1. Introduction

Maritime transportation is a major contributor to climate change, accounting for around 3% of global greenhouse gas (GHG) emissions. The International Maritime Organization (IMO), the key decision maker for the industry, has set ambitious targets to cut and eradicate GHGs. The target is to reduce emissions by 20% by 2030, 70% by 2040, and reach net-zero emissions around 2050, comparable to 2008 levels. To achieve these targets, feasible infrastructure, regulatory changes, long-term technological advancements, and short- to medium-term transitional solutions are needed.

The maritime industry seeks alternative solutions such as using hydrogen (H2), ammonia (NH3), methanol (CH3OH), liquefied natural gas (LNG), and biofuels to cut GHGs. However, each alternative fuel option has its own advantages and disadvantages. Among alternative fuels, hydrogen and ammonia stand out due to their carbon-neutral combustion, compatibility with internal combustion engines, and compliance with stringent environmental regulations. Ammonia offers higher energy density, global distribution, and a well-established infrastructure, while hydrogen stands out for its higher thermal efficiency. However, the high production costs, safety concerns, and lack of a widespread, developed supply infrastructure continue to hinder their widespread adoption. Furthermore, large-scale use of these fuels in long-distance maritime transport is unlikely in the short term. However, the use of hydrogen and ammonia in port operations creates opportunities for early adoption for enabling both sustainable port management and significant reductions in shipping emissions.

Although there are various emission sources in the port area, such as vessels, cranes, forklifts, trucks, and tugboats, they represent the high-impact focal area of port operations in terms of emission production due to their frequent berthing operations. The fuel-intensive berthing cycles cause high emissions despite tugboats’ relatively small size compared to other ship types during port operations. The blending of hydrogen and ammonia in tugboat engines is a promising option to overcome this issue, which would provide both local emissions reductions and broader systemic benefits by linking port decarbonization to improved urban air quality in adjacent coastal cities. Recent developments show that low-carbon tug operations are moving from concept to practice. The IMO has adopted a new 2023 GHG Strategy and life-cycle (well-to-wake) guidelines, providing a common basis to compare marine fuels [

1]. A critical analysis of the strategy indicated that it consists of ambitious and concrete goals but it is crucial to focus on life cycle cost (LCC) calculations for economic measures [

2]. In addition, a recent study stated that a sustainable strategy should be led by alignment with policies, incentives, and innovation [

3]. To achieve the goals and strategies, studies from a regionally comparative perspective is also recommended [

4].

Recent developments show that low-carbon tug boat operations shift from concept to practice. The IMO has adopted a new 2023 GHG Strategy and life-cycle (well-to-wake) guidelines, providing a common basis to compare marine fuels [

1]. On the pilot side, NYK’s ammonia-fueled tug Sakigake completed a three-month trial in Tokyo Bay [

5], the Hydrotug 1 started hydrogen dual-fuel operations in Port of Antwerp [

6]. These steps strengthen the real-world and policy context for evaluating diesel–H

2–NH

3 pathways in port duty.

Hydrogen and ammonia have been investigated to reduce emissions in several studies from different perspectives. Life cycle assessment (LCA) applications indicate that these fuels significantly reduce GHGs, particulate matter (PM), and black carbon (BC) [

7,

8]. However, production efficiency, energy requirements, and storage constraints remain key challenges [

9]. Comparative evaluations highlight ammonia’s advantage in long-term energy storage due to its higher energy density [

9], while hydrogen-enriched LNG presents a transitional pathway with notable emission reductions [

10]. Despite promising GHG reduction potential, high production costs hinder widespread adoption, necessitating policy support such as carbon pricing and subsidies [

10,

11]. Furthermore, methodological inconsistencies in LCA studies underscore the need for standardization to enhance comparability and policy relevance [

12]. Advances in electro-ammonia and biofuels show potential for decarbonization, though scalability and infrastructure challenges persist [

13,

14]. Research on innovative hydrogen production methods, such as underground coal gasification and methane-assisted fuel cells, suggests promising efficiency improvements, though water and resource constraints [

15].

