Abstract

Sericulture sustains rural livelihoods in Asia, Africa, and Latin America, where it provides income for women, elderly workers, and smallholder households. Yet this sector faces a critical technological divide: traditional reeling methods remain labor-intensive and uncompetitive, while industrial innovations advance along trajectories that are poorly suited to low-resource contexts. This article presents a patent landscape of silk-reeling technologies retrieved from Espacenet and PATENTSCOPE (2000–2024), comprising 212 unique records. Patents were evaluated against six criteria: resource efficiency, knowledge accessibility, durability and reparability, context adaptability, equity and inclusion, and by-product valorization. This review reveals a strong industrial bias, with most patents emphasizing energy-intensive steaming, mechanized feeding, and digital control, while only a small fraction addresses rural conditions or social inclusion. Current innovations therefore tend to marginalize traditional producers from emerging bio-based value chains. This study contributes to discussions on how technological design can support rural sericulture, highlighting the need for resource-efficient, modular, and socially inclusive solutions. Future research should extend patent analysis to mulberry cultivation, silkworm breeding, and by-product recovery to fully integrate sericulture into the circular bioeconomy.

1. Introduction

Sericulture represents a relevant case within the agricultural bioeconomy, as it transforms mulberry biomass and silkworms (Bombyx mori) into silk, a renewable and biodegradable material of high economic and cultural value [1]. This activity remains a significant rural practice across much of the Global South. In Asia, countries such as China and India continue to lead global production, while Thailand and Vietnam emulate their role in Southeast Asian rural economies [2,3]. Beyond Asia, countries in Latin America such as Brazil [4], Mexico, and Colombia [5] represent the expansion of sericulture activities and similar initiatives can be found in parts of the Middle East, Africa [6], and other regions [5,7]. Collectively, these countries illustrate how traditional silk production has been adopted as a strategy to generate employment, diversify rural livelihoods, and sustain smallholder economies. It provides stable jobs and income for rural households, supporting diversification and reducing vulnerability to poverty and urban migration [8].

At the same time, the global silk market is projected to expand significantly, with an estimated growth of USD 5 billion between 2024 and 2028, at a compound annual rate of 9.24%. Notably, about 64% of this growth is expected to originate in the Asia-Pacific region [9]. This projected expansion underscores the growing economic relevance of silk value chains and situates sericulture as a strategic activity within global bioeconomy transitions, particularly in regions where it continues to sustain rural livelihoods.

Beyond its economic role, sericulture also embodies cultural identity and artisanal knowledge, linking smallholder households to long-standing bio-cultural traditions. In many regions, silk rearing and reeling are closely tied to ritual practices, clothing styles, and community identity, making them as much cultural as economic endeavors [10]. The skills required to manage silkworms, prepare cocoons, and reel or weave silk thread are transmitted across generations, often through women’s labor, and represent a reservoir of tacit knowledge that industrial processes cannot easily substitute. As such, sericulture functions simultaneously as a livelihood and as a cultural practice, sustaining forms of heritage that risk erosion if rural producers are excluded from innovation trajectories.

Yet these producers face persistent constraints: reliance on labor-intensive and ergonomically demanding tools, limited access to capital or electricity, and weak connections to markets. Rural production is typically household- or community-based, relying on family labor—often women and elderly workers—who operate with hand-reeling devices, charkha-type machines, or other low-mechanization tools [11]. Output volumes are small, quality is variable, and production is deeply tied to cultural and artisanal traditions. By contrast, industrial sericulture is organized in vertically integrated factories, using automated reeling lines, programmable logic controllers, and energy-intensive steaming and drying systems to generate high-volume, standardized filament destined for the global textile market. Technical advances in industrial sericulture have expanded rapidly in the past two decades, driven by technological advancements (automated technologies, climate-controlled rearing systems, and digital monitoring), genetic improvements, and sustainable practices [12].

In addition to these technological divides, sericulture is also entering new trajectories that extend beyond conventional reeling. One of the most recent trends is the promotion of circular economy supply chains, where silk by-products are valorized for feed, food, biomedicine, and other applications that open the door to entirely new uses in textiles and other industries, complementing the sericulture agroindustry [13,14].

Notwithstanding these advances, the benefits of technological evolution in sericulture are not evenly distributed. Small communities often have access only to raw silk yet lack opportunities to capture additional value from by-products such as sericin, fibroin, or pupae, reinforcing their marginal position in emerging bio-based value chains. This underscores a widening gap: while industrial actors are driving bioeconomy-oriented innovation, traditional producers are constrained by outdated tools and excluded from value streams. The diffusion of automation and capital-intensive equipment has widened the performance gap between traditional and modern sericulture systems [15]. While some hybrid forms persist—such as contract farming or semi-mechanized reeling—the trajectory suggests erosion rather than balance as small producers struggle to compete in supply consistency, product quality, and cost efficiency.

Frugal innovation and the circular bioeconomy provide complementary perspectives for assessing these challenges. Frugal innovation emphasizes the design of affordable, adaptable, and socially inclusive solutions under resource-constrained conditions, ensuring that technologies are usable by smallholders and marginalized groups [16]. The circular bioeconomy frame, in turn, prioritizes resource efficiency, renewable materials, and the valorization of by-products into a new stream, aligning technological development with sustainability goals [17].

This study connects these perspectives, analyzing silk production patents to determine their alignment with the dual goals of resource inclusion and circularity, thereby determining their potential to integrate traditional sericulture into bio-based value chains. Previous research on sericulture has largely addressed the biological and agronomic dimensions of silkworm rearing [18,19,20,21] or examined the socioeconomic significance of silk production in rural livelihoods [22,23,24,25,26]. By contrast, the technological dimension remains insufficiently examined—particularly how intellectual property (IP) reflects the orientations of sericulture innovation and its alignment with the conditions of smallholder producers.

IP provides a strategic lens in this regard [27]. Patents, in particular, function not only as legal protections but also as structured repositories of technical knowledge. Because they disclose detailed descriptions of inventions, they provide systematic evidence of technological trajectories [28,29]. In addition to documenting technological change, patents also embody economic significance by reflecting industrial investment patterns, value capture, and spatial and institutional concentrations [30].

Analyzing patent activity therefore makes it possible to determine whether advances in silk reeling foster the inclusion of rural producers in circular value chains, or whether they reinforce industrial dominance and exclusion [31]. In the case of sericulture, patent analysis thus not only traces technological trajectories but also reveals how industrial dominance in specific regions translates into economic asymmetries that shape the prospects of rural development and inclusion in bio-based value chains.

It is important to note that this study focuses specifically on patents related to silk reeling. While valuable silk by-products are central to bioeconomy discussions, their recovery depends directly on how reeling is performed, since this process determines the quality and availability of downstream residues. Reeling therefore represents a critical technological bottleneck: if innovations remain industrially oriented and unsuitable for smallholders, opportunities for by-product valorization and integration into circular value chains cannot be realized.

Building on these perspectives, this study integrates the concepts of frugal innovation and the circular bioeconomy to examine how technological development in sericulture reflects broader patterns of inclusion and resource use. By analyzing patent activity as a proxy for technological trajectories, the research aims to uncover whether the direction of innovation in silk reeling aligns with sustainable and socially inclusive principles.

In this context, we hypothesize that the global patent landscape for silk-reeling technologies between 2000 and 2024 shows a predominantly industrial orientation, with limited attention to the frugal and circular criteria required for adoption by rural smallholder communities. This proposition is examined through a systematic evaluation of 212 patents using a six-criterion framework encompassing resource efficiency, knowledge accessibility, reparability, social inclusion, by-product valorization, and adaptability to low-resource environments.

