Design and Evaluation of a Compact IoT-Enabled Microfarm for Decentralized Urban Agriculture Applied to the Cultivation of Pleurotus ostreatus (Oyster Mushroom)

Abstract

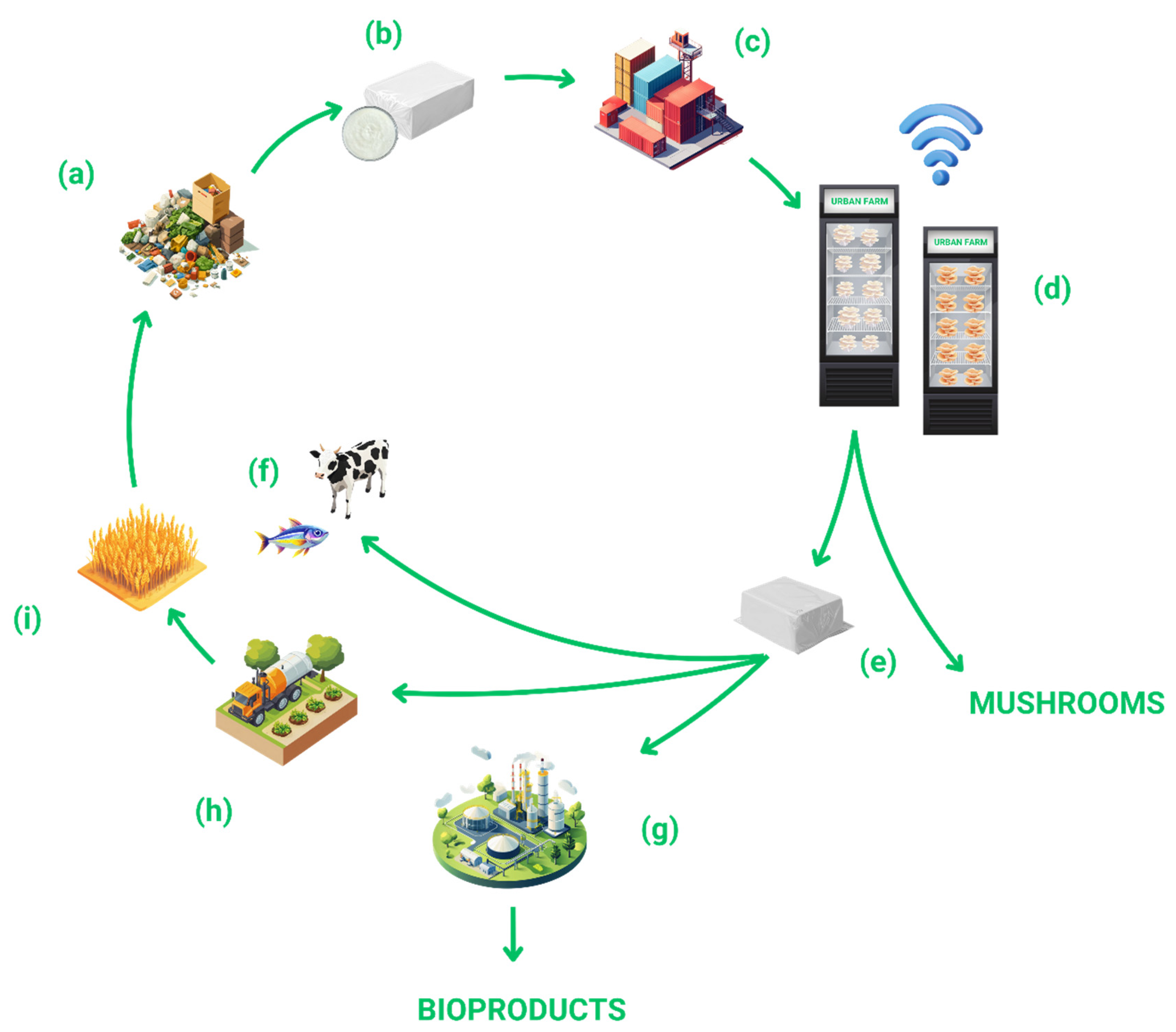

1. Introduction

2. Materials and Methods

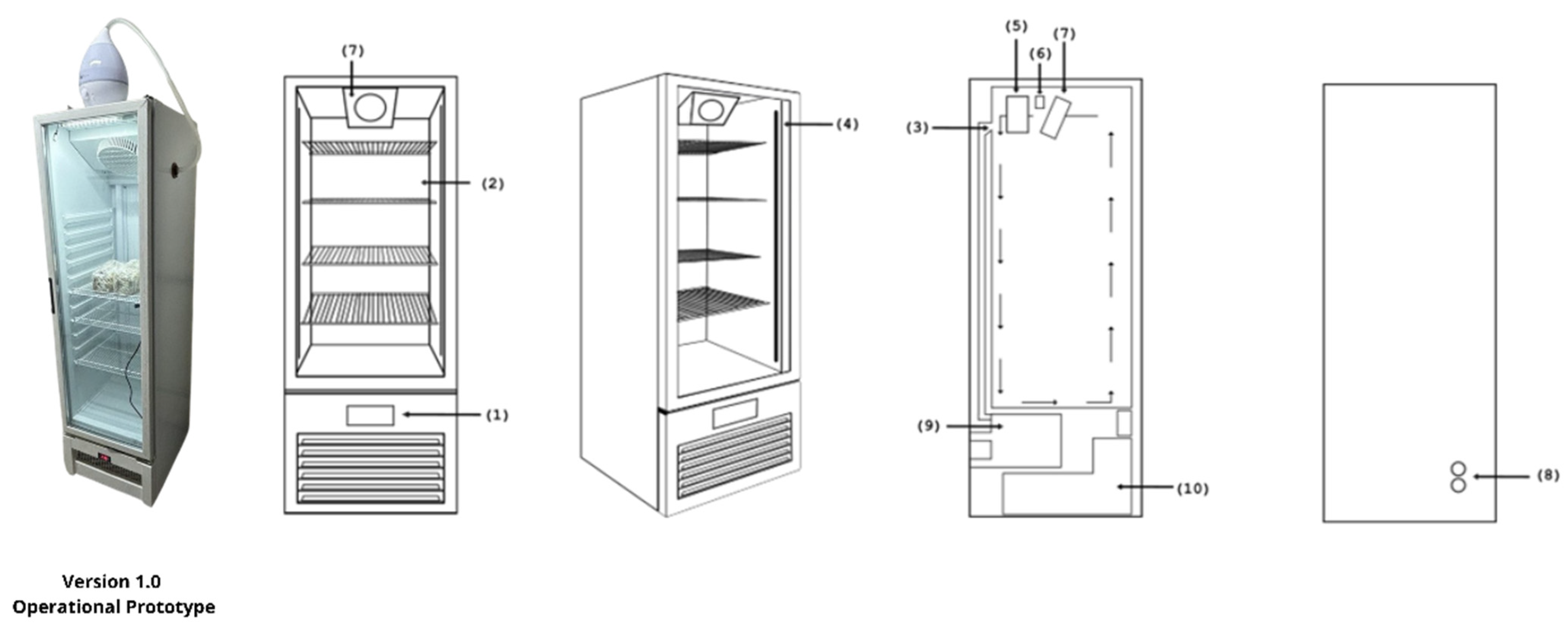

2.1. Fruiting Chamber Construction

2.2. IoT-Based Monitoring and Control System

| Algorithm 1. Basic control logic for temperature and humidity. |

| 1. IF DHT data is valid THEN |

| 2. IF temperature > setpointTemp + hysteresisTemp THEN |

| 3. TURN ON temperature relay |

| 4. ELSE IF temperature ≤ setpointTemp THEN |

| 5. TURN OFF temperature relay |

| 6. END IF |

| 7. ELSE |

| 8. TURN OFF temperature relay |

| 9. END IF |

| 10. IF DHT data is valid THEN |

| 11. IF humidity < setpointHumidity THEN |

| 12. TURN ON humidity relay |

| 13. ELSE |

| 14. TURN OFF humidity relay |

| 15. END IF |

| 16. ELSE |

| 17. TURN OFF humidity relay |

| 18. END IF |

2.3. Cultivation of Pleurotus ostreatus (Oyster mushroom)

2.4. Cultivation Monitoring and Analytical Procedures

