Ventilation Technology of Diesel Locomotive Railway Tunnels: Current Trends, Sustainable Solutions and Future Prospects

Abstract

1. Introduction

1.1. Safe Ventilation: A Critical Factor in Ensuring Safe Operation of Railway Tunnel

1.2. Insufficient Ventilation in Railway Tunnels Potentially Leads to Engineering Issues and Safety Incidents

1.3. Main Goal and Organization of This Paper

2. Development of Diesel Locomotives and Railway Tunnels

2.1. Development of Railway Tunnel

2.2. Development of Diesel Locomotives

3. Components and Classification of the Ventilation System of the Diesel Locomotive Railway Tunnel

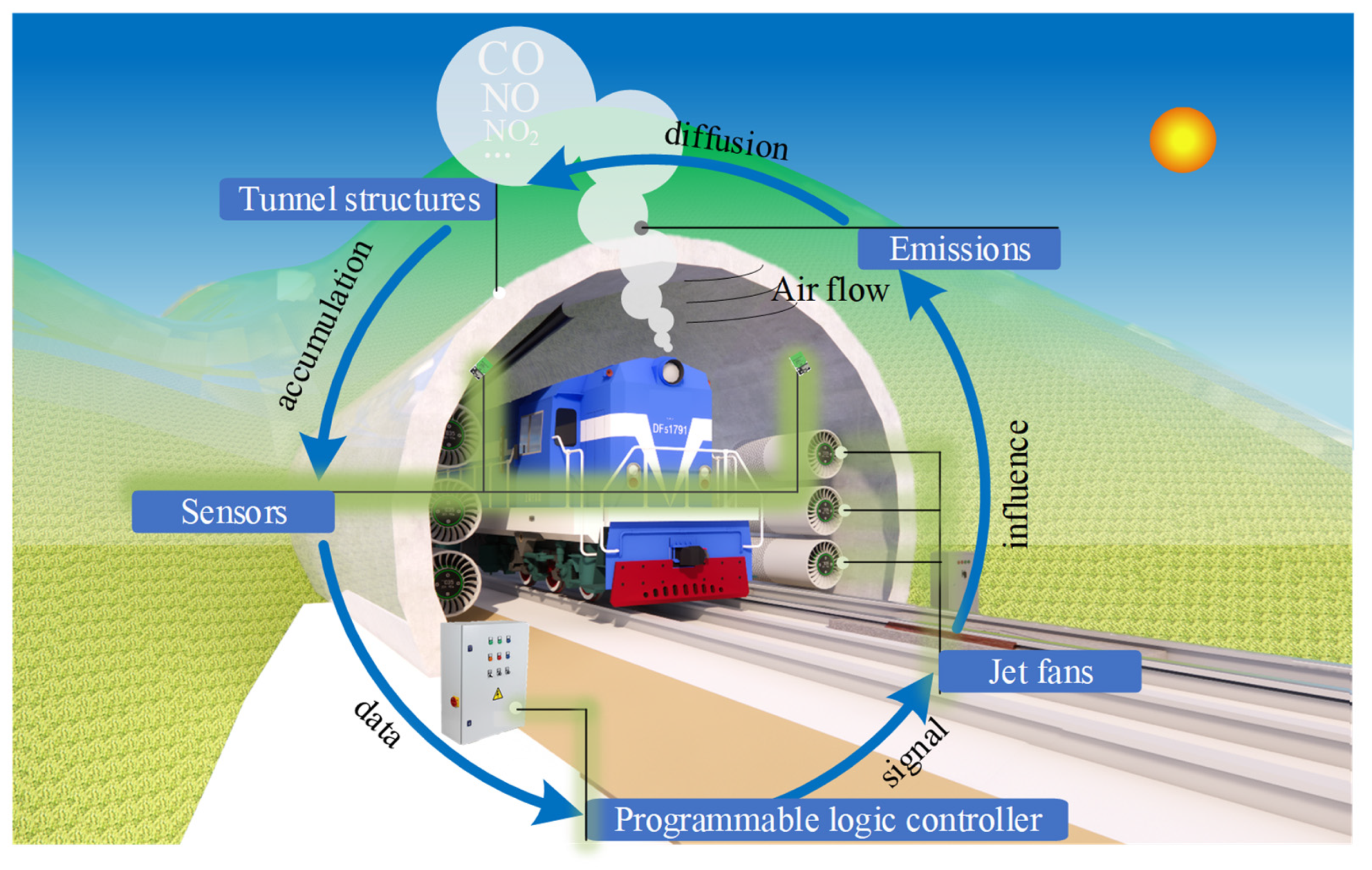

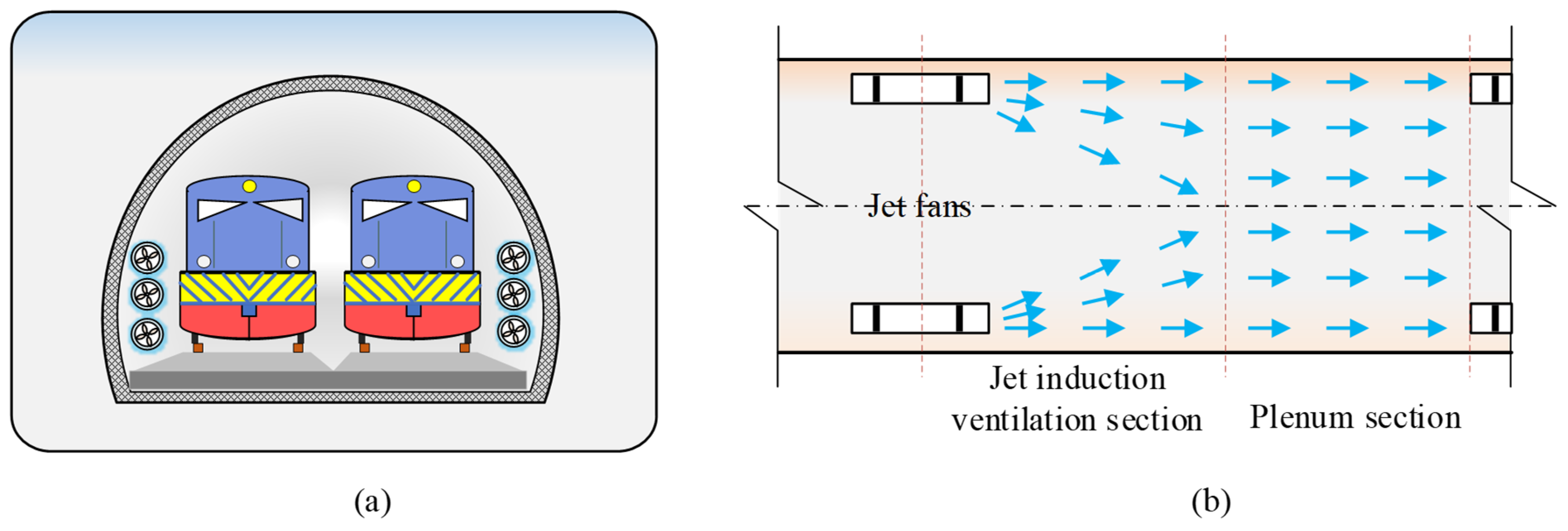

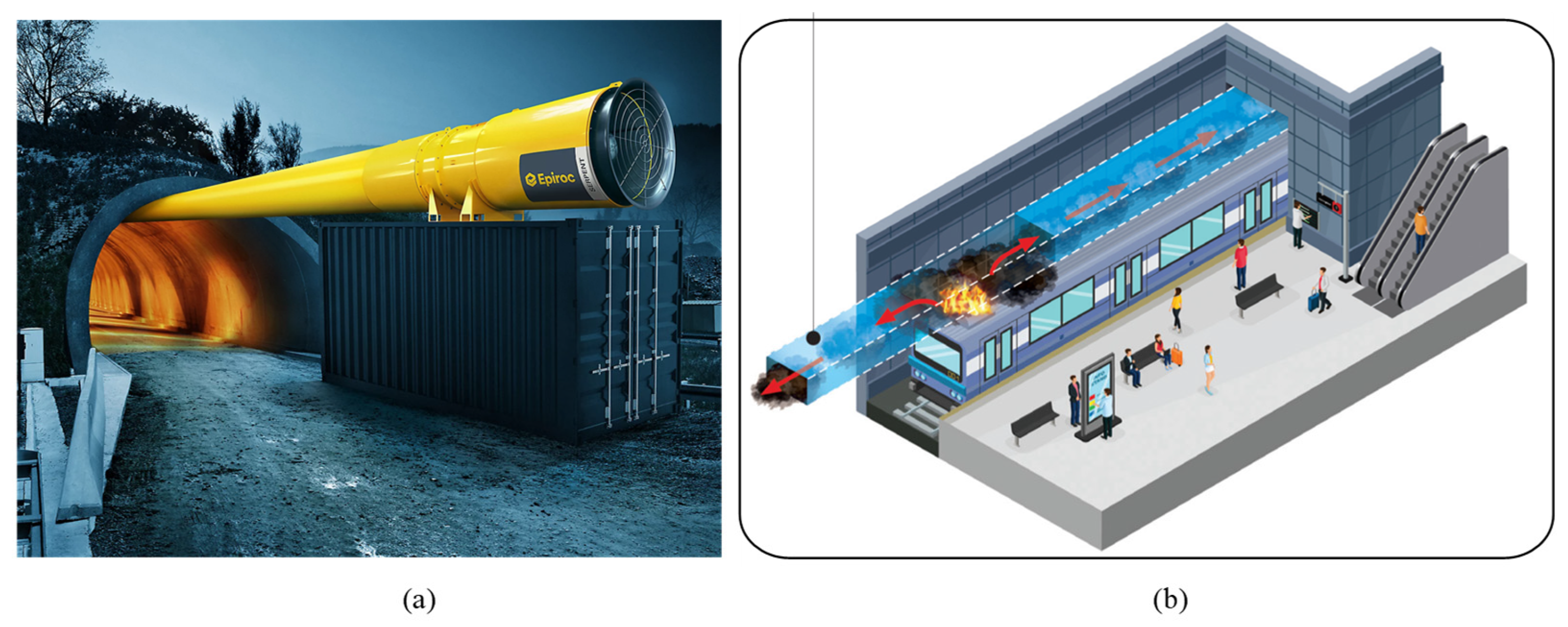

3.1. Components of Tunnel Ventilation System

3.1.1. Emissions

3.1.2. Tunnel Structures

3.1.3. Sensors

3.1.4. Programmable Logic Controller

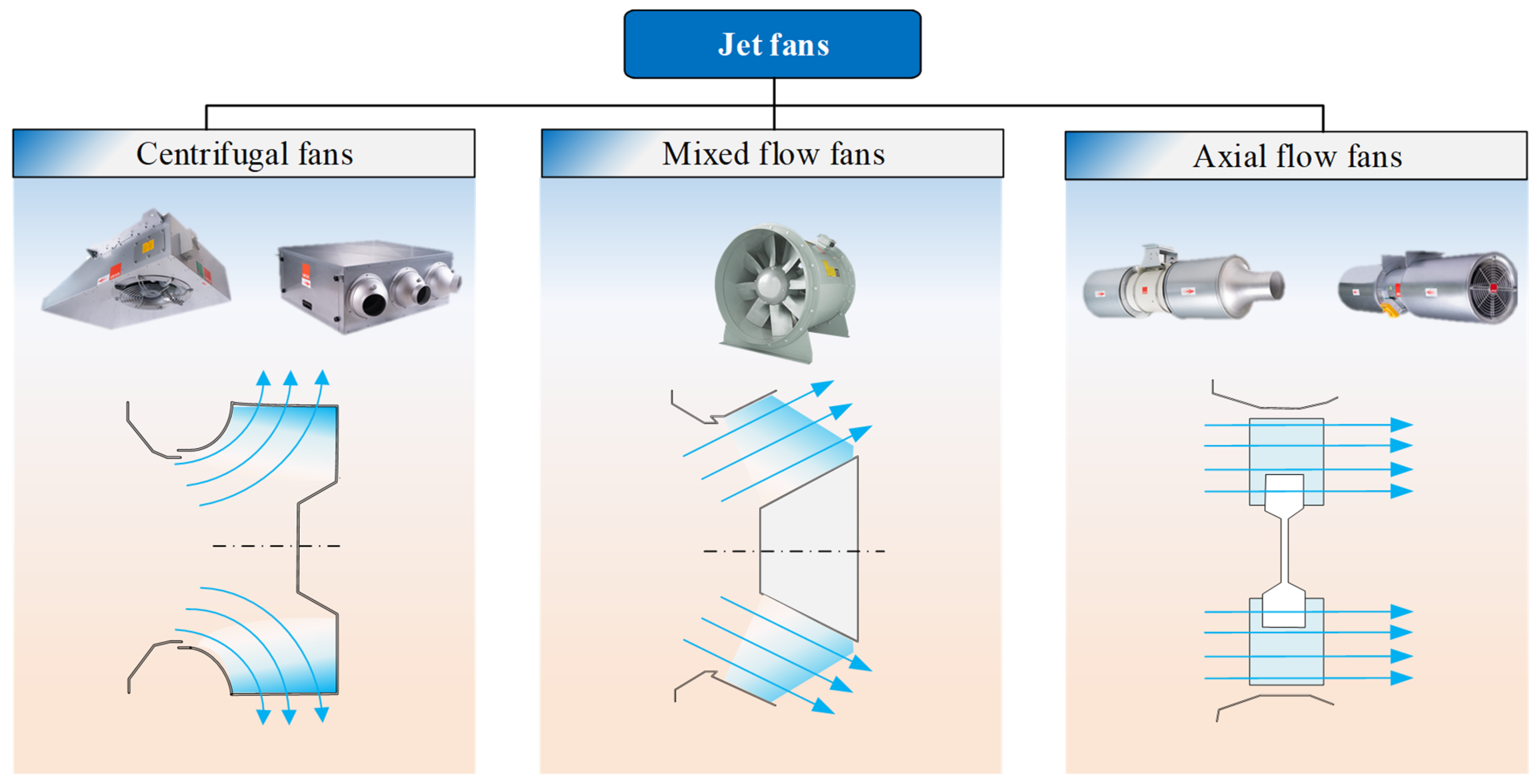

3.1.5. Auxiliary Ventilation Equipment

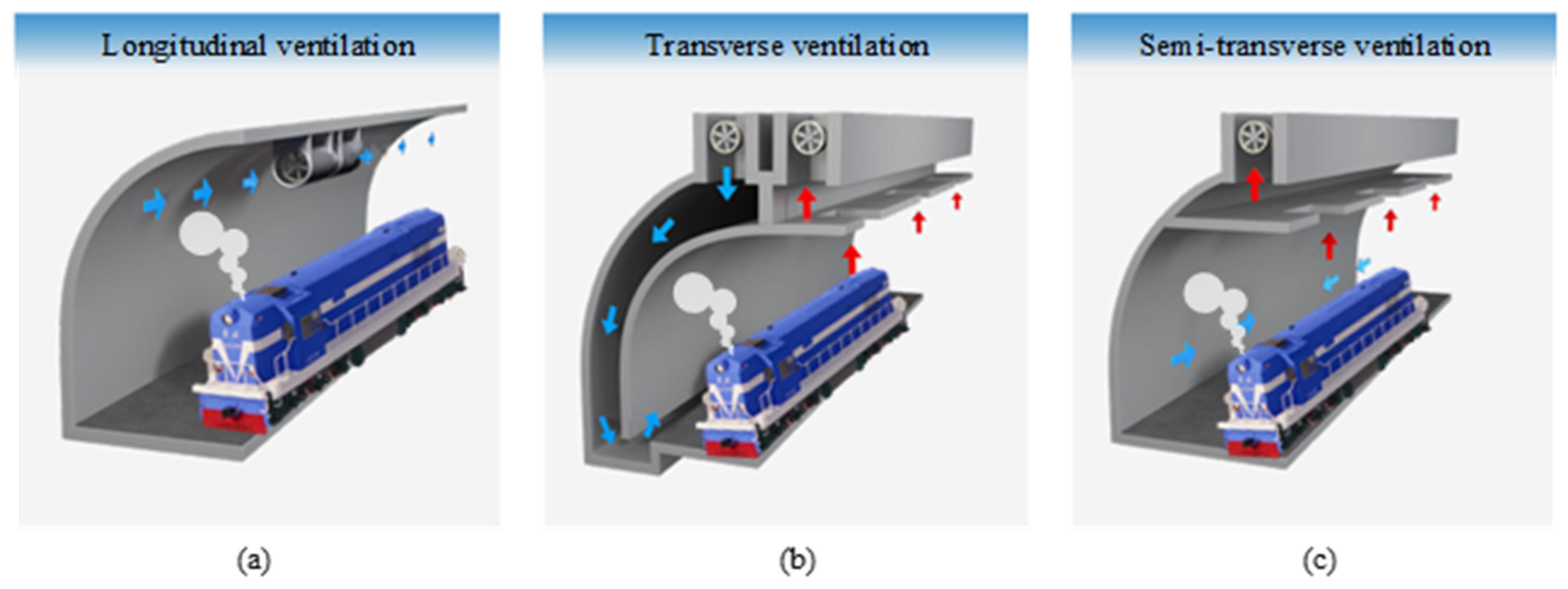

3.2. Classification of the Tunnel Ventilation System

3.3. Energy Consumption of Different Ventilation Strategies

4. Ventilation Standards for Diesel Locomotive Railway Tunnels

4.1. Primary Pollutant

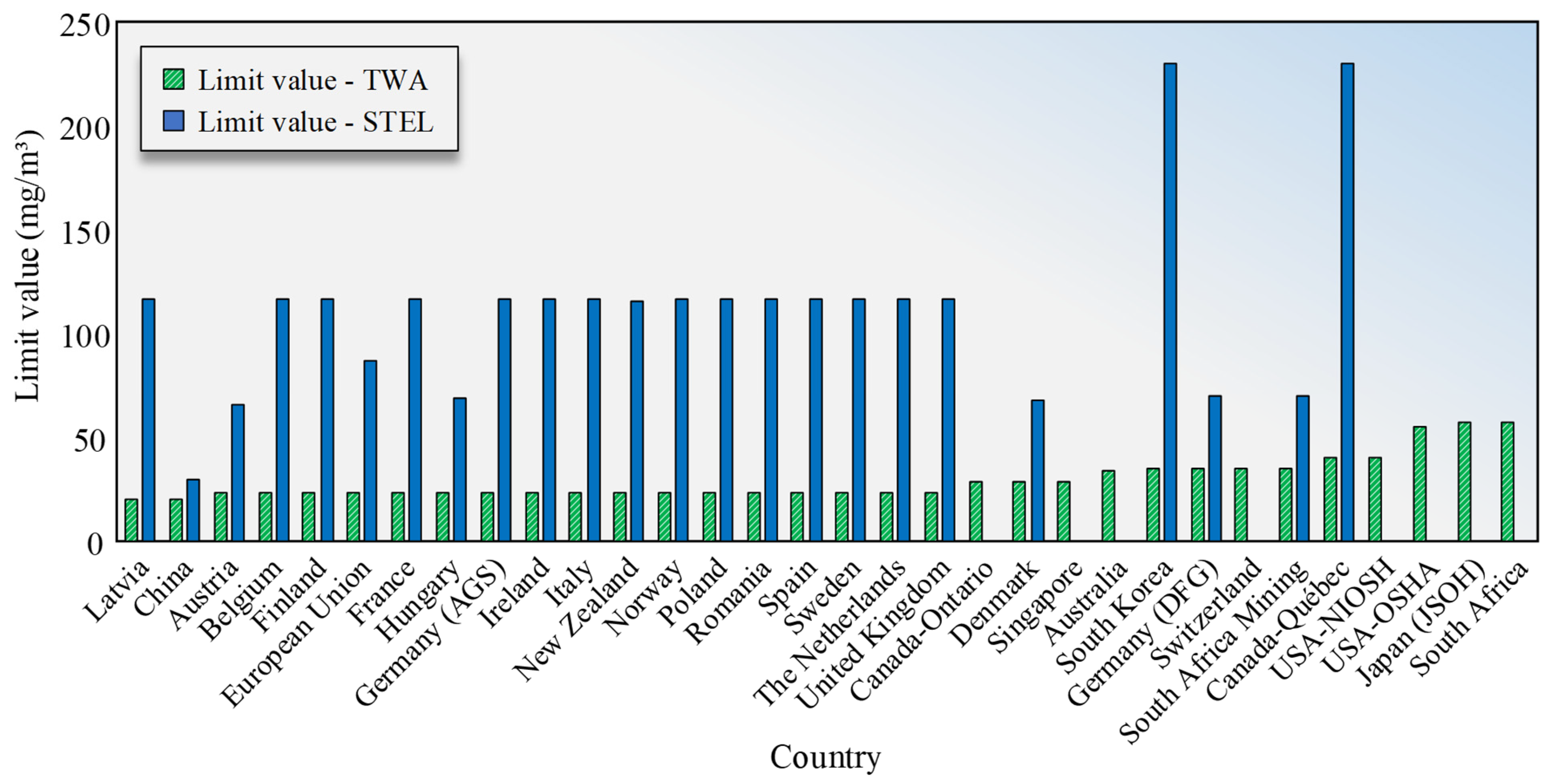

4.2. Ventilation Standards of the Main Countries Around the World

- PC-TWA: The average allowable exposure concentration over an 8 h workday or a 40 h workweek, calculated using time weighting.

- PC-STEL: The maximum allowable concentration for short-term exposure (15 min), provided that the PC-TWA is not exceeded.

- MAC: The peak concentration that must not be exceeded at any time during the workday in the workplace.

