Abstract

Coastal Bangladesh faces severe drinking water scarcity due to salinity intrusion. To address this challenge, the study assesses the socio-technical and economic factors shaping the performance of small-scale reverse osmosis (RO) desalination plants through field audits, household surveys, stakeholder interviews, and water quality analysis. Community acceptance was evaluated using the Theory of Planned Behavior (TPB). Feedwater was highly contaminated, with average TDS 3732.63 mg/L, hardness 636.36 mg/L, iron (Fe) 3.23 mg/L, and turbidity 14.63 NTU. Despite this, RO systems demonstrated strong performance, achieving removal efficiencies of 95.15% for salts, 95.95% for hardness, and 91.67% for alkalinity, with an average recovery rate of 37.25% (range: 20–60%). Treated water met WHO and Bangladesh standards, with mean concentrations of TDS (195.54 mg/L), Fe (0.21 mg/L), arsenic (0.0085 mg/L), and turbidity (1.09 NTU). However, inadequate operator training and a lack of maintenance threaten sustainability. Energy consumption increased by 0.1 kWh/m3 per 1000 mg/L rise in salinity, while financial constraints hinder membrane replacement. TPB analysis revealed positive attitudes and perceived behavioral control as key adoption drivers. Untreated brine discharge (mean TDS 12,900 mg/L) posed significant environmental risks. This study provides micro-level insights to inform policy and strengthen the sustainability of decentralized RO systems in climate-vulnerable coastal regions.

1. Introduction

Freshwater scarcity is worsening due to population growth, climate change, pollution, overextraction, and rising demand, affecting a significant portion of the global population [1]. More than 40% of the global population struggles with water scarcity, and over 700 million people do not have access to safe drinking water [2]. In response, desalination technology is gaining attention as a solution to the growing water crisis [2]. Once limited to arid regions, desalination is increasingly adopted by coastal communities facing climate-induced stress and anthropogenic pressures [3]. The desalination industry has expanded rapidly, with 18,753 operational plants supplying about 153.7 million cubic meters of freshwater each day [4]. Reverse osmosis (RO) is currently the most commonly applied desalination technology due to the reduced operational cost and energy consumption [5]. This global momentum toward desalination carries significant implications for vulnerable coastal regions such as Bangladesh, where the crisis of safe drinking water is especially acute due to rising salinity in both surface and groundwater sources [6]. Approximately 35 million people in the coastal belt are affected by varying degrees of salinity in their drinking water [7], which has direct implications for public health, including hypertension, pre-eclampsia, and other waterborne diseases [8]. Accelerated sea-level rise, tidal surges, frequent cyclones, and reduced upstream freshwater flow have increased salinity levels in aquifers and surface water bodies beyond safe limits [9]. These hydrological and climatic stressors have placed severe pressure on traditional water sources in coastal Bangladesh, including rainwater harvesting and ponds. While rainwater harvesting is viable during the monsoon, its reliability declines in the prolonged dry season due to limited storage and erratic rainfall [10,11]. Additionally, cyclones and storm surges intensify pond salinization, rendering this vital alternative water source unsuitable for drinking [12]. These challenges are compounded by the lack of proper maintenance and economic constraints that hinder the effectiveness and sustainability of traditional systems [13].

Moreover, women and girls are primarily responsible for water collection, frequently walking up to 5 km each day [14]. This burden not only exposes them to physical hardship and health risks but also limits their opportunities for education and economic participation [15]. Salinity and water insecurity reinforce existing gender inequalities, increasing the vulnerability of women, particularly from poor and marginalized households [16]. Recent studies highlight that addressing water insecurity in coastal Bangladesh requires a gender-sensitive approach that recognizes and mitigates these disproportionate impacts [16,17]. In response to the limitations of traditional systems, desalination technology, particularly RO, has emerged as an adopted solution for providing safe drinking water in saline-prone regions [18]. Globally, RO has become the dominant desalination technology, accounting for approximately 70% of desalination capacity due to its technical efficiency and declining operational costs [19]. The adoption of decentralized, small-scale RO plants is recognized as a resilient strategy for addressing water scarcity in vulnerable coastal communities, aligning with global trends toward sustainable and adaptive water management [20].

Since 2015, there has been a notable rise in private investments in small-scale RO desalination plants in coastal Bangladesh [21]. The production capacity of these plants is about 20–60 m3 per day, and they operate by purifying brackish shallow groundwater with semi-permeable membranes [22]. Hoque [21] identified 63 RO plants in Paikgacha and 68 in Dacope Upazilas (third-level administrative units in Bangladesh) of Khulna District, reflecting a significant expansion of this technology in response to local demand for safe drinking water. These plants are often community-managed or operated by local entrepreneurs, providing year-round access to potable water and reducing dependence on unreliable traditional sources. Despite the growing number of RO treatment plants, research has largely concentrated on water quality, with limited attention to socio-technical and economic dynamics, operational and financial viability, user perceptions, and brine management [23,24].

Critical research gaps persist concerning the operational and financial viability of small-scale RO systems, the role of user perceptions and behavioral factors in adoption, and the sustainable management of brine disposal. These gaps constrain the development of evidence-based strategies for resilient and sustainable water supply in coastal Bangladesh. The study is guided by three core research questions. First, it evaluates the technical and operational performance of small-scale RO plants under saline groundwater conditions. Second, it analyzes the economic determinants of their long-term sustainability. Third, it examines the role of community perceptions and behavioral drivers in household adoption, alongside current practices for brine disposal and potential reuse options. The overarching objective is to conduct an integrated socio-technical and economic analysis of small-scale RO desalination plants in coastal Bangladesh. By combining technical audits, economic assessments, water quality analysis, and a theory of planned behavior framework, the study advances knowledge on decentralized desalination. It provides policy-relevant insights for building sustainable water supply systems in climate-vulnerable regions.

2. Materials and Methods

2.1. Study Area

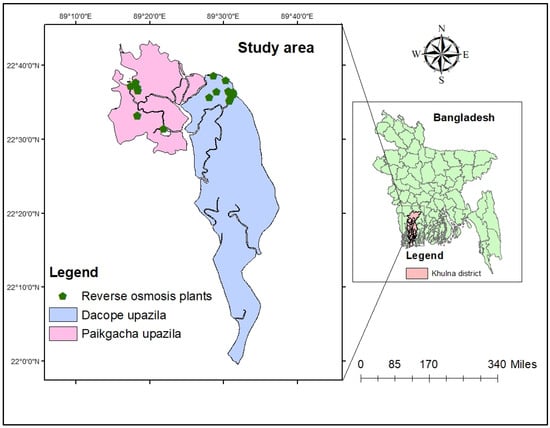

This study was conducted between May 2024 and May 2025 in the coastal Upazilas of Paikgacha and Dacope, located in southern Bangladesh. The study area includes Chalna Municipality and Pankhali Union in Dacope Upazila, along with Loskor and Godaipur Unions in Paikgacha Upazila (Figure 1). These areas are particularly vulnerable to salinity intrusion [8], making them critical locations for assessing the performance of RO desalination technology. Paikgacha Upazila was chosen due to the significant presence of privately funded RO plants. At the same time, Dacope Upazila was selected because the RO plants in this area are primarily funded by NGOs, donors, and the government [21].

Figure 1.

Study area map showing Dacope and Paikgacha Upazilas in coastal Bangladesh.

Dacope Upazila covers an area of approximately 991.57 km2, located between 22°24′ and 22°40′ North Latitude and 89°24′ to 89°35′ East Longitude. It is bounded by Batiaghata Upazila on the north, Pasur River on the south, Rampal and Mongla Upazilas on the east, Paikgacha and Koyra Upazilas on the west. The southern part of this Upazila is surrounded by the Sundarbans. Its geographical location in close proximity to the coast and tidal rivers makes it highly susceptible to salinity intrusion, especially during the dry season when freshwater inflows from upstream are limited. The study area within Dacope includes Chalna Municipality and Pankhali Union, which have been identified as critical zones for drinking water stress.

Paikgacha Upazila, on the other hand, lies between 22°28′ to 22°43′ North latitudes and 89°14′ to 89°28′ East longitudes, occupying an area of approximately 411.19 km2. It is bounded on the north by Tala Upazila of Satkhira District and Dumuria Upazila of Khulna District, on the east by Batiaghata Upazila, and on the west by Asashuni and Kaliganj Upazilas of Satkhira District. The Upazila is crisscrossed by tidal rivers and canals, including the Shibsa and Kopotakkho Rivers, which act as conduits for saline water intrusion. The study area in Paikgacha includes Loskor and Godaipur Unions, which are particularly impacted by salinity and seasonal water shortages.

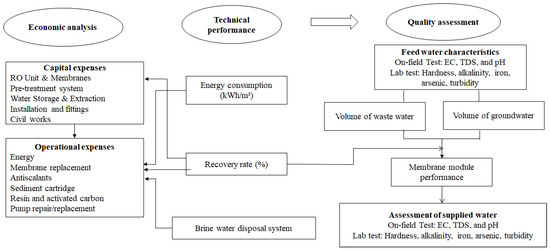

2.2. Economic-Technical Performance Framework

An integrated Economic-Technical Performance Framework (Figure 2) guided the collection of technical and economic data from 20 purposively selected RO plants in coastal Bangladesh. Between 19 and 25 May 2025, a reconnaissance survey was conducted to gain an overall understanding of the study area and the operational and management conditions of existing RO plants. Among the 32 RO plants visited, malfunctions and operational failures were more frequent in donor-, NGO-, and government-funded facilities than in privately funded ones, often due to weak ownership and limited accountability. These differences indicate that funding type itself may bias performance outcomes, reinforcing the need to capture all categories of RO plants in the final selection for audit. Accordingly, from the 32 plants initially surveyed, 20 were purposively selected for audit to represent different funding types (6 government-supported, 6 privately operated, 5 NGO-supported, and 3 donor-funded), operational status (11 functional, 9 non-functional), and age (<1 year to 5 years). While this variation allowed for assessment of performance deterioration over time, it may also introduce bias, as older plants inherently show lower recovery and salt rejection due to membrane aging and insufficient maintenance. Therefore, the analysis accounted for both funding model and plant age, noting that newer systems typically align with manufacturer specifications.

