Multi-Objective Sustainable Operational Optimization of Fluid Catalytic Cracking

Abstract

1. Introduction

2. Problem Formulation

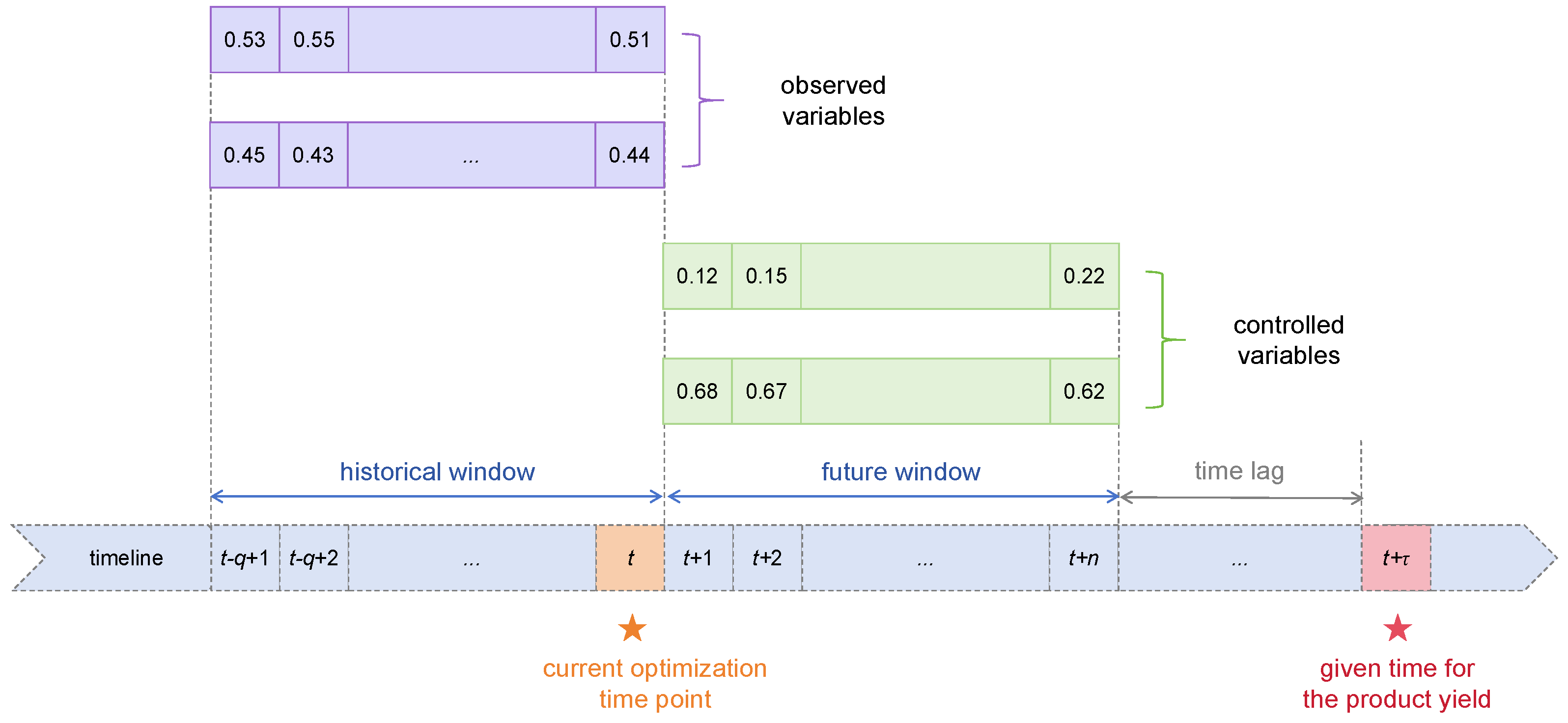

2.1. Problem Description

2.2. Optimization Model

3. Proposed Algorithm

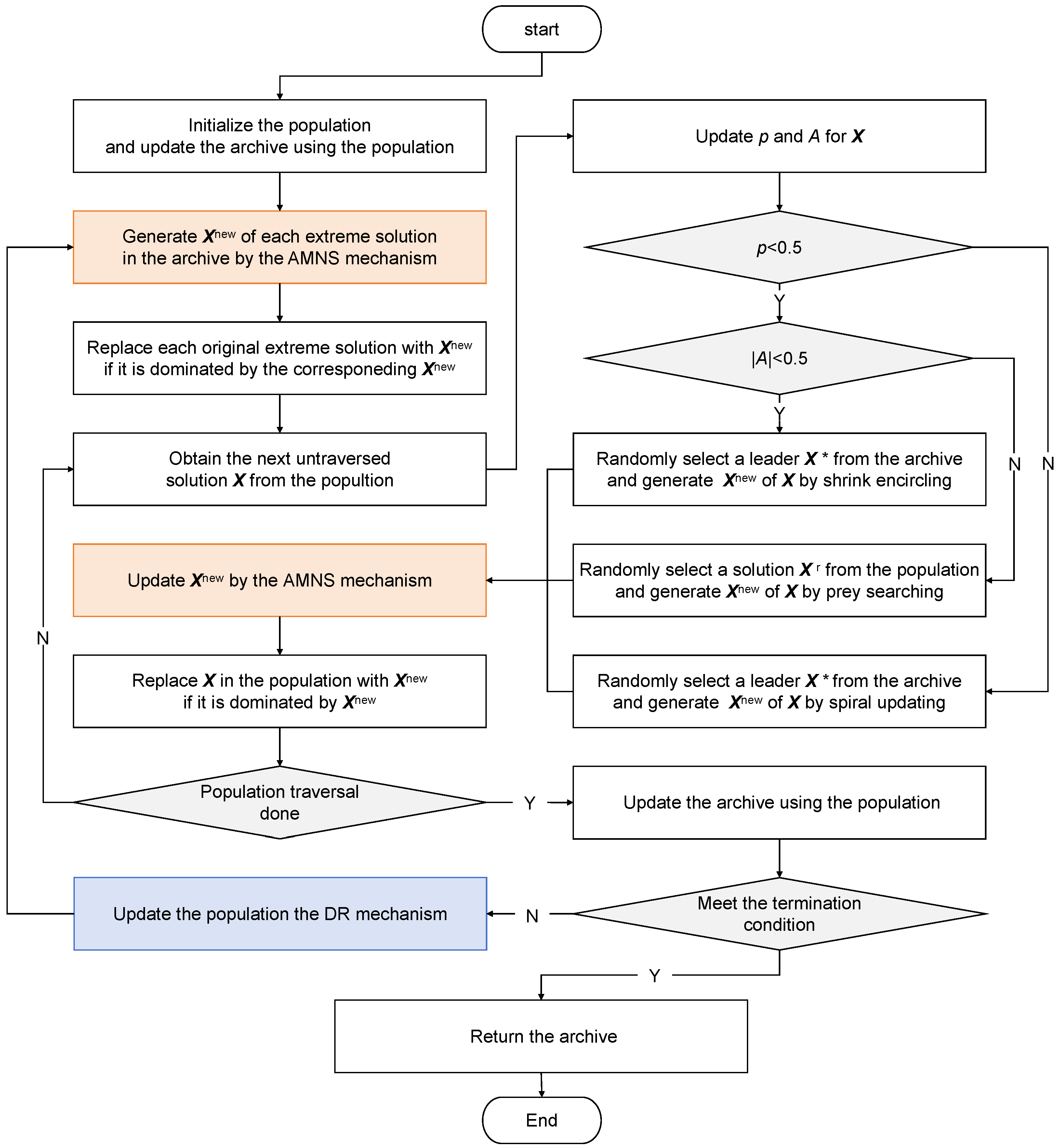

3.1. IMOWOA Framework

