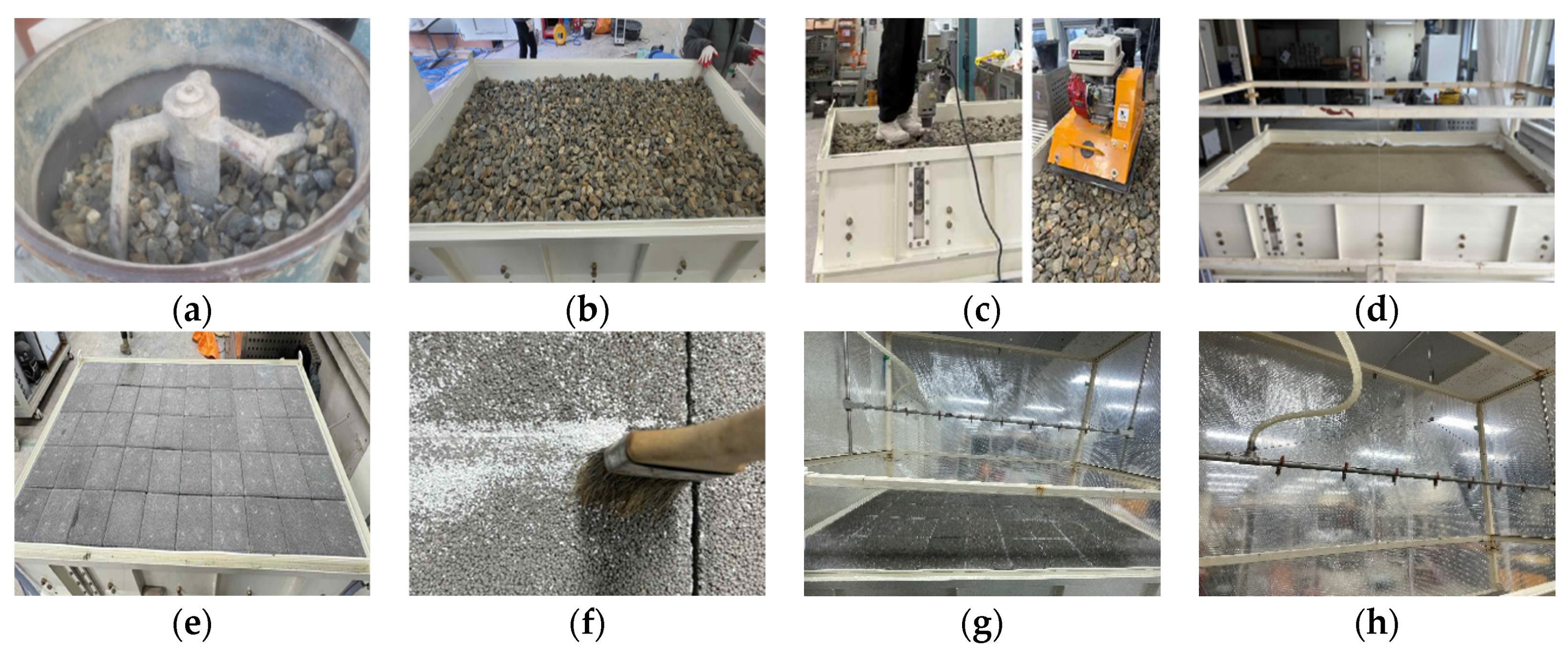

3.2.2. Large-Scale Measurement Equipment and Methods

4. Results

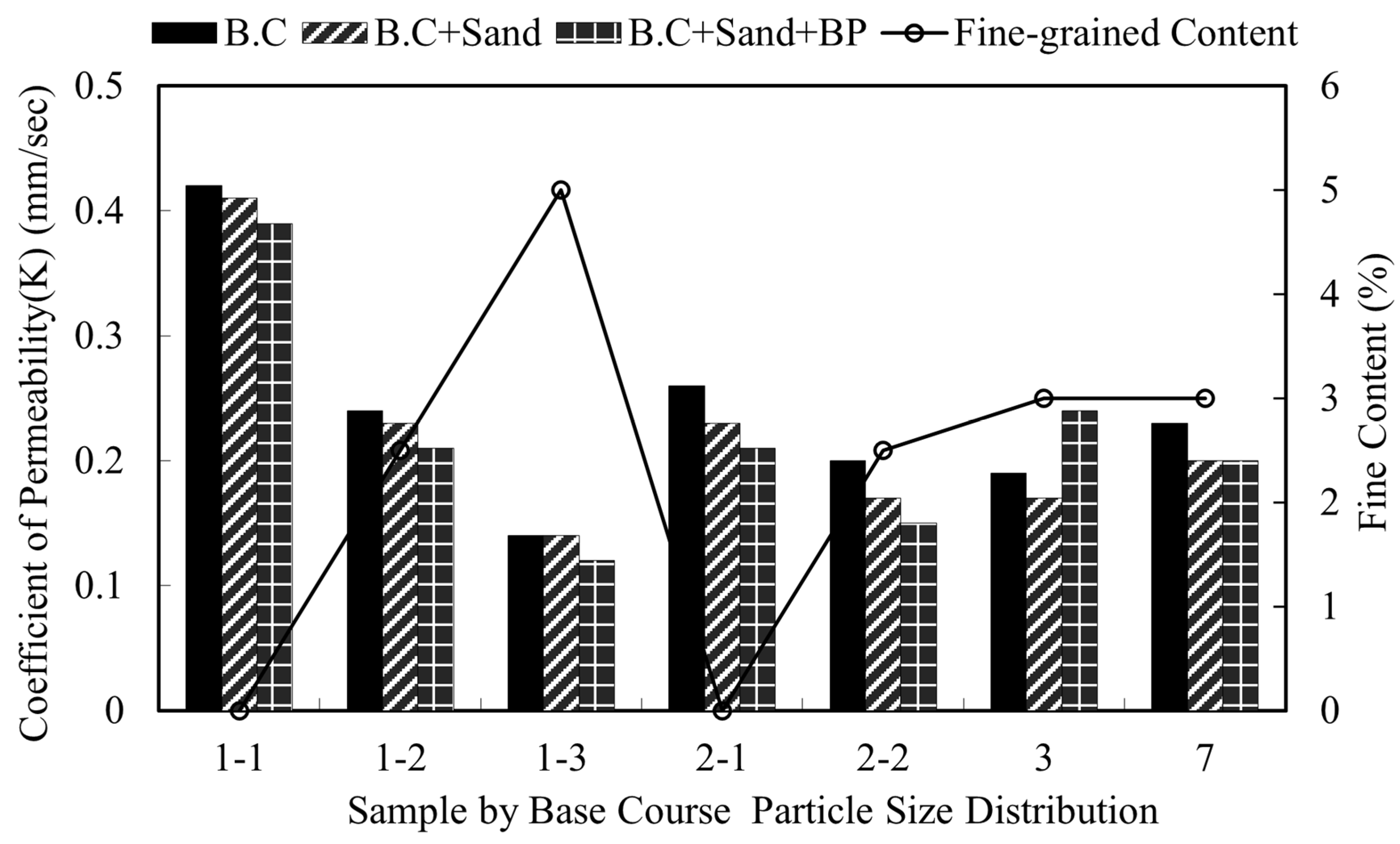

4.1. Permeability Test Results Using the Small-Scale Apparatus

Permeability Test Results

4.2. Permeability Test Results Using the Large-Scale Apparatus

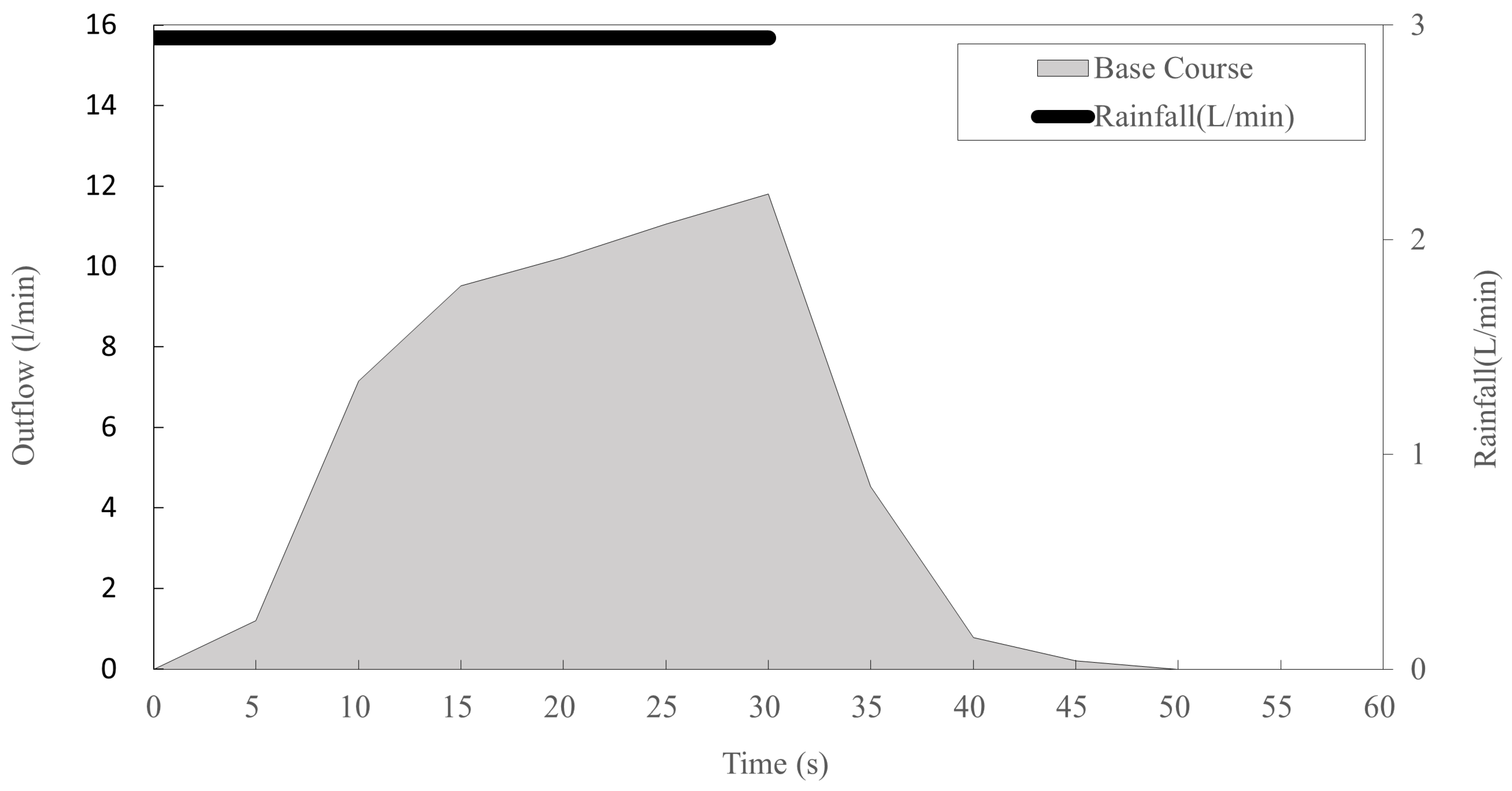

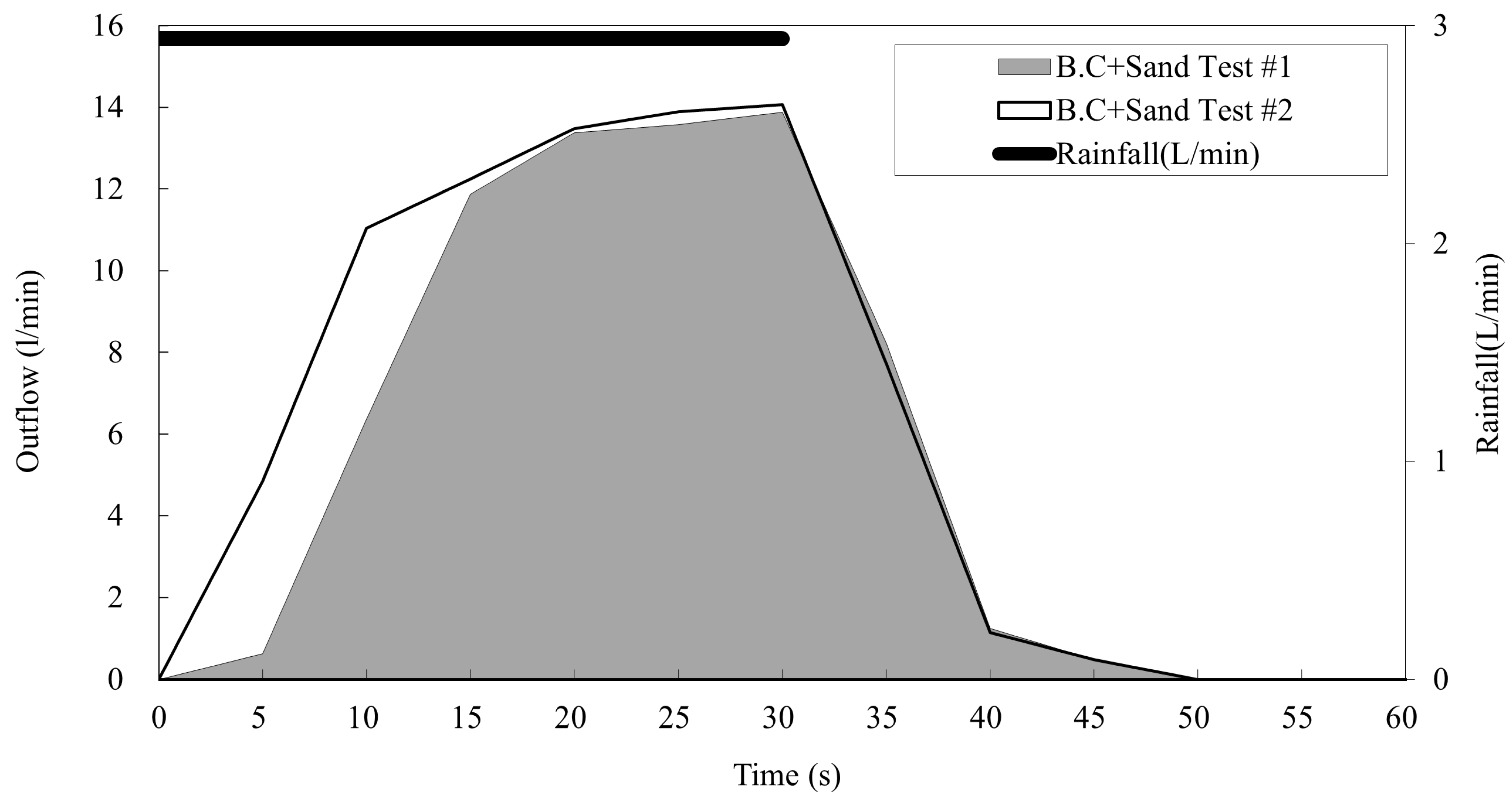