Figure 2.

Economic-technical performance framework.

In comparison, older systems illustrate the realities of sustained operation under local conditions. Technical performance was assessed through on-site audits, operational monitoring, and water quality analysis. Key indicators included energy consumption (kWh/m3), water recovery rate (%), membrane performance, and brine disposal practices. Water flux and feedwater characteristics were evaluated via field-based tests (EC, TDS, pH) and laboratory analyses (hardness, alkalinity, iron, arsenic, turbidity), enabling identification of performance bottlenecks, particularly in membrane efficiency. Treated water quality was benchmarked against national drinking water standards.

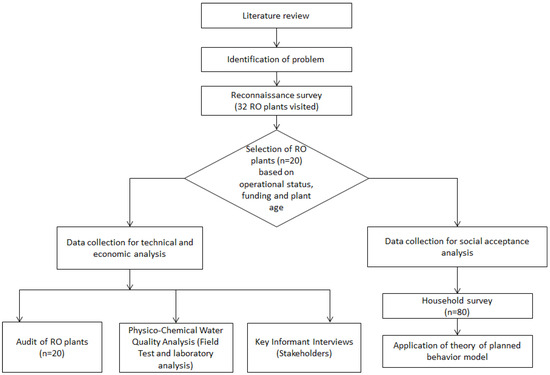

Economic analysis encompassed both capital (RO units, pre-treatment systems, civil works) and operational (membrane replacement, chemical use, maintenance) cost components. This framework clarified cost-performance interactions and long-term financial sustainability. The study examined brine disposal practices to evaluate potential environmental concerns arising from brine water management in RO desalination systems. Particular focus was given to the method and site of brine water discharge and any observable environmental impacts. The study also evaluated the practical feasibility of alternative brine management options suitable for small-scale RO installations. The overall process of site selection and the integration of technical, economic, and social data collection methods is illustrated in Figure 3.

Figure 3.

Flowchart of the methodology showing the process of site selection and data collection.

2.3. Water Sampling and Analysis

On-site water quality tests were conducted using a multimeter (Hanna HI981199) to measure pH, electrical conductivity (EC), and total dissolved solids (TDS) at three stages: feedwater, desalinated water, and brine water of 11 functional RO plants. Water quality sampling was conducted in May 2025, aligning with the dry season in coastal Bangladesh when salinity levels typically peak due to reduced freshwater inflow and minimal rainfall [6]. This study focused on dry-season sampling to capture the worst-case conditions for RO plant feedwater quality and performance. Our reconnaissance survey further informed this decision, as we observed that during the rainy season, almost 50% of RO plants are either shut down or operated only for short periods each day because a significant portion of the coastal population depends on freely available rainwater harvesting. Water samples were also collected for laboratory analysis of hardness, alkalinity, turbidity, iron (Fe), and arsenic (As). For Fe and As analysis, 250 mL high-density polyethylene (HDPE) bottles were used and acidified with 2% nitric acid. Separate 500 mL HDPE bottles were used for turbidity, alkalinity, and hardness. All samples were stored at 4 °C until analysis. All analyses were conducted following the American Public Health Association standard method [25]. Total hardness (as CaCO3) and alkalinity were determined using titrimetric (EDTA) methods. Salinity was estimated from the measured TDS (mg/L) by dividing it by a conversion factor of 0.55, which is commonly applied for drinking water [26,27]. Although this factor can vary between 0.5 and 0.7 depending on water source, 0.55 was adopted here as the standard for potable water [26,27]. As and Fe concentrations were measured using Atomic Absorption Spectroscopy (AAS, Model: AA-7000; Shimadzu, Japan). As was quantified via the hydride generation AAS (HG-AAS) technique employing a T-shaped quartz absorption cell (VGA 76/77, Varian). The analysis was conducted at a wavelength of 193.7 nm with a 0.5 nm slit width, using argon as the carrier gas at a flow rate of 0.1 L min−1. Sodium borohydride (0.6% w/v) served as the reductant, while hydrochloric acid (5 M) was used as the acid reagent. Fe concentration was determined using direct flame AAS (F-AAS) with an air–acetylene flame at a wavelength of 248.3 nm. The limits of detection, calculated as three times the standard deviation of blank measurements, were found to be 0.0005 μg L−1 for As and 0.009 μg L−1 for Fe, which were sufficient to detect trace levels in aqueous samples. To ensure reliable measurements of As and Fe, laboratory quality assurance and quality control (QA/QC) protocols were strictly followed. Analytical-grade ultrapure reagents (Sigma-Aldrich, Taufkirchen, Germany) and deionized water (resistivity 18.2 MΩ·cm at 25 °C; EC 0.2 µS/cm) were used for all sample and standard preparations. Calibration curves (coefficient of determination, r2 ≥ 0.999) were generated using Certified Reference Materials (CRM) traceable to the National Institute of Standards and Technology (NIST, USA). Calibration was verified with check standards after every five samples, and additional standard solutions (Scharlau, Barcelona, Spain) were analyzed to confirm instrumental accuracy and dependability. Accuracy was validated through replicate analysis of CRMs and matrix spike recoveries, which fell within the acceptable range of 90–110%. Precision was evaluated by triplicate measurements, with relative standard deviation (RSD) values maintained below 5%.

2.4. Social Acceptance Assessment

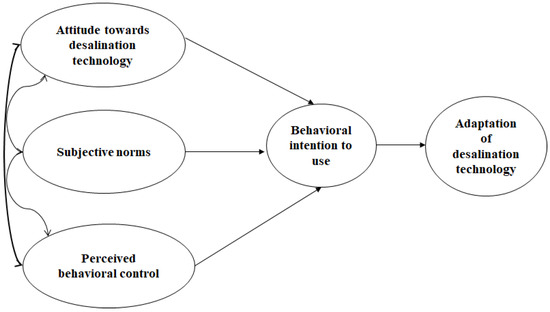

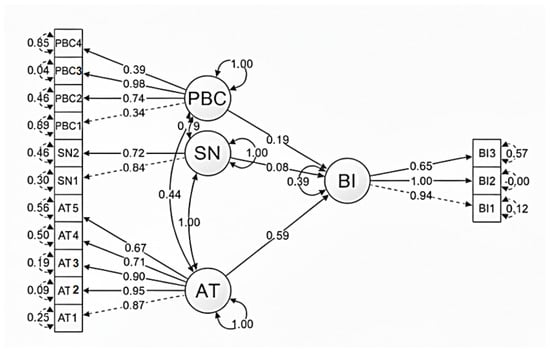

A structured questionnaire was used to assess residents’ perceptions of using RO-treated water. The 3-point Likert scale items assessed attitude (5 items), subjective norms (2 items), perceived behavioral control (4 items), and intention (3 items). The Theory of Planned Behavior (TPB) (Figure 4) was applied to assess the social acceptance of RO desalination technology, with reliability tested using Cronbach’s alpha, average variance extracted (AVE), and composite reliability (CR) [28]. Based on TPB, the intention to engage in the behavior is its most direct predictor, which is generally predicted by attitudes, subjective norms, and perceived behavioral control [29]. The constructs and scale items are shown in Table A1.

Figure 4.

Framework of theory of planned behavior model [29].

2.4.1. Attitude

Attitude denotes an individual’s overall evaluation of a behavior, shaped by beliefs about its outcomes [30]. In this study, it reflects perceptions of RO water’s effectiveness, safety, and usefulness. This construct was derived from respondents’ perceptions of whether RO water fulfills household needs, mitigates water scarcity, and ensures superior cleanliness. A positive attitude, anchored in trust and recognition of benefits, is likely to strengthen the intention to adopt RO-treated water.

2.4.2. Subjective Norm

Subjective norm refers to perceived social pressure to engage in a behavior, based on others’ expectations [28]. It was assessed by exploring whether respondents felt encouraged by family, friends, or community members to use RO water, and whether such use was considered normative. Social endorsement is anticipated to influence behavioral intention positively.

2.4.3. Perceived Behavioral Control

Perceived behavioral control reflects individuals’ perceived ease or difficulty in performing a behavior, influenced by internal capacities and external conditions [29,31]. This study examined respondents’ access to RO-treated water, affordability, willingness to pay, and understanding of the technology. Lower perceived barriers are expected to strengthen adoption intention.

2.4.4. Behavioral Intention

Behavioral intention signifies readiness to act and is the most direct predictor of behavior in TPB [29,32]. It was evaluated through respondents’ willingness to use RO water for daily needs, switch from existing sources, and recommend its use. High intention reflects a greater likelihood of future adoption, shaped by attitude, social norms, and control.

2.5. Sample Size and Sampling Strategy

The sample size was determined based on Hatcher’s (1994) guideline of at least five respondents per item [33]. For the 14-item TPB constructs, a minimum of 70 responses was required; this study included 80 participants [33]. A stratified purposive sampling approach was used to ensure representation across user categories: 68.8% were regular or seasonal users, and 31.3% were non-users of RO-treated water. The sample comprised 55% males and 45% females. In addition to community voices, key informant interviews (KIIs) were conducted with institutional stakeholders such as academicians, government officials, and suppliers of RO plants.