3.2. Population Initialization

3.3. Adaptive Multi-Neighborhood Search Mechanism

| Algorithm 1 AMNS mechanism |

| Require: the solution , |

| the current iteration count g, |

| the maximum number of iterations |

|

3.4. Dynamic Restart Mechanism

| Algorithm 2 DR mechanism |

| Require: the population , |

| the current iteration count g, |

| the maximum number of iterations , |

| the stagnation iteration count for objective 1 , |

| the stagnation iteration count for objective 2 , |

|

3.5. Archive Maintenance

4. Experiment Results

4.1. Evaluation Metric and Test Instance

4.2. Performance Comparison

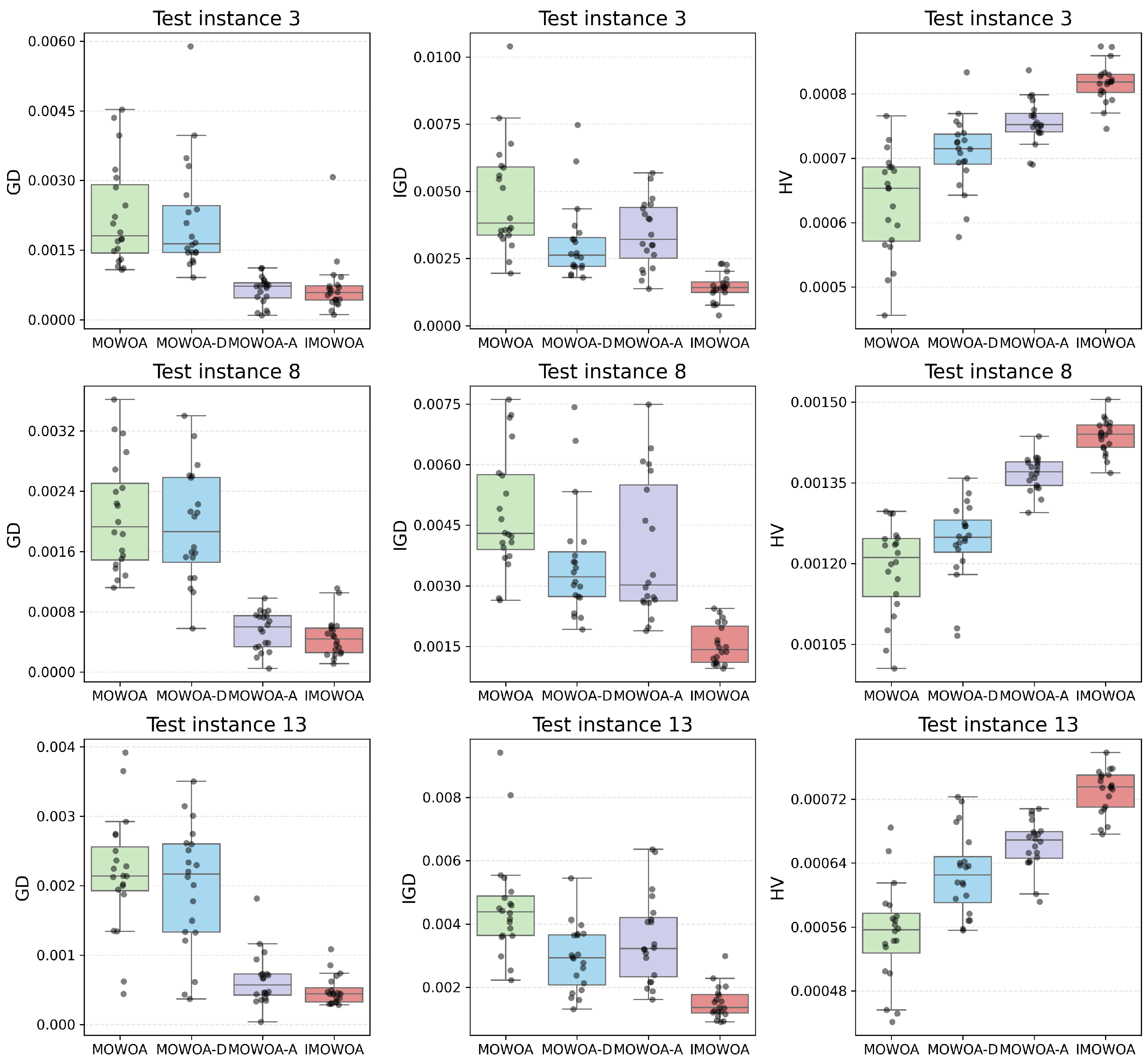

