Life Cycle Assessment of Rooftop Hydroponic Production Systems: A Case Study of ComCrop in Singapore

Abstract

1. Introduction

1.1. Measuring Environmental Impacts of Urban Agriculture

1.2. Singapore and High-Tech Farming

2. Materials and Methods

2.1. LCA Goal and Scope

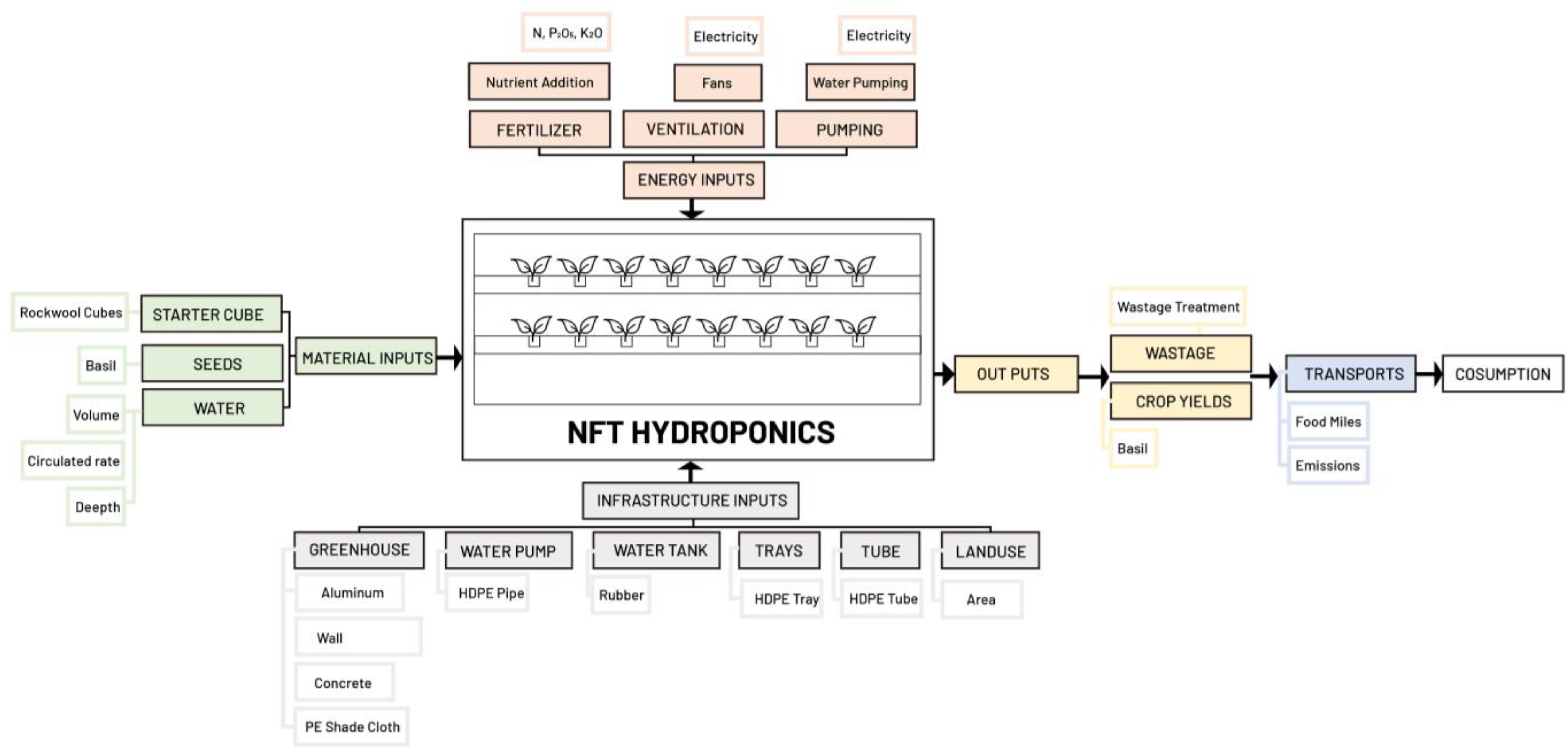

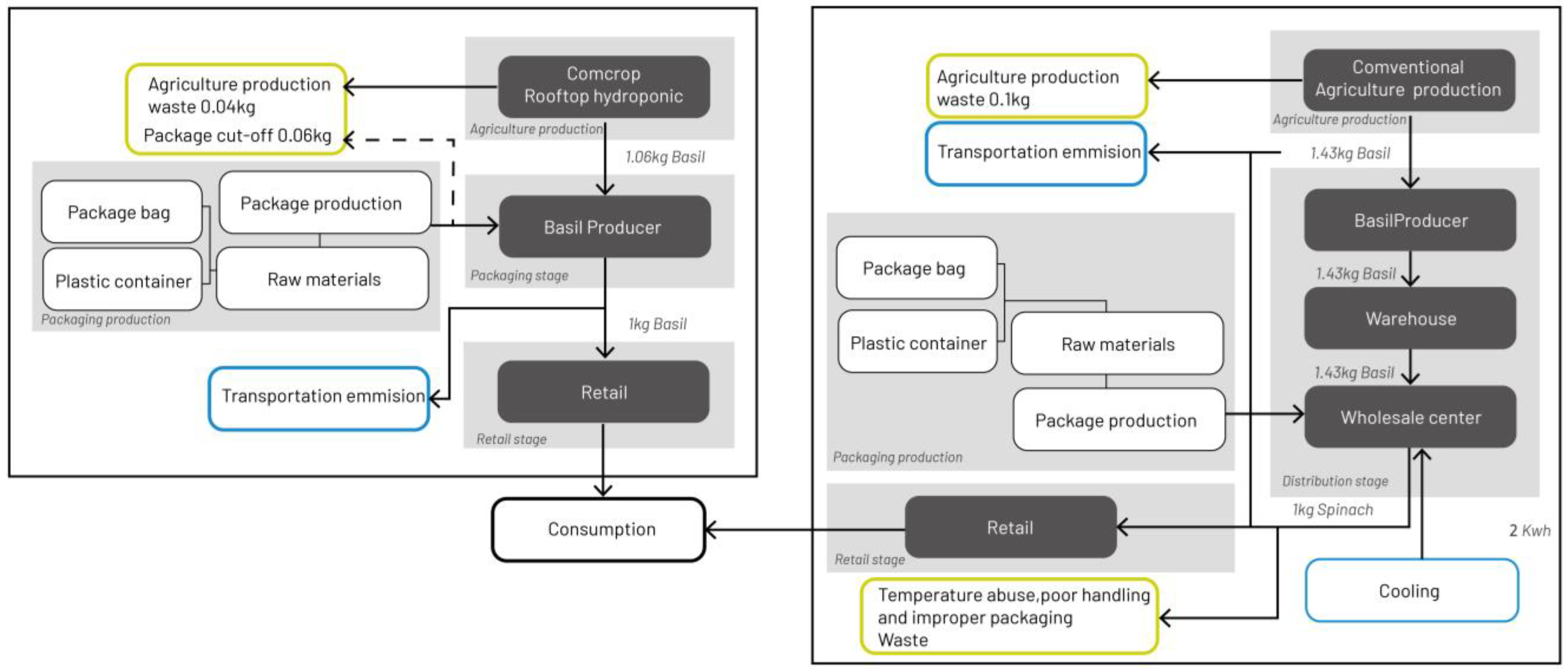

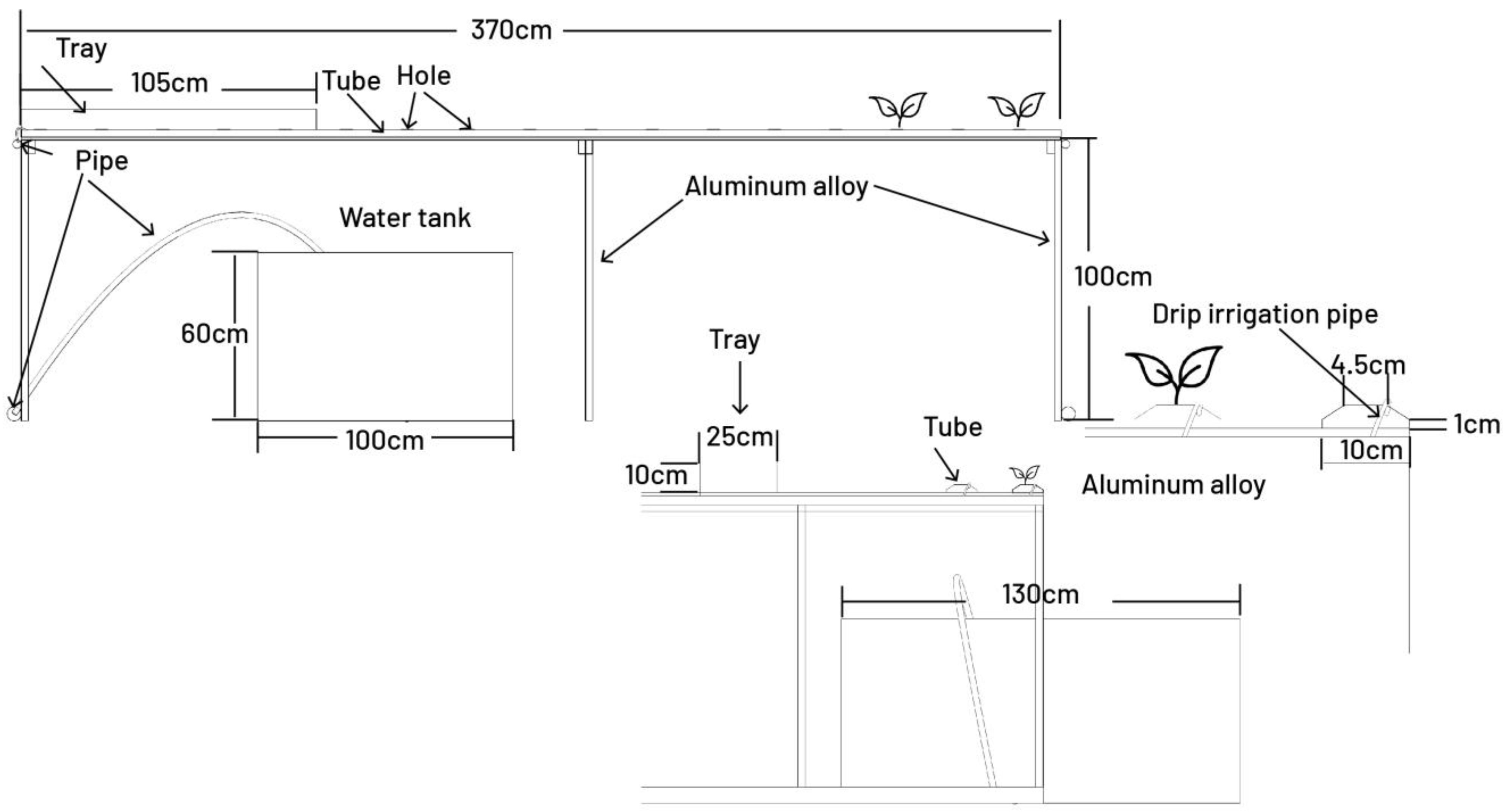

2.2. Life Cycle Inventory (LCI)

2.3. Life Cycle Impact Assessment (LCIA)

2.4. Interpretation and Analysis

3. Results

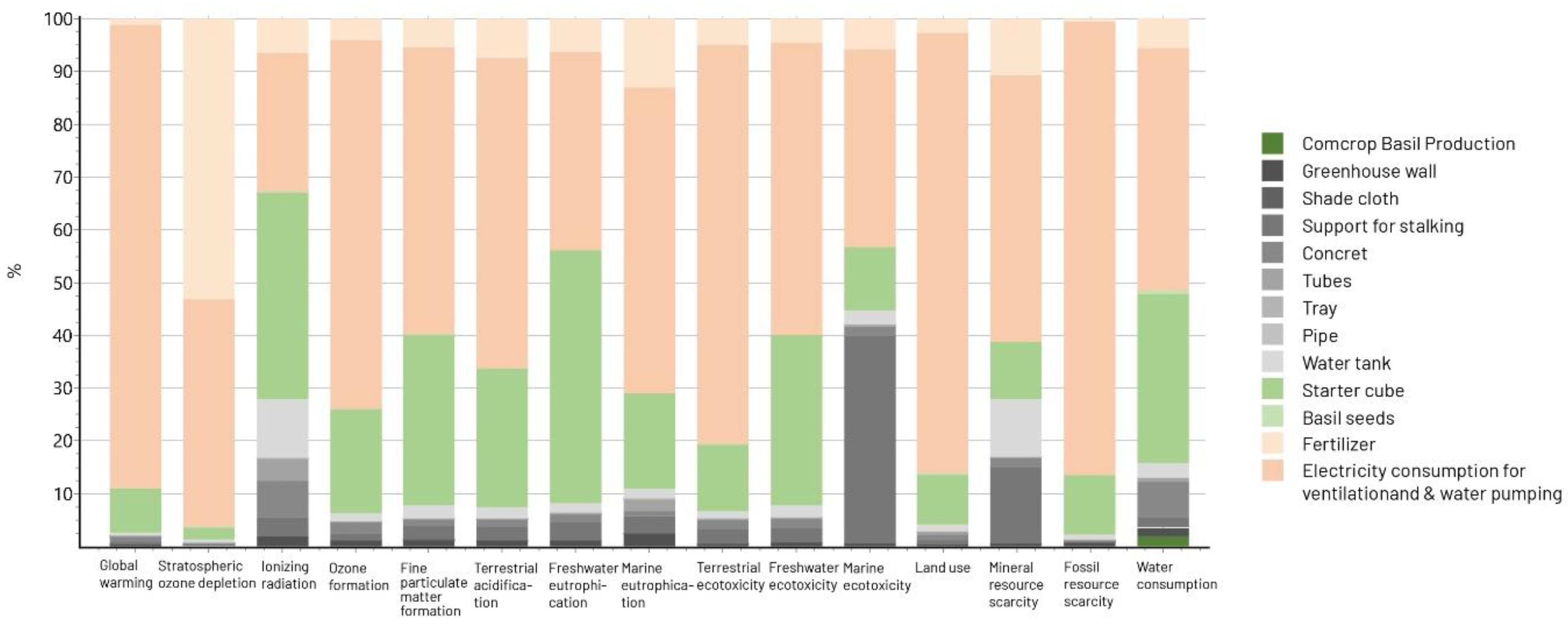

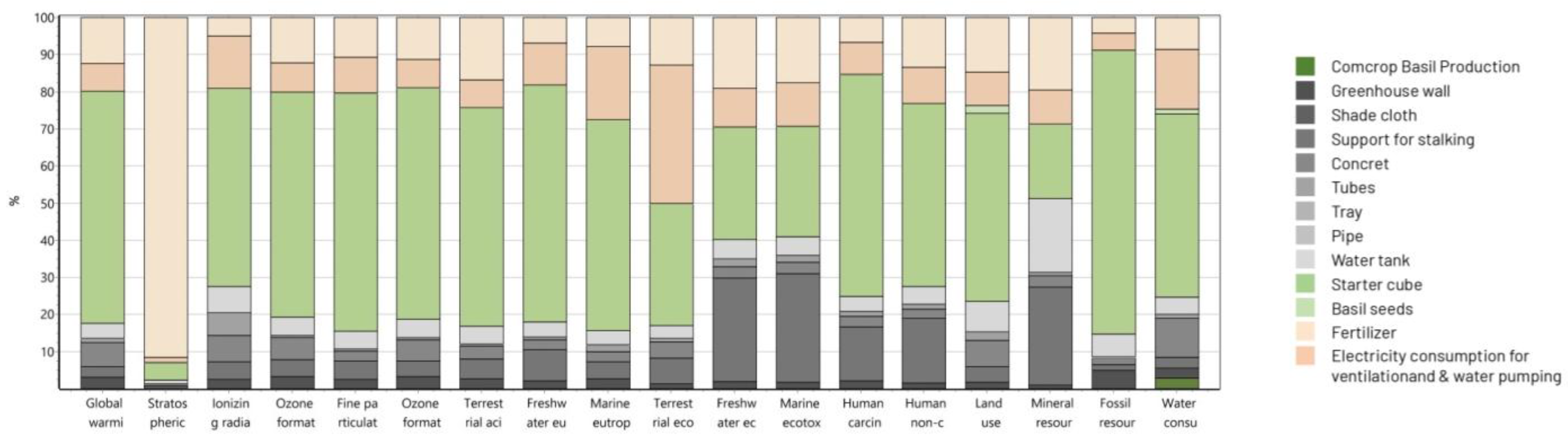

3.1. Life Cycle Impact Assessment (LCIA) of Rooftop Hydronics

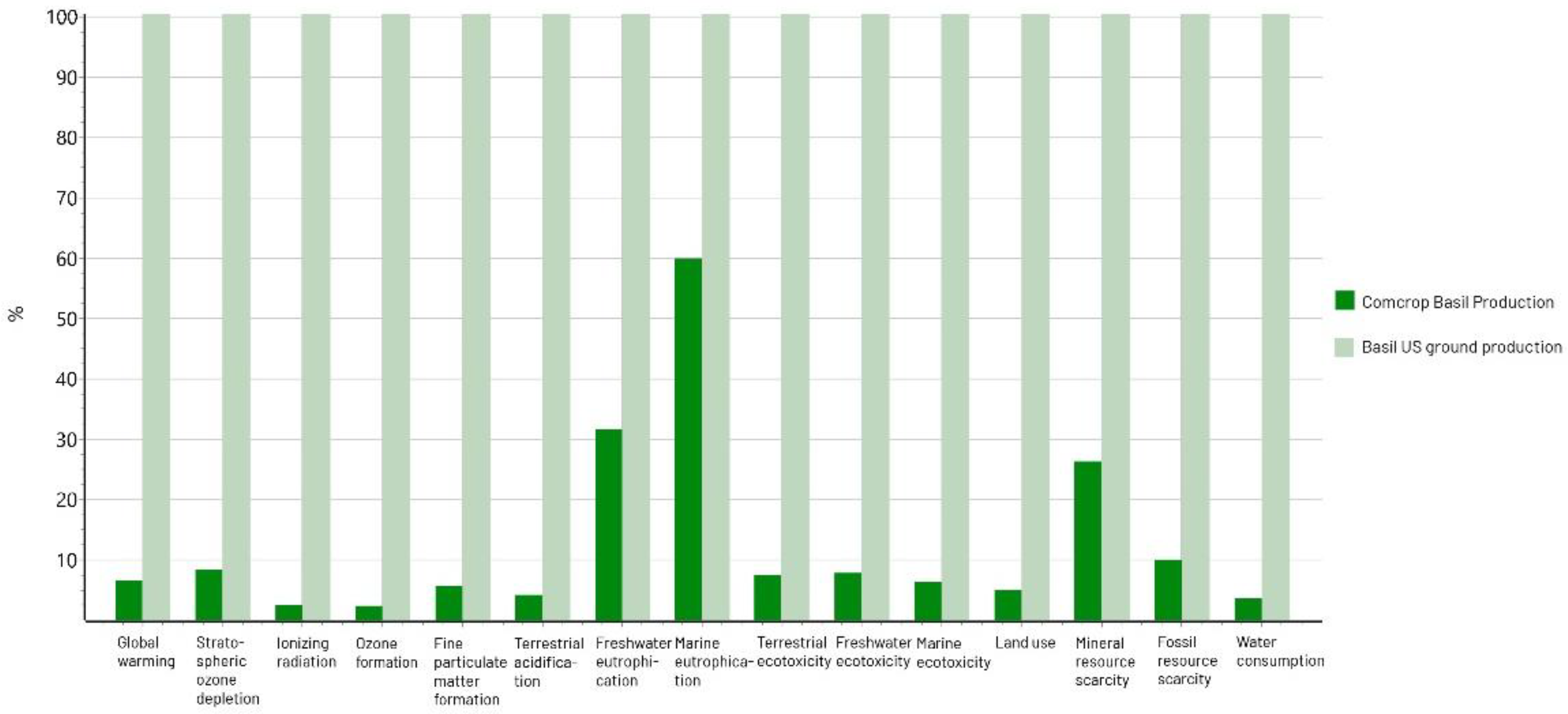

3.2. LCIA of Rooftop Hydronics Versus Conventional Agriculture

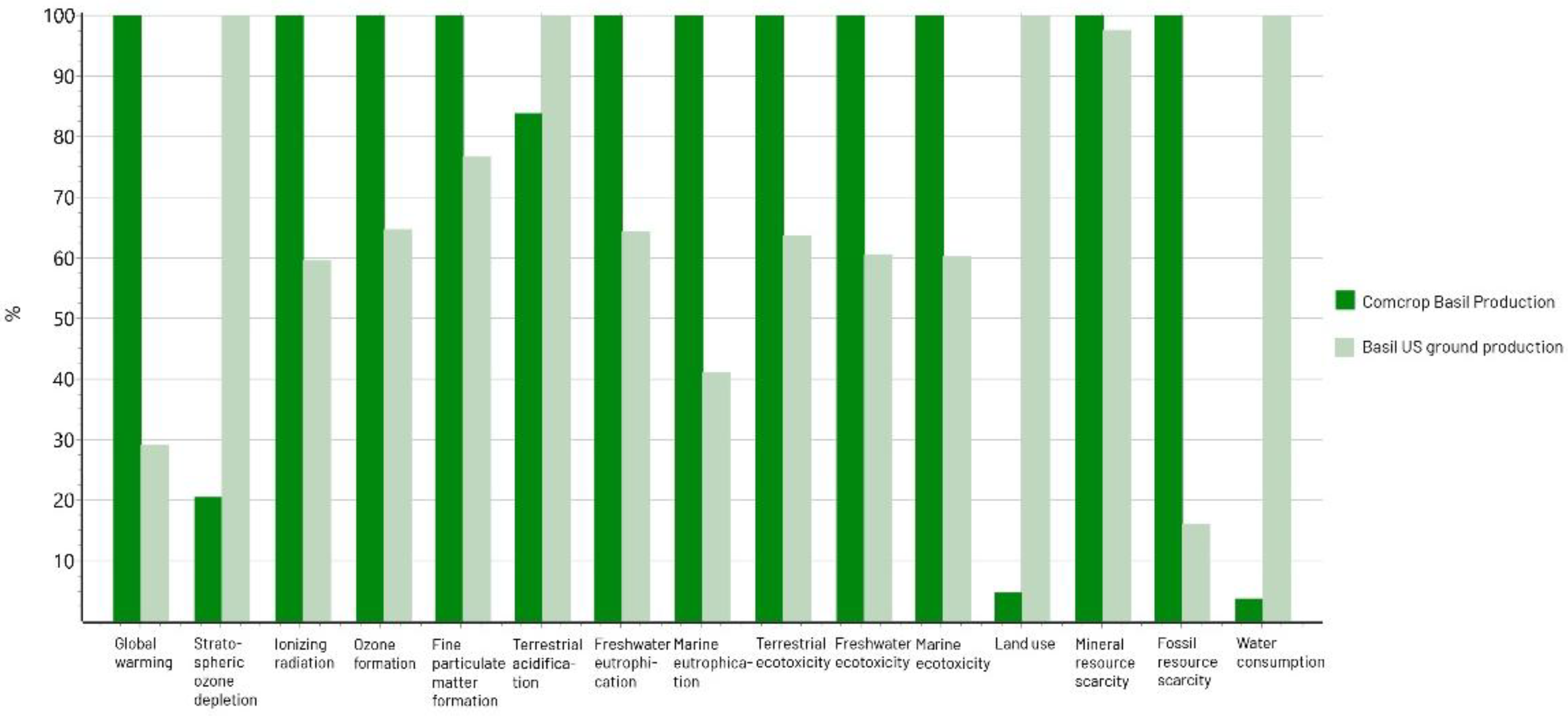

3.3. Sensitivity Analysis Converting to Renewable Energy

4. Discussion

4.1. Limitations

4.2. Recommendations

4.3. Suggestions for Future Research

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CO2 | Carbon Dioxide |

| LCA | Life Cycle Assessment |

