Packaged Bread and Its Carbon Footprint: Balancing Convenience and Waste

Abstract

1. Introduction

2. Carbon Footprint of Bread and Packaged Sliced Bread: Analysis and Comparisons

- -

- Packaging Materials: Sliced bread requires more complex, multi-layered packaging (plastic bags, transport cartons, labels, etc.), significantly increasing its environmental impact.

- -

- Additional Processing: Pre-slicing and hermetic packaging require extra industrial steps with higher energy consumption compared to traditional bread.

- -

- Ingredients and Additives: Sliced bread often contains emulsifiers, enzymes, and preservatives to maintain softness and extend shelf life, the production of which contributes to the overall CF.

- -

- Waste Amplification: While sliced bread has a longer shelf life, its packaging and portioning can generate more waste (though the overall impact depends on domestic consumption behavior vs. the waste reduction from extended shelf life).

3. Methodology

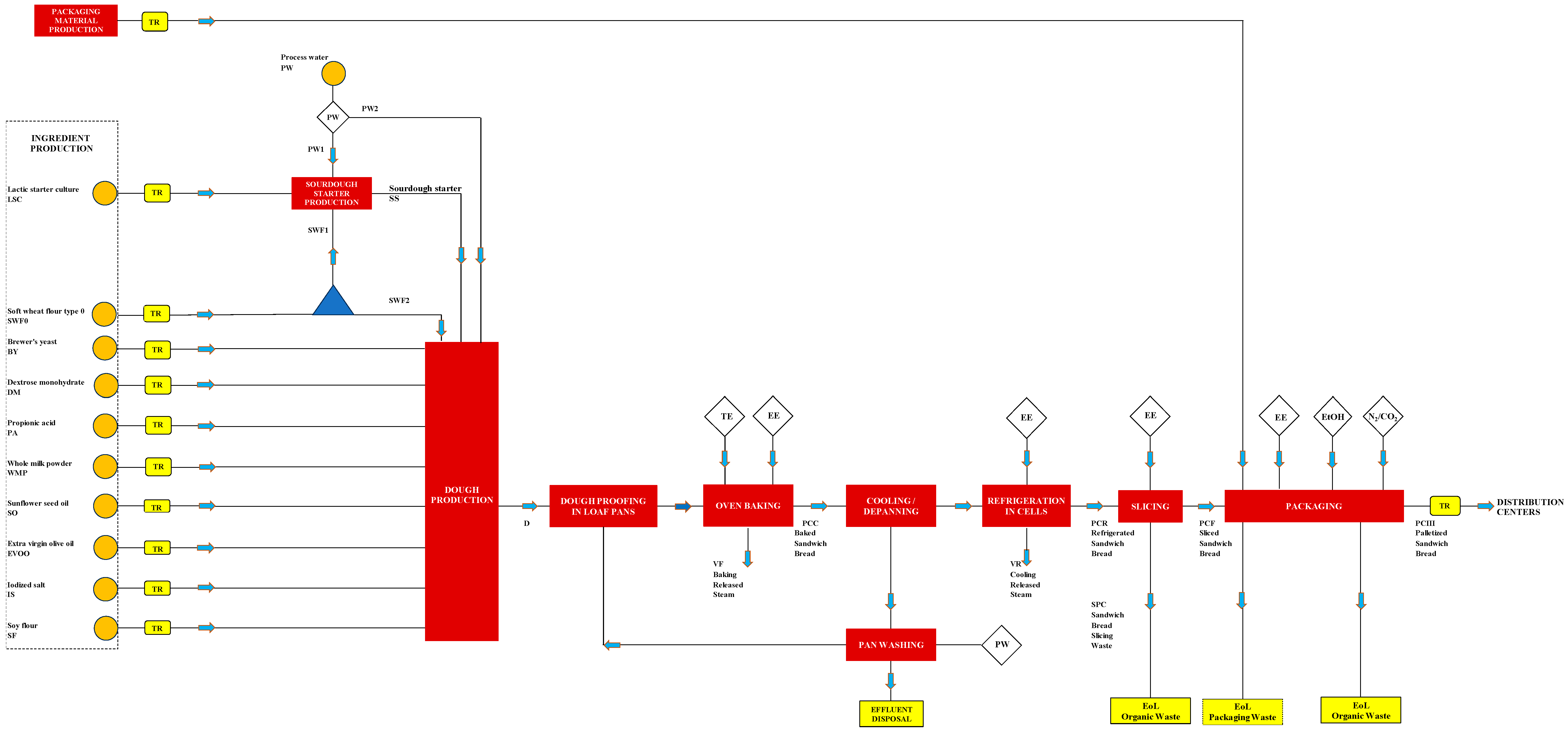

3.1. Defining Objectives and Scope

- (U1)

- The production of raw materials, auxiliary materials, and ingredients.

- (U2)

- The production of packaging materials.

- (U3)

- The transportation of raw materials, auxiliary materials, and packaging from their production sites (PS) to the company gate (FG).

- (C1)

- The preparation of sourdough, kneading, leavening, baking, refrigeration, slicing, and packaging of the sliced bread.

- (C2)

- The use of electricity and mains gas.

- (D1)

- The end-of-life of waste and by-products generated during the production and packaging of sliced bread, as well as the disposal of wastewater.

3.1.1. Exclusions from the System Boundaries

3.1.2. Geographical, Temporal, and Technological Boundaries

3.1.3. Data Acquisition

3.1.4. Data Quality Evaluation

3.2. Life Cycle Inventory

- (1)

- Preparation and long kneading of the dough to promote the development of the gluten network and give the dough elasticity and tenacity. To produce conventional white sliced bread, Table 1 lists the ingredients with their mass fraction (zi) and ratio (Zi/SWF0) referred to soft wheat flour type 0 (SWF0).

- (2)

- Dough leavening: The dough is leavened at 37 °C and 80% relative humidity (RH) for 1.5–2 h. Each dough block of about 1.8 kg (see Figure S2a in the electronic Supplementary Material) was divided into equal portions (generally 7 loaves), as illustrated in Figure S2b. Each loaf is placed into a special rectangular pan (Figure S3a), lightly greased or lined with parchment paper, to give it the characteristic shape of sandwich bread. Figure S3b shows the seven loaves placed in each pan before being put into the proofing cabinet (Figure S4). Finally, Figure S3c shows the loaves at the end of the proofing process, where the increase in volume causes them to completely fill the pan.

- (3)

- Dough baking in a Rotor oven (Figure S5) at 210 °C for 20–25 min. The baking takes place in pans placed on a rotating rack, which allows the ventilated air to evenly touch the product being baked. The air is conveyed and distributed within the chamber through adjustable ducts. This promotes the evaporation of water and the formation of the crust and the characteristic soft crumb. The oven is also equipped with a large cascade steamer, composed of individual cast-iron elements that cover the entire back wall of the oven, designed to deliver water vapor to completely envelop the product. The oven is powered by natural gas.

- (4)

- Cooling of the product to room temperature. After baking, the racks with the pans are removed from the oven (Figure S6a) to allow them to cool to room temperature.

- (5)

- Removal of the sandwich loaves from the pans with the cooked loaves repositioned on the racks (Figure S6b) for storage in a cold room for 24 h.

- (6)

- Slicing the whole sandwich loaf into slices with a base of 12 cm, a height of 12 cm, and a thickness of 1.3 cm (Figure S7a) using automatic slicers (Figure S7b). The average moisture and protein contents of each sliced sandwich bread were 36.4 ± 0.6% (w/w), and 9.64 ± 0.14% (w/w), respectively. The initial and final slices are discarded because their crust is less appealing, their shape is irregular, and they are more exposed to heat, making them more susceptible to burning or uneven browning. In addition to the end slices, any trim and broken slices of bread are also discarded. All these scraps are not repurposed for products like breadcrumbs or croutons but donated to local livestock farms for reuse. Table 2 shows the mass variation of the leavened dough after oven baking, cooling in the refrigerated cell, and slicing, which includes discarding the end slices and broken ones. The bread’s weight decreases by about 12% after baking and by approximately 14% after cooling. The total scraps (end and broken slices) account for about 13% of the weight, resulting in a final yield from production of pre-sliced bread of approximately 73.4% of the initial weight, with a potential variation of 3%. The higher the packaged slice yield, the smaller the overall Carbon Footprint (CF) will be. This is because a higher yield directly reduces the volume of by-products that need to be allocated for secondary uses like animal feed. While valorization into animal feed is beneficial, reducing the initial waste stream is always the primary way to minimize the CF and limit the need for downstream valorization efforts.

