A Conceptual Framework of the Technological Integration of Industry 4.0 with Sustainability Concepts

Abstract

1. Introduction

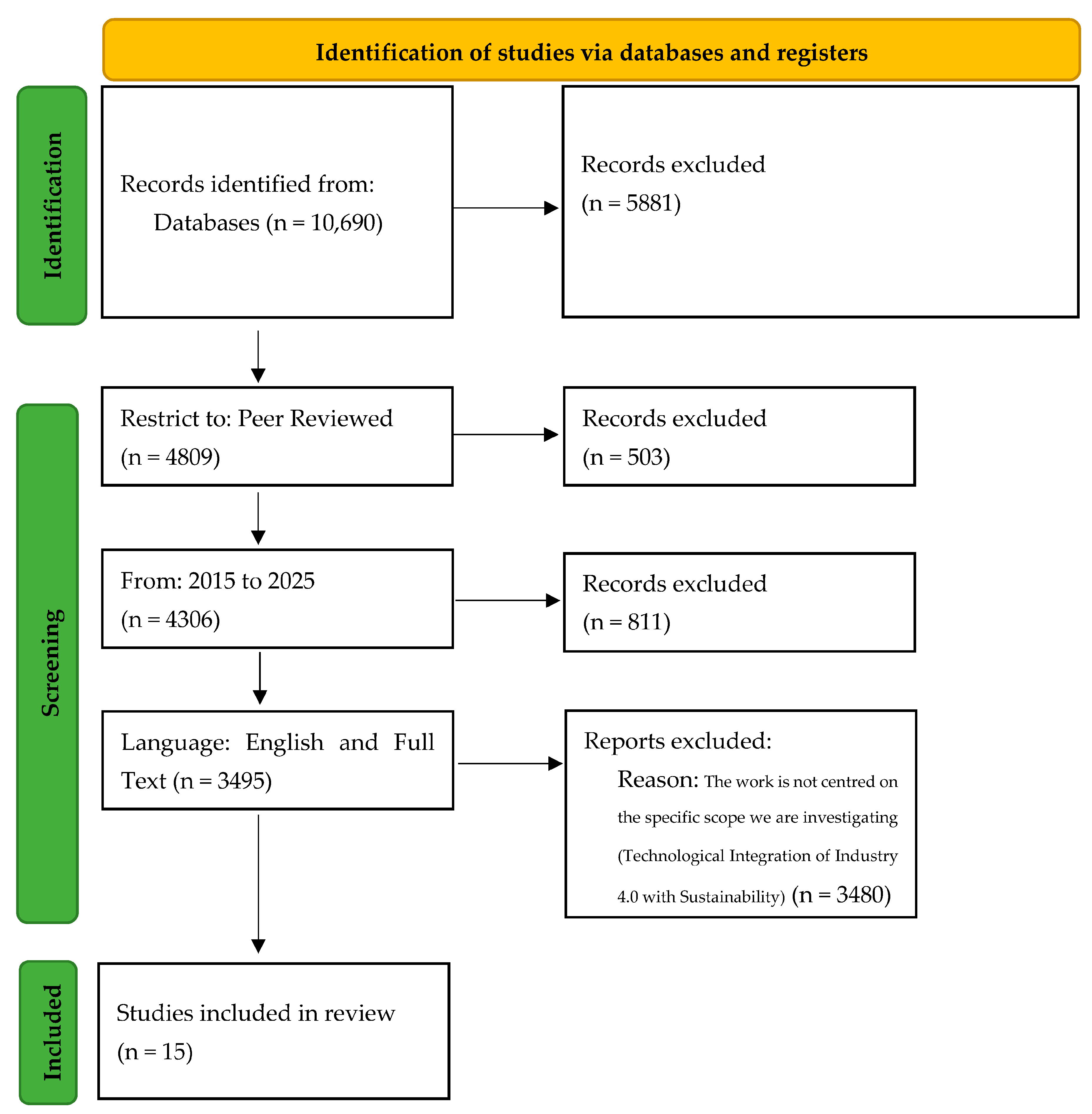

2. Systematic Review

3. Methodologies and Analysis

3.1. Methodology

3.2. Summary and Analysis of Selected Articles

- Big Data and Data Analytics (BDA)

- Simulation (SIM)

- Horizontal and Vertical Integration (HVI)

- Industrial Internet of Things (IIoT)

- Autonomous Robots (ROB)

- Cloud Computing (CLO)

- Cyber-Physical Systems and Security (CPS)

- Augmented Reality (ARL)

- Additive Manufacturing (AMF)

- On the one hand, to map the technological emphasis in the literature, highlighting which pillars of Industry 4.0 have been prioritized;

- On the other, to assess the depth of sustainable integration, verifying whether studies consider the three pillars of sustainability in a balanced manner or whether they prioritize only one dimension to the detriment of the others.

