Abstract

Feed and water scarcity are major challenges for the sustainability of livestock production, particularly in semi-arid regions with structural limitations in resource availability. In this context, the valorization of agro-industrial by-products contributes to circular agriculture, reduces waste, and promotes more efficient resource use, in line with the United Nations Sustainable Development Goals. This study evaluated the inclusion of partial mixed tomato residue (PMR) silage in sheep diets and its effects on productive performance, total water intake, and meat quality. Eighteen ewe lambs were assigned to two groups: control (concentrate and deferred pasture) and PMR (tomato residue silage and deferred pasture). The PMR silage had a pH of 3.97 and was mainly characterized by lactic and acetic acids, with minor amounts of propionic and butyric acids. The butyric acid concentration (8.9 g kg−1 DM) slightly exceeded the recommended threshold (0.5% DM), suggesting some clostridial activity but remaining below levels associated with severe deterioration. Animals fed PMR silage showed a 36% higher dry matter intake (p = 0.001), with greater intake of total digestible nutrients and fiber. This translated into a 54% higher average daily gain (p = 0.02) and an 11% greater final body weight compared with the control group (p = 0.02). Dietary water intake was also higher in the PMR group, reducing direct water consumption from drinkers by 38% (p < 0.001). Meat quality parameters were unaffected by the diet. Pesticide residue screening by LC-MS/MS revealed no detectable levels of abamectin, cymoxanil, chlorothalonil, difenoconazole, or mancozeb in silage. In meat samples, only chlorothalonil was tested and it was not detected. However, the use of PMR silage increased direct energy demand due to transport and compaction, while feeding costs per unit of weight gain were reduced. Overall, PMR silage proved to be a safe, fermentatively stable, and effective feeding alternative that enhances performance, reduces direct water intake, and maintains meat quality, representing a viable strategy for small ruminant production in water-limited regions.

1. Introduction

The scarcity of feed and water is a major challenge to the sustainability of livestock production, particularly in semi-arid regions [1,2], which cover approximately 18% of the Earth’s land surface and face structural limitations such as low water availability and restricted access to inputs [3]. This limitation directly undermines the United Nations Sustainable Development Goals (SDGs), particularly SDG 2 (zero hunger and sustainable agriculture), SDG 6 (clean water and sanitation), and SDG 12 (responsible consumption and production), which promote the efficient use of natural resources and the sustainability of production systems [4]. These challenges highlight the need for resilient and sustainable livestock practices in vulnerable environments.

In this context, the valorization of agro-industrial by-products in ruminant feeding has emerged as a sustainable alternative, contributing to waste utilization and mitigating environmental impacts associated with improper disposal [5,6]. Such practices strengthen circular agriculture by reducing waste streams and transforming them into productive feed resources. A promising example is tomato processing residue, composed of peels, seeds, and pulp, which has high moisture content and a nutritional profile suitable for small ruminant diets [7,8].

Global tomato production reached approximately 192 million tons in 2023 [9], generating large volumes of underutilized residues. During industrial processing, tomato pomace can account for 2–10% of the raw fruit weight, depending on the processing method [10]. Its high moisture content suggests a potential influence on animal water intake, but no studies have investigated this relationship.

Beyond nutritional aspects, the processing of residues into silage also entails mechanized operations such as transport and compaction, which increase direct energy demand and may affect feeding costs [11,12]. These aspects are rarely addressed in studies on agro-industrial by-products, leaving open questions about possible trade-offs between environmental and economic dimensions.

Another critical issue is that tomato cultivation is often associated with intensive pesticide use and contamination of fresh tomatoes [13,14,15]. Although regulations in Brazil and internationally define strict residue limits for final products [16,17,18], by-products such as pomace are not routinely monitored. This lack of monitoring highlights the importance of complementary screening to ensure feed and food safety, since pesticide residues present in feed could potentially be transferred (carry-over) to animal tissues [19].

Despite growing interest in using agro-industrial residues in animal feeding, no studies have simultaneously assessed their effects on productive performance, water intake (direct and dietary), and quality meat. This gap hinders the safe adoption of such practices in vulnerable regions. Therefore, this study aimed to evaluate the effects of including partial mixed tomato residue silage in sheep diets on productive performance, total water intake, and meat quality, considering its sustainable use in small ruminant production systems. Additional observations were also made on energy demand in the experimental sector and on economic costs to provide a broader sustainability perspective.

2. Materials and Methods

All experimental procedures involving animals were reviewed and approved by the Ethics Committee on the Use of Animals of the State University of Montes Claros (CEUA/UNIMONTES, protocol no. 229/2021). The study was conducted in accordance with the institutional guidelines and the Brazilian national regulations for the care and use of animals in research (CONCEA/MCTI), which are aligned with the principles of the ARRIVE guidelines and Directive 2010/63/EU on the protection of animals used for scientific purposes.

2.1. Location and Animals

The experiment was conducted at the Experimental Farm of the State University of Montes Claros (UNIMONTES), located in Janaúba, a semi-arid region of Minas Gerais, Brazil (coordinates: −15°72′95″, −43°32′16″). During the experimental period, the air temperature (dry bulb) averaged 24.43 ± 0.33 °C, dew point was 15.10 ± 0.44 °C, and relative humidity was 58.51 ± 1.50%. The recorded rainfall was zero mm [20]. Eighteen crossbred ewe lambs, under one year of age, with an initial average body weight of 19.68 ± 1.68 kg were used. All animals had a comparable nutritional and health status at the beginning of the trial. Prior to the trial, all animals underwent a health protocol including internal parasite control.