4.2.1. Chinese Standards

| Year | 2005 | 2014 | 2022 | 2024 | |

|---|---|---|---|---|---|

| Standard | Allowable Concentration and Measurement of Locomotive Exhaust in Railway Operating Tunnel (TB/T 1912-2005) [53] | Guidelines for Design of Ventilation of Highway Tunnels (JTG/TD70/2-02-2014) [54] | The Coal Mine Safety Rules (2022) [57] | Code for Design on Operation Ventilation of Railway Tunnel (TB10068-2024) [52] | |

| CO | PC-TWA | 30 | — | — | 20 |

| PC-STEL | 100 | 172.5 (20 min, L ≤ 1000 m) 115.0 (20 min, L > 3000 m) | — | 30 | |

| MAC | — | — | 27.5 | — (H< 2000 m) | |

| 20 (2000 m ≤ H ≤ 3000 m) | |||||

| 15 (H > 3000 m) | |||||

| NO2 | PC-TWA | 10 | — | — | 5 |

| PC-STEL | 20 | 1.88 (20 min) | — | 10 | |

| MAC | — | — | 4.7 | — | |

| NO | PC-TWA | 15 (H < 3000 m) | |||

| PC-STEL | — | ||||

| MAC | — | ||||

| Quartz dust | PC-TWA | 8 (MSiO2 < 10%) 1 (MSiO2 > 10%) | |||

| PC-STEL | 10 (MSiO2 < 10%) 2 (MSiO2 > 10%) | ||||

| MAC | — | ||||

| Marble dust (Calcium carbonate, CAS: No.1317-65-3) | PC-TWA | 4 | |||

| PC-STEL | — | ||||

| MAC | — | ||||

| Plant- and animal-based particulates | PC-TWA | 2 | |||

| PC-STEL | 4 | ||||

| MAC | — | ||||

| Other dust | PC-TWA | 8 | |||

| PC-STEL | — | ||||

| MAC | — |

4.2.2. US Standards

4.2.3. German Standards

4.2.4. The European Union Standards

4.2.5. World Health Organization (WHO)

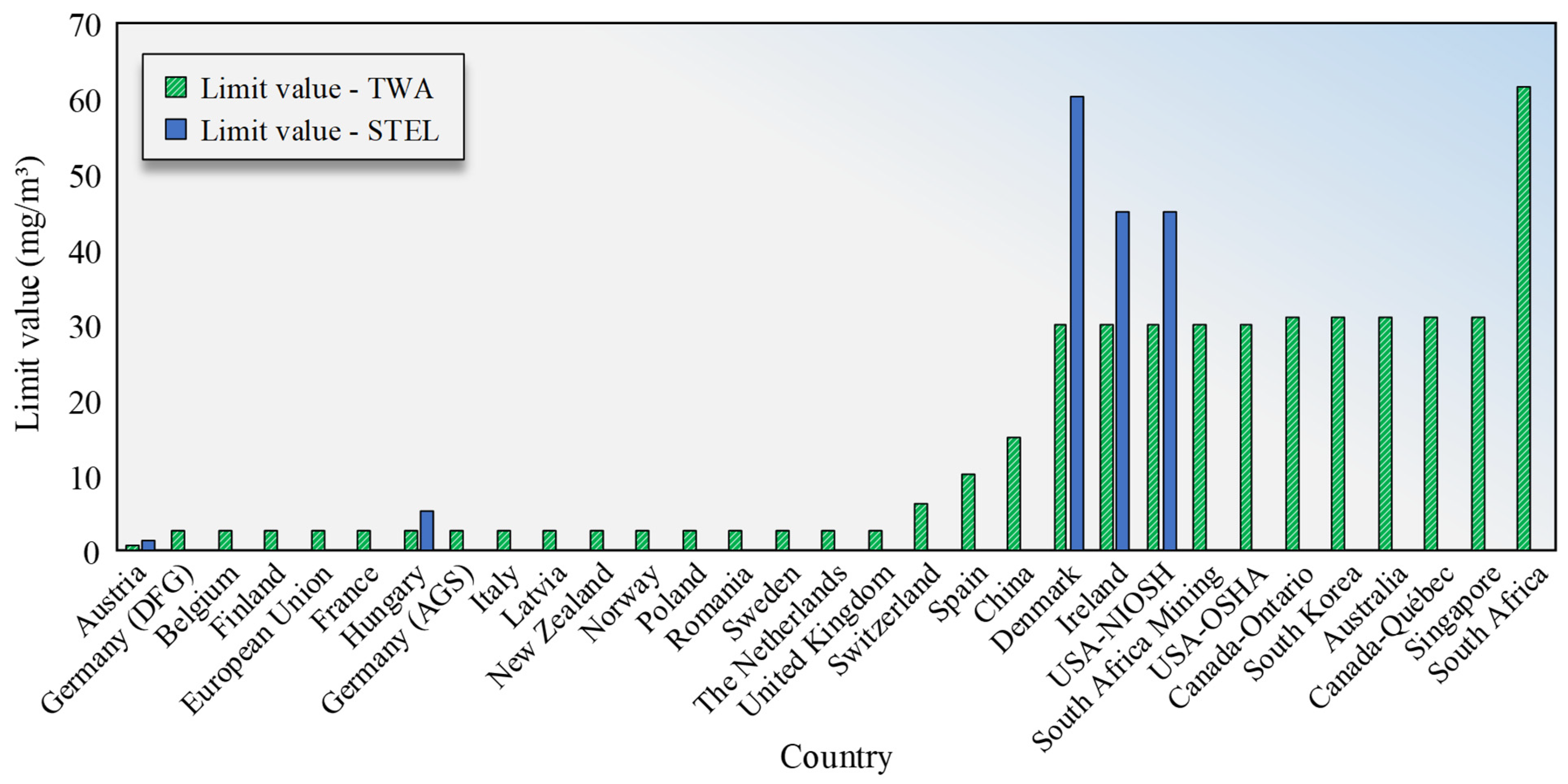

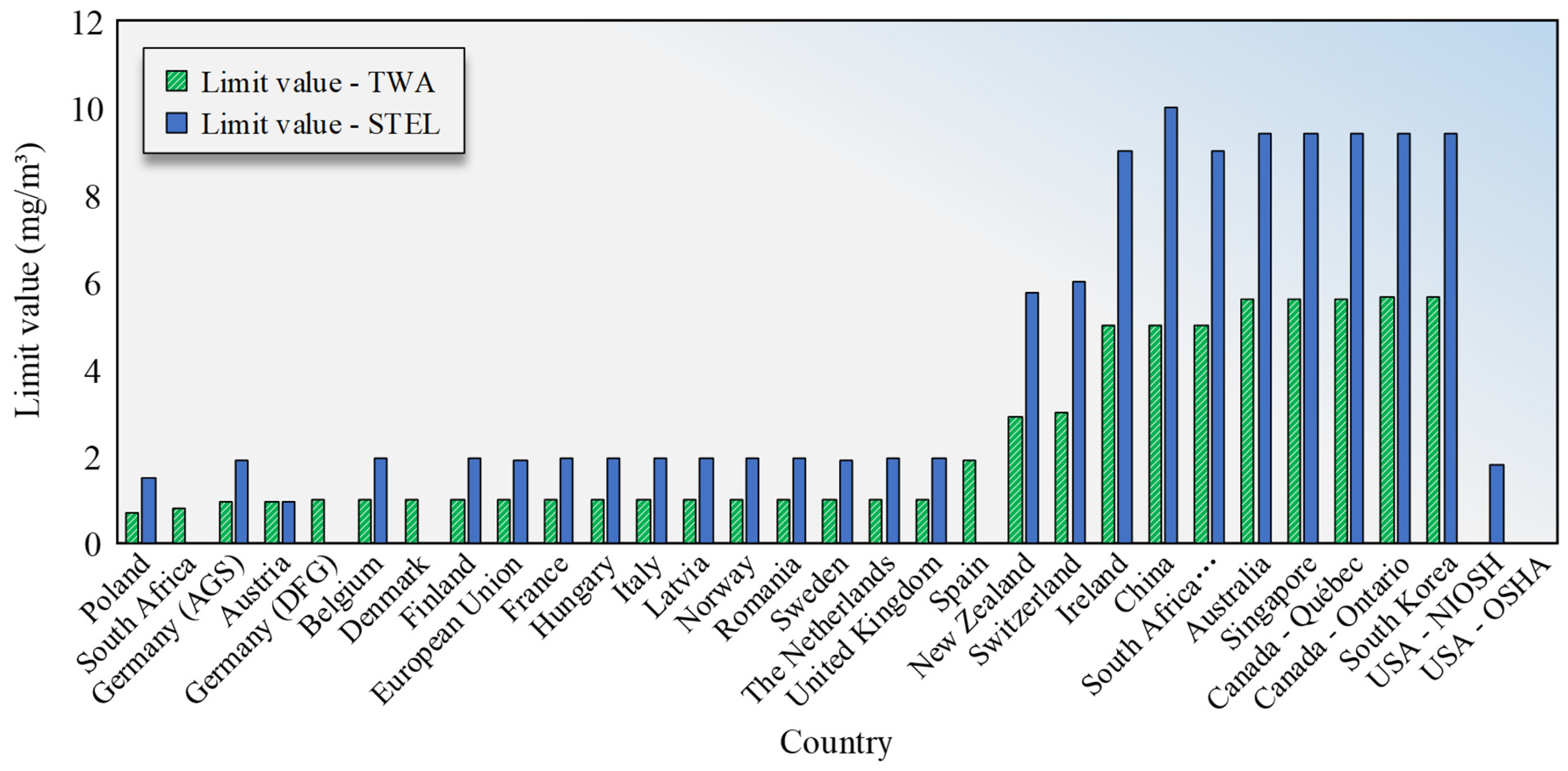

4.3. Comparative Analysis

5. Research Methods Applied for Railway Tunnel Ventilation Analysis

5.1. Theoretical Analysis

- (1)

- Dilution Theory

- (2)

- Piston Effect Theory

- Steady flow calculation

- 2.