| USA | United States of America |

| GHG | Greenhouse Gas |

| UA | Urban Agriculture |

| NFT | Nutrient Film Technique |

| LCI | Life Cycle Inventory |

| LCIA | Life Cycle Inventory Assessment |

References

- Benis, K.; Turan, I.; Reinhart, C.; Ferrão, P. Putting rooftops to use—A Cost-Benefit Analysis of food production vs. energy generation under Mediterranean climates. Cities 2018, 78, 166–179. [Google Scholar] [CrossRef]

- UN-Habitat. Urbanization and Development: Emerging Futures; United Nations Human Settlement Programme (UN-Habitat): Nairobi, Kenya, 2016. [Google Scholar]

- Ge, M.; Friedrich, J.; Vigna, L. Where Do Emissions Come from? 4 Charts Explain Greenhouse Gas Emissions by Sector. World Resources Institute. Available online: https://www.wri.org/insights/4-charts-explain-greenhouse-gas-emissions-countries-and-sectors (accessed on 22 October 2025).

- Mok, W.K.; Tan, Y.X.; Chen, W.N. Technology innovations for food security in Singapore: A case study of future food systems for an increasingly natural resource-scarce world. Trends Food Sci. Technol. 2020, 102, 155–168. [Google Scholar] [CrossRef] [PubMed]

- Van Passel, S. Food miles to assess sustainability: A revision. Sustain. Dev. 2013, 21, 1–17. [Google Scholar] [CrossRef]

- Astee, L.Y.; Kishnani, N.T. Building integrated agriculture: Utilising rooftops for sustainable food crop cultivation in Singapore. J. Green Build. 2010, 5, 105–113. [Google Scholar] [CrossRef]

- Coffman, R.R. Vegetated Roof Systems: Design, Productivity, Retention, Habitat, and Sustainability in Green Roof and Ecoroof Technology. Ph.D. Thesis, The Ohio State University, Columbus, OH, USA, 2007. [Google Scholar]

- Fisher, S.; Karunanithi, A. Contemporary Comparative LCA of Commercial Farming and Urban Agriculture for Selected Fresh Vegetables Consumed in Denver, Colorado. Vashon. In Proceedings of the 9th International Conference on Life Cycle Assessment in the Agri-Food Sector, San Francisco, CA, USA, 8–10 October 2014. [Google Scholar]

- Newman, P. Green urbanism and its application to Singapore. Environ. Urban. Asia 2010, 1, 149–170. [Google Scholar] [CrossRef]

