Microplastic Behavior in Sludge Pretreatment and Anaerobic Digestion: Impacts, Mechanistic Insights, and Mitigation Strategies

Abstract

1. Introduction

2. MP Behavior and Influence During Sludge Pretreatment

2.1. Exposure Conditions in Sludge Pretreatment

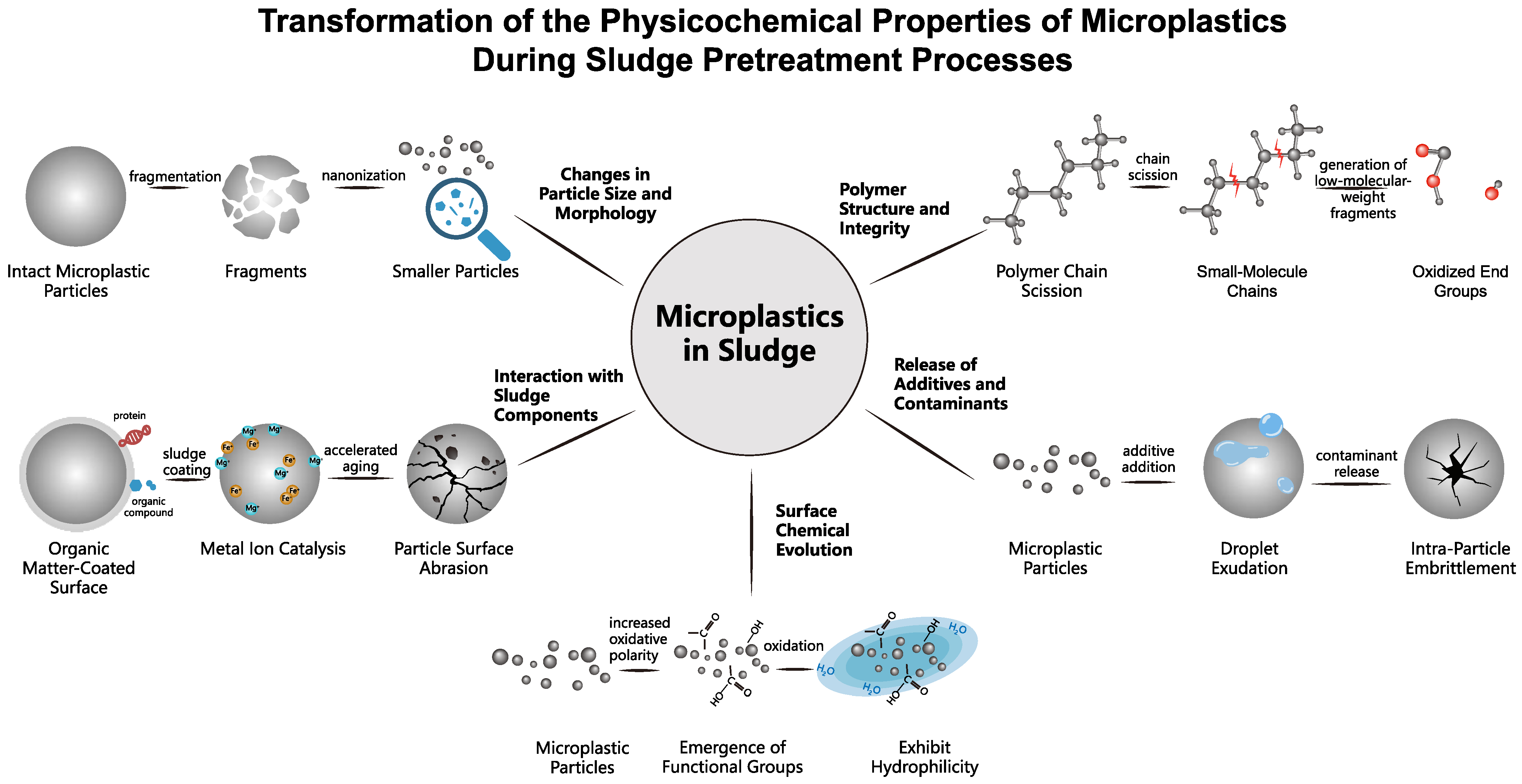

2.2. Physicochemical Transformation of MPs

2.2.1. Particle Size and Morphology

2.2.2. Polymer Structure and Integrity

2.2.3. Surface Chemistry Evolution

2.2.4. Additive and Pollutant Leaching

2.2.5. Interactions with Sludge Components

2.3. Regulatory Effects on Organic Matter Release

2.3.1. Surface Polarity and Sludge Floc Disruption

2.3.2. Interference in EPS Networks

2.3.3. Catalytic or Inhibitory Chemical Effects

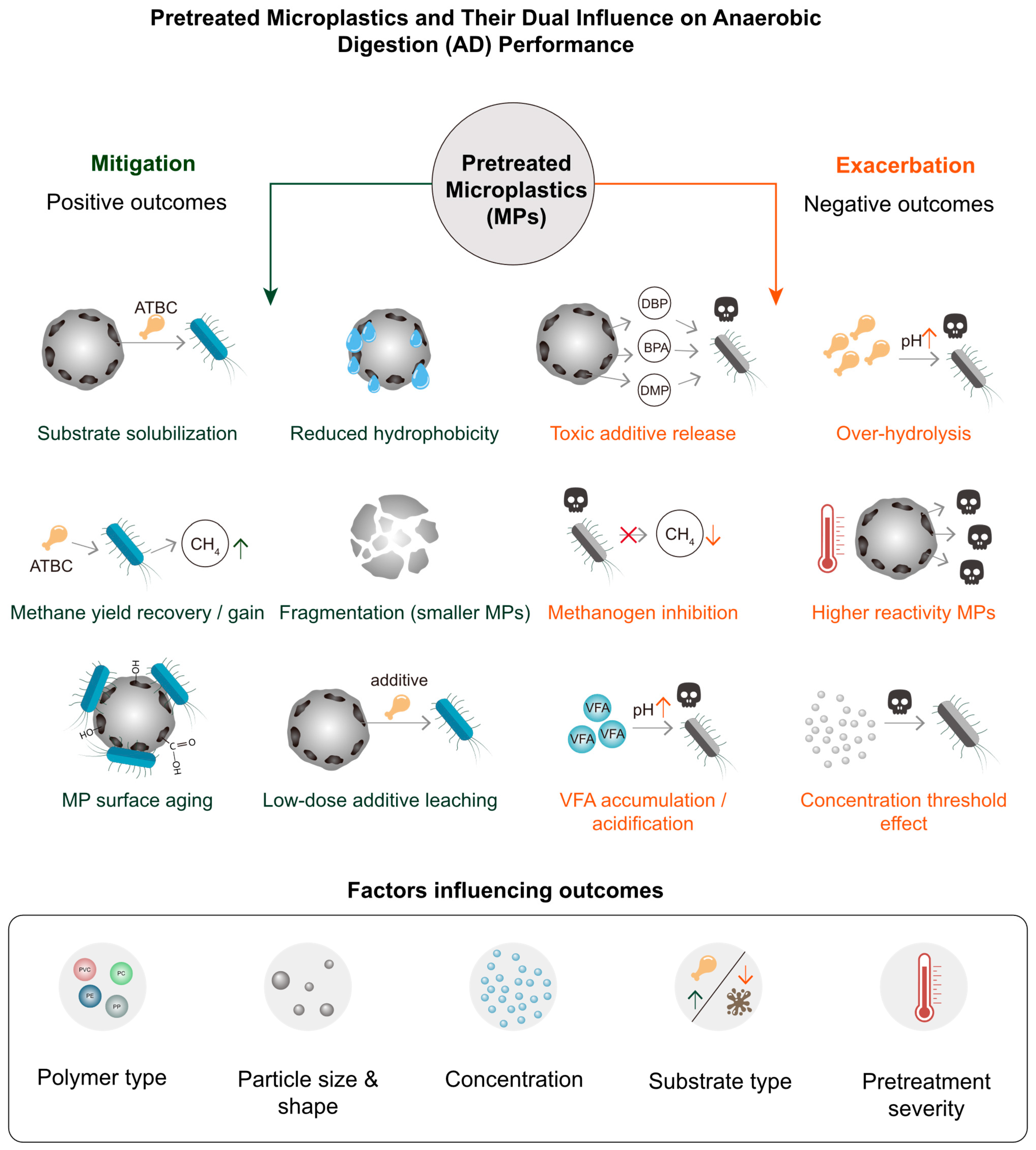

3. Induction Effect of Pretreatment on MPs on Sludge Anaerobic

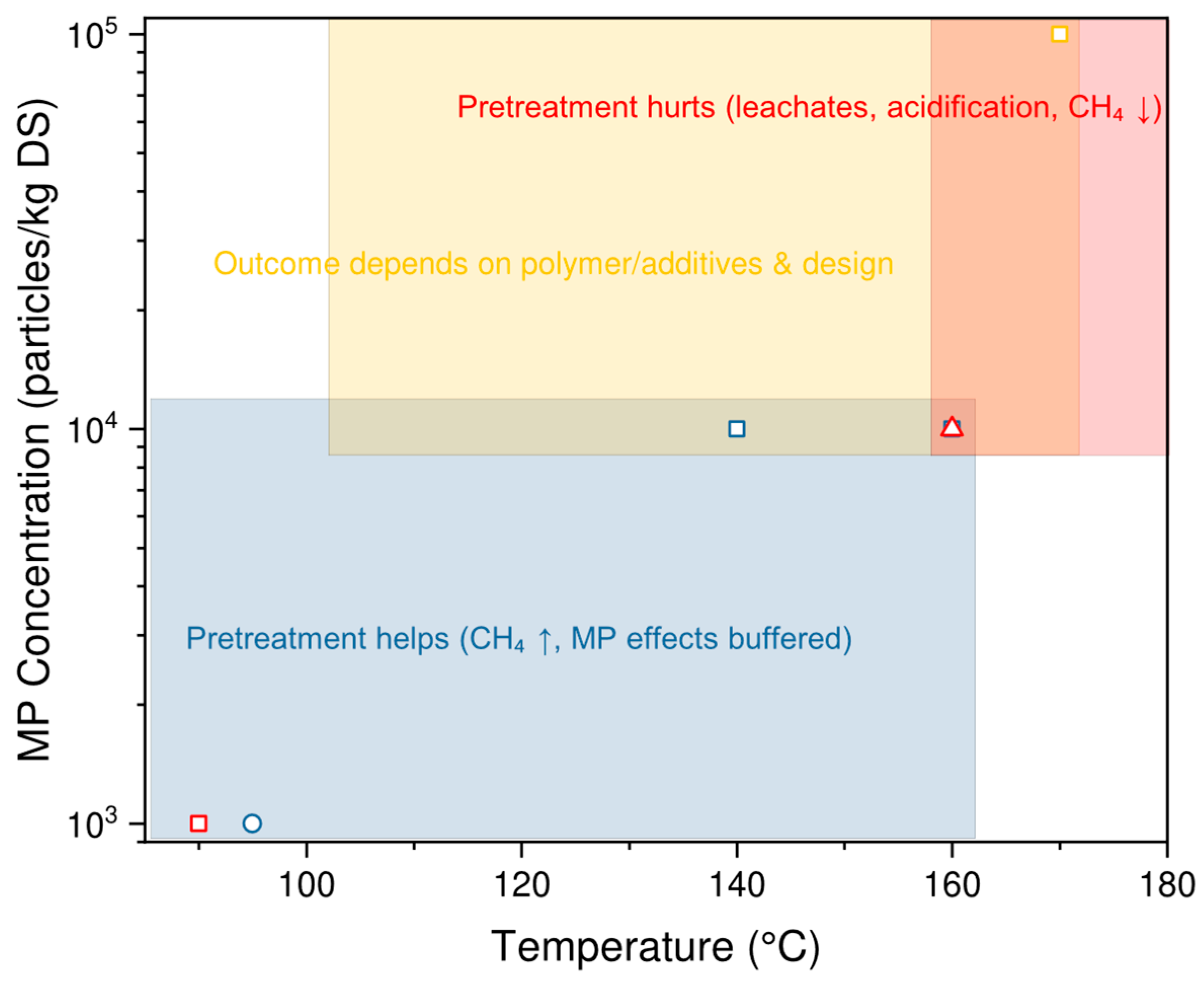

3.1. Overall Performance Impacts on AD

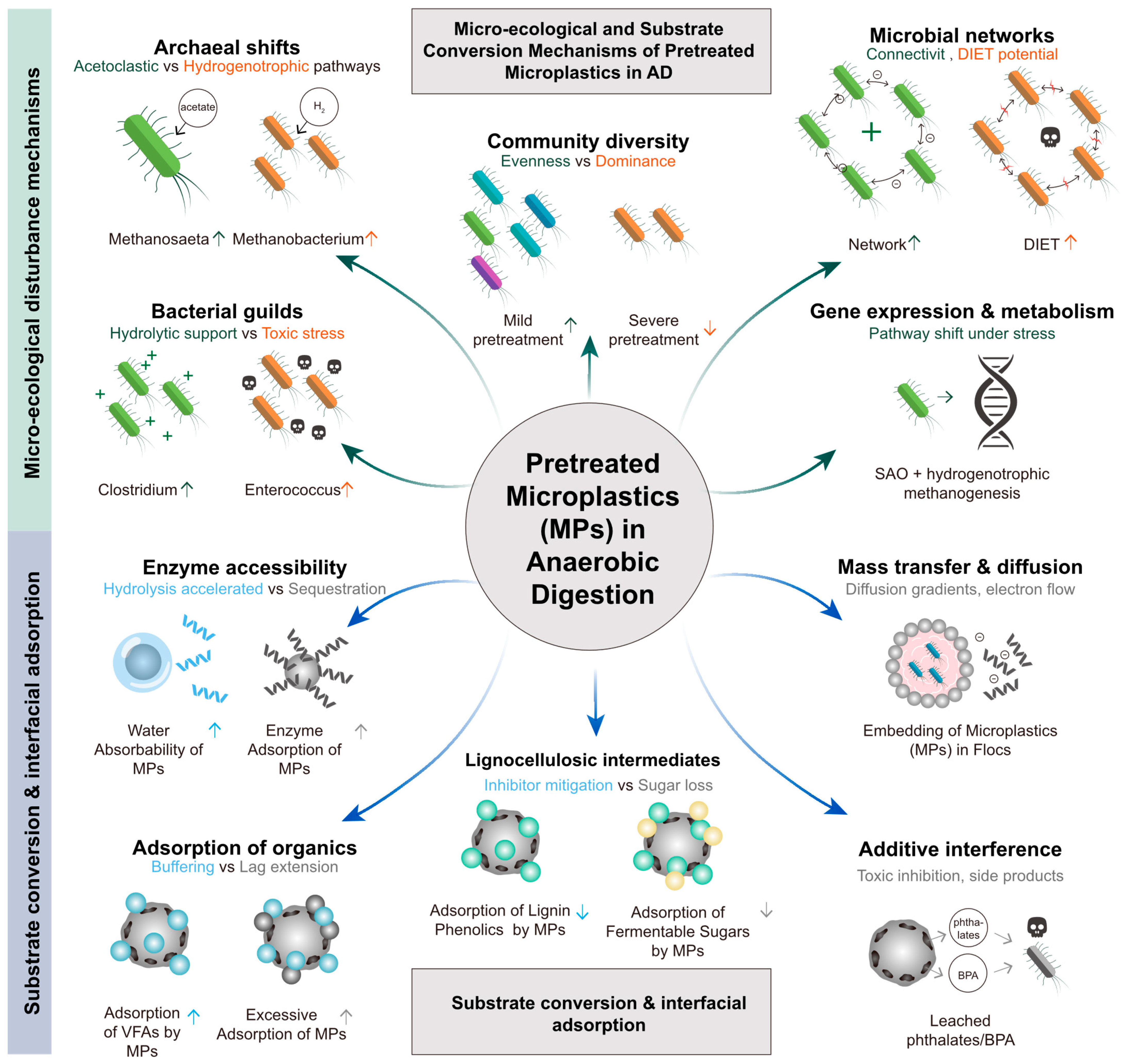

3.2. Micro-Ecological Disturbance Mechanisms

3.3. Substrate Conversion and Interfacial Adsorption

3.4. Migration Behavior and Risk Pathways Within the System

4. Mitigation of MP Impacts on AD

4.1. Adsorption-Based Strategies

4.2. Process Optimization Strategies

4.2.1. Operational Controls

4.2.2. Reactor Configuration Innovations

4.2.3. Co-Digestion and Resilient Microbial Communities

4.2.4. System Resilience and Long-Term Adaptation

5. Conclusions and Implications

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| MPs | Microplastics |

| AD | Anaerobic Digestion |

| PE | Polyethylene |

| PP | Polypropylene |

| PS | Polystyrene |

| PVC | Polyvinyl Chloride |

| ROS | Reactive Oxygen Species |

| TH | Thermal Hydrolysis |

| EPS | Extracellular Polymeric Substances |

| DBP | dibutyl phthalate |

| DMP | dimethyl phthalate |

References