2. Materials and Methods

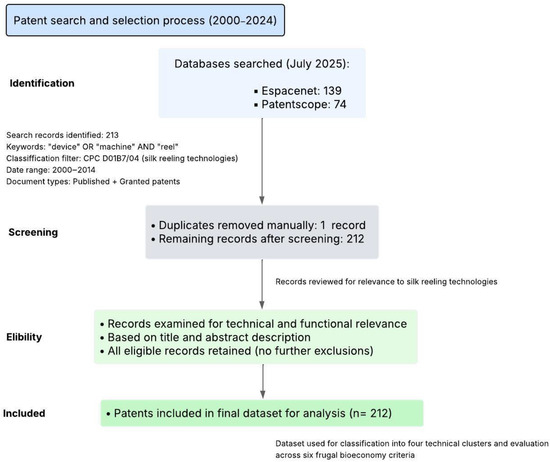

In July 2025, a comprehensive patent landscape review was performed using two major international repositories: Espacenet, managed by the European Patent Office, and Patentscope, administered by the World Intellectual Property Organization (Figure 1). Together, these databases cover more than one hundred jurisdictions, providing free access to both published applications and granted patents. The analysis was restricted to patent data rather than scientific publications because the objective was to trace the direction of applied technological development and the priorities of commercial and industrial innovation. Unlike scientific articles, which primarily reflect academic research, patents provide a direct measure of technologies intended for market deployment. Given the study’s focus on innovation pathways and industrial bias, patents offer a more appropriate and complementary proxy for examining the bioeconomy sericulture. The search protocol was adapted from the systematic approach described by Suárez et al. [32].

Figure 1.

Methodological summary of the patent landscape analysis.

The strategy combined the keywords “device” OR “machine” with the truncated form “Reel” (wildcard operator “*”) to capture all variations in the term, such as “reeling.” In addition, Cooperative Patent Classification (CPC) code D01B7/04—specifically linked to silk-reeling technologies—was incorporated to improve the precision of retrieval.

Search filters were applied to limit the results to the years 2000–2024 to include both pending and granted patent documents, and to restrict the query to titles and abstracts. Boolean operators were applied to ensure both comprehensive coverage and retrieval precision. Duplicates across the two platforms were identified and removed manually. This process yielded 139 records from Espacenet and 74 from Patentscope, which together formed the initial dataset. One record was redundant, so it was deleted from the analysis.

After consolidating the dataset, the selected patents were examined to identify recurring technological themes and relationships among innovation types. This analysis aimed to capture the main directions of technical development within the silk-reeling sector and to structure them into coherent categories for subsequent evaluation.

To identify the main technological clusters, patent titles and abstracts were examined through an iterative text analysis that combined keyword frequency with close reading to capture their functional context. Keywords referring to related technical processes or components were grouped under broader functional categories and subsequently refined through manual review to preserve coherence and relevance. This approach yielded four clusters—energy-intensive drying and steaming systems, automation of end-finding, feeding and twisting, control architectures involving sensors and motors, and specialized components and materials.

To evaluate the suitability of patented silk-reeling technologies for rural and small-scale contexts, all patents were manually coded in two stages. In the first stage, each document was assigned to one of three suitability categories: A (suitable), when the abstract described features such as simplified construction, reduced energy demand, or ease of handling; B (partly suitable), when favorable elements (e.g., partial labor saving or modularity) coexisted with limiting requirements such as specialized parts of high energy inputs; and C (not suitable), when the description emphasized complex automation, intensive power use or electronic control with no sign of adaptation to smallholder contexts. To enhance reliability and reduce subjective bias, two researchers independently applied these criteria to the full dataset and compared results. Differences were discussed until consensus was reached, ensuring consistency in classification.

In the second stage, a structured framework of assessment criteria was applied. These dimensions focused on essential aspects of accessibility and usability: resource efficiency, knowledge accessibility, durability and reparability, context adaptability, equity and inclusion, and, given the increasing emphasis on the circular bioeconomy, an additional criterion—by-product valorization—was incorporated to capture the extent to which patents facilitate the recovery and use of sericin, fibroin, pupae, or wastewater streams (Table 1).

Table 1.

Patent evaluation criteria for silk-reeling technologies.

Patent abstracts and descriptive notes were reviewed for explicit or implicit references related to these criteria. Each criterion was assessed using a binary classification (Yes/No) based on explicit evidence in the patent abstract. To verify coding reliability, 15% of the patent sample was independently re-screened by a second researcher using the same evaluation criteria. The consistency between both rounds confirmed a high inter-coder reliability, with no discrepancies observed in cluster or category assignments. Connections between clusters and criteria were established whenever at least one patent within a cluster contained an explicit textual mention of that criterion in its abstract. This framework enabled a systematic assessment of how far the patented technologies align with the practical conditions of smallholder sericulture.

Finally, visual outputs such as temporal distribution charts, geographical maps, and technology trend diagrams were generated using Lucid.app (https://lucid.app, accessed on 10 September 2025) and Canva (https://www.canva.com, accessed on 5 September 2025) to highlight patterns and emerging directions within the global silk-reeling patent landscape. These outputs facilitated the visualization of temporal, geographical, and technological patterns in the global silk-reeling patent landscape.

3. Results

3.1. Geographical Distribution of Patents and Types of Assignees

The vast majority of patent filings originate from China, with scattered contributions from Japan and India (Table 2). This distribution is consistent with Asia’s historic leadership in sericulture but also reflects where industrial research and development infrastructure are stronger. This contrast is most pronounced in regions where sericulture remains a traditional small-scale subsistence activity, such as Southeast Asia, Latin America, and parts of Africa, which are largely absent from the patent landscape.

Table 2.

Silk-reeling patents by country of origin and assignee category.

The treemap illustrates the significant concentration of silk-reeling patents in China, with accounts for over 97% of the total dataset (207 patents). Other countries, such as Japan (3 patents) and India (2 patents), appear only marginally, underscoring China’s near-monopoly in this technological domain.

The pie chart further disaggregates the data by assignee type, revealing that the majority of patents are held by companies (78%), followed by universities (8.8%) and SMEs (7.7%). Individual inventors and public research institutes remain marginal contributors. This distribution suggests that innovation in silk-reeling technologies is largely driven by the private sector, with limited but notable input from academia.

Overall, the figure highlights two key patterns: the geographic concentration of technological development in China and the institutional dominance of corporate actors in shaping innovation trajectories.

3.2. Technological Cluster Trends

The patent landscape reveals four distinct technological clusters in silk-reeling machines, identified through a qualitative analysis of patent titles, abstracts, and technical descriptions. Cluster 1 encompasses energy-intensive drying and steaming systems designed for industrial throughput but constrained by high resource demands. Cluster 2 focuses on the automation of end-finding, feeding, and twisting processes. Cluster 3 comprises control architectures that rely on sensors, motors, and programmable logic controllers (PLCs). Finally, Cluster 4 captures specialized components and materials.

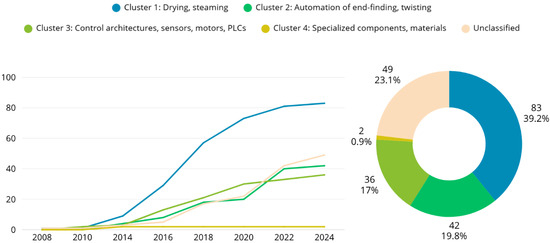

To trace the technological trajectories of silk-reeling machines, we analyzed the patent dataset both by year of publication and through cumulative trends (Figure 2). While annual counts highlight short-term fluctuations, cumulative distributions provide a clearer picture of long-term dynamics within each cluster. This approach enables us to identify which technological pathways have matured, which remain marginal, and which have emerged only recently.

Figure 2.

Cumulative patent trends and overall distribution in silk-reeling technologies across technological cluster (2005–2024).

The figure shows that energy-intensive drying and steaming systems represent the dominant trajectory, with a sharp rise after the mid-2010s, followed by stabilization, suggesting both technological maturity and possible saturation. Automation of end-finding, feeding, and twisting and control architectures based on sensors, motors, and PLCs followed similar upward trends, albeit at a slower pace, reflecting industry efforts to digitalize and streamline reeling processes. In contrast, specialized components and materials form a small but persistent cluster, indicating incremental innovation focused on durability, precision, and subsystem optimization.

The coexistence of these patterns reveals a dual dynamic: on the one hand, large-scale industrial designs have driven the bulk of patenting; on the other, more modest but strategically important refinements at the component level have continued to shape the technological landscape.

