1. Introduction

Concrete is the most widely used construction material globally, with annual production exceeding 30 billion metric tons, accounting for over 8% of global carbon dioxide emissions and nearly half of the world’s raw material consumption [

1]. Therefore, it is essential to move beyond the prevailing short-term mindset centered on profit maximization and the continuous consumption of virgin raw materials. This is why Europe is setting two major goals: a 55% reduction in harmful emissions by 2035 and a fully circular economy by 2050 [

2].

The transition to sustainable construction in Europe creates both significant challenges and unique opportunities for material innovation, especially around the use of concrete and cement. The core concept of this sustainable transition is the circular economy, an economic model aimed at closing cycles and minimizing waste. Unlike the traditional linear economy, based on a take–make–use–discard model, the circular economy promotes a system where products, materials, and resources remain in use for as long as possible and are reused, repurposed, or recycled with minimal loss of value. To achieve this major goal, the construction industry is exploring alternatives to Portland cement, such as recycled fly ash, blast furnace slag, and silica fume, residues from coal combustion, steel production, and silicon metal manufacturing, respectively. These byproducts are also called supplementary cementitious materials (SCMs), which are commonly finely divided materials that are used in combination with Portland cement in concrete or mortar to enhance performance and sustainability. They contribute to the properties of hardened concrete through pozzolanic or latent hydraulic reactions, improving strength and durability. Also, the use of SCMs in concrete presents significant environmental advantages across multiple dimensions. By partially replacing Portland cement, SCMs help reduce greenhouse gas emissions associated with clinker production, contributing to the mitigation of global warming. Additionally, SCMs promote resource efficiency by conserving virgin raw materials and utilizing industrial byproducts such as fly ash and blast furnace slag. This not only lowers the environmental footprint of concrete but also supports waste valorization by diverting materials from landfills and minimizing disposal impacts. As such, SCMs play a critical role in advancing low-carbon, circular construction practices aligned with global sustainability goals [

3].

Alternative concrete mixtures using SCMs are already being experimented with within the Netherlands and Belgium. For example, TU Delft developed geopolymer concrete mixtures based on fly ash and metakaolin, activated with caustic soda and sodium silicate, which can achieve strengths of up to 160 MPa [

4]. In Belgium, VITO is investigating combinations of blast furnace slag, fly ash, and silica fume, which with chemical activation provide an equivalent performance to traditional cement [

5]. Similarly, low-quality aluminum dross, a by-product of the aluminum industry, was able to effectively replace 20% of the cement content after undergoing water washing and particle size control [

6].

Recent studies have expanded the scope of SCMs by exploring agricultural residues such as rice husk ash and wheat straw ash, which show promising pozzolanic activity and contribute to low-carbon concrete formulations [

7]. Additionally, eco-innovative concrete incorporating alternative aggregates and SCMs has demonstrated structural viability for infrastructure applications, with reduced environmental footprints and enhanced durability [

8]. A broader review of emerging cementitious materials highlights the potential of natural pozzolans, volcanic ash, and treated industrial by-products to replace Portland cement while maintaining mechanical performance and reducing embodied carbon [

9].

Although these projects provide interesting performance results, an integrated assessment of the environmental impact over the entire life cycle of the applied concrete is often lacking. As highlighted by Salati et al. (2025), the dynamic nature of buildings, subject to changes in use, maintenance, and renovation complicates the definition of system boundaries and temporal parameters, making traditional LCA approaches insufficient for capturing long-term environmental impacts [

10]. Moreover, Scherz et al. (2022) emphasize that LCA is rarely embedded in procurement and design processes due to fragmented data availability, limited stakeholder expertise, and a lack of regulatory incentives [

11]. These challenges hinder the integration of LCA into early-stage decision-making, despite its potential to guide material choices and reduce embodied carbon. Addressing these gaps requires standardized methodologies, improved data access, and stronger institutional frameworks to support LCA adoption across the construction sector.