- (7)

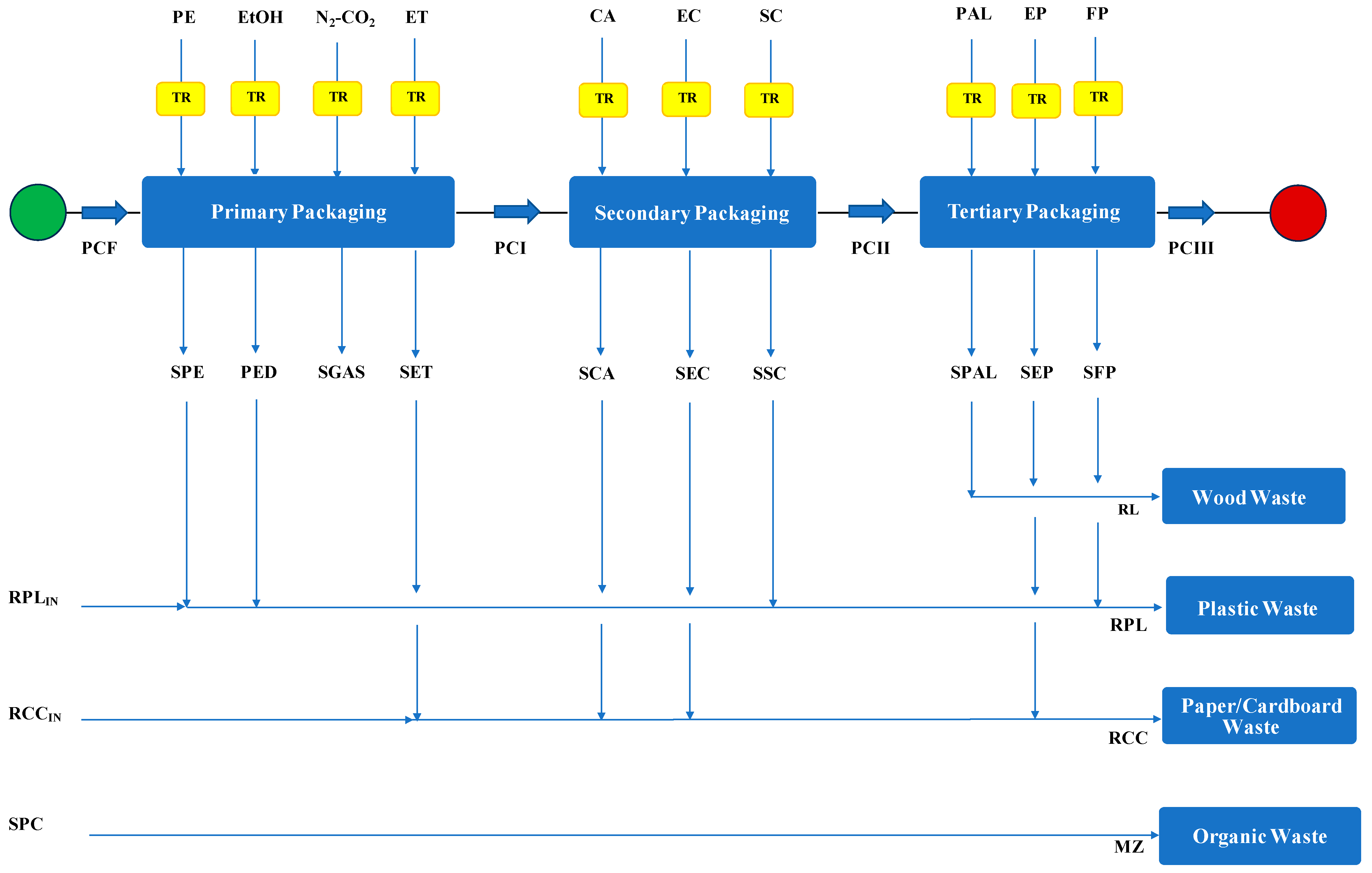

- Primary packaging in a modified atmosphere: Four slices of bread are placed into a 5.8-g polyethylene (PE) food bag. An automatic machine then removes the air from the bag, sprays the slices with 1.5 mL of a 94% (v/v) ethanol solution, and fills the bag with a modified atmosphere (a gas mixture of 50% N2 and 50% CO2). The package is then sealed and an adhesive paper label weighing 1.2 g is added. This modified atmosphere packaging extends the sandwich bread’s shelf life by at least 45 days.The hydroalcoholic solution is supplied in 10-L high-density polyethylene drums for food use, each with a unit mass of 350 g. This aqueous solution primarily consists of ethyl alcohol (94.0 ± 0.3% v/v), with minor quantities of other substances such as propylene glycol (0.36%) and glycerol (0.2%). Given the composition and density of the individual components at 20 °C (ethanol: 789 kg/m3; propylene glycol: 1036 kg/m3; glycerol: 1261 kg/m3; water: 1000 kg/m3), the mixture is estimated to have a density of 799.5 kg/m3, meaning 1.5 mL has a mass of approximately 1.2 g. According to Italian Ministry of Health Decree no. 312 of 13 July 1998 [33], special bread can be treated with ethyl alcohol (Art. 1b) when it is sold in sealed, waterproof packaging, either sliced or whole (Art. 2). This is permitted as long as the quantity of ethanol does not exceed 2% by weight of the food, expressed on a dry-matter basis (db), and the product label includes the phrase “treated with ethyl alcohol.” In this case, the addition of 1.5 mL of the hydroalcoholic solution (of which 1.41 mL, or 1.128 g, is ethanol) to a package of four slices weighing 143 g (equivalent to 90.96 g db) results in an ethanol/dry matter ratio of 1.124%, which is well within the legal limit.The modified atmosphere packaging uses a gas mixture in packs of 16 cylinders. Each cylinder has a 50-L capacity and an empty weight of 80 kg. Loaded to a pressure of 100 bar, each cylinder contains about 7.5 kg of the gas mixture, resulting in a weight ratio between the full cylinder and the gas mixture of 11.67 kg/kg. Since each package of sandwich bread has a volume of 1365 cm3 (13 cm × 15 cm × 7 cm), approximately 2.1 g of the gas mixture is injected into it, while 0.2 g is released into the environment. A single 50-L gas cylinder can therefore package approximately 3261 primary packages, which corresponds to 466 kg of sliced bread.Figure 2 shows the block diagram for the primary modified atmosphere packaging of sandwich bread slices.

- (8)

- Secondary packaging: Eight 143-g packages of sliced sandwich bread are placed into a 167-g recycled cardboard box. The box is then sealed with 4-g of PE tape, and a 2-g paper label is added, as shown in Figure 2.

- (9)

- Tertiary Packaging: The cardboard boxes are assembled onto a 25-kg EPAL wooden pallet for transport. Each pallet holds 16 cartons per layer, with 12 layers total. The boxes are secured to the pallet using 2.3 kg of heat-shrinkable PE film, and the pallet is then labeled with two 4.8-g paper tags, as shown in Figure 2.

- (10)

- Storage of the palletized product at room temperature.

- (11)

- Transportation of the product to distribution centers by truck.

- (12)

- The disposal of both processing and post-consumer packaging waste.