4.3. Ablation Study

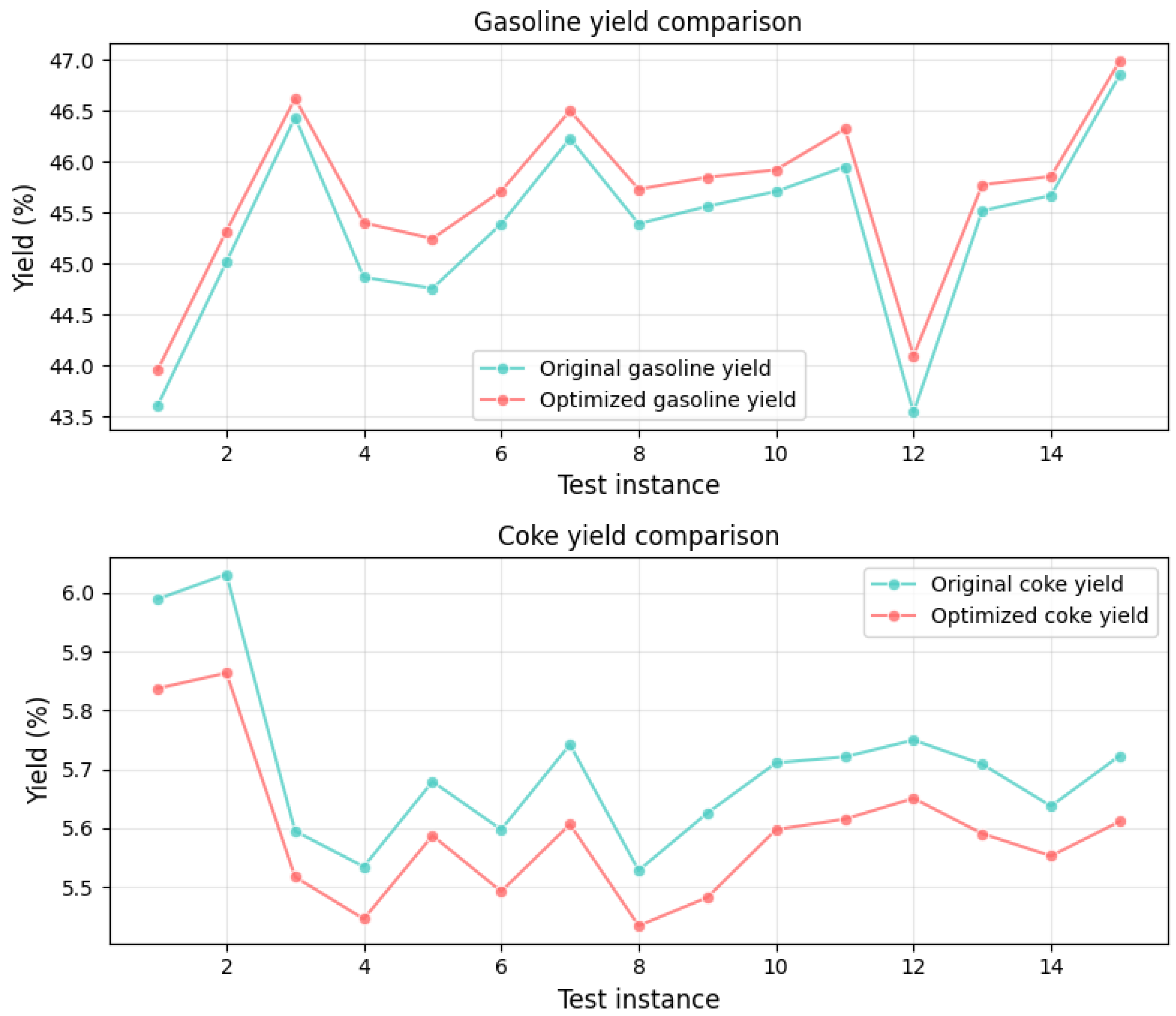

4.4. Result Evaluation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, Y.; Lu, S.; Yan, X.; Gao, S.; Cui, X.; Cui, Z. Life cycle assessment of petroleum refining process: A case study in China. J. Clean. Prod. 2020, 256, 120422. [Google Scholar] [CrossRef]