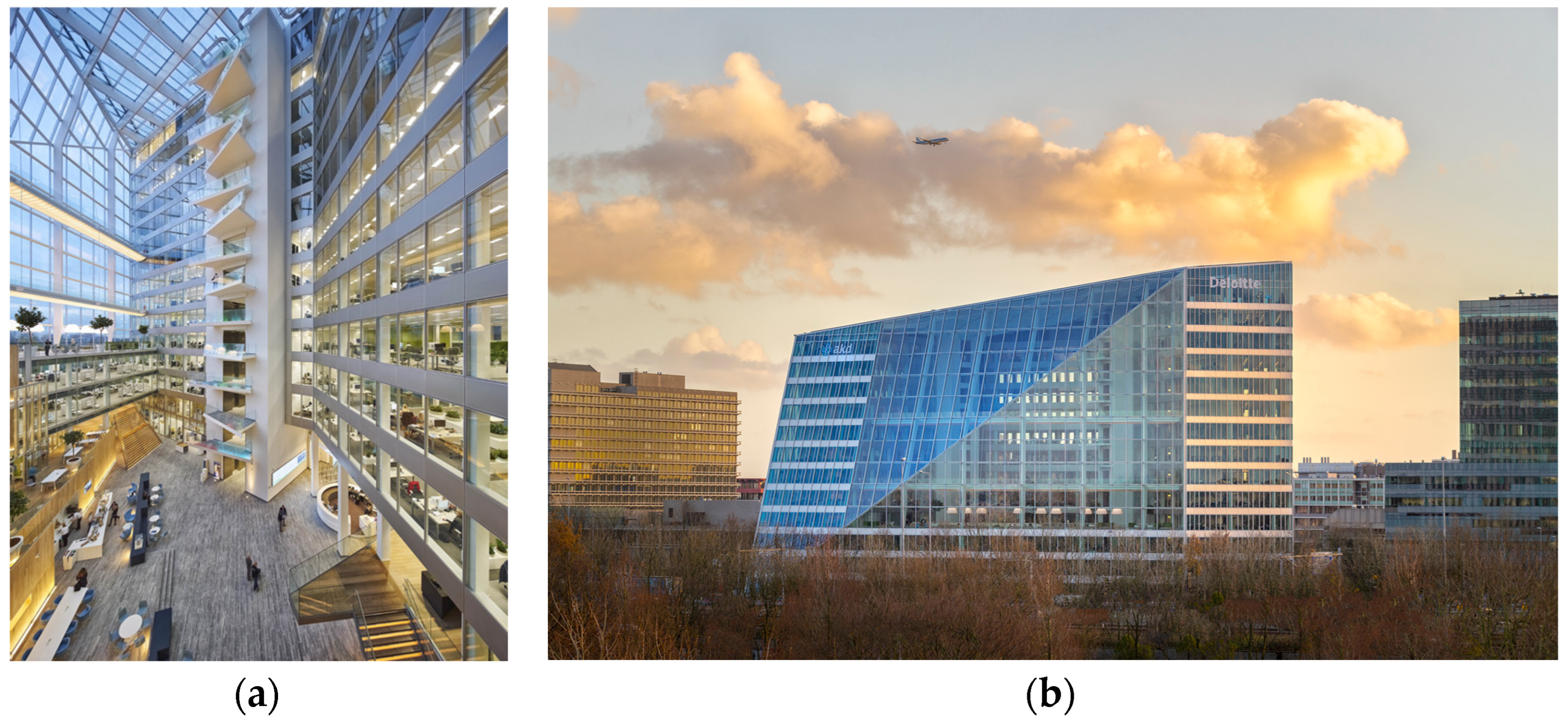

This study contributes to this ongoing effort by emphasizing the integration of a comprehensive environmental analysis and strategic material selection for a green-certified commercial building located in the Netherlands named The Edge. This building project, completed in 2015, is located in Amsterdam and was certified by BREEAM, one of the world’s leading sustainability assessment methods for buildings and infrastructure [

12]. Since little detailed information is available on the exact concrete composition and concrete strength of the mix used in the case study, this research analyzes the environmental impact of the concrete used based on assumptions of reference projects with similar sustainability ambitions. These reference projects were carefully chosen based on a number of criteria. For example, each reference project is also a BREEAM-certified and circular building and contains specific and transparent data on the concrete mixtures, binder substitutes, mechanical strengths, and environmental impact. Therefore, these reference projects not only offer assumptions regarding mix composition and mechanical performance but also provide actual impact data, which can be used to validate the assumptions made for the building The Edge in Amsterdam. Qualitative methods, including a literature review, comparative case studies, and semi-structured expert interviews, were recently presented by Hiulong Wong et al. (2025) in their study “Potential of BREEAM-C to Support Building Circularity Assessment: Insights from Case Study and Expert Interview” [

13]. Similarly, the methodology employed by Eberhardt et al. (2021) [

14] closely aligns with the approach of evaluating environmental impacts through reference projects when direct data is lacking. In their study, the authors formulate environmental design guidelines for circular building components by analyzing a series of conceptual design variants, each modeled on reference scenarios that embody circular economy principles, for example, by using BREEAM-certified buildings with documented design, construction, and performance data as a reference.

The core method used in this research was a life cycle analysis (LCA) with a cradle-to-grave approach. LCA is a science-based method able to assess the total environmental impact of a building material, from raw material extraction (cradle) to waste disposal (grave). The importance of LCA in this research lies in its ability to estimate and compare the environmental performance of conventional Portland cement-based concrete and mixes incorporating SCMs such as fly ash and blast furnace slag. This includes evaluating potential impacts on global warming, acidification, ecotoxicity, and other critical environmental categories, in relation to the planetary boundaries, scientifically defined limits within which humanity can operate safely to avoid triggering abrupt or irreversible environmental change at the global scale [

15].

In summary, this study offers an innovative assessment approach for a structural material employed in a green-certified building through the application of a life cycle assessment. By comparing traditional and circular concrete mixtures across reference projects and applying those insights to the building The Edge, this study not only substantiates the environmental benefits of circular concrete solutions but also connects the findings to some of the most pressing environmental challenges on the global scale.