2.2. Semi-Feedlot and Diets

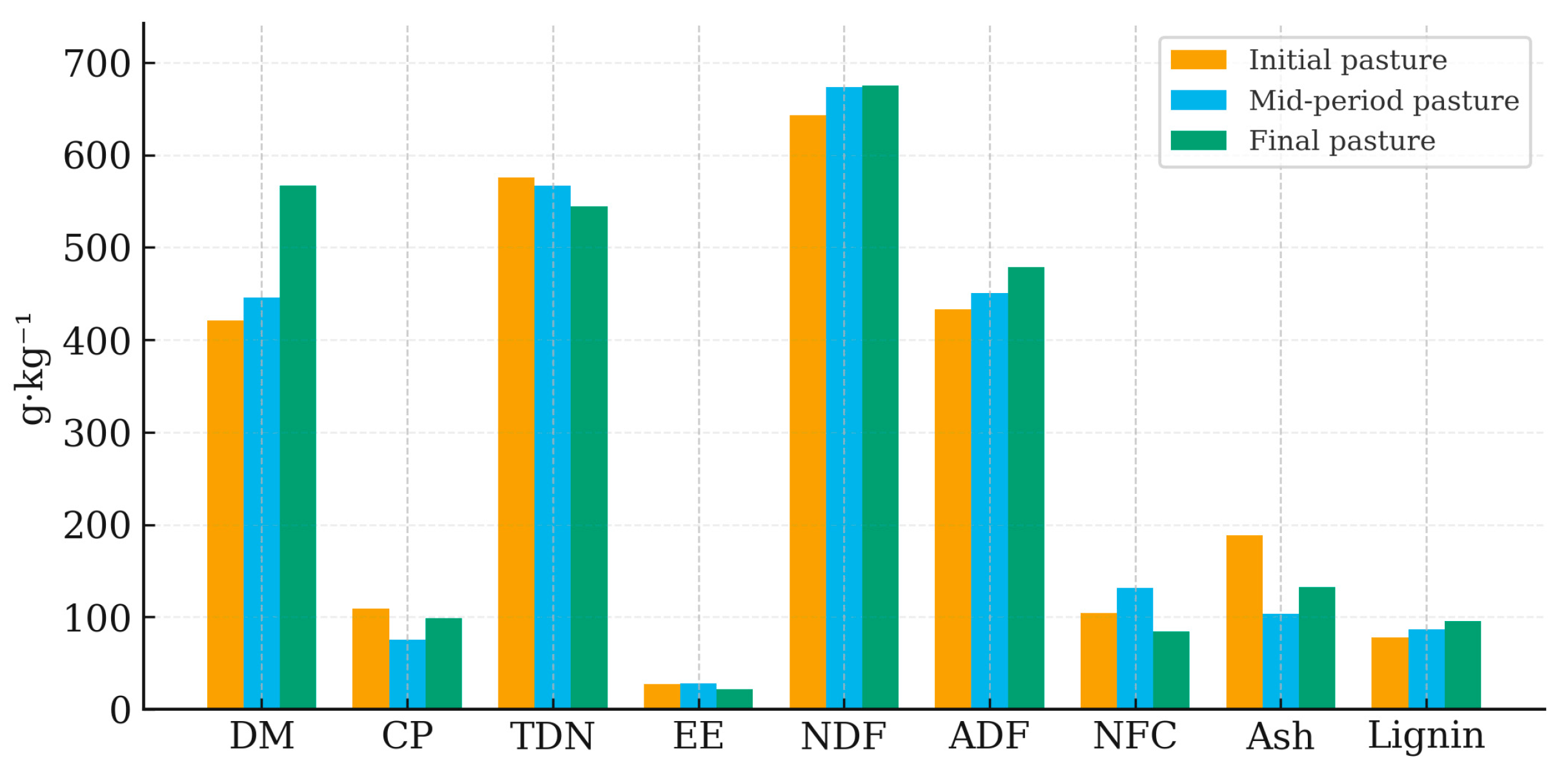

Animals were kept under a semi-feedlot system for 52 days, including a 12-day adaptation period and a 40-day data collection phase. Each morning at 9:00 a.m., the animals were moved to a collective paddock of 0.32 ha, composed of a mixed pasture of Buffel grass (Cenchrus ciliaris) and Sabi grass (Urochloa mocambisensis) in estimated proportions of 30% and 70%, respectively, based on visual observations of fresh matter. At the start of the experiment, the pasture had an average dry matter yield of 5.8 ton ha−1 and an average height of 64.8 cm. Botanical composition and forage productivity were estimated using the total collection quadrat method. The mean chemical composition of the deferred pasture during the trial is shown in Figure 1.

Figure 1.

Mean composition of deferred pasture over the experimental period. Abbreviations: DM, Dry matter (g kg−1, as-fed basis); CP, Crude protein (g kg−1, DM); TDN, Total digestible nutrients (g kg−1, DM); EE, Ether extract (g kg−1, DM); NDF, Neutral detergent fiber (g kg−1, DM); ADF, Acid detergent fiber (g kg−1, DM); NFC, Non-fibrous carbohydrates (g kg−1, DM); Ash (g kg−1, DM); Lignin (g kg−1, DM).

At 3:00 p.m., animals were returned to individual pens (1.5 m2), equipped with feeders and drinkers, with concrete flooring, wood shavings bedding, and shelter. Animals remained in the pens until the next morning. The animals were randomly assigned to two groups (n = 9 per group) in a completely randomized design by random draw, considering each individual animal as the experimental unit. One group received a control diet consisting of concentrate and mineral mix, while the other group was fed a partial mixed ration (PMR) silage containing concentrate ingredients, tomato agro-industrial residue, and mineral mix.

The tomato residue was collected directly from a processing plant over two consecutive days. The company follows standardized procedures in both processing and sourcing raw material from farms, ensuring consistency of the residue. Previous studies have shown the nutritional suitability of tomato residue for sheep feeding [21] and its potential for quality silage production [22].

The PMR silage was prepared manually on a cemented surface immediately after the tomato residue was delivered to the farm. The processing plant and the experimental farm were located 22 km apart. The procedure was carried out in batches of approximately 200 kg, in which the tomato residue was mixed with the other ingredients in the previously established proportions. The silage was stored in a silage pile, lined with plastic sheeting both beneath and above the material. Compaction was performed using a tractor and by manual trampling to ensure adequate exclusion of air. The silo was sealed and remained under fermentation for eight months before opening due to logistical constraints in the experimental schedule.

Planned diets were formulated at the beginning of the experiment targeting an average daily gain of 200 g per animal [23]. Both diets were isoenergetic, providing 689.7 g kg−1 of total digestible nutrients on a dry matter basis. The experimental diet with PMR silage contained 144.5 g kg−1 of crude protein, while the control diet contained 166.4 g kg−1. Dry matter intake was estimated at 3.4% of body weight, based on previous trials under similar environmental and animal conditions [24,25] and the nutrient requirements of small ruminants [23].

For the planned control group, the diet was composed of 43.8% concentrate (836.5 g kg−1 TDN, 240.0 g kg−1 CP) and 56.2% deferred pasture (575.3 g kg−1 TDN, 109.0 g kg−1 CP) on a DM basis, with concentrate supplied at 1.8% of body weight and pasture offered ad libitum. For the PMR group, the diet consisted of 89.1% PMR silage (703.8 g·kg−1 DM TDN, 148.8 g·kg−1 DM CP) and 10.9% deferred pasture (575.3 g·kg−1 DM TDN, 109.0 g·kg−1 DM CP), with the PMR silage offered ad libitum (adjusted daily to maintain 5% refusals) and pasture available during grazing periods. Thus, the diets were nutritionally comparable, with energy intentionally matched and CP kept within recommended ranges for small ruminants, reflecting practical feeding strategies under semi-arid conditions.

2.3. Estimation of Pasture Intake, Feed Analysis, and Animal Performance

Pasture dry matter intake was estimated using the internal marker method, specifically indigestible neutral detergent fiber (iNDF), quantified through a 240 h in situ rumen incubation [26]. Representative samples of pasture, silages, concentrate, and feces were incubated in the rumen of two fistulated steers previously adapted for 15 days to a corn silage-based diet. The material was inserted into non-woven textile bags (12 cm × 7 cm, 60 µm porosity), maintaining a ratio of 20 mg of dry matter per cm2 of surface area, and incubated in the ventral ruminal sac. After incubation, bags were thoroughly rinsed under running water, oven-dried at 55 °C for 72 h, and analyzed for dry matter and neutral detergent fiber content. The undigested residue was classified as iNDF.

Pasture samples were collected using the hand-plucking technique to mimic animal selection [27]. These samples were taken at three time points during the trial, matching the fecal collection days. For each sampling event, six subsamples (two per treatment) were collected and pooled by group. Trained personnel manually selected the plant parts most likely to be ingested by the lambs.

Intake of silage and concentrate was quantified individually based on daily feed delivery and refusals. The contribution of pasture to total dry matter intake was estimated using the iNDF concentrations in the feed components and feces, applying a mass balance approach.

Fecal material was collected directly from the rectal ampulla at the same three sampling points, homogenized within each group, and pooled for further analysis. All feed and fecal samples were oven-dried at 55 °C and ground to 1 mm (feeds) or 0.5 mm (feces) particle size. Laboratory analyses followed standard protocols and included dry matter (DM), crude protein (CP), ether extract (EE), ash, neutral detergent fiber (NDF), acid detergent fiber (ADF), and lignin [26,28]. Non-fiber carbohydrates (NFC) and total digestible nutrients (TDN) were estimated based on the nutrient composition.

Body weight was recorded weekly without fasting to calculate average daily gain (ADG), and feed efficiency was determined by the ratio of ADG to total dry matter intake.

2.4. Pesticide Residue Analysis in PMR Silage

Pesticide residue analysis was conducted on the PMR silage, which represented the feed supplied to the animals, since the other ingredients were of commercial origin or deferred pasture, not typically traced for pesticide use. The selection of active ingredients—abamectin, cymoxanil, chlorothalonil, difenoconazole, and mancozeb—was based on consultations with local agricultural technicians, reflecting their frequent use in tomato production.

Analyses were performed using liquid chromatography–tandem mass spectrometry (LC-MS/MS) on an LCMS-8040 triple-quadrupole system (Shimadzu, Kyoto, Japan), operated with LabSolutions software, version 5.92 (Shimadzu, Kyoto, Japan), employing a five-point calibration curve and analytical controls at 10 and 100 µg kg−1. Quantification was based on the relative response of chromatographic peaks, with detection limits of 10 µg kg−1 for abamectin, cymoxanil, and difenoconazole; 25 µg kg−1 for chlorothalonil; and 50 µg kg−1 for mancozeb.