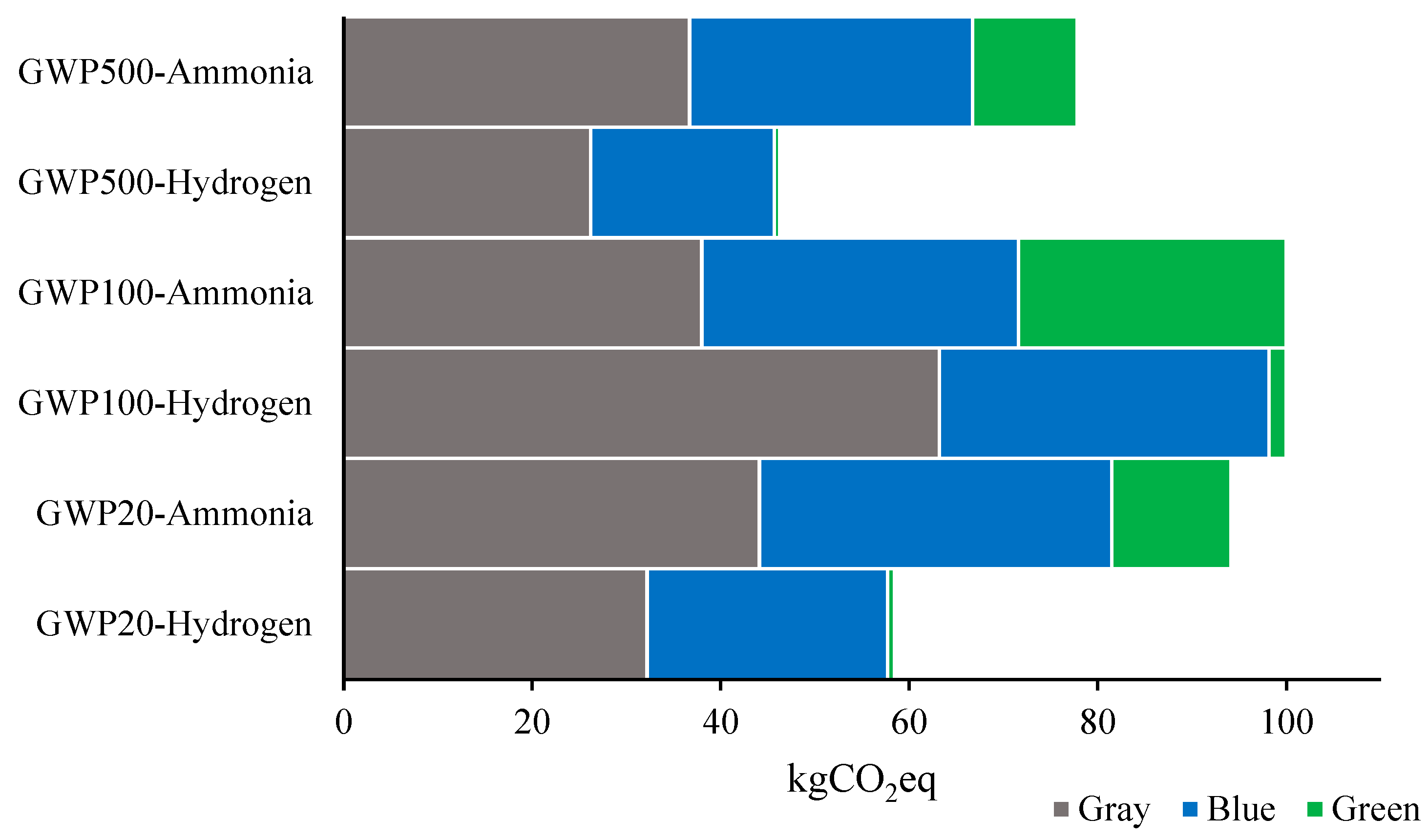

Addressing these challenges through technological advancements and regulatory interventions is essential for the viable integration of hydrogen and ammonia in maritime applications. Previous studies experienced methodological variation that restricts comparison. Common issues include inconsistent system boundaries, mismatched functional units, uneven treatment of non-CO2 climate forcers (CH4, N2O), varying grid-mix/credit-allocation assumptions, and TEA boundary choices that neglect mid-life replacements. We use a harmonized WtW–GWP100 basis with per-kWh engine-level normalization, accounting for CO2/CH4/N2O and uncertainty/robustness tests to resolve variations.

Also, several studies have extensively explored ammonia and hydrogen as alternative fuels in internal combustion engines, focusing on their combustion characteristics, performance, and emissions. Ammonia–hydrogen co-combustion has been investigated in both compression and spark-ignition engines, demonstrating improvements in thermal efficiency and combustion stability. Pyrc et al. [

16] found that a 12% hydrogen energy share enhanced efficiency but increased nitrogen oxides (NO

x) emissions. Stefano [

17] observed that hydrogen addition improved ammonia’s ignition and combustion rate, though performance remained lower than gasoline-fueled operation. Compression ratio adjustments have also been shown to optimize efficiency. Dual-fuel studies highlight ammonia’s potential for emission reduction, though challenges remain. Liu et al. [

18] observed that increasing ammonia energy share up to 60% in diesel engines suppressed combustion, delayed pressure rise, and reduced NO

x and CO

2 emissions, but elevated unburned NH

3 and N

2O. Yousefi et al. [

19] reported a 58% NO

x reduction with a 40% ammonia blend, though thermal efficiency slightly declined. In contrast, Jamrozik et al. [

20] found that 42% ammonia energy share optimized efficiency while reducing CO

2 and soot emissions.

Although there are many studies examining the blending of both hydrogen and ammonia fuels with diesel fuel, most of them concentrate either on production pathways using LCA or on combustion and cost performance through techno-economic assessment. Few have attempted to integrate these perspectives, and comprehensive frameworks combining LCA, techno-economic assessment, and structured decision-making tools are scarce. Moreover, research on the usage of tri-fuel remains limited to a small number of engine studies, highlighting a clear gap in port-duty, well-to-wake LCA/TEA/MCDM assessments [

21].