- Hartmann, N.B.; Hüffer, T.; Thompson, R.C.; Hassellöv, M.; Verschoor, A.; Daugaard, A.E.; Rist, S.; Karlsson, T.; Brennholt, N.; Cole, M.; et al. Are we speaking the same language? Recommendations for a definition and categorization framework for plastic debris. Environ. Sci. Technol. 2019, 53, 1039–1047. [Google Scholar] [CrossRef] [PubMed]

- Gigault, J.; Ter Halle, A.; Baudrimont, M.; Pascal, P.-Y.; Gauffre, F.; Phi, T.-L.; El Hadri, H.; Grassl, B.; Reynaud, S. Current opinion: What is a nanoplastic? Environ. Pollut. 2018, 235, 1030. [Google Scholar] [CrossRef]

- Sun, J.; Dai, X.; Wang, Q.; van Loosdrecht, M.C.M.; Ni, B.-J. Microplastics in wastewater treatment plants: Detection, occurrence and removal. Water Res. 2019, 152, 21–37. [Google Scholar] [CrossRef]

- Murphy, F.; Ewins, C.; Carbonnier, F.; Quinn, B. Wastewater Treatment Works (WwTW) as a source of microplastics in the aquatic environment. Environ. Sci. Technol. 2016, 50, 5800–5808. [Google Scholar] [CrossRef]

- Carr, S.A.; Liu, J.; Tesoro, A.G. Transport and fate of microplastic particles in wastewater treatment plants. Water Res. 2016, 91, 174–182. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, J.; Liu, H.; Guo, X.; Zhang, X.; Yao, X.; Cao, Z.; Zhang, T. A review of the removal of microplastics in global wastewater treatment plants: Characteristics and mechanisms. Environ. Int. 2021, 146, 106277. [Google Scholar] [CrossRef]

- Lares, M.; Ncibi, M.C.; Sillanpää, M.; Sillanpää, M. Occurrence, identification and removal of microplastic particles and fibers in conventional activated sludge process and advanced MBR technology. Water Res. 2018, 133, 236–246. [Google Scholar] [CrossRef]

- Li, X.; Chen, L.; Mei, Q.; Dong, B.; Dai, X.; Ding, G.; Zeng, E.Y. Microplastics in sewage sludge from the wastewater treatment plants in China. Water Res. 2018, 142, 75–85. [Google Scholar] [CrossRef] [PubMed]

