Sustainable Management of Wastewater Sludge Through Co-Digestion, Mechanical Pretreatment and Recurrent Neural Network (RNN) Modeling

Abstract

1. Introduction

2. Methodology

2.1. Materials and Experimental Setup

2.2. Reactor Setup and Analytical Methods

2.3. Energy and Environmental Aspects

2.4. Recurrent Neural Network (RNN) Modeling

3. Results and Discussion

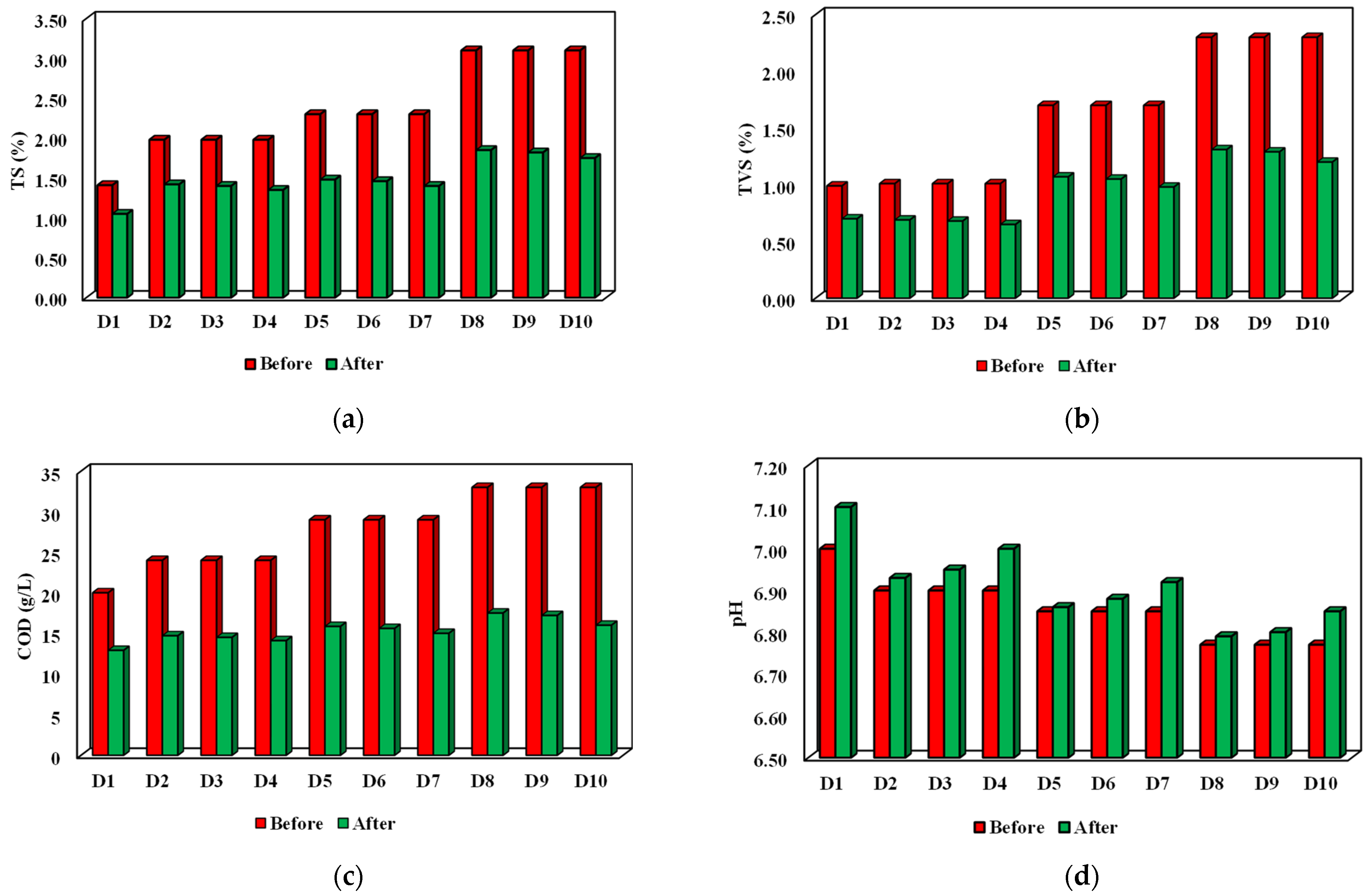

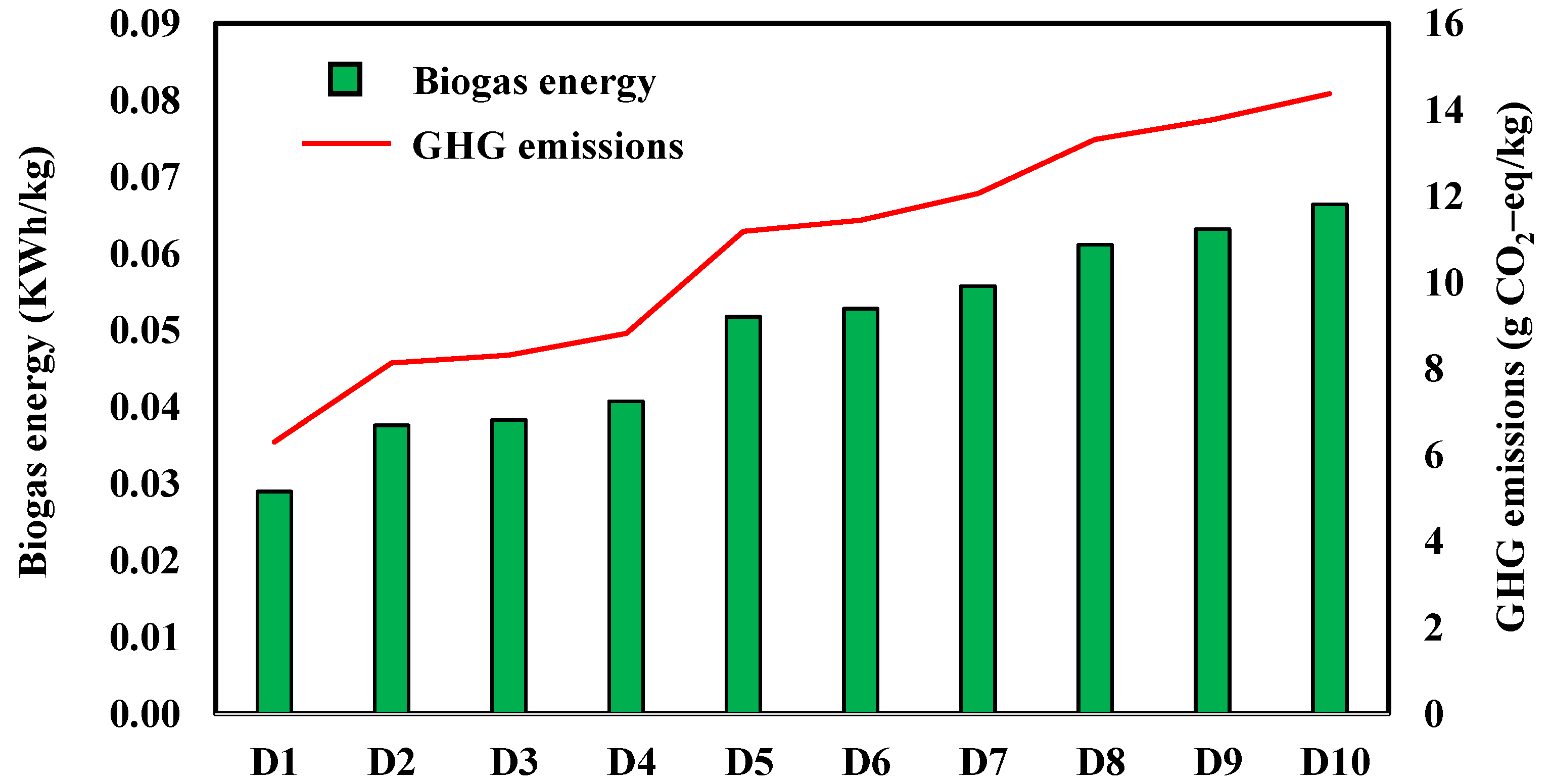

3.1. Experimental Results

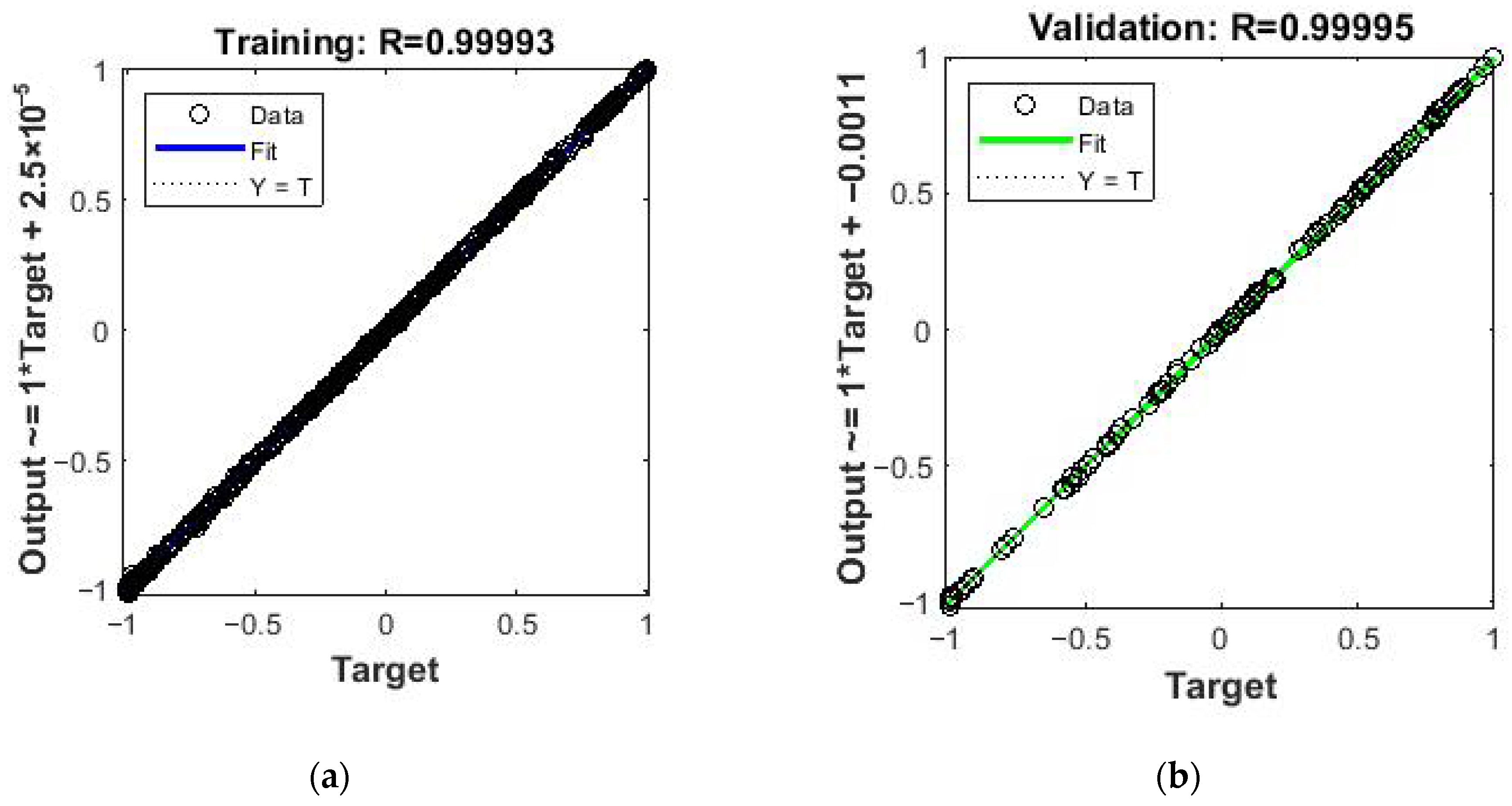

3.2. RNN Modeling Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Azarmanesh, R.; Qaretapeh, M.Z.; Zonoozi, M.H.; Ghiasinejad, H.; Zhang, Y. Anaerobic co-digestion of sewage sludge with other organic wastes: A comprehensive review focusing on selection criteria, operational conditions, and microbiology. Chem. Eng. J. Adv. 2023, 14, 100453. [Google Scholar] [CrossRef]