The IMO’s 2023 GHG Strategy and well-to-wake guidance set clear decarbonization goals, but the port-duty literature lacks an integrated assessment. Tugboat studies rarely integrate LCA–TEA–MCDM under realistic duty cycles or quantify safety/storage and retrofit restrictions within costs and rankings. This study addresses the remaining gaps by conducting a holistic evaluation of hydrogen–ammonia–diesel tri-fuel co-combustion in a tugboat engine. Specifically, it contributes by (i) assessing gray, blue, and green hydrogen and ammonia production pathways through LCA, (ii) modelling dual-fuel and tri-fuel engine scenario based on the Wärtsilä 9L20DF engine, (iii) quantifying economic performance using life-cycle cost (LCC), capital expenditure (CAPEX), and operational expenditure (OPEX) analysis, and (iv) applying multi-criteria decision-making (MCDM) methods, including CRITIC (CRiteria Importance Through Intercriteria Correlation), and TOPSIS (Technique for Order Preference by Similarity to Ideal Solution), to identify optimal fuel blending strategies. The study combines scientific rigor with practical applicability, providing findings that support the IMO’s well-to-wake framework, guiding effective carbon pricing systems, and advising policymakers and industry stakeholders on sustainable port operations.

3. Case Study

This study focused on the widely used dual-fuel Wärtsilä 9L20DF platform due to the lack of commercially operating ammonia–hydrogen marine engines. Currently, directly comparable real-engine tri-fuel (diesel–H

2–NH

3) datasets are unavailable, and existing experiments are engine-specific (hardware, calibration, operating map). Therefore, our study is bounded by model-based assumptions rather than engine-based empirical validation. While the resulting framework is intended to serve as a transparent baseline that informs experimental design and guides future engine-specific validation efforts. The properties of the tugboat are shown in

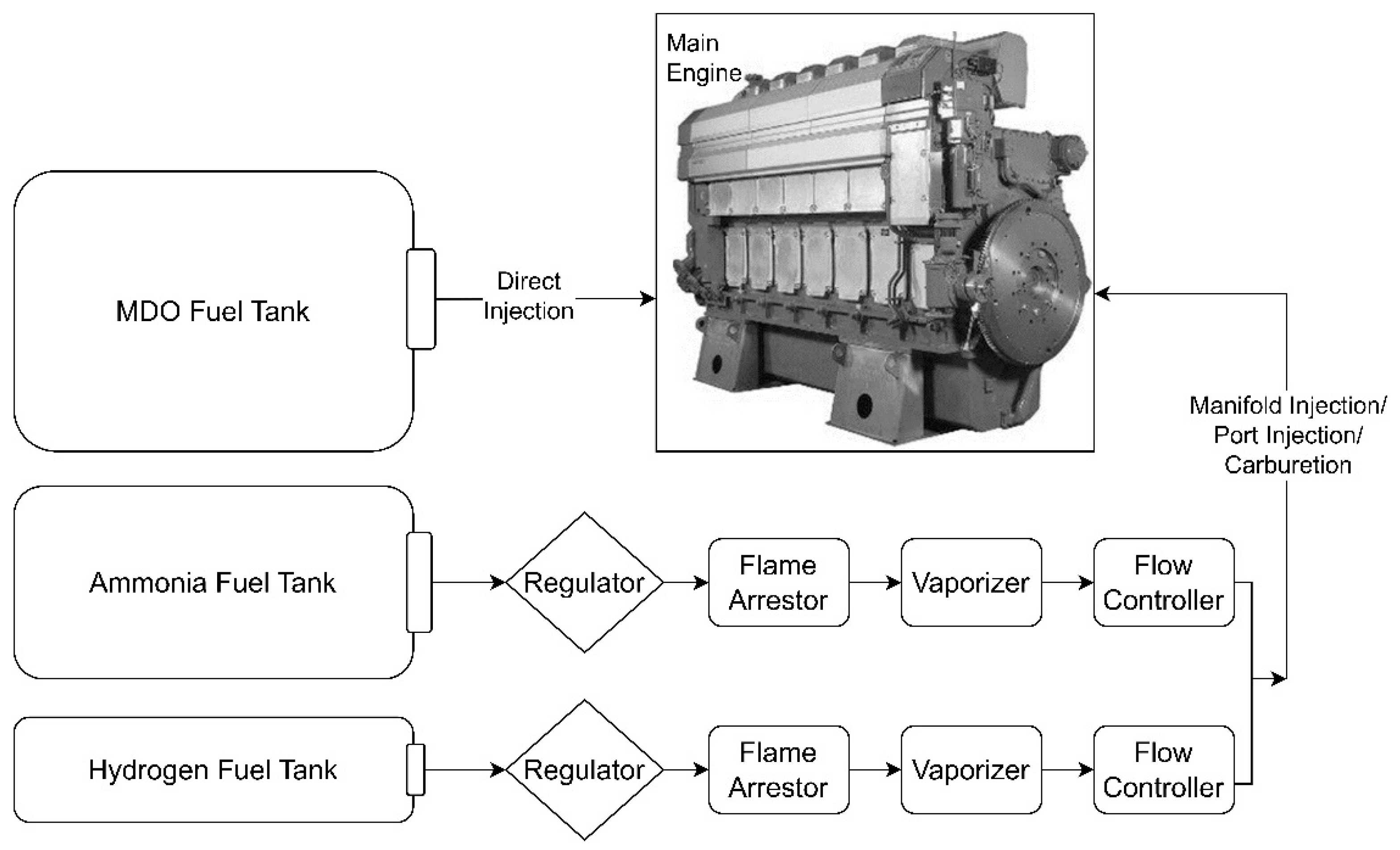

Table 3. Moreover, the Wärtsilä 9L20DF, installed on the reference tugboat, is widely deployed in port-duty service; its platform can be extended with a second gaseous line to enable tri-fuel operation. This allows for consistent CAPEX/OPEX accounting and enhances the external validity of the case study. The tugboat engine is originally designed to operate on dual fuels and can be adapted with minimal modifications to accommodate hydrogen–ammonia fuel mixtures. The components required for the combustion of these fuels are illustrated in