3.2.1. Material Balance of Sandwich Bread Production

3.2.2. Packaging Formats of Various Ingredients and Additives

3.2.3. Logistics of Input and Output Materials

3.2.4. Energy Sources

3.2.5. Fugitive Emissions of Refrigerant Gases

3.2.6. Process Water Consumption

3.2.7. Process Aids

3.2.8. Overall Waste Management

- -

- Plastic, paper, and cardboard: This includes packaging from ingredients (like paper bags and HDPE drums), finished product packaging (such as PE bags, cardboard, labels, and heat-shrink PE film), and packaging used to deliver bread to stores.

- -

- Wood: This includes damaged pallets.

- -

- Food Scraps: Damaged bread, end slices, and trimming scraps are given to local livestock farms for free, and they handle the transportation.

3.3. Environmental Impact Assessment

3.4. Sensitivity Analysis

- -

- Differential Approach: Mathematically determine sensitivity by taking the partial derivative of CF with respect to a single factor (xi), while holding all other factors (xj) fixed.

- -

- One-Factor-At-a-Time (OFAT) Approach: Systematically adjust a single factor (xi) away from its nominal value, leaving all the other (xj) at their baseline, to directly observe the change. This allows for easy comparison since all tests reference the same starting point.

- (i).

- Use of electrical energy entirely sourced from the national medium-voltage grid.

- (ii).

- Use of grid and photovoltaic electrical energy obtained from solar panels installed on-site (the reference company case).

- (iii).

- Use of entirely photovoltaic electrical energy.

- (iv).

- Rail transport for ingredients and the finished product.

3.5. Dataset Uncertainty Estimation

4. Results

4.1. Data Quality Rating

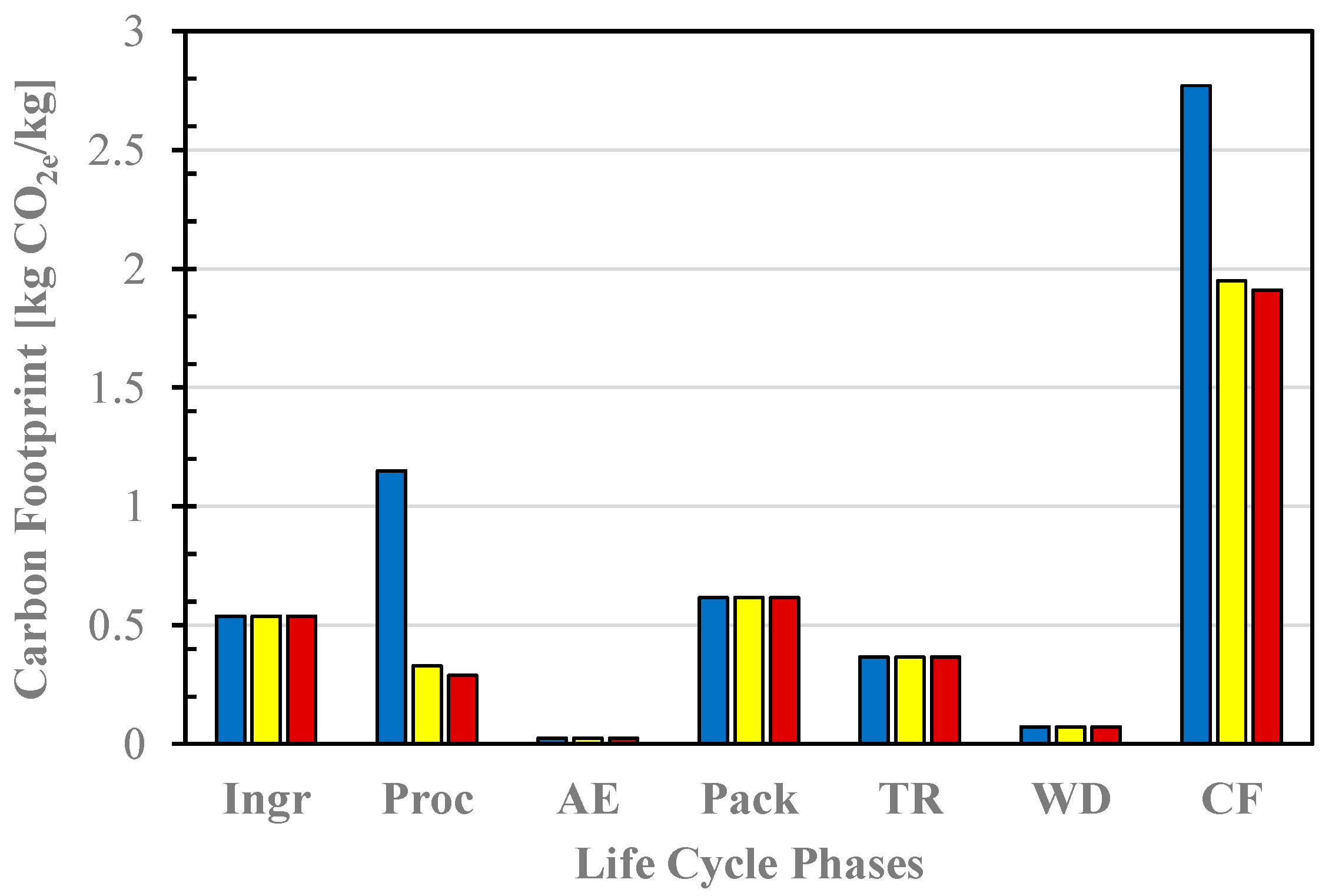

4.2. Carbon Footprint of Conventional Sliced White Bread

- i.

- Economic allocation: Applying the economic allocation criterion based on the waste being given away for free results in assigning zero environmental impact to the feed portion, thereby attributing the entire 2.77 kg CO2e/kg to the salable bread. This approach is generally criticized as it relies on a non-market or zero-price transaction rather than the material’s true economic value.

- ii.

- Material Balance Allocation: In contrast, the material balance allocation criterion assigns the impact proportionally to the mass split. This allocates 14.9% of the total CF to the waste stream and the remaining 85.1% to the packaged sliced bread, resulting in a CF of (0.851 × 2.77≅) 2.36 kgCO2e/kg for the bread.

- iii.

- Substitution/System Expansion: Alternatively, a substitution approach can be used, which is generally preferred when by-product streams enter another system. By comparing the waste bread (protein content of 9.69%) to the conventional animal feed it replaces—de-oiled soybean meal (protein content of about 50% with a CF of 2.556 kg CO2e/kg per Table S6—a CO2e credit of approximately 0.5 kg CO2e/kg can be attributed to the waste for displacing virgin feed. Consequently, the overall CF of the packaged conventional sliced white bread, derived from this system expansion and credit, is reduced to about 2.68 kg CO2e/kg.

4.3. Sensitivity Analysis Results

4.4. Effect of Using Photovoltaic Electricity on the Sliced Bread CF

4.5. Uncertainty Assessment of the Estimated Carbon Footprint

- i.

- 100% Grid vs. 95% PV: The large reduction in CF when transitioning from 100% Grid to 95% PV (~30% reduction) was statistically significant at the 95% confidence level. This confirmed that the observed mitigation effect was robust and not due to data variability.

- ii.

- 95% PV vs. 100% PV: The minor additional reduction in CF when transitioning from 95% PV to 100% PV was not statistically significant at the 95% confidence level. This indicates the calculated difference of 2.1% (from 1.95 to 1.91 kg CO2e/kg) lies within the combined uncertainty range of the two estimates.

4.6. Potential Mitigation Opportunities and Future Analysis

- (a)

- Packaging and Process Optimization: In the 100% Grid Electricity scenario, optimizing the sliced bread packaging is the first key opportunity, given that the production phase of packaging materials is responsible for approximately 22% of emissions. Further mitigation actions should focus on reformulating the packaging to reduce the ratio between gross weight and net weight, which is currently 1.35 kg/kg of sliced bread (Table 4). This would benefit both the reduction of packaging waste and the optimization of transportation. Despite the LCA results identify this as a priority, implementing any reduction in packaging mass is contingent upon external technical confirmation that the required modified atmosphere and product shelf life are unaltered.