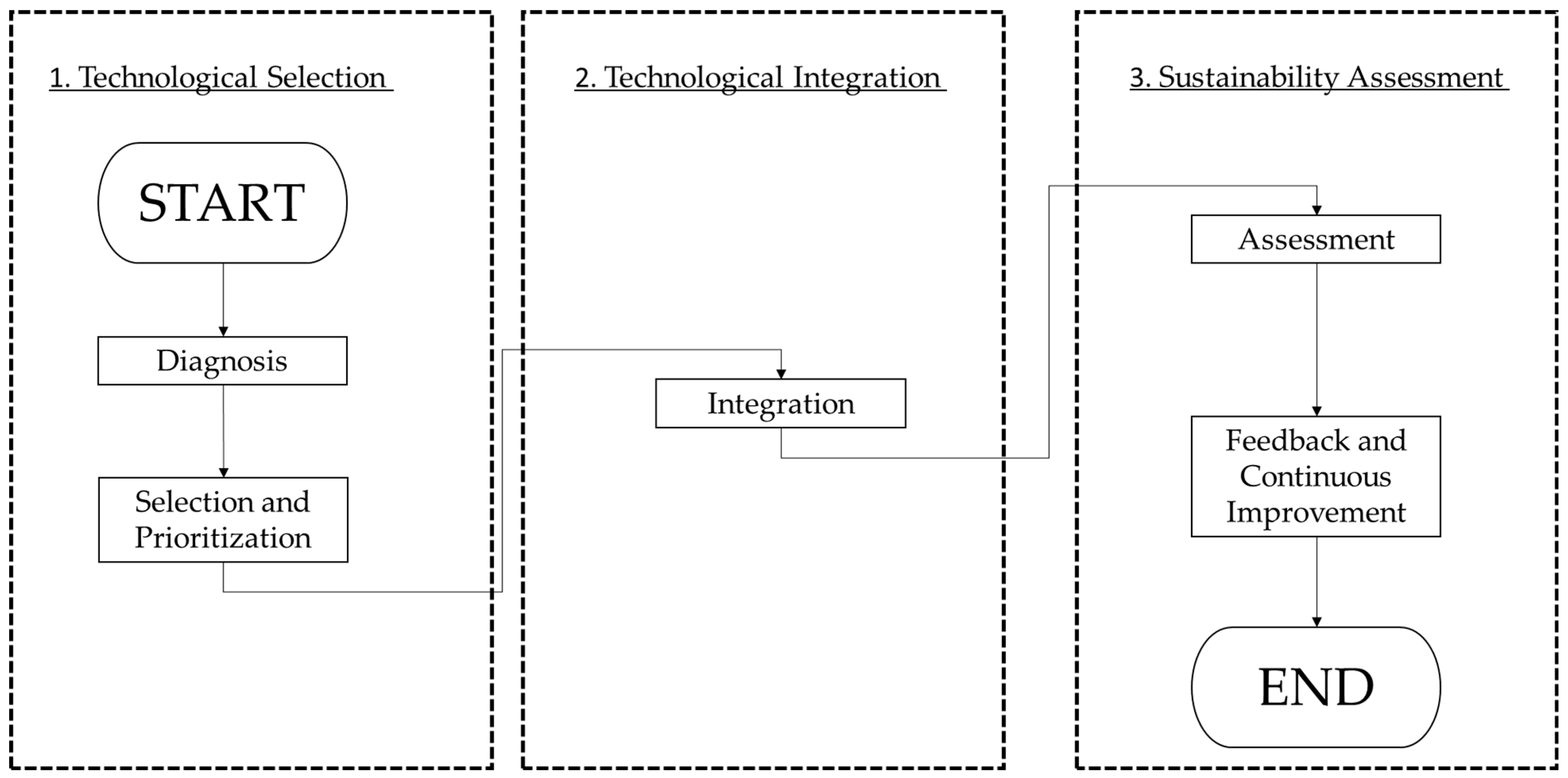

4. Development of the Framework

4.1. Framework Proposal

- Technological Selection—identification and prioritization of Industry 4.0 technologies most suitable for the industrial context under analysis;

- Technological Integration—exploration of complementarities and synergies between selected technologies, ensuring interoperability, security, and scalability;

- Sustainability Assessment—evaluation of the technological integration’s impacts on the three sustainability dimensions: environmental, economic, and social. Each technology, or combination of technologies, is assessed using practical sustainability indicators to ensure measurable and actionable outcomes. For the environmental dimension, this includes monitoring energy consumption, material waste, resource reuse, and pollutant emissions. For the economic dimension, indicators focus on cost reduction, operational efficiency, and return on investment. For the social dimension, the evaluation considers workplace safety, employee inclusion, skills development, and broader community impact. In other words, it is not sufficient to simply implement a technology, such as using IoT to monitor energy; the framework provides guidance on how to measure performance, adjust processes, and follow best practices to maximize positive sustainability outcomes.

- 1.

- Diagnosis—mapping organizational challenges, sustainability goals, and current technological maturity.

- 2.

- Selection and Prioritization—evaluation of Industry 4.0 technologies (e.g., IoT, Big Data, Additive Manufacturing) using multicriteria approaches that consider not only operational efficiency but also sustainability potential.

- 3.

- Integration—design of interoperable and secure systems that combine technologies to maximize performance and sustainability outcomes.

- 4.

- Assessment—definition and monitoring of quantitative and qualitative indicators to measure the impact of the integration on environmental, social, and economic pillars.

- 5.

- Feedback and Continuous Improvement—incorporation of results into the organizational strategy, allowing for technological adjustments, scalability, and alignment with evolving sustainability standards.

4.2. Characteristics and Benefits of the Framework

- Systemic Orientation—emphasizes the interdependence between technology and sustainability rather than treating them as separate dimensions.

- Multidimensional Evaluation—integrates environmental, economic, and social criteria to guarantee a holistic analysis of industrial transformation.

- Iterative Logic—adopts a cyclical and adaptive process, incorporating continuous monitoring and improvement of technological applications.

- Flexibility and Scalability—applicable across diverse industrial contexts, from small- and medium-sized enterprises to large-scale corporations, and adaptable to different levels of technological maturity.

- Alignment with International Standards—consistent with global agendas such as the United Nations Sustainable Development Goals (SDGs), ISO 14000 family (environmental management) [105], and RAMI 4.0 (Industry 4.0 architecture).

- Environmental Benefits: reduction in energy consumption, emissions, and industrial waste; promotion of circular economy practices such as recycling and remanufacturing.

- Economic Benefits: increased operational efficiency, cost reduction through predictive maintenance and optimized resource allocation, and enhanced resilience of value chains.

- Social Benefits: improved working conditions through automation of hazardous tasks, enhanced worker qualification supported by augmented reality and training technologies, and increased social responsibility and inclusiveness.

- Strategic Alignment—technological projects must be connected to corporate sustainability strategies, avoiding isolated initiatives with limited long-term impact.

- Lifecycle Perspective—decisions should consider the full lifecycle of products and processes, applying tools such as Life Cycle Assessment (LCA).

- Stakeholder Engagement—workers, suppliers, policymakers, and local communities should be involved from the planning phase to strengthen social acceptance and collaboration.

- Standardization and Interoperability—projects should adopt open standards to facilitate integration and scalability, reducing vendor lock-in.

- Circular Economy Principles—technological design should encourage resource efficiency, recyclability, and reusability of materials.

- Resilience and Risk Management—integration projects should anticipate risks related to cybersecurity, supply chain disruptions, and climate impacts, reinforcing organizational resilience.

- Continuous Monitoring—projects must embed indicators that allow for real-time tracking of technological performance and sustainability outcomes.

4.3. Framework Analysis in Case Studies

- Diagnosis: Identify areas where employee training programs are inefficient, knowledge retention is low, and engagement is limited.

- Technological Selection: Select augmented reality (AR) training modules, cloud-based learning management systems, and AI-driven feedback platforms to enhance training effectiveness and monitor employee progress.

- Technological Integration: Combine AR modules with cloud storage to enable accessible, interactive training sessions across multiple office locations. AI tools analyze engagement and learning outcomes, offering personalized recommendations.