According to the official Brazilian monographs [29], these compounds are authorized for tomato production and have established maximum residue limits (MRLs): 0.01 mg kg−1 for abamectin, 0.5 mg kg−1 for cymoxanil, 3 mg kg−1 for chlorothalonil, 0.9 mg kg−1 for difenoconazole, and 2 mg kg−1 for mancozeb. These benchmarks contextualize the detection limits applied here (10–50 µg kg−1), which are well below the MRLs, thus ensuring sufficient sensitivity for food safety assessment.

2.5. Quantification of Organic Acids in Silage Using HPLC

Organic acids in the silage samples were quantified by high-performance liquid chromatography (HPLC) using a Prominence LC-20A system (Shimadzu, Kyoto, Japan), equipped with a UV/Vis detector (SPD-20A), an autosampler, and a column oven. Chromatographic separation was achieved using a Rezex ROA-Organic Acid H+ column (300 × 7.8 mm; Phenomenex, Torrance, CA, USA), thermostated at 60 °C. The mobile phase consisted of 0.0025 N sulfuric acid, pumped isocratically at a flow rate of 0.6 mL min−1.

Sample injection volume was 5 μL. Organic acids were detected at 210 nm and quantified using external calibration curves based on certified standards. The profile included lactic, acetic, propionic, and butyric acids, which are typically reported as the main fermentation products in silages. The analysis was performed to confirm the quality of the fermentation process and ensure the suitability of the silage for animal feeding.

2.6. Water Intake from Drinker and Feed

Water intake was manually measured while animals were housed in individual pens, as no drinkers were available in the collective paddock. During the day, animals grazed in deferred pastures without water access and were accustomed to returning to the corral to drink, a common practice in semi-arid regions [30].

Each day at 3:00 p.m., 10 kg of water was offered in individual buckets. The following morning, refusals were weighed, and consumption was calculated as the difference. Buckets were then refilled with 10 kg of water. To estimate evaporation, three buckets containing 10 kg of water were placed in a 13.5 m long corridor under the same environmental conditions but out of animal reach. The shed presented homogeneous and stable microclimatic conditions, justifying the use of three buckets as representative replicates. Water was replaced daily, and mass variation was recorded to correct for evaporation losses ruminants [31].

Total water intake included both water from the drinker and moisture in the feed (PMR silage, concentrate, and pasture). For this, the dry matter content of offered and consumed feed was used to estimate water intake via diet. The calculation was based on the difference between the amount offered and the amount refused.

Water activity (AW) of the feed was assessed at the beginning and end of the experiment, in triplicate for each ingredient (deferred pasture, PMR silage, concentrate, and silage refusals). Measurements were performed using an AquaLab Series 3TE water activity meter (Decagon Devices, Inc., Pullman, WA, USA). The average AW was 0.973 ± 0.002 for PMR silage, 0.967 ± 0.001 for deferred pasture, 0.613 ± 0.035 for the concentrate, and 0.929 ± 0.004 for silage refusals.

2.7. Pre-Slaughter Procedures, Slaughter, and Meat Analysis

At the end of the feedlot period, animals underwent a 16 h fasting period (solids only) and were then transported 50 km to a commercial abattoir, where slaughter followed national technical regulations [32,33]. Stunning was performed via electrical narcosis, followed by exsanguination and viscera removal. Carcasses were initially weighed, chilled at 2 °C for 24 h, and then reweighed to obtain cold carcass weight.

A cut between the 12th and 13th ribs of the left half-carcass was made to expose the longissimus dorsi area, which was traced onto paper, scanned, and analyzed using Bio7 software, version 3.5 (https://bio7.org). Subcutaneous fat thickness was measured using a caliper. The Longissimus lumborum muscle was collected for pH, electrical conductivity, color, water-holding capacity (WHC), and shear force analyses. pH was measured directly in the muscle using a digital meter in triplicate. For color assessment, 2.54 cm-thick samples were exposed to air at 4 °C for 30 min and analyzed using a Hunter MiniScan EZ spectrophotometer in the CIE L*, a*, b* system (five readings per sample).

WHC was determined by the filter paper pressure method [34], using three subsamples (0.295 to 0.305 g) pressed at 10 kg for 5 min. Filter paper imprints were scanned and analyzed using Bio7. Two loin samples (2.54 cm thick) were grilled to 42 °C, turned, and cooked to 71 °C [35]. After 15 min of cooling at 16 °C, samples were weighed, and six cylindrical subsamples (1.27 cm diameter) were collected along the muscle fibers for shear force analysis [36].

Muscle samples from 13 animals (eight from the experimental group and five from the control) were analyzed for chlorothalonil residues. One sample per animal was randomly selected within each group. Chlorothalonil was chosen due to its recognized carcinogenic potential in humans [37].

Residue analysis was performed using LC-MS/MS with a five-point calibration curve specific to chlorothalonil. Analytical controls at 10 and 100 µg kg−1 were used to monitor sensitivity and linearity. The quantification limit was 10 μg kg−1, in accordance with muscle matrix requirements. When residues were detected, results were expressed in μg kg−1; values below the quantification limit were reported as “ND” (not detected). Chlorothalonil was the only compound analyzed in meat samples because it is widely used in tomato production and is considered particularly relevant for human health due to its potential carcinogenic effects [38].

2.8. On-Farm Energy Demand, and Economic Costs

Energy consumption was estimated considering only the direct energy used in the experimental sector of the farm, derived from diesel and electricity, an approach commonly adopted in agricultural studies [39,40]. Three main operations were included: (i) transport of tomato residue, performed in two round trips (22 km each way) with two pickup trucks, assuming an average consumption of 8 km·L−1; (ii) silage compaction, with a tractor operated for 30 min, considering a consumption of 10 L·h−1; and (iii) fertilization of the experimental paddock (0.32 ha), where two 50 kg bags of reactive natural phosphate and two 50 kg bags of single superphosphate were applied in a single pass using a broadcast spreader, adopting an average consumption of 6 L·ha−1.

In addition to these operations, electricity use in the experimental sector was considered, including an electronic scale (100 W, 0.5 h·day−1) and two 60 W lamps (1 h·day−1). Diesel volumes were converted into energy using the factor of 35.8 MJ·L−1 [41], and electricity using the factor of 3.6 MJ·kWh−1. The final result was expressed in megajoules (MJ) per animal, taking as reference the target slaughter weight of the group that achieved the highest final body weight, in order to standardize the comparison between treatments.

Economic costs were estimated from the actual dry matter intake observed in each group, considering supplement and pasture separately. Unit prices of inputs were obtained at the time of the experiment and converted into U.S. dollars using the Central Bank of Brazil PTAX average exchange rate [42]. The following values were used: corn (USD 0.36 kg−1 DM), soybean meal (USD 0.49 kg−1 DM), mineral mix (USD 1.14 kg−1), limestone (USD 0.08 kg−1 DM), agro-industrial tomato residue (USD 0.03 kg−1 as-fed; USD 0.083 kg−1 DM), deferred pasture (USD 0.11 kg−1 DM), and diesel (USD 1.26 L−1). The cost of supplements (concentrate and PMR silage) was calculated by multiplying ingredient proportions by their respective prices. Daily costs per animal were obtained by multiplying supplement and pasture intake by their unit costs and adding diesel costs associated with farm operations. For the control group, diesel use referred only to paddock fertilization, whereas for the PMR group it also included transport of tomato residue and silage compaction.

Labor was also considered. One worker, hired at 1.5 times the official Brazilian minimum wage for a six-hour workday, was responsible for daily feeding management, corresponding to one hour of work per day, including Sundays. Based on the official minimum wage established in Brazil for 2022 (BRL 1212.00 month−1), the hourly cost was calculated by dividing the adjusted monthly wage by the contracted workload (180 h month−1), resulting in USD 1.92 h−1 after conversion using the Central Bank of Brazil PTAX average exchange rate [42]. To allow comparison between treatments, costs were accumulated until animals reached a common target slaughter weight, defined as the final body weight of the group that achieved the highest value at the end of the experiment. It should be noted that fixed costs such as land value, infrastructure depreciation, and capital investment were not included, as the analysis focused exclusively on variable costs directly associated with feed, labor, and fuel during the experimental period, following the distinction between variable and ownership costs commonly adopted in farm management studies [43].