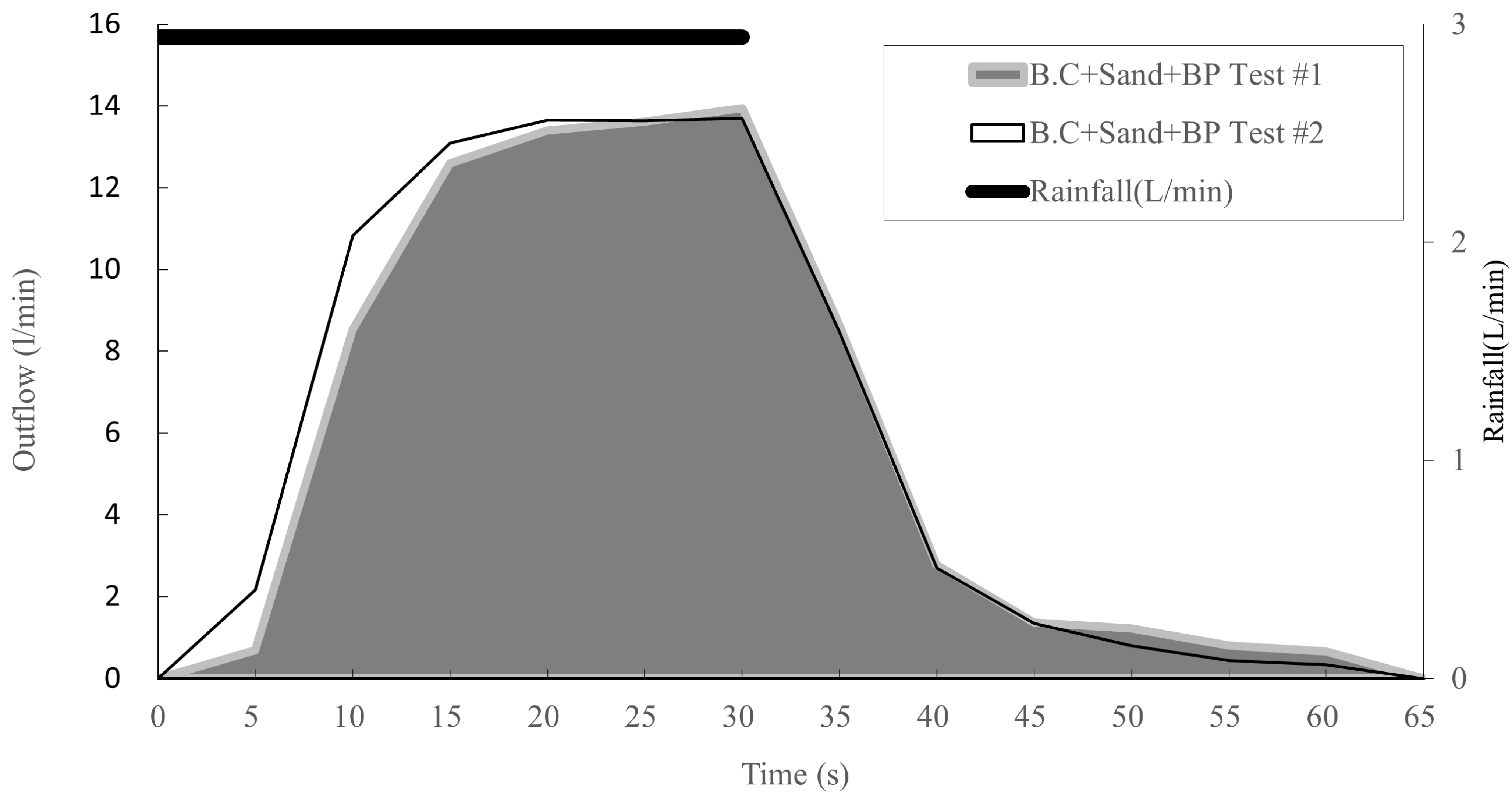

Measurement of Subsurface Runoff and Hydrograph Analysis by Pavement Structure

- Time to initiation (T1): The elapsed time from the onset of rainfall to the first occurrence of subsurface outflow.

- Time to peak (Tp): The elapsed time from the onset of rainfall to the occurrence of the maximum discharge.

- Lag time: The time interval between the peak inflow and the corresponding peak outflow (under constant rainfall conditions.

- Base time: The total duration from the beginning of outflow to its complete cessation.

- Peak discharge (Qp): The maximum outflow rate that can be transmitted through the pavement structure, representing the effective infiltration capacity.