- Sustainability Assessment: Evaluate the potential impacts on social sustainability, including enhanced employee satisfaction, better skills development, and reduced resource usage (e.g., printed training materials).

- Feedback and Continuous Improvement: Regularly update training modules based on AI feedback, fostering continuous learning and alignment with organizational sustainability goals.

- Diagnosis: Map high paper usage areas, repetitive manual processes, and bottlenecks in invoice processing and document management.

- Technological Selection: Implement document digitization, cloud-based storage, automated workflow systems, and data analytics platforms to optimize document flow and decision-making.

- Technological Integration: Integrate automated workflows with cloud storage and analytics dashboards, allowing real-time tracking of invoices, approvals, and budget allocations.

- Sustainability Assessment: Assess environmental sustainability (reduction in paper use), economic benefits (time and cost savings), and social impact (reduced administrative burden and improved work experience).

- Feedback and Continuous Improvement: Continuously monitor process efficiency, adjust workflows, and introduce new digital tools to enhance sustainability outcomes and departmental productivity.

- Diagnosis: Identify energy-intensive processes, underutilized digital resources, and areas prone to delays or errors.

- Technological Selection: Adopt IoT sensors for energy monitoring, AI-driven chatbots to automate routine customer interactions, and cloud platforms for digital ticket management.

- Technological Integration: Connect IoT sensors with cloud dashboards for real-time energy monitoring while integrating AI chatbots into existing customer service software to reduce repetitive tasks and improve response times.

- Sustainability Assessment: Focus on environmental sustainability (reduced energy consumption), economic sustainability (optimized staffing and operational costs), and social sustainability (enhanced customer experience and employee satisfaction).

- Feedback and Continuous Improvement: Adjust digital workflows based on performance indicators, expand chatbot functionalities, and incorporate insights to continuously enhance sustainability practices and operational efficiency.

4.4. Comparative Synthesis of the Framework

- HR Department: Integration of AR, AI, and cloud systems enhances employee skills, engagement, and knowledge management, addressing social sustainability.

- Finance and Administrative Department: Digitization, workflow automation, and analytics improve operational efficiency and reduce resource consumption, aligning with environmental and economic goals.

- Customer Service Department: IoT, AI chatbots, and cloud dashboards optimize energy use, reduce manual workload, and improve customer interactions, delivering multidimensional sustainability benefits.

- It links all technological pillars, avoiding fragmented or isolated technology adoption.

- It incorporates a structured methodology (diagnosis, selection, integration, assessment, feedback) that guides practical decision-making.

- It explicitly addresses all sustainability dimensions, ensuring balanced outcomes.

- It is flexible and adaptable to various departments and organizational contexts beyond traditional manufacturing environments.

5. Results

- Diagnosis: Identified skills gaps, training bottlenecks, and employee engagement challenges.

- Selection and Prioritization: AR-based training tools and AI-driven learning platforms were prioritized for their ability to deliver interactive, personalized learning experiences.

- Integration: AR tools were integrated with cloud platforms to enable real-time progress tracking, collaborative learning, and cross-departmental knowledge sharing.

- Assessment: Employee engagement, satisfaction, and learning progression were monitored using qualitative feedback and digital logs.

- Feedback and Continuous Improvement: Insights from performance data informed iterative adjustments to training programs, supporting continuous skill development.

- Diagnosis: Identified high levels of manual processing, paper consumption, and duplicated workflows.

- Selection and Prioritization: Big Data analytics, workflow automation software, and IoT-enabled energy monitoring were selected for their potential to streamline processes and reduce resource usage.

- Integration: Automated workflows were linked to cloud platforms for centralized monitoring, while IoT devices tracked energy consumption in office equipment.

- Assessment: Efficiency gains and reductions in paper use and energy consumption were monitored digitally.

- Feedback and Continuous Improvement: Adjustments were made to optimize workflows, enhance reporting accuracy, and align operational processes with sustainability goals.

- Diagnosis: Identified high call volumes, repetitive inquiries, and manual tracking of customer interactions.

- Selection and Prioritization: AI chatbots and integrated cloud dashboards were prioritized to automate routine tasks and optimize resource allocation.

- Integration: IoT-enabled dashboards connected service data with operational metrics, enabling real-time monitoring of customer interactions.

- Assessment: Key indicators included response times, customer satisfaction, and workload reduction.

- Feedback and Continuous Improvement: Continuous updates to chatbot knowledge bases and dashboard functionalities improved service efficiency and quality over time.

6. Discussions

- Big Data and IIoT are well-explored, particularly in manufacturing efficiency and environmental monitoring.

- Social sustainability, employee engagement, and administrative efficiency remain underrepresented.

- Augmented Reality, workflow automation, and cloud-based integration for service and administrative contexts are seldom addressed.

- Combining underrepresented technologies (e.g., AR, cloud collaboration, AI chatbots) with operational and sustainability goals.

- Addressing social sustainability systematically in HR and customer service departments.

- Providing an iterative, continuous improvement logic that ensures ongoing alignment with sustainability objectives.

- HR Department: Converges with literature emphasizing digital skill development but extends it by integrating AR and AI with social sustainability, highlighting employee engagement outcomes not widely discussed internationally.

- Finance and Administration: Aligns with studies on operational efficiency and energy monitoring, but introduces a multidimensional evaluation, linking cost reduction with environmental benefits and process optimization.

- Customer Service: Contrasts with traditional manufacturing-focused studies by showing how Industry 4.0 technologies can optimize service processes and reduce manual workload, demonstrating the framework’s versatility across sectors.

- Iterative Learning: Continuous feedback loops allow departments to adapt processes over time, a feature often absent in previous studies that report static interventions.

- Theoretical Contribution: Provides a systemic model integrating all Industry 4.0 pillars with sustainability principles, filling a gap in both conceptual and applied literature.

- Practical Contribution: Demonstrates actionable pathways for managers and practitioners to implement technology-driven sustainability strategies across administrative, financial, and HR departments—not only manufacturing contexts.