2.6. Reliability, Validity, and Model Fitness of Theory of Planned Behavior Constructs

All TPB constructs demonstrated acceptable reliability, with CR values above the 0.60 threshold. Convergent validity was confirmed for Attitude, Subjective Norm, and Behavioral Intention with AVE values exceeding 0.50 (Table 1). Although the AVE for PBC was slightly below the recommended level (0.442), it is considered acceptable since its CR was 0.728, satisfying the guideline that AVE above 0.40 is adequate when CR exceeds 0.60 [34,35]. Two PBC items (PBC1 and PBC4) showed relatively low loadings (0.335 and 0.390); however, they were retained to preserve the conceptual coverage of dimensions of accessibility and user knowledge at the community level. For behavioral intention (BI), the indicator BI2 was constrained to 1.000 to establish the measurement scale and achieve model identification. This is a standard procedure in confirmatory factor analysis and does not imply a perfect empirical loading [36]. Discriminant validity was also established, as the square roots of AVE exceeded inter-construct correlations (Table 2).

Table 1.

Measurement model reliability and convergent validity.

Table 2.

Correlations of discriminant validity.

Univariate analysis (Table S1) showed no skewness > 3 or kurtosis > 10, satisfying the normality criteria defined by Kline [36]. Structural equation modeling (SEM) was conducted in JASP software (version 0.19.2) using Maximum Likelihood (ML) estimation. The standard errors from the ML estimation were used to construct 95% confidence intervals for all parameter estimates, providing a measure of precision and reliability. The structural model showed an acceptable fit. Incremental fit indices met the recommended cutoffs, with Comparative Fit Index (CFI) = 0.968 and Tucker–Lewis Index (TLI) = 0.959 (threshold ≥ 0.95). Absolute fit indices were also satisfactory, with Normed Fit Index (NFI) = 0.924 and Goodness-of-Fit Index (GFI) = 0.969 (threshold ≥ 0.90). The error of approximation was within acceptable limits, with Root Mean Square Error of Approximation (RMSEA) = 0.0758 (threshold ≤ 0.08) [36,37]. Residual diagnostics further supported model adequacy, with Standardized Root Mean Square Residual (SRMR) = 0.072 (<0.08) and χ2/df < 3, both indicating acceptable error distribution. The squared multiple correlations (R2) ranged from 0.43 to 0.92, with the majority of indicators above 0.60. Factor loadings were generally strong (>0.65 for most indicators), reinforcing the reliability of the measurement model. Multicollinearity was not a concern, as variance inflation factor (VIF) values were below 2.2 (threshold < 5.0) and tolerance values exceeded 0.4 (threshold > 0.2). The statistical significance of the regression coefficients was determined using p-values, with a significance level of p < 0.05, and 95% confidence intervals (CI) were reported to indicate the precision and reliability of the estimates.

Descriptive and inferential statistics were performed using the Statistical Package for the Social Sciences (IBM SPSS, version 27.0). Data management and preliminary statistical analyses were carried out in Microsoft Excel (version 2013). ArcGIS software (version 10.3.1) was employed to map the study area.

3. Results and Discussion

3.1. RO Treatment Process

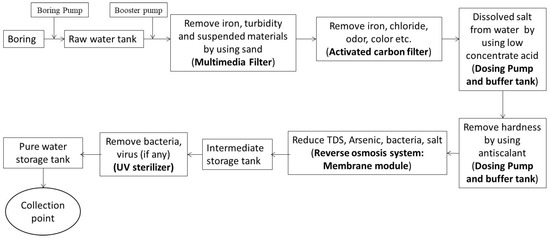

The design capacity of these plants typically ranges from 500 to 2000 L per hour. The primary water source for all RO plants is groundwater, with varying depths ranging from 25.91 m to 121.92 m. The basic procedure (Figure 5) of an RO plant in coastal Bangladesh involves filtering raw water through multiple stages, including sediment filtration (using MF or UF cartridges), quartz sand, activated carbon, softener, RO membrane, and ultraviolet sterilization to produce and store pure water. Ozone generators were used in only three donor-funded RO plants for effective disinfection and improved membrane performance [38], whereas privately funded plants did not include them to reduce capital costs.

Figure 5.

RO treatment process flow chart.

All RO stations used spiral-wound membrane elements, with “4 × 40” polyamide thin-film composite (TFC) membranes being the most common. The most widely used membrane brands were VONTRON and Heron, as detailed in Table S2. Although the use of antiscalant, a chemical used to prevent scale formation on RO membranes [39], is a common practice in RO systems, many plant operators lack a proper understanding of its role. As a result, some of the operators stopped using it due to the misconception that it might pose health risks. This concern was reflected among 18% of consumers, who expressed negative perceptions about chemicals added to drinking water, fearing potential long-term health effects.

3.2. Water Quality of Feedwater and Treated Water

The quality of RO feedwater (groundwater) and treated water is summarized in Table 3. 100% of the feedwater samples showed elevated levels of EC, TDS, salinity, hardness, and Fe compared to both WHO and Bangladesh drinking water standards [40,41]. The high salinity and TDS levels indicated severe saltwater intrusion, a common issue in the coastal aquifers of Bangladesh [42].

Table 3.

Concentration of physico-chemical parameters in feed and treated water samples of the RO plants.

As contamination was detected in 9.09% of feedwater samples, exceeding the permissible limit of the Bangladesh standard (0.05 mg/L) [40]. Fe concentrations, however, were significantly high in all samples (mean 3.23 mg/L), far exceeding both WHO (0.3 mg/L) and national (1 mg/L) thresholds [41], indicating poor raw water quality and the need for advanced treatment processes.

Feedwater parameters were interrelated, influencing RO performance. EC and TDS were strongly correlated (r = 0.832, p = 0.001) as expected, with TDS also significantly associated with Fe (r = 0.620, p = 0.042). As and Fe were closely linked (r = 0.714, p = 0.014), and both showed strong correlations with turbidity, indicating that As is often adsorbed onto or co-precipitated with iron (oxy)hydroxide particles, which contribute to turbidity during groundwater discharge [43]. These associations implied that turbid, mineral-rich water may reduce membrane efficiency due to complex contaminant interactions [44].

In contrast, the treated water quality (Table 3) demonstrated substantial improvement across all measured parameters. In this study, TDS removal efficiencies ranged from 86% to 98%, confirming the high effectiveness of the audited RO plants in ensuring potable water. These results are consistent with Islam et al. [23], who documented 75–96% TDS removal in southwest coastal Bangladesh, though in their case, 10–20% of treated water samples still exceeded WHO thresholds for TDS and EC, underscoring operational and compliance challenges. By contrast, all treated water samples in the present study met both the WHO and Bangladesh standards, suggesting relatively better operation and maintenance. Comparable findings were reported in Sri Lanka, where Indika et al. [45] observed that feedwater salinity > 2000 mg/L was consistently reduced to <500 mg/L, aligning with WHO guidelines. Salinity and hardness levels were also significantly lowered, with final concentrations well within WHO and Bangladesh drinking water standards. The removal of turbidity, Fe, and As further underscored the system’s capacity to eliminate particulate matter and improve both aesthetic quality and chemical safety, particularly by reducing toxic elements such as As commonly associated with iron (oxy)hydroxide complexes in groundwater. Importantly, the treated water met national and WHO standards for the physico-chemical parameters assessed in this study, suggesting that the RO plants effectively removed dissolved salts, multivalent ions, and suspended solids. These results align closely with the performance outcomes reported by Islam et al. [23], and Shamsuzzoha et al. [24].

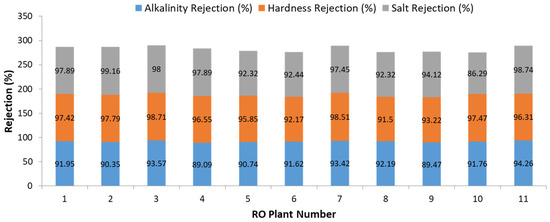

3.3. Salt Rejection

Salt rejection efficiency is a key indicator of the technical performance of RO systems. The studied plants demonstrated generally high but variable salt rejection rates, ranging from 86.29% to 99.16%, with an average of 95.15% (Figure 6). Notably, 54.55% of the systems achieved rejection efficiencies above 95%, indicating strong effectiveness in removing dissolved salts from saline groundwater. However, these values fall slightly below the manufacturer-stated minimum efficiency of 98.5–99%, suggesting potential performance gaps due to operational or water quality factors. The observed rejection rates are consistent with findings from coastal Sri Lanka, where small-scale RO plants reported an average salt rejection of 95.9% [45]. In Tunisia, a long-term evaluation of a full-scale brackish RO plant reported a decline in salt rejection capacity over time, with increased solute permeability and higher product water salinity attributed mainly to calcium sulfate fouling and inadequate antiscalant performance, underscoring the importance of robust pre-treatment and chemical dosing to sustain salt rejection [46].

Figure 6.

Hardness, alkalinity, and salt rejection by RO plants.

3.4. Hardness and Alkalinity Rejection

In addition to salt removal, the rejection of hardness and alkalinity is a critical performance indicator for RO plants, especially in groundwater-fed plants [45], where these parameters are typically elevated. The studied RO plants demonstrated high removal efficiency for both, with hardness rejection ranging from 91.50% to 98.71% (mean 95.95%) and alkalinity rejection from 89.09% to 94.26% (mean 91.67%) (Figure 6). Notably, 72.73% of the plants achieved average hardness rejection above 95%, reflecting a strong capacity for demineralizing hard water. This is primarily due to the effective exclusion of multivalent ions such as Ca2+ and Mg2+, influenced by their interaction with the surface chemistry of polyamide TFC membranes [47]. High hardness removal improves consumer acceptance and aligns with desirable drinking water standards [48].