- Korni, R.D.; Bora, T.; Majji, A.; Panda, J. Liquisolid technique for solubility enhancement of a poorly soluble thrombin inhibitor: Optimization using design of experiments and artificial neural networks. Prospect. Pharm. Sci. 2025, 23, 97–109. [Google Scholar]

- Jafari, G.; Ardabili, S.; Pourdarbani, R.; Abbaszadeh, B.; Hernandez-Hernandez, M. Sustainable biomethane production from sewage sludge and wheat straw co-digestion in the presence of polypyrrole Fe3O4 nanoparticles and alkaline pretreatment: Life cycle assessment point of view. Acta Technol. Agric. 2023, 3, 133–141. [Google Scholar] [CrossRef]

- Gao, J.; Li, J.; Wachemo, A.C.; Yuan, H.; Zuo, X.; Li, X. Mass conversion pathway during anaerobic digestion of wheat straw. RSC Adv. 2020, 10, 27720–27727. [Google Scholar] [CrossRef]

- Alrowais, R.; Said, N.; Alotaibi, A.; Hatata, A.; Essa, M.A.; Abdel daiem, M.M. Comparing the effect of mesophilic and thermophilic anaerobic co-digestion for sustainable biogas production: An experimental and recurrent neural network model study. J. Clean. Prod. 2023, 392, 136248. [Google Scholar] [CrossRef]

- Rani, P.; Bansal, M.; Pathak, V.V. Experimental and kinetic studies for improvement of biogas production from KOH pretreated wheat straw. Curr. Res. Green Sustain. Chem. 2022, 5, 100283. [Google Scholar] [CrossRef]

- Said, N.; Alrowais, R.; Abdel-Daiem, M.M.; Mostafa, N.A. Bio-Waste to Bioenergy: Critical Assessment of Sustainable Energy Supply Chain in Egypt. Resources 2025, 14, 131. [Google Scholar] [CrossRef]

- Said, N.; Alrowais, R.; Abdel-Daiem, M. Effect of physical and chemical treatment on the characteristics of wheat straw as fuel for energy applications. BioResources 2024, 19, 953. [Google Scholar] [CrossRef]

- Elsayed, M.; Andres, Y.; Blel, W. Anaerobic co-digestion of linen, sugar beet pulp, and wheat straw with cow manure: Effects of mixing ratio and transient change of co-substrate. Biomass Convers. Biorefin. 2023, 13, 11831–11840. [Google Scholar] [CrossRef]

- Rahmani, A.M.; Tyagi, V.K.; Ahmed, B.; Kazmi, A.A.; Ojha, C.S.P.; Singh, R. Critical insights into anaerobic co-digestion of wheat straw with food waste and cattle manure: Synergistic effects on biogas yield and kinetic modeling. Environ. Res. 2022, 212, 113382. [Google Scholar] [CrossRef] [PubMed]

- Zdeb, M. Anaerobic Digestion of Wheat Straw Pretreated with Soaking in Water and Alkali Medium. J. Ecol. Eng. 2021, 22, 246–254. [Google Scholar] [CrossRef]

- Rajput, A.A.; Sheikh, Z. Effect of inoculum type and organic loading on biogas production of sunflower meal and wheat straw. Sustain. Environ. Res. 2019, 29, 4. [Google Scholar] [CrossRef]

- Kamusoko, R.; Mukumba, P. Potential of wheat straw for biogas production by anaerobic digestion in South Africa: A review. Energies 2024, 17, 4662. [Google Scholar] [CrossRef]

- Shang, X.; Song, S.; Yang, J. Comparative environmental evaluation of straw resources by LCA in China. Adv. Mater. Sci. Eng. 2020, 2020, 4781805. [Google Scholar] [CrossRef]

- Sarkar, O.; Rova, U.; Christakopoulos, P.; Matsakas, L. Biogas potential of organosolv pretreated wheat straw as mono and co-substrate: Substrate synergy and microbial dynamics. Sci. Rep. 2024, 14, 18442. [Google Scholar] [CrossRef]

- Álvaro, A.G.; Palomar, C.R.; Redondo, D.H.; Torre, R.M.; de Godos Crespo, I. Simultaneous production of biogas and volatile fatty acids through anaerobic digestion using cereal straw as substrate. Environ. Technol. Innov. 2023, 31, 103215. [Google Scholar] [CrossRef]