3. Results

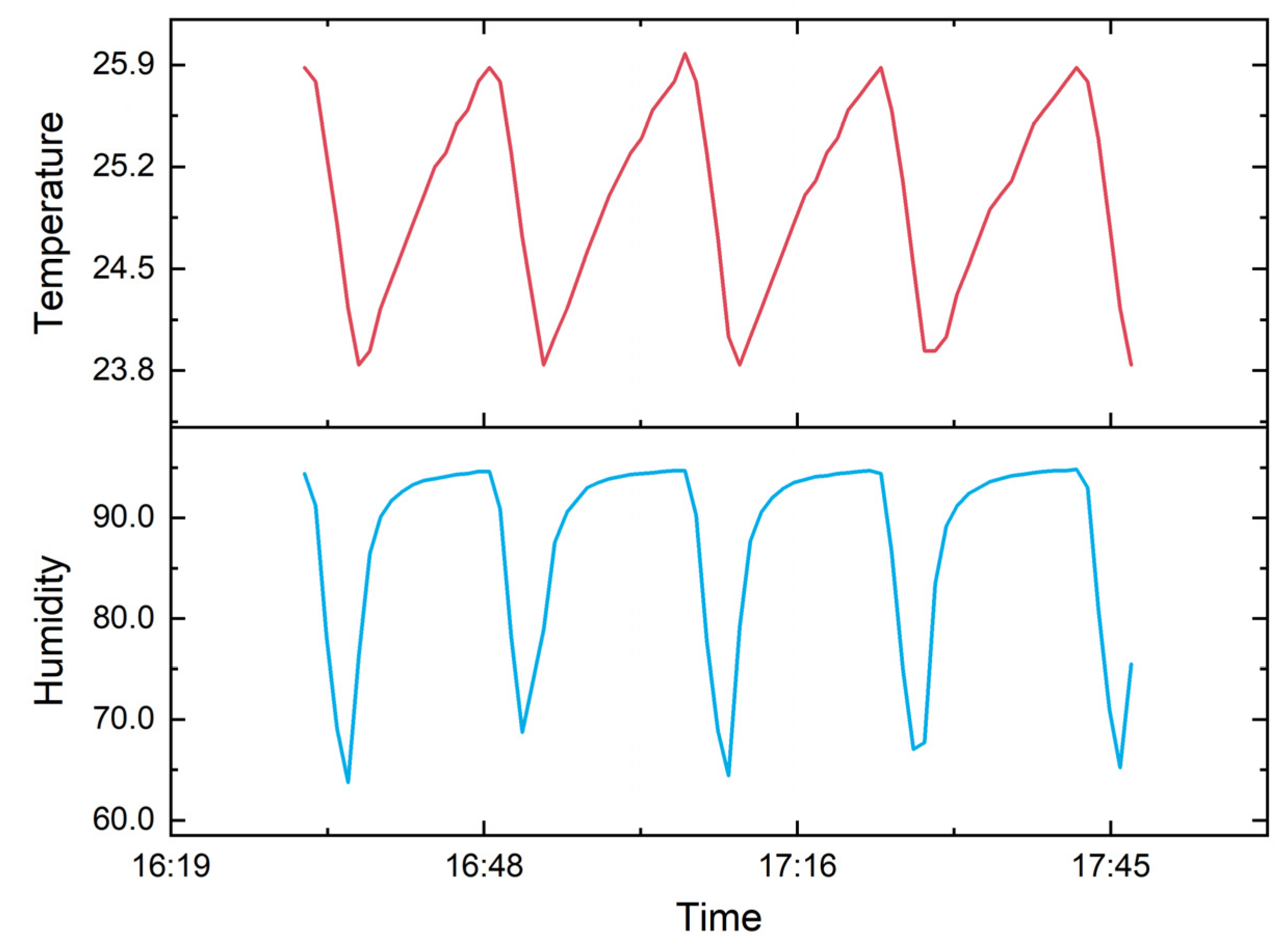

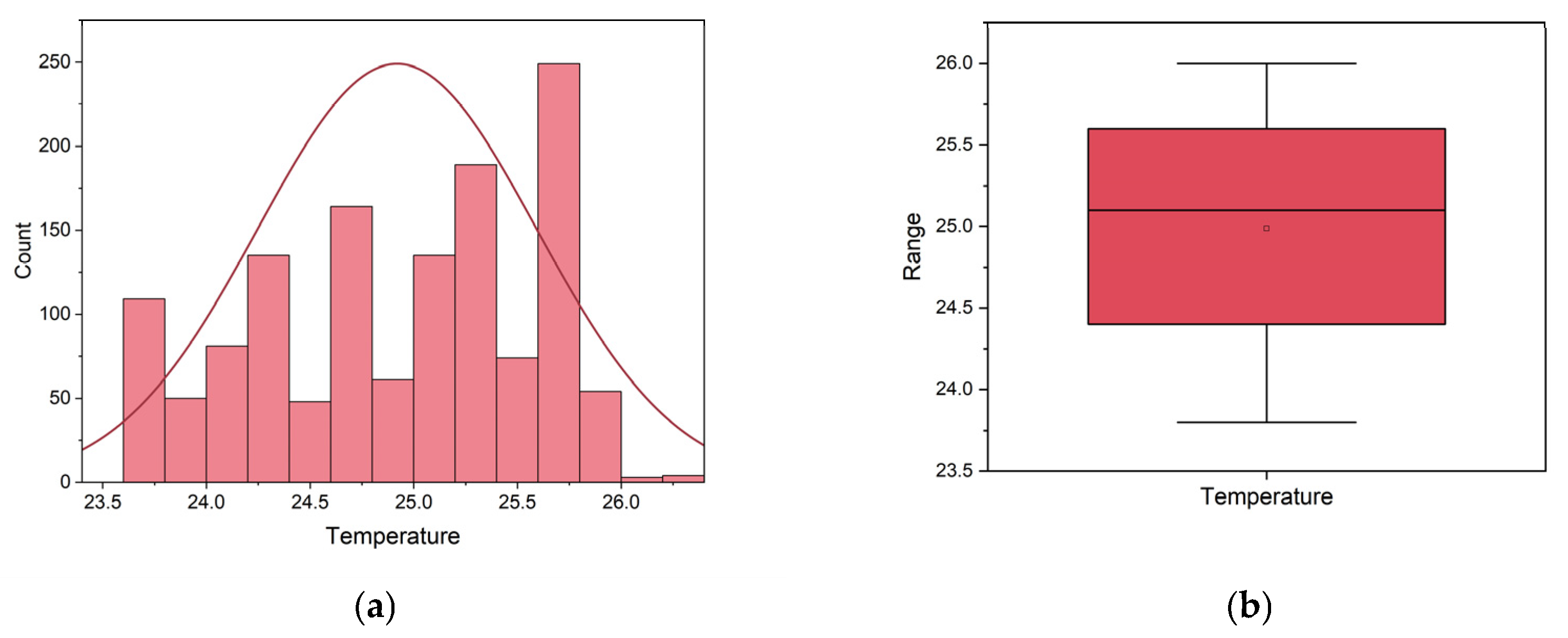

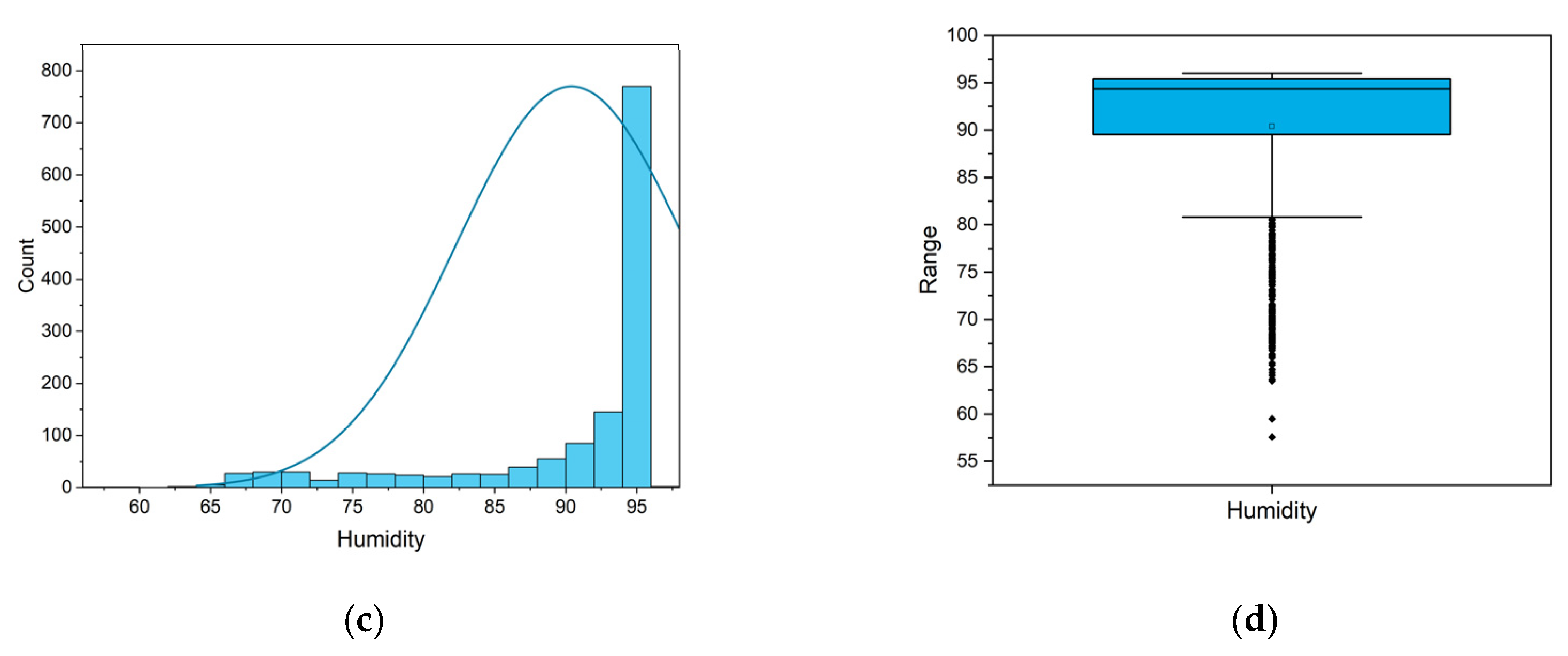

3.1. Environmental Performance

3.2. Cultivation Performance

4. Discussion

5. Conclusions

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| IoT | Internet of Things |

| CEA | Controlled Environment Agriculture |

| PDA | Potato Dextrose Agar |

| RH | Relative Humidity |

| BE | Biological Efficiency |

| SMS | Spent Mushroom Substrate |

| INMET | Instituto Nacional de Meteorologia (Brazilian National Institute of Meteorology) |

References

- Aggarwal, B.; Rajora, N.; Raturi, G.; Dhar, H.; Kadam, S.B.; Mundada, P.S.; Shivaraj, S.M.; Varshney, V.; Deshmukh, R.; Barvkar, V.T.; et al. Biotechnology and urban agriculture: A partnership for the future sustainability. Plant Sci. 2024, 338, 111903. [Google Scholar] [CrossRef]

- Badami, M.G.; Ramankutty, N. Urban agriculture and food security: A critique based on an assessment of urban land constraints. Glob. Food Sec. 2015, 4, 8–15. [Google Scholar] [CrossRef]