Similarly, 81.82% of the plants achieved alkalinity rejection rates above 90%, indicating effective removal of bicarbonates and carbonates that contribute to buffering capacity and affect pH stability in treated water. These high rejection efficiencies depend not only on membrane properties but also on the quality of feedwater. In the study by Indika et al. [45], an average of 86.6% alkalinity rejection was achieved. Comparable performance has been documented in India, where a village RO plant in Vidhani, Jaipur, Rajasthan, reported nearly 97% hardness removal [49].

Although RO membranes efficiently remove hardness and alkalinity, complete demineralization may pose health risks. Importantly, none of the audited RO plants were equipped with remineralization units, which are typically installed to restore essential minerals stripped during desalination. Treated water hardness ranged from 5 to 41 mg/L as CaCO3. Approximately 45.45% of the plants produced treated water with TDS below 100 mg/L, further indicating insufficient mineral content. According to the WHO, hardness in drinking water typically ranges from 10 to 500 mg/L. Water contributes 5–20% of daily Ca and Mg intake, and evidence suggests that very soft waters (<75 mg/L) may adversely affect mineral balance [50]. Long-term consumption of low-mineral or demineralized water has been associated with adverse effects such as decreased bone mineral density, increased risk of osteoporosis, dental caries, and potential cardiovascular problems due to deficiencies in essential minerals like calcium and magnesium [51]. WHO guidance emphasizes the importance of remineralizing desalinated water to restore calcium and magnesium [41]. Epidemiological evidence further suggests protective effects against cardiovascular mortality when magnesium concentrations in drinking water are at or above 10 mg/L [52]. To mitigate these risks, post-treatment remineralization using a calcite contactor is recommended.

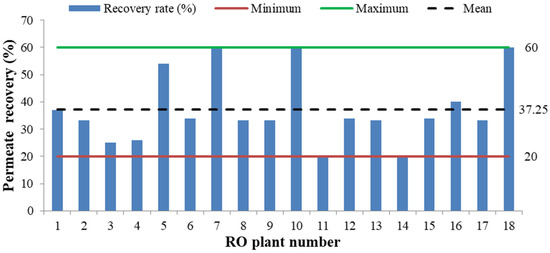

3.5. Permeate Recovery

Permeate recovery rate is a critical operational parameter for RO systems, reflecting the efficiency of converting feedwater into treated water [53]. The recovery rates of the studied RO plants showed considerable variability, ranging from 20% to 60%, with a mean recovery rate of 37.25% (Figure 7). This variability can be explained by the age and condition of the membranes installed in the respective plants. Notably, RO plants, equipped with comparatively new membranes, achieved the highest recovery rates (60%). In contrast, plants operating with four-year-old membranes showed the lowest recovery rates (20%), indicating performance deterioration likely due to membrane aging, fouling, or scaling.

Figure 7.

Permeate recovery of RO plants.

Over time, membrane aging leads to reduced permeability, which requires higher feed pressure to maintain permeate flow. This often leads to reduced recovery rates to protect membrane integrity and minimize scaling or fouling risks. The overall low average recovery rate (37.25%) reflects the challenging feedwater conditions, particularly the high hardness, alkalinity, Fe, and salinity levels (Table 3), which necessitate cautious operation to minimize scaling risks. Maintaining an optimal recovery rate is essential, as higher recovery can reduce operational costs, but excessive recovery may accelerate scaling and fouling, leading to membrane damage and reduced lifespan [19]. Conversely, persistently low recovery rates, as seen in most plants, lead to higher brine production, energy waste, and increased operational costs. Comparable challenges have been reported in Sri Lanka’s North Central Province, where Indika et al. [45] evaluated 101 community-based RO stations. They found an average recovery of 38.7%, with nearly 89% of systems operating below 50% recovery, despite design expectations of 50–85% [45]. The study attributed low recovery to membrane fouling, scaling, and sub-optimal operating pressures, compounded by operators’ limited technical training.

In contrast, a case study in Jepara, Central Java (Indonesia) operated a 50 m3/day plant that consistently sustained 50% recovery, a performance attributed to robust pre-treatment and scheduled membrane chemical cleaning protocols [54]. Large-scale municipal RO plants in Spain (El Prat de Llobregat) have demonstrated that high recovery (75%) and stable long-term performance can be achieved through robust pre-treatment, integration of energy recovery devices, and professional operation and maintenance [55]. Although such large-scale systems differ fundamentally from the small-scale community plants in Bangladesh, the Spanish experience underscores the importance of design optimization, preventive maintenance, and energy efficiency, principles that are equally relevant for improving the sustainability of decentralized RO plants in saline-prone coastal regions.

3.6. Influence of FeedWater Chemistry on RO Plant Performance

In small-scale RO plants operating under the complex hydro-geochemical conditions of coastal Bangladesh, variations in feedwater quality, particularly in EC, TDS, turbidity, hardness, alkalinity, and pH, can significantly influence membrane rejection efficiency and overall system productivity. The correlation analysis (Table 4) highlights how specific water quality parameters impact the rejection rates of key ions such as salt, As, hardness, and alkalinity.

Table 4.

Pearson correlation coefficients between feedwater chemistry and ion rejection efficiency in a small-scale RO plant.

Salt and hardness rejection showed strong negative correlations with EC (r = −0.71, CI [−0.90, −0.26], p = 0.011 for salt; r = −0.60, CI [−0.85, −0.12], p = 0.032 for hardness) and with TDS (r = −0.68, CI [−0.89, −0.22], p = 0.015 for salt; r = −0.61, CI [−0.86, −0.14], p = 0.032 for hardness). These findings indicate that elevated salinity tends to impair membrane rejection efficiency. This aligns with the well-established phenomenon of concentration polarization, where higher ionic concentrations at the membrane surface increase osmotic pressure and scaling risk, thereby reducing performance [56].

Turbidity exhibited moderate negative correlations with the rejection of most ions, including salt (r = −0.51, CI [−0.80, −0.05], p = 0.045) and As (r = −0.46, CI [−0.78, 0.02], p = 0.068). This suggests that inadequate pre-treatment of turbid surface or shallow groundwater, a common issue in rural plants, may contribute to membrane fouling and reduced rejection efficiency [44]. Particulate matter and organic load are likely contributors to this decline [19].

Interestingly, alkalinity rejection showed a significant positive correlation with feedwater alkalinity (r = 0.57, CI [0.09, 0.83], p = 0.024). This implies that under higher alkalinity conditions, membranes may exhibit improved rejection of bicarbonate and related ions. This could result from favorable ionic interactions or membrane selectivity in high-alkalinity environments, consistent with findings from studies on RO performance in similar water chemistries [45].

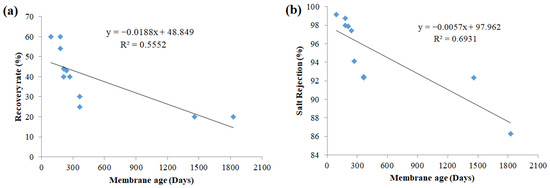

Table 5 presents the correlations between operational variables and system performance. As expected, membrane age was negatively correlated with salt rejection (r = −0.60, CI [−0.84, −0.14], p = 0.034), product output (r = −0.64, CI [−0.86, −0.20], p = 0.024), and recovery rate (r = −0.58, CI [−0.83, −0.11], p = 0.039) (Figure 8). These results reflect the degradation of membranes over time due to fouling, scaling, or mechanical wear, challenges that are often exacerbated in community-managed or donor-funded plants lacking routine maintenance protocols. The observed decline in performance reinforces the need for systematic membrane replacement and cleaning schedules.

Table 5.

Pearson correlation coefficients between operational parameters and RO plant performance.

Figure 8.

Relationships between membrane age and performance indicators: (a) recovery rate (%) and (b) salt rejection (%).

Operating pressure showed strong positive correlations with salt rejection (r = 0.72, CI [0.32, 0.90], p = 0.009), hardness rejection (r = 0.65, CI [0.16, 0.87], p = 0.021), As rejection (r = 0.60, CI [0.10, 0.85], p = 0.034), and product output (r = 0.78, CI [0.43, 0.92], p = 0.004). These relationships highlight pressure optimization as a key operational factor for enhancing both water quality and yield [57]. While higher pressure increases energy demand, it is essential for maintaining membrane performance, particularly under high-salinity conditions.

The recovery rate showed a moderate negative correlation with salt rejection (r = −0.55, CI [−0.82, 0.05], p = 0.057), which supports theoretical expectations that increasing recovery can elevate solute concentration near the membrane, causing concentration polarization and reducing rejection efficiency. Conversely, actual product output was positively correlated with recovery rate (r = 0.52, CI [0.01, 0.81], p = 0.040), emphasizing the trade-off between water yield and salt removal efficiency. These findings provide valuable insights for optimizing the performance of small-scale RO plants in coastal Bangladesh. Improvements in feedwater pre-treatment, pressure management, and membrane maintenance can significantly enhance both the quality and quantity of drinking water in regions challenged by salinity and poor water quality.

3.7. Brine Disposal Practices and Emerging Solutions

The by-product of the desalination process is called brine, also known as concentrate [58]. Brine water from RO plants poses significant environmental challenges due to its high concentrations of salts [59]. All audited RO plants lacked safe or designated disposal systems, even though their low recovery rates (<50%) resulted in the generation of large volumes of brine. Table 6 presents the characteristics of brine obtained from 11 RO plants. The mean TDS level of 12,900 mg/L falls within the range reported by Martinetti et al. [60] and Walker et al. [61], who documented TDS values between 7500–21,035 mg/L for brackish water RO systems. To quantify salinity loads, a mass balance was performed using the mean feedwater TDS of 3732.63 mg/L and an average recovery of 37.25%. For every 100 L of feedwater, ~37.25 L of product water and 62.75 L of brine are generated. The incoming salt mass (373.26 g) is partitioned into 6.74 g (1.8%) in the product water and 366.52 g (98.2%) in the brine stream, which had a mean TDS of 12,900 mg/L (range 9000–17,300 mg/L). For a typical small-scale RO plant (1000 L/h capacity) operating 3–8 h/day, as observed in field audits (6–8 h in the dry season; 3–5 h in the rainy season), daily brine volumes range from 5.6 to 12.0 m3.