- Abdel daiem, M.M.; Hatata, A.; Said, N. Modeling and optimization of semi-continuous anaerobic co-digestion of activated sludge and wheat straw using Nonlinear Autoregressive Exogenous neural network and seagull algorithm. Energy 2022, 241, 122939. [Google Scholar] [CrossRef]

- Abdel daiem, M.M.; Hatata, A.; Galal, O.H.; Said, N.; Ahmed, D. Prediction of biogas production from anaerobic Co-digestion of Waste Activated sludge and wheat straw using two-dimensional mathematical models and an artificial neural network. Renew. Energy 2021, 178, 226–240. [Google Scholar] [CrossRef]

- Witaszek, K.; Kupryaniuk, K.; Kupryaniuk, J.; Panasiewicz, J.; Czekała, W. Optimization of Straw Particle Size for Enhanced Biogas Production: A Comparative Study of Wheat and Rapeseed Straw. Energies 2025, 18, 1794. [Google Scholar] [CrossRef]

- Lee, W.; Kim, Y.; Kim, H.; Kim, M. Comparison of anaerobic co-digestion of food waste and livestock manure at various mixing ratios under mesophilic and thermophilic temperatures. Sustainability 2024, 16, 7653. [Google Scholar] [CrossRef]

- Victorin, M.; Davidsson, Å.; Wallberg, O. Characterization of mechanically pretreated wheat straw for biogas production. Bioenergy Res. 2020, 13, 833–844. [Google Scholar] [CrossRef]

- Stanley, J.T.; Thanarasu, A.; Kumar, P.S.; Periyasamy, K.; Raghunandhakumar, S.; Periyaraman, P.; Devaraj, K.; Dhanasekaran, A.; Subramanian, S. Potential pre-treatment of lignocellulosic biomass for the enhancement of biomethane production through anaerobic digestion-A review. Fuel 2022, 318, 123593. [Google Scholar] [CrossRef]

- Uthirakrishnan, U.; Sharmila, V.G.; Merrylin, J.; Kumar, S.A.; Dharmadhas, J.S.; Varjani, S.; Banu, J.R. Current advances and future outlook on pretreatment techniques to enhance biosolids disintegration and anaerobic digestion: A critical review. Chemosphere 2022, 288, 132553. [Google Scholar] [CrossRef]

- Garuti, M.; Sinisgalli, E.; Soldano, M.; Fermoso, F.G.; Rodriguez, A.J.; Carnevale, M.; Gallucci, F. Mechanical pretreatments of different agri-based feedstock in full-scale biogas plants under real operational conditions. Biomass Bioenergy 2022, 158, 106352. [Google Scholar] [CrossRef]

- Al-Da’asen, A.; Al-Harahsheh, A.; Al-Hwaiti, M.; Irshaid Irshaid, F. Biogas production via anaerobic codigestion of chemically treated wheat straw with sewage sludge or cow manure. Biomass Convers. Biorefin. 2024, 14, 5505–5516. [Google Scholar] [CrossRef]

- SDGR. The Sustainable Development Goals Report; The United Nations Statistics Division: New York, NY, USA, 2025. [Google Scholar]

- Al Husban, W. The Impact of Integrating Sustainable Development Goals on Students’ Awareness and Pro-Environmental Behavior: A Case Study of Jordan. Sustainability 2025, 17, 2588. [Google Scholar] [CrossRef]

- Isenkul, M.E.; Güneş-Durak, S.; Kocak, Y.P.; Pir, İ.; Tüfekci, M.; Demirkol, G.T.; Sevgen, S.; Çığgın, A.S.; Tüfekci, N. Predicting biogas production in real scale anaerobic digester under dynamic conditions with machine learning approach. Environ. Res. Commun. 2025, 7, 65016. [Google Scholar] [CrossRef]

- Ashraf, M.T.; Sieborg, M.U.; Yde, L.; Rhee, C.; Shin, S.G.; Triolo, J.M. Biomethanation in a thermophilic biotrickling filter—pH control and lessons from long-term operation. Bioresour. Technol. Rep. 2020, 11, 100525. [Google Scholar] [CrossRef]