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Smith, J.; Brown, A. Industry 4.0 and the transformation of manufacturing systems. Int. J. Prod. Res. 2022, 60, 843–860. [Google Scholar] [CrossRef]

- Davis, L.; Walker, S.; Thompson, H. Digitalisation, value chains and global competitiveness: A study of Industry 4.0. J. Manuf. Syst. 2021, 58, 563–576. [Google Scholar] [CrossRef]

- Alsaoudi, T.; Acquaye, A.; Swarnakar, V.; Khalfan, M. Exploring the intersection of Industry 4.0 technologies, circular economy, and sustainable performance: A systematic literature review and future research directions. Heliyon 2025, 11, e43529. [Google Scholar] [CrossRef]

- Wilson, R.; Green, P.; Harris, M. Artificial intelligence and sustainable manufacturing: Opportunities and challenges. Sustain. Prod. Consum. 2023, 35, 222–234. [Google Scholar] [CrossRef]

- Martínez, P.; García, E.; Rodríguez, M. Additive manufacturing and industrial sustainability: A review. J. Clean. Prod. 2022, 330, 129766. [Google Scholar] [CrossRef]

- Tavares-Lehmann, A.T.; Varum, C. Industry 4.0 and Sustainability: A Bibliometric Literature Review. Sustainability 2021, 13, 3493. [Google Scholar] [CrossRef]

- Beier, G.; Niehoff, S.; Hoffmann, M. Industry 4.0: A step towards achieving the SDGs? A critical literature review. Discov. Sustain. 2021, 2, 22. [Google Scholar] [CrossRef]

- Espina-Romero, L.; Vilchez Pirela, R.A.; Gutiérrez Hurtado, H. Challenges and Opportunities in the Implementation of AI in Manufacturing: A Bibliometric Analysis. Science 2024, 6, 60. [Google Scholar] [CrossRef]

- Jamwal, V.; Mittal, R.K.; Zafar, A. Industry 4.0 and circular economy: A review and a conceptual framework. Procedia Comput. Sci. 2021, 185, 113–119. [Google Scholar] [CrossRef]

- Ejsmont, K.; Grzybowska, K.; Lasota, J. Integrating Industry 4.0 technologies for sustainable manufacturing: A systematic review. Sustainability 2020, 12, 3150. [Google Scholar] [CrossRef]

- Martín Gómez, A.M.; Agote Garrido, A.; Lama, J.R. A Framework for Sustainable Manufacturing: Integrating Industry 4.0 Technologies with Industry 5.0 Values. Sustainability 2024, 16, 1364. [Google Scholar] [CrossRef]

- Rossi, L.; Pirotta, M.; Canetta, L.; Sorlini, M. Framework to Support Digital and Sustainable Manufacturing: From Research Environments to Industrial Applications. In Proceedings of the 2025 IEEE International Conference on Engineering, Technology, and Innovation (ICE/ITMC), Valencia, Spain, 16–19 June 2025; IEEE: New York, NY, USA, 2025. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, Y.; Zhang, H. Big Data analytics in Industry 4.0: Opportunities for sustainable operations. J. Clean. Prod. 2022, 345, 131094. [Google Scholar] [CrossRef]

- Abbasnejad, B.; Soltani, S.; Karamoozian, A.; Gu, N. A systematic literature review on the integration of Industry 4.0 technologies in sustainability improvement of transportation construction projects: State-of-the-art and future directions. Smart Sustain. Built Environ. Press 2024. [Google Scholar] [CrossRef]

- Brennan, R.W.; Lyu, G. Towards Sustainable Cyber-Physical Manufacturing Systems. IFAC-PapersOnLine 2024, 58, 345–350. [Google Scholar] [CrossRef]

- Patrício, L.; Costa, L.; Varela, L.; Ávila, P. Sustainable Implementation of Robotic Process Automation Based on a Multi-Objective Mathematical Model. Sustainability 2023, 15, 15045. [Google Scholar] [CrossRef]

- Patrício, L.; Varela, L.; Silveira, Z. Framework for Integrating Requirements Engineering and DevOps Practices in Robotic Process Automation with a Focus on Optimizing Human–Computer Interaction. Appl. Sci. 2025, 15, 3485. [Google Scholar] [CrossRef]

- Patrício, L.; Varela, L.; Silveira, Z.; Felgueiras, C.; Pereira, F. A Framework for Integrating Robotic Process Automation with Artificial Intelligence Applied to Industry 5.0. Appl. Sci. 2025, 15, 7402. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Industry 4.0, digitisation, and sustainability excellence: Nine future research directions. Technol. Forecast. Social. Change 2021, 163, 120451. [Google Scholar] [CrossRef]

- Torbacki, W. Towards Sustainable Industry 4.0: An MCDA-Based Assessment Framework for Manufacturing and Logistics. Sustainability 2025, 17, 5082. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, Y.; Zhou, X. Smart manufacturing and sustainability: A bibliometric analysis of Industry 4.0 research. Sustainability 2022, 14, 10783. [Google Scholar] [CrossRef]

- Nguyen, T.; Kim, J.; Kim, J. Digital twin technology for circular economy and sustainable manufacturing: A review. J. Manuf. Syst. 2023, 66, 451–466. [Google Scholar] [CrossRef]

- Kumar, A.; Gupta, M.; Shankar, R. Technology integration for sustainable manufacturing: A review and future research agenda. J. Clean. Prod. 2023, 383, 135259. [Google Scholar] [CrossRef]

- Likert, J.; Smith, R.; Wilson, P. Additive and subtractive manufacturing for sustainability: A systematic review. Manuf. Rev. 2021, 8, 12. [Google Scholar] [CrossRef]

- Rossi, M.; Locatelli, G.; Broccardo, P.; Galati, F. The role of AI in sustainable smart factories: Evidence from European manufacturers. Sustainability 2023, 15, 3892. [Google Scholar] [CrossRef]

- dos Santos, C.A.F.; Zen, A.C. Value creation and capture in innovation ecosystems. Int. J. Innov. 2022, 10, 21470. [Google Scholar] [CrossRef]

- Verma, P.; Dahiya, R.; Bansal, P.; Singh, R.; Kumar, V. Blockchain applications in supply-chain traceability for the circular economy. Comput. Ind. Eng. 2022, 169, 108148. [Google Scholar] [CrossRef]

- Moreno, M.; Valencia, J. Augmented reality and worker–machine interaction: Enhancing safety and inclusivity in Industry 4.0. Hum. Factors Ergon. Manuf. 2022, 32, 511–528. [Google Scholar] [CrossRef]

- Çınar, Z.M.; Nuhu, A.A.; Zeeshan, Q.; Korhan, O.; Asmael, M.; Safaei, B. Machine Learning in Predictive Maintenance towards Sustainable Smart Manufacturing in Industry 4.0. Sustainability 2020, 12, 8211. [Google Scholar] [CrossRef]