Table 6.

Characteristics of brine.

Brine water was discharged directly into open land, canals, municipal drains, rivers, or agricultural fields without any treatment or dilution, increasing risks of soil salinization, groundwater contamination, and ecosystem disruption [62]. The hydrogeology of Paikgacha and Dacope Upazilas exacerbates brine disposal risks. Both areas lie within the Ganges–Brahmaputra Delta, characterized by multi-layered aquifers where shallow zones (<100 m) are already impacted by seawater intrusion from tidal rivers such as the Shibsa, Kopotakkho, and Pasur, as well as their proximity to the Sundarbans mangrove forest. The low-lying deltaic topography (elevations < 5 m above sea level), coupled with permeable silty-clay soils and dense canal networks, facilitates rapid movement of contaminants into surface water and shallow groundwater, amplifying risks of soil salinization and ecosystem degradation [62]. In one instance, brine was initially discharged into a watermelon cultivation field, but farmers reported adverse effects on watermelon growth, leading to the cessation of its use for irrigation. The brine was then redirected to a nearby pond, where an increase in carp fish cultivation was observed, indicating a potential brine disposal solution through reuse.

Repurposing brine for controlled aquaculture using saline-tolerant species such as tilapia (up to 24 ppt), barramundi (up to 55+ ppt), and brine shrimp (Artemia) offers a potential reuse pathway at the local scale [63,64,65]. Nevertheless, its long-term viability is constrained by environmental risks. Given that coastal Bangladesh already has a well-established aquaculture sector, particularly in shrimp farming, this approach may be both technically and economically feasible in the regional context [66]. Brine-fed aquaculture has the potential to enhance food production while simultaneously reducing direct environmental discharge [62]. Additionally, an integrated reuse system that combines fish cultivation, duckweed feed loops, and halophyte farming has demonstrated potential in inland desalination contexts [67].

At another site, an eight-year-old RO plant faced operational shutdown due to the loss of its previous brine water disposal location, which is now repurposed for a cyclone shelter. With no alternative site and limited funds to replace damaged membranes, the plant’s functionality is at risk. In a different instance, brine water was discharged on third-party land, raising future land-use concerns. Anticipating potential future restrictions or disputes over land use, the plant owner has prepared an alternative arrangement to dispose of the brine water by injecting it into a nearby groundwater body through a dedicated well. A study on the Nile Delta aquifer showed that both brackish water extraction and brine injection led to a 4.38% increase in salt mass balance compared to the baseline without intervention [58]. It accounts for approximately 17% of brine disposal in the United States [68]. Depending on site-specific geological conditions, these wells typically range from 500 to 1500 m in depth [69]. However, the primary environmental concern is the potential contamination of adjacent freshwater aquifers used for drinking water [59]. A study on the Nile delta aquifer showed that both brackish water extraction and brine injection led to an increase in salt mass balance, specifically a 4.38% rise compared to the baseline without extraction or injection [70]. Therefore, construction of injection wells should only proceed after thorough hydrogeological assessments and pilot-scale testing [58,68]. Table 7 summarizes the brine disposal options, highlighting their technical feasibility, environmental risks, and the associated regulatory or monitoring requirements.

Table 7.

Brine disposal options for small-scale RO plants in coastal Bangladesh.

3.8. Consumer Behavior Toward RO Water: A TPB Model Analysis

The analysis using the TPB provides deep insights into the factors driving the adoption of small-scale RO desalination systems among coastal Bangladeshi consumers. The demographic data reveal a predominantly male sample (55%), with the majority aged 41–60 years (43.75%), engaged in labor (38.70%) and agriculture (26.30%). Most households are small (<5 members, 52.50%) and low-income (<10,000 BDT monthly, 55%), with 30% having secondary education and 26.10% being illiterate. These characteristics suggest economic and educational challenges that may impact adoption. Detailed demographic data of the respondents in the questionnaire survey are presented in Table S3.

Attitude stands out as the most influential predictor of behavioral intention (β = 0.592, 95% CI [0.41, 0.74], p < 0.001), highlighting the critical role of local perceptions in shaping adoption decisions. The significant effect of attitude on intention implies that individuals who perceive RO water as clean, safe, and practically useful are more likely to express willingness to adopt it. In coastal Bangladesh, where groundwater and surface water sources are contaminated with saline intrusion and As, the perception of RO water as clean, safe, and practical resonates strongly with residents’ lived experiences. This finding aligns with Lili et al. [28], who noted similar positive evaluations of desalinated water in water-scarce regions, suggesting that targeted awareness campaigns emphasizing health benefits and taste improvements could enhance adoption rates.

Perceived behavioral control (PBC) also emerged as a significant factor (β = 0.189, 95% CI [0.01, 0.35], p = 0.04), with components such as ease of access, affordability, willingness to pay, and knowledge of the desalination process playing pivotal roles. Affordability remains a barrier, given that 75% of households are single-earner and 55% earn below 10,000 BDT (82.02 USD) monthly. The inclusion of knowledge about desalination processes in the PBC construct suggests that hands-on training sessions, potentially delivered through local NGOs, could empower communities to maintain and operate RO systems effectively. This is particularly relevant in remote areas where technical support is scarce, and community-led maintenance could sustain long-term adoption. These findings emphasize that limited access, high costs, low willingness to pay, and lack of knowledge of the desalination process act as barriers to adoption. Similarly, Lili et al. [28], found that perceived behavioral control is shaped by income, public awareness of desalinated water, and the availability of infrastructure, indicating that greater financial capacity, stronger awareness, and improved infrastructure increase residents’ willingness to use desalinated water. Subjective norm was not a significant direct predictor of behavioral intention (β = 0.102, 95% CI [−0.02, 0.25], p = 0.085), but it showed strong correlations with both attitude (r = 0.611, p < 0.01) and behavioral intention (r = 0.546, p < 0.01), highlighting its indirect relevance.

The path diagram supports (Figure 9) the TPB framework, with high factor loadings (0.75–0.89 for attitude, 0.80–0.89 for PBC, 0.73–0.80 for BI) confirming the measurement model’s reliability. The path diagram highlights significant positive correlations among the exogenous predictors. Specifically, attitude and subjective norm were correlated (r = 0.44, p < 0.01), as were subjective norm and perceived behavioral control (r = 0.79, p <0.01), and attitude and perceived behavioral control (r = 0.67, p < 0.01). These strong intercorrelations are consistent with the theoretical interrelationships expected within the TPB framework, indicating that these psychological constructs are interrelated.

Figure 9.

Path analysis of the standardized direct effects of TPB variables (AT: Attitude, PBC: Perceived Behavioral Control, SN: Subjective Norm, BI: Behavioral Intention).

3.9. Cost Analysis

The financial and operational sustainability of community-based RO plants in coastal Bangladesh is shaped by a complex interplay of socio-economic, technical, and environmental factors. 64.29% of the plants charge 50 paisa (0.0041 USD) per liter, while the overall price range spans from 50 to 75 paisa (0.0041 to 0.0062 USD) per liter. This pricing reflects the low- to middle-income status of the target population and is essential to ensure affordability in socio-economically vulnerable communities. However, in the case of mobile delivery services, water is sold at 1 BDT (0.0082 USD) per liter, while the water quality is not necessarily guaranteed in an authorized way. They are rapidly increasing in number, yet adequate rules and regulations for initiation and operation are lacking.

The average production cost per liter is approximately 35 paisa, with average monthly revenue around 10,000 BDT (82 USD), which includes operator salaries. In privately owned RO plants, operators are often the owners themselves or their family members, minimizing labor costs. An example of average monthly balance for a typical RO plant, regular monthly cost, irregular costs, and a detailed breakdown of capital cost is presented in Tables S4–S7.

RO system and filtration units account for 40%, and membranes account for 16% of total capital investment. A major financial challenge lies in membrane replacement, which has an average cost of 60,000 BDT (492 USD) (at 15,000 BDT (123 USD) per unit). This expense alone comprises 68.65% of total irregular maintenance costs. While most community-based plants can manage regular monthly expenses, they struggle with sudden or scheduled membrane replacements due to limited savings and poor financial planning. These replacement gaps often lead to plant shutdowns. Indika et al. [45] highlighted membrane fouling and associated low recovery rates as major concerns that increase production costs and contribute to the economic difficulties of the community-based organization in Sri Lanka.