- Di Bella, G.; Corsino, S.F.; De Marines, F.; Lopresti, F.; La Carrubba, V.; Torregrossa, M.; Viviani, G. Occurrence of microplastics in waste sludge of wastewater treatment plants: Comparison between membrane bioreactor (MBR) and conventional activated sludge (CAS) technologies. Membranes 2022, 12, 371. [Google Scholar] [CrossRef]

- Nizzetto, L.; Futter, M.; Langaas, S. Are agricultural soils dumps for microplastics of urban origin? Environ. Sci. Technol. 2016, 50, 10777–10779. [Google Scholar] [CrossRef] [PubMed]

- Crossman, J.; Hurley, R.R.; Futter, M.; Nizzetto, L. Transfer and transport of microplastics from biosolids to agricultural soils and the wider environment. Sci. Total Environ. 2020, 724, 138334. [Google Scholar] [CrossRef]

- Appels, L.; Baeyens, J.; Degrève, J.; Dewil, R. Principles and potential of the anaerobic digestion of waste-activated sludge. Prog. Energy Combust. Sci. 2008, 34, 755–781. [Google Scholar] [CrossRef]

- Mahon, A.M.; O’Connell, B.; Healy, M.G.; O’Connor, I.; Officer, R.; Nash, R.; Morrison, L. Microplastics in sewage sludge: Effects of treatment. Environ. Sci. Technol. 2017, 51, 810–818. [Google Scholar] [CrossRef] [PubMed]

- Wei, W.; Huang, Q.-S.; Sun, J.; Dai, X.; Ni, B.-J. Revealing the mechanisms of polyethylene microplastics affecting anaerobic digestion of waste activated sludge. Environ. Sci. Technol. 2019, 53, 9604–9613. [Google Scholar] [CrossRef]

- Wei, W.; Huang, Q.-S.; Sun, J.; Wang, J.-Y.; Wu, S.-L.; Ni, B.-J. Polyvinyl chloride microplastics affect methane production from the anaerobic digestion of waste activated sludge through leaching toxic, bisphenol A. Environ. Sci. Technol. 2019, 53, 2509–2517. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Zhao, M.; Li, C.; Miao, H.; Huang, Z.; Dai, X.; Ruan, W. Evaluation the impact of polystyrene micro and nanoplastics on the methane generation by anaerobic digestion. Ecotoxicol. Environ. Saf. 2020, 205, 111095. [Google Scholar] [CrossRef]