- Unsteady flow calculation

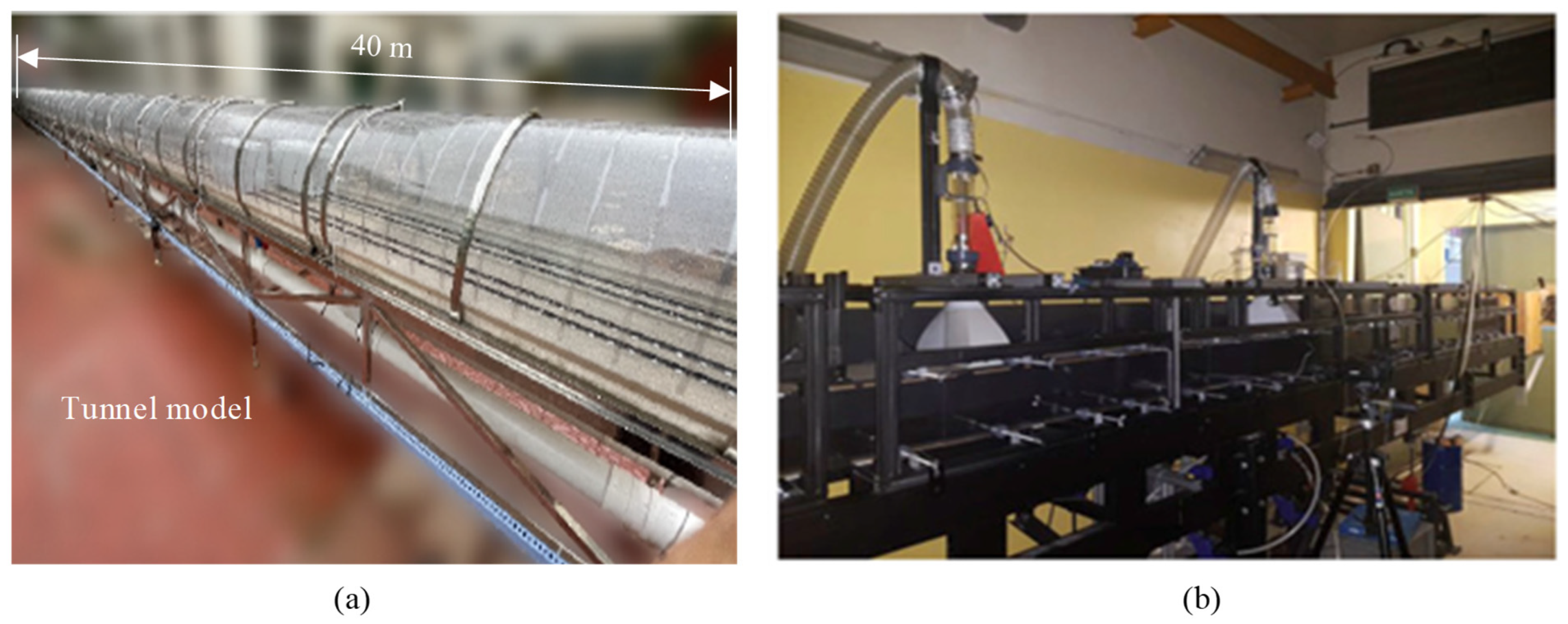

5.2. Scale Model Experiments

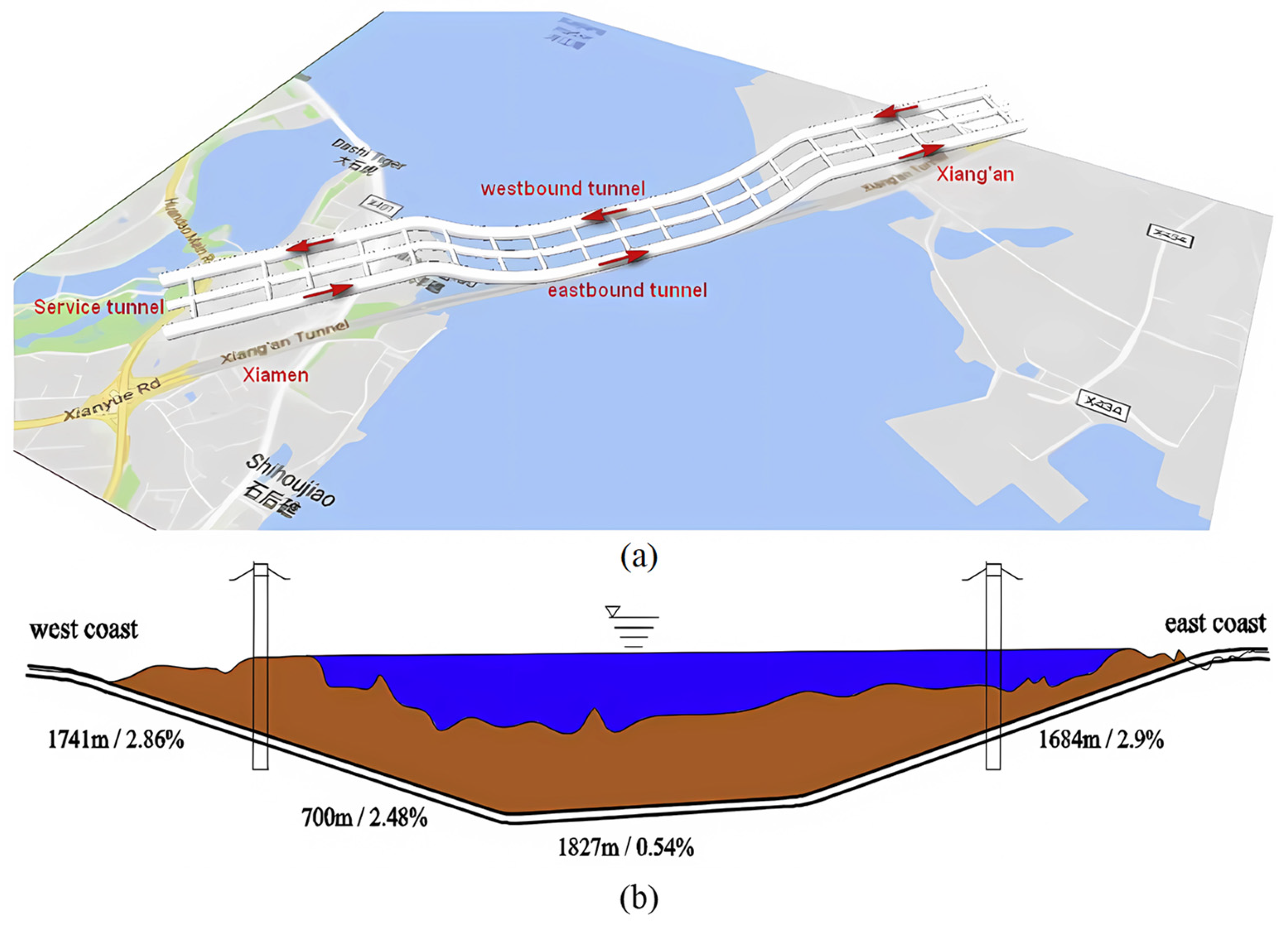

5.3. Field Tests

5.4. Numerical Simulation

6. Main Factors Affecting the Ventilation Effect of Diesel Locomotive Railway Tunnels

6.1. Pollutant Concentration and Its Distribution

6.2. Cross-Section Size, Length, and Gradient of the Tunnel

- (1)

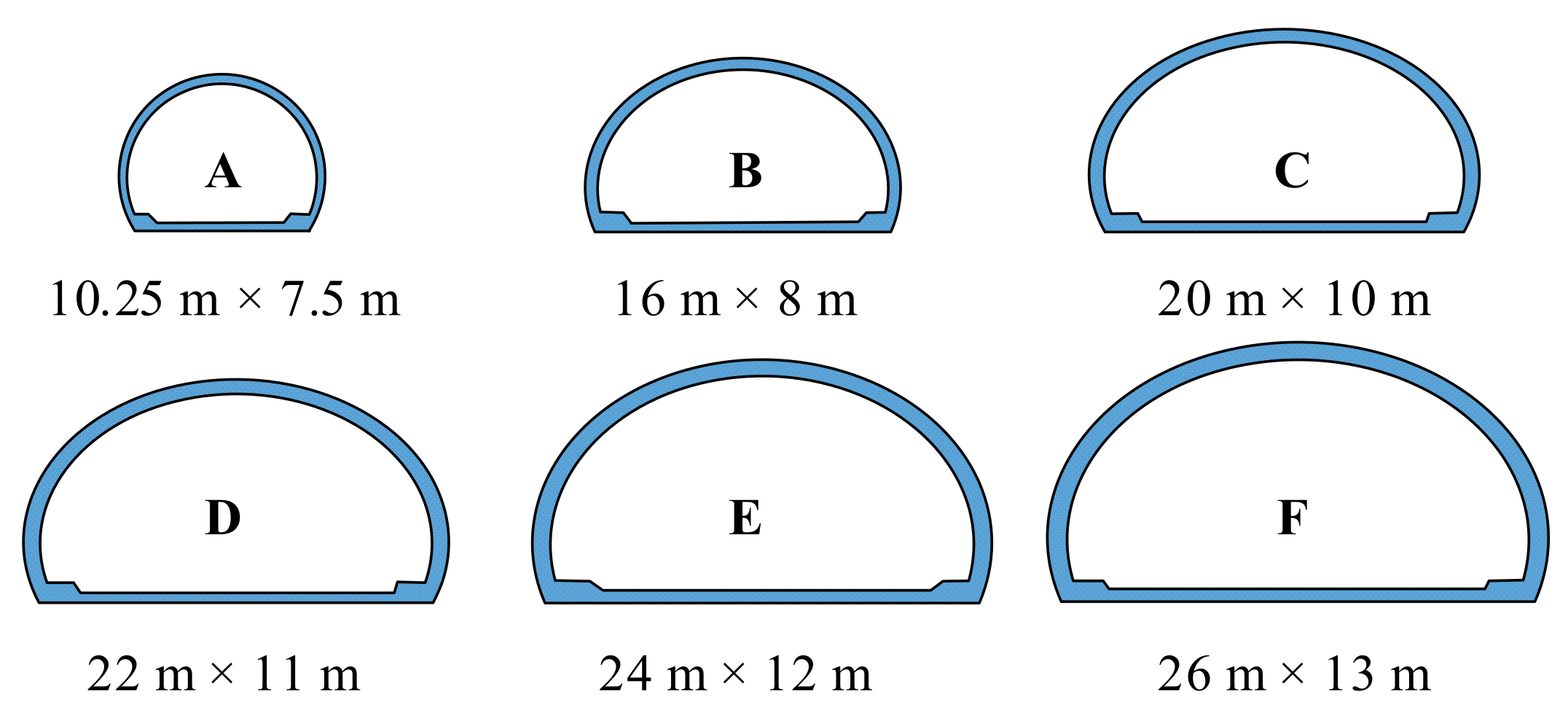

- Cross-section size

- (2)

- Cross-section shape

- (3)

- Tunnel length

- (4)