3. Methodology

This research adhered to the four-phase methodology established by the ISO—International Organization for Standardization (

Figure 2), employing the open access online software Building for Environmental and Economic Sustainability (BEES), developed by the U.S. Department of Commerce’s National Institute of Standards and Technology (NIST) [

18]. In the first phase, goal and scope definition, a cradle-to-grave approach was adopted, assuming a service life of 60 years without major maintenance interventions on the concrete structure. The selected functional unit was 1 yd

3 (~0.76 m

3), with a transportation distance of 50 mi (~80.47 km); both parameters were set to the default values recommended by the software, as the specific delivery plants for the case study are not known. Naturally, this selection does not fully reflect the specific conditions in the Netherlands; these aspects will be examined in greater detail in future research. In the second phase, inventory analysis, data were sourced from the Ecoinvent database, accessed via the Microsoft SQL server integrated into the BEES online version 2.1 software, which incorporates SimaPro version 8.0 and Ecoinvent 2017. Although the case study was completed in 2015, slightly prior to 2017, the production processes for concrete mixes and components have remained largely unchanged over short timeframes, owing to the substantial investments required for technological modifications. The third phase, impact assessment, included the environmental impact categories suggested by BEES and strongly related to the planetary boundaries, ensuring a comprehensive evaluation from the local to the global scale. The planetary boundary framework defines safe limits for eight key Earth system processes, such as climate change, biodiversity loss, land use, and others, within which humanity can operate to avoid irreversible environmental damage. Crossing these boundaries increases the risk of destabilizing the planet’s life-support systems [

15]. Finally, during the results interpretation phase, concrete mixes were ranked from 1 to 4 for each impact category based on their relative magnitude, where 1 represented the lowest environmental impact and 4 the highest. This methodology was previously proposed by authors in reference [

19].

For this case study, due to the lack of publicly available data on the specific concrete used in the building, the analysis was based on comparable reference projects with BREEAM certification and aligned sustainability objectives, for which detailed concrete mix information was accessible. In addition to estimating the environmental impact of conventional concrete composed solely of Portland cement (100% PC), three alternative mixes were evaluated based on the BREEAM reference project. These included concrete replacing Portland cement with 40% fly ash (40% FA), 50% blast furnace slag (50% BFS), and a combination of both, 20% fly ash and 30% blast furnace slag (20% FA + 30% BFS). The mix compositions evaluated are described in

Figure 2.

4. Results

First, preliminary research was conducted into BREEAM-certified reference projects and their concrete mix compositions. The first reference project is the WWF Living Planet Centre located in Woking, England (

Figure 3). This serves as the headquarters of the World Wide Fund for Nature and was designed by Hopkins Architects. Like The Edge, this is a commercial building and received a BREEAM certification upon completion in 2013, with a score of 90.1%. This is slightly lower than The Edge, which achieved a score of 98.1%. In the concrete used, 70% of the cement was replaced with ground granulated blast furnace slag, and 99% of the aggregates consisted entirely of recycled concrete aggregate. Estimations indicate that this resulted in an approximate 42% reduction in embodied carbon [

20].

A second reference project for The Edge is One Angel Square in Manchester, England, designed by 3Dreid. The building was completed in 2013 and received a BREEAM Outstanding certification shortly before its opening in 2012, with a top score of 95.16%. Alternative binders were also used in the concrete applied here, with 60–70% of the cement being replaced by ground granulated blast furnace slag [

22,

23]. More details about its design are given in

Figure 4.

Finally, a third reference project is the Bloomberg European HQ in London (

Figure 5), designed by Foster + Partners as a landmark in the City of London, focused on sustainability and collaboration [

25]. This European operational center was completed in 2017 and received a BREEAM Outstanding certification with a score of 98.5%, the highest ever awarded [

26]. The cement used in the concrete was replaced by approximately 50% fly ash and ground granulated blast furnace slag. In addition, prefabricated interface elements and structural columns with lower embodied carbon were used [

27].

All three of these reference projects are highly relevant for forming well-founded assumptions. Like The Edge, they have achieved the highest sustainability classification within BREEAM, making them strong qualitative benchmarks. All three projects mentioned above used low-CO

2 concrete in load-bearing elements such as columns, floors, and façade panels, which is similar to the applications in The Edge.

Table 1 summarizes the general aspects of the buildings and the concrete mix-related strategies assessed under BREEAM.

Therefore, based on the preceding review, the case study may incorporate SCMs such as fly ash and blast furnace slag as part of its strategy to significantly reduce embodied CO

2 emissions. Considering that cement replacement levels in the reference certified buildings range from 50% to 70%, this research analyzed the following mixes using a more conservative 50% cement replacement level to evaluate the environmental implications of the concrete used in the case study (

Table 2).

Following the proposed LCA methodology, the environmental impact categories assessed, closely linked to the nine planetary boundaries, are presented for each concrete mix.

- (a)

Global warming potential and climate change

The global warming potential, expressed in carbon dioxide equivalents, is a quantitative indicator derived from LCA that directly links product or process emissions to their contribution to climate change, reflected in long-term shifts in temperature and weather patterns.