- Li, L.; Geng, S.; Li, Z.; Song, K. Effect of microplastic on anaerobic digestion of wasted activated sludge. Chemosphere 2020, 247, 125874. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Zhang, Y.; Zhao, Y.; Zhang, L.; Zhang, X. Inhibition of aged microplastics leachates on methane production from anaerobic digestion of sludge identification of key components. J. Hazard. Mater. 2023, 446, 130717. [Google Scholar] [CrossRef]

- Jiang, C.; Ni, B.-J.; Zheng, X.; Lu, B.; Chen, Z.; Gao, Y.; Zhang, Y.; Zhang, S.; Luo, G. The changes of microplastics’ behavior in adsorption and anaerobic digestion of waste activated sludge induced by hydrothermal pretreatment. Water Res. 2022, 221, 118744. [Google Scholar] [CrossRef]

- Mirsoleimani Azizi, S.M.; Hai, F.I.; Lu, W.; Al-Mamun, A.; Dhar, B.R. A review of mechanisms underlying the impacts of (nano)microplastics on anaerobic digestion. Bioresour. Technol. 2021, 329, 124894. [Google Scholar] [CrossRef]

- Wang, J.; Ma, D.; Feng, K.; Lou, Y.; Zhou, H.; Liu, B.; Xie, G.; Ren, N.; Xing, D. Polystyrene nanoplastics shape microbiome and functional metabolism in anaerobic digestion. Water Res. 2022, 219, 118606. [Google Scholar] [CrossRef]

- Shi, J.; Dang, Q.; Zhang, C.; Zhao, X. Insight into effects of polyethylene microplastics in anaerobic digestion systems of waste activated sludge: Interactions of digestion performance, microbial communities and antibiotic resistance genes. Environ. Pollut. 2022, 310, 119859. [Google Scholar] [CrossRef]

- Barber, W.P.F. Thermal hydrolysis for sewage treatment: A critical review. Water Res. 2016, 104, 53–71. [Google Scholar] [CrossRef] [PubMed]

- Wilson CANovak, J.T. Hydrolysis of macromolecular components of primary and secondary wastewater sludge by thermal hydrolytic pretreatment. Water Res. 2009, 43, 4489–4498. [Google Scholar] [CrossRef] [PubMed]

- Rühl, J.; Agrawal, S.; Engelhart, M. Efficacy of thermal hydrolysis for boosting specific methane yield depending on temperature-normalized solids retention time in an activated sludge process. Environ. Sci. Water Res. Technol. 2022, 8, 2971–2980. [Google Scholar] [CrossRef]

- Kepp, U.; Machenbach, I.; Weisz, N.; Solheim, O.E. Enhanced stabilisation of sewage sludge through thermal hydrolysis—Three years of experience with full-scale plant. Water Sci. Technol. 2000, 42, 89–96. [Google Scholar] [CrossRef]

- Ferrentino, R.; Langone, M.; Fiori, L.; Andreottola, G. Full-scale sewage sludge reduction technologies: A review with a focus on energy consumption. Water 2023, 15, 615. [Google Scholar] [CrossRef]

- Abelleira-Pereira, J.M.; Pérez-Elvira, S.I.; Sánchez-Oneto, J.; de la Cruz, R.; Portela, J.R.; Nebot, E. Enhancement of methane production in mesophilic anaerobic digestion of secondary sewage sludge by advanced thermal hydrolysis pretreatment. Water Res. 2015, 71, 330–340. [Google Scholar] [CrossRef]

- Han, W.; Liu, X.; Wang, Y.; Zhang, S.; Yang, Q. The interaction between sludge microplastics during thermal hydrolysis of sludge. J. Hazard. Mater. 2024, 480, 135816. [Google Scholar] [CrossRef]

- Chen, H.; Wu, Y.; Zou, Z.; Yang, X.; Tsang, Y.F. Thermal hydrolysis alleviates polyethylene microplastic-induced stress in anaerobic digestion of waste activated sludge. J. Hazard. Mater. 2024, 470, 134124. [Google Scholar] [CrossRef]

- Li, X.; Wang, X.; Chen, L.; Huang, X.; Pan, F.; Liu, L.; Dong, B.; Liu, H.; Li, H.; Dai, X.; et al. Changes in physicochemical and leachate characteristics of microplastics during hydrothermal treatment of sewage sludge. Water Res. 2022, 222, 118876. [Google Scholar] [CrossRef]

- Pérez-Elvira, S.I.; Sapkaite, I.; Fdz-Polanco, F. Evaluation of thermal steam-explosion key operation factors to optimize biogas production from biological sludge. Water Sci. Technol. 2015, 72, 937–945. [Google Scholar] [CrossRef]

- Mirsoleimani Azizi, S.M.; Haffiez, N.; Mostafa, A.; Hussain, A.; Abdallah, M.; Al-Mamun, A.; Bhatnagar, A.; Dhar, B.R. Low-and high-temperature thermal hydrolysis pretreatment for anaerobic digestion of sludge: Process evaluation and fate of emerging pollutants. Renew. Sustain. Energy Rev. 2024, 200, 114453. [Google Scholar] [CrossRef]

- Ngo, P.L.; Young, B.R.; Brian, K.; Baroutian, S. Thermal hydrolysis of primary sludge waste activated sludge mixture: Biogas production formation of inhibitors. J. Clean. Prod. 2023, 428, 139354. [Google Scholar] [CrossRef]

- Bougrier, C.; Delgenès, J.-P.; Carrère, H. Effects of thermal treatments on five different waste activated sludge samples: Solubilisation physical properties anaerobic digestion. Chem Eng. J. 2008, 139, 236–244. [Google Scholar] [CrossRef]

- Wang, X.; Andrade, N.; Shekarchi, J.; Fischer, S.J.; Torrents, A.; Ramirez, M. Full scale study of Class A biosolids produced by thermal hydrolysis pretreatment and anaerobic digestion. Waste Manag. 2018, 78, 43–50. [Google Scholar] [CrossRef] [PubMed]

- Akiya, N.; Savage, P.E. Roles of water for chemical reactions in high-temperature water. Chem. Rev. 2002, 102, 2725–2750. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Huang, X.; Ma, S.; He, J. Thermo-alkaline pretreatment of excess sludge: Effects of temperature on volatile fatty acids accumulation microbial community. J. Environ. Manag. 2023, 342, 118244. [Google Scholar] [CrossRef]

- Pereira, P.; Savage, P.E.; Pester, C.W. Neutral hydrolysis of post-consumer polyethylene terephthalate waste in different phases. ACS Sustain. Chem. Eng. 2023, 11, 6866–6877. [Google Scholar] [CrossRef]

- Ghosal, K.; Nayak, C. Recent advances in chemical recycling of polyethylene terephthalate waste into value-added products for sustainable coating solutions–hope vs. hype. Mater. Adv. 2022, 3, 1974–1992. [Google Scholar] [CrossRef]

- Maeng, D.Y.; Jeon, H.; Kim, H. Kinetics of alkaline hydrolysis of synthetic organic esters. Int. J. Chem. Kinet. 2022, 54, 437–448. [Google Scholar] [CrossRef]