- Dunnett, N.; Kingsbury, N. Planting Green Roofs and Living Walls; Timber Press: Portland, OR, USA, 2008. [Google Scholar]

- Oberndorfer, E.; Lundholm, J.; Bass, B.; Coffman, R.R.; Doshi, H.; Dunnett, N.; Gaffin, S.; Köhler, M.; Liu, K.K.Y.; Rowe, B. Green roofs as urban ecosystems: Ecological structures, functions, and services. BioScience 2007, 57, 823–833. [Google Scholar] [CrossRef]

- Proksch, G. Urban Rooftops as Productive Resources: Rooftop Farming Versus Conventional Green Roofs. 2011. In Proceedings of the ARCC 2011—Considering Research: Reflecting upon Current Themes in Architectural Research, Detroit, MI, USA, 20–24 April 2011. [Google Scholar]

- Gruda, N.; Tanny, J. Protected crops. In Horticulture: Plants for People and Places Volume 1; Springer: Berlin/Heidelberg, Germany, 2014; pp. 327–405. [Google Scholar]

- Gruda, N. Do soilless culture systems have an influence on product quality of vegetables? J. Appl. Bot. Food Qual. 2009, 82, 141–147. [Google Scholar]

- Pomoni, D.I.; Koukou, M.K.; Vrachopoulos, M.G.; Vasiliadis, L. A Review of Hydroponics and Conventional Agriculture Based on Energy and Water Consumption, Environmental Impact, and Land Use. Energies 2023, 16, 1690. [Google Scholar] [CrossRef]

- Ren, X.; Li, J.; He, F.; Lucey, B. Impact of climate policy uncertainty on traditional energy and green markets: Evidence from time-varying granger tests. Renew. Sustain. Energy Rev 2023, 173, 113058. [Google Scholar] [CrossRef]

- Singapore Food Agency. Urban Agriculture Feasibility Study; Singapore Food Agency: Singapore, 2024. [Google Scholar]

- Orsini, F. Rooftop Urban Agriculture; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 2017. [Google Scholar]

- Pimentel, D.; Berger, B.; Filiberto, D.; Newton, M.; Wolfe, B.; Karabinakis, E.; Clark, S.; Poon, E.; Abbett, E.; Nandagopal, S. Water resources: Agricultural and environmental issues. BioScience 2004, 54, 909–918. [Google Scholar] [CrossRef]

- Fisher, S. Engineering Perspective of Water Use for Urban Agriculture. In New forms of Urban Agriculture: An Urban Ecology Perspective; Diehl, J.A., Harpreet, K., Eds.; Springer: Singapore, 2021; pp. 121–140. [Google Scholar]

- Rufí-Salís, M.; Petit-Boix, A.; Villalba, G.; Sanjuan-Delmás, D.; Parada, F.; Ercilla-Montserrat, M.; Arcas-Pilz, V.; Muñoz-Liesa, J.; Rieradevall, J.; Gabarrell, X. Recirculating water and nutrients in urban agriculture: An opportunity towards environmental sustainability and water use efficiency? J. Clean. Prod. 2020, 261, 121213. [Google Scholar] [CrossRef]

- Somerville, C.; Cohen, M.; Pantanella, E.; Stankus, A.; Lovatelli, A. Small-scale aquaponic food production: Integrated fish and plant farming. In FAO Fisheries and Aquaculture Technical Papers; FAO: Rome, Italy, 2014; p. 589. [Google Scholar]

- Miller-Robbie, L.; Ramaswami, A.; Amerasinghe, P. Wastewater treatment and reuse in urban agriculture: Exploring the food, energy, water, and health nexus in Hyderabad, India. Environ. Res. Lett. 2017, 12, 075005. [Google Scholar] [CrossRef]

- Small, G.; Shrestha, P.; Metson, G.S.; Polsky, K.; Jimenez, I.; Kay, A. Excess phosphorus from compost applications in urban gardens creates potential pollution hotspots. Environ. Res. Commun. 2019, 1, 091007. [Google Scholar] [CrossRef]

- Lin, B.B.; Egerer, M.H. Urban agriculture: An opportunity for biodiversity and food provision in urban landscapes. In Urban Biodiversity; Routledge: Oxfordshire, UK, 2017; pp. 71–86. [Google Scholar]

- Van Os, E.A.; Gieling, T.H.; Lieth, J.H. Technical equipment in soilless production systems. In Soilless Culture; Elsevier: London, UK, 2019; pp. 587–635. [Google Scholar]

- Martin, M.; Molin, E. Environmental Assessment of an Urban Vertical Hydroponic Farming System in Sweden. Sustainability 2019, 11, 4124. [Google Scholar] [CrossRef]

- Romeo, D.; Vea, E.B.; Thomsen, M. Environmental Impacts of Urban Hydroponics in Europe: A Case Study in Lyon. Procedia CIRP 2018, 69, 540–545. [Google Scholar] [CrossRef]

- Savvas, D.; Gianquinto, G.; Tuzel, Y.; Gruda, N. 12. Soilless Culture. In Good Agricultural Practices for Greenhouse Vegetable Crops; FAO: Rome, Italy, 2013; p. 303. [Google Scholar]

- Sanyé-Mengual, E.; Cerón-Palma, I.; Oliver-Solà, J.; Montero, J.I.; Rieradevall, J. Environmental analysis of the logistics of agricultural products from roof top greenhouses in Mediterranean urban areas. J. Sci. Food Agric. 2013, 93, 100–109. [Google Scholar] [CrossRef]

- Shafique, M.; Azam, A.; Rafiq, M.; Ateeq, M.; Luo, X. An overview of life cycle assessment of green roofs. J. Clean. Prod. 2020, 250, 119471. [Google Scholar] [CrossRef]

- Blidariu, F.; Grozea, A. Increasing the economical efficiency and sustainability of indoor fish farming by means of aquaponics-review. Sci. Pap. Anim. Sci. Biotechnol. 2011, 44, 1–8. [Google Scholar]

- Hauschild, M.; Jeswiet, J.; Alting, L. From life cycle assessment to sustainable production: Status and perspectives. CIRP Ann. 2005, 54, 1–21. [Google Scholar] [CrossRef]

- Hollmann, R.E. An Aquaponics Life Cycle Assessment: Evaluating an Inovative Method for Growing Local Fish and Lettuce. Master’s Thesis, University of Colorado Denver, Denver, CO, USA, 2017. [Google Scholar]

- Svoboda, S. Note on life cycle analysis. In Pollution Prevention in Corporate Strategy; National Pollution Prevention Center for Higher Education, University of Michigan: Ann Arbor, MI, USA, 1995. [Google Scholar]

- Maldini, I.; Klepp, I.G.; Laitala, K. The environmental impact of product lifetime extension: A literature review and research agenda. Sustain. Prod. Consum. 2025, 56, 561–578. [Google Scholar] [CrossRef]

- Curran, M.A. (Ed.) Life Cycle Assessment Handbook: A Guide for Environmentally Sustainable Products; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Mietz, L.K.; Civit, B.M.; Arena, A.P. Life cycle assessment to evaluate the sustainability of urban agriculture: Opportunities and challenges. Agroecol. Sustain. Food Syst. 2024, 48, 983–1007. [Google Scholar] [CrossRef]

- Lan, K.; Yao, Y. Integrating Life Cycle Assessment and Agent-Based Modeling: A Dynamic Modeling Framework for Sustainable Agricultural Systems. J. Clean. Prod. 2019, 238, 117853. [Google Scholar] [CrossRef]

- Romeiko, X.X. A comparative life cycle assessment of crop systems irrigated with the groundwater and reclaimed water in northern China. Sustainability 2019, 11, 2743. [Google Scholar] [CrossRef]

- Pushkar, S. Modeling the substitution of natural materials with industrial byproducts in green roofs using life cycle assessments. J. Clean. Prod. 2019, 227, 652–661. [Google Scholar] [CrossRef]

- Sanyé-Mengual, E.; Oliver-Solà, J.; Montero, J.I.; Rieradevall, J. An environmental and economic life cycle assessment of rooftop greenhouse (RTG) implementation in Barcelona, Spain. Assessing new forms of urban agriculture from the greenhouse structure to the final product level. Int. J. Life Cycle Assess. 2015, 20, 350–366. [Google Scholar] [CrossRef]

- Wong, N.H.; Tay, S.F.; Wong, R.; Ong, C.L.; Sia, A. Life cycle cost analysis of rooftop gardens in Singapore. Build. Environ. 2003, 38, 499–509. [Google Scholar] [CrossRef]

- Rufí-Salís, M.; Calvo, M.J.; Petit-Boix, A.; Villalba, G.; Gabarrell, X. Exploring nutrient recovery from hydroponics in urban agriculture: An environmental assessment. Resour. Conserv. Recycl. 2020, 155, 104683. [Google Scholar] [CrossRef]

- Jeanneret, P.; Baumgartner, D.U.; Knuchel, R.F.; Koch, B.; Gaillard, G. An expert system for integrating biodiversity into agricultural life-cycle assessment. Ecol. Indic. 2014, 46, 224–231. [Google Scholar] [CrossRef]

- Mujkic, S.; Andakudi Kesavan, K.N. Life Cycle Assessment of Lettuce Production Systems: A Case Study Performed at Hollbium; KTH Royal Institute of Technology: Stockholm, Sweden, 2020. [Google Scholar]

- Delaide, B.; Delhaye, G.; Dermience, M.; Gott, J.; Soyeurt, H.; Jijakli, M.H. Plant and fish production performance, nutrient mass balances, energy and water use of the PAFF Box, a small-scale aquaponic system. Aquac. Eng. 2017, 78, 130–139. [Google Scholar] [CrossRef]

- Kyaw, T.Y.; Ng, A.K. Smart Aquaponics System for Urban Farming. Energy Procedia 2017, 143, 342–347. [Google Scholar] [CrossRef]

- Singapore Food Agency. Available online: https://www.sfa.gov.sg/food-import-export (accessed on 5 September 2019).