Figure 1. Given that this system closely resembles a conventional dual-fuel system and that no commercially available engine currently operates on an ammonia–hydrogen fuel blend, all calculations in this study have been conducted based on the existing Wärtsilä 9L20DF engine. This engine is a suitable reference both technologically and economically for evaluating the combustion of the ammonia–hydrogen–diesel fuel blends.

In this study, an economic comparison is conducted between a conventional CI marine engine and a gas-fuel-assisted CI marine engine. To facilitate this comparison, the impact of operating the Wärtsilä 9L20DF engine with different fuel ratios on OPEX will be examined, along with the effect of the required modifications for combustion on CAPEX. For clarity, the conventional CI engine will be denoted as C-CIE, the dual-fuel CI engine as DF-CIE, and the tri-fuel CI engine as TF-CIE. Since the primary engine under consideration is the Wärtsilä 9L20DF, all calculations will be based on the modifications applied to this engine. Consequently, calculations for the C-CIE mode involve removing specific components from the original DF-CIE. In contrast, calculations for the TF-CIE mode are based on the addition of specific components to the existing DF-CIE engine configuration.

To facilitate configurations, engine-level performance, emissions, and cost parameters are normalized per-kW and per-kWh. Operational profile, space/weight ratio, and integration limitations (hazard zoning/ventilation, bunkering interface, permissions) determine vessel-level suitability. Thus, engine-level findings are informative and need vessel-specific screening for correct applicability.

To calculate CAPEX values, it is essential to determine the engine’s initial investment cost. Since the engine considered in this study is a DF engine, achieving the C-CIE mode requires the removal of components necessary for LNG fuel usage from the engine system. Similarly, to enable the simultaneous use of hydrogen and ammonia fuels—thereby transitioning to TF-CIE mode—additional components must be integrated into the DF engine to facilitate the combustion of a second gaseous fuel. Based on the values provided in the literature, CI engine first investment cost is 310 USD/kW, and dual-fuel power system first investment cost is between 1250–1450 USD/kW [

56,

57], the initial investment costs have been calculated separately for each of the three operational modes. These calculations have been conducted considering a 20-year lifespan (n) and a fixed 10% discount rate (R) [

57]. In DF mode, gas fuel consumption is quite high, thus causing too much storage cost. However, in this study, low gas fuel ratios are considered, so it is considered that TF-CIE mode will be similar to DF-CIE mode in terms of cost. In addition, the infrastructure required for the first gas fuel can be used by the second gas fuel line with a small number of components. It is considered that the first investment costs of C-CIE, DF-CIE, and TF-CIE are 310 USD/kW [

58], 1250 USD/kW [

56], and 1450 USD/kW [

59], respectively. The investment costs and CAPEX values of C-CIE, DF-CIE, and TF-CIE modes are calculated as USD 516,150, USD 2,081,250, and USD 2,414,250, and USD 60,623, USD 244,450, USD 283,562, respectively.

MDO prices were sourced from Ship&Bunker, while the prices of gray, blue, and green hydrogen were obtained from literature data, as seen in

Table 4. OPEX values have been calculated separately for each fuel energy share ratio, as presented in

Table 5, within the limits that ensure efficient combustion and low emissions. For instance, the ammonia ratio has been constrained to a maximum of 50%, as higher concentrations lead to reduced combustion efficiency and NH

3 leakage. Similarly, H

2 content has been limited to 24%, as exceeding this threshold increases NO

x emissions and the risk of knocking [

54]. The selection of energy share ratios of fuels is based on combustion efficiency, emissions, knocking propensity, and storage challenges. Additionally, recommendations from the literature were considered to ensure the feasibility and reliability of the selected energy share ratios. After determining the energy share ratios, the fuel consumption rates for marine diesel oil (MDO) were obtained from the engine’s catalog data [

60]. The specified SFC values in g/kWh are then converted to kJ/kWh, considering the lower heating value (LHV) of each fuel. Subsequently, based on the energy share ratios, the SFC values for hydrogen, ammonia, and MDO were determined for each operational scenario. For the calculation of annual fuel consumption costs, Equation (3) and (4) are applied. For comparison, only the conditions in which the engine operates at full load have been considered. It is assumed that the engines operate at full load for 3000 h per year with 1665 kW power [

57].