- Choy, Y.K.; Onuma, A.; Lee, K.E. The Nexus of Industrial–Urban Sustainability, the Circular Economy, and Climate–Ecosystem Resilience: A Synthesis. Sustainability 2025, 17, 2620. [Google Scholar] [CrossRef]

- Sundaramoorthy, S.; Kamath, D.; Nimbalkar, S.; Price, C.; Wenning, T.; Cresko, J. Energy Efficiency as a Foundational Technology Pillar for Industrial Decarbonization. Sustainability 2023, 15, 9487. [Google Scholar] [CrossRef]

- Chen, J.; Zhu, J.; Qin, X.; Xie, W. Reducing Octane Number Loss in Gasoline Refining Process by Using the Improved Sparrow Search Algorithm. Sustainability 2023, 15, 6571. [Google Scholar] [CrossRef]

- Bechara, C.A.; Alnouri, S.Y. Energy assessment strategies in carbon-constrained industrial clusters. Energy Convers. Manag. 2022, 254, 115204. [Google Scholar] [CrossRef]

- Johnson, E.; Vadenbo, C. Modelling Variation in Petroleum Products’ Refining Footprints. Sustainability 2020, 12, 9316. [Google Scholar] [CrossRef]

- Simayi, M.; Hao, Y.; Li, J.; Shi, Y.; Ren, J.; Xi, Z.; Xie, S. Historical volatile organic compounds emission performance and reduction potentials in China’s petroleum refining industry. J. Clean. Prod. 2021, 292, 125810. [Google Scholar] [CrossRef]

- Talaei, A.; Oni, A.O.; Ahiduzzaman, M.; Roychaudhuri, P.S.; Rutherford, J.; Kumar, A. Assessment of the impacts of process-level energy efficiency improvement on greenhouse gas mitigation potential in the petroleum refining sector. Energy 2020, 191, 116243. [Google Scholar] [CrossRef]

- Zhao, S.; Song, Q.; Liu, L.; Li, J.; Zhao, D. Uncovering the lifecycle carbon emissions and its reduction pathways: A case study of petroleum refining enterprise. Energy Convers. Manag. 2024, 301, 118048. [Google Scholar] [CrossRef]

- Ferella, F.; D’Adamo, I.; Leone, S.; Innocenzi, V.; De Michelis, I.; Vegliò, F. Spent FCC E-Cat: Towards a Circular Approach in the Oil Refining Industry. Sustainability 2019, 11, 113. [Google Scholar] [CrossRef]

- Bai, P.; Etim, U.J.; Yan, Z.; Mintova, S.; Zhang, Z.; Zhong, Z.; Gao, X. Fluid catalytic cracking technology: Current status and recent discoveries on catalyst contamination. Catal. Rev. 2019, 61, 333–405. [Google Scholar] [CrossRef]

- Khaldi, M.K.; Al-Dhaifallah, M.; Taha, O. Artificial intelligence perspectives: A systematic literature review on modeling, control, and optimization of fluid catalytic cracking. Alex. Eng. J. 2023, 80, 294–314. [Google Scholar] [CrossRef]

- Wang, L.; Long, J.; Li, X.; Peng, H.; Ye, Z. Industrial units modeling using self-attention network based on feature selection and pattern classification. Chem. Eng. Res. Des. 2023, 200, 176–185. [Google Scholar] [CrossRef]