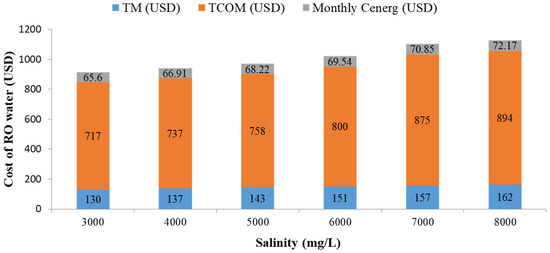

Electricity costs are another major burden, comprising 54% of monthly operational expenses. RO plants are billed under the LTD-2 tariff category at BDT 9.71 (0.08 USD)/kWh, and operators have raised concerns that further increases in electricity rates could make it unfeasible to maintain current water prices. Moreover, energy consumption is directly influenced by feedwater salinity. As salinity increases, so does the specific energy consumption (SEC), with a 0.1 kWh/m3 rise for every 1000 mg/L increase in salinity. Regression analysis indicated a strong positive association between feedwater salinity and energy demand, with R2 = 0.973 (n = 6). This linear relationship between salinity and SEC is also observed in the study by Hamdan et al. [71]. This trend significantly impacts total monthly costs, as demonstrated by a rise in energy expenses from USD 65.6 to USD 72.17 when salinity increases from 3000 to 8000 mg/L. Figure 10 illustrates the influence of feedwater salinity on key cost parameters. These findings underscore the need for salinity-adaptive system design and energy-efficient technologies in coastal regions. The integration of energy recovery devices could reduce operating pressure and lower electricity demand, thereby cutting per-m3 production costs and enhancing long-term economic sustainability [55]. A pilot project in Ecuador reported 3.90–4.58 kWh/m3 under baseline conditions, but redesign (multi-stage, recirculation) reduced this to 0.74–1.52 kWh/m3, achieving 63–81% savings. This proves that design innovation (staging, recirculation) directly improves energy efficiency, a missing dimension in Bangladesh’s small-scale systems [72]. RO plants in coastal Bangladesh are dependent on grid electricity. Atallah et al. [73] show that hybrid PV–diesel–battery systems can deliver reliable power at lower cost (USD 0.107/kWh), indicating that renewable integration can substantially reduce grid electricity dependency while enhancing the sustainability of recovery operations.

Figure 10.

Cost of RO water at different salinities considering the electricity price of 0.08 USD)/kWh (9.71 BDT/kWh). TM stands for total monthly cost, TCOM for total operation and maintenance cost, and CEnerg is the cost of electricity.

Routine tasks such as membrane changes, membrane cleaning, filter media replacement, and pump repairs are almost entirely dependent on external technicians, typically affiliated with RO suppliers based in nearby districts (e.g., Khulna, Satkhira). This dependency has created a regional syndicate-like control over spare parts and servicing, often inflating operational costs. Mismanagement, lack of preventive maintenance, poor site selection, and absence of governance mechanisms further aggravate economic sustainability. Many shutdown cases observed during the audit were linked to these systemic weaknesses, particularly when membrane replacement was delayed due to funding shortages.

3.10. Key Operational Issues and Practical Solutions for RO Plant Sustainability

Groundwater used in community-based RO plants in coastal Bangladesh shows extremely poor quality, with very high hardness (mean: 636.36 mg/L as CaCO3), elevated iron (3.23 mg/L), and alkalinity (877.45 mg/L), increasing the risk of membrane fouling and scaling. Ineffective control of recovery rate and concentrate flow further exacerbates these issues, reducing RO performance and membrane life. A key operational gap is the lack of standardized guidelines and trained operators.

Regular maintenance is critical to sustaining plant performance. Changing sediment filters is one of the most important routine tasks, yet practices vary widely. Sediment filters (MF/UF) are typically replaced based on visual indicators like discoloration or pressure drops, with 35% of plants replacing them every 15 days and others ranging from weekly to every three months. RO membranes, the system’s core component, degrade over time due to fouling and scaling, which reduce water recovery and increase pressure. In this study, replacement intervals ranged from 1 to 4 years, with 29% of plants replacing membranes within two years, and the rest every 3–4 years. However, periodic membrane chemical cleaning (acid + antiscalant), undertaken at least every six months, can extend membrane life [74], reduce specific power consumption (SPC) by approximately 12–13% after each cycle [49], and lower long-term costs. Yet, none of the audited plants followed such protocols, primarily due to insufficient operator training.

Public dissatisfaction reflects these shortcomings: 44.6% of users reported concerns, including visible impurities and unpleasant odors in the product water. Jeong et al. [75] demonstrated a structured implementation model in Vietnam, where local operators were formally trained, and industry partners ensured continuous after-service support. In Bangladesh, operator training is largely absent, with nearly 90% of the audited RO plants managed by untrained personnel. Importantly, the study observed that donor-, NGO-, and government-supported RO plants experienced disproportionately higher rates of operational breakdowns compared to privately financed systems, largely due to weak ownership, poor governance, and limited accountability following community handover. The absence of regulatory oversight contributes to inconsistent water quality, poor maintenance, and unsustainable groundwater extraction, challenges that have also been reported in similar decentralized RO systems globally [76]. Table 8 summarizes the operational challenges faced by small-scale RO plants in coastal Bangladesh, along with recommended solutions to enhance their performance and sustainability.

Table 8.

Operational challenges and solutions for small-scale RO plants in coastal Bangladesh.

4. Conclusions

This study assessed the socio-technical and economic performance of 20 small-scale RO desalination plants in coastal Bangladesh. RO systems achieved high salt rejection (mean 95.15%, range 86.29–99.16%), hardness removal (mean 95.95%), and alkalinity removal (mean 91.67%), producing treated water that consistently complied with WHO and Bangladesh drinking water standards for TDS, pH, turbidity, Fe, and As. However, low permeate recovery (mean 37.25%, range 20–60%), membrane fouling, and high electricity costs (54% of monthly operating expenses) threaten long-term sustainability. Brine disposal, with a mean TDS of 12,900 mg/L, remains unmanaged, posing risks of soil salinization and groundwater contamination. The Theory of Planned Behavior (TPB) analysis shows that attitudes (β = 0.592, p < 0.001) and perceived behavioral control (β = 0.189, p = 0.04) are significant predictors of RO water adoption, while subjective norms were not statistically significant. These findings emphasize the need for affordability, accessibility, and user knowledge to sustain community acceptance. Key recommendations include enforcing scheduled maintenance, operator training, and cost-recovery mechanisms for membrane replacement, alongside context-specific brine reuse strategies such as aquaculture. Future research should examine the environmental impacts of brine disposal and the feasibility of integrating remineralization technologies to address health risks from demineralized water. This study offers actionable insights for policymakers and practitioners to strengthen resilient, equitable, and sustainable water supply systems in climate-vulnerable coastal regions, contributing to Sustainable Development Goal 6.1.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/su17209335/s1. Table S1: Descriptive statistics from the univariate analysis of questionnaire items. Table S2: Specifications of selected reverse osmosis (RO) membrane models commonly used in coastal desalination plants of Bangladesh. Table S3: Demographic data of the respondents in the questionnaire survey. Table S4: An example of average monthly balance for a typical RO plant. Table S5: Regular monthly operational and maintenance cost. Table S6: Irregular or periodic maintenance costs associated with RO desalination systems. Table S7: Estimated capital investment breakdown for establishing a small-scale community RO desalination plant in coastal Bangladesh.

Author Contributions

Conceptualization, S.D.S. and S.B.M.; methodology, S.D.S. and S.B.M.; software, S.D.S.; validation, S.D.S. and S.B.M.; formal analysis, S.D.S.; investigation, S.D.S. and S.B.M.; resources, S.B.M.; data curation, S.D.S.; writing—original draft preparation, S.D.S.; writing—review and editing, S.D.S. and S.B.M.; visualization, S.D.S.; supervision, S.B.M.; project administration, S.B.M.; funding acquisition, S.B.M. All authors have read and agreed to the published version of the manuscript.

Funding

This study is funded by the Bangladesh University of Engineering and Technology (BUET) (CASR Meeting No. 381, Resolution No. 35, dated 8 January 2025). Partial travel support for fieldwork was provided by the REACH programme, funded by UK Aid from the UK Foreign, Commonwealth and Development Office (FCDO), for the benefit of developing countries (Programme Code 201880, funding reference: Oxford Reff: R34819). The REACH programme is led by the University of Oxford, with IWFM, BUET serving as the lead institution in Bangladesh. However, the views expressed and the information contained in it are not necessarily those of, or endorsed by, Research England or FCDO, which can accept no responsibility for such views or information or for any reliance placed on them.

Institutional Review Board Statement

This study was approved by the Institutional Review Board (IRB) of Bangladesh University of Engineering and Technology (BUET) (Approval No.: BUET/RISE/IRB/2025-07-003; Approval Date: 17 August 2025).

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data that support this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| RO | Reverse Osmosis |

| TDS | Total Dissolved Solids |

| EC | Electrical Conductivity |

| NTU | Nephelometric Turbidity Unit |

| WHO | World Health Organization |

| AVE | Average Variance Extracted |

| CR | Composite Reliability |

| PBC | Perceived Behavioral Control |

| TPB | Theory of Planned Behavior |

| KMO | Kaiser-Meyer-Olkin |

| SEM | Structural Equation Modeling |

| AAS | Atomic Absorption Spectroscopy |

| HG-AAS | Hydride Generation Atomic Absorption Spectroscopy |

| F-AAS | Flame Atomic Absorption Spectroscopy |

| HDPE | High-Density Polyethylene |

Appendix A

Table A1.

Constructs and its scale items.

Table A1.