- (i)

- Cluster 1. Energy-intensive drying and steaming systems: high efficiency goals versus resource intensity.

A significant number of patents focus on drying technologies that employ infrared (IR) heaters, electrical resistance rods, vacuum infiltration chambers, ultraviolet (UV) lamps, or combinations thereof. These designs emphasize uniform cocoon heating, humidity control and process stability, aiming to optimize reelability and silk quality. The prevalence of these patents highlights the centrality of energy and thermal regimes on industrial silk processing.

Standard, common features include welded sheet-metal enclosures, ducting, coils, and cabinet-type structures. Spare-part dependencies are recurrent, with IR emitters, UV tubes, compressors, sensors, and electronic controllers appearing across documents. Wei, X. and Wei, Z. [33] introduce a cocoon reeling and steaming drum with internal spray nozzles and a motorized rotation system, providing continuous wet-heat exposure within a sealed vessel. The design emphasizes homogeneous steaming, ensuring that cocoons are uniformly softened for subsequent reeling.

Similarly, Yueqin, S. [34] explores a hybrid process that combines vacuum steaming with ultrasonic assistance, aiming to enhance sericin swelling and thread release. Both filings reflect an early focus on replacing open boiling vats with enclosed vessels that stabilize thermal delivery and introduce auxiliary technologies to improve reeling efficiency.

Technological attention shifts toward refined steaming and drying systems. Zhou et al. [35] employ a rotating electric heating rod with an integrated air channel, improving cocoon agitation and evenness of temperature distribution. In parallel, Zhong [36] discloses a dehumidifying and drying system that unites IR heating with an internal dehumidification circuit. The design addresses both the need to evaporate water bound in silk filaments and the ambient humidity that often interferes with reeling efficiency. This dual thermal pathway underlines a trend toward integrated climate management in post-cocoon processing.

Also, the same inventor introduces a drying system for silk-reeling machines [37] that combines IR heating elements with motor-driven reel rotation. The configuration is designed to maintain a controlled thermal environment throughout the drying cycle, with additional integration of sensors and wireless monitoring to regulate process parameters. The system illustrates a strong emphasis on stable power input and closed-loop control, positioning drying as an energy-intensive but precision-oriented stage in reeling workflows.

Later patent filings introduce multi-modal and more sophisticated control of drying and steaming. Wen, Z. [38] develops a drying mechanism that employs electric heating wires in combination with UV lamps. By combining thermal drying with UV exposure, the apparatus not only accelerates moisture removal but also incorporates a sterilization function. This design enhances quality control by coupling microbial safety and filament integrity in a single system, achieved through the addition of energy.

Fei, J. [39] integrates heating elements, forced convection and guided roller pathways within a drying, and sterilizing box, reflecting a convergence of drying and hygienic treatment functions. Wen, Z. [40] offers an alternative path by incorporating vacuum infiltration into cocoon treatment. Instead of high-temperature boiling, reduced pressure enables deeper penetration of water or other treatment solutions into cocoon layers. This technique represents a shift away from purely thermal solutions toward pressure-based diffusion, with the aim of improving end-finding efficiency and reducing sericin loss during the reeling process. In the most recent example, Masaru, H. [41] emphasizes short, high-temperature exposures and controlled immersion to minimize protein damage, signaling interest in precision thermal management that preserves cocoon integrity.

Taken together, the analyzed patents converge on a standard trajectory, with silk processing increasingly being framed as controlled, energy-dependent operation. This reveals an increasing technological layering, moving from straightforward vessel designs to complex chambers to incorporate multiple energy inputs, controlled airflow, and process monitoring. While these solutions address recognized bottlenecks in industrial mills, they also signal the consolidation of a design logic in which silk processing depends increasingly on regulated thermal environments and automated handling of moisture and heat transfer.

This technological paradigm extends directly to the next cluster, where automation is applied not only to drying but also to delicate stages of end-finding, feeding, and twisting, shifting further responsibilities from manual skill to engineered control architectures.

- (ii)

- Cluster 2. Automation and simplification of end-finding, feeding, and twisting processes: substituting labor through mechanical precision.

Another prominent cluster addresses the mechanization of traditionally manual tasks, such as cocoon-end detection, which feeds into reeling and twisting of filaments. These patents typically describe mechanical subsystems integrated into reeling machines, sometimes supported by auxiliary devices (e.g., water-flow pots, rotary brushes, or guiding rollers). The focus is on reducing labor demand and increasing throughput by minimizing manual intervention at critical points in the reeling sequence.

Mink, A. [42] discloses a silk-yarn-reeling machine that automates end-fixing and winding through crosier pulley units and oscillating spreading mechanisms. The focus is on replacing manual winding consistency with gear-driven spreading, one of the first steps toward mechanical end handling. Wei and Wei [43] add refinements through ceramic eyelets to reduce breakage, indicating interest in stabilizing thread paths once automation begins.

In a mid-phase, Qin, C. [44] presents an automatic twisting method that integrates sensors and sequential drum arrangements. The system achieves precise thread manipulation but it increases dependence on control electronics and requires higher technical oversight. In the same period, Huang, J. [45] proposes a 1400 rpm electromechanical twister, reducing repetitive manual twisting while retaining modular installation.

Liu, J. et al. [46] extend automation to cocoon feeding with a synchronized brushing mechanism and thermal conditioning, highlighting an evolution from stand-alone twisting modules toward multi-stage automatic feeding systems. The arrangement is designed to stabilize end-finding and maintain consistent cocoon input for large-scale reeling operations. Ding, R. et al. [47] introduces a cocoon-feeding device equipped with a signal-based prompting unit, an optical sensor, and a cocoon funnel-roller system. The sensor detects the number of cocoons being introduced and activates the prompting unit to maintain a consistent feed. The device integrates with the reeling lines to reduce interruptions in cocoon supply by automating detection and adjustments of flow rates.

Additionally, Yu, L. and Yu, H. [48] outline a machine for automatically drawing silk threads, featuring limiting rollers paired with cleaning brushes. As silk moves through the system, the rollers constrain and align it while the brushes remove impurities and prevent tangling. The coordinating arrangement supports thread stabilization and continuous silk extraction during reeling. Jin, Y. et al. [49] advances roughness-removing swing assemblies, embedding silk-separating plates with synchronized oscillations, showing the cluster’s progression toward combining automation with error prevention.

These patents demonstrate a trend toward automation of traditionally manual operations in silk reeling, including twisting, cocoon feeding, brushing, and thread cleaning. The innovations emphasize motorized drives, roller assemblies, sensor-based detection and synchronized feeding systems, reflecting a convergence on precision mechanics and electronic control for efficiency and uniformity.

Automation in this cluster is conceived as a sequential replacement of hand-intensive tasks, embedding mechanized sub-units into larger reeling workflows. This defines a technological pathway centered on consistency, throughput, and integration into industrialized production environments, setting the stage for comparison with subsequent clusters of control architectures and component specialization.

- (iii)

- Cluster 3. Control architectures reliant on sensors, motors, and programmable logic controllers (PLCs): embedded intelligence and centralized process supervision.

A third group of patents is characterized by the integration of electronic control systems, including optical or magnetic sensors, automated motor drives, feedback loops, and programmable logic units. These architectures enable real-time monitoring of silk tension, fineness, or breakage and facilitate precise adjustment of reeling parameters. Their appearance across different machine types indicates a clear trend toward digitalization and fine-grained process control.

Duan, Z. and Duan, J. [50], based on earlier developments, introduce small devices with protective sleeves and supporting modules, signaling the first attempts to embed mechanical guidance with minimal electronics. By 2014, Wei, X. and Wei, Z. [33] had already combined thermal chambers with motorized drives and early sensor inputs, foreshadowing a control-oriented evolution.

Later on, Tan, Z. et al. [51] disclose a fully integrated control system that incorporates sensors for silk cutting and dual-motor drives, organized within a control cabinet, establishing the template for PLC-based reeling architectures. In 2018, Yao, Y. et al. [52] extended this by incorporating Hall sensors and crank-rocker mechanisms for detecting raw silk fineness, showing an evolution toward precision monitoring and feedback integration.