5. Discussion

5.1. Comparison of Permeability Performance According to Base Layer Gradation Characteristics

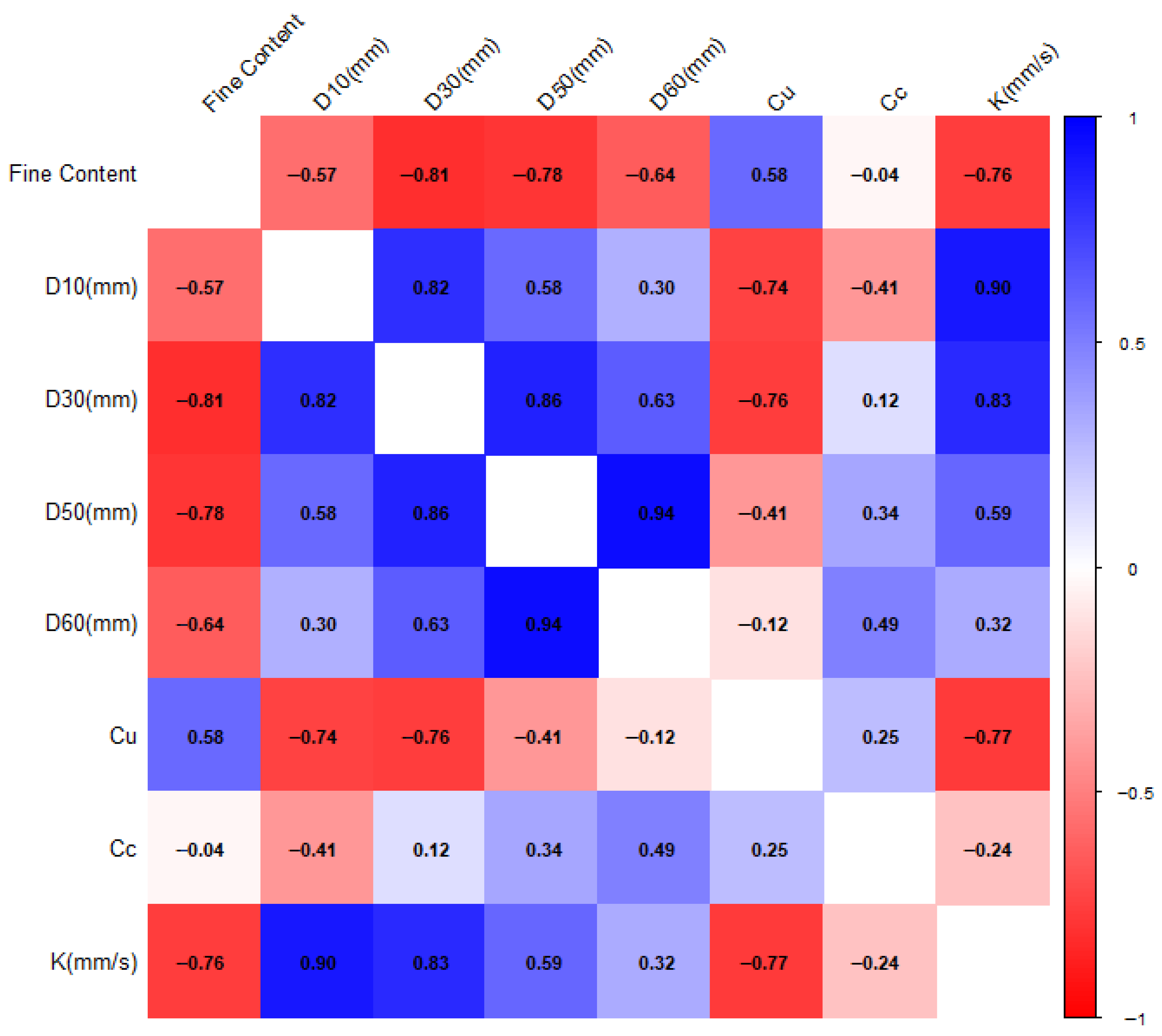

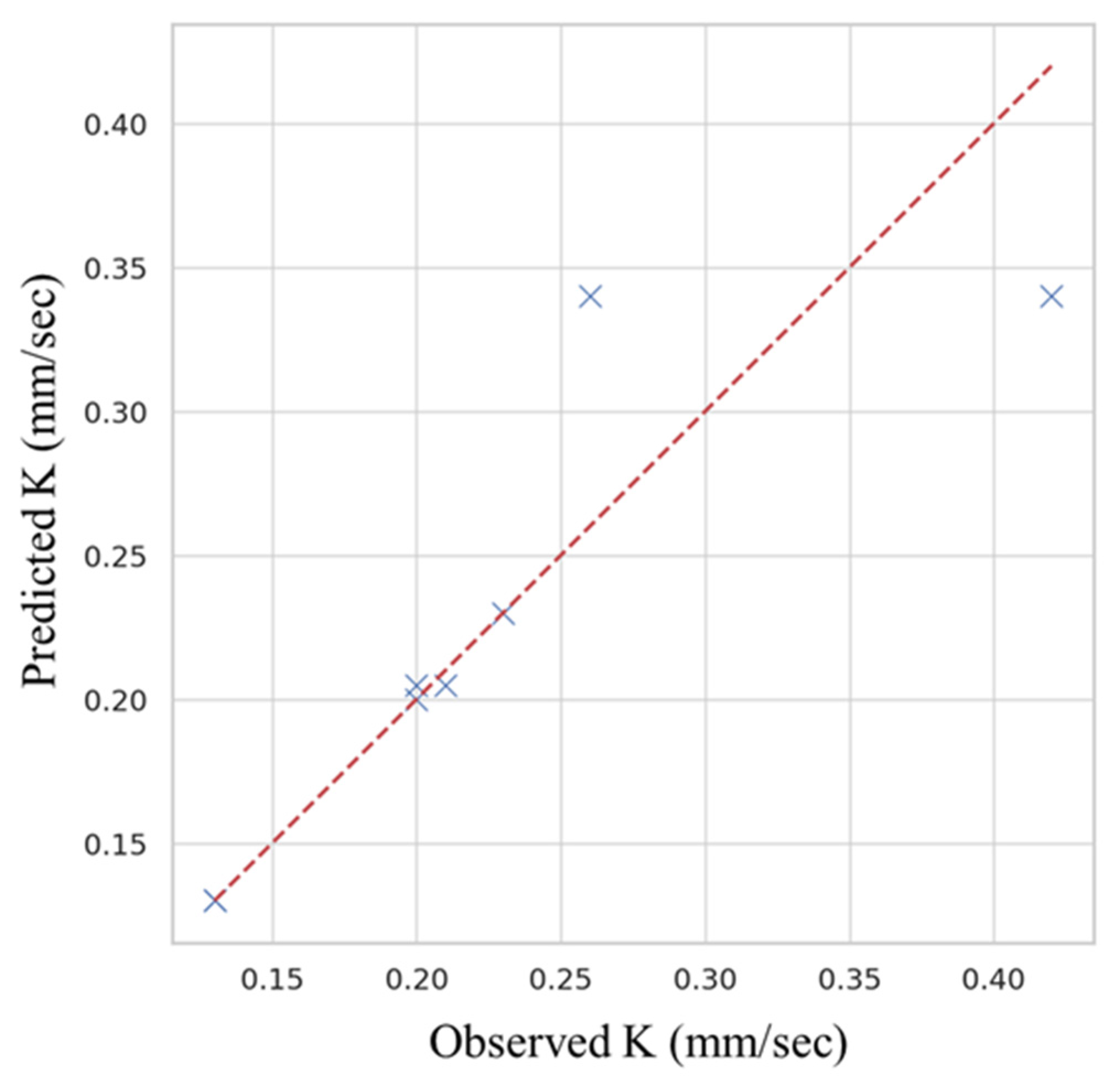

5.2. Evaluation of Particle Size Characteristics and Permeability Coefficient Based on Statistical Analysis

5.3. Comparison of Permeability Performance According to Structural Configuration of the Permeable Block Pavement System

5.4. Analysis of Runoff Hydrographs by Pavement Structure

6. Conclusions

- As expected, the coefficient of permeability decreased with an increase in the fines content in the base aggregates. For every 2.5% increase in particles smaller than 0.075 mm, the permeability coefficient decreased by up to 0.21 mm/s. Aggregates with a lower coefficient of uniformity (Cu) exhibited a marked reduction in permeability, indicating that uniform gradations are less hydraulically conductive.

- When applying the gradation corresponding to ASTM No. 57, permeability was so high that maintaining a constant head condition during testing was not possible. Most particles were distributed between 4.75 mm and 13.2 mm, and the results are consistent with prior research showing that single-sized gradations provide higher hydraulic conductivity due to uniform pore pathways.

- When the fines content exceeded 5%, the volume of water infiltrating into the sublayer decreased, and surface runoff became more dominant, leading to a significant reduction in infiltration performance.

- The permeability coefficient tended to decrease as the bedding layer and permeable block layer were added above the base layer, with a maximum reduction of 0.07 mm/s. Even though the upper layers exhibited higher intrinsic permeability than the base, the hydraulic conductivity of the lower layers was found to be the primary governing factor for the overall permeability of the pavement system.

- Analysis of runoff behavior under a rainfall intensity of 88.2 mm/h using the large-scale rainfall simulator revealed that the time to initial outflow decreased by up to 33 s when the bedding and block layers were added above the base layer. The permeable block surface contributed to flow attenuation and hydraulic stabilization, gradually reducing discharge velocity. The storage capacity was the highest in the base-only configuration, reaching approximately 36%.