- (b)

- Transportation Modal Shift: A quantified reduction in greenhouse gas emissions could be achieved by replacing road transport with rail transport for all ingredients (SWF0, BY, DM, SI, PA, WMP, SO, EVOO, and SF), the finished product, and the return of pallets from distribution centers to the reconditioning company. Based on this modal shift, the sliced bread’s carbon footprint might be supplementary reduced by an additional 8.7%, that is, from 2.77 to 2.53 kg CO2e/kg. This reduction turned out to be statistically significant at the 95% confidence level on the assumption of an unchanged overall standard uncertainty (uT) value.

- (c)

- On-site Gas and Refrigerant Management: Further opportunities focus on mitigating the environmental impact associated with auxiliary inputs and fugitive emissions.

- (c1)

- Modified Atmosphere Gases: The environmental impact of managing the gases used to create the modified atmosphere inside the PE bags could be reduced by adopting an on-site system for generating gaseous nitrogen. This system would filter, dehumidify, and compress air to feed a hollow-fiber membrane module, separating the air into an oxygen permeate and 99.5% pure nitrogen retentate. This solution, requiring an estimated energy consumption between 0.5 kWh/(STP m3) [41] and 0.556 kWh/(STP m3) [42], would eliminate the need to transport nitrogen cylinders. The potential transition to liquid carbon dioxide storage at low pressure (e.g., 2 bar) could also be considered. Supplying CO2 via tanker trucks to on-site cryogenic tanks, rather than using high-pressure cylinders, could reduce the overall impact of transport. However, this switch must be carefully evaluated based on the associated acquisition and operational costs (e.g., for cryogenic tanks and receiving infrastructure), which can vary significantly depending on overall annual consumption.

- (c2)

- Refrigerants: To reduce the environmental impact of fugitive emissions, the refrigerated cells currently charged with the high Global Warming Potential (GWP) refrigerant R404a could be converted to use propane (R290), a refrigerant gas with a similarly negligible ozone depletion potential but a significantly lower GWP (approximately 3 kg CO2e/kg) compared to the R404 blend [43].

5. Discussion and Conclusions

- -

- Packaging materials: The multiple layers of packaging—from plastic bags to transport cartons—add substantially to the product’s environmental impact.

- -

- Additional processing: Slicing and hermetic packaging require extra industrial steps and energy consumption.

- -

- Ingredients and additives: The production of emulsifiers and preservatives used to extend shelf life also contributes to the overall CF.

- -

- Shelf life and waste: Although a longer shelf life can reduce household waste, the packaging and portioning process itself generates more waste at the industrial level.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| AE | Emission to air |

| BY | Brewer’s yeast [kg] |

| C | Completeness |

| CA | Cartons [kg] |

| CaF | Cattle farm |

| CAGR | Compound annual growth rate [%] |

| CED | Cumulative Energy Demand [MJ/kg] |

| CF | Carbon footprint [kg CO2e/kg] |

| CFR | Reference Carbon footprint [kg CO2e/kg] |

| D | Dough [kg] |

| db | Dry matter basis |

| DC | Distribution center |

| DM | Dextrose monohydrate [kg] |

| DQI | Data quality indicator |

| DQR | Data quality rating |

| EA | Emissions to air |

| EC | Carton label [kg] |

| EE | Electrical energy |

| EFi | Emission factor of the i-th activity |

| EFiR | Reference emission factor of the i-th activity |

| EoL | End of Life |

| EP | Pallet paper label [kg] |

| EPMC | Euro pallet managing center |

| ET | Bag paper label [kg] |

| EtOH | Hydroalcoholic solution of ethanol [kg] |

| EVOO | Extra virgin olive oil [kg] |

| FG | Factory gate |

| FP | Shrink film for pallets [kg] |

| GE | Grid electricity |

| GEPC | Grid electricity referred to sandwich bread sliced |

| GHG | Greenhouse Gas |

| GR | Geographical representativeness |

| GWP | Global Warming Potential [kg CO2e/kg] |

| HDPE | High-density polyethylene |

| IBC | Intermediate bulk container |

| Ingr | Ingredients |

| IPCC | Intergovernmental Panel on Climate Change |

| IS | Iodized salt [kg] |

| LCA | Life-cycle assessment |

| LCI | Life-cycle inventory |

| LCV | Light Commercial Vehicle |

| LN | Sourdough starter [kg] |

| LSC | Lactic starter culture [kg] |

| Mi | Mass of sandwich bread after the i-th processing stage [g] |

| MPPi | Mass of all components on the pallet (i) per unit mass of the i-th ingredient [kg/kg] |

| MV | Medium voltage |

| MWCS | Municipal waste collection service |

| MZ | Sandwich bread waste used in animal feeding [kg] |

| P | Parameter uncertainty/precision |

| PA | Calcium propionate [kg] |

| Pack | Packaging |

| PAL | EPAL wooden pallet [kg] |

| PAS | Publicly Available Specification |

| PCC | Baked sandwich bread [kg] |

| PCF | Sliced sandwich bread to be packed [kg] |

| PCI | Sliced sandwich bread in PE bags [kg] |

| PCII | Sliced sandwich bread in cartons [kg] |

| PCIII | Sliced sandwich bread in pallets [kg] |

| PCR | Refrigerated sandwich bread [kg] |

| PE | Polyethylene and PE bag [kg] |

| PED | Empty HDPE drum [kg] |

| PHA | Polyhydroxyalkanoates |

| PLA | Polylactic acid |

| PM | Packaging material |

| Proc | Processing step |

| PS | Production site |

| PV | Photovoltaic power |

| PW | Process water [kg] |

| R | Reliability |

| RCC | Paper and cardboard waste [kg] |

| RCCIN | Paper-cardboard waste resulting from ingredient packages {kg] |

| RH | Relative humidity [%] |

| RL | Wood waste [kg] |

| RMS | Root mean square method |

| RPL | Plastic waste [kg] |

| RPLIN | Plastic waste resulting from ingredient packages [kg] |

| SC | Scotch tape [kg] |

| SCA | Carton waste [kg] |

| SEC | Carton label waste [kg] |

| SEP | Pallet label waste [kg] |

| SET | Bag label waste [kg] |

| SF | Soy flour [kg] |

| SFP | Shrink film waste [kg] |

| SGAS | Modified atmosphere waste [kg] |

| SGHGE | Specific greenhouse gas emissions [kg CO2e/kg] |

| SO | Sunflower seed oil [kg] |

| SPAL | EPAL wooden pallet waste [kg] |

| SPC | Sandwich bread waste [kg] |

| SPE | PE bag waste [kg] |

| SS | Sourdough starter [kg] |

| SSC | Scotch tape waste [kg] |

| STP | Stand temperature and pressure (273.15 K, 1 bar) |

| SWF0 | Soft wheat flour type 0 [kg] |

| SWF1 | Soft wheat flour used to produce the sourdough starter [kg] |

| SWF2 | Soft wheat flour used to produce the dough [kg] |

| TE | Thermal energy |

| TeR | Technological representativeness |

| TiR | Time-related representativeness |

| TR | Transportation |

| ui | Standard uncertainty contribution for each individual life cycle step/process flow |

| uT | Overall standard uncertainty for the final Carbon Footprint result, calculated using the Root Mean Square (RMS) method. |

| VF | Steam released during bread loaf baking [kg] |

| VR | Steam released during bread loaf cooling [kg] |

| WCC | Waste collection center |

| WD | Waste disposal |

| WMP | Whole milk powder [kg] |

| xi | Generic i-th independent variable |

| xiR | Reference value of the i-th independent variable |

| zi | Mass fraction of the i-th ingredient in the dough [% w/w] |

| Zi/SWF0 | Mass ratio of the i-th ingredient in the dough per unit of soft wheat flour [g/g] |

| σg | Geometric standard deviation. |

| Ψi | Magnitude of the generic i-th activity [kg, kWh, or kg km] |

| ΨiR | Reference value of the generic i-th activity [kg, kWh, or kg km] |

Appendix A. Data Quality Assessment Using the Pedigree Matrix

- Reliability (R): Measures how the data were obtained (e.g., primary measurement vs. literature).

- Completeness (C): Determines if all relevant input and output flows for the process have been included in the data set.