- Luan, H.; Wu, C.; Xiu, G.; Ju, F.; Ling, H.; Pan, H. Study on emission factors of FCC flue gas pollutants in petroleum refineries. Environ. Sci. Pollut. Res. 2023, 29, 33400–33410. [Google Scholar] [CrossRef] [PubMed]

- Huang, M.; Zheng, Y.; Li, S.; Xu, S. Enhancing Transient Event Trigger Real-Time Optimization for Fluid Catalytic Cracking Unit Operation with Varying Feedstock. Ind. Eng. Chem. Res. 2019, 58, 20340–20356. [Google Scholar] [CrossRef]

- Otten-Weinschenker, J.; Mönnigmann, M. Robust optimization of stiff delayed systems: Application to a fluid catalytic cracking unit. Optim. Eng. 2022, 23, 2025–2050. [Google Scholar] [CrossRef]

- Santander, O.; Kuppuraj, V.; Harrison, C.A.; Baldea, M. Integrated Production Planning and Model Predictive Control of a Fluidized Bed Catalytic Cracking-Fractionator Unit. Ind. Eng. Chem. Res. 2023, 62, 2752–2767. [Google Scholar] [CrossRef]

- John, Y.M.; Patel, R.; Mujtaba, I.M. Maximization of propylene in an industrial FCC unit. Appl. Petrochem. Res. 2018, 8, 79–95. [Google Scholar] [CrossRef]

- Chen, C.; Lu, N.; Wang, L.; Xing, Y. Intelligent selection and optimization method of feature variables in fluid catalytic cracking gasoline refining process. Comput. Chem. Eng. 2021, 150, 107336. [Google Scholar] [CrossRef]

- Chen, Q.; Ding, J.; Chai, T.; Pan, Q. Evolutionary Optimization Under Uncertainty: The Strategies to Handle Varied Constraints for Fluid Catalytic Cracking Operation. IEEE Trans. Cybern. 2022, 52, 2249–2262. [Google Scholar] [CrossRef]

- Li, T.; Long, J.; Zhao, L.; Du, W.; Qian, F. A bilevel data-driven framework for robust optimization under uncertainty – applied to fluid catalytic cracking unit. Comput. Chem. Eng. 2022, 166, 107989. [Google Scholar] [CrossRef]

- Wang, P.; Yang, C.; Tian, X.; Cao, Y. Multi-objective optimization of two-stage-riser fluidized catalytic pyrolysis process for maximizing propylene. In Proceedings of the 2016 35th Chinese Control Conference (CCC), Chengdu, China, 27–29 July 2016; pp. 9471–9474. [Google Scholar] [CrossRef]

- Tai, X.Y.; Ocone, R.; Christie, S.D.; Xuan, J. Multi-objective optimisation with hybrid machine learning strategy for complex catalytic processes. Energy AI 2022, 7, 100134. [Google Scholar] [CrossRef]

- Jarullah, A.T.; Awad, N.A.; Mujtaba, I.M. Optimal design and operation of an industrial fluidized catalytic cracking reactor. Fuel 2017, 206, 657–674. [Google Scholar] [CrossRef]

- Liu, X.; Liu, Y.; He, X.; Xiao, M.; Jiang, T. Multi-Objective Nonlinear Programming Model for Reducing Octane Number Loss in Gasoline Refining Process Based on Data Mining Technology. Processes 2021, 9, 721. [Google Scholar] [CrossRef]

- Bohorquez, J.F.C.; Tovar, L.P.; Maciel, M.R.W.; Melo, D.C.; Filho, R.M. Surrogate-model-based, particle swarm optimization, and genetic algorithm techniques applied to the multiobjective operational problem of the fluid catalytic cracking process. Chem. Eng. Commun. 2020, 207, 612–631. [Google Scholar] [CrossRef]

- Wan, L.; Deng, K.; Li, X.; Zhao, L.; Long, J. Multi-objective optimization strategy for industrial catalytic cracking units: Kinetic model and enhanced SPEA-2 algorithm with economic, CO2, and SO2 emission considerations. Chem. Eng. Sci. 2023, 282, 119331. [Google Scholar] [CrossRef]