- Kleindorfer, P.; Van Wassenhove, L. Closed-loop supply chains and Industry 4.0: Designing for remanufacturing and reuse. Prod. Oper. Manag. 2019, 28, 2021–2038. [Google Scholar] [CrossRef]

- Monostori, L.; Kádár, B.; Bauernhansl, T.; Kondoh, S.; Kumara, S.; Reinhart, G.; Sauer, O.; Schuh, G.; Sihn, W.; Ueda, K. Cyber-physical systems in manufacturing. CIRP Ann. 2016, 65, 621–641. [Google Scholar] [CrossRef]

- Liu, Y.; Li, B.; Zhang, X.; Zhao, Y. Energy consumption optimisation in smart factories using IoT and AI. Energy Rep. 2022, 8, 678–692. [Google Scholar] [CrossRef]

- Hu, S.; Li, N.; Wang, Q. Life-cycle assessment and Industry 4.0 technologies: A meta-analysis. J. Clean. Prod. 2022, 354, 131624. [Google Scholar] [CrossRef]

- Caiado, R.; Scavarda, L.F.; Azevedo, B.; De Mattos Nascimento, D.L.; Quelhas, O.L.G. Challenges and Benefits of Sustainable Industry 4.0 for Operations and Supply Chain Management—A Framework Headed toward the 2030 Agenda. Sustainability 2022, 14, 830. [Google Scholar] [CrossRef]

- Chatterjee, S.; Ghosh, D.; Roy, S.; Chakrabarti, S. Human-centric Industry 4.0 and the implications for socio-economic sustainability. Sustainability 2023, 15, 2097. [Google Scholar] [CrossRef]

- Meshcheryakova, T.; Bisht, Y.S.; Dixit, S.; Chidananda, K.; Kumari, N.; Garg, D. Augmented Reality and AI in Smart Manufacturing: An Empirical Investigation. BIO Web Conf. 2024, 86, 01066. [Google Scholar] [CrossRef]

- Zhang, L.; Zhou, Y.; Zhou, Y.; Wen, Y.; Goh, M. Big Data-driven circular economy: Opportunities and challenges. Resour. Conserv. Recycl. 2023, 184, 106489. [Google Scholar] [CrossRef]

- Zenezini, G.; Lagorio, A.; Mangano, G.; Pinto, R.; Rafele, C. Implementing Digital Twins in Supply Chain Management: A Maturity Model. IFAC-PapersOnLine 2025, 59, 1516–1521. [Google Scholar] [CrossRef]

- Herrmann, J.; Thiede, S.; Rösch, J.; Hengstebeck, M. Usability and sustainability: A review of augmented reality in production systems. Procedia CIRP 2022, 110, 263–268. [Google Scholar] [CrossRef]

- McKinsey, E.; Dorffer, C. Circular economy, Industry 4.0 and sustainability in the automotive sector: Case studies and empirical evidence. J. Clean. Prod. 2022, 361, 132456. [Google Scholar] [CrossRef]

- Nguyen, P.; Tran, Q.; Le, T. Sustainability performance metrics in smart manufacturing: Development and validation. Sustain. Prod. Consum. 2023, 35, 1017–1031. [Google Scholar] [CrossRef]

- Aigbogun, O.; Kalam, A.; Miraz, M.H.H.; Ya’u, A.; Ha Jin, H.; Hasan, M.T.; Sarkar, J. Sustainable supply chain visibility management on the ground of blockchain awareness: A systematic literature review. Multidiscip. Rev. 2025, 8, e2025266. [Google Scholar] [CrossRef]

- El-Kassar, A.; Singh, S. Green innovation and Industry 4.0 technologies: An empirical investigation. Int. J. Prod. Econ. 2023, 258, 108497. [Google Scholar] [CrossRef]

- Dosso, M. Technological readiness in Europe. In Industry 4.0 and Regional Transformations; Routledge: London, UK, 2020; pp. 214–237. [Google Scholar] [CrossRef]

- Khan, S.; Singh, P.; Kumar, A. Mapping interoperability in Industry 4.0 ecosystems: Implications for circular manufacturing. J. Manuf. Appl. Sci. 2024, 14, 9648. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, X.; Li, P. Cyber-physical systems for sustainable industrial processes: A systematic review. J. Manuf. Syst. 2022, 63, 225–240. [Google Scholar]

- Morales, R.; Sanchez, F.; Gutierrez, D. Additive manufacturing and environmental sustainability: Review and prospects. J. Clean. Prod. 2022, 338, 130–148. [Google Scholar]

- Nguyen, T.; Pham, H.; Le, Q. IoT-based energy monitoring in smart factories: Sustainability assessment. Sustain. Energy Technol. Assess. 2021, 46, 101–119. [Google Scholar]

- Wu, J.; Chen, L.; Xu, Y. Smart manufacturing and circular economy: Integration for sustainable production. Resour. Conserv. Recycl. 2022, 178, 106–122. [Google Scholar]

- Alves, R.; Santos, M.; Pereira, J. Digital twins and sustainability performance in manufacturing. Comput. Ind. 2022, 139, 103–118. [Google Scholar]

- He, W.; Li, Q.; Tan, R. Big Data analytics in sustainable supply chain management: A review. Int. J. Prod. Res. 2022, 60, 2321–2343. [Google Scholar]

- Lopez, M.; Fernandez, P.; Garcia, J. Artificial intelligence for predictive maintenance and energy efficiency: Evidence from Industry 4.0. J. Clean. Prod. 2023, 382, 135–150. [Google Scholar]

- Patel, K.; Sharma, A. Sustainable manufacturing through AI and machine learning: Systematic review. Sustain. Prod. Consum. 2022, 31, 45–63. [Google Scholar]

- Li, H.; Chen, J.; Zhang, L. Cloud computing and Industry 4.0: Implications for sustainable manufacturing. J. Ind. Inf. Integr. 2021, 22, 125–138. [Google Scholar]

- Rodriguez, A.; Fernandez, L. Integrating AR in manufacturing for social sustainability: A systematic review. Comput. Ind. Eng. 2022, 164, 135–150. [Google Scholar]

- Tan, C.; Xu, D.; Wang, Y. Collaborative robotics and social responsibility in Industry 4.0. J. Manuf. Technol. Manag. 2022, 33, 501–525. [Google Scholar]

- Cheng, S.; Li, Z.; Zhang, Y. Industry 4.0 technologies and circular economy: Conceptual linkages and applications. Sustain. Prod. Consum. 2021, 29, 101–120. [Google Scholar]