- de Oliveira Alves, D.; de Oliveira, L.; Müh, D.D. Commercial urban agriculture for sustainable cities. Cities 2024, 150, 105017. [Google Scholar] [CrossRef]

- McClintock, N. Why farm the city? Theorizing urban agriculture through a lens of metabolic rift. Camb. J. Reg. Econ. Soc. 2010, 3, 191–207. [Google Scholar] [CrossRef]

- Orsini, F.; Kahane, R.; Nono-Womdim, R.; Gianquinto, G. Urban agriculture in the developing world: A review. Agron. Sustain. Dev. 2013, 33, 695–720. [Google Scholar] [CrossRef]

- Murugesan, S. Sustainable food security: Edible and medicinal mushroom. In Sustainable Agriculture Towards Food Security; Dhanarajan, A., Ed.; Springer: Singapore, 2017; pp. 223–246. [Google Scholar] [CrossRef]

- Miles, P.G.; Chang, S.-T. Mushrooms: Cultivation, Nutritional Value, Medicinal Effect, and Environmental Impact; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Wasser, S.P. Current findings, future trends, and unsolved problems in studies of medicinal mushrooms. Appl. Microbiol. Biotechnol. 2011, 89, 1323–1332. [Google Scholar] [CrossRef]

- Contato, A.G.; Conte-Junior, C.A. Lion’s Mane mushroom (Hericium erinaceus): A neuroprotective fungus with antioxidant, anti-inflammatory, and antimicrobial potential—A narrative review. Nutrients 2025, 17, 1307. [Google Scholar] [CrossRef]

- Grimm, D.; Wösten, H.A.B. Mushroom cultivation in the circular economy. Appl. Microbiol. Biotechnol. 2018, 102, 7795–7803. [Google Scholar] [CrossRef]

- D’souza, V.M.; Bhalla, R. Controlled environment agriculture: An opportunity for customizing secondary metabolite production. In Phytopharmaceuticals and Biotechnology of Herbal Plants, 1st ed.; CRC Press: Boca Raton, FL, USA, 2022. [Google Scholar]

- Ragaveena, S.; Edward, A.S.; Surendran, U. Smart controlled environment agriculture methods: A holistic review. Rev. Environ. Sci. Biotechnol. 2021, 20, 887–913. [Google Scholar] [CrossRef]

- Thong-un, N.; Wongsaroj, W. Productivity enhancement using low-cost smart wireless programmable logic controllers: A case study of an oyster mushroom farm. Comput. Electron. Agric. 2022, 195, 106798. [Google Scholar] [CrossRef]