To calculate annual lubrication oil costs, Equation (5) was utilized. The LOP value is assumed to be USD 3.5 per liter, and the specific lubrication oil consumption rate for the selected engine is considered to be 0.4 g/kWh [

57]. The annual LOC value is calculated as USD 7867 for all cases. For maintenance and repair costs, the specific maintenance cost was assumed to be 0.0022 USD/kWh for the C-CIE mode and 0.0033 USD/kWh for the DF-CIE mode [

65]. To calculate annual MR costs Equation (6) is utilized. The annual MR costs for C-CIE and DF-TF-CIE modes are USD 10,989 and USD 16,483, respectively.

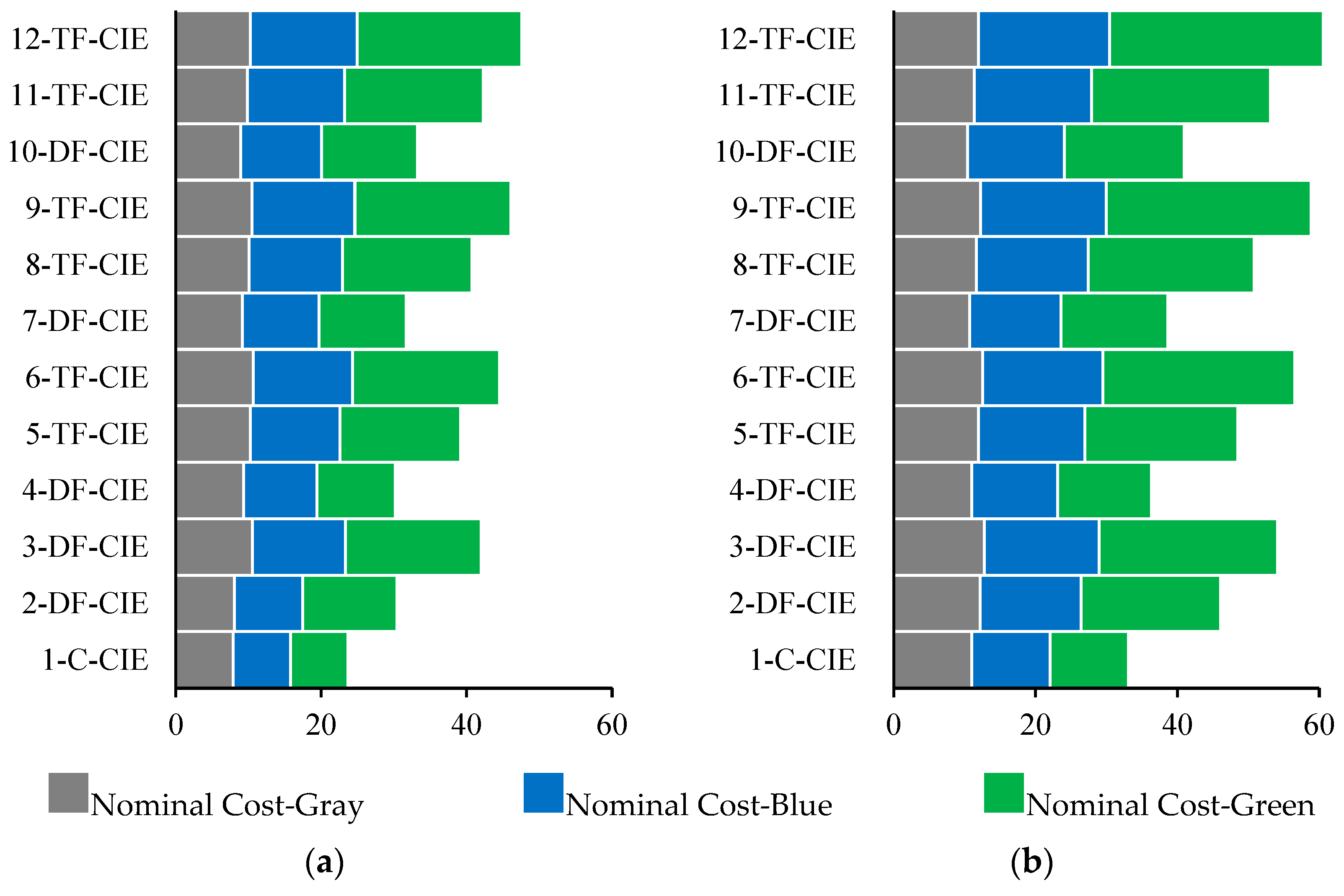

A 20-year LCC analysis was conducted using a 3% discount rate to account for cost escalation and the time value of money as presented in

Table 6. This approach provides a comprehensive financial assessment, balancing inflationary effects with discounting to evaluate the economic feasibility of alternative fuel strategies in marine propulsion systems.