Direct energy use was estimated based on technical coefficients of diesel and electricity consumption, with a ±10% [44] margin adopted to account for operational variability. In contrast, economic costs were calculated from the experimental data on intake and performance, and thus variability is expressed as mean ± standard error in the results section.

2.9. Statistical Analysis

Statistical analyses were performed using R software (version 4.4.1) and RStudio (version 2024.12.0 Build 467) [45] with support from the tidyverse, car, and emmeans packages. For each response variable, an ANCOVA linear model was fitted, with treatment group as a fixed effect and initial body weight as a covariate. Models were fitted using the lm() function. When the covariate was significant (p < 0.05), adjusted means were estimated using emmeans. Otherwise, raw group means were presented.

Residual normality was tested with the Shapiro–Wilk test, and homogeneity of variance with Levene’s test. Residual standard error was reported as a measure of model precision. The variables total daily water intake, drinker water intake per day, feed water intake per kg of body weight gain, and total water intake per kg of gain did not meet normality assumptions. These variables were log-transformed, except for total daily water intake, which was transformed using the reciprocal function (x−1). After transformation, residuals met the model assumptions.

3. Results

3.1. Pesticide Residues and Silage Fermentation Profile

Pesticide residue screening in the PMR silage revealed no quantifiable levels of abamectin, cymoxanil, chlorothalonil, difenoconazole, or mancozeb. All values were below the quantification limits and were classified as not detected (Table 1).

Table 1.

Ingredients and chemical composition of the concentrate and partial mixed ration (PMR) silage used in the experimental diets, including pesticide residue screening.

The PMR silage sample contained 72.5 g kg−1 DM of lactic acid, 43.2 g kg−1 DM of acetic acid, 10.0 g kg−1 DM of propionic acid, and 8.9 g kg−1 DM of butyric acid.

3.2. Animal Performance, Nutrient Intake, and Water Consumption

Lambs fed the PMR silage showed higher daily dry matter intake from the supplement compared to the control group (p = 0.001) (Table 2). Total dry matter intake and deferred pasture intake were also higher in the PMR group (p < 0.02). The inclusion of PMR silage resulted in greater intake of total digestible nutrients, ether extract, non-fiber carbohydrates, and lignin (p < 0.02). Fiber fractions, including neutral detergent fiber and acid detergent fiber, were also significantly higher in the PMR group compared to the control (p < 0.001).

Table 2.

Nutrient intake and performance of lambs grazing deferred pasture and supplemented with either concentrate or partial mixed ration silage containing tomato agro-industrial residue.

To better illustrate the differences between the planned and the actual intake, the composition of the experimental diets is presented in Table 3.

Table 3.

Planned and intake composition of the experimental diets.

The PMR group showed higher average daily gain (213 vs. 139 g day−1) and final body weight (27.8 vs. 25.0 kg) than the control group (p = 0.02). Feed efficiency did not differ between treatments (p = 0.46).

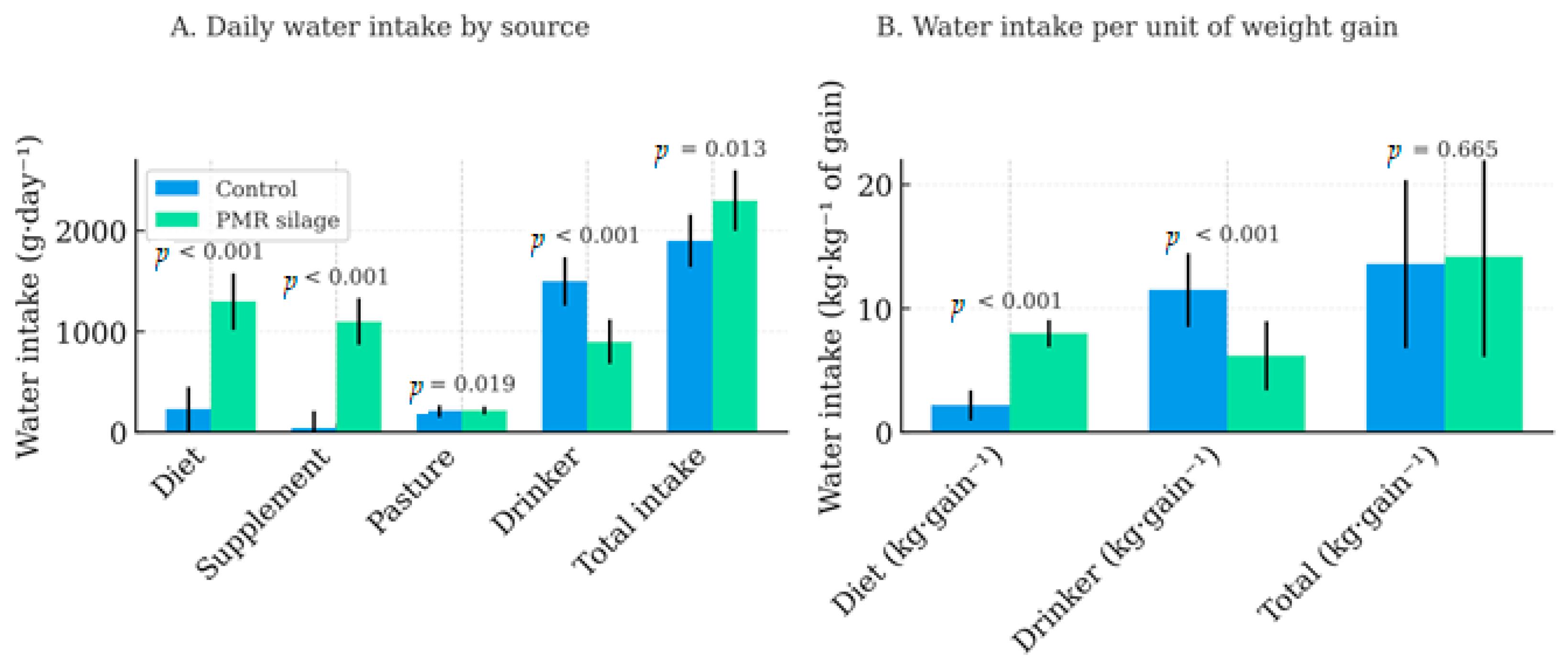

Animals fed PMR silage had more than 430% higher dietary water intake compared to the control group (p < 0.001) (Figure 2). The supplement fraction was nearly 60 times greater in the PMR group (p < 0.001). Total dietary water intake was 22% higher in PMR-fed animals (p < 0.001). Water consumption from drinkers was 38% lower in PMR-fed animals (p < 0.001). When expressed per kilogram of body weight gain, total water intake did not differ significantly between treatments (p = 0.67).

Figure 2.

Water intake of lambs grazing deferred pasture and supplemented with either concentrate (Control) or partially mixed ration (PMR) silage containing tomato agro-industrial residue. Error bars represent standard error of the mean (SE).

3.3. Carcass Traits and Meat Quality

Hot and cold carcass weights were greater in the PMR group (p < 0.02), while carcass yields (hot and cold), loin eye area, and subcutaneous fat thickness were similar between groups (p > 0.09) (Table 4). Regarding meat quality, cooking losses were higher in animals fed PMR silage (p = 0.02). Other physicochemical traits of the meat—including pH, color (L*, a*, b*), electrical conductivity, water-holding capacity, and shear force—did not differ between groups (p > 0.09).

Table 4.

Non-carcass components, carcass traits, and meat quality of lambs grazing deferred pasture and supplemented with either concentrate or partial mixed ration silage containing tomato agro-industrial residue, including screening for chlorothalonil residue in meat.

Chlorothalonil residue screening in meat from both PMR and control groups revealed no measurable concentrations, with all values classified as not detected.

3.4. On-Farm Energy Use and Economic Costs

Direct energy consumption in the experimental sector varied between treatments. For the control group, the estimated total was 5.9 ± 0.6 MJ per animal, resulting from paddock fertilization (3.8 MJ animal−1) and electricity use for the scale and lighting (2.1 MJ animal−1). In the PMR group, the total consumption was 112.6 ± 11.3 MJ per animal, of which 107.4 MJ came from tomato residue transport and silage compaction, 3.8 MJ from fertilization, and 1.4 MJ from electricity. Values were standardized considering the target slaughter weight of 27.81 kg (final average of the PMR group), in order to enable uniform comparison between treatments.