- Diehl, J.A.; Sweeney, E.; Wong, B.; Sia, C.S.; Yao, H.; Prabhudesai, M. Feeding cities: Singapore’s approach to land use planning for urban agriculture. Glob. Food Secur. 2020, 26, 100377. [Google Scholar] [CrossRef]

- National Environment Agency. Greenhouse Gas Inventory. Available online: https://www.nea.gov.sg/our-services/climate-change-energy-efficiency/climate-change/greenhouse-gas-inventory (accessed on 25 October 2025).

- Singapore Food Agency. Food Farms in Singapore. Available online: https://www.sfa.gov.sg/fromSGtoSG/farms (accessed on 9 October 2019).

- Ludher, E.K.; Deakin, M.; Diamantini, D.; Borreli, N. Singapore’s smart governance of food. In The Governance of City Food Systems: Case Studies from Around the World; Fondazione Giangiacomo Feltrinelli: Milan, Italy, 2016; pp. 131–154. [Google Scholar]

- iGrow Pre-Owned. ComCrop Completes 2nd Rooftop Farm in Singapore. Available online: https://www.igrowpreowned.com/igrownews/ComCrop-completes-2nd-rooftop-farm-in-singapore (accessed on 21 October 2019).

- Bernstein, S. Aquaponic Gardening: A Step-by-Step Guide to Raising Vegetables and Fish Together; New Society Publishers: Gabriola Island, BC, Canada, 2011. [Google Scholar]

- ComCrop. Available online: www.ComCrop.com (accessed on 5 September 2019).

- Goedkoop, M.O.; Leijting, J.; Ponsioen, T.; Meijer, E. Introduction to LCA with SimaPro. Available online: https://pre-sustainability.com/files/2014/05/SimaPro8IntroductionToLCA.pdf (accessed on 15 January 2020).

- Tridge. Global Market Overview of Japanese Mustard Spinach. Available online: https://www.tridge.com/intelligences/japanese-mustard-spinach (accessed on 20 January 2020).

- Hauschild, M.Z.; Goedkoop, M.; Guinée, J.; Heijungs, R.; Huijbregts, M.; Jolliet, O.; Margni, M.; De Schryver, A.; Humbert, S.; Laurent, A.; et al. Identifying best existing practice for characterization modeling in life cycle impact assessment. Int. J. Life Cycle Assess. 2013, 18, 683–697. [Google Scholar] [CrossRef]

- Agri-Food & Veterinary Authority of Singapore. Good Handling Practices in Packing House for Vegetables; Agri-Food & Veterinary Authority of Singapore: Singapore, 2014. [Google Scholar]

- Forchino, A.A.; Lourguioui, H.; Brigolin, D.; Pastres, R. Aquaponics and sustainability: The comparison of two different aquaponic techniques using the Life Cycle Assessment (LCA). Aquac. Eng. 2017, 77, 80–88. [Google Scholar] [CrossRef]

- Boxman, S.E.; Zhang, Q.; Bailey, D.; Trotz, M.A. Life Cycle Assessment of a Commercial-Scale Freshwater Aquaponic System. Environ. Eng. Sci. 2017, 34, 299–311. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Bare, J.C. Life Cycle Impact Assessment Workshop Summary, Midpoints versus endpoints: The sacrifices and benefits. Int. J. Life Cycle Assess. 2000, 5, 319–326. [Google Scholar] [CrossRef]

- Apte, J.S.; Marshall, J.D.; Cohen, A.J.; Brauer, M. Addressing global mortality from ambient PM2. 5. Environ. Sci. Technol. 2015, 49, 8057–8066. [Google Scholar] [CrossRef] [PubMed]

- Brauer, M.; Freedman, G.; Frostad, J.; Van Donkelaar, A.; Martin, R.V.; Dentener, F.; Dingenen, R.V.; Estep, K.; Amini, H.; Apte, J.S.; et al. Ambient air pollution exposure estimation for the global burden of disease 2013. Environ. Sci. Technol. 2016, 50, 79–88. [Google Scholar] [CrossRef]

- Hauschild, M.Z.; Bonou, A.; Olsen, S.I. Life cycle interpretation. In Life Cycle Assessment: Theory and Practice; Springer International Publishing: Berlin/Heidelberg, Germany, 2017; pp. 323–334. [Google Scholar]

- National Climate Change Secretariate. Singapore’s Approach to Alternative Energy. Available online: https://www.nccs.gov.sg/singapores-climate-action/singapore-approach-to-alternative-energy/ (accessed on 20 February 2020).

- Heath, G.A.; Frischknecht, R.; Itten, R.; Wyss, F.; Blanc, I.; Raugei, M.; Sinha, P.; Wade, A. Life Cycle Assessment of Future Photovoltaic Electricity Production from Residential-Scale Systems Operated in EUROPE (No. NREL/TP-6A20-73849; IEA-PVPS T12-05: 2015); National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2015. [Google Scholar]

- US Energy Information Administration, Singapore. Available online: https://www.eia.gov/international/analysis/country/SGP (accessed on 15 February 2020).

- Wuebbles, D. Ozone Depletion. Available online: https://www.britannica.com/science/ozone-depletion (accessed on 15 September 2019).

- Ministry of Trade and Industry Singapore. Energy Supply. Available online: https://www.mti.gov.sg/energy-and-carbon/energy-supply/ (accessed on 27 October 2025).

- Volza. Basil Imports in World from United Arab Emirates—Market Size & Demand Based on Import Trade Data. Available online: https://www.volza.com/p/basil/import/coo-united-arab-emirates/ (accessed on 25 October 2025).

- FutureMine AI Intelligent Resource Recovery. Basil Extracts Market by Applications: South Korea, Singapore, United Kingdom, Australia. Available online: https://www.linkedin.com/pulse/basil-extracts-market-applications-v9f8f/ (accessed on 25 October 2025).

- Malin, N. Life cycle assessment for whole buildings: Seeking the holy grail. Build. Des. Constr. 2005, 5, 6–11. [Google Scholar]

- Gaines, L.; Stodolsky, F. Lifecycle Analysis: Uses and Pitfalls (No. ANL/ES/CP-92346; CONF-970655-1); Argonne National Lab: Argonne, IL, USA, 1997. [Google Scholar]

| Variable | Definition | Data/Measurement | Data Source | |

|---|---|---|---|---|

| Material inputs | ||||

| Seeds | Leafy greens and herbs, as other plants develop extensive root systems that can easily block the channels [49]. | Basil number | Seeding time | Farm |

| Starter cube | The plants in the growing tubes (channel/gully) are typically suspended above the water by placing seedlings in a starter cube | Cost (SGD) | Public | |

| Dividing unit of inventory item by the life span of the component | Farm | |||

| Total water volume | The sources of water loss are evaporation, evapotranspiration, spillage, leakage, and water exchange [47]. | Water tank/reservoir capacity (L) | Farm | |

| Total water volume (L) | ||||

| Energy Inputs | ||||

| Water pumping | The whole production system water circulation [47,61]. | Spending hours per day/week and cost of electricity (W)(h) | Farm | |

| Ventilation | Fans to alleviate the high temperature | Spending hours per day/week and cost of electricity (W)(h) | Farm | |

| Fertilizer use | Nutrient addition of plants production [62]. | Fertilizer | Farm/ Literature | |

| Nutrient retention time in nutrient solution tank and the floating system unit (h) | Farm | |||

| Use frequency and usage | ||||

| Fertilizer nutrient elements | ||||

| Infrastructure Inputs | ||||

| PE film/mesh | Infrastructure raw materials [48]. | Dividing unit of inventory item by the life span of the component. | LCA software or Farm | |

| Concrete | ||||

| Aluminum | ||||

| PE Shade Cloth | ||||

| HDPE Pipe | Pumping water pipe | |||

| Steel Pipe | Pumping water pipe | |||

| Rubber tank | Used for water tank | |||

| HDPE Tray | Plant/seeding tray | |||

| HDPE tray | Plant/seeding tube | Tube length (cm) and growing density (Number of plants) | Farm | |