- Tunnel gradient

6.3. Operation Conditions of the Train

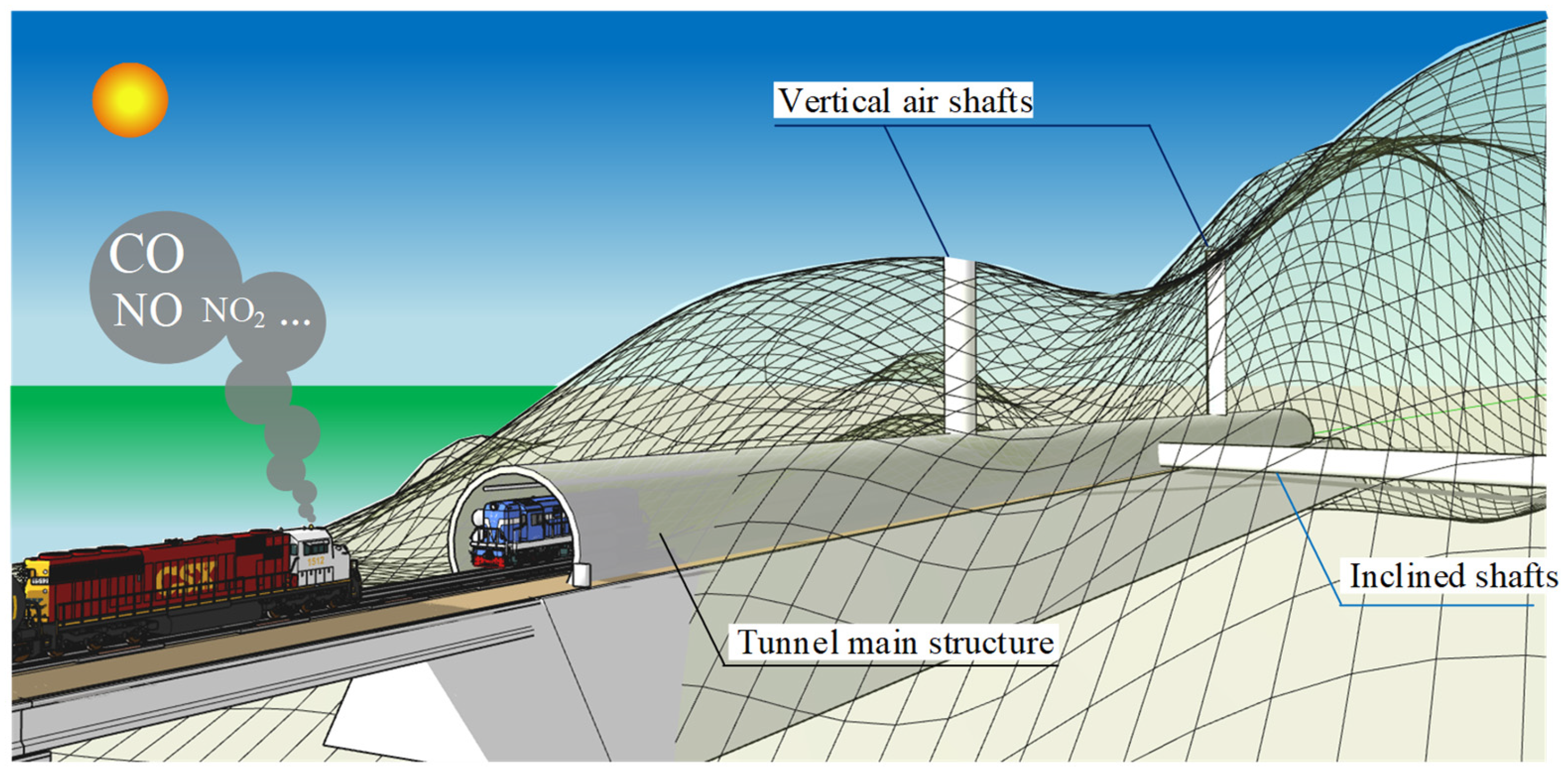

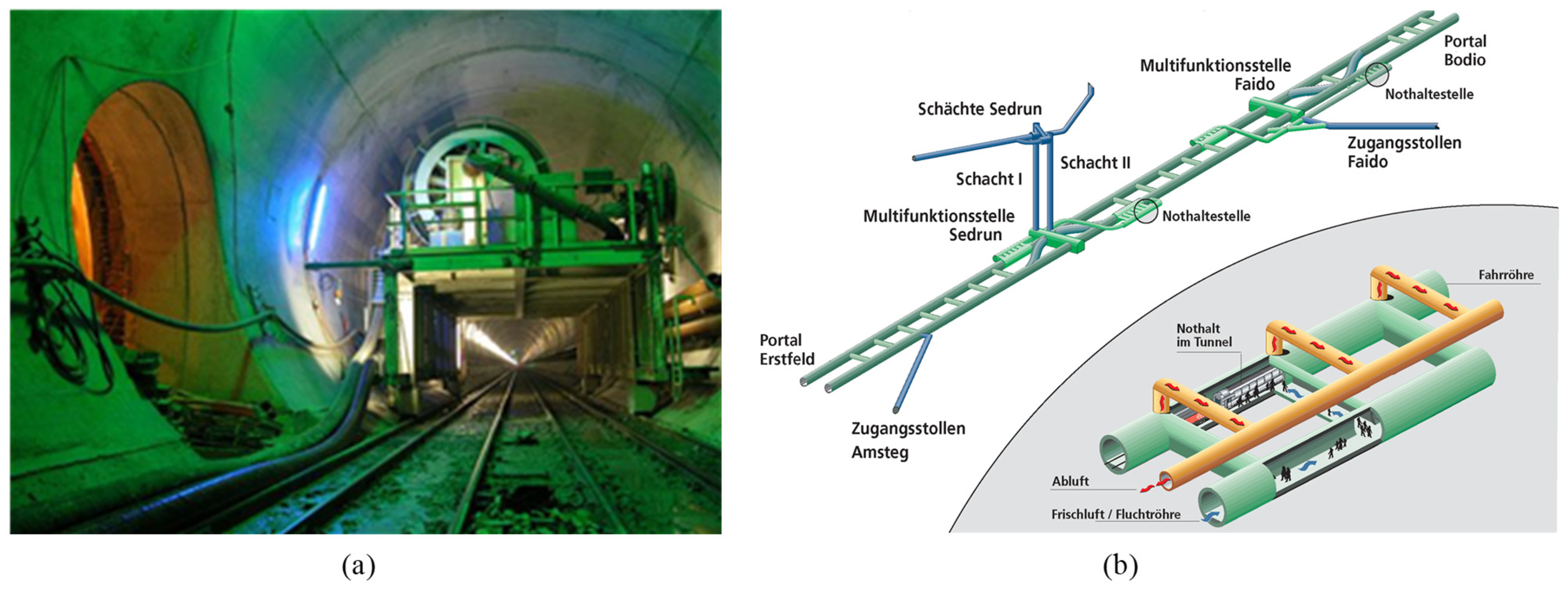

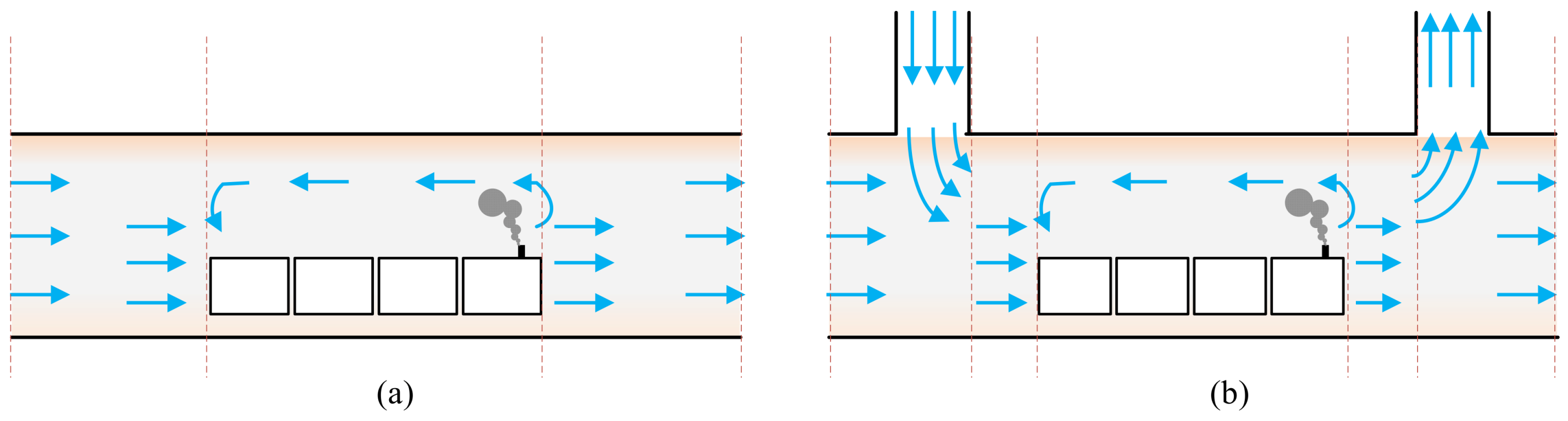

6.4. Ventilation Structures

- (1)

- Influence of vertical shafts and inclined shafts

- (2)

- Influence of transverse passages

6.5. Effect of Auxiliary Ventilation Equipment

6.6. External Environmental Condition

- (1)

- Altitude

- (2)

- Temperature

- (3)

- Natural wind

6.7. Diffusion Coefficient

7. Ventilation Control for Diesel Locomotives Railway Tunnels

7.1. Traditional Ventilation Control Modes

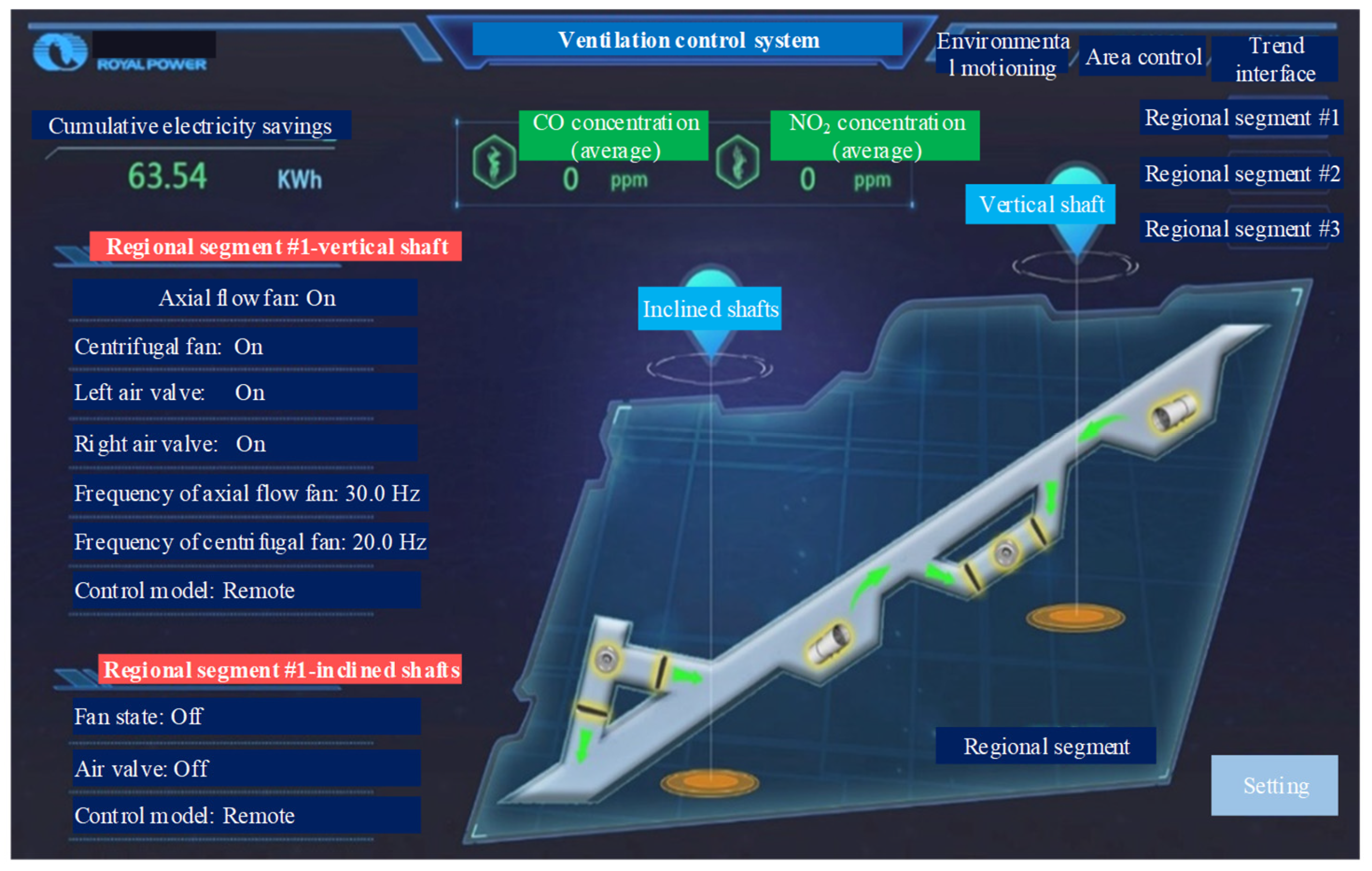

7.2. Sensor-Based Active Control

7.3. Intelligent Control

8. Conclusions

- Diesel locomotives are the preferred form of railway freight train traction in developing countries with weak power infrastructure, as well as in high-altitude areas and permafrost regions. With the continuous development of these areas and the progress of the construction technology for ultra-long, ultra-wide and deeply buried railway tunnels, researching the ventilation issues of diesel locomotive railway tunnels is of great value for ensuring the safe operation and emergency rescue of railways in developing countries, high-altitude areas and permafrost regions.

- Currently, the consideration and control requirements for pollutants in tunnels in the regulations of various countries are becoming more comprehensive. In particular, special attention should be paid to three pollutants: CO, NO and NO2. EU countries, represented by the UK and France, have significantly higher control requirements for pollutant concentrations in tunnels than other countries. In contrast, the regulatory standards of countries such as the US and Canada are more lenient. The determination of pollutant concentration limits in tunnels in a region should take into account the tunnel length, the altitude of the tunnel location and the population density, as well as the economic development status.

- Combining multiple research methods, such as theoretical analysis, scale models, field tests, and numerical simulations, has become a new research approach. Experience and theories provide the basic direction and framework for conducting tests and simulations. Field tests can determine as realistic boundary parameters as possible for simulation analysis, while simulation analysis can reduce the trial-and-error cost of field tests. Finally, the research results obtained based on systematic simulation analysis and experimental verification can provide a basis for the further improvement of ventilation theories.

- The working efficiency of railway tunnel ventilation systems is related to the specific concentration distribution of pollutants in the tunnel, the size parameters, ventilation structure and ventilation equipment of the tunnel, as well as the operating conditions of trains. Different influencing factors often jointly change the ventilation performance through complex coupling effects. The comprehensive influence of external environmental conditions such as altitude, temperature and humidity, and natural wind can be macro-embodied by the diffusion coefficient. The accurate determination of the diffusion coefficient requires long-term on-site monitoring.

- Currently, tunnel ventilation control technology has advanced from traditional timing and manual control to intelligent control. The control technology based on sensors and PID has been widely used but still has limitations. In the future, the main trends are intelligence and integration. Intelligent algorithms such as fuzzy control and neural network control will be deeply integrated to assist in obtaining more accurate and effective monitoring data, help determine more reasonable ventilation schemes and contribute to achieving more precise and intelligent ventilation control. At the same time, multi-system integration will be strengthened, considering factors such as traffic and the environment, and greater emphasis will be placed on energy conservation and environmental protection to meet the future development needs of green and low-carbon.

- Critical research gaps persist in achieving intelligent and green-low-carbon tunnel ventilation. A “safety–efficiency–resilience” coordinated control framework remains underdeveloped. Current studies predominantly focus on single-objective optimization of safety or energy efficiency, lacking integrated theoretical frameworks and resilient design methodologies capable of maintaining system safety and energy performance under disturbances such as equipment failures, traffic congestion, or extreme fire scenarios.

- For emission control in diesel locomotive railway tunnels, it is imperative to establish dynamic carbon emission assessment and optimization models covering the entire lifecycle from construction and operation to decommissioning. Such models would enable accurate quantification of the carbon footprint associated with various ventilation strategies, thereby supporting evidence-based low-carbon design decisions.

- A fundamental challenge in engineering applications of multi-physics real-time simulation and digital twin technology lies in balancing fluid dynamics model accuracy with computational efficiency, particularly in ultra-long tunnel scenarios. Achieving second-level prediction and proactive control of pollutant dispersion and ventilation response remains a critical unsolved problem.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- RailSlider. The Role of Rail Transport in Intermodal Freight Transport. Available online: https://www.railsider.com/en/the-role-of-rail-transport-in-intermodal-freight-transport (accessed on 10 July 2025).

- Transportation Infrastructure and Equipment. In Logistics Transportation Systems; Elsevier: Amsterdam, The Netherlands, 2020; pp. 59–88. ISBN 9780128159743.

- World Rail Market Study 2024. Available online: https://www.dvvmedia-shop.de/en/World-Rail-Market-Study-2024/978-3-96892-235-5 (accessed on 10 July 2025).

- Vocational Training at VTG. Four Good Reasons to Transport Goods by Rail. Available online: https://www.vtg.com/news-and-insights/stories/four-good-reasons-to-transport-goods-by-rail (accessed on 28 October 2025).

- ZhiYan Consulting. 2025–2031 China Coal Transportation Industry Market Research and Future Trend Forecast Report; Report Number R977775; ZhiYan Consulting: Beijing, China, 2025. (In Chinese) [Google Scholar]

- Barbosa, F.C. Fuel Cell Rail Technology Review: A Tool for an Autonomous Rail Electrifying Strategy. In Proceedings of the 2019 Joint Rail Conference, Snowbird, UT, USA, 9–12 April 2019. [Google Scholar] [CrossRef]

- Ablyalimov, O.; Avdeyeva, A. Operation of Locomotives of Diesel Traction on Hilly Section of Railway. E3S Web Conf. 2023, 401, 01058. [Google Scholar] [CrossRef]

- Gotthard Base Tunnel | Definition, Switzerland, Opening, & Facts | Britannica. Available online: https://www.britannica.com/topic/Gotthard-Base-Tunnel (accessed on 10 July 2025).

- Rennie, R.P.; Jegier, Z.; Katz, M. Effect of diesel locomotive operation on atmospheric conditions in a railway tunnel. Can. J. Chem. Eng. 1960, 38, 123–128. [Google Scholar] [CrossRef]

- Sun, J.Y.; Fang, Z.; Chen, J.J. Full-Scale Experiment of Longitudinal Ventilation Smoke Control System and Central Smoke Exhaust System in City Underwater Tunnel. Procedia Eng. 2013, 52, 330–335. [Google Scholar] [CrossRef][Green Version]

- Fruhwirt, D.; Sturm, P.; Steiner, H.; Borchiellini, R. Development of a methodology for studying tunnel climate in long railway tunnels and for optimizing the design process of cross-passage cooling systems. Tunn. Undergr. Space Technol. 2023, 138, 105194. [Google Scholar] [CrossRef]

- Ali, N.; Qi, Z. Defensible citadel: History and architectural character of the Lahore Railway Station. Front. Archit. Res. 2020, 9, 805–819. [Google Scholar] [CrossRef]

- Gong, J.F.; Wang, W.; Li, X.; He, W.; Yuan, Y. Statistics of China′s railway tunnels by the end of 2024 and overview of tun-nels of new projectsin 2024. Tunn. Constr. 2025, 45, 636–653. (In Chinese) [Google Scholar]

- History of U.S. Diesel-Electric AC Traction-Railway Age. Available online: https://www.railwayage.com/mechanical/locomotives/a-history-of-ac-traction/ (accessed on 10 July 2025).