- Patnaik, P.; Yang, C.H.; Huber, E. Kinetics of phthalate reactions with ammonium hydroxide in alkaline waters. Water Res. 2001, 35, 3034–3038. [Google Scholar] [CrossRef]

- Abedsoltan, H.; Achilias, D.S. A focused review on recycling and hydrolysis techniques of polyethylene terephthalate. Polym. Eng. Sci. 2023, 63, 2651–2674. [Google Scholar] [CrossRef]

- Campanelli, J.R.; Kamal, M.R.; Cooper, D.G. Akinetic study of the hydrolytic degradation of polyethylene terephthalate at high temperatures. J. Appl. Polym. Sci. 1993, 48, 443–451. [Google Scholar] [CrossRef]

- von der Esch, E.; Lanzinger, M.; Kohles, A.J.; Schwaferts, C.; Weisser, J.; Hofmann, T.; Glas, K.; Elsner, M.; Ivleva, N.P. Simple generation of suspensible secondary microplastic reference particles via ultrasound treatment. Front. Chem. 2020, 8, 169. [Google Scholar] [CrossRef] [PubMed]

- Hwangbo, S.; Kim, I.Y.; Ko, K.; Park, K.; Hong, J.; Kang, G.; Wi, J.-S.; Kim, J.; Lee, T.G. Preparation of fragmented polyethylene nanoplastics using a focused ultrasonic system and assessment of their cytotoxic effects on human cells. Environ. Pollut. 2024, 362, 125009. [Google Scholar] [CrossRef]

- Alvim, C.B.; Bes-Piá, M.A.; Mendoza-Roca, J.A. An innovative approach to the application of ultrasounds to remove polyethylene microspheres from activated sludge. Sep. Purif. Technol. 2021, 264, 118429. [Google Scholar] [CrossRef]

- Lambert, S.; Wagner, M. Formation of microscopic particles during the degradation of different polymers. Chemosphere 2016, 161, 510–517. [Google Scholar] [CrossRef]

- Julienne, F.; Delorme, N.; Lagarde, F. From macroplastics to microplastics: Role of water in the fragmentation of polyethylene. Chemosphere 2019, 236, 124409. [Google Scholar] [CrossRef]

- Kalogerakis, N.; Karkanorachaki, K.; Kalogerakis, G.C.; Triantafyllidi, E.; Avgeropoulos, A.; Lyberatos, G.; Gotsis, A.D. Microplastics generation: Onset of fragmentation of polyethylene films in marine environment mesocosms. Front. Mar. Sci. 2017, 4, 84. [Google Scholar] [CrossRef]

- Nakatani, H.; Ohshima, Y.; Uchiyama, T.; Motokucho, S. Degradation and fragmentation behavior of polypropylene and polystyrene in water. Sci. Rep. 2022, 12, 18501. [Google Scholar] [CrossRef]

- Gigault, J.; Pedrono, B.; Maxit, B.; Ter Halle, A. Marine plastic litter: The unanalyzed nano-fraction. Environ. Sci. Nano 2016, 3, 346–350. [Google Scholar] [CrossRef]

- Mattsson, K.; Johnson, E.V.; Malmendal, A.; Linse, S.; Hansson, L.-A.; Cedervall, T. Brain damage and behavioural disorders in fish induced by plastic nanoparticles delivered through the food chain. Sci. Rep. 2017, 7, 11452. [Google Scholar] [CrossRef]

- Yang, T.; Luo, J.; Nowack, B. Characterization of nanoplastics, fibrils, and microplastics released during washing and abrasion of polyester textiles. Environ. Sci. Technol. 2021, 55, 15873–15881. [Google Scholar] [CrossRef]

- Ahn, Y.; Colin, X.; Roma, G. Atomic scale mechanisms controlling the oxidation of polyethylene: A first-principles study. Polymers 2021, 13, 2143. [Google Scholar] [CrossRef] [PubMed]

- Gardette, M.; Thérias, S.; Gardette, J.-L.; Janecska, T.; Földes, E.; Pukánszky, B. Photo- and thermal-oxidation of polyethylene: Comparison of mechanisms and influence of unsaturation content. Polym. Degrad. Stab. 2013, 98, 2383–2390. [Google Scholar] [CrossRef]

- Salvalaggio, M.; Bagatin, R.; Fornaroli, M.; Fanutti, S.; Palmery, S.; Battistel, E. Multi-component analysis of low-density polyethylene oxidative degradation. Polym. Degrad. Stab. 2006, 91, 2775–2785. [Google Scholar] [CrossRef]

- Yoshioka, T.; Kameda, T.; Imai, S.; Okuwaki, A. Dechlorination of poly(vinyl chloride) using NaOH in ethylene glycol under atmospheric pressure. Polym. Degrad. Stab. 2008, 93, 1138–1141. [Google Scholar] [CrossRef]

- Luo, H.; Tu, C.; He, D.; Zhang, A.; Sun, J.; Li, J.; Xu, J.; Pan, X. Interactions between microplastics and contaminants: A review focusing on the effect of aging process. Sci. Total Environ. 2023, 899, 165615. [Google Scholar] [CrossRef] [PubMed]

- Hungwe, D.; Hosokawa, S.; Xu, H.; Yamasaki, Y. The role of NaOH in the hydrothermal dehydrochlorination of polyvinyl chloride. Polym. Degrad. Stab. 2023, 208, 110266. [Google Scholar] [CrossRef]

- Maddela, N.R.; Kakarla, D.; Venkateswarlu, K.; Megharaj, M. Additives of plastics: Entry into the environment potential risks to human ecological health. J. Environ. Manag. 2023, 348, 119364. [Google Scholar] [CrossRef]

- Sun, B.; Hu, Y.; Cheng, H.; Tao, S. Releases of brominated flame retardants (BFRs) from microplastics in aqueous medium: Kinetics and molecular-size dependence of diffusion. Water Res. 2019, 151, 215–225. [Google Scholar] [CrossRef] [PubMed]

- Henkel, C.; Hüffer, T.; Hofmann, T. Polyvinyl chloride microplastics leach phthalates into the aquatic environment over decades. Environ. Sci. Technol. 2022, 56, 14507–14516. [Google Scholar] [CrossRef]

- Henkel, C.; Lamprecht, J.; Hüffer, T.; Hofmann, T. Environmental factors strongly influence the leaching of di(2-ethylhexyl) phthalate from PVC microplastics. Water Res. 2023, 236, 120434. [Google Scholar] [CrossRef]

- Yu, Y.; Ding, Y.; Zhou, C.; Ge, S. Aging of polylactic acid microplastics during hydrothermal treatment of sewage sludge and its effects on heavy metals adsorption. Environ. Res. 2023, 216, 114532. [Google Scholar] [CrossRef] [PubMed]

- Vo, T.-P.; Rintala, J.; Dai, L.; Oh, W.-D.; He, C. The role of ubiquitous metal ions in degradation of microplastics in hot-compressed water. Water Res. 2023, 245, 120672. [Google Scholar] [CrossRef]

- Hu, K.; Zhou, P.; Yang, Y.; Hall, T.; Nie, G.; Yao, Y.; Duan, X.; Wang, S. Degradation of microplastics by a thermal Fenton reaction. ACS ES&T Eng. 2021, 2, 110–120. [Google Scholar] [CrossRef]