- Ng, P.; Wong, K.; Lee, T. Additive manufacturing in sustainable supply chains: A systematic review. J. Clean. Prod. 2022, 334, 1309–1326. [Google Scholar]

- Kim, J.; Park, S.; Lee, D. 3D printing and environmental sustainability: Impacts and opportunities. Resour. Conserv. Recycl. 2022, 180, 106–124. [Google Scholar]

- Huang, F.; Zhou, X.; Wang, H. On-demand production and resource efficiency: Role of additive manufacturing. Sustain. Energy Technol. Assess. 2022, 51, 102–119. [Google Scholar]

- Smith, R.; Johnson, M. Digital transformation in sustainable manufacturing: Evidence and trends. J. Manuf. Syst. 2023, 65, 220–242. [Google Scholar]

- Zhou, W.; Chen, Y.; Liu, L. Industry 4.0 and green supply chain integration: Systematic review. Sustain. Prod. Consum. 2022, 31, 75–92. [Google Scholar]

- Ali, S.; Khan, M.; Rahman, A. Collaborative robots for social sustainability: Systematic evidence. J. Manuf. Technol. Manag. 2022, 33, 543–565. [Google Scholar]

- Moreno, J.; Gonzalez, R. AR and worker training in smart factories: A review. Comput. Ind. Eng. 2022, 164, 153–172. [Google Scholar]

- Wang, Y.; Liu, Z.; Zhou, H. Human-robot collaboration for sustainable operations: A review. Robot. Comput.-Integr. Manuf. 2022, 74, 102–120. [Google Scholar]

- Perez, L.; Torres, F.; Martinez, S. Augmented reality applications for workplace safety in Industry 4.0. Saf. Sci. 2022, 154, 107–125. [Google Scholar]

- Singh, P.; Gupta, R.; Kumar, V. AI-driven optimisation for sustainable manufacturing: Evidence from industrial case studies. J. Clean. Prod. 2022, 370, 145–163. [Google Scholar]

- Choi, H.; Lee, S.; Park, J. Big Data applications for environmental monitoring in smart factories. Sustain. Energy Technol. Assess. 2022, 53, 115–132. [Google Scholar]

- Nguyen, Q.; Tran, T.; Pham, L. Conceptual frameworks for Industry 4.0 and sustainability: Review and analysis. J. Ind. Inf. Integr. 2023, 29, 120–138. [Google Scholar]

- Garcia, A.; Ramirez, J. Sustainability assessment frameworks for Industry 4.0: Systematic review. Sustain. Prod. Consum. 2023, 34, 61–80. [Google Scholar]

- Hernandez, P.; Lopez, D. Empirical applications of Industry 4.0 technologies for sustainability outcomes. J. Clean. Prod. 2023, 380, 140–158. [Google Scholar]

- Fernandez, M.; Santos, R.; Oliveira, P. Methodological approaches for integrating Industry 4.0 and sustainability: Evidence from case studies. Comput. Ind. Eng. 2023, 167, 110–130. [Google Scholar]

- Kaur, R.; Singh, S.; Sharma, P. Industrial adoption of smart technologies for sustainable operations: Review and perspectives. Int. J. Prod. Res. 2023, 61, 4112–4134. [Google Scholar]

- Han, J.; Park, K.; Kim, S. Cross-sectoral applications of Industry 4.0 for sustainability. J. Manuf. Syst. 2023, 66, 260–282. [Google Scholar]

- Liu, Y.; Wu, T.; Chen, J. Computational simulations for assessing Industry 4.0 sustainability impacts. Robot. Comput.-Integr. Manuf. 2023, 76, 120–138. [Google Scholar]

- Zhang, J.; Li, H.; Wang, S. Simulation-based approaches for sustainable smart manufacturing. Sustain. Prod. Consum. 2023, 36, 105–123. [Google Scholar]

- Patel, A.; Kumar, R.; Sharma, A. Conceptual models linking Industry 4.0 technologies to sustainability. J. Clean. Prod. 2023, 385, 150–169. [Google Scholar]

- Martinez, R.; Torres, L.; Gonzalez, F. Integrative frameworks for Industry 4.0 and the triple bottom line. J. Ind. Inf. Integr. 2023, 30, 140–160. [Google Scholar]

- Chen, X.; Li, Y.; Wang, Q. Dynamic models for technological adoption and sustainability in Industry 4.0 contexts. Comput. Ind. Eng. 2023, 168, 115–135. [Google Scholar]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; The PRISMA Group. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef] [PubMed]

- Elkington, J. Cannibals with Forks: The Triple Bottom Line of 21st Century Business; Capstone: Oxford, UK, 1997. [Google Scholar]

- World Commission on Environment and Development (WCED). Our Common Future; Oxford University Press: Oxford, UK, 1987. [Google Scholar]

- Kagermann, H. Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0: Securing the Future of German Manufacturing Industry. In Final Report of the Industrie 4.0 Working Group; Acatech—National Academy of Science and Engineering: Frankfurt am Main, Germany, 2013. [Google Scholar]

- Lasi, H.; Fettke, P.; Kemper, H.-G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Mourtzis, D.; Tsoubou, S.; Angelopoulos, J. Otimização da confiabilidade de células robóticas com base em gêmeos digitais e manutenção preditiva. Electronics 2023, 12, 1999. [Google Scholar] [CrossRef]

- Agostinelli, S.; Marrella, A.; Mecella, M. Towards Intelligent Robotic Process Automation for BPMers. arXiv 2021, arXiv:2001.00804. [Google Scholar] [CrossRef]

- Jiménez-Ramírez, A.; Reijers, H.A.; Barba, I.; Del Valle, C. A Method to Improve the Early Stages of the Robotic Process Automation Lifecycle. Lect. Notes Bus. Inf. Process. 2021, 406, 3–18. [Google Scholar] [CrossRef]

- Kokina, J.; Blanchette, S. Early Evidence of Digital Labor in Accounting: Innovation with Robotic Process Automation. Int. J. Account. Inf. Syst. 2019, 35, 100431. [Google Scholar] [CrossRef]

- Taqi, H.M.M.; Nayeem, I.; Bari, A.B.M.M.; Anam, M.Z.; Ali, S.M. Addressing challenges to cloud manufacturing in Industry 4.0 environment using an integrated approach: Implications for sustainability. Green Technol. Sustain. 2025, 3, 100166. [Google Scholar] [CrossRef]