- Talavera, J.M.; Tobón, L.E.; Gómez, J.A.; Culman, M.A.; Aranda, J.M.; Parra, D.T.; Quiroz, L.A.; Hoyos, A.; Garreta, L.E. Review of IoT applications in agro-industrial and environmental fields. Comput. Electron. Agric. 2017, 142, 283–297. [Google Scholar] [CrossRef]

- He, L.; Fu, L.; Fang, W.; Sun, X.; Suo, R.; Li, G.; Zhao, G.; Yang, R.; Li, R. IoT-based urban agriculture container farm design and implementation for localized produce supply. Comput. Electron. Agric. 2022, 203, 107445. [Google Scholar] [CrossRef]

- Elewi, A.; Hajhamed, A.; Khankan, R.; Duman, S.; Souag, A.; Ahmed, A. Design and implementation of a cost-aware and smart oyster mushroom cultivation system. Smart Agric. Technol. 2024, 8, 100439. [Google Scholar] [CrossRef]

- Najmurrokhman, A.; Kusnandar; Daelami, A.; Nurlina, E.; Komarudin, U.; Ridhatama, H. Development of temperature and humidity control system in Internet-of-Things based oyster mushroom cultivation. In Proceedings of the 2020 3rd International Seminar on Research of Information Technology and Intelligent Systems (ISRITI), Yogyakarta, Indonesia, 10–11 December 2020; pp. 551–555. [Google Scholar] [CrossRef]

- Ariffin, M.A.M.; Ramli, M.I.; Zainol, Z.; Amin, M.N.M.; Ismail, M.; Adnan, R.; Ahmad, N.D.; Husain, N.; Jamil, N. Enhanced IoT-Based Climate Control for Oyster Mushroom Cultivation Using Fuzzy Logic Approach and NodeMCU Microcontroller. Pertanika J. Sci. Technol. 2021, 29, 2863–2885. [Google Scholar] [CrossRef]

- Bunluewong, K.; Surinta, O. Semi-Automated Mushroom Cultivation House Using Internet of Things. Eng. Access 2021, 7, 181–188. [Google Scholar]

- Rukhiran, M.; Sutanthavibul, C.; Boonsong, S.; Netinant, P. IoT-based mushroom cultivation system with solar renewable energy integration: Assessing the sustainable impact of the yield and quality. Sustainability 2023, 15, 13968. [Google Scholar] [CrossRef]

- Ramli, M.I.; Ariffin, M.A.M.; Zainol, Z.; Amin, M.N.M.; Hirawan, D.; Sumitra, I.D.; Jamil, N. Design of a Smart Portable Farming Kit for Indoor Cultivation Using the Raspberry Pi Platform. Pertanika J. Sci. Technol. 2023, 31, 1731–1754. [Google Scholar] [CrossRef]

- Chong, J.L.; Chew, K.W.; Peter, A.P.; Ting, H.Y.; Show, P.L. Internet of Things (IoT)-Based Environmental Monitoring and Control System for Home-Based Mushroom Cultivation. Biosensors 2023, 13, 98. [Google Scholar] [CrossRef]

- Kaewkorakot, K.; Traiwan, C.; Weeplian, T.; Tiyayon, P.; Thanatthirapich, K.; Pansak, W.; Kiravittaya, S. Smart Mushroom Cultivation House: Engineering Development and Data Analysis. Eng. J. 2024, 28, 183–196. [Google Scholar] [CrossRef]

- Dayananda, S.H.; Thaneswer, P.; Jiten, S.H.; Naseeb, S.; Anubhab, P. Design and Implementation of an IoT-Based Microclimate Control System for Oyster Mushroom Cultivation. Int. J. Agric. Technol. 2024, 20, 1431–1450. [Google Scholar]

- Guragain, D.P.; Shrestha, B.; Bajracharya, I. A low-cost centralized IoT ecosystem for enhancing oyster mushroom cultivation. J. Agric. Food Res. 2024, 15, 100952. [Google Scholar] [CrossRef]

- Dias, E.S. Mushroom cultivation in Brazil: Challenges and potential for growth. Ciênc. Agrotec. 2010, 34, 795–803. [Google Scholar] [CrossRef]

- Vaz Júnior, S. (Ed.) Biomassa para Química Verde, 1st ed.; Embrapa Agroenergia: Brasília, Brazil, 2013. [Google Scholar]

- Ahmad, Y.A.; Gunawan, T.S.; Mansor, H.; Hamida, B.A.; Hishamudin, A.F.; Arifin, F. On the evaluation of DHT22 temperature sensor for IoT application. In Proceedings of the 8th International Conference on Computer and Communication Engineering (ICCCE 2021), Kuala Lumpur, Malaysia, 22–23 June 2021; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2021; pp. 131–134. [Google Scholar] [CrossRef]

- Liu, T. Digital-Output Relative Humidity & Temperature Sensor/Module DHT22 (also Named AM2302); Aosong Electronics: Guangzhou, China, 2013; Available online: https://ardustore.dk/error/DHT22%20Datasheet.pdf (accessed on 12 September 2025).