- Liu, Y.; Chu, M.; Ye, Q.; Li, J.; Han, D. Multi-objective optimization of FCC separation system based on NSGA-II. Chem. Eng. Sci. 2025, 302, 120829. [Google Scholar] [CrossRef]

- Khaldi, M.K.; Al-Dhaifallah, M.; Taha, O.; Mahmood, T.; Alharbi, A. Computational modeling of a Fluid Catalytic Cracking Unit. Ain Shams Eng. J. 2025, 16, 103661. [Google Scholar] [CrossRef]

- Wang, Y.; Chu, J.; Lu, K. Neural Network Prediction of Gasoline and Diesel Production at Catalytic Cracking Main Fractionator. In Proceedings of the 2019 International Conference on Machine Learning, Big Data and Business Intelligence (MLBDBI), Taiyuan, China, 8–10 November 2019; pp. 233–236. [Google Scholar] [CrossRef]

- Bengio, Y.; Simard, P.; Frasconi, P. Learning long-term dependencies with gradient descent is difficult. IEEE Trans. Neural Netw. 1994, 5, 157–166. [Google Scholar] [CrossRef]

- Almuhaini, S.H.; Sultana, N. Bayesian-Optimization-Based Long Short-Term Memory (LSTM) Super Learner Approach for Modeling Long-Term Electricity Consumption. Sustainability 2023, 15, 13409. [Google Scholar] [CrossRef]

- Zhang, X.; Zou, Y.; Li, S.; Xu, S. Product Yields Forecasting for FCCU via Deep Bi-directional LSTM Network. In Proceedings of the 2018 37th Chinese Control Conference (CCC), Wuhan, China, 25–27 July 2018; pp. 8013–8018. [Google Scholar] [CrossRef]

- Bannoud, M.A.; da Silva, C.A.M.; Martins, T.D. Applications of metaheuristic optimization algorithms in model predictive control for chemical engineering processes: A systematic review. Annu. Rev. Control 2024, 58, 100973. [Google Scholar] [CrossRef]

- Mirjalili, S.; Lewis, A. The Whale Optimization Algorithm. Adv. Eng. Softw. 2016, 95, 51–67. [Google Scholar] [CrossRef]

- Zhang, P.; Liu, X.; Yi, Z.; He, Q. Improved Multi-Objective Beluga Whale Optimization Algorithm for Truck Scheduling in Open-Pit Mines. Sustainability 2024, 16, 6939. [Google Scholar] [CrossRef]

- Sapnken, F.E.; Khalili Tazehkandgheshlagh, A.; Salomon Diboma, B.; Hamaidi, M.; Gopdjim Noumo, P.; Wang, Y.; Gaston Tamba, J. A whale optimization algorithm-based multivariate exponential smoothing grey-holt model for electricity price forecasting. Expert Syst. Appl. 2024, 255, 124663. [Google Scholar] [CrossRef]

- Pang, S.; Guo, S.; Wang, L.; Li, Y.; Li, X.; Liu, Z. Mass personalization-oriented integrated optimization of production task splitting and scheduling in a multi-stage flexible assembly shop. Comput. Ind. Eng. 2021, 162, 107736. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Zitzler, E.; Laumanns, M.; Thiele, L. SPEA2: Improving the strength Pareto evolutionary algorithm. Tik Rep. 2001, 103. [Google Scholar]

- Mirjalili, S.; Saremi, S.; Mirjalili, S.M.; dos S. Coelho, L. Multi-objective grey wolf optimizer: A novel algorithm for multi-criterion optimization. Expert Syst. Appl. 2016, 47, 106–119. [Google Scholar] [CrossRef]

| Variable No. | Observed Variable | Controlled Variable |

|---|---|---|

| 1 | Regenerated catalyst temperature | Reaction temperature |

| 2 | Spent catalyst temperature | Reaction pressure |

| 3 | Oil gas temperature | Regenerator pressure |

| 4 | Gasoline yield | Lifting steam flow rate |

| 5 | Coke yield | Liquid feedstock temperature |

Test Instance | NSGA-II (Mean/Std) | SPEA-2 (Mean/Std) | MOGWO (Mean/Std) | IMOWOA (Mean/Std) |