- Time-related Representativeness (TiR): Measures the currency of the data, favoring recent information that reflects current production practices.

- Geographical Representativeness (GR): Evaluates whether the data originates from the same geographical region as the modeled process.

- Technological Representativeness (TeR): Assesses how closely the data set’s technology aligns with the LCA study’s technology.

- Parameter Uncertainty (P): Relates to the quantitative variability of the data, often quantified using the geometric standard deviation.

| DQI | R | C | TiR | GR | TeR | P | Score |

|---|---|---|---|---|---|---|---|

| Data Flow Item | |||||||

| Wheat Flour (1st Ingr contributor) | 1 | 1 | 1 | 1 | 1 | 1 | 1.00 |

| Data from factory inventory checks. | Data covers all the quantities yearly used. | Data refers to the study period. | Flour sourced from Italian suppliers. | Flour fits technology specification. | ≤5% | ||

| Cartons (1st PM contributor) | 1 | 1 | 2 | 3 | 2 | 2 | 1.83 |

| Data from factory inventory checks. | Data covers all the quantities yearly used. | ≤5-years old secondary data. | Regional/national data. | Current industrial technology. | ~10% | ||

| PE bags (2nd PM contributor) | 1 | 1 | 2 | 2 | 2 | 2 | 1.67 |

| Data from factory inventory. | Data covers all the quantities yearly used. | ≤5-years old secondary data. | Regional data. | Current industrial technology. | ~10% | ||

| Thermal Energy | 1 | 1 | 1 | 2 | 2 | 1 | 1.33 |

| Quantity from monthly gas bills. | Monthly metered data. | Data refers to the study period. | Sourced from the national gas grid. | Current oven Technology. | Gas-meter precision: 2–5%. | ||

| Grid Electricity | 1 | 1 | 1 | 2 | 2 | 1 | 1.33 |

| Quantity from monthly energy bills. | Monthly metered data. | Data refers to the study period. | Sourced from the national MV grid. | Current equipment technology. | Power-meter precision: 2–5%. | ||

| Photovoltaic | 1 | 1 | 1 | 1 | 1 | 1 | 1.00 |

| Electricity | Quantity calculated from monthly energy bills. | PV production and export data from monthly bills. | Data refers to the study period. | Sourced from the on-site PV system. | Specific on-site PV system. | Calculated combined uncertainty: 7–10%. | |

| Transport | 1 | 1 | 2 | 3 | 1 | 3 | 1.83 |

| Quantity and transport means from factory data. | Primary data inputs for the transport modelling. | Data covers the study period with Ecoinvent v3.10 treated as up to date. | Delivery distances estimated via Micheline distance-meter. | Technologically specific transport LCI data. | Background LCI data with unknown Uncertainty. | ||

| Waste Disposal | 3 | 3 | 1 | 2 | 1 | 3 | 2.17 |

| Quantities estimated using average waste rates. | Quantities estimated, not measured. | Data refers to the study period with LCI disposal scenarios treated as up to date. | Waste delivered to local centers using national waste disposal scenarios. | LCI waste disposal treatments regarded as up to date. | Typical uncertainty of secondary LCI data: 20–30%. |

Appendix B. Dataset Uncertainty P Criterion Calculation

| P Score | Data Quality Description | σg |

|---|---|---|

| 1 | Verified, measured data (e.g., from supplier) | 1.05 |

| 2 | Estimated or literature data (good representativity) | 1.10 |

| 3 | Estimated or literature data (fair representativity) | 1.20 |

| 4 | Professional judgment or high uncertainty | 1.50 |

| 5 | Highly uncertain, estimated data (e.g., proxy) | 2.00 |

| Electricity | National Grid | Partial Photovoltaic | Total Photovoltaic | |||||

|---|---|---|---|---|---|---|---|---|

| (100% Grid) | (95% PV) | (100% PV) | ||||||

| Life Cycle Step | Pi Score | σgi | CFi [%] | ui [%] | CFi [%] | ui [%] | CFi [%] | ui [%] |

| Wheat Flour | 1 | 1.05 | 19.39 | 0.97 | 27.55 | 1.38 | 28.13 | 1.41 |

| Cartons (Packaging) | 2 | 1.10 | 16.70 | 1.67 | 23.72 | 2.39 | 24.223 | 2.42 |

| PE bags (Packaging) | 2 | 1.10 | 5.56 | 0.56 | 7.90 | 0.79 | 8.067 | 0.81 |

| Thermal Energy | 1 | 1.05 | 1.36 | 0.07 | 0.78 | 0.04 | 0.70 | 0.04 |

| Grid Electrical Energy | 1 | 1.05 | 38.29 | 1.91 | 0.76 | 0.04 | - | - |

| Photovoltaic Electricity | 1 | 1.05 | - | - | 15.39 | 0.77 | 14.47 | 0.72 |

| Transport | 3 | 1.20 | 13.22 | 2.64 | 18.77 | 3.75 | 19.17 | 3.83 |

| Waste Disposal | 3 | 1.20 | 2.66 | 0.53 | 3.78 | 0.76 | 3.86 | 0.77 |

| uT | 3.87 | 4.84 | 4.93 | |||||

References

- Pianetapane. Italmopa: Ogni Anno Prodotti 4 mln di Tonnellate di Farina. 2020. Available online: https://www.pianetapane.it/italmopa-ogni-anno-prodotti-4-mln-di-tonnellate-di-farina/ (accessed on 19 October 2025).

- Vitale, A. L’Italia del Pane: I Consumi Sono Però la Metà Della Romania. 2024. Available online: https://www.lidentita.it/italia-paese-del-pane-ma-i-consumi-sono-quasi-la-meta-della-romania/ (accessed on 19 October 2025).

- Tinkler, K. Breaking Bread: A Global Perspective on Annual Bread Consumption per Capita. 2023. Available online: https://www.geordiebakers.co.uk/blog/breaking-bread-a-global-perspective-on-annual-bread-consumption-per-capita (accessed on 19 October 2025).

- Mordor Intelligence. Bread Market Size—Industry Report on Share, Growth Trends & Forecasts Analysis (2025–2030). 2025. Available online: https://www.mordorintelligence.com/industry-reports/bread-market (accessed on 19 October 2025).

- Grand View Research. Packaged Bread Market Size, Share & Trends Analysis Report by Product (White Bread, Brown Bread, Multigrain Bread, Whole Wheat Bread, Sourdough), by Packaging, by Distribution, by Region, and Segment Forecasts, 2024–2030. Report ID: GVR-4-68040-482-2. Available online: https://www.grandviewresearch.com/industry-analysis/packaged-bread-market-report (accessed on 19 October 2025).

- Jensen, J.K.; Arlbjørn, J.S. Product carbon footprint of rye bread. J. Clean. Prod. 2014, 82, 45–57. [Google Scholar] [CrossRef]

- Espinoza-Orias, N.; Stichnothe, H.; Azapagic, A. The carbon footprint of bread. Int. J. Life Cycle Assess. 2011, 16, 351–365. [Google Scholar] [CrossRef]

- Notarnicola, B.; Tassielli, G.; Renzulli, P.A.; Monforti, F. Energy flows and greenhouses gases of EU (European Union) national breads using an LCA (Life Cycle Assessment) approach. J. Clean. Prod. 2017, 140, 455–469. [Google Scholar] [CrossRef]

- Barilla G. e R. Fratelli. Mulino Bianco Pan Bauletto Bianco. EPD® Declaration, Registration No. EPD-IES-0000223:004 (S-P-00223). 2025. Available online: http://www.environdec.com/en/Detail/epd223 (accessed on 19 October 2025).

- Andersson, K.; Ohlsson, T. Life cycle assessment of bread produced on different scales. Int. J. Life Cycle Assess. 1999, 4, 25–40. [Google Scholar] [CrossRef]

- Moudrý, J., Jr.; Jiroušková, Z.; Hyšpler, R.; Konvalina, P.; Plch, R.; Moudrý, J. Carbon dioxide equivalent emission load within production and processing of wheat under conditions of organic and conventional farming systems. Agron. Ser. Sci. Res./Lucr. Ştiinţifice 2011, 54, 38–41. Available online: https://repository.iuls.ro/xmlui/handle/20.500.12811/3419 (accessed on 19 October 2025).