- Ejigu, N.; Sitotaw, B.; Girmay, S.; Assaye, H. Evaluation of oyster mushroom (Pleurotus ostreatus) production using water hyacinth (Eichhornia crassipes) biomass supplemented with agricultural wastes. Int. J. Food Sci. 2022, 2022, 9289043. [Google Scholar] [CrossRef]

- Silva, W.L.; Dereczynski, C.P. Climatological characterization and observed trends in climatic extremes in the State of Rio de Janeiro. Anuário Inst. Geociências 2017, 37, 123–138. [Google Scholar] [CrossRef]

- Ahmad, I.; Fuad, I.; Khan, Z.K. Mycelia growth of pink oyster (Pleurotus djamor) mushroom in different culture media and environmental factors. Agric. Food Sci. Res. 2015, 2, 6–11. [Google Scholar]

- Atila, F.; Tüzel, Y.; Pekşen, A.; Cano, A.F.; Fernández, J.A. The effect of different fruiting temperatures on the yield and nutritional parameters of some wild and hybrid Hericium isolates. Sci. Hortic. 2021, 280, 109915. [Google Scholar] [CrossRef]

- Choi, S.-G.; Jang, K.-Y.; Kim, G.-H.; Kong, W.-S.; Jo, J.-S.; Kim, H.-Y.; Yoo, Y.-B. Cultural characteristics and phylogenetic relationships based on RFLP analysis in Pleurotus species. J. Mushroom 2014, 12, 145–153. [Google Scholar] [CrossRef]

- Gaitán-Hernández, R.; Esqueda, M.; Gutiérrez, A.; Sánchez, A.; Beltrán-García, M.; Mata, G. Bioconversion of agrowastes by Lentinula edodes: The high potential of viticulture residues. Appl. Microbiol. Biotechnol. 2006, 71, 432–439. [Google Scholar] [CrossRef]

- Gorai, B.; Sharma, R. Determination of optimum temperature and pH for mycelial growth of Pleurotus spp./strains. Int. J. Microbiol. Res. 2018, 10, 1287–1289. [Google Scholar] [CrossRef]

- Harith, N.; Abdullah, N.; Sabaratnam, V. Cultivation of Flammulina velutipes mushroom using various agro-residues as a fruiting substrate. Pesqui. Agropecu. Bras. 2014, 49, 181–188. [Google Scholar] [CrossRef]

- Hu, Y.; Xue, F.; Chen, Y.; Qi, Y.; Zhu, W.; Wang, F.; Wen, Q.; Shen, J. Effects and mechanism of the mycelial culture temperature on the growth and development of Pleurotus ostreatus (Jacq.) P. Kumm. Horticulturae 2023, 9, 95. [Google Scholar] [CrossRef]

- Jang, K.-Y.; Jhune, C.-S.; Park, J.-S.; Cho, S.-M.; Weon, H.-Y.; Cheong, J.-C.; Choi, S.-G.; Sung, J.-M. Characterization of fruitbody morphology on various environmental conditions in Pleurotus ostreatus. Mycobiology 2003, 31, 145–150. [Google Scholar] [CrossRef]

- Lee, K.K.; Kristanti, R.A.; Yulisa, A.; Rubiyatno; Ningsih, F.; Syafrudin, M.; Hernandes, E.; Albescu, M. Biosorption of synthetic dye by macrofungi. Ind. Domest. Waste Manag. 2022, 2, 61–70. [Google Scholar] [CrossRef]

- Markovic, M.; Rajkovic, S.; Miric, M.; Mitic, D.; Rakonjac, L. Growth conditions of mycelium medicinal mushroom Lentinula edodes (Berk.) Pegl. in the substrate colonization phase. Sci. Res. Essays 2011, 6, 4133–4140. [Google Scholar] [CrossRef]

- Nashiruddin, N.I.; Chua, K.S.; Mansor, A.F.; Rahman, R.A.; Lai, J.C.; Azelee, N.I.W.; El Enshasy, H. Effect of growth factors on the production of mycelium-based biofoam. Clean Technol. Environ. Policy 2022, 24, 351–361. [Google Scholar] [CrossRef]

- Raman, J.; Jang, K.Y.; Oh, Y.L.; Oh, M.; Im, J.H.; Lakshmanan, H.; Sabaratnam, V. Cultivation and nutritional value of prominent Pleurotus spp.: An overview. Mycobiology 2020, 49, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Sales-Campos, C.; Eira, A.F.D.; Jesus, M.A.D.; Campagnolli, F.; Andrade, M.C.N.D. Crescimento micelial de Pleurotus ostreatus em resíduo de Simarouba amara. Pesqui. Agropecu. Bras. 2008, 43, 1633–1635. [Google Scholar] [CrossRef]

- Sudheer, S.; Alzorqi, I.; Ali, A.; Cheng, P.G.; Siddiqui, Y.; Manickam, S. Determination of the biological efficiency and antioxidant potential of Lingzhi or Reishi medicinal mushroom, Ganoderma lucidum (Agaricomycetes), cultivated using different agro-wastes in Malaysia. Int. J. Med. Mushrooms 2018, 20, 57–66. [Google Scholar] [CrossRef]

- Xiong, S.; Martin, C.; Eilertsen, L.; Wei, M.; Myronycheva, O.; Larsson, S.H.; Jönsson, L.J. Energy-efficient substrate pasteurisation for combined production of shiitake mushroom (Lentinula edodes) and bioethanol. Bioresour. Technol. 2019, 274, 65–72. [Google Scholar] [CrossRef] [PubMed]

- Zăgrean, V.; Neață, G.; Stănciulescu, B. Influence of temperature on mycelial growth of some Pleurotus eryngii and Lentinula edodes strains in vitro. Bull. Univ. Agric. Sci. Vet. Med. Cluj-Napoca Hortic. 2017, 74, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Wang, Y.; Zhang, Z.; Sun, L.; Wei, Y.; Bao, X.; Xin, G. Postharvest short-time partial dehydration affects shiitake mushroom (Lentinus edodes) storage quality and umami taste. Sci. Hortic. 2021, 287, 110274. [Google Scholar] [CrossRef]