- Vickers, R.L. The Beginnings of Diesel Electric Traction. Trans. Newcom. Soc. 1999, 71, 115–127. [Google Scholar] [CrossRef]

- Sutton, G.P. History of Liquid-Propellant Rocket Engines in Russia, Formerly the Soviet Union. J. Propuls. Power 2003, 19, 1008–1037. [Google Scholar] [CrossRef]

- Rao, N.U. The general motors GF6C electric locomotive. IEEE Trans. Ind. Appl. 1986, I, 502–511. [Google Scholar] [CrossRef]

- Allen, J.G.; Newmark, G.L. The Life and Death of North American Rail Freight Electrification. Transp. Res. Rec. 2018, 2672, 166–175. [Google Scholar] [CrossRef]

- Han, C.Y. 50 years of development of railway diesel locomotives in China. Railw. Locomot. Mot. Car 2008, 9, 1–7+17+51. (In Chinese) [Google Scholar]

- Development and Reform Department of China National Railway Group Co., Ltd. 2024 Statistical Bulletin; China National Railway Group Co., Ltd.: Beijing, China, 2025. (In Chinese) [Google Scholar]

- Urbański, P.; Huang, Y.; Gallas, D.; Zhou, J.L.; Merkisz, J. Real-world assessment of the energy consumption and emissions performance of a novel diesel-electric dual-drive locomotive. Sustain. Energy Technol. Assess. 2024, 71, 104017. [Google Scholar] [CrossRef]

- Al-Tony, F.E.S.; Lashine, A. Cost-benefit analysis of railway electrification: Case study for Cairo-Alexandria railway line. Impact Assess. Proj. Apprais. 2000, 18, 323–333. [Google Scholar] [CrossRef][Green Version]

- Xu, L.; Huang, M.; Niu, J. Numerical study of indoor flow field and ventilation performance of the power room of a diesel locomotive under crosswind. J. Wind Eng. Ind. Aerodyn. 2023, 241, 105545. [Google Scholar] [CrossRef]

- Dedík, M.; Gašparík, J.; Záhumenská, Z.; Ľupták, V.; Hřebíček, Z. Proposal of the measures to increase the competitiveness of rail freight transport in the EU. Nase More 2018, 65, 202–207. [Google Scholar] [CrossRef]

- Zhao, D.P.; Wen, S.X.; Yang, B.H. Influence of Installation Position of Jet Fan on Ventilation Effect in Disaster Prevention Ventilation of Railway Tunnel. China Railw. Sci. 2021, 42, 59–70. (In Chinese) [Google Scholar]

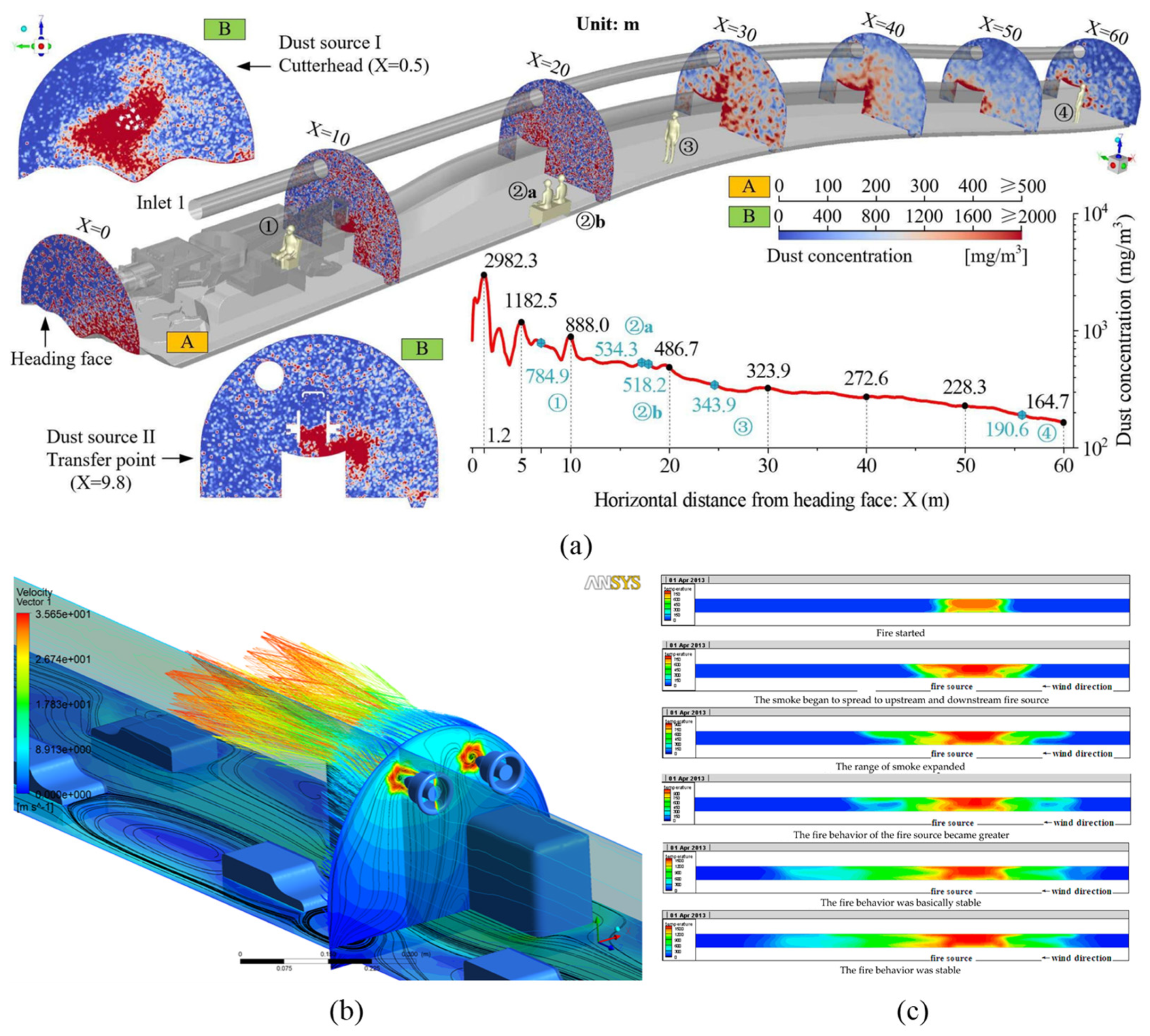

- Yao, Y.; Wang, R.; Xia, Z.; Ren, F.; Zhao, J. Numerical study of the characteristics of smoke spread in tunnel fires during construction and method for improvement of smoke control. Case Stud. Therm. Eng. 2022, 34, 102043. [Google Scholar] [CrossRef]

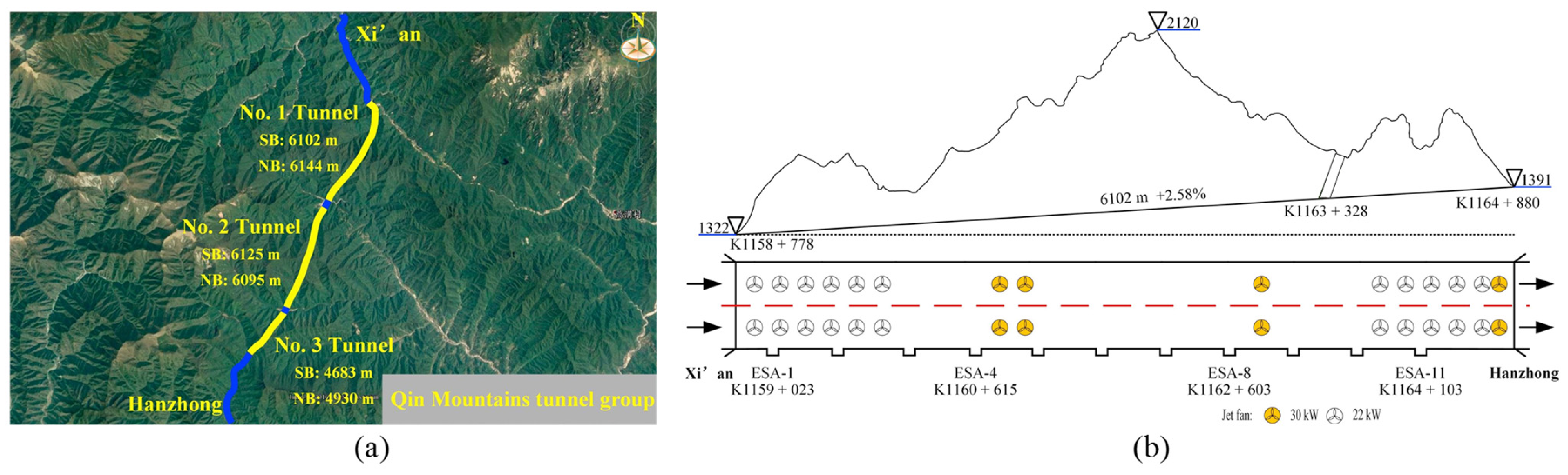

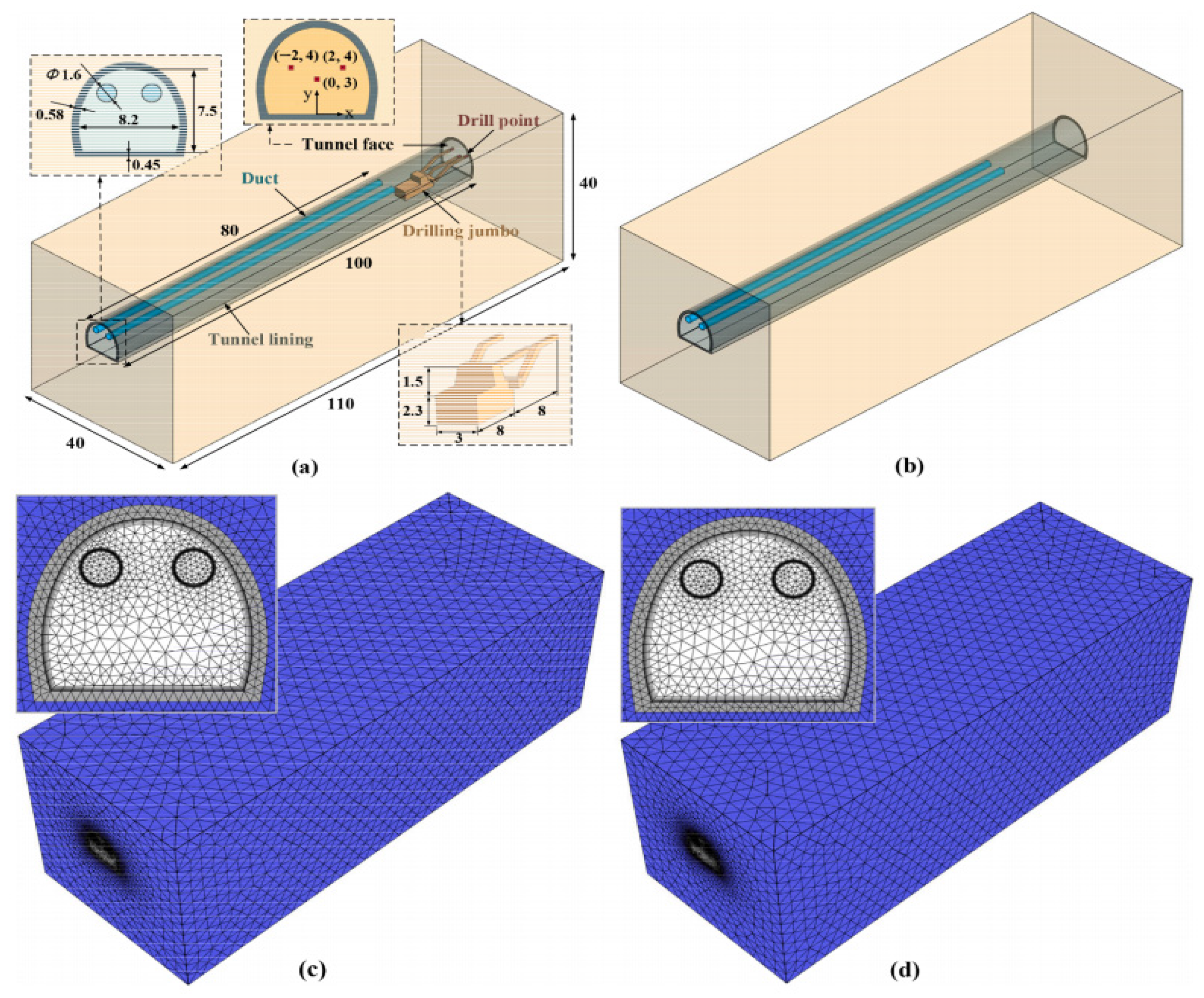

- Han, N.; Hou, K.; Xu, J.; Liu, X.; He, M.; Li, N. Numerical study on ventilation cooling in a high geothermal tunnel of the Sichuan-Tibet Railway considering the tunnel drilling process. Int. J. Heat Fluid Flow 2024, 109, 109504. [Google Scholar] [CrossRef]

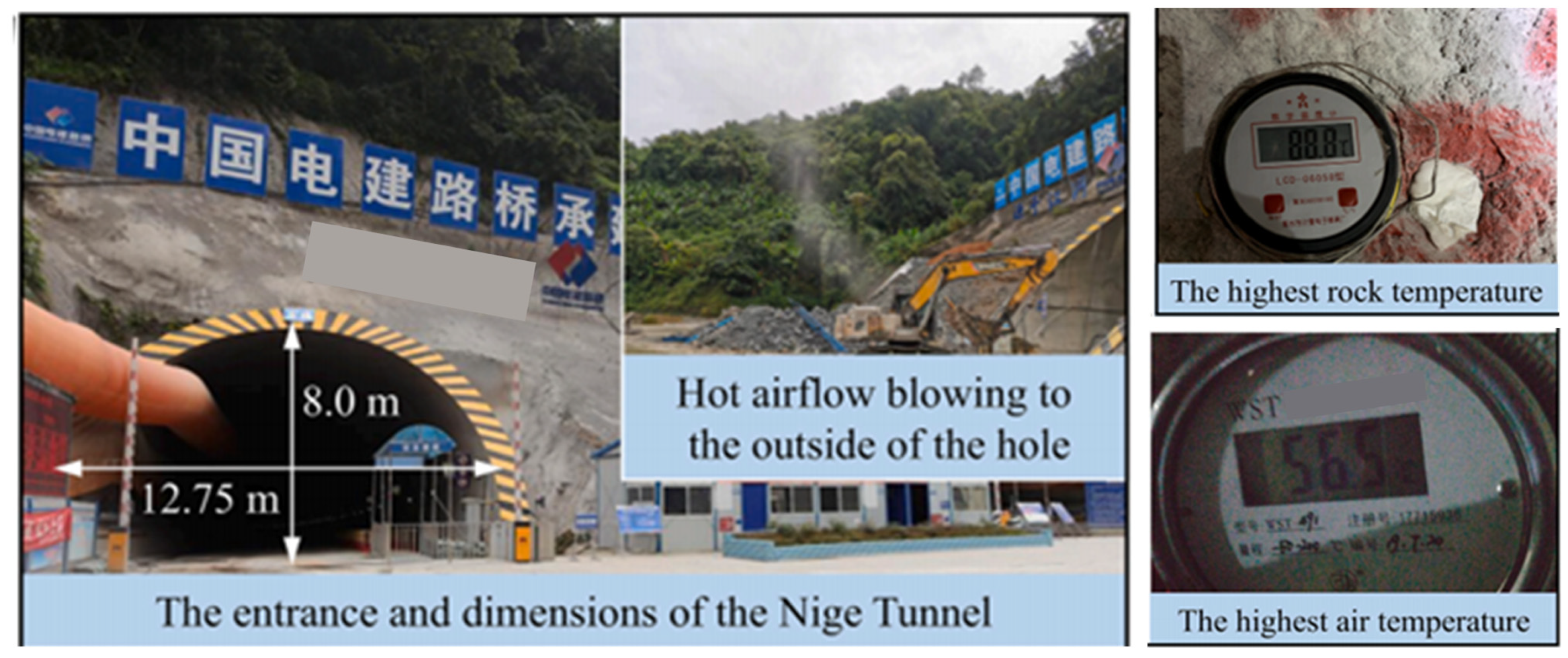

- Zhou, P.; Feng, Y.; Zhou, F.; Wei, Z.; Gou, S.; Xu, H.; Wang, Z. Evaluation system of worker comfort for high geothermal tunnel during construction: A case study on the highway tunnel with the highest temperature in China. Tunn. Undergr. Space Technol. Inc. Trenchless Technol. Res. 2023, 135, 105028. [Google Scholar] [CrossRef]