- Goucher, L.; Bruce, R.; Cameron, D.D.; Koh, S.L.; Horton, P. The environmental impact of fertilizer embodied in a wheat-to-bread supply chain. Nat. Plants 2017, 3, 17012. Available online: https://research.manchester.ac.uk/en/publications/the-environmental-impact-of-fertilizer-embodied-in-a-wheat-to-bre (accessed on 19 October 2025). [CrossRef] [PubMed]

- Freire Melquíades, T.; Moreira Coelho, L., Jr.; Monica Carvalho, M. Pegada de carbono da produção de pão francês em padaria no nordeste brasileiro. Rev. Agro. Amb. 2020, 13, 1471–1492. [Google Scholar] [CrossRef]

- Korsaeth, A.; Jacobsen, A.Z.; Roer, A.-G.; Henriksen, T.M.; Sonesson, U.; Bonesmo, H.; Skjelvåg, A.O.; Strømman, A.H. Environmental life cycle assessment of cereal and bread production in Norway. Acta Agric. Scand. Sect. A-Anim. Sci. 2012, 62, 242–253. [Google Scholar] [CrossRef]

- Moresi, M. Il Carbon Footprint del Pane. Atti dei Georgofili. 2016. Available online: https://www.georgofili.net/articoli/scheda/4307 (accessed on 19 October 2025).

- BSI. Publicly Available Specification (PAS 2050) for the Assessment of the Life Cycle Greenhouse Gas Emission of Goods and Services; British Standards Institution: London, UK, 2011. [Google Scholar]

- Intergovernmental Panel on Climate Change (IPCC). Revised 1996 IPCC Guidelines for National Greenhouse Gas Inventories; IPCC/OECD/IEA: Paris, France, 1997. [Google Scholar]

- Câmara-Salim, I.; Almeida-García, F.; González-García, S.; Romero-Rodríguez, A.; Ruíz-Nogueiras, B.; Pereira-Lorenzo, S.; Feijoo, G.; Moreira, M.T. Life cycle assessment of autochthonous varieties of wheat and artisanal bread production in Galicia, Spain. Sci. Total Environ. 2020, 713, 136720. [Google Scholar] [CrossRef] [PubMed]

- Crosnier, A.; Baudry, G.; Jeangros, L.; Meier, E.S.; Cisco, G.; Spring, L.; Barjolle, D. True cost accounting for food application: Environmental, social and health impacts of bread. J. Clean. Prod. 2025, 524, 146224. [Google Scholar] [CrossRef]

- Notarnicola, B.; Sala, S.; Castellani, V.; Tassielli, G.; Renzulli, P.A.; Goralczyk, M. Environmental impact of the European food basket using LCA. In Proceedings of the International Conference on Life Cycle Assessment as Reference Methodology for Assessing Supply Chains and Supporting Global Sustainability Challenges: LCA for feeding the Planet and Energy for Life; Scalbi, S., Dominici Loprieno, A., Sposato, P., Eds.; ENEA: Rome, Italy, 2015; pp. 21–24. Available online: https://backend.orbit.dtu.dk/ws/portalfiles/portal/118779492/LCA2015.pdf (accessed on 6 November 2025).

- Kulak, M.; Nemecek, T.; Frossard, E.; Chable, V.; Gaillard, G. Life cycle assessment of bread from several alternative food networks in Europe. J. Clean. Prod. 2015, 90, 104–113. [Google Scholar] [CrossRef]

- Braschkat, J.; Patyk, A.; Quirin, M.; Reinhardt, G. Life cycle assessment of bread production e a comparison of eight different scenarios. In Proceedings of the 4th International Conference on “Life Cycle Assessment in the Agri-food Sector”, Horsens, Denmark, 6–8 October 2003; Available online: https://www.ifeu.de/en/publication/life-cycle-assessment-of-bread-production-a-comparison-of-eight-different-scenarios/ (accessed on 6 November 2025).

- ISO 14040:2006; Environmental Management e Life Cycle Assessment e Principles and Framework. International Organization for Standardization: Genève, Switzerland, 2006.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Genève, Switzerland, 2006.

- Petersson, T.; Secondi, L.; Magnani, A.; Antonelli, M.; Dembska, K.; Valentini, R.; Varotto, A.; Castaldi, S. A multilevel carbon and water footprint dataset of food commodities. Sci. Data 2021, 8, 127. [Google Scholar] [CrossRef] [PubMed]

- Petersson, T.; Secondi, L.; Magnani, A.; Antonelli, M.; Dembska, K.; Valentini, R.; Varotto, A.; Castaldi, S. SU-EATABLE_LIFE: A Comprehensive Database of Carbon and Water Footprints of Food Commodities. Figshare 2021, 13271111. [Google Scholar] [CrossRef]

- Clune, S.; Crossin, E.; Verghese, K. Systematic review of greenhouse gas emissions for different fresh food categories. J. Clean. Prod. 2017, 140, 766–783. [Google Scholar] [CrossRef]

- Cimini, A.; Cibelli, M.; Moresi, M. Environmental impact of pasta. In Environmental Impact of Agro-Food Industry and Food Consumption; Galanakis, C., Ed.; Academic Press: San Diego, CA, USA, 2020; Chapter 5; pp. 101–127. [Google Scholar] [CrossRef]

- Moresi, M.; Cimini, A. Comparative environmental impact assessment of resistant starch-rich pastas produced from high-amylose soft wheat or malted bean flour. Sustainability 2024, 16, 8931. [Google Scholar] [CrossRef]

- Thrane, M.; Krieger, T.M.; Zhang, X.; Braun, M.; Hwang, D.C.; Paulsen, P.W.; Orcutt, M.W. Soy protein: Environmental impacts, production, applications and nutrition. In Sustainable Protein Sources. Advances for a Healthier Tomorrow, 2nd ed.; Nadathur, S., Wanasundara, J.P.D., Scanlin, L., Eds.; Academic Press: New York, NY, USA, 2024; Chapter 2; pp. 31–54. [Google Scholar] [CrossRef]

- Weidema, B.P.; Wesnæs, M.S. Data quality management for life cycle inventories—An example of using data quality indicators. J. Clean. Prod. 1996, 4, 167–174. [Google Scholar] [CrossRef]

- European Commission, Joint Research Centre. Product Environmental Footprint (PEF) Guide: Consolidated Version; Institute for Environment and Sustainability (IES): Ispra, Italy, 2012; pp. 37–49. Available online: https://pdf4pro.com/view/product-environmental-footprint-pef-guide-6271fd.html (accessed on 24 October 2025).

- Italian Ministry of Health. Decreto 13 July 1998, No. 312. Regolamento Recante Norme per il Trattamento con Alcool Etilico del Pane Speciale Preconfezionato. Gazzetta Ufficiale della Repubblica Italiana. Serie Generale no. 200. 28 August 1998. Available online: https://www.normattiva.it/atto/caricaDettaglioAtto?atto.dataPubblicazioneGazzetta=1998-08-28&atto.codiceRedazionale=098G0364&tipoDettaglio=multivigenza (accessed on 19 October 2025).

- Johnson, A. R-404A Refrigerant Fact & Info Sheet. 2019. Available online: https://refrigeranthq.com/r-404a-refrigerant-fact-info-sheet/ (accessed on 19 October 2025).