Recent developments proposed by Ding, R. et al. [53] demonstrate a lighter, modular path by utilizing encoder signals to automate winding count, indicating diversification into smaller, sensor-specific control modules. Xu, L. and Xu, S. [54] advance into real-time algorithmic adjustment with dual speed-measurement and data processing for silk fineness stabilization. This reflects the full integration of electronics and metrology.

Control architectures emerge as a defining axis of recent silk reeling innovation, progressively embedding layers of sensors, motor coordination, algorithm regulation, and in some cases, wireless transmission. The technological logic emphasizes continuous sensing, closed-loop feedback and supervisory controllers, ranging from lightweight counting systems to full algorithmic regulation of fineness.

While the degree of electronic sophistication varies, the typical trajectory is toward embedding sensors and programmable logic as integral components of silk production. This reflects a clear evolution from basic to electromechanical assistance to increasingly software-mediated production environments in which stability and quality control are pursued primarily through electronic oversight.

- (iv)

- Cluster 4. Specialized components and materials: incremental and mechanical innovations.

Although numerically smaller than other groups, a distinct subset of patents focuses on specialized components and materials. These inventions target isolated stages of the reeling process through the refinement of ceramic eyelets, precision rollers, guiding plates, and friction elements. Rather than proposing full machine architectures, they concentrate on durability, precision, and adaptability, aiming to reduce filament breakage and improve consistency in silk quality. Wei, X. and Wei, Z. [43] introduce ceramic eyelets designed to reduce stress concentration in silk slivers of horizontal reeling machines, representing the earliest cluster focused on specialized, durable components. Unlike earlier static ceramic or spring-based solutions, this patent introduces greater control over mechanical tolerances, ensuring consistency in the alignment and handling of cocoon silk under variable operating conditions.

Zhang, W. [55] expands this trajectory with a guide plate system incorporating filter screens and micro-motorized push rods. Beyond static guiding, the device actively dislodges silk accumulations from the plate surface through scheduled push-rod movements, ensuring a continuous thread flow during reeling. The integration of filtering, guiding, and active cleaning into a single component indicates a step toward multi-functionality, where specialized parts not only channel silk but also reduce downtime associated with clogging or irregular accumulation.

Recent patent filings, such as Jin, Y. et al. [56], present a silk-reeling machine with a dedicated roughness-removal mechanism, where cocoon filaments pass through a dividing plate that automatically cuts off coarse silk strands. This design demonstrates the incorporation of cutting/separating subsystems directly into reeling grooves, optimizing quality at the component level rather than through downstream inspection.

Wang, J. et al. [57] advance this concept further with a silk-separating plate featuring adjustable seams. By allowing operators to modify slit width to match cocoon or filament size, the plate embodies a move toward a reconfigurable and precision-tuned module rather than fixed geometries.

The analysis of patents focused on specialized components revealed a progressive refinement of individual machine elements into adaptive and precision-oriented subsystems. Early ceramic eyelets and fixed guiding plates gradually gave way to designs that integrated auxiliary mechanical functions and automated roughness removal and adjustable geometries. The relatively modest number of patents in this cluster underscores its niche character, yet its contributions are significant. This trajectory highlights a technological pathway where quality assurance is increasingly embedded at the component level, shifting from static fixtures to configurable modules. The concentration of these developments in recent years confirms an industry trend toward precision and modular adaptability as defining features of specialized component innovation.

3.3. Clusters Against Evaluation Criteria

The clusters described above illustrate the main technological directions assessed in silk-reeling patents. In a first step, all documents were classified into three categories according to their overall suitability for rural contexts: A (suitable), B (partly suitable), and C (not suitable). This classification was carried out focusing on whether the technologies described could realistically be adopted in smallholder settings.

Category A included patents that explicitly or implicitly described features such as simplified construction, reduced energy demand, or ease of handling, suggesting that they could be operated in low-resource environments. Category B grouped patents that presented some favorable elements, such as partial labor saving or modularity, but also contained requirements that could limit their use in rural contexts (e.g., dependence on specialized parts or higher power inputs). Category C comprised patents dominated by features associated with industrial-scale use, such as complex automation, high energy dependence, or sophisticated electronic control, with no evidence of adaptation to smallholder conditions.

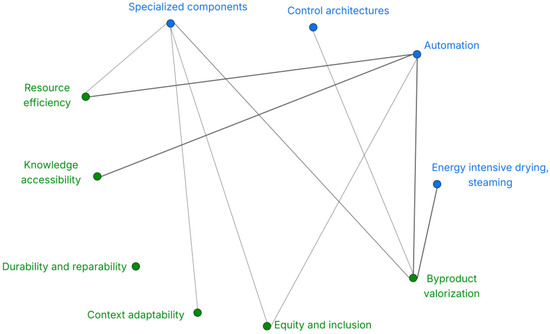

To examine this portfolio in greater detail, a second layer of analysis was applied using six evaluation criteria: resource efficiency, knowledge accessibility, durability and reparability, context adaptability, equity and inclusion, and by-product valorization. Figure 3 presents the outcomes of this assessment.

Figure 3.

Linkages between technological clusters and frugal innovation criteria in silk-reeling patents. Connections were established when at least one patent within a given cluster explicitly mentioned a specific frugal or circular criterion. Blue nodes represent technological clusters, and green nodes represent frugal or circular innovation criteria.

The categorization of patents into three suitability groups shows that only a small fraction was classified as A (suitable, 12%) or B (Partly suitable, 5%), while the vast majority fell into group C (not suitable, 83%). These groups were analyzed against the six evaluation criteria; explicit references were scarce, but some differences between categories were observed:

- Resource efficiency: 4% of A patents include terms such as low cost or simplified materials, usually in the context of describing machine parts or structural components rather than the entire system. In category B, 9% of patents included similar terms, often referring to sub-units or auxiliary devices rather than complete reeling machines. No mentions of this criterion were present in C patents, despite this being the largest group. The data show that explicit statements about lowering cost or material simplification were isolated and scattered, with no group showing consistent emphasis.

- Knowledge accessibility: References to ease of use were limited to 4% of A patents. The terms assessed included “simple operation”, “easy to use”, and “labor saving”. These mentions were found in abstracts describing mechanisms for cocoon feeding or thread handling, presented as ways to reduce manual intervention. No such references were present in B or C, even though many patents in these groups describe automation or mechanization processes. The results indicate that explicit descriptions of operator-friendly design features were scarce and confined to a small share of A.

- Durability and reparability: Across the three categories, no abstracts contained words directly related to this criterion. Terms such as “durable”, “easy maintenance”, “long lasting”, or “repairable” were not detected in any group. This absence is consistent in A, B, and C patents alike, with no indications that reparability or maintenance concerns were addressed in the dataset.

- Context adaptability: Mentions of rural or small-scale applicability were observed only in C, where 4.5% of patents included terms such as “household” or “rural”. These references generally appeared in descriptions of compact devices, sometimes presented as suitable for use outside large factories. However, these same patents also contained other technical requirements—such as reliance on stable electricity, integration of electronic controllers, or dependence on specialized components—that led to their overall classification as not suitable for rural contexts. It is also relevant that the references to “household” or “rural” were often framed in relation to production zones where sericulture is already an intensive activity, particularly in countries like China or India, rather than areas where infrastructure limitations are more severe. Neither A nor B patents contained explicit mentions of rural, household, or small-scale use, indicating that such contextual references were rare and restricted to a small subset of the least suitable group.

- Equity and inclusion: Mentions related to ergonomics, safety, or accessibility appeared sporadically. In 4% of patents, terms such as “ergonomic” or “safety” were used, often associated with operator positioning or handling during reeling. In C, 2.3% of patents included similar references, again in the context of operator safety, but with no broader inclusiveness claims. No B patents contained mentions of this criterion. Overall, references to ergonomics or accessibility were minimal and dispersed, with no systematic occurrence across categories.