Constructs and its scale items.

| Construct | Item Code | Statement |

|---|---|---|

| Attitude (AT) | AT1 | I believe the RO plant can meet my family’s drinking water demand. |

| AT2 | I think using desalinated water is beneficial for alleviating the water crisis. | |

| AT3 | I believe desalination should be promoted more vigorously to solve water scarcity. | |

| AT4 | I find RO water a convenient source of drinking water. | |

| AT5 | I believe RO water is cleaner and safer than other water sources. | |

| Subjective Norm (SN) | SN1 | My friends, neighbors, and family members encourage me to use RO water. |

| SN2 | Most people in my community believe using RO water is a good practice. | |

| Perceived Behavioral Control (PBC) | PBC1 | I find it easy to get an adequate supply of desalinated water in my area. |

| PBC2 | I can afford to use desalinated water even if its price is higher. | |

| PBC3 | I am willing to pay more for desalinated water even if its price increases. | |

| PBC4 | I have sufficient knowledge about the desalination production and treatment process. | |

| Behavioral Intention (BI) | BI1 | I would prefer to use desalinated water for drinking and household purposes. |

| BI2 | I will recommend desalinated water to my family, friends, and colleagues. | |

| BI3 | I am willing to switch to RO water from my current water source. |

References

- Sirohi, R.; Kumar, Y.; Madhavan, A.; Sagar, N.A.; Sindhu, R.; Bharathiraja, B.; Bharatiraja, B.; Pandey, H.O.; Tarafdar, A. Engineered nanomaterials for water desalination: Trends and challenges. Environ. Technol. Innov. 2023, 30, 103108. [Google Scholar] [CrossRef]

- Shemer, H.; Wald, S.; Semiat, R. Challenges and Solutions for Global Water Scarcity. Membranes 2023, 13, 612. [Google Scholar] [CrossRef]

- Villada-Canela, M. Understanding Social Aspects on Desalination for Community Adaptation and Resilience in Baja California, México. Soc. Sci. 2025, 14, 110. [Google Scholar] [CrossRef]

- Lee, K.; Jepson, W. Toward sustainable desalination: A patent analysis of technology-development trajectories. Sustain. Sci. Pract. Policy 2025, 21, 2450112. [Google Scholar] [CrossRef]

- Yuan, Z.; Han, L.; Wang, X. Optimal configuration of integrated energy system considering heat enhancement and combined operation of low head seawater pumped storage and reverse osmosis. Energy Convers. Manag. 2025, 325, 119376. [Google Scholar] [CrossRef]

- Haq, M.I.; Shamsudduha, M.; Zahid, A.; Ahmed, K.M.; Kamal, A.S.M.M.; Taylor, R.G. What drives changes in surface water salinity in coastal Bangladesh? Front. Water 2024, 6, 1220540. [Google Scholar]

- Ashrafuzzaman, M.; Gomes, C.; Guerra, J. The Changing Climate Is Changing Safe Drinking Water, Impacting Health: A Case in the Southwestern Coastal Region of Bangladesh (SWCRB). Climate 2023, 11, 146. [Google Scholar] [CrossRef]

- Rahman, M.S.; Hossain, K.M.; van Loenhout, J.; Wallemacq, P.; Guha-Sapir, D. Effects of Salinity on Health due to Environmental Exposure: Experiences from Bangladesh. In Coastal Disaster Risk Management in Bangladesh; Routledge: London, UK, 2023. [Google Scholar]

- Akhter, T.; Naz, M.; Salehin, M.; Arif, S.T.; Hoque, S.F.; Hope, R.; Rahman, M.R. Hydrogeologic Constraints for Drinking Water Security in Southwest Coastal Bangladesh: Implications for Sustainable Development Goal 6.1. Water 2023, 15, 2333. [Google Scholar] [CrossRef]

- Rashid, M.B.; Siddique, M.A.B.; Khan, R.; Habib, M.A.; Islam, M.S.; Akbor, M.A.; Haque, A.J.M.E.; Sheik, M.R.; Kabir, M.A.; Sarker, M.N.; et al. Correction to: Human exposures to multiple water sources in the southwestern coastal region of Bangladesh: Water quality, pollution sources, and preliminary health risks appraisals. Environ. Sci. Pollut. Res. Int. 2023, 30, 95035. [Google Scholar] [CrossRef]

- Haque, C.E.; Shehab, M.K.; Faisal, I.M. Meeting climate change challenges in coastal Bangladesh: A study of technology-based adaptations in water use in Satkhira District. PLOS Clim. 2025, 4, e0000460. [Google Scholar] [CrossRef]

- Tsai, C.; Hoque, M.A.; Vineis, P.; Ahmed, K.M.; Butler, A.P. Salinisation of drinking water ponds and groundwater in coastal Bangladesh linked to tropical cyclones. Sci. Rep. 2024, 14, 5211. [Google Scholar] [CrossRef]

- Khan, M.S.; Paul, S.K. Quality and efficiency assessment, health issues and management practices of pond sand filter water in coastal Bangladesh. Int. J. Energy Water Resour. 2024, 8, 311–325. [Google Scholar] [CrossRef]

- Amin, M.N.; Hossain, M.A.; Islam, M.R.; Mondal, S.; Ali, M.H. The health impact of climate change on the women in reproductive age: A study of coastal communities in Satkhira, Bangladesh. Front. Public Health 2025, 13, 1560498. [Google Scholar] [CrossRef]

- Esha, A. Beyond drinking water supply infrastructure: Gendered lived experiences in coastal Bangladesh. Gend. Dev. 2024, 32, 707–725. [Google Scholar] [CrossRef]

- Khanam, D.; Kabir, Z.; Dina, S.A.; Islam, A.R.M.T. Experiencing the Impacts of Climate Change-Induced Salinity by Women in Coastal Region of Bangladesh. J. Clim. Action Res. Policy 2023, 1, 2450001. [Google Scholar] [CrossRef]

- Ahmed, Z.; Ahmed, M.N.Q.; Hussain, A.B.; Alam, R.; Ambinakudige, S.; Kamal, M.M.; Chowdhury, M.A. Do Socio-demographic Factors Influence Water-fetching Practices? Evidence from the Southwestern Coastal Region of Bangladesh. Soc. Nat. Resour. 2023, 36, 1491–1509. [Google Scholar] [CrossRef]

- Shabib, B.; Tatan, Y.; Elbaz, A.; Aly Hassan, M.A.; Hamouda, M.A.; Maraqa, M.A. Advancements in reverse osmosis desalination: Technology, environment, economy, and bibliometric insights. Desalination 2025, 598, 118413. [Google Scholar] [CrossRef]

- Tayeh, Y.A.; Alazaiza, M.Y.D.; Alzghoul, T.M.; Bashir, M.J. A comprehensive review of RO membrane fouling: Mechanisms, categories, cleaning methods and pre-treatment technologies. J. Hazard. Mater. Adv. 2025, 18, 100684. [Google Scholar] [CrossRef]

- Ouali, S.; Doucoure, A. Adopting sea water reverse osmosis desalination technologies for sustainable development: Lessons learnt from Algiers Science and Technology for membranes 2023 workshop. Front. Membr. Sci. Technol. 2024, 3, 1352799. [Google Scholar] [CrossRef]

- Hoque, S.F. Socio-spatial and seasonal dynamics of small, private water service providers in Khulna district, Bangladesh. Int. J. Water Resour. Dev. 2023, 39, 89–112. [Google Scholar] [CrossRef]

- Roman, O.; Hoque, S.F.; Ford, L.; Salehin, M.; Alam, M.M.; Hope, R.; Hall, J.W. Optimizing Rural Drinking Water Supply Infrastructure to Account for Spatial Variations in Groundwater Quality and Household Welfare in Coastal Bangladesh. Water Resour. Res. 2021, 57, e2021WR029621. [Google Scholar] [CrossRef]

- Islam, M.A.; Akber, M.A.; Ghosh, P.K. Water quality of small-scale desalination plants in southwest coastal Bangladesh. Water Supply 2018, 18, 1606–1616. [Google Scholar] [CrossRef]

- Shamsuzzoha, M.; Rasheduzzaman, M.; Ghosh, R.C. Building Resilience for Drinking Water Shortages through Reverse Osmosis Technology in Coastal Areas of Bangladesh. Procedia Eng. 2018, 212, 559–566. [Google Scholar] [CrossRef]

- American Public Health Association (APHA). Standard Methods for the Examination of Water and Wastewater; American Public Health Association: Washington, DC, USA, 2012. [Google Scholar]

- Debnath, P.; Mamun, M.M.A.A.; Karmakar, S.; Uddin, M.S.; Nath, T.K. Drinking water quality of Chattogram city in Bangladesh: An analytical and residents’ perception study. Heliyon 2022, 8, e12247. [Google Scholar] [CrossRef] [PubMed]

- Government of South Australia. Salinity and Drinking Water: SA Health. Available online: https://www.sahealth.sa.gov.au/wps/wcm/connect/public+content/sa+health+internet/public+health/water+quality/salinity+and+drinking+water (accessed on 7 June 2025).

- Lili, D.; Ying, Y.; Qiuhui, H.; Mengxi, L. Residents’ acceptance of using desalinated water in China based on the theory of planned behaviour (TPB). Mar. Policy 2021, 123, 104293. [Google Scholar] [CrossRef]

- Ajzen, I. The theory of planned behavior. Organ. Behav. Hum. Decis. Process. 1991, 50, 179–211. [Google Scholar] [CrossRef]

- Ajzen, F. Understanding Attitudes and Predicting Social Behavior; Prentice-Hall: Upper Saddle River, NJ, USA, 1980; Available online: https://www.scienceopen.com/book?vid=c20c4174-d8dc-428d-b352-280b05eacdf7 (accessed on 21 July 2025).