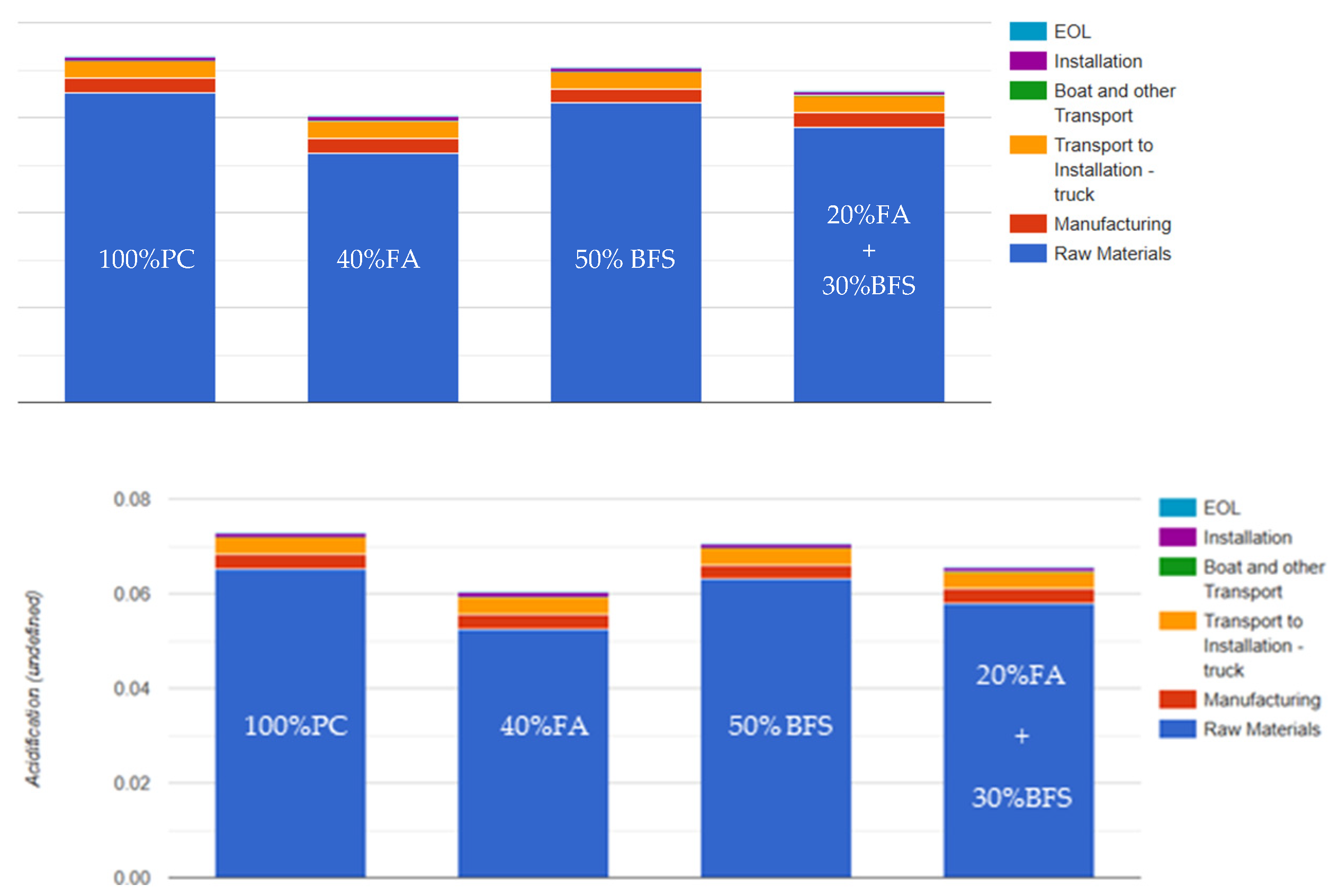

Figure 6 presents the global warming potential results for the reference concrete mix (100% PC) and the alternative mixes incorporating fly ash (40% FA), blast furnace slag (50% BFS), and a combination of both (20% FA + 30% BFS). The results indicate that the most environmentally favorable mixes are those in which Portland cement is partially replaced with blast furnace slag (50% BFS) or with a combination of fly ash and slag (20% FA + 30% BFS). Across all concrete mixes, the life cycle phases contributing most significantly to global warming potential are raw material extraction, manufacturing, and transportation, with raw materials being the dominant contributor. On a global scale, it is worth noting that current atmospheric carbon dioxide concentrations exceed 420 ppm, surpassing the planetary boundary threshold of 350 ppm and placing climate change firmly in the high-risk zone for Earth system stability [

29].

- (b)

Acidification potential and ocean acidification

Although acidification potential in the LCA is driven by acidifying gases, typically expressed in kilograms of sulfur dioxide equivalents, ocean acidification results from the decrease in ocean pH due to the absorption of atmospheric carbon dioxide. When CO

2 dissolves in seawater, it forms carbonic acid, which lowers pH and reduces the availability of carbonate ions. Both phenomena reflect how human emissions disrupt natural pH balances. Notably, some advanced LCA models now include ocean acidification as a distinct impact category, using characterization factors that link carbon dioxide emissions to changes in ocean pH [

30].