- The constant-head tests conducted using the small-scale apparatus indicated that permeable base materials with a permeability coefficient greater than 0.2 mm/s can sufficiently accommodate the designated rainfall intensity. However, since the peak discharge measured in the large-scale system was comparable to the applied rainfall intensity, further research is required to evaluate the integration and capacity compatibility between the pavement drainage system and the connected stormwater management infrastructure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yu, H.; Zhu, Z.; Zhang, Z.; Yu, J.; Oeser, M.; Wang, D. Recycling Waste Packaging Tape into Bituminous Mixtures towards Enhanced Mechanical Properties and Environmental Benefits. J. Clean. Prod. 2019, 229, 22–31. [Google Scholar] [CrossRef]

- Chester, L.; Arnold, C.J.; Gibbons, C.J. Impervious Surface Coverage: The Emergence of a Key Environmental Indicator. J. Am. Plan. Assoc. 1996, 62, 243–258. [Google Scholar] [CrossRef]

- Lepeska, T. The Impact of Impervious Surfaces on Ecohydrology and Health in Urban Ecosystems of Banska Bystrica (Slovakia). Soil Water Res. 2016, 11, 29–36. [Google Scholar] [CrossRef]

- Yu, H.; Zhu, Z.; Leng, Z.; Wu, C.; Zhang, Z.; Wang, D.; Oeser, M. Effect of mixing sequence on asphalt mixtures containing waste tire rubber and warm mix surfactants. J. Clean. Prod. 2020, 246, 119008. [Google Scholar] [CrossRef]

- Marchioni, M.L.; Becciu, G. Permeable Pavement Used in Sustainable Drainage Systems (SUDs): A Synthetic Review of Recent Literature. WIT Trans. Built Environ. 2014, 183–194. [Google Scholar]

- Kim, H.; Jung, M.; Mallari, K.J.B.; Pak, G.; Kim, S.; Kim, S.; Yoon, J. Assessment of Porous Pavement Effectiveness on Runoff Reduction under Climate Change Scenarios. Desalination Water Treat. 2015, 53, 3142–3147. [Google Scholar] [CrossRef]

- Baek, S.S.; Choi, D.H.; Jung, J.W.; Lee, H.J.; Lee, H.; Yoon, K.S.; Cho, K.H. Optimizing Low Impact Development (LID) for Stormwater Runoff Treatment in Urban Areas, Korea: Experimental and Modeling Approach. Water Res. 2015, 86, 122–131. [Google Scholar] [CrossRef]

- Woods Ballard, B.; Wilson, S.; Udale-Clarke, H.; Illman, S.; Scott, T.; Ashley, R.; Kellagher, R. The SuDS Manual; CIRIA C753; Construction Industry Research and Information Association: London, UK, 2015; Available online: https://www.ciria.org/ItemDetail?iProductCode=C753F&Category=FREEPUBS (accessed on 9 October 2025).

- National Research Council, Division on Earth, Water Science, Technology Board; Committee on Reducing Stormwater Discharge Contributions to Water Pollution. Urban stormwater management in the United States; National Academies Press: Washington, DC, USA, 2009. [Google Scholar]

- Kim, J.C.; Jung, K.S. A Study on the Analysis of Reduction Effects and Comparison of Economic Feasibility by Applying the LID Technique. J. Korean Soc. Hazard Mitig. 2024, 24, 39–47. [Google Scholar] [CrossRef]

- Hein, D.K.; Schaus, L. Permeable Pavement Design and Construction: What Have We Learned Recently? In Green Streets, Highways, and Development 2013: Advancing the Practice; American Society of Civil Engineers: Reston, VA, USA, 2013; pp. 31–44. [Google Scholar] [CrossRef]

- Alsubih, M.; Arthur, S.; Wright, G.; Deonie, A. Experimental study on hydrological performance of a permeable pavement. Urban Water J. 2017, 14, 427–434. [Google Scholar] [CrossRef]

- Ministry of Environment. Manual for Applying Low Impact Development (LID) Techniques in Environmental Impact Assessment; Ministry of Environment: Sejong, Republic of Korea, 2013.

- Ministry of Environment. Low Impact Development (LID) Design Guidelines; Ministry of Environment: Sejong, Republic of Korea, 2016.

- Ministry of Land, Infrastructure, and Transport (MOLIT). Guidelines for Sidewalk Installation and Management; MOLIT: Sejong, Republic of Korea, 2021.

- KS F 2523; Standard Terminology for Aggregates. Korean Industrial Standards. Korean Standards Association: Seoul, Republic of Korea, 2024.

- Han, S.I.; Chung, Y.W.; Ahn, J.Y.; Lee, K.G.; Kim, K.Y. Busan National University Korea Low Impact Development Technology Manual for Road and Transportation System; National Library of Korea: Seoul, Republic of Korea, 2019.

- Smith, D.R. Permeable Interlocking Concrete Pavements: Design, Specifications, Construction, Maintenance; Interlocking Concrete Pavement Institute (ICPI): Herndon, VA, USA, 2011. [Google Scholar]

- Brattebo, B.O.; Booth, D.B. Long-Term Stormwater Quantity and Quality Performance of Permeable Pavement Systems. Water Res. 2003, 37, 4369–4376. [Google Scholar] [CrossRef]

- BS EN 13242:2013; Aggregates for unbound and hydraulically bound materials for use in civil engineering work and road construction. British Standards Institution(BSI): Lundon, UK, 2013.

- Wilson, S.; Maclntosh-Watson, M.; Morrell, D.; Urding, T.; Gorst, N. Design & Construction of Concrete Block Permeable Pavements, 7th ed.; Interpave: Leicester, UK, 2018. [Google Scholar]

- AS/NZS 4456:2003; Masonry Units and Segmental Pavers—Methods of Test. Standards Australia: Sydney, Australia; Standards New Zealand: Wellington, New Zealand, 2003.

- Choi, Y.J.; Ahn, D.; Nguyen, T.H.; Ahn, J. Assessment of Field Compaction of Aggregate Base Materials for Permeable Pavements Based on Plate Load Tests. Sustainability 2018, 10, 3817. [Google Scholar] [CrossRef]

- Indraratna, B.; Nguyen, V.T.; Rujikiatkamjorn, C. Hydraulic conductivity of saturated granular soils determined using a constriction-based technique. Can. Geotech. J. 2012, 49, 607–613. [Google Scholar] [CrossRef]

- Taylor, S.A.; Zettler, D.; Radcliffe, D.E. Effect of grain size distribution and compaction on permeability. J. Hydrol. Eng. 2012, 17, 378–383. [Google Scholar]

- Choi, Y.; Ahn, D.; Lee, Y.; Ahn, J. Compaction quality monitoring of open-graded aggregates by light weight deflectometer and soil stiffness gauge. Sustainability 2020, 12, 2521. [Google Scholar] [CrossRef]

- ASTM C-1701; Standard Test Method for Density and Void Content of Hardened Pervious Concrete. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2017.