- Dolci, V.; Bigliardi, B.; Petroni, A.; Pini, B.; Filippelli, S.; Tagliente, L. Integrating Industry 4.0 and Circular Economy: A Conceptual Framework for Sustainable Manufacturing. Procedia Comput. Sci. 2024, 232, 1711–1720. [Google Scholar] [CrossRef]

- Prayitno, K.A.; Wicaksono, H. Optimizing the Sustainability of Collaborative Logistics in Urban Area through Ontologies and Causal Artificial Intelligence: A Conceptual Framework. Procedia CIRP 2024, 130, 1070–1076. [Google Scholar] [CrossRef]

- Mohan, S.V.; Katakojwala, R. The circular chemistry conceptual framework: A way forward to sustainability in Industry 4.0. Curr. Opin. Green Sustain. Chem. 2021, 28, 100434. [Google Scholar] [CrossRef]

- Zhao, T.; Song, C.; Yu, J.; Xing, L.; Xu, F.; Li, W.; Wang, Z. Leveraging Immersive Digital Twins and AI-Driven Decision Support Systems for Sustainable Water Reserves Management: A Conceptual Framework. Sustainability 2025, 17, 3754. [Google Scholar] [CrossRef]

- Tutore, I.; Parmentola, A.; di Fiore, M.C. A conceptual model of artificial intelligence effects on circular economy actions. Corp. Soc. Responsib. Environ. Manag. 2024, 31, 4772–4782. [Google Scholar] [CrossRef]

- Liao, M.; Lan, K.; Yao, Y. Sustainability implications of artificial intelligence in the chemical industry: A conceptual framework. J. Ind. Ecol. 2022, 26, 164–182. [Google Scholar] [CrossRef]

- Bibri, S.E.; Alexandre, A.; Sharifi, A.; Krogstie, J. Environmentally sustainable smart cities and their converging AI, IoT, and big data technologies and solutions: An integrated approach to an extensive literature review. Energy Inform. 2023, 6, 9. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.; Misra, S.C.; Singh, G. Leveraging Additive Manufacturing for Enhanced Supply Chain Resilience and Sustainability: A Strategic Integration Framework. Glob. J. Flex. Syst. Manag. 2024, 25, 343–368. [Google Scholar] [CrossRef]

- Elghaish, F.; Matarneh, S.T.; Edwards, D.J.; Pour Rahimian, F.; El-Gohary, H.; Ejohwomu, O. Applications of Industry 4.0 digital technologies towards a construction circular economy: Gap analysis and conceptual framework. Constr. Innov. 2022, 22, 647–670. [Google Scholar] [CrossRef]

- Jaaron, A.A.M.; Backhouse, C.J. Can Industry 4.0 hold the answer for mitigating intertemporal tensions in sustainable manufacturing? A conceptual model. Technol. Anal. Strateg. Manag. 2023, 35, 949–961. [Google Scholar] [CrossRef]

- Abubakr, M.; Abbas, A.T.; Tomaz, I.; Soliman, M.S.; Luqman, M.; Hegab, H. Sustainable and Smart Manufacturing: An Integrated Approach. Sustainability 2020, 12, 2280. [Google Scholar] [CrossRef]

- Jankovic, S.D.; Curovic, D.M. Strategic Integration of Artificial Intelligence for Sustainable Businesses: Implications for Data Management and Human User Engagement in the Digital Era. Sustainability 2023, 15, 15208. [Google Scholar] [CrossRef]

- Soltovski, R.; Volpe Rodrigues, T.; Pontes, J.; Resende, L.M.M. Theoretical framework of the Industry 4.0 risks from sustainability perspective. Rev. Compet. Sustentabilidade—ComSus 2021, 8, 1–20. [Google Scholar] [CrossRef]

- Ejaz, M.R.; Hegedűs, D. Designing a Conceptual Framework for Industry 4.0 Technologies to Enable Circular Economy Ecosystem. Manag. Glob. Transit. 2023, 21, 121–148. [Google Scholar] [CrossRef]

- Díaz de Junguitu, A.; Allur, E. The Adoption of Environmental Management Systems Based on ISO 14001, EMAS, and Alternative Models for SMEs: A Qualitative Empirical Study. Sustainability 2019, 11, 7015. [Google Scholar] [CrossRef]

| PICO Component | Definition/Association | Brief Description |

|---|---|---|

| P (Population) | Industrial organizations implementing or planning to implement Industry 4.0 technologies (IoT, Big Data, AI, Additive Manufacturing, CPS, AR, Advanced Robotics) | Represents the group of interest for the study, focusing on real-world industrial contexts where technological adoption impacts operational efficiency, environmental sustainability, and social outcomes- |

| I (Intervention) | Integration of Industry 4.0 technologies with sustainability principles | Refers to the purposeful implementation of technologies aimed at optimizing performance while aligning with environmental, economic, and social objectives. This integration acts as an enabler of sustainable industrial development. |

| C (Comparison) | Organizations with comprehensive integration strategies vs. those with partial or non-sustainability-focused adoption | Provides a contrast to assess differential impacts on resource efficiency, emissions, economic performance, and social outcomes. Helps identify factors that facilitate or hinder effective integration. |

| O (Outcome) | Identification of best practices and evaluation of operational, social, and environmental impacts | Defines the expected results of the study, guiding the development of a conceptual framework for sustainable technological integration in Industry 4.0 contexts. |

| Research Strings | |

| Group 1 | “Systemic View” OR “Holistic View” OR “Integrated Approach” OR “Conceptual Framework” OR “Framework Proposal” OR “Theoretical Framework” OR “Reference Model” OR “Integration Model” OR “Conceptual Model” OR “Methodological Framework” OR “Architectural Framework” OR “Systemic Integration” OR “Strategic Integration” OR “Operational Framework” OR “Analytical Framework” OR “Design Framework” OR “Implementation Framework” OR “Structural Model” OR “Organizational Model” OR “Process Framework” OR “Sustainability Framework” OR “Digital Integration Model” OR “Technological Integration Model” OR “Enterprise Architecture” OR “Innovation Framework” OR “Decision-Making Framework” OR “Performance Assessment Framework” OR “Industrial Integration Model” OR “Cyber-Physical Integration Model” OR “Smart Manufacturing Framework” |