Figure 7 presents the acidification potential results, indicating that the most favorable concrete mix in terms of this environmental parameter is the one with 40% fly ash (40% FA), which is completely different to the global warming potential result (i.e., 50% BFS). Fly ash generally exhibits a lower acidification potential compared to blast furnace slag due to differences in their origin, composition, and processing requirements. As a by-product of coal combustion, fly ash is typically collected with minimal additional treatment, resulting in lower associated emissions of acidifying gases. In contrast, blast furnace slag originates from the high-temperature reduction of iron ore in blast furnaces, a process that often involves sulfur-rich raw materials and energy-intensive granulation and grinding steps, factors that contribute to higher acidifying emissions. Moreover, the sulfur content in blast furnace slag is typically higher than in fly ash, further increasing its acidification potential during processing and transport [

31].

As with global warming potential, the life cycle phases contributing most significantly to acidification potential are raw material extraction, manufacturing, and transportation, with raw materials being the dominant contributor. As a reference point, since the onset of the industrial era, the ocean’s surface pH has decreased by approximately 0.1 units, corresponding to a 30–40% increase in acidity, thereby breaching the planetary boundary for ocean acidification [

32].

- (c)

Ozone depletion potential and stratospheric ozone depletion

The ozone depletion potential in the LCA and the stratospheric ozone depletion planetary boundary are closely related conceptually.