| Land use | Hydroponic area/greenhouse area | Greenhouse area (m2) Hydroponic area (m2) | Farm | |

| Outputs | ||||

| Crop Yields | Leafy greens harvesting | Basil (kg) (Number) | Harvesting time | Farm |

| Wastage | Dead vegetables and waste from picking, packaging, transportation, and selling | Percentage of the wastage of the production and transportation | Farm | |

| Wastage treatment | Dead vegetables and waste from picking, packaging, transportation, and selling | Recycling method | Farm | |

| Transportation | ||||

| Food miles | The transport distance to a retail outlet or customer | Kilometer (km) | Farm | |

| Emissions | Carbon emissions of transport from farm to retail outlet or customer | GHG Emission | LCA software | |

| Variable | Material | Lifespan | Units | Quantity per kg |

|---|---|---|---|---|

| Infrastructure Inputs | ||||

| Wall | PE | 15 | kg | 5.4 × 10−4 |

| Shade cloth | PE | 10 | kg | 1.0 × 10−5 |

| Support for stalking | Aluminum | 50 | kg | 1.2 × 10−5 |

| Concrete | Concrete | 50 | m3 | 2.05 × 10−5 |

| Land use | Greenhouse area (m2) Hydroponic area (m2) | 25 | m2 | 14 |

| Tubes | HDPE | 25 | kg | 7.28 × 10−4 |

| Tray | HDPE | 25 | kg | 5.2 × 10−6 |

| Pipe | PE | 15 | kg | 6.0 × 10−6 |

| Water tank | Rubber | 25 | kg | 6.8 × 10−4 |

| Material Inputs | ||||

| Seeds | Seeds | kg | 52 | |

| Water | Water | l | 0.02 | |

| Starter cube | Perlite | kg | 7.25 × 10−3 | |

| Fertilizers | N | kg | 4.8 × 10−4 | |

| P2O5 | kg | 1.2 × 10−4 | ||

| K2O2 | kg | 1.2 × 10−4 | ||

| Ca(NO3)2 | kg | 6.0 × 10−5 | ||

| Mg(NO3)2 | kg | 3.0 × 10−5 | ||

| Energy Inputs | ||||

| Ventilation | Electricity | kw/h | 0.0168 | |

| Water Pumping | Electricity | kw/h | 0.528 | |

| Transport Inputs | ||||

| Transport (seed) | Transport van | tkm | 8.32 × 10−6 | |

| Transport (fertilizers) | Transport van | tkm | 3.42 × 10−6 | |

| Outputs | Material | Units | Quantity per kg |

|---|---|---|---|

| Wastage | Plant waste | kg | 0.04 |

| Package cut-off | kg | 0.1 | |

| Compost | kg | 0 | |

| Transport (wastage) | Transport vehicle | tkm | 0 |

| Impact Category (Unit) | Total | Basil Production | Infrastructure Inputs | Material Inputs | Energy Inputs | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Greenhouse | ||||||||||||||

| Greenhouse Wall | Shade Cloth | Stalking Support | Concrete | Tubes | Tray | Pipe | Water Tank | Starter Cube | Basil Seeds | Electricity | Fertilizer | |||

| Global warming (kg CO2 eq) | 2.99 × 10−1 | 0.00 × 1000 | 1.38 × 10−3 | 2.33 × 10−5 | 1.34 × 10−3 | 3.00 × 10−3 | 4.47 × 10−4 | 3.19 × 10−6 | 1.44 × 10−5 | 1.91 × 10−3 | 2.88 × 10−2 | 2.32 × 10−5 | 2.56 × 10−1 | 5.76 × 10−3 |

| Stratospheric ozone depletion (kg CFC11 eq) | 2.21 × 10−7 | 0.00 × 1000 | 2.90 × 10−10 | 5.40 × 10−12 | 6.65 × 10−10 | 4.10 × 10−10 | 3.06 × 10−10 | 2.19 × 10−12 | 3.08 × 10−12 | 1.22 × 10−9 | 5.70 × 10−9 | 9.85 × 10−11 | 9.89 × 10−8 | 1.14 × 10−7 |

| Ionizing radiation (kBq Co-60 eq) | 2.25 × 10−3 | 0.00 × 1000 | 5.32 × 10−5 | 5.31 × 10−7 | 9.99 × 10−5 | 1.54 × 10−4 | 1.30 × 10−4 | 9.31 × 10−7 | 3.53 × 10−7 | 1.51 × 10−4 | 1.14 × 10−3 | 1.06 × 10−6 | 4.10 × 10−4 | 1.05 × 10−4 |

| Ozone formation, human health (kg NOx eq) | 3.12 × 10−4 | 0.00 × 1000 | 3.28 × 10−6 | 4.99 × 10−8 | 4.59 × 10−6 | 6.15 × 10−6 | 5.85 × 10−7 | 4.18 × 10−9 | 3.10 × 10−8 | 5.00 × 10−6 | 6.17 × 10−5 | 1.02 × 10−7 | 2.18 × 10−4 | 1.24 × 10−5 |

| Fine particulate matter formation (kg PM2.5 eq) | 1.40 × 10−4 | 0.00 × 1000 | 1.73 × 10−6 | 2.52 × 10−8 | 3.50 × 10−6 | 1.92 × 10−6 | 3.29 × 10−7 | 2.35 × 10−9 | 1.58 × 10−8 | 3.41 × 10−6 | 4.53 × 10−5 | 4.57 × 10−8 | 7.60 × 10−5 | 7.60 × 10−6 |

| Ozone formation, terrestrial ecosystems (kg NOx eq) | 3.25 × 10−4 | 0.00 × 1000 | 3.61 × 10−6 | 5.33 × 10−8 | 4.64 × 10−6 | 6.24 × 10−6 | 6.04 × 10−7 | 4.32 × 10−9 | 3.32 × 10−8 | 5.43 × 10−6 | 6.88 × 10−5 | 1.05 × 10−7 | 2.23 × 10−4 | 1.25 × 10−5 |

| Terrestrial acidification (kg SO2 eq) | 3.37 × 10−4 | 0.00 × 1000 | 3.93 × 10−6 | 6.33 × 10−8 | 8.03 × 10−6 | 5.20 × 10−6 | 7.32 × 10−7 | 5.23 × 10−9 | 3.93 × 10−8 | 7.40 × 10−6 | 8.84 × 10−5 | 1.30 × 10−7 | 1.98 × 10−4 | 2.53 × 10−5 |

| Freshwater eutrophication (kg P eq) | 2.80 × 10−5 | 0.00 × 1000 | 3.22 × 10−7 | 4.24 × 10−9 | 1.28 × 10−6 | 4.35 × 10−7 | 1.08 × 10−7 | 7.69 × 10−10 | 2.67 × 10−9 | 6.03 × 10−7 | 9.83 × 10−6 | 6.43 × 10−9 | 1.44 × 10−5 | 1.07 × 10−6 |

| Marine eutrophication (kg N eq) | 1.71 × 10−6 | 0.00 × 1000 | 3.01 × 10−8 | 3.12 × 10−10 | 5.16 × 10−8 | 2.89 × 10−8 | 2.01 × 10−8 | 1.43 × 10−10 | 2.13 × 10−10 | 4.37 × 10−8 | 6.33 × 10−7 | 3.80 × 10−10 | 8.10 × 10−7 | 8.67 × 10−8 |

| Terrestrial ecotoxicity (kg 1,4-DCB) | 5.33 × 10−1 | 0.00 × 1000 | 2.55 × 10−3 | 4.97 × 10−5 | 1.47 × 10−2 | 9.21 × 10−3 | 1.82 × 10−3 | 1.30 × 10−5 | 2.93 × 10−5 | 7.08 × 10−3 | 6.84 × 10−2 | 1.39 × 10−4 | 4.03 × 10−1 | 2.69 × 10−2 |

| Freshwater ecotoxicity (kg 1,4-DCB) | 2.08 × 10−2 | 0.00 × 1000 | 4.25 × 10−5 | 7.47 × 10−7 | 6.24 × 10−4 | 6.89 × 10−5 | 4.55 × 10−5 | 3.25 × 10−7 | 4.31 × 10−7 | 1.19 × 10−4 | 6.77 × 10−4 | 2.51 × 10−6 | 1.88 × 10−2 | 4.27 × 10−4 |

| Marine ecotoxicity (kg 1,4-DCB) | 2.57 × 10−2 | 0.00 × 1000 | 5.55 × 10−5 | 9.74 × 10−7 | 9.13 × 10−4 | 9.21 × 10−5 | 5.99 × 10−5 | 4.28 × 10−7 | 5.63 × 10−7 | 1.57 × 10−4 | 9.26 × 10−4 | 3.25 × 10−6 | 2.30 × 10−2 | 5.51 × 10−4 |