- Shroff, K.C.; Shah, N.G. Prediction Modelling to Enhance Anaerobic Co-digestion Process of OFMSW and Bio-flocculated Sludge Using ANN. Pollution 2024, 10, 481–494. [Google Scholar]

- Ling, J.Y.X.; Chan, Y.J.; Chen, J.W.; Chong, D.J.S.; Tan, A.L.L.; Arumugasamy, S.K.; Lau, P.L. Machine learning methods for the modelling and optimisation of biogas production from anaerobic digestion: A review. Environ. Sci. Pollut. Res. 2024, 31, 19085–19104. [Google Scholar] [CrossRef]

- Adeleke, O.; Olatunji, K.O.; Madyira, D.M.; Jen, T.-C. Application of multimodal machine learning-based analysis for the biomethane yields of NaOH-pretreated biomass. Sci. Rep. 2025, 15, 24372. [Google Scholar] [CrossRef]

- Maruejols, L.; Höschle, L.; Yu, X. Energy independence, rural sustainability and potential of bioenergy villages in Germany: Machine learning perspectives. Int. Food Agribus. Manag. Rev. 2025, 1, 1–33. [Google Scholar] [CrossRef]

- Rice, E.W.; Bridgewater, L.; Association, A.P.H. Standard Methods for the Examination of Water and Wastewater; American Public Health Association: Washington, DC, USA, 2012; Volume 10. [Google Scholar]

- Jafari-Sejahrood, A.; Najafi, B.; Faizollahzadeh Ardabili, S.; Shamshirband, S.; Mosavi, A.; Chau, K. Limiting factors for biogas production from cow manure: Energo-environmental approach. Engineering Appl. Comput. Fluid Mech. 2019, 13, 954–966. [Google Scholar] [CrossRef]

- IPCC. Climate Change 2023: Synthesis Report; Intergovernmental Panel on Climate Change (IPCC): Geneva, Switzerland, 2023. [Google Scholar]

- Alharbi, H.S. Efficient Swell Risk Prediction for Building Design Using a Domain-Guided Machine Learning Model. Buildings 2025, 15, 2530. [Google Scholar] [CrossRef]

- Ibrahim, A.F.; Hussein, M.A. Leveraging machine learning for prediction and optimization of texture properties of sustainable activated carbon derived from waste materials. Sci. Rep. 2025, 15, 11313. [Google Scholar] [CrossRef] [PubMed]

- Habchi, S.; El Bari, H. Optimization study using response surface methodology and artificial neural networks on the co-digestion of food waste and poultry slaughterhouse waste, with hydrochar as an effective enhancer. Bioresour. Technol. Rep. 2025, 29, 102061. [Google Scholar] [CrossRef]

- Sherstinsky, A. Fundamentals of recurrent neural network (RNN) and long short-term memory (LSTM) network. Phys. D Nonlinear Phenom. 2020, 404, 132306. [Google Scholar] [CrossRef]

- Ahmed, D.; Wagdy, R.; Said, N. Evaluation of biogas production from anaerobic co-digestion of sewage sludge with microalgae and agriculture wastes. BioResources 2019, 14, 8405–8412. [Google Scholar] [CrossRef]

- Hamzah, N.; Tokimatsu, K.; Yoshikawa, K. Solid fuel from oil palm biomass residues and municipal solid waste by hydrothermal treatment for electrical power generation in Malaysia: A review. Sustainability 2019, 11, 1060. [Google Scholar] [CrossRef]

- Gallegos, D.; Wedwitschka, H.; Moeller, L.; Zehnsdorf, A.; Stinner, W. Effect of particle size reduction and ensiling fermentation on biogas formation and silage quality of wheat straw. Bioresour. Technol. 2017, 245, 216–224. [Google Scholar] [CrossRef]

- Dai, X.; Hua, Y.; Dai, L.; Cai, C. Particle size reduction of rice straw enhances methane production under anaerobic digestion. Bioresour. Technol. 2019, 293, 122043. [Google Scholar] [CrossRef] [PubMed]

- Turek, A.; Wieczorek, K.; Wolf, W.M. Digestion procedure and determination of heavy metals in sewage sludge—An analytical problem. Sustainability 2019, 11, 1753. [Google Scholar] [CrossRef]