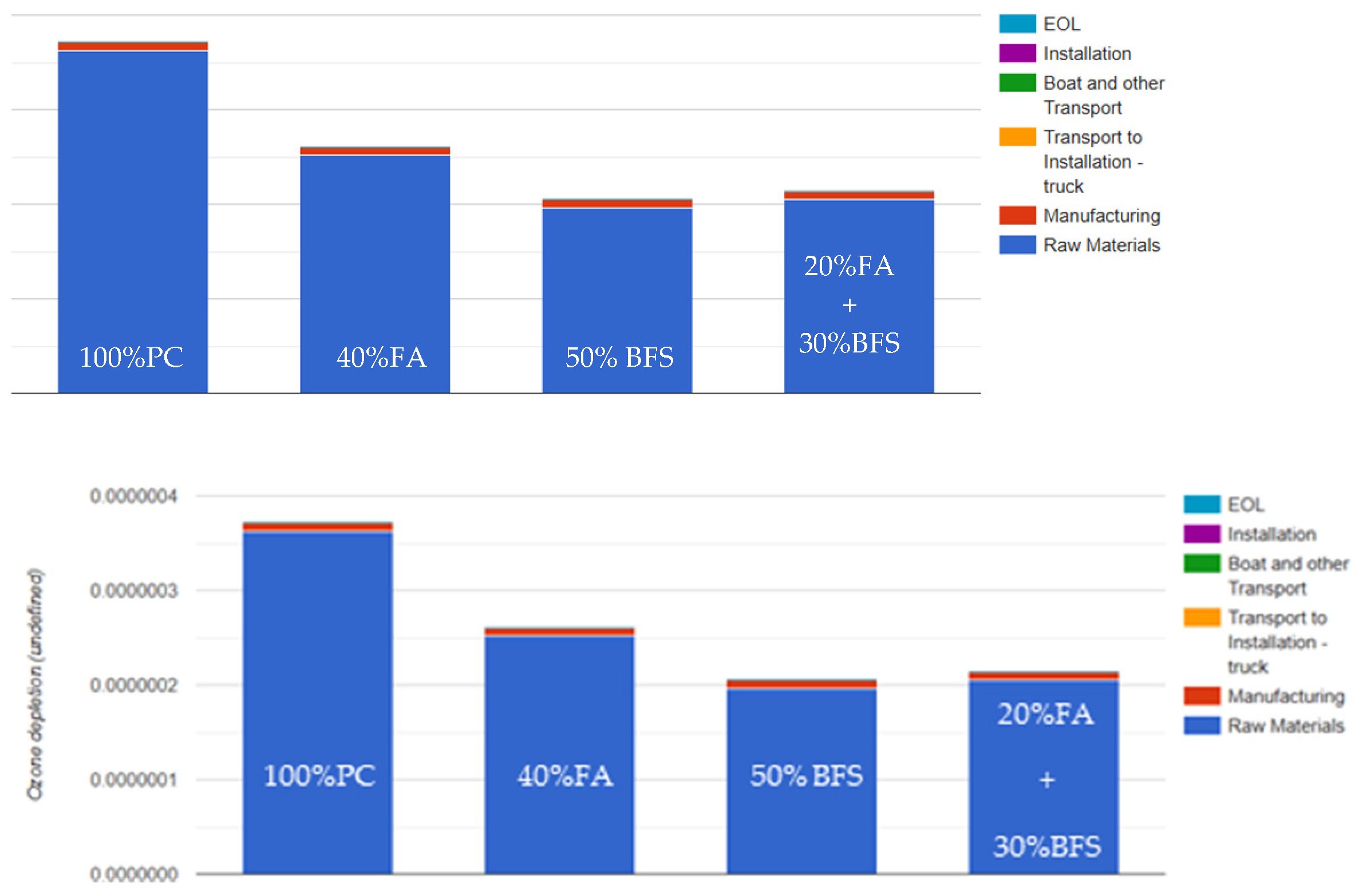

Figure 8 presents the ozone depletion potential results for the various concrete mixtures considered for the case study. The concrete mix containing a 50% replacement of Portland cement with blast furnace slag (50% BFS) demonstrates the most favorable performance with respect to this environmental parameter. In this case, the life cycle phases contributing to ozone depletion potential are primarily raw material extraction and manufacturing, with raw materials being the most significant. Thanks to international agreements like the Montreal Protocol, the stratospheric ozone depletion planetary boundary is currently considered to be within the safe operating space. However, recent LCA research continues to refine characterization models to include short-lived substances and legacy emissions, ensuring that product-level assessments remain aligned with global sustainability thresholds [

33].

- (d)

Eutrophication potential and biogeochemical flows

The eutrophication potential in the LCA and the biogeochemical flow planetary boundary are closely linked, as both address the environmental consequences of excessive nutrient loading, primarily nitrogen and phosphorus, into ecosystems.

Figure 9 presents the eutrophication potential results for various concrete mixtures considered for use in The Edge. Similarly to the ozone depletion results, the concrete mix with a 50% replacement of Portland cement by blast furnace slag (50% BFS) demonstrates the most favorable performance with respect to eutrophication potential. Also, major environmental impacts arise from the raw material, manufacturing, and transportation phases. In comparison, the impacts from the construction and end-of-life phases are negligible, at close to zero in this modeled LCA and case study. As of the 2025 Planetary Health Check, the biogeochemical flow boundary, covering nitrogen and phosphorus cycles, has been severely transgressed, placing it among the seven out of nine planetary boundaries currently breached [

34].

- (e)

Water use potential and global fresh water use

Although operating at different scales, the water use impact category in the LCA and the global freshwater use planetary boundary are conceptually aligned, as both are measured using volumetric units of consumed water. However, LCA water use metrics have been adjusted recently using regional scarcity weighting, such as m

3 water-equivalent-deprived (e.g., AWARE method) or m

3 H

2O eq (as used in midpoint impact categories) [

35,

36].