| Human carcinogenic toxicity (kg 1,4-DCB) | 4.97 × 10−3 | 0.00 × 1000 | 3.94 × 10−5 | 6.18 × 10−7 | 2.76 × 10−4 | 5.16 × 10−5 | 2.58 × 10−5 | 1.84 × 10−7 | 4.89 × 10−7 | 7.56 × 10−5 | 1.13 × 10−3 | 1.01 × 10−6 | 3.24 × 10−3 | 1.27 × 10−4 |

| Human non-carcinogenic toxicity (kg 1,4-DCB) | 1.53 × 10−1 | 0.00 × 1000 | 8.49 × 10−4 | 1.36 × 10−5 | 9.72 × 10−3 | 1.37 × 10−3 | 8.26 × 10−4 | 5.90 × 10−6 | 8.11 × 10−6 | 2.63 × 10−3 | 2.76 × 10−2 | 1.06 × 10−5 | 1.02 × 10−1 | 7.47 × 10−3 |

| Land use (m2a crop eq) | 4.14 × 10−3 | 0.00 × 1000 | 1.33 × 10−5 | 2.06 × 10−7 | 3.17 × 10−5 | 5.30 × 10−5 | 1.68 × 10−5 | 1.20 × 10−7 | 1.22 × 10−7 | 6.28 × 10−5 | 3.82 × 10−4 | 1.56 × 10−5 | 3.46 × 10−3 | 1.12 × 10−4 |

| Mineral resource scarcity (kg Cu eq) | 5.32 × 10−4 | 0.00 × 1000 | 2.71 × 10−6 | 5.75 × 10−8 | 7.65 × 10−5 | 8.94 × 10−6 | 2.26 × 10−6 | 1.62 × 10−8 | 2.92 × 10−8 | 5.76 × 10−5 | 5.80 × 10−5 | 1.35 × 10−7 | 2.69 × 10−4 | 5.65 × 10−5 |

| Fossil resource scarcity (kg oil eq) | 1.24 × 10−1 | 0.00 × 1000 | 9.22 × 10−4 | 1.64 × 10−5 | 3.19 × 10−4 | 3.02 × 10−4 | 6.87 × 10−5 | 4.91 × 10−7 | 1.01 × 10−5 | 1.18 × 10−3 | 1.46 × 10−2 | 6.62 × 10−6 | 1.06 × 10−1 | 8.04 × 10−4 |

| Water consumption (m3) | 1.05 × 10−3 | 2.00 × 10−5 | 1.73 × 10−5 | 4.62 × 10−7 | 1.95 × 10−5 | 7.12 × 10−5 | 8.05 × 10−6 | 5.75 × 10−8 | 1.43 × 10−7 | 3.10 × 10−5 | 3.36 × 10−4 | 8.99 × 10−6 | 4.83 × 10−4 | 5.83 × 10−5 |

| Scenario | Yield (kg/m2) | Water Consumption (L/kg) | Fertilizer Use (kg/kg) | Land Use (m2/kg) |

|---|---|---|---|---|

| Rooftop hydroponic system | 890.0 | 0.02 | 6.0 | 0.41 |

| Conventional agriculture | 164.3 | 0.53 | 28.9 | 2.22 |

| Impact Category | Unit | Basil (ComCrop) | Basil (USA) |

|---|---|---|---|

| Global warming | kg CO2 eq | 5.90 × 10−1 | 8.90 × 1000 |

| Stratospheric ozone depletion | kg CFC11 eq | 3.11 × 10−7 | 3.75 × 10−6 |

| Ionizing radiation | kBq Co-60 eq | 1.67 × 10−3 | 6.38 × 10−2 |

| Ozone formation, Human health | kg NOx eq | 9.86 × 10−4 | 4.33 × 10−2 |

| Fine particulate matter formation | kg PM2.5 eq | 5.06 × 10−4 | 9.11 × 10−3 |

| Ozone formation, Terrestrial ecosystems | kg NOx eq | 1.05 × 10−3 | 4.37 × 10−2 |

| Terrestrial acidification | kg SO2 eq | 1.15 × 10−3 | 2.72 × 10−2 |

| Freshwater eutrophication | kg P eq | 1.20 × 10−5 | 3.83 × 10−5 |

| Marine eutrophication | kg N eq | 2.42 × 10−6 | 4.06 × 10−6 |

| Terrestrial ecotoxicity | kg 1,4-DCB | 1.18 × 1000 | 1.59 × 101 |

| Freshwater ecotoxicity | kg 1,4-DCB | 2.59 × 10−4 | 3.35 × 10−3 |

| Marine ecotoxicity | kg 1,4-DCB | 1.04 × 10−3 | 1.62 × 10−2 |

| Human carcinogenic toxicity | kg 1,4-DCB | 4.13 × 10−3 | 1.09 × 10−2 |

| Human non-carcinogenic toxicity | kg 1,4-DCB | 7.66 × 10−2 | 1.10 × 1000 |

| Land use | m2a crop eq | 1.34 × 10−2 | 2.75 × 10−1 |

| Mineral resource scarcity | kg Cu eq | 1.13 × 10−3 | 4.33 × 10−3 |

| Fossil resource scarcity | kg oil eq | 2.90 × 10−1 | 2.88 × 1000 |

| Water consumption | m3 | 5.58 × 10−3 | 1.52 × 10−1 |

| Impact Category | Unit | Basil (ComCrop) Without Transportation | Basil (USA) Without Transportation |

|---|---|---|---|

| Global warming | kg CO2 eq | 5.87 × 10−1 | 1.72 × 10−1 |

| Stratospheric ozone depletion | kg CFC11 eq | 3.09 × 10−7 | 1.49 × 10−6 |

| Ionizing radiation | kBq Co-60 eq | 1.87 × 10−2 | 1.12 × 10−2 |

| Ozone formation, Human health | kg NOx eq | 9.66 × 10−4 | 6.27 × 10−4 |

| Fine particulate matter formation | kg PM2.5 eq | 5.01 × 10−4 | 3.86 × 10−4 |

| Ozone formation, Terrestrial ecosystems | kg NOx eq | 1.03 × 10−3 | 6.39 × 10−4 |

| Terrestrial acidification | kg SO2 eq | 1.13 × 10−3 | 1.35 × 10−3 |

| Freshwater eutrophication | kg P eq | 1.03 × 10−4 | 6.62 × 10−5 |

| Marine eutrophication | kg N eq | 1.07 × 10−5 | 4.41 × 10−6 |

| Terrestrial ecotoxicity | kg 1,4-DCB | 1.12 × 1000 | 7.11 × 10−1 |

| Freshwater ecotoxicity | kg 1,4-DCB | 3.11 × 10−2 | 1.89 × 10−2 |

| Marine ecotoxicity | kg 1,4-DCB | 3.91 × 10−2 | 2.36 × 10−2 |

| Human carcinogenic toxicity | kg 1,4-DCB | 1.35 × 10−2 | 6.18 × 10−3 |

| Human non-carcinogenic toxicity | kg 1,4-DCB | 3.46 × 10−1 | −3.01 × 10−1 |

| Land use | m2a crop eq | 1.30 × 10−2 | 2.56 × 10−1 |

| Mineral resource scarcity | kg Cu eq | 1.12 × 10−3 | 1.09 × 10−3 |

| Fossil resource scarcity | kg oil eq | 2.89 × 10−1 | 4.74 × 10−2 |

| Water consumption | m3 | 5.57 × 10−3 | 1.48 × 10−1 |

| Impact Category (unit) | Total | ComCrop Basil Production (Solar) | Infrastructure Inputs | Material Inputs | Energy Inputs | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Greenhouse | ||||||||||||||

| Greenhouse Wall | Shade Cloth | Stalking Support | Concrete | Tubes | Tray | Pipe | Water Tank | Starter Cube | Basil Seeds | Photovoltaic Cell | Fertilizer | |||

| Global warming (kg CO2 eq) | 1.27 × 10−1 ++ | 0.00 × 1000 | 1.38 × 10−3 | 2.33 × 10−5 | 1.34 × 10−3 | 3.00 × 10−3 | 4.47 × 10−4 | 3.19 × 10−6 | 1.44 × 10−5 | 1.91 × 10−3 | 2.88 × 10−2 | 2.32 × 10−5 | 8.41 × 10−2 ++ | 5.76 × 10−3 |

| Stratospheric ozone depletion (kg CFC11 eq) | 1.65 × 10−7 + | 0.00 × 1000 | 2.90 × 10−10 | 5.40 × 10−12 | 6.65 × 10−10 | 4.10 × 10−10 | 3.06 × 10−10 | 2.19 × 10−12 | 3.08 × 10−12 | 1.22 × 10−9 | 5.70 × 10−9 | 9.85 × 10−11 | 4.27 × 10−8 ++ | 1.14 × 10−7 |