|---|---|---|---|---|

|

GD

IGD HV |

GD

IGD HV |

GD

IGD HV |

GD

IGD HV | |

| 1 | (+,+,+) (+,+,+) (+,+,+) | |||

| 2 | (+,+,+) (+,+,+) (+,+,+) | |||

| 3 | (+,+,+) (+,+,+) (+,+,+) | |||

| 4 | (+,+,+) (+,+,+) (+,+,+) | |||

| 5 | (+,+,+) (+,+,+) (+,+,+) | |||

| 6 | (+,+,+) (+,+,+) (+,+,+) | |||

| 7 | (+,+,+) (+,+,+) (+,+,+) | |||

| 8 | (+,+,+) (+,+,+) (+,+,+) | |||

| 9 | (+,+,+) (+,+,+) (+,+,+) | |||

| 10 | (+,+,+) (+,+,+) (+,+,+) | |||

| 11 | (+,+,+) (+,+,+) (+,+,+) | |||

| 12 | (+,+,+) (+,+,+) (+,+,+) | |||

| 13 | (+,+,+) (+,+,+) (+,+,+) | |||

| 14 | (+,+,+) (+,+,+) (+,+,+) | |||

| 15 | (+,+,+) (+,+,+) (+,+,+) |

Test Instance | MOWOA (Mean/Std) | MOWOA-D (Mean/Std) | MOWOA-A (Mean/Std) | IMOWOA (Mean/Std) |

|---|---|---|---|---|

|

GD

IGD HV |

GD

IGD HV |

GD

IGD HV |

GD

IGD HV | |

| 1 | (+,+,=) (+,+,+) (+,+,=) | |||

| 2 | (+,=,=) (+,+,+) (+,+,=) | |||

| 3 | (+,+,=) (+,+,+) (+,+,+) | |||

| 4 | (+,+,=) (+,+,+) (+,+,+) | |||

| 5 | (+,+,=) (+,+,+) (+,+,+) | |||

| 6 | (+,+,=) (+,+,+) (+,+,+) | |||

| 7 | (+,+,=) (+,+,+) (+,+,+) | |||

| 8 | (+,+,=) (+,+,+) (+,+,+) | |||

| 9 | (+,+,=) (+,+,+) (+,+,+) | |||

| 10 | (+,+,+) (+,+,+) (+,+,+) | |||

| 11 | (+,+,=) (+,+,+) (+,+,+) | |||

| 12 | (+,+,=) (+,+,+) (+,+,+) | |||

| 13 | (+,+,=) (+,+,+) (+,+,+) | |||

| 14 | (+,+,=) (+,+,+) (+,+,+) | |||

| 15 | (+,+,=) (+,+,+) (+,+,+) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pang, S.; Lin, Y.; Shi, H.; Yin, R.; Tao, R.; Li, D.; Li, C. Multi-Objective Sustainable Operational Optimization of Fluid Catalytic Cracking. Sustainability 2025, 17, 10045. https://doi.org/10.3390/su172210045

Pang S, Lin Y, Shi H, Yin R, Tao R, Li D, Li C. Multi-Objective Sustainable Operational Optimization of Fluid Catalytic Cracking. Sustainability. 2025; 17(22):10045. https://doi.org/10.3390/su172210045

Chicago/Turabian StylePang, Shibao, Yang Lin, Hongxun Shi, Rui Yin, Ran Tao, Donghong Li, and Chuankun Li. 2025. "Multi-Objective Sustainable Operational Optimization of Fluid Catalytic Cracking" Sustainability 17, no. 22: 10045. https://doi.org/10.3390/su172210045

APA StylePang, S., Lin, Y., Shi, H., Yin, R., Tao, R., Li, D., & Li, C. (2025). Multi-Objective Sustainable Operational Optimization of Fluid Catalytic Cracking. Sustainability, 17(22), 10045. https://doi.org/10.3390/su172210045