| AND | |

| Group 2 | “Industry 4.0” OR “Industrie 4.0” OR “I4.0” OR “Smart Manufacturing” OR “Intelligent Manufacturing” OR “Digital Manufacturing” OR “Advanced Manufacturing” OR “Cyber-Physical Systems” OR “CPS” OR “Industrial Internet of Things” OR “IIoT” OR “Connected Industry” OR “Big Data” OR “Data Analytics” OR “Artificial Intelligence” OR “AI” OR “Machine Learning” OR “Deep Learning” OR “Cloud Computing” OR “Edge Computing” OR “Fog Computing” OR “Robotics” OR “Autonomous Robots” OR “Collaborative Robots” OR “Cobots” OR “Additive Manufacturing” OR “3D Printing” OR “Rapid Prototyping” OR “Augmented Reality” OR “AR” OR “Virtual Reality” OR “VR” OR “Simulation” OR “Digital Twin” OR “Smart Factory” OR “Industrial Automation” OR “Industrial Cyber-Physical Systems” OR “Intelligent Systems” OR “Predictive Maintenance” OR “Industrial AI” OR “Smart Production” |

| AND | |

| Group 3 | “Sustainability” OR “Sustainable” OR “Social Sustainability” OR “Environmental Sustainability” OR “Economic Sustainability” OR “Sustainable Development” OR “Corporate Social Responsibility” OR “CSR” OR “Circular Economy” OR “Green Practices” OR “Eco-friendly” OR “Resource Efficiency” OR “Sustainable Innovation” OR “Sustainable Production” OR “Sustainable Practices” OR “Climate Action” OR “Environmental Management” OR “Green Economy” OR “Responsible Consumption” OR “Renewable Resources” OR “Low-carbon Economy” OR “Carbon Footprint” OR “Clean Technology” OR “Sustainable Business” OR “Sustainable Policy” OR “Sustainable Growth” OR “Energy Efficiency” OR “Sustainable Supply Chain” OR “Environmental Protection” OR “Social Responsibility” |

| Title | Keywords (KW) | Abstract (AB) |

|---|---|---|

| n = 282 articles | n = 361 articles | n = 10,047 articles |

| Title | Set 1 | Set 2 | Set 3 |

|---|---|---|---|

| Initial result: | 282 | 361 | 10047 |

| 1—Restrict to: Peer Reviewed | 103 | 55 | 4651 |

| 2—Type of fonts: Academic Journals; Conference Materials; Books | 88 | 54 | 4640 |

| 3—From: 2015 to 2025 | 88 | 51 | 4167 |

| 4—Language: English | 87 | 14 | 3611 |

| 5—Restrict to: Full Text | 82 | 13 | 3400 |

| Article | 1—BDA | 2—SIM | 3—HVI | 4—IIoT | 5—ROB | 6—CLO | 7—CPS | 8—ARL | 9—AMF | % Pillars p/Article |

|---|---|---|---|---|---|---|---|---|---|---|

| [90] | X | X | X | X | X | 56% | ||||

| [91] | X | X | X | X | X | X | X | 78% | ||

| [92] | X | X | X | X | 44% | |||||

| [93] | X | X | X | X | 44% | |||||

| [94] | X | X | X | X | X | X | X | 78% | ||

| [95] | X | 11% | ||||||||

| [96] | X | X | 22% | |||||||

| [97] | X | X | X | X | X | X | X | 78% | ||

| [98] | X | X | X | X | X | 56% | ||||

| [99] | X | X | X | X | X | X | X | X | X | 100% |

| [100] | X | X | X | X | X | X | 67% | |||

| [101] | X | X | X | X | X | X | X | X | X | 100% |

| [102] | X | X | X | 33% | ||||||

| [103] | X | X | X | X | X | X | 67% | |||

| [104] | X | X | X | X | X | X | X | 78% | ||

| % Articles p/pillar | 100% | 47% | 73% | 80% | 47% | 73% | 87% | 20% | 20% |

| Article | Environmental | Social | Economic | % Pillars p/Article |

|---|---|---|---|---|

| [90] | X | X | 67% | |

| [91] | X | X | 67% | |

| [92] | X | X | X | 100% |

| [93] | X | X | 67% | |

| [94] | X | 33% | ||

| [95] | X | X | X | 100% |

| [96] | X | X | 67% | |

| [97] | X | X | X | 100% |

| [98] | X | 33% | ||

| [99] | X | X | 67% | |

| [100] | X | X | 67% | |

| [101] | X | X | X | 100% |

| [102] | X | X | 67% | |

| [103] | X | X | 67% | |

| [104] | X | X | 67% | |

| % Articles p/pillar | 87% | 40% | 87% |

| Framework Pillars | Literature Coverage | Framework Coverage | Notes |

|---|---|---|---|

| Big Data and Analytics | High | High | Framework consolidates integration with IoT and CPS |

| Simulation | Medium | High | Emphasizes iterative testing and operational feedback |

| Horizontal/Vertical Integration | Medium | High | Focus on interoperability across departments |

| IIoT | High | High | Monitors energy/resource use and operational efficiency |

| Autonomous Robots | Medium | Medium | Applicable to administrative tasks (automation of repetitive work) |

| Cloud Computing | High | High | Supports multi-department collaboration and scalability |

| CPS and Security | High | High | Ensures cyber-physical connectivity and data security |

| Augmented Reality | Low | High | Used in HR for training, enhancing engagement and social sustainability |

| Additive Manufacturing | Low | Medium | Applicable to resource-saving prototypes and process optimization |

| Sustainability Dimension | Literature Coverage | Framework Coverage | Notes |

|---|---|---|---|

| Environmental | 87% | High | Reduced energy use, paperless workflows, waste reduction |

| Economic | 87% | High | Increased efficiency, operational cost savings, optimized workflows |

| Social | 40% | High | Focus on HR development, employee engagement, service quality |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Patrício, L.; Varela, L.; Silveira, Z. A Conceptual Framework of the Technological Integration of Industry 4.0 with Sustainability Concepts. Sustainability 2025, 17, 10160. https://doi.org/10.3390/su172210160

Patrício L, Varela L, Silveira Z. A Conceptual Framework of the Technological Integration of Industry 4.0 with Sustainability Concepts. Sustainability. 2025; 17(22):10160. https://doi.org/10.3390/su172210160

Chicago/Turabian StylePatrício, Leonel, Leonilde Varela, and Zilda Silveira. 2025. "A Conceptual Framework of the Technological Integration of Industry 4.0 with Sustainability Concepts" Sustainability 17, no. 22: 10160. https://doi.org/10.3390/su172210160

APA StylePatrício, L., Varela, L., & Silveira, Z. (2025). A Conceptual Framework of the Technological Integration of Industry 4.0 with Sustainability Concepts. Sustainability, 17(22), 10160. https://doi.org/10.3390/su172210160