| Ionizing radiation (kBq Co-60 eq) | 8.59 × 10−4 ++ | 0.00 × 1000 | 4.77 × 10−6 ++ | 5.41 × 10−8 ++ | 9.33 × 10−6 ++ | 1.60 × 10−5 ++ | 1.12 × 10−5 ++ | 8.00 × 10−8 ++ | 3.50 × 10−8 ++ | 2.31 × 10−5 ++ | 1.01 × 10−4 ++ | 1.82 × 10−7 ++ | 6.79 × 10−4 (-) | 1.40 × 10−5 ++ |

| Ozone formation, Human health (kg NOx eq) | 2.95 × 10−4 + | 0.00 × 1000 | 3.28 × 10−6 | 4.99 × 10−8 | 4.59 × 10−6 | 6.15 × 10−6 | 5.85 × 10−7 | 4.18 × 10−9 | 3.10 × 10−8 | 5.00 × 10−6 | 6.17 × 10−5 | 1.02 × 10−7 | 2.01 × 10−4 + | 1.24 × 10−5 |

| Fine particulate matter formation (kg PM2.5 eq) | 2.33 × 10−4 (-) | 0.00 × 1000 | 1.72 × 10−6 | 2.52 × 10−8 | 3.50 × 10−6 | 1.92 × 10−6 | 3.28 × 10−7 | 2.34 × 10−9 | 1.57 × 10−8 | 3.40 × 10−6 | 4.53 × 10−5 | 4.56 × 10−8 | 1.69 × 10−4 (-) | 7.51 × 10−6 |

| Ozone formation, Terrestrial ecosystems (kg NOx eq) | 3.13 × 10−4 | 0.00 × 1000 | 3.61 × 10−6 | 5.33 × 10−8 | 4.64 × 10−6 | 6.24 × 10−6 | 6.04 × 10−7 | 4.32 × 10−9 | 3.32 × 10−8 | 5.43 × 10−6 | 6.88 × 10−5 | 1.05 × 10−7 | 2.11 × 10−4 + | 1.25 × 10−5 |

| Terrestrial acidification (kg SO2 eq) | 4.18 × 10−4 (-) | 0.00 × 1000 | 3.93 × 10−6 | 6.32 × 10−8 | 8.03 × 10−6 | 5.20 × 10−6 | 7.32 × 10−7 | 5.23 × 10−9 | 3.93 × 10−8 | 7.40 × 10−6 | 8.84 × 10−5 | 1.30 × 10−7 | 2.79 × 10−4 (-) | 2.50 × 10−5 |

| Freshwater eutrophication (kg P eq) | 7.79 × 10−6 ++ | 0.00 × 1000 | 3.69 × 10−8 ++ | 4.67 × 10−10 ++ | 1.22 × 10−7 ++ | 4.67 × 10−8 ++ | 1.20 × 10−8 ++ | 8.59 × 10−11 ++ | 2.97 × 10−10 ++ | 6.43 × 10−8 ++ | 1.64 × 10−6 ++ | 1.51 × 10−9 ++ | 5.66 × 10−6 ++ | 2.14 × 10−7 ++ |

| Marine eutrophication (kg N eq) | 3.38 × 10−6 (-) | 0.00 × 1000 | 1.01 × 10−8 ++ | 6.24 × 10−11 ++ | 1.31 × 10−8 ++ | 3.73 × 10−9 ++ | 9.59 × 10−9 ++ | 6.85 × 10−11 ++ | 5.64 × 10−11 ++ | 7.14 × 10−9 ++ | 7.37 × 10−8 ++ | 1.09 × 10−10 ++ | 3.21 × 10−6 (-) | 5.22 × 10−8 + |

| Terrestrial ecotoxicity (kg 1,4-DCB) | 2.07 × 1000 (-) | 0.00 × 1000 | 2.53 × 10−3 | 4.94 × 10−5 | 1.46 × 10−2 | 9.17 × 10−3 | 1.79 × 10−3 | 1.28 × 10−5 | 2.91 × 10−5 | 7.04 × 10−3 | 6.81 × 10−2 | 1.39 × 10−4 | 1.94 × 1000 (-) | 2.69 × 10−2 |

| Freshwater ecotoxicity (kg 1,4-DCB) | 1.25 × 10−4 | 0.00 × 1000 | 7.30 × 10−7 | 1.23 × 10−8 | 3.66 × 10−6 | 1.34 × 10−6 | 4.61 × 10−7 | 3.29 × 10−9 | 7.81 × 10−9 | 2.60 × 10−6 | 4.24 × 10−5 | 3.27 × 10−8 | 6.85 × 10−5 | 4.89 × 10−6 |

| Marine ecotoxicity (kg 1,4-DCB) | 1.98 × 10−3 ++ | 0.00 × 1000 | 2.36 × 10−6 ++ | 4.33 × 10−8 | 1.29 × 10−4 ++ | 6.55 × 10−6 ++ | 1.61 × 10−6 ++ | 1.15 × 10−8 ++ | 2.63 × 10−8 ++ | 8.05 × 10−6 ++ | 5.60 × 10−5 ++ | 1.14 × 10−7 ++ | 1.75 × 10−3 ++ | 2.28 × 10−5 ++ |

| Human carcinogenic toxicity (kg 1,4-DCB) | 1.20 × 10−3 ++ | 0.00 × 1000 | 7.88 × 10−6 ++ | 1.35 × 10−7 ++ | 6.74 × 10−5 ++ | 1.02 × 10−5 ++ | 7.40 × 10−6 ++ | 5.28 × 10−8 ++ | 1.07 × 10−7 ++ | 2.21 × 10−5 ++ | 3.11 × 10−4 ++ | 3.09 × 10−7 ++ | 7.36 × 10−4 ++ | 3.56 × 10−5 ++ |

| Human non-carcinogenic toxicity (kg 1,4-DCB) | 4.45 × 10−2 ++ | 0.00 × 1000 | 2.09 × 10−4 ++ | 3.33 × 10−6 ++ | 1.47 × 10−3 ++ | 3.64 × 10−4 ++ | 9.54 × 10−5 ++ | 6.81 × 10−7 ++ | 2.01 × 10−6 ++ | 5.08 × 10−4 ++ | 3.56 × 10−3 ++ | −2.29 × 10−5 (-) | 3.69 × 10−2 ++ | 1.46 × 10−3 ++ |

| Land use (m2a crop eq) | 2.38 × 10−3 + | 0.00 × 1000 | 1.33 × 10−5 | 2.06 × 10−7 | 3.17 × 10−5 | 5.30 × 10−5 | 1.68 × 10−5 | 1.20 × 10−7 | 1.22 × 10−7 | 6.28 × 10−5 | 3.82 × 10−4 | 1.56 × 10−5 | 1.69 × 10−3 ++ | 1.12 × 10−4 |

| Mineral resource scarcity (kg Cu eq) | 9.33 × 10−4 (-) | 0.00 × 1000 | 2.71 × 10−6 | 5.75 × 10−8 | 7.65 × 10−5 | 8.94 × 10−6 | 2.26 × 10−6 | 1.62 × 10−8 | 2.92 × 10−8 | 5.76 × 10−5 | 5.80 × 10−5 | 1.35 × 10−7 | 6.70 × 10−4 (-) | 5.65 × 10−5 |

| Fossil resource scarcity (kg oil eq) | 4.03 × 10−2 ++ | 0.00 × 1000 | 9.22 × 10−4 | 1.64 × 10−5 | 3.19 × 10−4 | 3.02 × 10−4 | 6.87 × 10−5 | 4.91 × 10−7 | 1.01 × 10−5 | 1.18 × 10−3 | 1.46 × 10−2 | 6.62 × 10−6 | 2.20 × 10−2 ++ | 8.04 × 10−4 |

| Water consumption (m3) | 3.31 × 10−3 (-) | 2.00 × 10−5 | 1.73 × 10−5 | 4.62 × 10−7 | 1.95 × 10−5 | 7.12 × 10−5 | 8.05 × 10−6 | 5.75 × 10−8 | 1.43 × 10−7 | 3.10 × 10−5 | 3.36 × 10−4 | 8.99 × 10−6 | 2.74 × 10−3 (-) | 5.83 × 10−5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Diehl, J.A.; Cheng, J. Life Cycle Assessment of Rooftop Hydroponic Production Systems: A Case Study of ComCrop in Singapore. Sustainability 2025, 17, 10523. https://doi.org/10.3390/su172310523

Diehl JA, Cheng J. Life Cycle Assessment of Rooftop Hydroponic Production Systems: A Case Study of ComCrop in Singapore. Sustainability. 2025; 17(23):10523. https://doi.org/10.3390/su172310523

Chicago/Turabian StyleDiehl, Jessica Ann, and Jing Cheng. 2025. "Life Cycle Assessment of Rooftop Hydroponic Production Systems: A Case Study of ComCrop in Singapore" Sustainability 17, no. 23: 10523. https://doi.org/10.3390/su172310523

APA StyleDiehl, J. A., & Cheng, J. (2025). Life Cycle Assessment of Rooftop Hydroponic Production Systems: A Case Study of ComCrop in Singapore. Sustainability, 17(23), 10523. https://doi.org/10.3390/su172310523