- Sheng, G.P.; Yu, H.Q.; Li, X.Y. Extracellular polymeric substances (EPS) of microbial aggregates in biological wastewater treatment systems: A review. Biotechnol. Adv. 2010, 28, 882–894. [Google Scholar] [CrossRef]

- Flemming, H.-C.; Wingender, J. The biofilm matrix. Nat. Rev. Microbiol. 2010, 8, 623–633. [Google Scholar] [CrossRef]

- Wei, S.; Zeng, F.; Zhou, Y.; Zhao, J.; Wang, H.; Gao, R.; Liang, W. Phototransformation of extracellular polymeric substances in activated sludge and their interaction with microplastics. RSC Adv. 2023, 13, 26574–26580. [Google Scholar] [CrossRef]

- Huang, Y.; Hu, T.; Lin, B.; Ke, Y.; Li, J.; Ma, J. Microplastics-biofilm interactions in biofilm-based wastewater treatment processes: A review. Environ. Pollut. 2024, 361, 124836. [Google Scholar] [CrossRef] [PubMed]

- Hermabessière, L.; Dehaut, A.; Paul-Pont, I.; Lacroix, C.; Jezequel, R.; Soudant, P.; Duflos, G. Occurrence and effects of plastic additives in marine environments: A review. Chemosphere 2017, 182, 781–793. [Google Scholar] [CrossRef]

- Lithner, D.; Larsson, Å.; Dave, G. Environmental and health hazard ranking and assessment of plastic polymers based on chemical composition. Sci. Total Environ. 2011, 409, 3309–3324. [Google Scholar] [CrossRef] [PubMed]

- Teuten, E.L.; Saquing, J.M.; Knappe, D.R.U.; Barlaz, M.A.; Jonsson, S.; Björn, A.; Rowland, S.J.; Thompson, R.C.; Galloway, T.S.; Yamashita, R.; et al. Transport release of chemicals from plastics to the environment to wildlife. Philos Trans R. Soc. B 2009, 364, 2027–2045. [Google Scholar] [CrossRef]

- Chen, H.; Tang, M.; Yang, X.; Tsang, Y.F.; Wu, Y.; Wang, D.; Zhou, Y. Polyamide 6 microplastics facilitate methane production during anaerobic digestion of waste activated sludge. Chem. Eng. J. 2021, 408, 127251. [Google Scholar] [CrossRef]

- Wei, W.; Hao, Q.; Chen, Z.; Bao, T.; Ni, B.-J. Polystyrene nanoplastics reshape the anaerobic granular sludge for recovering methane from wastewater. Water Res. 2020, 182, 116041. [Google Scholar] [CrossRef]

- Fu, S.-F.; Ding, J.-N.; Zhang, Y.; Li, Y.-F.; Zhu, R.; Yuan, X.-Z.; Zou, H. Exposure to polystyrene nanoplastic leads to inhibition of anaerobic digestion system. Sci. Total Environ. 2018, 625, 64–70. [Google Scholar] [CrossRef]

- Feng, Y.; Feng, L.-J.; Liu, S.-C.; Duan, J.-L.; Zhang, Y.-B.; Li, S.-C.; Sun, X.-D.; Wang, S.-G.; Yuan, X.-Z. Emerging investigator series: Inhibition and recovery of anaerobic granular sludge performance in response to short-term polystyrene nanoparticle exposure. Environ. Sci. Water Res. Technol. 2018, 4, 1902–1911. [Google Scholar] [CrossRef]

- Zeng, Y.; Tang, X.; Fan, C.; Tang, L.; Zhou, M.; Zhang, B.; Wang, R.; Li, G. Evaluating the effects of different pretreatments on anaerobic digestion of waste activated sludge containing polystyrene microplastics. ACS ES&T Water 2022, 2, 117–127. [Google Scholar] [CrossRef]

- Chen, H.; Zou, Z.; Tang, M.; Yang, X.; Tsang, Y.F. Polycarbonate microplastics induce oxidative stress in anaerobic digestion of waste activated sludge by leaching bisphenol A. J. Hazard. Mater. 2023, 443, 130158. [Google Scholar] [CrossRef]

- Wang, C.; Wei, W.; Chen, Z.; Wang, Y.; Chen, X.; Ni, B.-J. Polystyrene microplastics and nanoplastics distinctively affect anaerobic sludge treatment for hydrogen and methane production. Sci. Total Environ. 2022, 850, 158085. [Google Scholar] [CrossRef]

- Cesaro, A.; Pirozzi, F.; Zafirakou, A.; Alexandraki, A. Microplastics in sewage sludge destined to anaerobic digestion: The potential role of thermal pretreatment. Chemosphere 2022, 309, 136669. [Google Scholar] [CrossRef]

- Zhang, Y.-T.; Wei, W.; Huang, Q.-S.; Wang, C.; Wang, Y.; Ni, B.-J. Insights into the microbial response of anaerobic granular sludge during long-term exposure to polyethylene terephthalate microplastics. Water Res. 2020, 179, 115898. [Google Scholar] [CrossRef] [PubMed]

- Wei, W.; Wang, C.; Shi, X.; Zhang, Y.-T.; Chen, Z.; Wu, L.; Ni, B.-J. Multiple microplastics induced stress on anaerobic granular sludge and an effectively overcoming strategy using hydrochar. Water Res. 2022, 222, 118895. [Google Scholar] [CrossRef]

- Azizi, S.M.M.; Hai, F.I.; Lu, W.; Al-Mamun, A.; Dhar, B.R. Thermal hydrolysis of sludge counteracts polystyrene nanoplastic-induced inhibition in anaerobic digestion. ACS EST Engg. 2022, 2, 285–295. [Google Scholar] [CrossRef]

- Mirsoleimani Azizi, S.M.M.; Zakaria, B.S.; Haffiez, N.; Dhar, B.R. Granular activated carbon remediates antibiotic resistance propagation and methanogenic inhibition induced by polystyrene nanoplastics in sludge anaerobic digestion. Bioresour. Technol. 2023, 377, 128938. [Google Scholar] [CrossRef]

- Wang, C.; Wei, W.; Zhang, Y.-T.; Chen, X.; Ni, B.-J. Hydrochar alleviated the inhibitory effects of polyvinyl chloride microplastics nanoplastics on anaerobic granular sludge for wastewater treatment. Chem. Eng. J. 2023, 452, 139302. [Google Scholar] [CrossRef]

- Iyare, P.U.; Ouki, S.K.; Bond, T. Microplastics removal in wastewater treatment plants: A critical review. Environ. Sci.: Water Res. Technol. 2020, 6, 2664–2675. [Google Scholar] [CrossRef]

- Gies, E.A.; LeNoble, J.L.; Noël, M.; Etemadifar, A.; Bishay, F.; Hall, E.R.; Ross, P.S. Retention of microplastics in a major secondary wastewater treatment plant in Vancouver, Canada. Mar. Pollut. Bull. 2018, 133, 553–561. [Google Scholar] [CrossRef]

- Mason, S.A.; Garneau, D.; Sutton, R.; Chu, Y.; Ehmann, K.; Barnes, J.; Fink, P.; Papazissimos, D.; Rogers, D.L. Microplastic pollution is widely detected in, U.S. municipal wastewater treatment plant effluent. Environ. Pollut. 2016, 218, 1045–1054. [Google Scholar] [CrossRef]