5. Conclusions

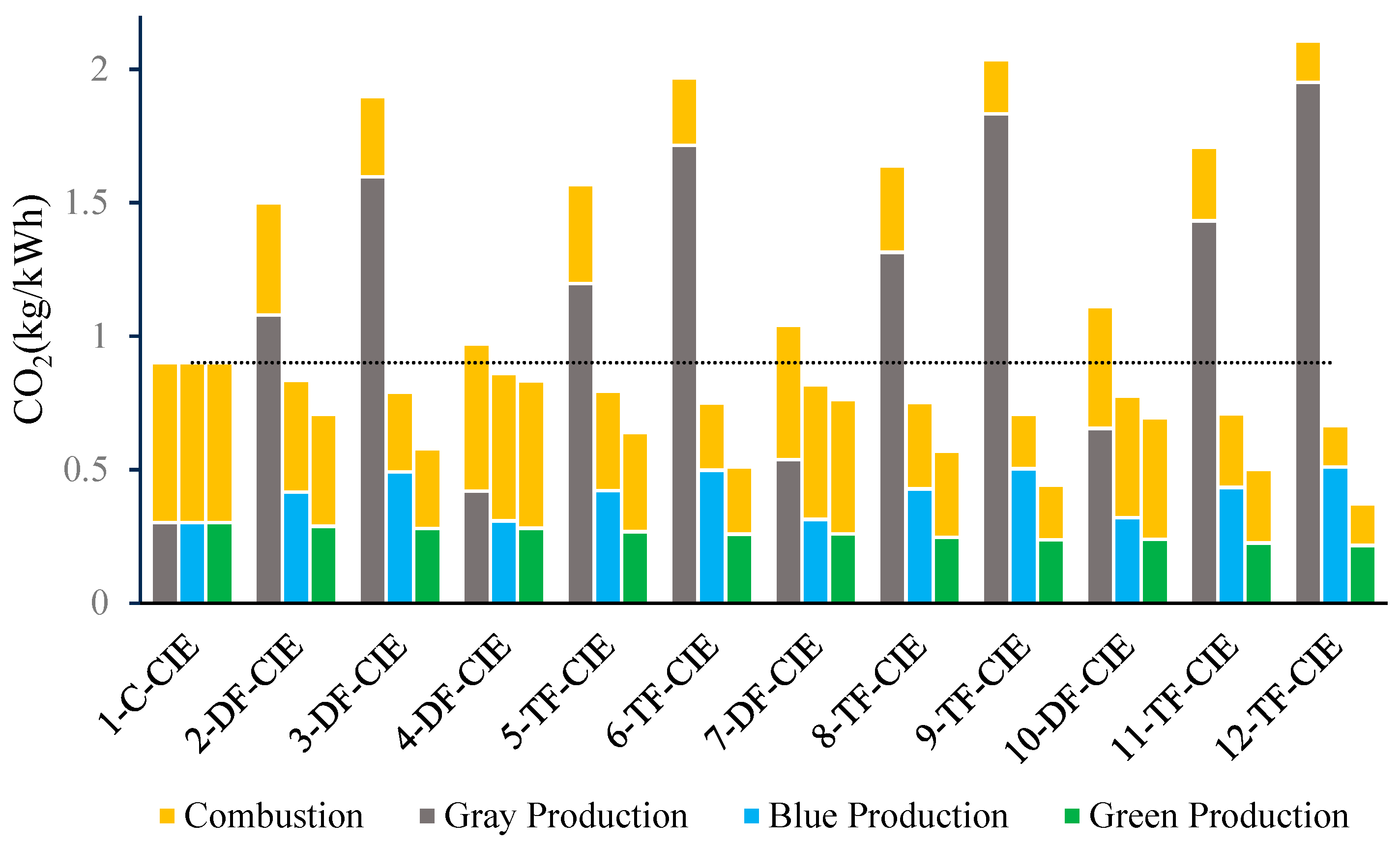

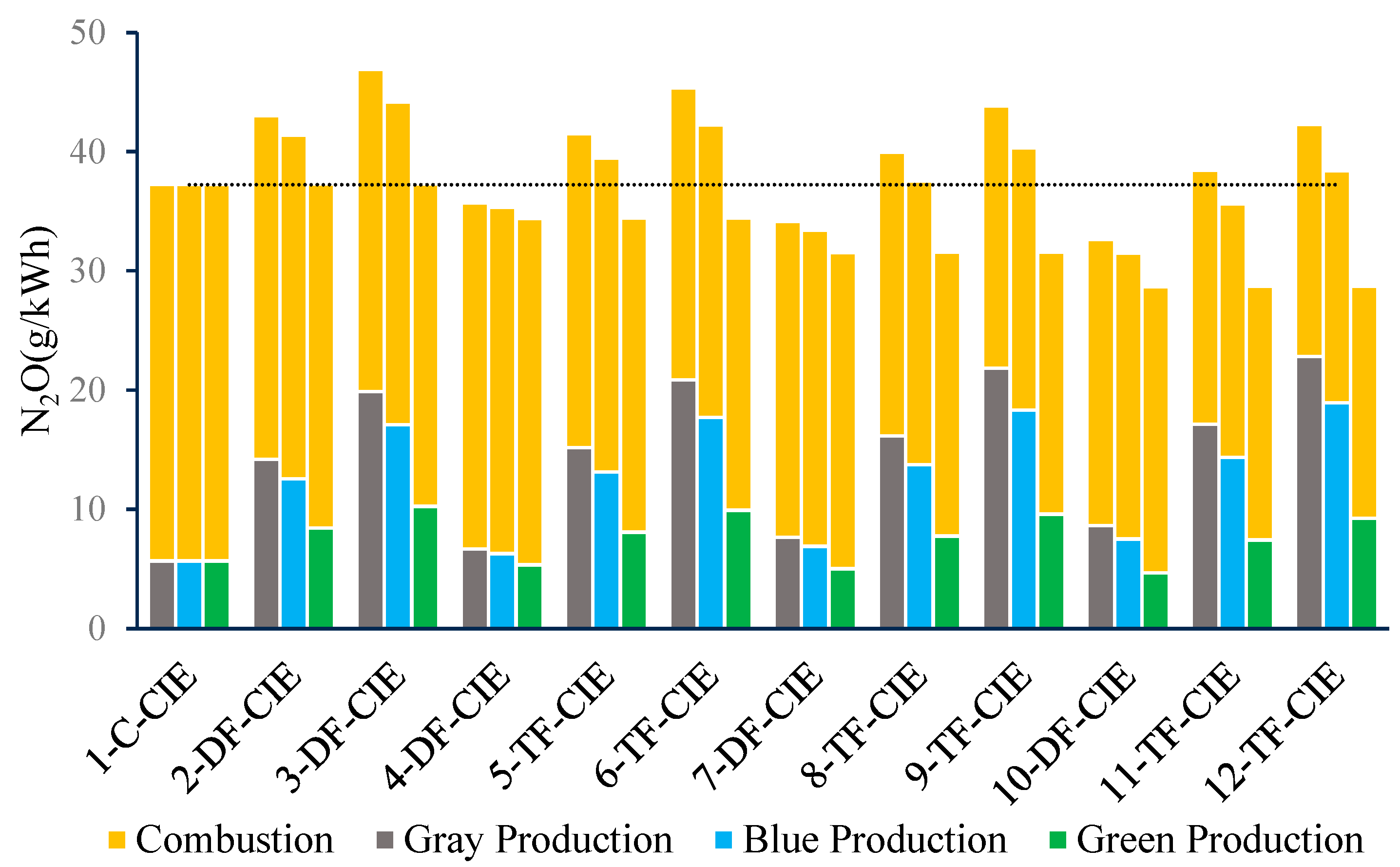

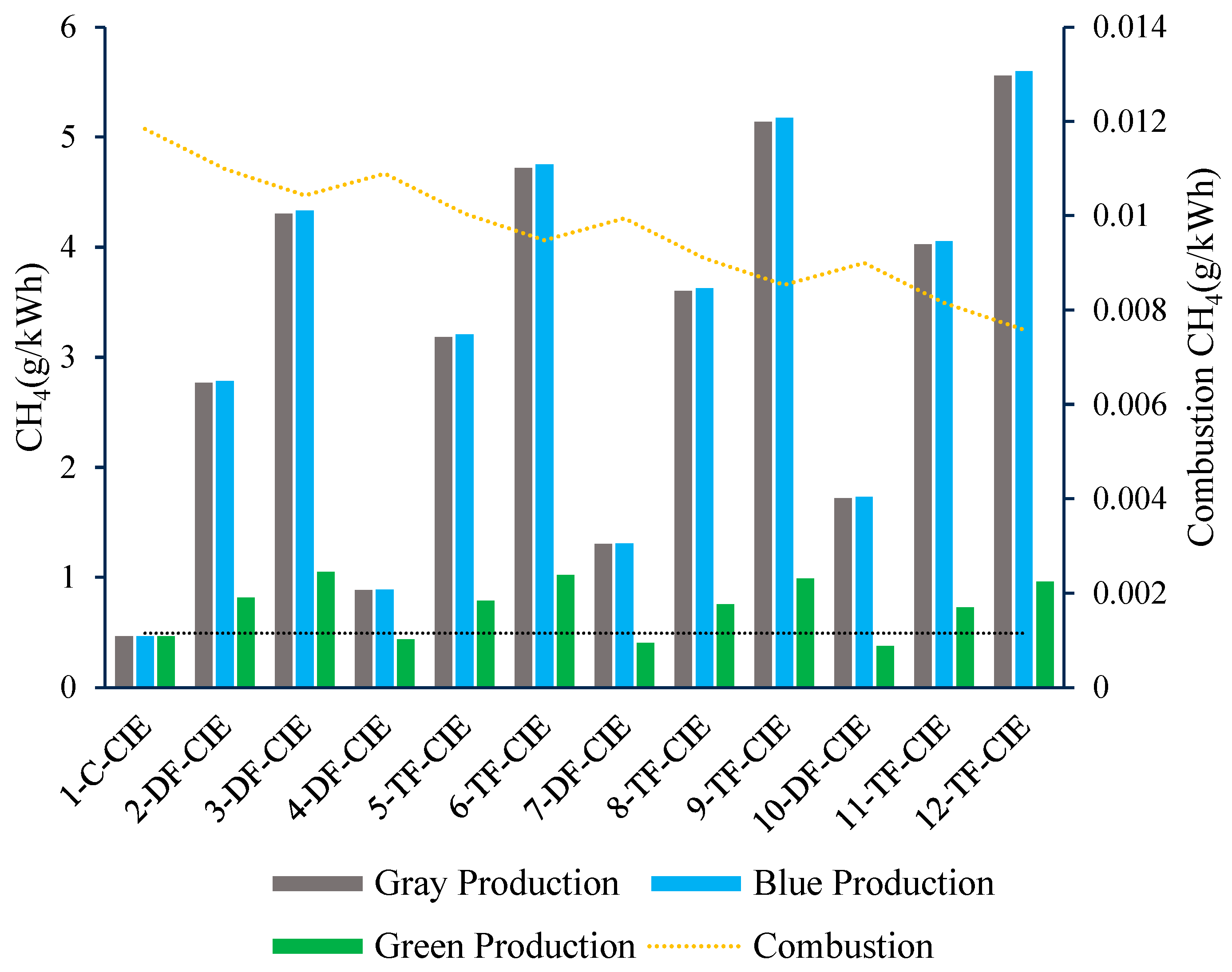

This study provides a comprehensive evaluation of fuel blend modes incorporating varying shares of hydrogen, ammonia, and MDO, focusing on their environmental performance—through combustion and production emissions—and economic feasibility via LCC analysis. The results clearly demonstrate that increasing the share of hydrogen and ammonia leads to significant reductions in combustion-related GHG emissions across CO2, N2O, and CH4 gases examined.

However, upstream emissions from gray and blue production pathways, especially for CH4 and N2O, can offset part of the environmental gains, highlighting the critical importance of clean fuel sourcing. Although nitrogen oxide emissions released during ammonia production are not included in the scope of this study due to a lack of data, it is intended to complete the data set in future studies due to the environmental risks caused by these gases. Among all options, green production consistently offers the lowest emissions, but incurs the highest LCC, often doubling the cost of conventional fossil-based pathways. While modes with high green fuel content (e.g., Modes 10–12) achieve the best environmental outcomes, their financial burden underscores the need for strong policy support, including carbon pricing, subsidies, and infrastructure development. Intermediate modes (e.g., Modes 5–8), which balance moderate shares of hydrogen and ammonia, emerge as promising transitional solutions by offering substantial emission reductions at more manageable cost levels.