- By-product valorization: This criterion showed the highest relative frequency among the six assessed, although it was still limited overall. Mentions of sericin, fibroin, pupae, or related applications appeared in 18.2% of B patents, 8% of A patents, and 6.8% of C patents. The terms were most often identified in abstracts that referred to silk proteins (sericin or fibroin) as functional elements, occasionally in relation to biomedical or material applications. A smaller number of abstracts referred to pupae as a potential by-product, generally in connection with feed uses. Mentions of wastewater or effluents were rare and appeared mainly in patents otherwise oriented toward industrial reeling systems. Overall, by-products valorization was the only criterion with non-negligible frequencies across all categories, but references remained fragmentary and concentrated in patents primarily describing reeling machinery rather than explicit by-product recovery processes.

To visualize how the six evaluation criteria intersect with the four technological clusters, a chord diagram was constructed linking clusters and criteria based on the presence of relevant terms in patent abstracts (Figure 3). The diagram represents each cluster and criterion as nodes, with connecting lines indicating where explicit mentions were recorded.

For automation, connections with resource efficiency and knowledge accessibility were established through mentions of terms such as “low cost”, “affordable”, “simple operation”, and “labor saving”. The link to equity and inclusion was created by references to “ergonomic design” and operator safety, while by-product valorization was connected through mentions of fibroin as a material with additional potential uses.

For specialized components, the link to resource efficiency was formed through descriptions of simplified or low-cost guiding elements. Context adaptability was established by the explicit use of “household” and “rural” in relation to small devices. Mentions of “ergonomics” connected this cluster to equity and inclusions, while references to fibroin and pupae provided the connection to by-product valorization.

For energy-intensive drying and steaming, the only connection identified was with by-product valorization, where abstracts referred to sericin and fibroin in the context of cocoon treatment and thermal processing. For control architectures, the sole link was also to by-product valorization based on mentions of sericin and fibroin in relation to monitoring or regulating silk quality. No connections were found to durability and reparability, as none of the patents included terms related to maintenance, repair, or longevity.

4. Discussion

4.1. Industrial Concentration and Technological Path Dependence

Between 2000 and 2024, patenting rose and concentrated geographically in Asia—especially in China. This concentration is so pronounced that the contributions of other countries—Japan and India—are almost imperceptible in comparison. Such a pattern points not only to China’s strong technological trajectory in sericulture but also to the country’s systemic prioritization of this sector through industrial policy, regional clustering, and integration with its textile and rural development strategies. In practical terms, this dominance suggests that the direction of technological innovation, the standards of machinery, and the potential for technology transfer to other contexts are being largely defined within the Chinese ecosystem.

From an institutional perspective, assignees are dominated by industrial firms and research institutes, making them the primary drivers of innovation in silk-reeling machinery. The distribution of patents reflects a pattern of industrial concentration, where larger companies dominate the innovation landscape by securing IP to reinforce their competitive advantage. Academic institutions appear engaged but only in a supporting role often linked to industry partnerships or applied research within agricultural and textile programs. Small and medium-sized enterprises contribute through niche developments and incremental improvements, which are frequently more closely aligned with frugal or small-scale contexts. Meanwhile, individual inventors and public research institutes remain peripheral, suggesting that grassroots or state-driven initiatives in this field are limited.

Overall, the concentration of silk-reeling patents in China, largely held by corporate assignees, highlights not only a path-dependent pattern of technological development but also a broader consolidation of value capture within the bioeconomy. This trend suggests significant implications for rural development: as innovation trajectories become increasingly centralized in industrial actors, smallholder households are left with limited opportunities to participate, widening the gap between regions with strong research and development (R&D) infrastructures and those where sericulture endures mainly as a livelihood strategy. It also highlights the importance of fostering greater participation from universities, SMEs, and public research organizations, particularly in the Global South, where frugal and inclusive approaches could open new pathways for technological development and community resilience.

Technically, filings clustered around four themes: energy-intensive drying systems, automation (end-finding/feeding/twisting), sensor- and PLC-based control architectures, and specialized components. On suitability, only a small share of documents fell into A (12%) or B (5%), while the majority were C (83%). Screening abstracts against six criteria showed low frequencies: resource efficiency (4% of A; 9% of B; 0% of C), knowledge accessibility (4% of A only), durability and reparability (0% across all groups), context adaptability (4.5% of C only), equity and inclusion (4% of A; 2.3% of C), and by-product valorization (18.2% of B; 8% of A; 6.8% of C).

Cross-analysis by cluster indicated that resource efficiency and knowledge accessibility appeared only in automation and specialized components; context adaptability was confined to specialized components; equity and inclusion appeared sporadically in automation and components; and by-product valorization was the only criterion present across all four clusters. Co-occurrence was minimal: most abstracts referenced at most one criterion, with no cases mentioning three or more simultaneously.

These results point to a strong industrial orientation in the current patent portfolio. The four identified technological clusters are dominated by designs that demand a stable energy supply, complex control systems, and specialized parts. These features align with the needs of industrial reeling mills but are largely inconsistent with the conditions of smallholder workshops where infrastructure and technical support are limited.

Within this industrial trajectory, smallholders are effectively neglected. The distribution of patents across A/B/C categories shows that only a tiny proportion could be considerably suitable or partially suitable, while the overwhelming majority fall into the not suitable group. Moreover, the low occurrence of criteria linked to frugal innovation—such as low-cost materials, simple operation, adaptability to rural contexts or inclusive ergonomics design—confirms that affordability, usability and accessibility are rarely explicit priorities in patent descriptions.

The findings reveal how silk-reeling innovations are following a trajectory of industrial upgrading. The concentration of patents in automation, control architectures, and energy-intensive processes signals a technological path that prioritizes throughput and precision while leaving little space for incremental or low-resource adaptations. Such a path limits opportunities for alternative innovation pathways that could address the challenges faced by smallholder sericulture.

4.2. Limits of Frugal Innovation and Circular Bioeconomy Principles in Current Reeling Technologies

From a frugal innovation perspective, the results highlight a structural misalignment between patented technologies and the conditions of rural sericulture. None of the documents reviewed referred to durability, ease of repair, or local fabrication. Mentions of ergonomics or safety were also rare, even though women and elderly workers constitute a significant share of the sericultural labor force. Energy- and water- intensive designs further highlight this gap, assuming reliable infrastructure that is often unavailable in rural settings. Another missing element is modularity: patents describe large, integrated systems with little scope for incremental adoption, whereas frugal approaches emphasize scalability and the possibility of adding or removing functions according to user capacity.

It is important to recognize that the absence of frugal features in the patent set does not necessarily imply that such solutions do not exist. Local artisans and producers may develop informal adaptations—such as simplified reeling devices or workshop level repairs—that remain outside formal IP systems. As a result, patents provide only a partial view of technological development, reflecting industrial priorities while overlooking informal innovations.

In another scenario, a further gap emerges in relation to the circular bioeconomy. By-product valorization was the only criterion with occurrences across all clusters, but references to sericin, fibroin, pupae, or effluents were limited and generally presented as secondary notes within technological descriptions. This suggests that, while circularity is not absent, it is not integrated as a central design principle in reeling technologies.

From a circular bioeconomy perspective, reeling machines could logically incorporate adaptations to collect wastewater separately for later sericin extraction, ensure gentler treatments that preserve fibroin integrity in residues, facilitate the separation and hygienic handling of pupae, enabling their use in feed or food, and reduce cross-contamination so that by-products are viable for downstream use.

Nevertheless, most industrial reeling machines are optimized only for filament quality and throughput. When valorization occurs, it typically takes place in separate processes (downstream chemical/biotech facilities). This has important implications for rural sericulture. In resource-limited settings, the absence of machine-level adaptations for collecting valuable by-products means that these potential value streams remain inaccessible to smallholders, reinforcing the marginal position of rural communities in bio-based value chains.

From an IP perspective, results show that while the principle of circularity has begun to register in patent filings, it is weakly embedded at the processing stage. In this sense, patents capture an early and partial recognition of circular opportunities, but not their systematic translation into technological development.