- Zurbano, L.Y.; Bellere, A.D.; Savilla, L.C. Mycelial growth, fruiting body production and proximate composition of Pleurotus djamor on different substrate. CLSU Int. J. Sci. Technol. 2017, 2, 20–30. [Google Scholar] [CrossRef]

- Sakamoto, Y. Influences of environmental factors on fruiting body induction, development and maturation in mushroom-forming fungi. Fungal Biol. Rev. 2018, 32, 236–248. [Google Scholar] [CrossRef]

- Kassim, M.R.M.; Mat, I.; Yusoff, I.M. Applications of internet of things in mushroom farm management. In Proceedings of the 13th International Conference on Sensing Technology (ICST 2019), Sydney, Australia, 2–4 December 2019; IEEE: Piscataway, NJ, USA, 2020. [Google Scholar] [CrossRef]

- Bellettini, M.B.; Fiorda, F.A.; Maieves, H.A.; Teixeira, G.L.; Ávila, S.; Hornung, P.S.; Maccari Júnior, A.; Ribani, R.H. Factors affecting mushroom Pleurotus spp. Saudi J. Biol. Sci. 2019, 26, 633–646. [Google Scholar] [CrossRef]

- Salifu, E.; Di Rauso Simeone, G.; Russo, G.; Rao, M.A.; Urciuoli, G.; El Mountassir, G. Influence of environmental conditions on the growth of Pleurotus ostreatus in sand. Biogeotechnics 2025, 3, 100137. [Google Scholar] [CrossRef]

- Khan, M.M.; Akram, M.T.; Janke, R.; Qadri, R.W.K.; Al-Sadi, A.M.; Farooque, A.A. Urban horticulture for food secure cities through and beyond COVID-19. Sustainability 2020, 12, 9592. [Google Scholar] [CrossRef]

- Urben, A.F. (Ed.) Produção de Cogumelos por Meio de Tecnologia Chinesa Modificada: Biotecnologia e Aplicações na Agricultura e na Saúde, 3rd ed.; Embrapa: Brasília, Brazil, 2017. [Google Scholar]

- Mohammed, M.F.; Azmi, A.; Zakaria, Z.; Tajuddin, M.F.N.; Isa, Z.M.; Azmi, S.A. IoT-Based Monitoring and Environment Control System for Indoor Cultivation of Oyster Mushroom. J. Phys. Conf. Ser. 2018, 1019, 012053. [Google Scholar] [CrossRef]

- Wajiran; Riskiono, S.D.; Prasetyawan, P.; Mulyanto, A.; Iqbal, M.; Prabowo, R. Control and Realtime Monitoring System for Mushroom Cultivation Fields Based on WSN and IoT. J. Phys. Conf. Ser. 2020, 1655, 012003. [Google Scholar] [CrossRef]

- SureHarvest. The Mushroom Sustainability Story: Water, Energy, and Climate Environmental Metrics; SureHarvest: Soquel, CA, USA, 2017; Available online: https://www.mushroomcouncil.com/wp-content/uploads/2017/12/Mushroom-Sustainability-Story-2017.pdf (accessed on 12 September 2025).

- Steenkamp, J.; Cilliers, E.J.; Cilliers, S.S.; Lategan, L. Food for thought: Addressing urban food security risks through urban agriculture. Sustainability 2021, 13, 1267. [Google Scholar] [CrossRef]

- Altieri, M.A.; Nicholls, C.I.; Henao, A.; Lana, M.A. Agroecology and the design of climate change-resilient farming systems. Agron. Sustain. Dev. 2015, 35, 869–890. [Google Scholar] [CrossRef]

- Jacques, P.J.; Jacques, J.R. Monocropping cultures into ruin: The loss of food varieties and cultural diversity. Sustainability 2012, 4, 2970–2997. [Google Scholar] [CrossRef]

- Paul, C.; Weber, M.; Knoke, T. Agroforestry versus farm mosaic systems—Comparing land-use efficiency, economic returns and risks under climate change effects. Sci. Total Environ. 2017, 587–588, 22–35. [Google Scholar] [CrossRef]

- Gursel, I.V.; Elbersen, B.; Meesters, K.P.H.; van Leeuwen, M. Defining circular economy principles for biobased products. Sustainability 2022, 14, 12780. [Google Scholar] [CrossRef]

- Guo, Y.; Chen, X.; Gong, P.; Wang, R.; Qi, Z.; Deng, Z.; Han, A.; Long, H.; Wang, J.; Yao, W.; et al. Advances in postharvest storage and preservation strategies for Pleurotus eryngii. Foods 2023, 12, 1046. [Google Scholar] [CrossRef]

- Silva, M.; Ramos, A.C.; Lidon, F.J.; Reboredo, F.H.; Gonçalves, E.M. Pre- and postharvest strategies for Pleurotus ostreatus mushroom in a circular economy approach. Foods 2024, 13, 1464. [Google Scholar] [CrossRef]

- Joniec, J.; Kwiatkowska, E.; Kwiatkowski, C.A. Assessment of the effects of soil fertilization with spent mushroom substrate in the context of microbial nitrogen transformations and the potential risk of exacerbating the greenhouse effect. Agriculture 2022, 12, 1190. [Google Scholar] [CrossRef]

- Kong, Y.; Ma, R.; Li, G.; Wang, G.; Liu, Y.; Yuan, J. Impact of biochar, calcium magnesium phosphate fertilizer and spent mushroom substrate on humification and heavy metal passivation during composting. Sci. Total Environ. 2022, 824, 153755. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.; Guan, H.; Zheng, H.; Wang, M.; Xu, P.; Dong, S.; Yang, Y.; Xiao, J. Novel liquid organic fertilizer: A potential way to effectively recycle spent mushroom substrate. J. Clean. Prod. 2022, 376, 134368. [Google Scholar] [CrossRef]