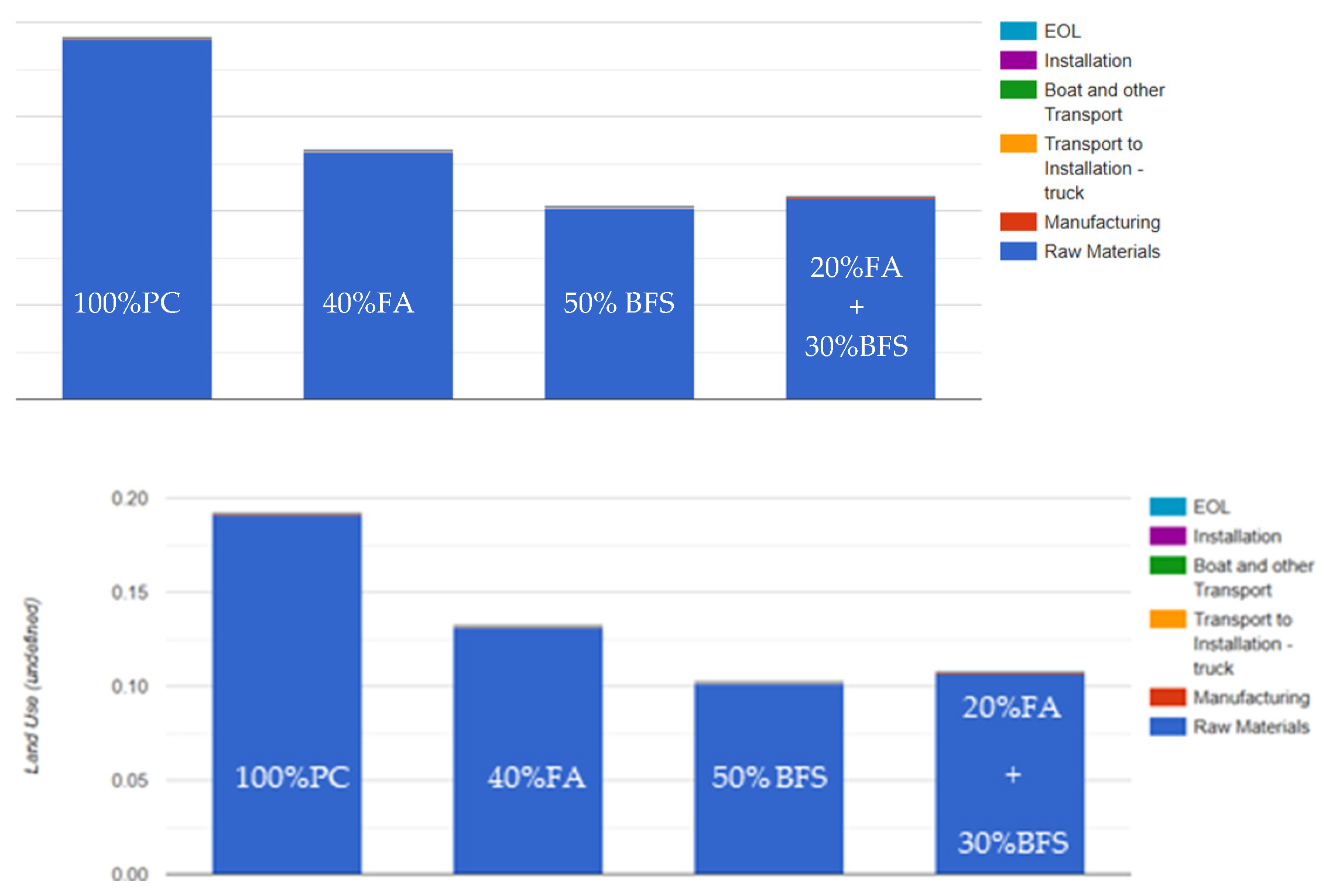

Figure 10 presents the water use potential for various concrete mixtures considered for the case study. The results show only minor differences among the evaluated mixes, including the reference concrete only using Portland cement. This suggests that the use of SCMs such as fly ash or blast furnace slag in concrete mixes has no significant impact on water use within the scope of this assessment. As of 2025, the planetary boundary for freshwater use has been breached, exceeding the estimated safe threshold of ~4000 km

3/year of blue water withdrawals. This transgression indicates that humanity is disrupting freshwater flows at a rate that threatens Earth system stability. Currently, more than 1.8 billion people live under conditions of absolute water scarcity (<500 m

3/person/year), and two thirds of the global population experience water stress during at least part of the year [

37].

- (f)

Land use potential and land-system change

The land use potential in the LCA and the land-system change planetary boundary are deeply interconnected, although they rely on distinct metrics.

Figure 11 illustrates the land use potential for various concrete mixtures considered for the building The Edge. The results indicate that the concrete mix with a 50% replacement of Portland cement by blast furnace slag (50% BFS) performs most favorably in this impact category. A notable difference is observed between mixes incorporating cement replacements and those using only Portland cement. Additionally, the raw material extraction phase emerges as the primary contributor to land use impacts. As of 2025, the planetary boundary for land-system change has been transgressed, with forest cover in tropical, temperate, and boreal biomes falling below safe thresholds. This widespread transformation has profound implications for biodiversity, carbon sequestration, climate regulation, and other related aspects [

29].

- (g)

Ecological toxicity and biodiversity loss

The relationship between ecotoxicity in the LCA and biodiversity loss within the planetary boundary framework is both conceptually and causally significant, although they rely on distinct indicators.

Figure 12 presents the ecotoxicity potential results for various concrete mixtures considered for the case study. Again, the mix with a 50% replacement of Portland cement by blast furnace slag (50% BFS) exhibits the lowest ecotoxicity impact, following the same trend observed across most environmental indicators. The planetary boundary for biosphere integrity, commonly referred to as biodiversity loss, has been critically transgressed, with extinction rates far exceeding natural background levels and more than 60% of global land area showing signs of ecological degradation. This makes it one of the most alarming breaches of the planetary boundary framework as of 2025 [

29].

- (h)