However, the findings from the MCDM analysis indicated that optimal performance could be achieved with maximal hydrogen and minimal ammonia concentrations when all parameters were assessed collectively. The calorific value of hydrogen, almost thrice that of MDO, significantly decreased fuel consumption. Furthermore, its absence of carbon resulted in a substantial decrease in CO2 emissions. Due to efficient production techniques, emissions associated with production are notably minimal. The poor calorific value of ammonia increased fuel consumption, while its nitrogen concentration augmented NOx emissions. Moreover, owing to limitations in storage capacity and safety hazards, scenarios involving simultaneous utilization of both fuels are seen as more advantageous for the industry. Ultimately, the findings underscore that a successful maritime energy transition must holistically address both environmental and economic dimensions. Advancing green fuel technologies, reducing production costs, and optimizing engine systems for low-emission combustion will be essential to meet long-term decarbonization goals in the shipping sector. Tri-fuel is a flexible approach for harbor tugs, allowing operators to increase H2/NH3 usage when conditions allow, reducing emissions, and maintaining diesel availability for starts and peak tasks, while aligning with policy goals as low-carbon fuels become more accessible.

As a challenging and long-term process, maritime decarbonization can only be achieved through the successful alignment of multiple components and stakeholders. Although the implementation of MEPC 83 decisions has been decided to be adjourned in MEPC ES.2, which was held in 14–17 October 2025, they opened a new door into maritime decarbonization and provided a basis for the introduction of global market-based measurements (MBMs). As IMO adopts WtW and LCA approaches for realistic carbon pricing as well as for calculating the environmental impacts of fuels, preliminary studies are needed more than ever to guide future work. In this context, the findings of this study provide an important contribution to the efforts for maritime decarbonization, and it is planned to focus on carbon pricing calculations with WtW in the future.