- Rolsky, C.; Kelkar, V.; Driver, E.; Halden, R.U. Municipal sewage sludge as a source of microplastics in the environment. Curr. Opin. Environ. Sci. Health 2020, 14, 16–22. [Google Scholar] [CrossRef]

- Dong, H.; Chen, Y.; Wang, J.; Zhang, Y.; Zhang, P.; Li, X.; Zou, J.; Zhou, A. Interactions of microplastics antibiotic resistance genes their effects on the aquaculture environments. J. Hazard. Mater. 2021, 403, 123961. [Google Scholar] [CrossRef]

- Seeley, M.E.; Song, B.; Passie, R.; Hale, R.C. Microplastics affect sedimentary microbial communities and nitrogen cycling. Nat. Commun. 2020, 11, 2372. [Google Scholar] [CrossRef]

- Qin, R.; Su, C.; Liu, W.; Tang, L.; Li, X.; Deng, X.; Wang, A.; Chen, Z. Effects of exposure to polyether sulfone microplastic on the nitrifying process and microbial community structure in aerobic granular sludge. Bioresour. Technol. 2020, 302, 122827. [Google Scholar] [CrossRef] [PubMed]

- He, D.; Luo, Y.; Lu, S.; Liu, M.; Song, Y.; Lei, L. Microplastics in soils: Analytical methods, pollution characteristics and ecological risks. Trends Anal. Chem. 2018, 109, 163–172. [Google Scholar] [CrossRef]

- Li, J.; Zhang, K.; Zhang, H. Adsorption of antibiotics on microplastics. Environ. Pollut. 2018, 237, 460–467. [Google Scholar] [CrossRef] [PubMed]

- Heyer, R.; Kohrs, F.; Reichl, U.; Benndorf, D. Metaproteomics of complex microbial communities in biogas plants. Microb. Biotechnol. 2015, 8, 749–763. [Google Scholar] [CrossRef]

- Barua, S.; Dhar, B.R. Advances towards understanding and engineering direct interspecies electron transfer in anaerobic digestion. Bioresour. Technol. 2017, 244, 698–707. [Google Scholar] [CrossRef] [PubMed]

- Morris, R.; Schauer-Gimenez, A.; Bhattad, U.; Kearney, C.; Struble, C.A.; Zitomer, D.; Maki, J.S. Methyl coenzyme M reductase (mcrA) gene abundance correlates with activity measurements of methanogenic H2/CO2-enriched anaerobic biomass. Microb. Biotechnol. 2014, 7, 77–84. [Google Scholar] [CrossRef]

- Passaris, I.; Van Gaelen, P.; Cornelissen, R.; Simoens, K.; Grauwels, D.; Vanhaecke, L.; Springael, D.; Smets, I. Cofactor F430 as a biomarker for methanogenic activity: Application to an anaerobic bioreactor system. Appl. Microbiol. Biotechnol. 2018, 102, 1191–1201. [Google Scholar] [CrossRef]

- Horne, A.J.; Lessner, D.J. Assessment of the oxidant tolerance of Methanosarcina acetivorans. FEMS Microbiol. Lett. 2013, 343, 13–19. [Google Scholar] [CrossRef]

- Ruan, D.; Zhou, Z.; Pang, H.; Yao, J.; Chen, G.; Qiu, Z. Enhancing methane production of anaerobic sludge digestion by microaeration: Enzyme activity stimulation, semi-continuous reactor validation and microbial community analysis. Bioresour. Technol. 2019, 289, 121643. [Google Scholar] [CrossRef] [PubMed]

- Tian, T.; Qiao, S.; Li, X.; Zhang, M.; Zhou, J. Nano-graphene induced positive effects on methanogenesis in anaerobic digestion. Bioresour. Technol. 2017, 224, 41–47. [Google Scholar] [CrossRef]

- Hatinoglu, M.D.; Sanin, F.D. Fate and effects of polyethylene terephthalate (PET) microplastics during anaerobic digestion of alkaline-thermal pretreated sludge. Waste Manag. 2022, 153, 376–385. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, X.; Han, W.; Jiao, J.; Ren, W.; Jia, G.; Huang, C.; Yang, Q. Migration and transformation modes of microplastics in reclaimed wastewater treatment plant and sludge treatment center with thermal hydrolysis and anaerobic digestion. Bioresour. Technol. 2024, 400, 130649. [Google Scholar] [CrossRef] [PubMed]

- Wei, W.; Chen, X.; Ni, B.-J. Different pathways of microplastics entering the sludge treatment system distinctively affect anaerobic sludge fermentation processes. Environ. Sci. Technol. 2021, 55, 11274–11283. [Google Scholar] [CrossRef] [PubMed]

- Gao, Z.; Qian, H.; Cui, T.; Ren, Z.; Wang, X. Comprehensive meta-analysis reveals the impact of non-biodegradable plastic pollution on methane production in anaerobic digestion. Chem. Eng. J. 2024, 484, 149703. [Google Scholar] [CrossRef]

- Wei, W.; Zhang, Y.-T.; Huang, Q.-S.; Ni, B.-J. Polyethylene terephthalate microplastics affect hydrogen production from alkaline anaerobic fermentation of waste activated sludge through altering viability and activity of anaerobic microorganisms. Water Res. 2019, 163, 114881. [Google Scholar] [CrossRef]

- Mao, R.; Lang, M.; Yu, X.; Wu, R.; Yang, X.; Guo, X. Aging mechanism of microplastics with UVirradiation its effects on the adsorption of heavy metals. J. Hazard. Mater. 2020, 393, 122515. [Google Scholar] [CrossRef]

- Omorogie, M.O.; Helmreich, B. Exploring the Potential of Amino-Functionalized Zeolite Series/H3PO4-Biochar for Environmental Microplastic Removal. Ind. Eng. Chem. Res. 2024, 63, 3947–3961. [Google Scholar] [CrossRef]

- Zhou, F.; Liu, S.; Zhang, X. Anaerobic membrane bioreactor for municipal wastewater treatment: A review of technology evolution, challenges, and engineering readiness. Crit. Rev. Environ. Sci. Technol. 2024, 54, 1862–1909. [Google Scholar] [CrossRef]

- Dang, Y.; Holmes, D.E.; Zhao, Z.; Woodard, T.L.; Zhang, Y.; Sun, D.; Lovley, D.R. Enhancing anaerobic digestion of complex organic waste with carbon-based conductive materials. Bioresour. Technol. 2016, 220, 516–522. [Google Scholar] [CrossRef] [PubMed]

- He, K.; Liu, Y.; Tian, L.; He, W.; Cheng, Q. Review in anaerobic digestion of food waste. Heliyon 2024, 10, e28200. [Google Scholar] [CrossRef]

- Wang, P.; Guo, Y.; Yu, M.; Riya, S.; Zheng, Y.; Ren, L. The effect and mechanism of polyethylene terephthalate microplastics on anaerobic co-digestion of sewage sludge and food waste. Biochem. Eng. J. 2023, 198, 109012. [Google Scholar] [CrossRef]

- Ji, G.; Xing, Y.; You, T. Biochar as adsorbents for environmental microplastics and nanoplastics removal. J. Environ. Chem. Eng. 2024, 12, 113377. [Google Scholar] [CrossRef]