- Kagawa, J. Health effects of diesel exhaust emissions * a mixture of air pollutants of worldwide concern. Toxicology 2002, 181, 349–353. [Google Scholar] [CrossRef]

- Mainiero, R.J.; Harris, M.L.; Rowland, J.H. Dangers of Toxic Fumes from Blasting. Proc. Annu. Conf. Explos. Blasting Tech. 2007, 33, 73. [Google Scholar]

- Park, D.; Yoon, Y.; Kwon, S.B.; Jeong, W.; Cho, Y.; Lee, K. The effects of operating conditions on particulate matter exhaust from diesel locomotive engines. Sci. Total Environ. 2012, 419, 76–80. [Google Scholar] [CrossRef] [PubMed]

- Sturm, P.; Fruhwirt, D.; Steiner, H. Impact of dust loads in long railway tunnels: In-situ measurements and consequences for tunnel facilities and operation. Tunn. Undergr. Space Technol. 2022, 122, 104328. [Google Scholar] [CrossRef]

- Yuan, W.; Ji, W.; Zhang, J.; Du, T.; Yuan, Y. Examining smoke control in fires occurring in railroad tunnels: A review. J. Therm. Anal. Calorim. 2024, 149, 13–39. [Google Scholar] [CrossRef]

- Silverman, D.T.; Samanic, C.M.; Lubin, J.H.; Blair, A.E.; Stewart, P.A.; Vermeulen, R.; Coble, J.B.; Rothman, N.; Schleiff, P.L.; Travis, W.D.; et al. The diesel exhaust in miners study: A nested case-control study of lung cancer and diesel exhaust. J. Natl. Cancer Inst. 2012, 104, 855–868. [Google Scholar] [CrossRef]

- Janssen, N.A.H.; Hoek, G.; Simic-Lawson, M.; Fischer, P.; van Bree, L.; Brink, H.T.; Keuken, M.; Atkinson, R.W.; Ross Anderson, H.; Brunekreef, B.; et al. Black carbon as an additional indicator of the adverse health effects of airborne particles compared with pm10 and pm2.5. Environ. Health Perspect. 2011, 119, 1691–1699. [Google Scholar] [CrossRef]

- Tsukue, N.; Okumura, H.; Ito, T.; Sugiyama, G.; Nakajima, T. Toxicological evaluation of diesel emissions on A549 cells. Toxicol. Vitr. 2010, 24, 363–369. [Google Scholar] [CrossRef]

- Chen, S.H. Research on the Evacuation and Rescue Technology for Disaster Prevention of High Altitude Extra-long Tunnel. J. Railw. Eng. Soc. 2016, 33, 76–81. (In Chinese) [Google Scholar]

- Chen, X.; Sun, S.; Wu, J.; Ling, T.; Li, L.; Shi, X.; Yang, H. Ventilation Design of an Extra-Long Single-Bore Double-Track Railway Tunnel with High Traffic Density. Sensors 2025, 25, 4009. [Google Scholar] [CrossRef]

- Kruger. Available online: https://www.krugerfan.com/media/view/1/?lang=en (accessed on 13 July 2025).

- Williams, E.E.; Didandeh, H.; Cahill, K.M. Design of an innovative high-efficiency fan for engine cooling. In Proceedings of the Institution of Mechanical Engineers—VTMS 10, Vehicle Thermal Management Systems Conference and Exhibition; Woodhead Publishing: Cambridge, UK, 2011; pp. 435–445. [Google Scholar]

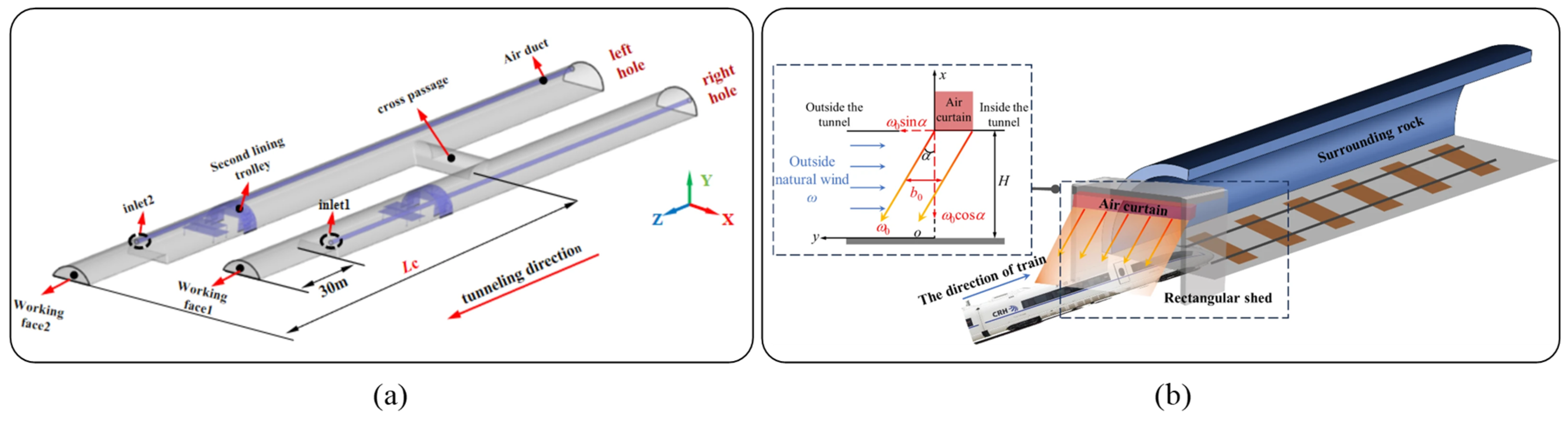

- Xiaoming, W.; Yu, Z.; Guang, Y.; Xinyu, Z.; Dong, L.; Hongliang, W.; Shiqiang, C.; Huan, D. Research on the ventilation and control method of double-hole complementary construction of long tunnel. Sci. Rep. 2025, 15, 5589. [Google Scholar] [CrossRef]

- Wang, R.; Fang, Z.; Wang, D.; Zhu, Z.; Li, H.; Wu, P.; Xu, Q.; Han, Y. Theoretical solution research on air curtain thermal insulation technology at tunnel portal in cold area. Sci. Rep. 2025, 15, 8780. [Google Scholar] [CrossRef]

- Vehicles Found Fused Together in Molten Mass after Tunnel Inferno | World News | The Guardian. Available online: https://www.theguardian.com/world/2001/oct/26/jonhenley1 (accessed on 10 July 2025).

- Ingason, H.; Lönnermark, A.; Li, Y.Z. Model of ventilation flows during large tunnel fires. Tunn. Undergr. Space Technol. Inc. Trenchless Technol. Res. 2012, 30, 64–73. [Google Scholar] [CrossRef]

- Zeng, Y.; Liu, K.; Fang, Y.; Zhang, X.; Bai, Y. Fire Model Test on Temperature Field in the Rescue Station of an Extralong Railway Tunnel. Adv. Civ. Eng. 2019, 2019, 1732572. [Google Scholar] [CrossRef]

- Tang, F.; He, Q.; Mei, F.; Wang, Q.; Zhang, H. Effect of ceiling centralized mechanical smoke exhaust on the critical velocity that inhibits the reverse flow of thermal plume in a longitudinal ventilated tunnel. Tunn. Undergr. Space Technol. 2018, 82, 191–198. [Google Scholar] [CrossRef]

- Ballesteros-tajadura, R.; Santolaria-morros, C.; Blanco-marigorta, E. Influence of the slope in the ventilation semi-transversal system of an urban tunnel. Tunn. Undergr. Space Technol. 2006, 21, 21–28. [Google Scholar] [CrossRef]

- Dastan, A.; Rahiminejad, M.; Sabz, M.; Abbasi, M. CFD simulations of a semi-transverse ventilation system in a long tunnel. Undergr. Space 2023, 11, 153–170. [Google Scholar] [CrossRef]

- Yuan, S.; Sun, X.; Liu, S.; Li, Y.; Du, P. Effectiveness of cluster-based inductive ventilation system in railway tunnels: Case study using full-scale experiment and fire dynamic simulation. Case Stud. Therm. Eng. 2022, 34, 102045. [Google Scholar] [CrossRef]

- Hajra, B.; Stathopoulos, T.; Bahloul, A. A wind tunnel study of the effects of adjacent buildings on near- fi eld pollutant dispersion from rooftop emissions in an urban environment. J. Wind Eng. 2013, 119, 133–145. [Google Scholar] [CrossRef]

- Wang, J.; Yuan, J.; Fang, Z.; Tang, Z.; Qian, P.; Ye, J. A model for predicting smoke back-layering length in tunnel fires with the combination of longitudinal ventilation and point extraction ventilation in the roof. Tunn. Undergr. Space Technol. 2018, 80, 16–25. [Google Scholar] [CrossRef]

- TB 10068-2024; Code for Design on Operation Ventilation of Railway Tunnel. National Railway Administration of the People’s Republic of China: Beijing, China, 2024.

- TB/T 1912-2005; Allowable Concentration and Measurement of Locomotive Exhaust in Railway Operating Tunnel. Ministry of Railways of the People’s Republic of China: Beijing, China, 2005.

- JTG/T D70/2-02-2014; Guidelines for Design of Ventilation of Highway Tunnels. Ministry of Transport of the People’s Republic of China: Beijing, China, 2014.

- TB 10068-2010; Code for Design on Operating Ventilation of Railway Tunnel. Ministry of Railways of the People’s Republic of China: Beijing, China, 2010.

- GBZ 2.1-2019; Occupational Exposure Limits for Hazardous Agents in the Workplace—Part 1: Chemical Hazardous Agents. National Health Commission of the People’s Republic of China: Beijing, China, 2019.

- Ministry of Emergency Management of the People’s Republic of China. Coal Mine Safety Regulations (Amended by: 2022); Ministry of Emergency Management of the People’s Republic of China: Beijing, China, 2022.

- Occupational Safety and Health Administration. Permissible Exposure Limits: OSHA Annotated Table Z-1; Occupational Safety and Health Administration: Washington, DC, USA, 2018.

- California Division of Occupational Safety and Health (Cal/OSHA). Permissible Exposure Limits For Chemical Contaminants (Table AC-1, Last Reviewed: 2025); California Division of Occupational Safety and Health: Bakersfield, CA, USA, 2025.

- National Institute for Occupational Safety and Health (NIOSH). NIOSH Pocket Guide to Chemical Hazards (Last Reviewed: 2020); National Institute for Occupational Safety and Health: Washington, DC, USA, 2020.

- American Conference of Governmental Industrial Hygienists (ACGIH). Threshold Limit Values for Chemical Substances and Physical Agents; American Conference of Governmental Industrial Hygienists: Cincinnati, OH, USA, 2024; ISBN 9781607261667. [Google Scholar]

- Federal Institute for Occupational Safety and Health of Germany (AGS). Occupational Exposure Limits. (TRGS 900, Amended by: 2024); Federal Institute for Occupational Safety and Health of Germany: Dortmund, Germany, 2024.

- German Research Foundation. Permanent Senate Commission for the Investigation of Health Hazards of Chemical Compounds in the Work Area; (MAK Commission). In List of MAK and BAT Values; German Research Foundation: Bonn, Germany, 2024. [Google Scholar]

- The Commission Of The European Communities. Establishing a Third List of Indicative Occupational Exposure Limit Values; The Commission Of The European Communities: Brussels, Belgium, 2017.

- The Council Of The European Union. Protection of Workers from Risks Related to Chemical Agents at Work (Council Directive 98/24/EC, Amended by: 2024); The Council Of The European Union: Brussels, Belgium, 2024.

- Miles, J. WHO Global Air Quality Guidelines: Particulate Matter (PM2.5 PM10), Ozone, Nitrogen Dioxide, Sulfur Dioxide Carbon Monoxide; WHO: Geneva, Switzerland, 2021; 290p. [Google Scholar]

- European Commission. COMMISSION REGULATION (EU) No 1303/2014 of 18 November 2014 concerning the technical specification for interoperability relating to ‘safety in railway tunnels’ of the rail system of the European Union. Off. J. Eur. Union 2014, 57, 394–420. [Google Scholar]

- National Fire Protection Association. NFPA 130 Standard for Fixed Guideway Transit and Passenger Rail Systems; National Fire Protection Association: Quincy, MA, USA, 2025.

- Group, M.; Blvd, M. Carbon Monoxide Concentration, Visibility and Smoke Simulation Underground Railway Stations in Case of Emergency. In Proceedings of the 20th International Transport and Air Pollution Conference 2014, Graz, Austria, 18–19 September 2014; pp. 1–14. [Google Scholar]

- Union International des Chemin Fer (UIC) UIC-Codex 779–9-Safety in Railway Tunnels. 2003. Available online: https://uic.org/com (accessed on 10 July 2025).

- Workplace safety and health of Singapore. Workplace Safety and Health (General Provisions) Regulations; Attorney-General’s Chambers of Singapore: Singapore City, Singapore, 2025. [Google Scholar]

- Safe Work Australia. Workplace Exposure Standards for Airborne Contaminants 2024; Safe Work Australia: Canberra, Australia, 2024. [Google Scholar]

- Japan Society for Occupational Health(JSOH). Occupational Exposure Limits; The Japan Society for Occupational Health (JSOH): Tokyo, Japan, 2024. [Google Scholar]

- Ministry of Labour and Social Inclusion of Norway. Regulations Concerning Action and Limit Values; The Norwegian Labour Inspection Authority: Trondheim, Norway, 2024.

- Ministry of Family, Labour and Social Policy of the Republic of Poland. Regulation on the Highest Permissible Concentrations and Intensities of Harmful Factors for Health in the Workplace (Dz.U. 2024 poz. 1017); Ministry of Family, Labour and Social Policy of the Republic of Poland: Warsaw, Poland, 2024. (In Polish)

- Abbasi, S.; Jansson, A.; Sellgren, U.; Olofsson, U. Particle Emissions From Rail Traffic: A Literature Review. Crit. Rev. Environ. Sci. Technol. 2013, 43, 2511–2544. [Google Scholar] [CrossRef]

- Ministry of Labour of Ontario, Canada. Regulation 833: Control of Exposure to Biological or Chemical Agents; Office of Legislative Counsel Ministry of the Attorney General: Toronto, ON, Canada, 2024.