- Fusi, A.; Guidetti, R.; Azapagic, A. Evaluation of environmental impacts in the catering sector: The case of pasta. J. Clean. Prod. 2016, 132, 146–160. [Google Scholar] [CrossRef]

- Cimini, A.; Cibelli, M.; Moresi, M. Cradle-to-grave carbon footprint of dried organic pasta: Assessment and potential mitigation measures. J. Sci. Food Agric. 2019, 99, 5303–5318. [Google Scholar] [CrossRef] [PubMed]

- Mariotta, C.; Tuscano, J. Imballaggi e rifiuti di imballaggio. In Rapporto Rifiuti Urbani; Rapporti 355/2021; ISPRA (Istituto Superiore per la Protezione e la Ricerca Ambientale): Rome, Italy, 2021; Chapter 4; pp. 189–222. Available online: https://www.isprambiente.gov.it/files2022/pubblicazioni/rapporti/rapportorifiutiurbani_ed-2021-n-355-conappendice_agg18_01_2022.pdf (accessed on 19 October 2025).

- IPCC (Intergovernmental Panel on Climate Change). Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Masson-Delmotte, V.P., Zhai, A., Pirani, S.L., Connors, C., Péan, S., Berger, N., Caud, Y., Chen, L., Goldfarb, M.I., Gomis, M., et al., Eds.; Cambridge University Press: Cambridge, UK, 2021; Available online: https://www.ipcc.ch/report/ar6/wg1/ (accessed on 19 October 2025).

- EcoInvent. System Models. 2024. Available online: https://ecoinvent.org/the-ecoinvent-database/system-models/#!/allocation (accessed on 19 October 2025).

- Saltelli, A.; Ratto, M.; Tarantola, S.; Campolongo, F. Sensitivity analysis practices: Strategies for model-based inference. Reliab. Eng. Syst. Saf. 2006, 91, 1109–1125. [Google Scholar] [CrossRef]

- MVS Engineering. Nitrogen Gas Use in Bottling Industry as a Counter Pressure Gas. White Paper. Available online: https://www.mvsengg.com/blog/nitrogen-gas-use-in-bottling-industry-as-a-counter-pressure-gas/ (accessed on 19 October 2025).

- Froehlich, P. Is Bottled Nitrogen a Greenhouse Gas? 2008. Available online: https://www.americanlaboratory.com/914-Application-Notes/34779-Is-Bottled-Nitrogen-a-Greenhouse-Gas/ (accessed on 19 October 2025).

- Senthil Kumar, K.; Rajagopal, K. Computational and experimental investigation of low ODP and low GWP HCFC-123 and HC-290 refrigerant mixture alternate to CFC-12. Energy Convers. Manag. 2007, 48, 3053–3062. [Google Scholar] [CrossRef]

), and from partial (

), and from partial ( ), or 100% (

), or 100% ( ) photovoltaic (PV) power.

) photovoltaic (PV) power.

), and from partial (

), and from partial ( ), or 100% (

), or 100% ( ) photovoltaic (PV) power.

) photovoltaic (PV) power.

| Ingredients | Mass Fraction (zi) | Mass Ratio (Zi/SWF0) * |

|---|---|---|

| [% w/w] | [g/g] | |

| Soft Wheat Flour Type 0 (SWF0) | 60.0 | 1 |

| Sourdough Starter | 12.0 | 0.200 |

| Block Brewer’s Yeast | 2.0 | 0.033 |

| Dextrose Monohydrate | 1.5 | 0.025 |

| Iodized Salt | 1.5 | 0.025 |

| Preservative (Propionic Acid) | 0.1 | 0.0017 |

| Whole Milk Powder | 0.7 | 0.0117 |

| Sunflower Seed Oil | 0.6 | 0.010 |

| Extra-Virgin Olive Oil | 0.6 | 0.010 |

| Soy Flour | 1.0 | 0.017 |

| Tap Water | 20.0 | - |

| Sandwich Bread | Mi [g] | Mi/M1 [%] |

|---|---|---|

| 1—Dough put into the pan and ready to be baked | 1800 | 100.00 |

| 2—Bread loaves removed from the oven and pan | 1585 | 88.06 |

| 3—Bread loaves removed from the pans and cooled in a refrigerated cell | 1553 | 86.28 |

| 4—End bread slices discarded | 156 | 8.67 |

| 5—Bread slices discarded during packaging | 75 | 4.17 |

| 6—Bread slices actually packaged | 1322 | 73.44 |

| Packaging Type | Technical Specifications | Unit |

|---|---|---|

| Primary Packaging | PE bags | |

| Mass of sandwich bread slices | 143 ± 2 | g |

| PE bag mass | 5.8 ± 0.1 | g |

| Width × Depth × Height | 13 × 7 × 15 | mm × mm × mm |

| Adhesive paper label mass of | 1.20 ± 0.06 | g |

| Hydroalcoholic solution mass | 1.2 ± 0.1 | g |

| CO2-N2 mixture mass | 2.1 ± 0.2 | g |

| Primary packaging overall mass | 153.3 ± 2.5 | g |

| Secondary Packaging | Cardboard carton | |

| No. of primary packages | 8 | - |

| Length × Width × Height | 290 × 200 × 155 | mm × mm × mm |

| Carton mass | 167 ± 2 | g |

| Adhesive paper label mass | 2.0 ± 0.1 | g |

| PE scotch tape mass | 4.0 ± 0.2 | g |

| Mass of sandwich bread per carton | 1.144 ± 0.020 | kg |

| Secondary packaging overall mass | 1.399 ± 0.020 | kg |

| Tertiary Packaging | Wooden EPAL pallet | |

| Pallet mass | 25.0 ± 0.2 | kg |

| Length × Width × Height | 1200 × 800 × 144 | mm × mm × mm |

| No. of cartons per layer | 16 | - |

| No. of layers per pallet | 12 | - |

| Overall height of pallet | 2.004 | m |

| Paper label per pallet | no. 2 × (2.4 ± 0.2) | g |

| Stretch-and-shrink PE film | 2.3 ± 0.3 | kg |

| Mass of sandwich bread per pallet | 219.65 ± 2.00 | kg |

| Tertiary packaging overall mass | 295.97 ± 5.00 | kg |

| Ingredient | Primary Packaging | RCCIN | RPLIN | MPPi | |

|---|---|---|---|---|---|

| Type | Mass [Kg] | [g/Kg] | [g/Kg] | [kg/Kg] | |

| Soft wheat flour type 0 | Bulk in tank | (13–15) × 103 | - | - | - |

| Compressed yeast | Paper-Cellophane bags | 0.5 | 35.86 | 1.43 | 1.059 |

| Dextrose monohydrate | Paper bags | 25 | 4.60 | 2.22 | 1.007 |

| Calcium propionate | Paper bags | 25 | 4.60 | 2.22 | 1.007 |

| Iodized salt | Paper bags | 25 | 4.60 | 2.22 | 1.007 |

| Whole milk powder | Paper bags | 25 | 4.60 | 2.22 | 1.007 |

| Sunflower seed oil | IBCs | 916 | - | - | 1.060 |

| Extra-virgin olive oil | IBC | 916 | - | - | 1.060 |

| Soy flour | Paper bags | 25 | 4.6 | 2.22 | 1.007 |

| EtOH solution | HDPE drums | 10 | - | 43.78 | 1.044 |

| CO2-N2 mixture | Stainless steel cylinders | 7.5 | - | - | 11.667 |

| Detergents | PE drums | 1.4 | - | 39.22 | 1.039 |

| Lubricating oils | PE drums | 1.4 | - | 53.03 | 1.053 |

| Input/Output Materials | From | To | Means of Transport | Load Capacity [Mg] | Distance [km] |

|---|---|---|---|---|---|

| Soft Wheat Flour Type 0 (SWF0) | PS | FG | Euro 5 semi-trailer truck | 16–32 | 788 |