Port authorities should consider transparent procurement with GHG intensity thresholds and safety gates. Pilot programs should be phased, with safety gates and screening metrics. Infrastructure and zoning plans should consider storage layout, ventilation, gas detection, spill containment, and standardized bunkering windows. Economic instruments like CAPEX grants, carbon pricing, and CfD/credit pass-throughs can be used to ease capital costs. An MRV framework and anonymized data can facilitate learning and procurement. Targeted training and joint HAZID/HAZOP drills can support workforce readiness and emergency preparedness.

A bench-scale tri-fuel (diesel–H2–NH3) test rig is planned for future work to monitor in-cylinder pressure and measure emissions (e.g., NOx, N2O, NH3 slip). Upon successful installation, it will be carried out validation campaigns to calibrate the combustion, efficiency, and emissions sub-models and verify the tri-fuel operating framework. The datasets will refine model parameters, uncertainty bounds, and update techno-economic and life-cycle results. In further stages, the test-rig results will be compared with real tugboat operational data obtained in port. As another future work, the harmonized WtW LCA–TEA–MCDM framework can be expanded to include methanol and LNG, as well as hybrid configurations where applicable, offering relevant benchmarks for policy analysis. Also, the LCA system boundary will be expanded to include transport-to-bunker stages as harmonized, high-resolution datasets for ammonia and hydrogen transportation become available—covering liquefied and compressed pathways, maritime/road/pipeline modes, terminal handling, conditioning (compression, liquefaction), boil-off, and venting. The expanded boundary will adopt uniform data structures and allocation rules to enhance comparability with future studies.