- Goh, E.; Ritchie, B.; Wang, J. Non-compliance in national parks: An extension of the theory of planned behaviour model with pro-environmental values. Tour. Manag. 2017, 59, 123–127. [Google Scholar] [CrossRef]

- Ahmmadi, P.; Rahimian, M.; Movahed, R.G. Theory of planned behavior to predict consumer behavior in using products irrigated with purified wastewater in Iran consumer. J. Clean. Prod. 2021, 296, 126359. [Google Scholar] [CrossRef]

- Hatcher, L. A Step-by-Step Approach to Using the SAS System for Factor Analysis and Structural Equation Modeling; SAS Institute: Cary, NC, USA, 1994; 618p. [Google Scholar]

- Gibson, K.E.; Lamm, A.J.; Lamm, K.W.; Holt, J. Integrating the Theory of Planned Behavior and Motivation to Explore Residential Water-Saving Behaviors. Water 2023, 15, 3034. [Google Scholar] [CrossRef]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E. Multivariate Data Analysis; Cengage: Andover, UK, 2019; 813p. [Google Scholar]

- Kline, R.B. Principles and Practice of Structural Equation Modeling, 4th ed.; Guilford Publications: New York, NY, USA, 2015; 553p. [Google Scholar]

- Hu, L.; Bentler, P.M. Cutoff criteria for fit indexes in covariance structure analysis: Conventional criteria versus new alternatives. Struct. Equ. Model. A Multidiscip. J. 1999, 6, 1–55. [Google Scholar] [CrossRef]

- Hogard, S.; Pearce, R.; Gonzalez, R.; Yetka, K.; Bott, C. Optimizing Ozone Disinfection in Water Reuse: Controlling Bromate Formation and Enhancing Trace Organic Contaminant Oxidation. Environ. Sci. Technol. 2023, 57, 18499–18508. [Google Scholar] [CrossRef]

- Pervov, A.; Andrianov, A. Deposition of calcium and magnesium from RO concentrate by means of seed crystallization and production of softened water for technical purposes. Desalination Water Treat. 2018, 110, 10–18. [Google Scholar] [CrossRef]

- ECR. Environment Conservation Rules, 2023; Department of Environment, Ministry of Environment, Forest and Climate Change, Government of the People’s Republic of Bangladesh: Dhaka, Bangladesh, 2023.

- WHO. Guidelines for Drinking-Water Quality: Fourth Edition Incorporating the First and Second Addenda; World Health Organization: Geneva, Switzerland, 2022. [Google Scholar]

- Ashrafuzzaman, M.; Artemi, C.; Santos, F.D.; Schmidt, L. Current and Future Salinity Intrusion in the South-Western Coastal Region of Bangladesh. Span. J. Soil Sci. 2022, 12, 10017. [Google Scholar] [CrossRef]

- MacKay, A.A.; Gan, P.; Yu, R.; Smets, B.F. Seasonal arsenic accumulation in stream sediments at a groundwater discharge zone. Environ. Sci. Technol. 2014, 48, 920–929. [Google Scholar] [CrossRef]

- Hafiz, M.A.; Hawari, A.H.; Yasir, A.T.; Alfahel, R.; Hassan, M.K.; Altaee, A. Impact of high turbidity on reverse osmosis: Evaluation of pre-treatment processes. Desalination Water Treat. 2020, 208, 96–103. [Google Scholar] [CrossRef]

- Indika, S.; Wei, Y.; Hu, D.; Ketharani, J.; Ritigala, T.; Cooray, T.; Hansima, M.A.C.K.; Makehelwala, M.; Jinadasa, K.B.S.N.; Weragoda, S.K.; et al. Evaluation of Performance of Existing RO Drinking Water Stations in the North Central Province, Sri Lanka. Membranes 2021, 11, 383. [Google Scholar] [CrossRef]

- Chebil, S.; Ruiz-García, A.; Farhat, S.; Bali, M. Long-Term Performance Evaluation and Fouling Characterization of a Full-Scale Brackish Water Reverse Osmosis Desalination Plant. Water 2024, 16, 1892. [Google Scholar] [CrossRef]

- Ketharani, J.; Hansima, M.A.C.K.; Indika, S.; Samarajeewa, D.R.; Makehelwala, M.; Jinadasa, K.B.S.N.; Weragoda, S.K.; Rathnayake, R.M.L.D.; Nanayakkara, K.G.N.; Wei, Y.; et al. A comparative study of community reverse osmosis and nanofiltration systems for total hardness removal in groundwater. Groundw. Sustain. Dev. 2022, 18, 100800. [Google Scholar] [CrossRef]

- Qasim, M.; Badrelzaman, M.; Darwish, N.N.; Darwish, N.A.; Hilal, N. Reverse osmosis desalination: A state-of-the-art review. Desalination 2019, 459, 59–104. [Google Scholar] [CrossRef]

- Singh, S.; Johari, A.; Gautam, A.K. Performance Study of Community Scale Reverse Osmosis Plant, Vidhani Jaipur. SKIT Res. J. 2019, 9, 28–32. [Google Scholar]

- WHO. Hardness in Drinking-Water: Background Document for Development of WHO Guidelines for Drinking-Water Quality; World Health Organization: Geneva, Switzerland, 2010. [Google Scholar]

- Kamalapriya, V.; Mani, R.; Venkatesh, V.; Kunhikannan, S.; Venkatesh, V., Sr. The Role of Low Mineral Water Consumption in Reducing the Mineral Density of Bones and Teeth: A Narrative Review. Cureus 2023, 15, e49119. [Google Scholar] [CrossRef] [PubMed]

- WHO. Calcium and Magnesium in Drinking-Water: Public Health Significance; World Health Organization: Geneva, Switzerland, 2009. [Google Scholar]

- Pazouki, P.; Teshnizi, E.S.; Bertone, E.; Helfer, F.; Stewart, R.A. Multi-criteria decision making for a holistic assessment of sustainable alternatives in SWRO desalination: A case study. Desalination 2022, 544, 116127. [Google Scholar] [CrossRef]

- Widiasa, I.N.; Paramita, V.; Kusumayanti, H. BWRO desalination for potable water supply enhancement in coastal regions. J. Coast. Dev. 2009, 12, 81–88. [Google Scholar]

- Sanz, J.; García, A.; Miró, J.; Miguel, C. Drinking water supply by reverse osmosis plants: Three years of experience at El Prat de Llobregat Municipality. Desalination Water Treat. 2013, 51, 124–131. [Google Scholar] [CrossRef]

- Ahmed, A.; Amin, S.; Mohamed, A.A. Fouling in reverse osmosis membranes: Monitoring, characterization, mitigation strategies and future directions. Heliyon 2023, 9, e14908. [Google Scholar] [CrossRef]

- Haidar, Z.A.; Al-Saud, M.; Orfi, J.; Al-Ansary, H. Reverse Osmosis Desalination Plants Energy Consumption Management and Optimization for Improving Power Systems Voltage Stability with PV Generation Resources. Energies 2021, 14, 7739. [Google Scholar] [CrossRef]

- Panagopoulos, A.; Haralambous, K.J.; Loizidou, M. Desalination brine disposal methods and treatment technologies—A review. Sci. Total Environ. 2019, 693, 133545. [Google Scholar] [CrossRef]

- Soliman, M.N.; Guen, F.Z.; Ahmed, S.A.; Saleem, H.; Khalil, M.J.; Zaidi, S.J. Energy consumption and environmental impact assessment of desalination plants and brine disposal strategies. Process Saf. Environ. Prot. 2021, 147, 589–608. [Google Scholar] [CrossRef]

- Martinetti, C.R.; Childress, A.E.; Cath, T.Y. High recovery of concentrated RO brines using forward osmosis and membrane distillation. J. Membr. Sci. 2009, 331, 31–39. [Google Scholar] [CrossRef]

- Walker, W.S.; Kim, Y.; Lawler, D.F. Treatment of model inland brackish groundwater reverse osmosis concentrate with electrodialysis—Part II: Sensitivity to voltage application and membranes. Desalination 2014, 345, 128–135. [Google Scholar] [CrossRef]

- Alsharhan, A.S.; Rizk, Z.E. Water Desalination: Environmental Impacts and Brine Management. In Water Resources and Integrated Management of the United Arab Emirates; Alsharhan, A.S., Rizk, Z.E., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 455–470. [Google Scholar]

- Fuadi, A.A.; Hasly, I.R.J.; Azkia, L.I.; Irham, M. Response of tilapia (Oreochromis niloticus) behaviour to salinity differences: A laboratory scale study. IOP Conf. Ser. Earth Environ. Sci. 2021, 674, 012060. [Google Scholar] [CrossRef]

- Partridge, G.J.; Lymbery, A.J. The effect of salinity on the requirement for potassium by barramundi (Lates calcarifer) in saline groundwater. Aquaculture 2008, 278, 164–170. [Google Scholar] [CrossRef]

- Van Stappen, G.; Sui, L.; Hoa, V.N.; Tamtin, M.; Nyonje, B.; de Medeiros Rocha, R.; Sorgeloos, P.; Gajardo, G. Review on integrated production of the brine shrimp Artemia in solar salt ponds. Rev. Aquac. 2020, 12, 1054–1071. [Google Scholar] [CrossRef]

- Haque, M.M.; Mahmud, M.N. Potential Role of Aquaculture in Advancing Sustainable Development Goals (SDGs) in Bangladesh. Aquac. Res. 2025, 2025, 6035730. [Google Scholar] [CrossRef]

- Oron, G.; Appelbaum, S.; Guy, O. Reuse of brine from inland desalination plants with duckweed, fish and halophytes toward increased food production and improved environmental control. Desalination 2023, 549, 116317. [Google Scholar] [CrossRef]

- Mickley, M. Updated and Extended Survey of US Municipal Desalination Plants; Desalination and Water Purification Research and Development Program Report No. 27; U.S. Department of the Interior Bureau of Reclamation Technical Service Center: Denver, CO, USA, 2018.

- Basile, A.; Nunes, S. Advanced Membrane Science and Technology for Sustainable Energy and Environmental Applications; Elsevier: Cambridge, UK, 2016. [Google Scholar]

- Abd-Elaty, I.; Shahawy, A.E.L.; Santoro, S.; Curcio, E.; Straface, S. Effects of groundwater abstraction and desalination brine deep injection on a coastal aquifer. Sci. Total Environ. 2021, 795, 148928. [Google Scholar] [CrossRef]

- Hamdan, H.; Saidy, M.; Alameddine, I.; Al-Hindi, M. The feasibility of solar-powered small-scale brackish water desalination units in a coastal aquifer prone to saltwater intrusion: A comparison between electrodialysis reversal and reverse osmosis. J. Environ. Manag. 2021, 290, 112604. [Google Scholar] [CrossRef]