The total costs accumulated up to the target slaughter weight (27.81 kg) differed between the groups. In the control group, the average cost per animal was USD 17.42 ± 2.10, resulting from supplement and pasture intake, along with labor costs and the occasional use of diesel for paddock fertilization. In the PMR group, the total average cost was USD 15.51 ± 2.25 per animal, including silage and pasture intake, labor costs, and the additional diesel required for tomato residue transport and silage compaction. When expressed as cost per kilogram of live weight gain up to the slaughter weight, the values corresponded to USD 10.96 ± 1.12 for the control group and USD 9.53 ± 1.08 for the PMR group.

4. Discussion

This study provides an integrated assessment of tomato residue silage in sheep diets, focusing on fermentation quality, animal performance, water intake, and meat quality under semi-arid conditions.

The fermentation profile of the tomato residue silage indicates that the ensiling process was overall effective, although not optimal. The pH of 3.97 and the predominance of lactic acid (72.5 g kg−1 DM) demonstrate adequate lactic fermentation, consistent with the expectation that lactic acid should be the main organic acid in well-preserved silages [46,47]. The moderate concentration of acetic acid (43.2 g kg−1 DM) suggests heterofermentative activity, which may improve aerobic stability but, when elevated, can reduce voluntary intake, although this effect was not observed in the present study. The presence of propionic acid (10.0 g kg−1 DM) also reflects heterofermentative activity, as reported in studies evaluating organic acid dynamics during ensiling [48]. Butyric acid concentrations above 0.5% DM are considered indicative of clostridial activity, while levels exceeding 1.0% DM are associated with severely deteriorated silages. In this study, the concentration of butyric acid reached 0.887% DM (8.87 g·kg−1 DM), which places the material in a warning zone but below the threshold of severe spoilage. Extended storage time (eight months) may have favored the activity of clostridia [46]. Tuoxunjiang et al. [49], evaluating a total mixed ration silage with 100 g kg−1 tomato pomace, reported no detection of butyric acid.

The inclusion level of tomato residue in our PMR silage (~38% DM) is comparable to the 35–40% range reported by Silva et al. [22] as optimal for fermentation and aerobic stability. This similarity reinforces that moderate inclusion levels of tomato by-products can enhance silage quality without impairing nutritional value. Localized deterioration was observed at the silo borders after opening, which reinforces the need for technical improvements in the ensiling process to ensure better preservation.

The absence of detectable residues in the silage should be interpreted with caution. Industrial tomato processing can already reduce pesticide residues, as reported by Corrias et al. [50], and the ensiling process may further contribute through microbial activity of lactic acid bacteria, which are also capable of degrading certain residues under experimental conditions [51,52,53]. Although the raw tomato residue was not analyzed in this study, screening the final silage offered to animals provided an additional safeguard. Considering that pesticide use in agriculture can result in residues in animal-derived foods and pose risks along the food chain, continuous monitoring remains an important complementary measure [54].

Regarding animal performance, lambs fed PMR silage had higher dry matter intake, as the silage was offered ad libitum and accounted for 89% of the total dietary dry matter. Although both diets were formulated (planned) to be isoenergetic and within recommended crude protein levels, the actual intake showed deviations, with the control diet resulting in less efficiency in practice. Its reliance on deferred pasture limited voluntary intake and digestibility. Ebeid et al. [55] and Tuoxunjiang et al. [49], evaluating buffaloes and dairy cows, respectively, reported that the inclusion of tomato pomace silage in the diets, at levels up to 100 and 250 g kg−1 DM, did not impair animal performance, reinforcing that tomato by-products can be safely incorporated into ruminant diets.

In contrast, the control group received a restricted concentrate supply (1.8% of body weight), combined with pasture offered ad libitum. However, pasture intake was lower than expected, as many animals lay down and ruminated after 1:00 p.m., possibly indicating satiety or low forage palatability [56], likely related to the high fiber content of the pasture, which reduces acceptability and intake efficiency [57]. In addition, animals fed silage had immediate access to feed in the trough, while control animals had to harvest most of their diet from pasture, further decreasing intake efficiency.

Higher dry matter intake in the PMR group resulted in greater intake of neutral and acid detergent fiber, fibrous and non-fibrous carbohydrates [58], with values similar to those reported by Weiss, Frobose, and Koch [59]. The good digestibility of tomato residue included in silage up to 45% has already been demonstrated [21]. Additionally, the PMR group had a higher intake of inorganic components. Consequently, actual intake of total digestible nutrients, ether extract, and lignin (g·day−1) was greater in the PMR group, explaining the higher average daily gain and final body weight. Nevertheless, feed efficiency remained similar between groups.

Regarding water intake, animals in the control group consumed on average 62% more water from the drinker compared with those fed PMR silage. This difference can be attributed to the high moisture content of the silage, which significantly contributed to the dietary water supply [60,61]. In fact, lambs in the PMR group consumed approximately 1.3 kg of water per day via feed, whereas the control group obtained only 244 g from this route. Similar findings have been reported with other high-moisture feed resources, such as cactus pear silages, which substantially increase water intake via diet [62]. This highlights the role of aqueous feeds as an alternative strategy to improve water balance in sheep diets under semi-arid conditions. From a broader perspective, water is a key nutrient for small ruminants, and their efficiency in using water resources has been recognized as a critical aspect for sustainable production in dry regions [30]. Although total water intake was higher in the PMR group, when adjusted per unit of weight gain, water use efficiency was similar between systems.

The higher hot and cold carcass weights in the PMR group were a direct consequence of their greater final body weight, while carcass yield, loin eye area, and subcutaneous fat thickness remained similar, indicating no effect on carcass finish.

Meat traits—pH, color (CIE L*, a*, b*), electrical conductivity, water-holding capacity (WHC), and shear force—did not differ between groups. In contrast to the present study, Valenti et al. [63] reported that the meat of lambs fed dried tomato pomace exhibited a lighter color. Variations in pH can affect texture, color, and water retention [64,65], but since the final pH remained stable, these attributes were also unchanged. Recorded values fell within the ideal range for lamb meat [66], and texture in all groups could be classified as tender [67].

The higher cooking loss observed in animals fed PMR silage may be related to their greater water intake, even though WHC and drip loss did not differ between groups. Although meat moisture content was not determined, it is plausible that increased water retention in tissues contributed to higher thermal losses, which could negatively affect industrial processing by increasing exudate during packaging, as suggested by Pang [68]. Future studies, including proximate analysis of meat, would help clarify this relationship. As no pesticide residues were detected in the silage, chlorothalonil was also not found in the meat.

From the perspective of energy expenditure, the inclusion of PMR silage substantially increased direct energy demand, mainly due to transport and compaction operations, which accounted for more than 90% of total consumption. This pattern is consistent with previous reports highlighting mechanized operations and fuel use as the main determinants of energy expenditure in livestock systems [69,70]. Despite the higher energy input, the PMR strategy reduced feeding costs per unit of live weight gain, suggesting greater efficiency in resource use.

From an economic standpoint, the lower cost observed in the PMR group can be attributed to the replacement of conventional diet ingredients with tomato residue, a low-cost by-product. The economic advantage, coupled with superior productive performance, underscores the potential of agro-industrial residues to enhance economic sustainability. However, the higher energy demand raises questions about trade-offs between environmental and economic dimensions, an aspect that warrants further investigation through broader system boundary analyses and investments in non-fossil energy [71,72]. An additional point in favor of PMR, as already discussed, is the reduction in drinking water demand due to the aqueous nature of the silage, which competes with human consumption.

From a sustainability perspective, the inclusion of tomato agro-industrial residue silage in sheep diets improved performance, maintained meat quality, and reduced direct water consumption through its high moisture content. These findings reinforce the potential of agro-industrial by-products as alternative feed resources in semi-arid systems, while also pointing to trade-offs related to energy use that warrant further evaluation.