Although industrial sericulture has achieved efficiency gains through the intensification of industry-based activities, the exclusion of small communities from technological design raises critical concerns. Sericulture is not only an agro-industrial sector but also a livelihood system embedded in rural economies and cultures. When reeling technologies are conceived solely for large-scale mills, smallholders remain confined to outdated tools, reinforcing income disparities and limiting intergenerational transmission of artisanal knowledge. This marginalization contributes to rural outmigration and the erosion of sericulture as a cultural practice, turning silk production into an increasingly industrial and geographically concentrated activity.

From a resource perspective, overlooking small communities also weakens the potential of the circular bioeconomy. Residues are generated during the reeling process regardless of scale, but if rural producers lack the means to capture value from them, these materials are discarded as waste. Local valorization of by-products could enhance food security, animal nutrition, and small-scale bio-based enterprises. This shifts the economic benefits of circularity away from producers and toward external actors, creating dependence rather than resilience.

The dominance of industrial priorities in the patent record underscores the limited incentive for firms to reorient innovation toward smallholders. While patents are designed to promote innovation, their current distribution in the sericulture sector often perpetuates technological inequalities. Industrial firms use IP as a mechanism of appropriation and exclusion, protecting technology that requires high capital investment and proprietary components. This creates a barrier for small and cooperative producers who lack the financial or technical capacity to license, replicate, or adapt patented machinery.

Even when patents expire, the technical documentation is frequently inaccessible due to language barriers, complex databases, or the absence of open engineering standards [58]. As several authors have noted, this dynamic transforms IP from a tool of dissemination into a mechanism of technological enclosure that narrows participation in innovation ecosystems [59,60,61].

A key reason for the limited presence of frugal innovation and repairable designs among the analyzed patents lies in the commercial logic of innovation within large firms. For companies investing in automation and control architectures, the dominant incentive is to pursue efficiency gains, productivity, and scalability. Developing low-cost, modular, or easily maintainable devices offers minimal competitive advantages in markets where profit margins depend on technological sophistication and planned equipment renewal. Consequently, the private sector tends to create a form of market failure that limits the diffusion of inclusive technologies.

These findings align with broader evidence of an “innovation gap” documented in other primary sectors, where formal R&D trajectories often diverge from the needs of low-resource environments. Studies on agricultural mechanization and rural technology diffusion consistently show that industrial innovation systems prioritize capital-intensive efficiency gains, leaving smallholders dependent on obsolete or imported equipment [62]. Similar patterns have been reported in renewable energy and low-cost manufacturing, where frugal innovations emerge informally but remain marginal within formal IP systems [63]. The present analysis extends this discussion to sericulture, demonstrating that industrial upgrading and IP concentration produce the same asymmetries—technological sophistication without social accessibility—observed in other domains of the Global South’s innovation landscape.

4.3. Policy, Cultural, and Environmental Frameworks for Inclusive Sustainability

This creates a space where policy intervention is essential to address structural problems. The first challenge lies in the technological gap separating industrial and traditional actors. A second issue is the institutional asymmetry, since the industrial sector benefits from dedicated funding, IP protection, and commercial incentives, whereas smallholders face fragmented assistance and limited access to extension or finance. Finally, the persistent absence of mechanisms linking rural cooperatives, research institutions, and the industry prevents collective upgrading.

To address this imbalance, development agencies and local governments can mobilize targeted funding, tax incentives, or procurement schemes that support technologies explicitly designed for resource-constrained environments. By doing so, they can counterbalance industrial path dependence and open room for alternative innovation trajectories. Policies that support decentralized reeling units, cooperative ownership models, or subsidies for modular machinery could directly enhance the viability of rural sericulture.

Beyond technological reorientation, institutional and market instruments such as Environmental, Social, and Governance (ESG) frameworks, Geographical Indications (GIs), and Designations of Origin (DOs) offer complementary pathways to mitigate the asymmetries created by industrial concentration. ESG standards can help internalize social and environmental performance into evaluation of industrial actors, promoting accountability along the value chain. Meanwhile, GIs and DOs provide mechanisms for territorial recognition and collective ownership, allowing rural cooperatives to capture added value linked to cultural heritage, ecological stewardship, and craftsmanship. Complementary cultural initiatives—such as living museums, community silk archives, and participatory heritage programs—can further promote the social appropriation of sericulture, strengthening local identity and enabling communities to reclaim and reinterpret their role within the evolving bioeconomy.

Several institutional models around the world demonstrate how governments and international organizations can operationalize frugal and open innovation principles. In India, the National Innovation Foundation (NIF-India) [64] has institutionalized support for grassroots innovators through small-grant funding, patent assistance, and technology diffusion programs, while Rural Technology Action Group network, coordinated by the Indian Institutes of Technology, codesigns affordable machinery and process improvements with rural producers.

In Latin America, the Community Technologies and Knowledge Research Center [65] (CITSAC, Mexico) represents an emerging regional initiative that promotes the production and exchange of community knowledge and strengthens community capacities and processes aimed at good living. CITSAC provides support and mentoring programs for community-based applied research projects in Indigenous and Afro-descendant communities.

At the global level, the UNDP Accelerator Labs [66] connect public agencies, researchers, and communities across more than 100 countries to identify, prototype, and scale low-cost solutions aligned with Sustainable Development Goals. Similarly, WIPO GREEN [67] provides an open innovation market place where inventors and companies can share or license environmentally sustainable technologies, facilitating technology transfer to resource-constrained resources. In the EU, Horizon Europe’s Open Innovation Test Beds [68] promote collaboration among industry, universities, and SMEs to validate circular bio-based technologies under real production conditions. Together, these initiatives exemplify how institutional frameworks can move beyond traditional R&D models to integrate inclusiveness, affordability, and sustainability as central dimensions of technological development.

In addition to socioeconomic asymmetries, the environmental dimension of sericulture also raises attention. Previous research presents a nuanced view of ecological impact of sericulture. On one hand, sericulture can be an environmentally compatible agroindustry, contributing to soil conservation, carbon sequestration, and agroforestry diversification when integrated with sustainable land use systems [69]. Mulberry cultivation helps to reduce erosion, restores degraded land, and promotes organic matter accumulation, supporting the idea of sericulture as a “green livelihood option”.

However, recent analysis warn that sericulture’s ecological benefits are increasingly undermined by climate change and intensification pressures [70]. Rising temperatures, erratic rainfall, and soil degradation directly affect mulberry productivity and silkworm survival, while unsustainable fertilizer and pesticide use in intensified rearing systems contributes to water and soil contamination. Industrial reeling units typically rely on steam boilers, electrical dryers, and mechanized winding systems that consume large amounts of thermal and electrical energy. These operations generate substantial wastewater containing residues and detergent effluents. Also, the high energy intensity of these systems also increases their indirect carbon footprint, especially in regions where electricity depends on fossil fuels.

In contrast, traditional reeling operates at lower energy scales and produces residues that are often reused as fertilizer or animal feed, aligning more closely with circular bioeconomy principles. Yet this environmental advantage is offset by lower process efficiency and greater sensitivity to climatic variability. Thus, while industrial systems exert a larger ecological load, traditional systems bear higher ecological vulnerability.

Universities and public research centers play a crucial role as boundary actors between formal R&D and community needs. Beyond conventional technology transfer to industry, they can experiment with low-cost prototypes, validate frugal design features, and incorporate ergonomic and gender-sensitive considerations often overlooked in industrial settings. More importantly, they can open community-facing pathways to innovation: participatory prototyping with producers, open licensing or non-exclusive agreements for cooperatives, and incubation schemes for producer-led enterprises. In this sense, universities bridge formal R&D and rural practices, making knowledge and design processes accessible to communities that otherwise remain excluded from industrial innovation circuits.

A useful contrast emerges with the policy frameworks of the European Union (EU), such as the Common Agricultural Policy, the Green Deal, and the farm-to-fork strategy, which explicitly link agricultural transformation to sustainability incentives, certification systems, consumer demand, and fair economic returns for farmers [71]. By contrast, the sericulture patent record reflects a predominantly industrial trajectory, characterized by concentration among corporate assignees and the relative absence of explicit attention to inclusiveness, adaptability to smallholder conditions, or integration of circular practices.