- Ministry of Employment and Social Solidarity of Quebec, Canada. Regulation Respecting Occupational Health and Safety (S-2.1, r. 13); Les Publications du Québec: Québec, QC, Canada, 2024. [Google Scholar]

- Ministry of Labour and Economy of the Republic of Austria. Limit Values Regulation 2024; The Austrian Amendment Act: Vienna, Austria, 2024. [Google Scholar]

- Spanish National Institute for Occupational Safety and Health. Occupational Exposure Limits for Chemical Agents 2024; Instituto Nacional de Seguridad y Salud en el Trabajo (INSST): Madrid, Spain, 2024. [Google Scholar]

- SODECA. Ventilation Systems for Tunnels and Underground Works. 2021. Available online: https://www.sodeca.com/soluciones/tuneles (accessed on 28 October 2025).

- Ministry of Labor and Social Policy of Italy. Consolidated Text on Health and Safety at Work. (Legislative Decree April 9, 2008, n.81, Amended by: 2025); Ministry of Labor and Social Policy of Italy: Roma, Italy, 2025.

- Netherlands Labour Authority. Working Conditions Regulation (Amended by: 2025); The Netherlands Labour Authority: Den Haag, The Netherlands, 2025.

- Swiss Accident Insurance Institution (Suva). Limit Values at the Workplace(Amended by: 2025); Federal Office of Public Health (FOPH): Bern, Switzerland, 2025.

- Health and Safety Authority of Ireland. Chemical Agents and Carcinogens Code of Practice 2021; HAS: Dublin, Ireland, 2021.

- Korea Occupational Safety and Health Agency (KOSHA) Exposure Standards for Chemical Substances and Physical Factors (Amended by: 2018). Available online: https://www.kosha.or.kr/english/legislation/occupationalSafetyAndHealth.do (accessed on 2 March 2025).

- The French National Research and Safety Institute (INRS). Occupational Exposure Limit Values (OELVs)—Chemical Substances; French National Research and Safety Institute (INRS): Paris, France, 2024. [Google Scholar]

- The Minister of Employment and Labour of South Africa. Regulations for Hazardous Chemical Agents 2021; Occupational Health and Safety Act: Pretoria, South Africa, 2021. [Google Scholar]

- Chaabat, F.; Salizzoni, P.; Creyssels, M.; Mos, A.; Wingrave, J.; Correia, H.; Marro, M. Smoke control in tunnel with a transverse ventilation system: An experimental study. Build. Environ. 2020, 167, 106480. [Google Scholar] [CrossRef]

- Tao, L.; Yan, X.; Zhang, Y.; Zeng, Y.; Fang, Y.; Bai, Y. Experimental and numerical study on the smoke and velocity distribution in an extra-long railway tunnel fire. Tunn. Undergr. Space Technol. 2021, 117, 104134. [Google Scholar] [CrossRef]

- Zhang, X.; Huang, Z.; Zhang, T.H.; Zhang, C.; Kang, C.; Wu, K. Scale Model Tests for Ventilation Characteristics of Urban Tunnels with Off-ramps. China J. Highw. Transp. 2019, 32, 123–131. (In Chinese) [Google Scholar]

- Tanaka, F.; Takezawa, K.; Hashimoto, Y.; Moinuddin, K.A.M. Critical velocity and backlayering distance in tunnel fires with longitudinal ventilation taking thermal properties of wall materials into consideration. Tunn. Undergr. Space Technol. 2018, 75, 36–42. [Google Scholar] [CrossRef]

- Cheng, H.H.; Miao, R.F.; Zhong, M.H.; Yang, X.; Long, Z.; Chen, J. Model experimental study on fire smoke control in underground interchange tunnel. J. Saf. Sci. Technol. 2024, 20, 143–150. (In Chinese) [Google Scholar]

- Zhang, X.; Xu, Z.; Ni, T.; Peng, J.; Zeng, J. Investigation on smoke temperature distribution in a double-deck tunnel fi re with longitudinal ventilation and lateral smoke extraction. Case Stud. Therm. Eng. 2019, 13, 100375. [Google Scholar] [CrossRef]

- Mei, F.; Tang, F.; Ling, X.; Yu, J. Evolution characteristics of fire smoke layer thickness in a mechanical ventilation tunnel with multiple point extraction. Appl. Therm. Eng. 2017, 111, 248–256. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Y.; Gao, Y.; Chen, L.; Li, T. Study the maximum temperature of diffusion smoke downstream in a longitudinal ventilated branched tunnel with different transverse fire locations. Tunn. Undergr. Space Technol. 2024, 146, 105663. [Google Scholar] [CrossRef]

- Zeng, M.Y.; Zhao, H.D. Ventilation and Disaster Prevention Technology of Swiss Gotthard Base Tunnel. High Speed Railw. Technol. 2010, 1, 42–46. (In Chinese) [Google Scholar]

- Jia, C.; Hu, Y.; Dai, L.; Shi, C.; Zheng, Y. Optimized ventilation design for high-geothermal tunnels considering worker comfort. Appl. Therm. Eng. 2025, 267, 125772. [Google Scholar] [CrossRef]

- Huang, F.; Wang, S.; Jiang, S.; Yang, D.; Hu, Z. Evolution and model prediction of mechanical ventilation temperature field in high-geotemperature tunnels: Experimental analysis and machine learning. Case Stud. Therm. Eng. 2025, 70, 106135. [Google Scholar] [CrossRef]

- Moreno, T.; Pérez, N.; Reche, C.; Martins, V.; De Miguel, E.; Capdevila, M.; Centelles, S.; Minguillón, M.C.; Amato, F.; Alastuey, A. Subway platform air quality: Assessing the influences of tunnel ventilation, train piston effect and station design. Atmos. Environ. 2014, 92, 461–468. [Google Scholar] [CrossRef]

- Fang, Y.; Fan, J.; Kenneally, B.; Mooney, M. Air flow behavior and gas dispersion in the recirculation ventilation system of a twin-tunnel construction. Tunn. Undergr. Space Technol. 2016, 58, 30–39. [Google Scholar] [CrossRef]

- Qian, C.; Chen, J.; Luo, Y.; Zhao, Z. Monitoring and analysis of the operational environment in an extra-long highway tunnel with longitudinal ventilation. Tunn. Undergr. Space Technol. 2019, 83, 475–484. [Google Scholar] [CrossRef]

- Niu, J.; Zhou, D.; Liang, X.; Liu, T.; Liu, S. Numerical study on the aerodynamic pressure of a metro train running between two adjacent platforms. Tunn. Undergr. Space Technol. 2017, 65, 187–199. [Google Scholar] [CrossRef]

- Sasmito, A.P.; Birgersson, E.; Ly, H.C.; Mujumdar, A.S. Some approaches to improve ventilation system in underground coal mines environment—A computational fluid dynamic study. Tunn. Undergr. Space Technol. 2013, 34, 82–95. [Google Scholar] [CrossRef]

- Apaydin, S.; Doner, N. Flow analysis in different geometries for optimization of exhaust manifold in a locomotive diesel engine. Ain Shams Eng. J. 2024, 15, 102974. [Google Scholar] [CrossRef]

- Tan, Z.; Huang, Z.Y.; Wu, K.; Xu, L.T. Simulation analysis of longitudinal ventilation system with jet fan speed control for MPC strategy in a road tunnel. In Proceedings of the 2012 15th International IEEE Conference on Intelligent Transportation Systems, Anchorage, AK, USA, 16–19 September 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 1471–1476. [Google Scholar]

- Colella, F.; Rein, G.; Borchiellini, R.; Carvel, R.; Torero, J.L.; Verda, V. Calculation and design of tunnel ventilation systems using a two-scale modelling approach. Build. Environ. 2009, 44, 2357–2367. [Google Scholar] [CrossRef]

- Wang, C.Y.; Zhang, H.; Xue, T.; Fang, L. A multi-factor CFD simulation to dust suppression in dynamic tunnel excavation. Tunn. Undergr. Space Technol. 2025, 159, 106458. [Google Scholar] [CrossRef]

- Šekularac, M.; Janković, N. Experimental and numerical analysis of flow field and ventilation performance in a traffic tunnel ventilated by axial fans. Theor. Appl. Mech. 2018, 45, 151–165. [Google Scholar] [CrossRef]

- Lai, H.; Wang, S.; Xie, Y. Study on the Fire Damage Characteristics of the New Qidaoliang Highway Tunnel: Field Investigation with Computational Fluid Dynamics (CFD) Back Analysis. Int. J. Environ. Res. Public Health 2016, 13, 1014. [Google Scholar] [CrossRef]

- Jain, S.; Kumar, S.; Kumar, S.; Sharma, T.P. Numerical simulation of fire in a tunnel: Comparative study of CFAST and CFX predictions. Tunn. Undergr. Space Technol. 2008, 23, 160–170. [Google Scholar] [CrossRef]

- Su, J. Research on the Subway Cross-ocean Tunnel Smoke Control Mode Based on SES Simulation Software. J. Railw. Eng. Soc. 2016, 33, 91–94+100. (In Chinese) [Google Scholar]

- Ars, C.; Gauthier, J.; Florsch, N. Underground ancient mine work ventilation modeling. J. Archaeol. Sci. Rep. 2021, 37, 102805. [Google Scholar] [CrossRef]

- Wei, D.; Du, C.; Xu, H.; Zhang, L. Influencing factors and correlation analysis of ventilation and cooling in deep excavation roadway. Case Stud. Therm. Eng. 2019, 14, 100483. [Google Scholar] [CrossRef]

- Zhang, S.; Qiu, R. Numerical simulation of the maximum temperature beneath ceiling for an impinging flame beneath a confined ceiling. Fire Saf. Sci. 2019, 28, 1–10. (In Chinese) [Google Scholar]

- Amouzandeh, A.; Zeiml, M.; Lackner, R. Real-scale CFD simulations of fire in single- and double-track railway tunnels of arched and rectangular shape under different ventilation conditions. Eng. Struct. 2014, 77, 193–206. [Google Scholar] [CrossRef]

- Chang, X.; Chai, J.; Luo, J.; Qin, Y.; Xu, Z.; Cao, J. Tunnel ventilation during construction and diffusion of hazardous gases studied by numerical simulations. Build. Environ. 2020, 177, 106902. [Google Scholar] [CrossRef]

- Wang, F.; Wang, M.; Carvel, R.; Wang, Y. Numerical study on fire smoke movement and control in curved road tunnels. Tunn. Undergr. Space Technol. 2017, 67, 1–7. [Google Scholar] [CrossRef]

- Yao, Y.; Zhang, Y.; Zhu, H.; Han, Z.; Zhang, S.; Zhang, X. Effects of ambient pressure on characteristics of smoke movement in tunnel fires. Tunn. Undergr. Space Technol. 2023, 134, 104981. [Google Scholar] [CrossRef]

- Ma, M.; Zhang, Z.; Chen, J.; Xiong, Q.; Hu, E.; Wang, T.; Xiao, Y. Physics-informed machine learning-driven active utilization of ventilation and heat exchange in large underground tunnels. Renew. Energy 2025, 250, 123283. [Google Scholar] [CrossRef]

- Lu, K.; Xia, K.; Shi, C.; Yang, M.; Wang, J.; Ding, Y. Investigation on the tunnel curvature effect upon the ceiling temperature of tunnel fires: A numerical simulation. Fire Technol. 2021, 57, 2839–2858. [Google Scholar] [CrossRef]

- Hu, L.H.; Tang, F.; Yang, D.; Liu, S.; Huo, R. Longitudinal distributions of CO concentration and difference with temperature field in a tunnel fire smoke flow. Int. J. Heat Mass Transf. 2010, 53, 2844–2855. [Google Scholar] [CrossRef]

- Talaee, M.R.; Kabiri, A.; Ebrahimi, M.; Hakimzadeh, B. Analysis of induced interior air flow in subway train cabin due to accelerating and decelerating. Int. J. Vent. 2019, 18, 204–219. [Google Scholar] [CrossRef]

- Hu, S.; Liao, Q.; Feng, G.; Huang, Y.; Shao, H.; Gao, Y.; Hu, F. Influences of ventilation velocity on dust dispersion in coal roadways. Powder Technol. 2020, 360, 683–694. [Google Scholar] [CrossRef]

- Huang, R.; Shen, X.; Wang, B.; Liao, X. Migration characteristics of CO under forced ventilation after excavation roadway blasting: A case study in a plateau mine. J. Clean. Prod. 2020, 267, 122094. [Google Scholar] [CrossRef]

- Vega, G.; Marı, K.; Ferna, M.; Tajadura, R.B.; Morros, C.S. Numerical 3D simulation of a longitudinal ventilation system: Memorial tunnel case. Tunn. Undergr. Space Technol. 2008, 23, 539–551. [Google Scholar] [CrossRef]

- Baldauf, R. Roadside vegetation design characteristics that can improve local, near-road air quality. Transp. Res. Part D Transp. Environ. 2017, 52, 354–361. [Google Scholar] [CrossRef]

- Gokce, H.B.; Arıoğlu, E.; Copty, N.K.; Onay, T.T.; Gun, B. Exterior air quality monitoring for the Eurasia Tunnel in Istanbul, Turkey. Sci. Total Environ. 2020, 699, 134312. [Google Scholar] [CrossRef]

- Chang, H.; Ren, R.; Wang, Y.; Li, J. Evaluation of Air Pollutants in Extra-Long Road Tunnel with the Combination of Pollutants Nonlinear Evolution and Machine Learning Method. Sustainability 2022, 14, 10710. [Google Scholar] [CrossRef]

- Marinello, S.; Lolli, F.; Gamberini, R. Roadway tunnels: A critical review of air pollutant concentrations and vehicular emissions. Transp. Res. Part D Transp. Environ. 2020, 86, 102478. [Google Scholar] [CrossRef]

- Sun, D.X.; Yao, B. Applicability of linear heat fire detection system in super-large section highway tunnels. Fire Saf. Sci. 2021, 30, 165–172. (In Chinese) [Google Scholar]

- Chi, D. Ventilation and Smoke Exhaust Design of Single-hole Double-track-Underground Tunnel. J. Railw. Eng. Society 2020, 37, 69–73. (In Chinese) [Google Scholar]

- Peltier, M.; Rotta Loria, A.F.; Lepage, L.; Garin, E.; Laloui, L. Numerical investigation of the convection heat transfer driven by airflows in underground tunnels. Appl. Therm. Eng. 2019, 159, 113844. [Google Scholar] [CrossRef]

- Liu, S.; Luo, Z.; Zhang, K.; Hang, J. Natural ventilation of a small-scale road tunnel by wind catchers: A CFD simulation study. Atmosphere 2018, 9, 411. [Google Scholar] [CrossRef]

- Kong, J.; Xu, Z.S.; Huang, J. Impact of the tunnel slope degree changes on the efficiency of the full jet fan lon-gitudinal ventilation. J. Saf. Environ. 2020, 20, 2211–2217. (In Chinese) [Google Scholar]

- Zheng, J.Y.; Sun, S.X.; Tian, W.H. Feasibility analysis of natural ventilation and airflow characteristics for die-sel-hauled train pollutants in high-altitude tunnels. Tunn. Constr. 2024, 44 (Suppl. S2), 300. (In Chinese) [Google Scholar]

- Gu, H.S.; Zhao, Y.S. Factors Affecting Piston Wind Speed of Maglev Trains in Tunnels. J. Tongji Univer-Sity (Nat. Sci.) 2003, 3, 324–328. (In Chinese) [Google Scholar]