5. Conclusions

The inclusion of silage made from partially mixed tomato agro-industrial residue in sheep diets improved productive performance and maintained meat quality. The silage showed generally adequate fermentation quality, although the butyric acid concentration indicated some clostridial activity. This strategy reduced drinking water consumption and feeding costs, reinforcing its potential as a sustainable alternative for small ruminant production in semi-arid systems. Moreover, sheep contribute to the environmental valorization of agro-industrial by-products by converting them into high-quality protein and recycling nutrients within the production chain. Future studies should further evaluate energy trade-offs and optimize ensiling practices.

Author Contributions

Conceptualization, J.R.M.R., L.L.d.S.O. and F.V.e.S.; Methodology, J.R.M.R., F.P.M., L.L.d.S.O., M.I.B.P., E.M.V.P. and F.V.e.S.; Formal analysis, F.P.M., E.M.V.P. and F.V.e.S.; Writing—original draft, A.M.d.S.; Writing—review & editing, J.R.M.R., L.K.F.V., F.P.M., L.L.d.S.O., M.I.B.P., E.M.V.P., A.V.L. and F.V.e.S.; Visualization, J.R.M.R. and A.V.L.; Project administration, A.M.d.S., L.K.F.V. and M.I.B.P.; Funding acquisition, F.V.e.S. All authors have read and agreed to the published version of the manuscript.

Funding

This article is part of a research project funded by FAPEMIG (project number APQ-02560-21). The authors also acknowledge the support provided by the Conselho Nacional de Desenvolvimento Científico e Tecnológico [National Council for Scientific and Technological Development] (CNPq) and the Fundação de Amparo à Pesquisa de Minas Gerais [Minas Gerais Research Support Foundation] (FAPEMIG) through research grants. This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES)—Finance Code 001.

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki and approved by the Ethics Committee on Animal Experimentation and Welfare of the Montes Claros State University (protocol code 229, approved on 10 May 2021).

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- De Souza Oliveira, B.Y.; de Silva Moura, C.M.; de Araújo, G.G.L.; Turco, S.H.N.; Voltolini, T.V.; Furtado, D.A.; de Medeiros, A.N.; Gois, G.C.; Campos, F.S. Thermoregulatory responses and ingestive behavior of sheep subjected to water restriction and high- and low-energy diets in a semi-arid environment. J. Therm. Biol. 2024, 119, 103749. [Google Scholar] [CrossRef] [PubMed]

- Barros de Freitas, A.C.; Bartholazzi, A., Jr.; Quirino, C.R.; da Costa, R.L.D. Water and food utilization efficiencies in sheep and their relationship with some production traits. Small Rumin. Res. 2021, 197, 106334. [Google Scholar] [CrossRef]

- Cherlet, M.; Hutchinson, C.; Reynolds, J.; Hill, J.; Sommer, S.; von Maltitz, G. World Atlas of Desertification; Publication Office of the European Union: Luxembourg, 2018; Available online: https://wad.jrc.ec.europa.eu/download (accessed on 24 June 2025).

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development; United Nations: New York, NY, USA, 2015. [Google Scholar]

- Jerónimo, E.; Cachucho, L.; Alves, H.; Guerreiro, O.; Paulos, K.; Costa, C.; Costa, J.; Gomes, S.; Alvarenga, N.; Alves, S.P.; et al. Partial replacement of concentrate in the lactating ewe’s diet with silages of agro-industrial by-products—Effect on milk composition and fatty acid profile, serum metabolites and growth of suckling lambs. Anim. Feed Sci. Technol. 2025, 325, 116345. [Google Scholar] [CrossRef]

- Lu, Z.; Wang, J.; Gao, R.; Ye, F.; Zhao, G. Sustainable valorisation of tomato pomace: A comprehensive review. Trends Food Sci. Technol. 2019, 86, 172–187. [Google Scholar] [CrossRef]

- Denek, N.; Can, A. Feeding value of wet tomato pomace ensiled with wheat straw and wheat grain for Awassi sheep. Small Rumin. Res. 2006, 65, 260–265. [Google Scholar] [CrossRef]

- Elbadrawy, E.; Sello, A. Evaluation of nutritional value and antioxidant activity of tomato peel extracts. Arab. J. Chem. 2016, 9, S1010–S1018. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. Our World in Data Tomato Production—FAO [Dataset] 2025; Food and Agriculture Organization: Rome, Italy, 2025; Available online: https://ourworldindata.org/grapher/tomato-production (accessed on 24 June 2025).

- Golub, N.; Galić, E.; Radić, K.; Smigic, N.; Djekić, I.; Pedisić, S.; Čepo, D.V. Microwave-Assisted Valorization of Tomato Pomace for Pectin Recovery: Improving Yields and Environmental Footprint. Foods 2025, 14, 1516. [Google Scholar] [CrossRef]

- Pishgar Komleh, S.H.; Keyhani, A.; Rafiee, S.; Sefeedpary, P. Energy use and economic analysis of corn silage production under three cultivated area levels in Tehran province of Iran. Energy 2011, 36, 3335–3341. [Google Scholar] [CrossRef]

- Azizpanah, A.; Namdari, M.; Abed, A.K. Integrated life cycle and data envelopment analysis of input optimization and environmental impacts in silage corn farming. Results Eng. 2025, 27, 106380. [Google Scholar] [CrossRef]

- Moura-Andrade, G.C.R.; Oetterer, M.; Tornisielo, V.L. Tomato as food—Production chain and pesticide residues. Pesticidas 2010, 20, 57–66. [Google Scholar] [CrossRef]

- Rafaela da Silva Costa, F.; Vitor de Melo Freitas, J.; Maria Barreto Amaral, S.; Larisse Pinheiro Uchia, M. Aparecida Liberato Milhome, Maria Multiresidue analysis of tomato and derived products: A brief review. Braz. J. Agrotechnol. 2021, 11, 328–335. [Google Scholar] [CrossRef]

- Agência Nacional de Vigilância Sanitária (ANVISA). Pesticide Residue Analysis Program in Food—PARA; Brazilian Health Regulatory Agency: Brasília, Brazil, 2019. Available online: https://www.gov.br/anvisa/pt-br/assuntos/agrotoxicos (accessed on 1 July 2025).

- Diário Oficial da União. Law No. 14.785, 27 December 2023. Provides for the Research, Experimentation, Production, Packaging and Labeling, Transportation, Storage, Marketing, Use, Import and Export of Pesticides, Their Components and Related Products, and Other Provisions; Diário Oficial da União: Brasília, Brazil, 2023. Available online: https://www.gov.br/agricultura/pt-br/assuntos/insumos-agropecuarios/insumos-agricolas/agrotoxicos/legislacao (accessed on 24 June 2025).

- National Health Surveillance Agency (ANVISA). Resolution RDC No. 4, 18 January 2012. Provides for the Conduct of Pesticide Residue Studies for the Purpose of Pesticide Registration in Brazil; Diário Oficial da União: Brasília, Brazil, 2012. Available online: https://bvsms.saude.gov.br/bvs/saudelegis/anvisa/2012/res0004_18_01_2012.html (accessed on 1 July 2025).

- Food and Agriculture Organization of the United Nations (FAO); World Health Organization (WHO). Codex Alimentarius—Pesticide Residues in Food and Feed, Maximum Residue Limits (MRLs); FAO: Rome, Italy; WHO: Geneva, Switzerland, 2024. [Google Scholar]

- Li, Z.; Xiong, J.; Fantke, P. Screening of pesticide distributions in foods of animal origin: A matrix-based approach for biotransfer factor modeling of grazing mammals. Environ. Sci. Process. Impacts 2022, 24, 609–624. [Google Scholar] [CrossRef]

- Instituto Nacional de Meteorologia (INMET). Climatic Data—Temperature, Humidity and Precipitation; INMET: Brasília, Brazil, 2025. Available online: https://portal.inmet.gov.br/ (accessed on 1 July 2025).

- Campos, W.E.; Saturnino, H.M.; Borges, A.L.C.C.; e Silva, R.R.; de Sousa, B.M.; Campos, M.M.; Rogério, M.C.P. Apparent digestibility of diets containing different proportions of industrial tomato residue. Ciênc. Anim. Bras. 2007, 8, 479–484. Available online: https://revistas.ufg.br/vet/article/view/1689 (accessed on 1 July 2025).