- Kitessa, W.M.; Fufa, F.; Abera, D. Biogas Production and Biofertilizer Estimation from Anaerobic Co-Digestion of Blends of Wastewater and Microalgae. Int. J. Chem. Eng. 2022, 2022, 3560068. [Google Scholar] [CrossRef]

- Hu, Y.; Ma, P.; Yang, Z.; Liu, S.; Li, Y.; Li, L.; Wang, T.; Siddique, K.H.M. The responses of crop yield and greenhouse gas emissions to straw returning from staple crops: A meta-analysis. Agriculture 2025, 15, 408. [Google Scholar] [CrossRef]

| Digester | D1 | D2 | D3 | D4 | D5 | D6 | D7 | D8 | D9 | D10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Sludge mass (kg) | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 |

| Straw ratio (%) | 0.0 | 0.5 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | 1.5 | 1.5 | 1.5 |

| Straw particle size | – | 5 cm | 1 cm | <2 mm | 5 cm | 1 cm | <2 mm | 5 cm | 1 cm | <2 mm |

| Parameters | Sludge | Straw | Sludge + 0.5% Straw | Sludge + 1% Straw | Sludge + 1.5% Straw |

|---|---|---|---|---|---|

| TS (%) | 1.41 | 92.80 | 1.98 | 2.30 | 3.10 |

| TVS (%) | 0.99 | 75.60 | 1.01 | 1.70 | 2.30 |

| COD (g/L) | 20.00 | ND | 24.00 | 29.00 | 33.00 |

| pH | 7.00 | 6.20 | 6.90 | 6.85 | 6.77 |

| C (% TS) | 30.20 | 48.90 | 16.33 | 22.90 | 29.02 |

| N (% TS) | 4.50 | 0.60 | 1.66 | 1.74 | 1.81 |

| C/N | 6.71 | 81.50 | 9.86 | 13.19 | 16.02 |

| The Structure of the RNN Model | Activation Function of the Hidden Layer’s | Error | Training Algorithm | ||

|---|---|---|---|---|---|

| Trainlm | Trainscg | Trainbr | |||

| (3–13–1) | tansig | RMSE | 0.0064 | 0.0267 | 0.0038 |

| radbas | RMSE | 1.1291 | 1.5249 | 1.3144 | |

| tribas | RMSE | 1.0481 | 1.8775 | 9.3391 | |

| Model | Error | # of Neuron | ||||

|---|---|---|---|---|---|---|

| 3 | 5 | 10 | 13 | 15 | ||

| RNN model | RMSE | 0.0355 | 0.0082 | 0.0051 | 0.0038 | 0.0142 |

| R2 | 0.9973 | 0.9997 | 0.9999 | 1.0000 | 0.9999 | |

| MAE | 0.0957 | 0.0288 | 0.0134 | 0.0093 | 0.0121 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alrowais, R.; Abdel-Daiem, M.M.; Nasef, B.M.; Metwally, A.A.; Said, N. Sustainable Management of Wastewater Sludge Through Co-Digestion, Mechanical Pretreatment and Recurrent Neural Network (RNN) Modeling. Sustainability 2025, 17, 9323. https://doi.org/10.3390/su17209323

Alrowais R, Abdel-Daiem MM, Nasef BM, Metwally AA, Said N. Sustainable Management of Wastewater Sludge Through Co-Digestion, Mechanical Pretreatment and Recurrent Neural Network (RNN) Modeling. Sustainability. 2025; 17(20):9323. https://doi.org/10.3390/su17209323

Chicago/Turabian StyleAlrowais, Raid, Mahmoud M. Abdel-Daiem, Basheer M. Nasef, Amany A. Metwally, and Noha Said. 2025. "Sustainable Management of Wastewater Sludge Through Co-Digestion, Mechanical Pretreatment and Recurrent Neural Network (RNN) Modeling" Sustainability 17, no. 20: 9323. https://doi.org/10.3390/su17209323

APA StyleAlrowais, R., Abdel-Daiem, M. M., Nasef, B. M., Metwally, A. A., & Said, N. (2025). Sustainable Management of Wastewater Sludge Through Co-Digestion, Mechanical Pretreatment and Recurrent Neural Network (RNN) Modeling. Sustainability, 17(20), 9323. https://doi.org/10.3390/su17209323