- Alimohammadi, N.; Demirer, G.N. Microplastics in anaerobic digestion: Occurrence impact mitigation strategies. J. Environ. Health Sci. Eng. 2024, 22, 397–411. [Google Scholar] [CrossRef] [PubMed]

| Pretreatment Method | Typical Operating Window | Dominant Stressors on MPs | Full-Scale Relevance |

|---|---|---|---|

| TH | 140–180 °C; 4–8 bar; 20–60 min | Hydrothermal aging, fragmentation, oxidation, additive leaching | Widely implemented |

| Thermo-alkaline | >150 °C; pH > 10; 30–60 min | Strong alkaline hydrolysis, surface deprotonation, plasticizer saponification | Site-specific |

| Ultrasonic pretreatment | 20–80 kHz; kJ L−1-scale energy inputs | Cavitation, micro-scale shear, particle fragmentation, surface pitting | Mostly pilot/local |

| Other (ozonation, mechanical, freeze–thaw) | Method-dependent | Oxidation, abrasion, crack formation | Less common |

| Authors Year | Substrate | Pretreatment | MP Type | MP Size | MP Dose | AD Conditions | Mechanistic Insight | Key Outcomes vs. Control | Ref. No. |

|---|---|---|---|---|---|---|---|---|---|

| Wei et al., 2019 | WAS | None | PE | tens–hundreds µm | 10–200 particles g−1 TS | Batch and semi-continuous, mesophilic | Mild EPS disturbance and surface interaction at elevated loads. | Low: ≈no effect; high: CH4 ↓ 10–20%, slight hydrolysis inhibition. | [14] |

| Wei et al., 2019 | WAS | None | PVC | 1 mm | 10–60 particles g−1 TS | Batch, mesophilic | BPA leaching; oxidative stress; acetoclastic methanogen suppression. | Low: slight CH4 ↑; higher: CH4 ↓ 20–25%, slower VFA conversion. | [15] |

| Li et al., 2020 | WAS | None | Mixed MPs (PE, PP, PET, PVC) | mainly 50–1000 µm | up to g kg−1 TS | Batch, mesophilic | Polymer- and dose-dependent toxicity; enzyme/particle interaction at high loads. | Env.-range: minor changes; elevated: CH4 ↓, more residual COD/solids. | [17] |

| Fu et al., 2018 | Sludge inoculum | None | PS NPs | 70–100 nm | up to hundreds µg L−1 | Batch, mesophilic | Cell attachment; ROS generation; membrane damage at nano-scale. | High NPs: delayed start-up, CH4 ↓ up to ~30–40%. | [77] |

| Zhang et al., 2020 | Anaerobic granular sludge (AGS) | None (chronic exposure) | PVC MPs | 75–300 µm | 15–150 MPs L−1 | Continuous AGS reactor, mesophilic | EPS loss; granule surface erosion; community imbalance. | Progressive PVC exposure: granule disintegration, CH4 and COD removal ↓ | [83] |

| Chen et al., 2021 | WAS | None | PA6 MPs | 100–300 µm | 5–50 particles g−1 TS | Batch AD, mesophilic | Surface aging; N-containing leachates reshape bacterial consortia. | Low–moderate: limited/neutral; higher: emerging CH4 inhibition, shifts in taxa. | [75] |

| Wei et al., 2022 | AGS treating wastewater | None vs. hydrochar | PE, PP, PET, PS (mixture) | 75–300 µm | mg L−1 range | Continuous AGS reactor, mesophilic | Combined physical and oxidative stress; weakening of granule structure at load. | Low MPs: stable AGS; high MPs: EPS ↓, granule damage, CH4 ↓ | [84] |

| Wang et al., 2022 | AGS + PS nanoplastics | Biochar dosing | PS NPs | ≤100 nm | tens–hundreds µg L−1 | AGS reactor/batch, mesophilic | NPs disturb EPS architecture; increase ROS; alter keystone populations. | Elevated NPs: CH4 ↓, diversity loss; moderate: partial resilience, measurable stress. | [21] |

| Wang et al., 2023 | AGS + PVC MPs/NPs | Hydrochar dosing | PVC MPs and NPs | micro- and nano-scale | fixed PVC + graded hydrochar | AGS/batch, mesophilic | Hydrochar sorption of MPs/additives; protection of EPS and granules. | PVC alone: strong inhibition; +hydrochar: CH4 and granule integrity largely restored. | [18] |

| Zeng et al., 2022 | WAS + PS MPs | Thermal/hydrothermal/chemical pretreatments | PS MPs | 75 µm | mg g−1 TS | BMP tests, mesophilic | TH enhances solubilization; modifies PS surfaces without major added toxicity. | TH improves CH4; tested PS levels do not negate TH benefits. | [79] |

| Azizi et al., 2022 | WAS + PS NPs | Conventional THP (80–160 °C) prior to AD | PS NPs | 80–100 nm | 50–150 µg L−1 | Batch and semi-continuous, mesophilic | TH reduces NP-induced stress and ARG propagation compared with conventional AD. | Conventional+NPs: inhibition, ARG ↑; TH–AD: CH4 maintained, impacts attenuated. | [85] |

| Azizi et al., 2023 | Primary sludge + PS NPs | THP (160 °C, varying solids content) | PS NPs | 80–100 nm | 150 µg L−1 | Batch, mesophilic | THP severity co-determines NP reactivity, toxicity and energy balance. | Optimized THP: stable CH4 with manageable NP effects; too mild/harsh: reduced net benefit. | [86] |

| Azizi et al., 2024 | TWAS/FPS + PS NPs | Low-temperature THP (90 °C, 90 min) | PS NPs | 80–100 nm | 150 µg L−1 | Batch and semi-continuous | Low-T THP partially ages NPs while improving sludge biodegradability. | Low-T THP: moderate mitigation of NP effects with favorable energy profile. | [33] |

| Wei et al., 2023; | AGS systems with multiple MPs and sorbents | Hydrochar/biochar/GAC; no THP or with THP | Mixed (PE, PP, PET, PS, PVC; MPs and NPs) | micro- to nano-scale | env.-relevant to elevated; multi-level sorbent doses | Batch and continuous | Carbonaceous media immobilize MPs, buffer toxicity, support syntrophy. | With sorbents: CH4 stabilize or recover; No sorbents: Significant inhibition and structural disruption | [87] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yue, P.; Chen, R. Microplastic Behavior in Sludge Pretreatment and Anaerobic Digestion: Impacts, Mechanistic Insights, and Mitigation Strategies. Sustainability 2025, 17, 10471. https://doi.org/10.3390/su172310471

Yue P, Chen R. Microplastic Behavior in Sludge Pretreatment and Anaerobic Digestion: Impacts, Mechanistic Insights, and Mitigation Strategies. Sustainability. 2025; 17(23):10471. https://doi.org/10.3390/su172310471

Chicago/Turabian StyleYue, Peng, and Rongwei Chen. 2025. "Microplastic Behavior in Sludge Pretreatment and Anaerobic Digestion: Impacts, Mechanistic Insights, and Mitigation Strategies" Sustainability 17, no. 23: 10471. https://doi.org/10.3390/su172310471

APA StyleYue, P., & Chen, R. (2025). Microplastic Behavior in Sludge Pretreatment and Anaerobic Digestion: Impacts, Mechanistic Insights, and Mitigation Strategies. Sustainability, 17(23), 10471. https://doi.org/10.3390/su172310471