- He, P.; Li, F.; Huang, L.; Xue, D.; Liu, W.; Xu, C. Chemical characterization and antioxidant activity of polysaccharide extract from spent mushroom substrate of Pleurotus eryngii. J. Taiwan Inst. Chem. Eng. 2016, 69, 48–53. [Google Scholar] [CrossRef]

- Nakajima, V.M.; Soares, F.E.F.; Queiroz, J.H. Screening and decolorizing potential of enzymes from spent mushroom composts of six different mushrooms. Biocatal. Agric. Biotechnol. 2018, 13, 58–61. [Google Scholar] [CrossRef]

- Moura, B.; Monteiro, H.; Mata, T.M.; Iten, M.; Martins, A.A. Environmental life cycle assessment of early-stage development of ergosterol extraction from mushroom bio-residues. J. Clean. Prod. 2022, 355, 131623. [Google Scholar] [CrossRef]

- Nowysz, A.; Mazur, Ł.; Vaverková, M.D.; Koda, E.; Winkler, J. Urban agriculture as an alternative source of food and water security in today’s sustainable cities. Int. J. Environ. Res. Public Health 2022, 19, 15597. [Google Scholar] [CrossRef] [PubMed]

| Ref. | Dimension (m) | Volume (m3) | Control Level | Parameters Controlled | Actuators/ Equipment | Publication Year |

|---|---|---|---|---|---|---|

| [18] | 5.47 × 3.47 × - | - | Semi-controlled | Humidity, air quality | Fan, water pump | 2021 |

| [19] | 8.00 × 4.00 × 2.30 | 73.6 | Semi-controlled | Humidity | Water pump | 2021 |

| [13] | - | - | Semi-controlled | Humidity, air quality | Water pump, fan | 2022 |

| [15] | 9.00 × 3.00 × 3.00 | 81.0 | Fully controlled | Temperature, humidity, air quality | Ultrasonic humidifier, air conditioner, fan, heater | 2022 |

| [20] | 1.50 × 1.50 × 0.80 | 1.8 | Semi-controlled | Humidity | Water pump | 2023 |

| [21] | 0.70 × 0.65 × 0.45 | 0.20 | Semi-controlled | Humidity | Ultrasonic humidifier | 2023 |

| [22] | 0.435 × 0.320 × 0.285 | 0.04 | Fully controlled | Humidity, air quality, temperature | Ultrasonic humidifier, fan, peltier | 2023 |

| [23] | 6.00 × 4.00 × - | - | Semi-controlled | Humidity | Water pump | 2024 |

| [24] | 3.50 × 2.50 × 3.00 | 26.3 | Semi-controlled | Humidity | Water pump, fan | 2024 |

| [16] | 14.00 × 7.00 × - | - | Fully controlled | Temperature, humidity, air quality | Air conditioner, water pump, fan | 2024 |

| [25] | - | - | Fully controlled | Temperature, humidity, air quality | Ultrasonic humidifier, air-conditioner, fan | 2024 |

| Equipment | Technical Specifications | Function |

|---|---|---|

| Glass-door refrigerator | Volume: 326 L; modified with external ports | Maintains chamber temperature and allows visual monitoring |

| Ultrasonic humidifier | 400 mL h−1 output | Generates fine mist to control internal humidity |

| Flange | PVC, 25 mm diameter | Connect the humidifier hose to the chamber wall |

| Silicone hose | Flexible tubing, 20 mm inner diameter, 1 m length | Delivers humidified air to the chamber interior |

| ESP32 microcontroller | ESP32-WROOM-32; 240 MHz dual-core CPU; integrated Wi-Fi and Bluetooth | Executes control logic and communicates with the cloud |

| DHT22 sensor | Measurement: 0–100% RH and −40 °C to +80 °C; accuracy: ±0.5 °C and ±2% (RH) | Measures temperature and humidity in real time |

| Two-channel Relay module | 5 V, 10 A per channel | Switches cooling and humidification devices automatically |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Foffano, M.O.A.; Michel, R.C.; Freire, D.M.G.; Cavalcanti, E.D.C. Design and Evaluation of a Compact IoT-Enabled Microfarm for Decentralized Urban Agriculture Applied to the Cultivation of Pleurotus ostreatus (Oyster Mushroom). Sustainability 2025, 17, 10332. https://doi.org/10.3390/su172210332

Foffano MOA, Michel RC, Freire DMG, Cavalcanti EDC. Design and Evaluation of a Compact IoT-Enabled Microfarm for Decentralized Urban Agriculture Applied to the Cultivation of Pleurotus ostreatus (Oyster Mushroom). Sustainability. 2025; 17(22):10332. https://doi.org/10.3390/su172210332

Chicago/Turabian StyleFoffano, Marlon O. A., Ricardo C. Michel, Denise M. G. Freire, and Elisa D. C. Cavalcanti. 2025. "Design and Evaluation of a Compact IoT-Enabled Microfarm for Decentralized Urban Agriculture Applied to the Cultivation of Pleurotus ostreatus (Oyster Mushroom)" Sustainability 17, no. 22: 10332. https://doi.org/10.3390/su172210332

APA StyleFoffano, M. O. A., Michel, R. C., Freire, D. M. G., & Cavalcanti, E. D. C. (2025). Design and Evaluation of a Compact IoT-Enabled Microfarm for Decentralized Urban Agriculture Applied to the Cultivation of Pleurotus ostreatus (Oyster Mushroom). Sustainability, 17(22), 10332. https://doi.org/10.3390/su172210332