While this does not imply that regulatory or policy initiatives are absent in these contexts, they remain far less visible in IP filings. The comparison therefore suggests that, unlike the EU model where regulatory frameworks deliberately steer technological development toward sustainability and equity, sericulture innovations in other regions risk reinforcing industrial concentration unless complementary policies—such as cooperative models, targeted R&D support, or inclusive innovation incentives—are strengthened.

Taken together, the evidence points to a need for joint action. Public policy can create enabling frameworks through funding, regulation, and incentives, while universities can expand the repertoire of innovation pathways to include community-centered models. Strengthening entrepreneurial capacities in rural sericulture—through training, technical extension, and improved market access—is as important as developing new technologies. Sustainable policy frameworks must also account for asymmetric ecological pressures, promoting energy-efficient reeling technologies alongside local adaption strategies to safeguard both environmental integrity and rural resilience. Only when policies and academic institutions work in tandem can rural producers adopt reeling technologies effectively and capture a greater share of value in emerging circular bioeconomy markets.

5. Conclusions

In summary, this study finds that technological innovation in silk reeling has advanced rapidly but unevenly, showing strong industrial concentration and weak inclusion of rural actors. The analysis highlights three overarching findings: (i) a persistent geographical and institutional concentration of patents, (ii) limited representation of frugal and circular principles in technology design, and (iii) the need for stronger policy and academic engagement to bridge these gaps.

This study suggests both dynamism and structural bias in the evolution of the sector over the past two decades. Patent activity expanded steadily after 2000 but was overwhelmingly concentrated in China, with only minor contributions from India and Japan. Regions where sericulture continues to sustain smallholder livelihoods—Latin America, Africa, and Southeast Asia—were virtually absent from the record.

The portfolio was dominated by industrial firms and research institutes, with limited participation from universities, SMEs, or individual inventors, underscoring the prevailing orientation toward corporate R&D agendas. Technological developments clustered around four trajectories: energy-intensive drying and steaming systems, automation of end-finding, feeding, and twisting, electronic control architectures, and specialized components and materials. Yet across these clusters, only 12% of patents were judged suitable and 5% partly suitable for smallholder adoption, while the vast majority (83%) were incompatible with rural contexts.

Evaluation against six frugal and circular innovation criteria indicated limited attention to resource efficiency and knowledge accessibility, while durability and reparability were absent. Reference to context adaptability, equity, and inclusion appeared only sporadically. By-product valorization was the only criterion present across all clusters, but even here it appeared as a secondary consideration rather than a design principle. Overall, the patent record reflects a trajectory of industrial upgrading that has primarily targeted efficiency gains in reeling and processing.

However, these advances have not been accompanied by equivalent attention to social inclusion, environmental adaptability, or cultural continuity, which remain peripheral within formal innovation pathways.

The contribution of this study lies in applying an IP lens to compare industrial innovation trajectories with the realities of traditional sericulture. Patent data, by their nature, largely captures the priorities of formal R&D and industrial actors; this inherent bias is well known. Yet precisely because patents reflect industrial activity, they provide a useful benchmark against which to contrast the conditions of rural sericulture, where innovation often takes the form of informal, workshop-level adaptions that rarely enter the IP system.

This distinction is particularly significant because sericulture is not only an agro-industrial sector but also a cultural practice and a livelihood system embedded in rural economies. For many communities around the Global South, silk production provides income diversification, employment, and intergenerational transmission of artisanal knowledge. The marginalization of these producers within formal innovation trajectories may therefore limit not only economic opportunities but also cultural heritage and social resilience.

The projected expansion of the global silk market further highlights this dynamic: rising consumer demand creates opportunities, but without deliberate policy and institutional interventions, the benefits risk concentrating in industrial actors rather than strengthening smallholder livelihoods. Positioning sericulture within broader debates on agricultural transformation therefore requires attention to both innovation pathways and the distribution of economic gains across producers, markets, and rural communities.

These findings suggest that, without deliberate reorientation, rural households could remain excluded from emerging bio-based value chains. Addressing this risk will depend on technologies that are modular, repairable, and affordable, as well as policies that encourage decentralized and smallholder-oriented sericulture. Universities can play a pivotal role as boundary institutions by co-developing low-cost prototypes, strengthening entrepreneurial capacities, and helping communities capture value from by-products.

Beyond recognizing this structural imbalance, several policy instruments could help address the market failures that discourage inclusive and low-cost innovation. These include targeted R&D incentives for small and modular machinery, open-licensing frameworks to reduce entry barriers for SMEs, and public–private partnerships that link universities with cooperatives and local enterprises to co-develop adaptable technologies. Expanding access to certification schemes and promoting the reuse of by-products could also align industrial efficiency with broader social and environmental goals. Such coordinated actions would allow universities, policymakers, and producers to operate as an integrated innovation system, ensuring that technological progress contributes directly to territorial development and social equity.

Barriers to technology transfer in sericulture include infrastructure limitations, low technological literacy, and weak institutional coordination. Addressing these requires joint action by universities, cooperatives, and public agencies to adapt and disseminate modular technologies suited to rural contexts.

Institutional experiences around the world show that innovation systems can be redesigned to promote inclusion and sustainability. By aligning research, policy, and community practice, these frameworks demonstrate that it is possible to translate frugal and open innovation principles into operational programs that foster accessibility, affordability, and local participation in technology development. They highlight the importance of creating and enabling environments where low-cost, adaptable solutions can emerge from collaboration between public institutions, academia, and local actors.

Such approaches confirm that inclusive technological transitions require more than isolated inventions—they depend on governance models that bridge formal R&D with community-based innovation.

At a broader theoretical level, this research demonstrates that patent landscapes can function as a diagnostic tool to assess patterns of inclusion and exclusion in technological transitions, offering valuable insights for the governance of innovations and sustainability. Future research should expand patent analysis beyond reeling to cover mulberry cultivation, silkworm breeding, and downstream by-product recovery. Comparative scientific studies across other agro-based value chains could help determine whether the industrial bias assessed in sericulture is systemic, while participatory, field-based approaches are needed to integrate the perspective of rural producers themselves. Only by aligning technological development with the principles of frugal innovation and the circular bioeconomy will traditional sericulture be allowed to evolve in ways that strengthen rural livelihoods, safeguard cultural traditions, and contribute to an inclusive and sustainable bio-based future.

Author Contributions

Conceptualization, S.A.-M. and E.O.-Z.; methodology, S.A.-M.; software, S.A.-M. and E.O.-Z.; validation, H.M. and C.V.M.-R.; formal analysis, M.F.S.-S., H.M. and C.V.M.-R.; investigation, M.S.-S.; resources, M.S.-S.; data curation, M.F.S.-S., H.M. and C.V.M.-R.; writing—original draft preparation, S.A.-M.; writing—review and editing, E.O.-Z.; visualization, S.A.-M. and E.O.-Z.; supervision, S.A.-M. and E.O.-Z.; project administration, S.A.-M. and E.O.-Z.; funding acquisition, S.A.-M. and E.O.-Z. All authors have read and agreed to the published version of the manuscript.

Funding

The research was funded by the Secretaria de Ciencia, Humanidades, Tecnología e Innovación (SECIHTI), grant number MADTEC-2025-M-651 and Secretaria de Investigación y Posgrado of IPN (Instituto Politécnico Nacional), grant number SIP 20253587, and the APC was funded by Secretaria de Ciencia, Humanidades, Tecnología e Innovación and Secretaria de Investigación y Posgrado of IPN.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available in this article.