| Compressed Yeast | PS | FG | Euro 5 semi-trailer truck | 16–32 | 854 |

| Dextrose Monohydrate | PS | FG | Euro 5 semi-trailer truck | 16–32 | 963 |

| Iodized Salt | PS | FG | Euro 5 semi-trailer truck | 16–32 | 157 |

| Calcium Propionate | PS | FG | Euro 5 semi-trailer truck | 16–32 | 963 |

| Whole Milk Powder | PS | FG | Euro 5 semi-trailer truck | 16–32 | 726 |

| Sunflower Seed Oil | PS | FG | Euro 5 semi-trailer truck | 16–32 | 142 |

| Extra-Virgin Olive Oil | PS | FG | Euro 5 semi-trailer truck | 16–32 | 142 |

| Soy Flour | PS | FG | Euro 5 semi-trailer truck | 16–32 | 870 |

| EtOH solution | PS | FG | Euro 5 semi-trailer truck | 16–32 | 960 |

| CO2-N2 Cylinders | PS | FG | Euro 5 semi-trailer truck | 16–32 | 92 |

| PE Film Rolls | PS | FG | Euro 5 semi-trailer truck | 16–32 | 103 |

| Adhesive paper labels | PS | FG | Euro 5 semi-trailer truck | 16–32 | 159 |

| Cardboard boxes | PS | FG | Euro 5 semi-trailer truck | 16–32 | 483 |

| PE tape and heat-shrink film | PS | FG | Euro 5 semi-trailer truck | 16–32 | 115 |

| EPAL pallets | EPMC | FG | Euro 5 semi-trailer truck | 16–32 | 92 |

| CD | EPMC | Euro 5 semi-trailer truck | 16–32 | 805 | |

| Detergents | PS | FG | LCV | 1.3 | 24 |

| Lubricating oils | PS | FG | LCV | 1.3 | 17 |

| Palletized sliced sandwich bread | FG | DC | Euro 5 semi-trailer truck | 16–32 | 713 |

| Plastic waste RPL | FG | WCC | MWCS | 13.9 | 26 |

| Paper/cardboard waste RCC | FG | WCC | MWCS | 13.9 | 26 |

| Wood waste RL | FG | WCC | MWCS | 13.9 | 26 |

| Organic waste (MZ) | FG | CaF | LCV | 1.3 | 30 |

| Absolute and Relative Consumption | Unit | Year 2021 | Year 2022 |

|---|---|---|---|

| Thermal Energy (TE) | kWh/year | 324,656 | 495,631 |

| Grid Electricity (GE) | kWh/year | 537,969 | 571,165 |

| Grid Electricity referred to sandwich bread only (GEPC) | kWh/year | 455,969 | 489,165 |

| Photovoltaic Electricity (PV) | kWh/year | 8,176,016 | 9,750,135 |

| Total Production of Baked Goods | Mg/year | 3772.5 | 3712.6 |

| Specific Thermal Energy | kWh/kg | 0.086 | 0.133 |

| Specific Grid Electricity | kWh/kg | 0.121 | 0.132 |

| Specific Photovoltaic Electricity | kWh/kg | 2.167 | 2.626 |

| Disposal Scenario | Landfill [%] | Recycling [%] | Incineration [%] |

|---|---|---|---|

| Paper and cardboard waste | 5.2 | 87.3 | 7.5 |

| Plastic waste | 6.7 | 48.7 | 44.6 |

| Wood waste | 35.4 | 62.4 | 2.2 |

| Electricity | National Grid (100% Grid) | Partial Photovoltaic (95% PV) | Total Photovoltaic (100% PV) | |||

|---|---|---|---|---|---|---|

| Life Cycle Stage | SGHGE [kg CO2e/kg] | [%] | SGHGE [kg CO2e/kg] | [%] | SGHGE [kg CO2e/kg] | [%] |

| Ingredients (Ingr) | 0.54 | 19.4 | 0.54 | 27.5 | 0.54 | 28.1 |

| Processing (Proc) | 1.15 | 41.5 | 0.33 | 16.9 | 0.29 | 15.2 |

| Emissions to Air (EA) | 0.03 | 1.0 | 0.03 | 1.4 | 0.03 | 1.4 |

| Packaging (Pack) | 0.62 | 22.3 | 0.62 | 31.6 | 0.62 | 32.3 |

| Transportation (TR) | 0.37 | 13.2 | 0.37 | 18.8 | 0.37 | 19.2 |

| Waste disposal (WD) | 0.07 | 2.7 | 0.07 | 3.8 | 0.07 | 3.9 |

| Carbon Footprint (CF) | 2.77 | 100.0 | 1.95 | 100.0 | 1.91 | 100.0 |

| Factor xi | Default Value | (ΔCF/CFR) | |||

|---|---|---|---|---|---|

| Ψi | Unit | EFi | Unit | [%] | |

| Soft wheat flour (SWF0) | 1000 | kg | 0.43 | kg CO2e/kg | 12.25 |

| Compressed yeast (BY) | 30.2 | kg | 0.82 | kg CO2e/kg | 0.70 |

| Monohydrate dextrose (DM) | 22.7 | kg | 1.47 | kg CO2e/kg | 0.94 |

| Calcium propionate (PA) | 1.5 | kg | 1.81 | kg CO2e/kg | 0.08 |

| Iodized salt (IS) | 22.7 | kg | 0.10 | kg CO2e/kg | 0.06 |

| Whole milk powder (WMP) | 10.6 | kg | 10.52 | kg CO2e/kg | 3.13 |

| Sunflower seed oil (SO) | 9.1 | kg | 0.99 | kg CO2e/kg | 0.25 |

| Extra-virgin olive oil (EVOO) | 9.1 | kg | 3.84 | kg CO2e/kg | 0.98 |

| Soy flour (SF) | 5.8 | kg prot. | 6.00 | kg CO2e/kg | 0.50 |

| Thermal energy (TE) | 171.0 | kWh | 0.28 | kg CO2e/kWh | 1.33 |

| Grid electricity (GE) | 3530.6 | kWh | 0.40 | kg CO2e/kWh | 39.37 |

| Deionized water | 1.2 | kg | 0.48 | kg CO2e/m3 | 0.02 |

| Lubricating oil | 17.9 | kg | 1.54 | kg CO2e/kg | 0.78 |

| Detergents | 1.3 | kg | 0.71 | kg CO2e/kg | 0.03 |

| PE bags | 52.5 | kg | 3.1 | kg CO2e/kg | 4.60 |

| N2 | 8.0 | kg | 0.2 | kg CO2e/kg | 0.05 |

| CO2 | 12.6 | kg | 0.6 | kg CO2e/kg | 0.20 |

| Ethanol | 10.8 | kg | 3.5 | kg CO2e/kg | 1.06 |

| Bag labels (ET) | 10.8 | kg | 2.8 | kg CO2e/kg | 0.86 |

| Cartons (CA) | 188.0 | kg | 2.6 | kg CO2e/kg | 13.82 |

| Carton labels (EC) | 2.2 | kg | 2.8 | kg CO2e/kg | 0.18 |

| Scotch tape (SC) | 4.5 | kg | 2.5 | kg CO2e/kg | 0.32 |

| Pallet labels (EP) | 0.03 | kg | 2.8 | kg CO2e/kg | 0.002 |

| Shrink wrap film (FP) | 13.4 | kg | 3.1 | kg CO2e/kg | 1.17 |

| SWF0 transport distance | 788 | km | 0.188 | kg CO2e/(Mg km) | 4.17 |

| Palletized sliced bread transport distance | 713 | km | 0.188 | kg CO2e/(Mg km) | 3.78 |

| Carbon Footprint (CFR) | 3559.8 kg CO2e/(1000 kg SWF0) | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moresi, M.; Nionelli, L.; Cimini, A. Packaged Bread and Its Carbon Footprint: Balancing Convenience and Waste. Sustainability 2025, 17, 9957. https://doi.org/10.3390/su17229957

Moresi M, Nionelli L, Cimini A. Packaged Bread and Its Carbon Footprint: Balancing Convenience and Waste. Sustainability. 2025; 17(22):9957. https://doi.org/10.3390/su17229957

Chicago/Turabian StyleMoresi, Mauro, Luana Nionelli, and Alessio Cimini. 2025. "Packaged Bread and Its Carbon Footprint: Balancing Convenience and Waste" Sustainability 17, no. 22: 9957. https://doi.org/10.3390/su17229957

APA StyleMoresi, M., Nionelli, L., & Cimini, A. (2025). Packaged Bread and Its Carbon Footprint: Balancing Convenience and Waste. Sustainability, 17(22), 9957. https://doi.org/10.3390/su17229957