- Silva, A.F.; Rigueira, J.P.S.; Albuquerque, C.J.B.; Rocha Junior, V.R.; Santos, A.S.; Silva, F.V.; Silva, M.F.P.; Porto, E.M.V.; Monção, F.P.; Silva, P.H.F. Nutritional value, fermentation characteristics and aerobic stability of maize grain silage rehydrated with increasing levels of wet tomato byproduct. J. Anim. Feed Sci. 2025, 34, 121–130. [Google Scholar] [CrossRef]

- NRC. Nutrient Requirements of Small Ruminants: Sheep, Goats, Cervids, and New World Camelids; The National Academies Press: Washington, DC, USA, 2007; ISBN 978-0-309-47323-1. Available online: https://nap.nationalacademies.org/catalog/11654/nutrient-requirements-of-small-ruminants-sheep-goats-cervids-and-new (accessed on 13 June 2025).

- Alves, A.M.d.J.T.; dos Santos Oliveira, L.L.; Silva, G.L.S.; Dornelas, M.E.O.; D’Angelo, M.F.S.V.; de Oliveira, D.F.; Lima, W.d.S.; Pereira, C.A.d.J.; e Silva, F.V. The effect of Momordica charantia extract on sheep infected with Haemonchus contortus. Res. Vet. Sci. 2024, 180, 105401. [Google Scholar] [CrossRef] [PubMed]

- de Oliveira, A.M.F.; e Silva, F.V.; dos Santos Oliveira, L.L.; Rocha Júnior, V.R.; Novaes, C.G.; Novais, F.C.; Rigueira, J.P.S. Mineral content of longissimus lumborum from growing lambs fed crude glycerin. Meat Sci. 2020, 169, 108222. [Google Scholar] [CrossRef]

- Detmann, E.; Silva, L.F.C.; Rocha, G.C.; Palma, M.N.N.; Rodrigues, J.P.P. Food Analysis Methods, INCT—Animal Science, 2nd ed.; Produção Independente: Viçosa, MG, Brazil, 2021. [Google Scholar]

- De Vries, M.F.W. Estimating Forage Intake and Quality in Grazing Cattle: A Reconsideration of the Hand-Plucking Method. J. Range Manag. 1995, 48, 370–375. [Google Scholar] [CrossRef]

- AOAC International. Official Methods of Analysis of AOAC International, 17th ed.; AOAC International: Gaithersburg, MD, USA, 2000. [Google Scholar]

- Agência Nacional de Vigilância Sanitária (ANVISA). Pesticide Monographs. Available online: https://www.gov.br/anvisa/pt-br/setorregulado/regularizacao/agrotoxicos/monografias (accessed on 24 June 2025).

- De Araújo, G.G.L.; Voltolini, T.V.; Chizzotti, M.L.; Turco, S.H.N.; de Carvalho, F.F.R. Water and small ruminant production. Rev. Bras. Zootec. 2010, 39, 326–336. [Google Scholar] [CrossRef]

- Al-Ramamneh, D.; Riek, A.; Gerken, M. Deuterium oxide dilution accurately predicts water intake in sheep and goats. Animal 2010, 4, 1606–1612. [Google Scholar] [CrossRef] [PubMed]

- Ministry of Agriculture, Livestock and Supply. Technical Regulation on Pre-Slaughter Handling and Humane Slaughter, and the Stunning Methods Authorized by the Ministry of Agriculture, Livestock and Supply; Ministry of Agriculture, Livestock and Supply: Brasília, Brazil, 2021. Available online: https://www.in.gov.br/en/web/dou/-/portaria-n-365-de-16-de-julho-de-2021-334038845 (accessed on 24 June 2025).

- Silva, F.V.; Borges, I.; Garcia, S.K.; Sá, H.C.M.; Silva, V.L.; Araújo, A.R.; Lima, J.A.; Oliveira, L.L.S.; Matos, A.M.; Toral, F.L.B. Effect of space allowance during transport of Dorper x Santa Inês lambs on biochemical stress parameters and meat quality. Small Rumin. Res. 2023, 219, 106910. [Google Scholar] [CrossRef]

- Hamm, R. Functional properties of the myofibrillar system and their measurements. In Muscle as Food; Bechtel, P.J., Ed.; Academic Press: Orlando, FL, USA, 1986; pp. 135–199. [Google Scholar]

- Ramos, E.M.; Gomide, L.A. Meat Quality Assessment: Fundamentals and Methodologies; Editora UFV: Viçosa, Brazil, 2017. [Google Scholar]

- Wheeler, T.L.; Shackelford, S.D.; Koohmaraie, M. Shear Force Procedures for Meat Tenderness Measurement; U.S. Meat Animal Research Center, USDA Agricultural Research Service: Clay Center, NE, USA, 2005. Available online: https://www.ars.usda.gov/ARSUserFiles/30400510/protocols/ShearForceProcedures.pdf (accessed on 1 July 2025).

- Soleimani, Y.; Shahsavari, M.J.; Sadeghi, P.; Sadeghi, H.; Aryanejad, A.; Qashami, Z.; Khazali, A.; Noori, N.; Karamian, S.; Nayebi, M.; et al. Chlorothalonil and Cancer: A Comprehensive Overview. Asian Pac. J. Environ. Cancer 2025, 1783, 20250316. [Google Scholar] [CrossRef]

- Sadighara, P.; Mahmudiono, T.; Marufi, N.; Yazdanfar, N.; Fakhri, Y.; Rikabadi, A.K.; Khaneghah, A.M. Residues of carcinogenic pesticides in food: A systematic review. Rev. Environ. Health 2024, 39, 659–666. [Google Scholar] [CrossRef]

- Kushwaha, A.; Wasnik, K.; Kumar, D.; Pandey, M.; Deepak Nannaware, A.; Kumar Verma, R. On-farm energy input-output and economic analysis of important essential oil-bearing Mint species in subtropical India. Energy Convers. Manag. X 2024, 23, 100617. [Google Scholar] [CrossRef]

- Ozbek, F.S. Estimating the Direct Energy Use in Agriculture: A Case Study for Turkey. Bull. Univ. Agric. Sci. Vet. Med. Cluj-Napoca. Agric. 2015, 72, 467–473. [Google Scholar] [CrossRef] [PubMed][Green Version]

- IPCC. 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Volume 2: Energy; Intergovernmental Panel on Climate Change: Hayama, Japan, 2006; Available online: https://www.ipcc-nggip.iges.or.jp/public/2006gl/ (accessed on 1 July 2025).

- Central Bank of Brazil. Time Series Management System (SGS)—Series 3695: U.S. Dollar (Selling)—Exchange Rate—PTAX—End of Period. Available online: https://www3.bcb.gov.br/sgspub/localizarseries/localizarSeries.do?method=prepararTelaLocalizarSeries (accessed on 1 October 2025).

- Kay, R.D.; Edwards, W.M.; Duffy, P.A. Farm Management, 8th ed.; McGraw-Hill Education: New York, NY, USA, 2016; Available online: https://archive.org/details/farmmanagement0000kayr_s7a1? (accessed on 1 October 2025).

- Radaideh, M.I.; Radaideh, M.I. Application of Stochastic and Deterministic Techniques for Uncertainty Quantification and Sensitivity Analysis of Energy Systems. Int. J. Energy Res. 2020, 44, 2517–2534. [Google Scholar] [CrossRef]

- R Core Team. R: A Language and Environment for Statistical Computing; R Core Team: Vienna, Austria, 2024; Available online: https://www.R-project.org/ (accessed on 1 October 2025).

- Kung, L.; Shaver, R.; Grant, R.; Schmidt, R. Silage review: Interpretation of chemical, microbial, and organoleptic properties. J. Dairy Sci. 2018, 101, 4020–4036. [Google Scholar] [CrossRef] [PubMed]

- Kung, L.; Shaver, R. Interpretation and Use of Silage Fermentation Analysis Reports; University of Wisconsin Extension, ForageLab: Madison, WI, USA, 2001; Available online: https://fyi.extension.wisc.edu/forage/files/2014/01/Fermentation.pdf (accessed on 1 October 2025).