- Xue, P.; You, S.; Chao, J.; Ye, T. Numerical investigation of unsteady airflow in subway influenced by piston effect based on dynamic mesh. Tunn. Undergr. Space Technol. 2014, 40, 174–181. [Google Scholar] [CrossRef]

- Chen, C.; Nie, H.X.; Li, Q. A Prediction Model for Distribution of CO Pollutant Concentration in Urban Bifurcated Tunnel Based on Traffic Wind Conditions. China J. Highw. Transp. 2022, 35, 161–169. (In Chinese) [Google Scholar]

- Li, Y.; Chen, T.; Xu, Z.; Kong, J.; Wang, M.; Fan, C. Influence of winding wall on the entrainment characteristics of air jet in curved road tunnels. Tunn. Undergr. Space Technol. 2019, 90, 330–339. [Google Scholar] [CrossRef]

- Tian, F.; Wang, H.Q.; Zhu, Z.L. Research on Ventilation of Extra-Long One-tube Railway Tunnel. J. Undergr. Space Eng. 2012, 8, 1550–1552. (In Chinese) [Google Scholar]

- Yang, S.; Ren, R.; Wang, Y. Study on Air Cabin Ventilation System by Local Structural Optimization during Tunnel Construction. Buildings 2022, 12, 2235. [Google Scholar] [CrossRef]

- Yang, S.; Ai, Z.; Zhang, C.; Dong, S.; Ouyang, X.; Liu, R.; Zhang, P. Study on Optimization of Tunnel Ventilation Flow Field in Long Tunnel Based on CFD Computer Simulation Technology. Sustainability 2022, 141, 11486. [Google Scholar] [CrossRef]

- Yoon, C.H.; Kim, M.S.; Kim, J. The evaluation of natural ventilation pressure in Korean long road tunnels with vertical shafts. Tunn. Undergr. Space Technol. 2006, 21, 2006. [Google Scholar] [CrossRef]

- Li, Z.; Liang, X.; Zhang, J. Influence of shaft on alleviating transient pressure in tunnel. J. Cent. South Univ. (Sci. Technol.) 2011, 42, 5–10. [Google Scholar]

- Luo, Z.F.; Wang, J.H.; Sun, Y.; Shang, J.X.; Wang, S.G. Application of intelligent ventilation system in a tunnel under construction. Tunn. Constr. 2023, 43 (Suppl. S2), 477–484. (In Chinese) [Google Scholar] [CrossRef]

- Xia, F.Y.; Song, S.Y.; Xie, Y.L. Application of Twin-Tube Complementary Ventilation in Highway Tunnels. Mod. Tunn. Technol. 2017, 54, 160–166. (In Chinese) [Google Scholar]

- Zhou, Y.; Bi, H.; Wang, H.; Lei, B. Critical velocity in the transverse passages of a railway tunnel rescue station with semi-transverse ventilation. Tunn. Undergr. Space Technol. 2019, 92, 103064. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, H.; Tan, Y.; Yang, H. Natural wind utilization in the vertical shaft of a super-long highway tunnel and its energy saving effect. Build. Environ. 2018, 145, 140–152. [Google Scholar] [CrossRef]

- Tuovinen, H.; Bengtson, S. Sensitivity Calculatlons of Tunnel Fires Uslng CFD. Fire Technol. 1996, 32, 99–119. [Google Scholar] [CrossRef]

- Hartman, P.; Huijben, H. Tunnel ventilation and safety in escape routes. Tunn. Undergr. Space Technol. 2006, 21, 293–294. [Google Scholar] [CrossRef]

- Barbato, L.; Cascetta, F.; Musto, M.; Rotondo, G. Fire safety investigation for road tunnel ventilation systems–an overview. Tunn. Undergr. Space Technol. 2014, 43, 253–265. [Google Scholar] [CrossRef]

- Tao, Y.; Hu, H.; Zhang, H.; Zhang, G.; Hao, Z.; Wang, L. A new ventilation system for extra-long railway tunnel construction by using the air cabin relay: A case study on optimization of air cabin parameters length. J. Build. Eng. 2022, 45, 103480. [Google Scholar] [CrossRef]

- Tang, H.H.; Wei, L.X.; Zhao, J.M.; Yu, Z.H.; Xie, Y.Q.; Xu, Z.S. Flow field characteristics and jet fan deflection angle at tunnel with over development. J. Railw. Sci. Eng. 2024, 21, 1114–1125. (In Chinese) [Google Scholar]

- Chen, T.; Li, Y.; Xu, Z.; Kong, J.; Liang, Y.; Wang, B.; Fan, C. Study of the optimal pitch angle of jet fans in road tunnels based on turbulent jet theory and numerical simulation. Build. Environ. 2019, 165, 106390. [Google Scholar] [CrossRef]

- Lee, S.-C.; Lee, S.; Lee, J. CFD analysis on ventilation characteristics of jet fan with different pitch angle. KSCE J. Civ. Eng. 2014, 18, 812–818. [Google Scholar] [CrossRef]

- Li, Z.J.; Lin, X.G.; Li, M.; Zhang, W.J.; Rao, B.W. Simulation analysis of CO diffusion for double tube tunneling excavated from single end. J. Railw. Sci. Eng. 2013, 10, 82–87. (In Chinese) [Google Scholar]

- Chen, X.Y.; Wu, J.; Ren, S. Pollutant difusion law during high-altitude tunnel construction. J. Zhejiang Univ. (Eng. Sci.) 2024, 58, 176–187. (In Chinese) [Google Scholar]

- Yan, G.; Wang, M.; Yu, L.; Duan, R.; Xia, P. Effects of ambient pressure on smoke movement patterns in vertical shafts in tunnel fires with natural ventilation systems. Build. Simul. 2020, 13, 931–941. [Google Scholar] [CrossRef]

- Liu, B.; Mao, J.; Xi, Y.; Hu, J. Effects of altitude on smoke movement velocity and longitudinal temperature distribution in tunnel fires. Tunn. Undergr. Space Technol. 2021, 112, 103850. [Google Scholar] [CrossRef]

- Zeng, Y.; Tao, L.; Luo, M.; Ye, X.; Yuan, Y. Influence of piston airflow and mechanical airflow on cooling effect of high-geothermal tunnels: A pilot study. J. Therm. Anal. Calorim. 2023, 148, 6151–6167. [Google Scholar] [CrossRef]

- Wang, M.; Wang, X.; Yu, L.; Deng, T. Field measurements of the environmental parameter and pollutant dispersion in urban undersea road tunnel. Build. Environ. 2019, 149, 100–108. [Google Scholar] [CrossRef]

- Tian, P.; Zheng, X.Q.; Liu, J.; Peng, K.F. Study on the Rule of Pollutant Dispersion and New Ventilation Mode in Super long Tunnels. Mod. Tunn. Technol. 2020, 57, 629–634. (In Chinese) [Google Scholar]

- Sun, S.X.; Zhang, Y.X.; Lei, P.S.; Yu, N.Y.; Li, Y. Natural Ventilation Threshold for Single-Track Railway Tunnel at High Altitude under Diesel Locomotive Traction. China Railw. Sci. 2015, 36, 63–69. (In Chinese) [Google Scholar]

- Sun, S.X.; Zhang, Y.X. Research on Operational Ventilation Technology for High-Altitude Diesel-Traction Railway Tunnels; China Railway Publishing House: Beijing, China, 2015. (In Chinese) [Google Scholar]

- Sun, S.X.; Song, W.J.; Zhang, Y.X. Operating Ventilation Technology for Diesel-hauled Train Crossing Extra -long Tunnels in High Altitude Plateau. J. Railw. Eng. Soc. 2017, 34, 1–5. (In Chinese) [Google Scholar]

- Jiang, X.; Xiang, Y.; Wang, Z.; Mao, Y.; Park, H. A numerical study on the effect of the shaft group arrangement on the natural ventilation performance in tunnel fires. Tunn. Undergr. Space Technol. 2020, 103, 103464. [Google Scholar] [CrossRef]

- Betta, V.; Cascetta, F.; Musto, M.; Rotondo, G. Fluid dynamic performances of traditional and alternative jet fans in tunnel longitudinal ventilation systems. Tunn. Undergr. Space Technol. 2010, 25, 415–422. [Google Scholar] [CrossRef]

- Sun, Z.P. Research on Ventilation Control Methods for Single-Track Railway Tunnels. Master’s Thesis, Southwest Jiaotong University, Chengdu, China, 2002. [Google Scholar]

- Fan, C.G.; Ji, J.; Gao, Z.H.; Han, J.Y.; Sun, J.H. Experimental study of air entrainment mode with natural ventilation using shafts in road tunnel fires. Int. J. Heat Mass Transf. 2013, 56, 750–757. [Google Scholar] [CrossRef]

- Li, Y.; Ling, L.; Chen, J. Combined grey prediction fuzzy control law with application to road tunnel ventilation system. J. Appl. Res. Technol. 2015, 13, 313–320. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Deng, M.; Hu, Y.J.; Hu, J.P.; Xie, Y.L. Fuzzy control of smoke from fires in single-bore two-way highway tunnels. J. Traffic Transp. Eng. 2012, 12, 13–21. (In Chinese) [Google Scholar] [CrossRef]

- Jan, Š.; Lukáš, F.; Jiří, C.; Jiří, Z. Model-based airflow controller design for fire ventilation in road tunnels. Tunn. Undergr. Space Technol. 2016, 60, 121–134. [Google Scholar] [CrossRef]

- Li, X.; Chen, X.L.; Li, Y.Z.; Zhang, L. Research on an Intelligent Control Mode. Technol. Highw. Transp. 2022, 38, 156–162. (In Chinese) [Google Scholar]

- Wu, K.; Yang, Q.; Kang, C.; Zhang, X.; Huang, Z. Adaptive Critic Design Based Control of Tunnel Ventilation System with Variable Jet Speed. J. Signal Process. Syst. 2017, 86, 269–278. [Google Scholar] [CrossRef]

- Chen, P.-H.; Lai, J.-H.; Lin, C.-T. Application of fuzzy control to a road tunnel ventilation system. Fuzzy Sets Syst. 1998, 100, 9–28. [Google Scholar] [CrossRef]

- Xia, F.Y.; Wang, Y.Q.; Xie, Y.L.; Hu, Y.J. Complementary ventilation mode for long highway tunnels. J. Traffic Transp. Eng. 2014, 14, 27–34. (In Chinese) [Google Scholar]

- Hong, Y.; Kang, J.H.; Fu, C.J. Numerical simulation of fire smoke control in inclined tunnels based on PID method. J. China Univ. Min. Technol. 2021, 50, 701–708. (In Chinese) [Google Scholar] [CrossRef]

- Si, L.; Cao, W.; Chen, X. Active disturbance rejection control of a longitudinal tunnel ventilation system. Energies 2020, 13, 1871. [Google Scholar] [CrossRef]

- Liu, R.; He, Y.; Zhao, Y.; Jiang, X.; Ren, S. Tunnel construction ventilation frequency-control based on radial basis function neural network. Autom. Constr. 2020, 118, 103293. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, X.; Huang, X.; Xiao, F.; Usmani, A. A real-time forecast of tunnel fire based on numerical database and artificial intelligence. Build. Simul. 2022, 15, 511–524. [Google Scholar] [CrossRef]

- Wu, X.; Park, Y.; Li, A.; Huang, X.; Xiao, F.; Usmani, A. Smart Detection of Fire Source in Tunnel Based on the Numerical Database and Artificial Intelligence. Fire Technol. 2021, 57, 657–682. [Google Scholar] [CrossRef]

- Zhang, X.; Jiang, Y.; Wu, X.; Nan, Z.; Jiang, Y.; Shi, J.; Zhang, Y.; Huang, X.; Huang, G.G.Q. AIoT-enabled digital twin system for smart tunnel fire safety management. Dev. Built Environ. 2024, 18, 100381. [Google Scholar] [CrossRef]

- Li, X.; Wang, S.; Ai, W.S.; Ding, Y.Y.; Chen, H. Tunnel fire ventilation control based on a linear active disturbance rejection al-gorithm. China J. Highw. Transp. 2025, 38, 186–200. (In Chinese) [Google Scholar]

| Indicator | OELs (mg/m3) | Notes | ||

|---|---|---|---|---|

| PC-TWA | PC-STEL | MAC | ||

| CO | — | — | 55 | OSHA PEL |

| 29 | — | 230 | Cal/OSHA PEL | |

| 40.25 (10 h) | — | 230 | NIOSH REL | |

| 28.75 | — | — | ACGIH TLVs | |

| NO | 30 mg/m3 | — | — | OSHA PEL |

| 30 | — | — | Cal/OSHA PEL | |

| 30.75 (10 h) | — | — | NIOSH REL | |

| 30.75 | — | — | ACGIH TLVs | |

| NO2 | — | — | 9 | OSHA PEL |

| — | 1.8 | — | Cal/OSHA PEL | |

| — | 1.88 (10 h) | — | NIOSH REL | |

| 0.38 | — | — | ACGIH TLVs | |

| Indicator | OELs (mg/m3) | Notes | ||

|---|---|---|---|---|

| PC-TWA | PC-STEL | MAC | ||

| CO | 23 | — | — | AGS |

| 35 | — | — | DFG | |

| NO | 2.5 | — | — | AGS |

| 0.63 | — | — | DFG | |

| NO2 | 0.95 | — | — | AGS |

| 0.95 | — | — | DFG | |

| Indicator | OELs(mg/m3) | Notes | ||

|---|---|---|---|---|

| PC-TWA | PC-STEL | MAC | ||

| CO | 23 | 117 | — | |

| NO | 2 | — | — | |

| NO2 | 0.96 | 1.91 | — | |

| Indicator | OELs (mg/m3) | Notes | ||

|---|---|---|---|---|

| PC-TWA | PC-STEL | MAC | ||

| CO | 7 (24 h) | — | — | Interim Target 1 |

| 4 (24 h) | — | — | AQG level | |

| NO | — | — | — | |

| NO2 | 0.120 (24 h) | — | — | Interim Target 1 |

| 0.050 (24 h) | — | — | Interim Target 2 | |

| 0.025 (24 h) | — | — | AQG level | |

| Research Method | Applicable Scenarios | Advantages | Limitations |

|---|---|---|---|

| Theoretical Analysis |

|

|

|

| Scale Model Experiment |

|

|

|

| Field Test |

|

|

|

| Numerical Simulation |

|

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Sun, S.; Wu, J.; Ling, T.; Li, L.; Shi, X.; Yu, J. Ventilation Technology of Diesel Locomotive Railway Tunnels: Current Trends, Sustainable Solutions and Future Prospects. Sustainability 2025, 17, 9766. https://doi.org/10.3390/su17219766

Chen X, Sun S, Wu J, Ling T, Li L, Shi X, Yu J. Ventilation Technology of Diesel Locomotive Railway Tunnels: Current Trends, Sustainable Solutions and Future Prospects. Sustainability. 2025; 17(21):9766. https://doi.org/10.3390/su17219766

Chicago/Turabian StyleChen, Xiaohan, Sanxiang Sun, Jianyun Wu, Tianyang Ling, Lei Li, Xianwei Shi, and Jie Yu. 2025. "Ventilation Technology of Diesel Locomotive Railway Tunnels: Current Trends, Sustainable Solutions and Future Prospects" Sustainability 17, no. 21: 9766. https://doi.org/10.3390/su17219766

APA StyleChen, X., Sun, S., Wu, J., Ling, T., Li, L., Shi, X., & Yu, J. (2025). Ventilation Technology of Diesel Locomotive Railway Tunnels: Current Trends, Sustainable Solutions and Future Prospects. Sustainability, 17(21), 9766. https://doi.org/10.3390/su17219766