- ASTM C-1781; Standard Test Method for Surface Infiltration Rate of Permeable Unit Pavement Systems. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2017.

- ASTM D-2434; Standard Test Methods for Measurement of Hydraulic Conductivity of Coarse-Grained Soils. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2022.

- Koohmishi, M. Hydraulic conductivity and water level in the reservoir layer of porous pavement considering gradation of aggregate and compaction level. Constr. Build. Mater. 2019, 203, 27–44. [Google Scholar] [CrossRef]

- Chen, S.; Adhikari, S.; You, Z. Relationship of coefficient of permeability, porosity, and air voids in fine-graded HMA. J. Mater. Civ. Engineering 2019, 31, 04018359. [Google Scholar] [CrossRef]

- KS F 2322; Standard Test Method for Permeability of Saturated Soils. Korean Industrial Standards. Korean Standards Association: Seoul, Republic of Korea, 2017.

- Jang, K.W. The Research Regarding the Coef. of Permeability of the Compacted Fine-Grained Soil. Doctoral Dissertation, Jeju National Unversity, Jeju, Republic of Korea, 2005. [Google Scholar]

- Choi, S.W.; Bae, W.H.; Lee, K.M.; Shin, K.J. Correlation between Crack Width and Water Flow of Cracked Mortar Specimens Measured by Constant Water Head Permeability Test. J. Korea Concr. Inst. 2017, 29, 267–273. [Google Scholar] [CrossRef]

- Schaus, L.; Hein, D. Use of Permeable Pavements [Tech Brief] (No. FHWA-HIF-23-076); Department of Transportation, Federal Highway Administration: Washington, DC, USA, 2023.

- KS F 4419; Concrete Interlocking Block for Sidewalk and Road. Korean Industrial Standards. Korean Standards Association: Seoul, Republic of Korea, 2021.

- Seoul Metropolitan Government. Sidewalk Construction Design and Implementation Manual Ver2.0; Seoul Metropolitan Government: Seoul, Republic of Korea, 2021.

- Chea, C.W.; Lee, H.J.; Lee, J.H.; Lee, M.G.; Song, C.S. Characteristics of Frost Heaving to Grain Size and Permeability of Aggregate Materials. Proc. Korean Geotechical Soc. Conf. 2010, 2010, 1103–1109. [Google Scholar]

- Koohmishi, M.; Azarhoosh, A. Assessment of permeability of granular drainage layer considering particle size and air void distribution. Constr. Build. Mater. 2021, 270, 121373. [Google Scholar] [CrossRef]

- Ghabchi, R.; Zaman, M.; Khoury, N.; Kazmee, H.; Solanki, P. Effect of gradation and source properties on stability and drainability of aggregate bases: A laboratory and field study. Int. J. Pavement Eng. 2013, 14, 274–290. [Google Scholar] [CrossRef]

- Oh, H.; Likos, W.J.; Edil, T.B. Drainability of Base Aggregate and Sand (No. NRRA202107); Minnesota, Department of Transportation: Saint Paul, MN, USA, 2021.

- Das, B.M. Advanced Soil Mechanics; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar] [CrossRef]

- Van Lopik, J.H.; Zazai, L.; Hartog, N.; Schotting, R.J. Nonlinear flow behavior in packed beds of natural an and variably graded granular materials. Transp. Porous Media 2020, 131, 957–983. [Google Scholar] [CrossRef]

- James, W.; von Langsdorff, H.; McIntyre, M. Permeable pavers designed for rapid renewal by considering sweeper mechanics: Initial field tests. J. Water Manag. Model. 2018, 26, C450. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, S.; Hu, G.; Yang, T.; Du, C.; Oeser, M. Infiltration capacity and structural analysis of permeable pavements for sustainable urban: Afull-scale case study. J. Clean. Prod. 2021, 288, 125111. [Google Scholar] [CrossRef]

| System | Definition | Benefits | Differences |

|---|---|---|---|

| SUDs (Sustainable Urban Drainage Systems) | Manage runoff on-site through distributed structure that mimic natural processes (UK-centric) |

|

|

| BMPs (Best Management Practices) | Structural and non-structural techniques for runoff quantity management and pollutant removal (North America-centric) |

|

|

| LID (Low Impact Development) | Small-scale, distributed techniques to maintain pre-development hydrologic conditions |

|

|

| Test Material | Abrasion Resistance | Plastic Index | Stability | Porosity | Specific Gravity |

|---|---|---|---|---|---|

| Crushed Aggregate | 20.9% | 1.90 | 8.6% | 38.8% | 2.65 |

| Sample | Bottom Out-Flow (g) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Base Course | Base Course + Sand | Base Course + Sand + BP | |||||||

| Test 1 | Test 2 | Test 3 | Test 1 | Test 2 | Test 3 | Test 1 | Test 2 | Test 3 | |

| 1-1 | 1486 | 1340 | 1304 | 966 | 960 | 968 | 692 | 696 | 694 |

| 1-2 | 680 | 670 | 670 | 500 | 510 | 530 | 290 | 300 | 290 |

| 1-3 | 420 | 400 | 410 | 320 | 330 | 320 | 210 | 210 | 190 |

| 2-1 | 810 | 770 | 780 | 460 | 430 | 470 | 390 | 380 | 380 |

| 2-2 | 670 | 670 | 670 | 380 | 390 | 410 | 310 | 310 | 320 |

| 2-3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 3 | 640 | 640 | 630 | 500 | 490 | 500 | 350 | 290 | 330 |