- Gheller, L.S.; Ghizzi, L.G.; Takiya, C.S.; Grigoletto, N.T.S.; Silva, T.B.P.; Marques, J.A.; Dias, M.S.S.; Freu, G.; Rennó, F.P. Different organic acid preparations on fermentation and microbiological profile, chemical composition, and aerobic stability of whole-plant corn silage. Anim. Feed Sci. Technol. 2021, 281, 115083. [Google Scholar] [CrossRef]

- Tuoxunjiang, H.; Yimamu, A.; Li, X.Q.; Maimaiti, R.; Wang, Y.L. Effect of ensiled tomato pomace on performance and antioxidant status in the peripartum dairy cow. J. Anim. Feed Sci. 2020, 29, 105–114. [Google Scholar] [CrossRef]

- Corrias, F.; Atzei, A.; Lai, C.; Dedola, F.; Ibba, E.; Zedda, G.; Canu, F.; Angioni, A. Effects of Industrial Processing on Pesticide Multiresidues Transfer from Raw Tomatoes to Processed Products. Foods 2020, 9, 1497. [Google Scholar] [CrossRef]

- Li, C.; Zhu, H.; Li, C.; Qian, H.; Yao, W.; Guo, Y. The present situation of pesticide residues in China and their removal and transformation during food processing. Food Chem. 2021, 354, 129552. [Google Scholar] [CrossRef]

- Okoye, C.O.; Wang, Y.; Gao, L.; Wu, Y.; Li, X.; Sun, J.; Jiang, J. The performance of lactic acid bacteria in silage production: A review of modern biotechnology for silage improvement. Microbiol. Res. 2023, 266, 127212. [Google Scholar] [CrossRef] [PubMed]

- Yuan, S.; Li, C.; Yu, H.; Xie, Y.; Guo, Y.; Yao, W. Screening of lactic acid bacteria for degrading organophosphorus pesticides and their potential protective effects against pesticide toxicity. LWT 2021, 147, 111672. [Google Scholar] [CrossRef]

- Jia, Q.; Liao, G.; Chen, L.; Qian, Y.; Yan, X.; Qiu, J. Pesticide residues in animal-derived food: Current state and perspectives. Food Chem. 2024, 438, 137974. [Google Scholar] [CrossRef]

- Ebeid, H.M.; Gawad, R.M.A.; Mahmoud, A.E.M. Influence of Ration Containing Tomato Pomace Silage on Performance of Lactating Buffaloes and Milk Quality. Asian J. Anim. Vet. Adv. 2015, 10, 14–24. [Google Scholar] [CrossRef][Green Version]

- Da Silva, J.A.; Poli, C.H.E.C.; Tontini, J.F.; Irigoyen, L.R.; Modesto, E.C.; Villalba, J.J. Ingestive Behavior of Young Lambs on Contrasting Tropical Grass Sward Heights. Front. Vet. Sci. 2020, 7, 643. [Google Scholar] [CrossRef] [PubMed]

- Moore, K.J.; Jung, H.-J.G. Lignin and Fiber Digestion. J. Range Manag. Arch. 2001, 54, 420–430. [Google Scholar] [CrossRef][Green Version]

- E Silva, F.V.; Borges, I.; Silva, V.L.; Lana, Â.M.Q.; Borges, A.L.C.C.; dos Reis, S.T.; Araújo, A.R.; Matos, A.M. Performance and carcass characteristics of lambs fed a solution of crude glycerin during feedlot and pre-slaughter lairage. Rev. Bras. Zootec. 2018, 47, e20170032. [Google Scholar] [CrossRef]

- Weiss, W.P.; Frobose, D.L.; Koch, M.E. Wet Tomato Pomace Ensiled with Corn Plants for Dairy Cows1. J. Dairy Sci. 1997, 80, 2896–2900. [Google Scholar] [CrossRef]

- Costa, R.G.; Treviño, I.H.; de Medeiros, G.R.; Medeiros, A.N.; Pinto, T.F.; de Oliveira, R.L. Effects of replacing corn with cactus pear (Opuntia ficus indica Mill) on the performance of Santa Inês lambs. Small Rumin. Res. 2012, 102, 13–17. [Google Scholar] [CrossRef]

- Costa, R.G.; Beltrão Filho, E.M.; de Medeiros, A.N.; Givisiez, P.E.N.; Queiroga, R.d.C.R.d.E.; Melo, A.A.S. Effects of increasing levels of cactus pear (Opuntia ficus-indica L. Miller) in the diet of dairy goats and its contribution as a water source. Small Rumin. Res. 2009, 82, 62–65. [Google Scholar] [CrossRef]

- Silva, T.S.; de Araujo, G.G.L.; Santos, E.M.; de Oliveira, J.S.; Campos, F.S.; Godoi, P.F.A.; Gois, G.C.; Perazzo, A.F.; Ribeiro, O.L.; Turco, S.H.N. Water intake and ingestive behavior of sheep fed diets based on silages of cactus pear and tropical forages. Trop. Anim. Health Prod. 2021, 53, 244. [Google Scholar] [CrossRef]

- Valenti, B.; Luciano, G.; Pauselli, M.; Mattioli, S.; Biondi, L.; Priolo, A.; Natalello, A.; Morbidini, L.; Lanza, M. Dried tomato pomace supplementation to reduce lamb concentrate intake: Effects on growth performance and meat quality. Meat Sci. 2018, 145, 63–70. [Google Scholar] [CrossRef]

- Knight, M.I.; Linden, N.; Ponnampalam, E.N.; Kerr, M.G.; Brown, W.G.; Hopkins, D.L.; Baud, S.; Ball, A.J.; Borggaard, C.; Wesley, I. Development of VISNIR predictive regression models for ultimate pH, meat tenderness (shear force) and intramuscular fat content of Australian lamb. Meat Sci. 2019, 155, 102–108. [Google Scholar] [CrossRef]

- Wu, G.; Farouk, M.M.; Clerens, S.; Rosenvold, K. Effect of beef ultimate pH and large structural protein changes with aging on meat tenderness. Meat Sci. 2014, 98, 637–645. [Google Scholar] [CrossRef]

- Lawrie, R.A.; Ledward, D. Lawrie’s Meat Science; Woodhead Publishing: Sawston, UK, 2014; ISBN 1-84569-161-X. [Google Scholar]

- Souza, X.R.; Bressan, M.C.; Pérez, J.R.O.; Faria, P.B.; Vieira, J.O.; Kabeya, D.M. Effects of genetic group, sex, and slaughter weight on the physicochemical properties of meat from growing lambs. Food Sci. Technol. 2004, 24, 543–549. [Google Scholar] [CrossRef]

- Pang, B.; Yu, X.; Bowker, B.; Zhang, J.; Yang, Y.; Zhuang, H. Effect of meat temperature on moisture loss, water properties, and protein profiles of broiler pectoralis major with the woody breast condition. Poult. Sci. 2021, 100, 1283–1290. [Google Scholar] [CrossRef]

- Jensen, T.A.; Antille, D.L.; Tullberg, J.N. Improving On-farm Energy Use Efficiency by Optimizing Machinery Operations and Management: A Review. Agric. Res. 2025, 14, 15–33. [Google Scholar] [CrossRef]

- Lampridi, M.; Kateris, D.; Sørensen, C.G.; Bochtis, D. Energy Footprint of Mechanized Agricultural Operations. Energies 2020, 13, 769. [Google Scholar] [CrossRef]

- Paris, B.; Vandorou, F.; Tyris, D.; Balafoutis, A.T.; Vaiopoulos, K.; Kyriakarakos, G.; Manolakos, D.; Papadakis, G. Energy Use in the EU Livestock Sector: A Review Recommending Energy Efficiency Measures and Renewable Energy Sources Adoption. Appl. Sci. 2022, 12, 2142. [Google Scholar] [CrossRef]

- Pestisha, A.; Gabnai, Z.; Chalgynbayeva, A.; Lengyel, P.; Bai, A. On-Farm Renewable Energy Systems: A Systematic Review. Energies 2023, 16, 862. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).