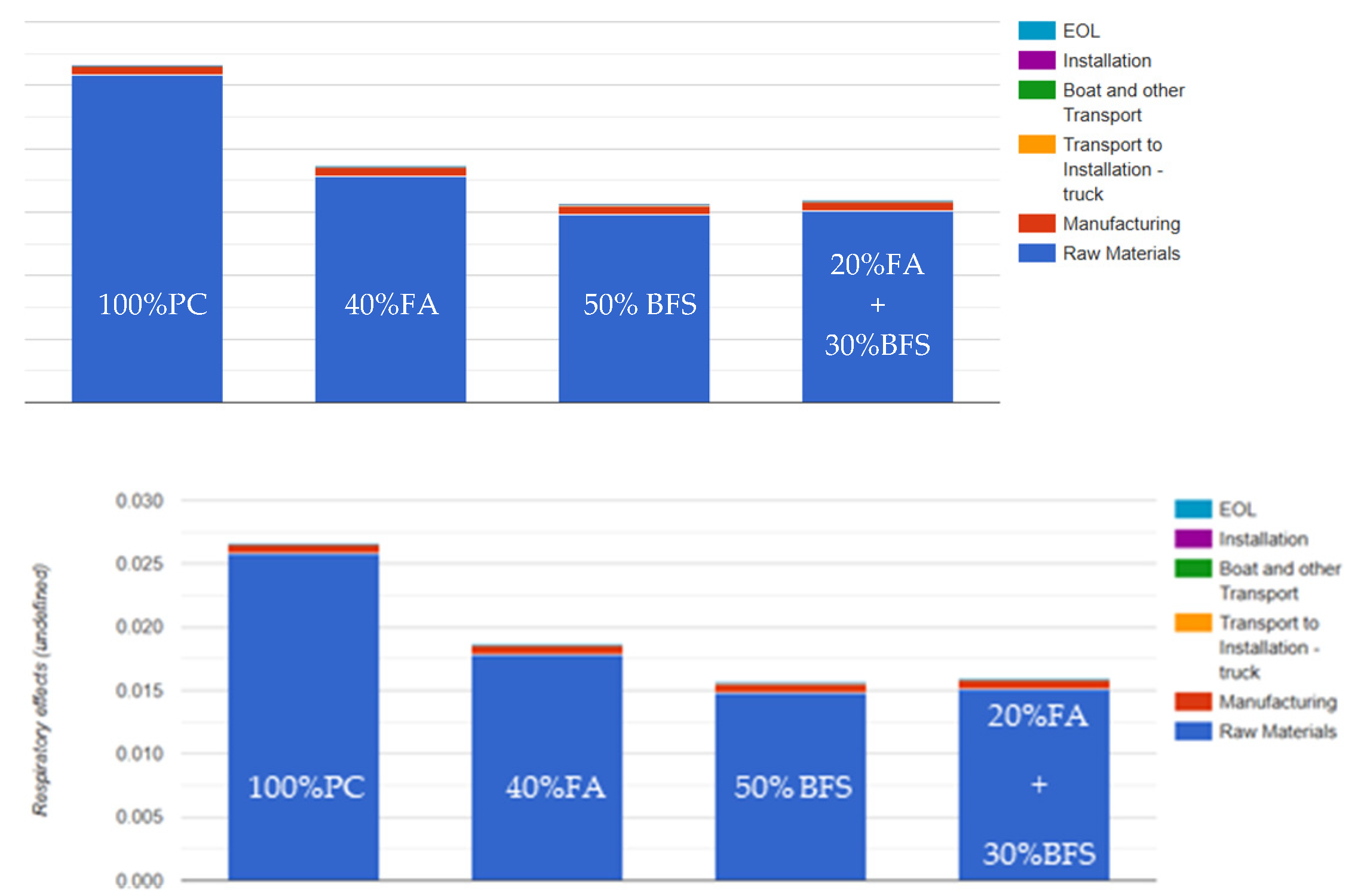

Respiratory effect potential and atmospheric aerosol loading

The respiratory effect potential in the LCA and the atmospheric aerosol loading planetary boundary are conceptually aligned, as both address the health and environmental impacts of airborne particulate matter, though they differ in scope and metrics.

Figure 13 presents the respiratory effect potential for various concrete mixtures considered for the studied building. The results show that the concrete mix with a 50% replacement of Portland cement by blast furnace slag (50% BFS) again demonstrates the best performance. On a global scale, the atmospheric aerosol loading planetary boundary remains within the safe operating space, making it one of only two boundaries not yet transgressed, alongside stratospheric ozone depletion, as already discussed [

34].

- (i)

Material decision analysis

Based on the LCA methodology applied and the assumptions made for the case study, the four concrete mixtures (including the reference) and their potential environmental impacts are summarized in

Table 3. Each mix was ranked from 1 to 4 across the environmental impact categories according to relative magnitude, where 1 indicates the lowest impact and 4 the highest. The most favorable concrete mix is the one in which Portland cement is replaced with blast furnace slag (50% BFS), showing the lowest environmental impact in all categories except acidification. The second-best option is concrete mix 3, which substitutes 50% of Portland cement with a combination of 20% fly ash and 30% blast furnace slag (20% FA + 30% BFS). The third-ranked alternative involves replacing 40% of Portland cement with fly ash (40% FA). Further details on the concrete mixes are provided in

Appendix A.

5. Conclusions

The comparative analysis of concrete mixtures using life cycle assessment reveals that strategic substitution of Portland cement with supplementary cementitious materials may significantly reduce environmental impacts. Among the evaluated options, the concrete mix incorporating 50% blast furnace slag (50% BFS) demonstrates the most favorable environmental performance across impact categories, with the exception of acidification. The second-best alternative, combining 20% fly ash and 30% slag (20% FA + 30% BFS), also offers substantial improvements over the reference concrete mix. The third-ranked option, with 40% fly ash replacement (40% FA), presents moderate benefits. These findings support the adoption of supplementary cementitious material-based concrete formulations in building projects, as they contribute to improved sustainability outcomes and align with low-carbon construction goals. Such strategies are consistent with the criteria of green building certifications, as exemplified by the building The Edge evaluated under BREEAM standards.

Beyond providing a quantitative life cycle assessment, this research introduces a complementary qualitative approach aimed at guiding designers, investors, and buyers in recognizing the critical role of structural material selection in shaping environmental outcomes. The study integrates both LCA impact categories and planetary boundaries to offer a more holistic sustainability perspective. Given the limited availability of data on the specific concrete mix used in the selected case study, the analysis drew on comparable reference projects certified under BREEAM and aligned with similar sustainability goals, where detailed concrete mix data was accessible. This approach underscores the value of transparent material documentation and informed decision-making in advancing low-carbon, environmentally responsible construction practices.

Future research will focus on expanding the dataset of real-world certified projects to improve the accuracy and representativeness of LCA modeling. Additionally, further investigation into regional variations in cementitious material availability and production, transportation distances, energy infrastructure, construction techniques, performance under diverse climatic conditions, and long-term durability impacts will be essential to refine sustainable concrete mix designs.