| 4 | - * | - | - | 500 | 510 | 500 | 660 | 680 | 670 |

| 5 | - | - | - | - | - | - | - | - | - |

| 6 | - | - | - | - | - | - | - | - | - |

| 7 | 780 | 770 | 780 | 500 | 510 | 530 | 370 | 350 | 360 |

| Type | 1-1 | 1-2 | 1-3 | 2-1 | 2-2 | 3 | 4 | 7 |

|---|---|---|---|---|---|---|---|---|

| Base Course | 0.42 | 0.21 | 0.13 | 0.26 | 0.20 | 0.20 | - | 0.23 |

| Base Course + Sand | 0.40 | 0.21 | 0.13 | 0.19 | 0.15 | 0.20 | 0.27 | 0.20 |

| Base Course + Sand + BP | 0.40 | 0.17 | 0.12 | 0.21 | 0.17 | 0.19 | 0.42 | 0.20 |

| Time (s) | Bottom Out-Flow (L) | ||||

|---|---|---|---|---|---|

| Base Course | Base Course + Sand | Base Course + Sand + BP | |||

| Test 1 | Test 1 | Test 2 | Test 1 | Test 2 | |

| 0 | 0 | 0 | 0 | 0 | 0 |

| 5 | 1.20 | 0.62 | 4.84 | 0.69 | 2.16 |

| 10 | 7.16 | 6.36 | 11.04 | 8.52 | 10.82 |

| 15 | 9.52 | 11.87 | 12.25 | 12.60 | 13.09 |

| 20 | 10.22 | 13.38 | 13.48 | 13.40 | 13.65 |

| 25 | 11.05 | 13.58 | 13.89 | 13.61 | 13.63 |

| 30 | 11.80 | 13.88 | 14.06 | 13.95 | 13.70 |

| 35 | 4.53 | 8.23 | 7.73 | 8.63 | 8.47 |

| 40 | 0.78 | 1.24 | 1.14 | 2.77 | 2.69 |

| 45 | 0.21 | 0.48 | 0.49 | 1.37 | 1.34 |

| 50 | 0 | 0 | 0 | 1.22 | 0.80 |

| 55 | 0 | 0 | 0 | 0.81 | 0.44 |

| 60 | 0 | 0 | 0 | 0.67 | 0.34 |

| Total Outflow | 56.47 | 69.67 | 78.92 | 78.24 | 81.13 |

| Parameter | Base Course | Base Course + Sand | Base Course + Sand + BP | ||

|---|---|---|---|---|---|

| Test 1 | Test 1 | Test 2 | Test 1 | Test 2 | |

| Q | 2.36 L/min | 2.80 L/min | 2.82 L/min | 2.74 L/min | 2.79 L/min |

| T1 (s) | 149 | 46 | 33 | 58 | 67 |

| T (s) | 1800 | 1800 | 1800 | 1200 | 1800 |

| Lag Time (s) | 1500 | 900 | 900 | 900 | 900 |

| Base Time (s) | 1200 | 1200 | 1200 | 1800 | 1800 |

| S | 35.98% | 21.01% | 10.52% | 26.28% | 24.23% |

| Sample | Fine Contene (%) | D10 (mm) | D30 (mm) | D50 (mm) | D60 (mm) | Cu | Cc | K (mm/s) |

|---|---|---|---|---|---|---|---|---|

| 1-1 | 0.0 | 0.40 | 9.00 | 16.33 | 20.00 | 50.00 | 10.13 | 0.42 |

| 1-2 | 2.5 | 0.27 | 3.68 | 13.17 | 16.97 | 63.62 | 3.00 | 0.21 |

| 1-3 | 5.0 | 0.19 | 1.80 | 9.81 | 13.89 | 74.40 | 1.25 | 0.13 |

| 2-1 | 0.0 | 0.40 | 9.00 | 16.33 | 20.00 | 50.00 | 10.13 | 0.26 |

| 2-2 | 2.5 | 0.27 | 3.68 | 13.17 | 16.97 | 63.62 | 3.00 | 0.20 |

| 2-3 | 5.0 | 0.19 | 1.80 | 9.81 | 13.89 | 74.4 | 1.25 | 0.00 |

| 3 | 3.0 | 1.16 | 9.00 | 13.00 | 15.00 | 12.89 | 4.64 | 0.20 |

| 4 | 0.1 | 9.00 | 10.60 | 12.20 | 13.00 | 1.44 | 0.96 | Too High |

| 5 | 0.0 | 12.5 | 17.43 | 21.29 | 22.71 | 1.82 | 1.07 | Too High |

| 6 | 0.0 | 5.53 | 10.75 | 15.20 | 17.20 | 3.11 | 1.21 | Too High |

| 7 | 3.0 | 1.29 | 4.31 | 11.00 | 14.75 | 11.43 | 0.97 | 0.23 |

| Model | Variables | Adjusted R2 | AICc |

|---|---|---|---|

| A | Fine Content, Cu, D10, D30, D10 × D30 | 0.913 | 6.91 |

| B | D10, D10 × D30 | 0.896 | −9.51 |

| C | Cu, D10, D10 × D30 | 0.892 | −5.33 |

| D | Fine Content, D10, D10 × D30 | 0.888 | −5.00 |

| E | Fine Content, D10, D30, D10 × D30 | 0.887 | 0.79 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cho, J.; Hong, S.; Jung, J.; Kim, I. Experimental Investigation of the Hydraulic Performance of a Permeable Block Pavement System Using a Multi-Scale Testing Apparatus. Sustainability 2025, 17, 10535. https://doi.org/10.3390/su172310535

Cho J, Hong S, Jung J, Kim I. Experimental Investigation of the Hydraulic Performance of a Permeable Block Pavement System Using a Multi-Scale Testing Apparatus. Sustainability. 2025; 17(23):10535. https://doi.org/10.3390/su172310535

Chicago/Turabian StyleCho, Jeongyeon, Sungjin Hong, Jongseok Jung, and Intai Kim. 2025. "Experimental Investigation of the Hydraulic Performance of a Permeable Block Pavement System Using a Multi-Scale Testing Apparatus" Sustainability 17, no. 23: 10535. https://doi.org/10.3390/su172310535

APA StyleCho, J., Hong, S., Jung, J., & Kim, I. (2025). Experimental Investigation of the Hydraulic Performance of a Permeable Block Pavement System Using a Multi-Scale Testing Apparatus. Sustainability, 17(23), 10535. https://doi.org/10.3390/su172310535