Acknowledgments

We sincerely thank the Secretaria de Ciencia, Humanidades, Tecnología e Innovación and the National Polytechnic Institute for providing the facilities and infrastructure essential to this research. Special gratitude is extended for their financial and administrative support in publishing this article. The authors used ChatGPT (OpenAI, model o3, June 2025) for language editing and accept full responsibility for the final text.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| CITSAC | Centro de Investigación en Tecnologías y Saberes Comunitarios |

| DOs | Designations of Origin |

| ESG | Environmental, Social, and Governance |

| EU | European Union |

| GIs | Geographical Indications |

| IP | Intellectual property |

| IR | Infrared |

| PLCs | Programmable logic controllers |

| R&D | Research and development |

| UV | Ultraviolet |

References

- Sawangloke, W.; Chanthes, S.; Nuttee, S. Measuring the labor productivity of sericultural farmers in Mahasarakham province, Thailand. Afr. J. Food Agric. Nutr. Dev. 2023, 23, 24383–24405. [Google Scholar] [CrossRef]

- Barcelos, S.; Salvador, R.; Vetroni-Barros, M.; Carlos de Francisco, A.; Graça-Guedes, M. Circularity of Brazilian silk: Promoting a circular bioeconomy in the production of silk cocoons. J. Environ. Manag. 2021, 296, 113373. [Google Scholar] [CrossRef] [PubMed]

- Đoan, V.V.D.; Duan, B.Q.; Truong, H.X.; Tuan, T.V.; Tan, T.K.; Anh, D.T.; Dang, B.Q.; Gil, H.S.; Nae, H.J. Development of Sericulture Value Chain in Vietnam; FFTC Agricultural Policy Platform: Taipei, Taiwan, 2022. [Google Scholar]

- Barcelos, S.M.B.D.; Salvador, R.; Guedes, M.d.G.; de Francisco, A.C. Opportunities for improving the environmental profile of silk cocoon production under brazilian conditions. Sustainability 2020, 12, 3214. [Google Scholar] [CrossRef]

- International Sericulture Comission. Available online: https://inserco.org/en/ (accessed on 1 August 2025).

- FAO. Out of Its Cocoon. Available online: https://www.fao.org/newsroom/story/out-of-its-cocoon/en (accessed on 13 August 2025).

- Thangavelu, K. Conservation status of silkworm genetic resources in India. In Conservation Status of Sericulture Germplasm Resources in the World—II. Conservation Status of Silkworm (Bombyx Mori) Genetic Resources in the World; Kee-Wook, S., Ed.; Food and Agriculture Organization of the United Nations: Bangkok, Thailand, 2003. [Google Scholar]

- Harshita Mala, P.; Thrilekha, D.; Reddy, H.; Gulabrao, D.P.; Shree, D.; Karan, S. The socioeconomic impact of sericulture on rural development. Int. J. Agric. Ext. Soc. Dev. 2024, 7, 631–636. [Google Scholar] [CrossRef]

- Silk Market Size Is Set to Grow by USD 5.00 Billion from 2024–2028, Increasing Requirement for Silk in Textile Industry Boostt the Market, AI Rol and Impact, Technavio. Available online: https://www.prnewswire.com/news-releases/silk-market-size-is-set-to-grow-by-usd-5-00-billion-from-2024-2028--increasing-requirement-for-silk-in-textile-industry-boost-the-market-ai-role-and-impact-technavio-302228546.html?utm_source= (accessed on 17 August 2025).

- Moreno-Nava, I.; Muñoz-Ruíz, C.V. Potencialidades de la sericicultura para la inclusión social y desarrollo post COVID-19 en la región Ciénega del Estado de Michoacán de Ocampo, México. In Patrimonio Cultural Inmaterial e Inclusión Social. Aportes Para la Agenda de Desarrollo de la era Post-COVID en América Latina y el Caribe; UNESCO: Paris, France, 2022. [Google Scholar]

- Gowrisankar, R.; Dasari, S.; Anas, M. Silk reeling techniques: Exploring traditional and advanced methods. J. Exp. Agric. Int. 2023, 45, 91–99. [Google Scholar] [CrossRef]

- Syeda, F.I.; Isharb, A.; Kumar, G.; Ajrawat, A.; Jeeva, S.; Devi, H.; Rajeswari, S.; Kumari, B. Recent innovations in sericulture: A comprehensive review of advancements in silk production and quality enhancement. Uttar Pradesh J. Zool. 2024, 45, 75–83. [Google Scholar] [CrossRef]

- Tassoni, L.; Cappellozza, S.; Zotte, A.-D.; Belluco, S.; Antonelli, P.; Marzolli, F.; Saviane, A. Nutritional Composition of Bombyx mori Pupae: A Systematic Review. Insects 2022, 13, 644. [Google Scholar] [CrossRef]

- Lujerdean, C.B.; Baci, G.-M.; Cucu, A.-A.; Dezmirean, D.S. The contribution of silk fibroin in biomedical engineering. Insects 2022, 13, 286. [Google Scholar] [CrossRef]

- Attri, K.S.; Sujatha, G.; Jekinakatti, B.; Thrilekha, D.; Devi, D.-L.; Garai, I.; Satapathy, S.-N.; Tripathy, A. Advancements in sericulture: Innovations and sustainability in silk. Uttar Pradesh J. Zool. 2024, 45, 305–317. [Google Scholar] [CrossRef]

- Hindocha, C.N.; Antonacci, G.; Barlow, J.; Harris, M. Defining frugal innovation: A critical review. BMJ Innov. 2021, 7, 647–656. [Google Scholar] [CrossRef]

- Mesa, J.A.; Sierra-Fontalvo, L.; Ortegon, K.; Gonzalez-Quiroga, A. Advancing circular bioeconomy: A critical review and assessment of indicators. Sustain. Prod. Consum. 2024, 46, 324–342. [Google Scholar] [CrossRef]

- Baci, G.-M.; Cucu, A.-A.; Giurgiu, A.-I.; Muscă, A.-S.; Bagameri, L.; Moise, A.R.; Bobiș, O.; Rațiu, A.C.; Dezmirean, D.S. Advances in Editing Silkworms (Bombyx mori) Genome by Using the CRISPR-Cas System. Insects 2021, 13, 28. [Google Scholar] [CrossRef]

- Zhu, K.; Chen, Y.; Chen, L.; Xiang, H. Comparative Silk Transcriptomics Illuminates Distinctive Impact of Artificial Selection in Silkworm Modern Breeding. Insects 2022, 13, 1163. [Google Scholar] [CrossRef]

- Ehsaan, I.A.; Alam, H.; Hussain, M.; Amjad, S.; Ali, K.; Amjad, M.; Khan, Q.; Imran, M.; Aneesa-Fatima, H.; Ali, W. Assessing the rearing performance of Bombyx mori (Linnaeus, 1758) on two different mulberry species. J. Wildl. Biodivers. 2025, 9, 175–187. [Google Scholar] [CrossRef]

- Liu, Z.; Li, C.; Yang, W.; Wu, Q.; Xiao, W.; Zhu, Y.; Wei, Q.; Dong, Z.; Zhang, G.; Lu, C.; et al. The Bombyx mori singed Gene Is Involved in the High-Temperature Resistance of Silkworms. Insects 2024, 15, 264. [Google Scholar] [CrossRef]

- Dewangan, S.-K. Livelihood opportunities through sericulture a model of Gharghoda tribal block, Raigarh Dist. Am. J. Environ. Sci. 2013, 9, 343–347. [Google Scholar] [CrossRef][Green Version]

- Reddy, Y.P.; Parasuramudu, M. Role of Sericulture in the Indian Economy. J. Res. Appl. Sci. Biotechnol. 2024, 3, 107–116. [Google Scholar] [CrossRef]

- Chatterjee, A. Development of Sericulture in Murshidabad with Special Reference to Women’s Participation. In Livelihood Enhancement Through Agriculture, Tourism and Health; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- Mushtaq, R.; Qadiri, B.; Lone, F.A.; Raja, T.A.; Singh, H.; Ahmed, P.; Sharma, R. Role of sericulture in achieving Sustainable Development Goals. Probl. Ekorozwoju 2023, 18, 199–206. [Google Scholar] [CrossRef]

- Sharma, K. Sericulture as profit-based industry. A review. Indian J. Pure Appl. Biosci. 2020, 8, 550–562. [Google Scholar] [CrossRef]

- van Rijn, T.; Kenneth-Timmis, J. Patent landscape analysis-Contributing to the identification of technology trends and informing research and innovation funding policy. Microb. Biotechnol. 2023, 16, 683–696. [Google Scholar] [CrossRef] [PubMed]

- What is Intellectual Property? World Intellectual Property Organization: Geneva, Switzerland, 2020.