Exploring the Sustainable Development Strategy of Wood Flour-Based Composite Materials in Outdoor Furniture

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Raw Materials

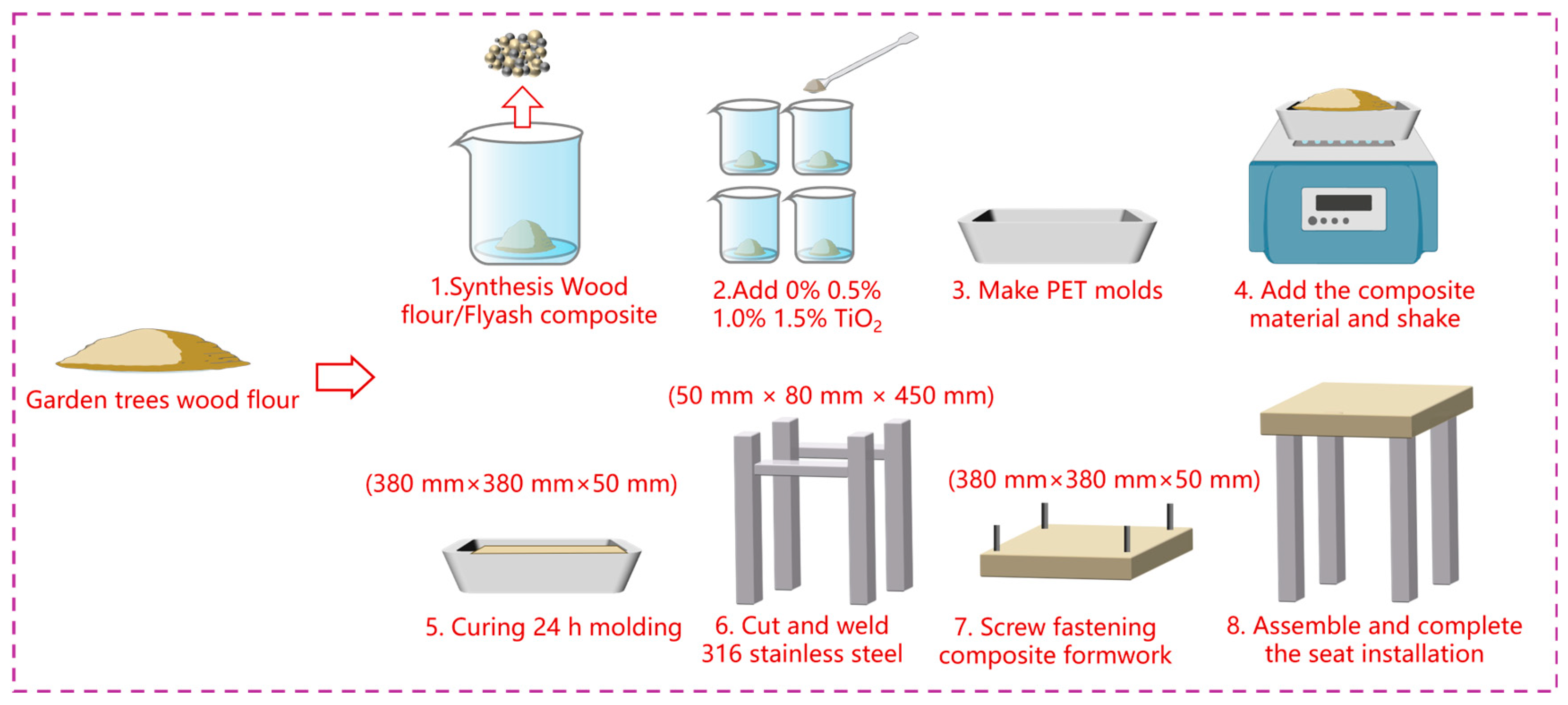

2.2. Preparation of Wood Flour-Based Composite Materials

2.2.1. Pretreatment of Fly Ash

2.2.2. Preparation of Wood Flour–Fly Ash-TiO2

2.3. Material Analysis

3. Results and Discussion

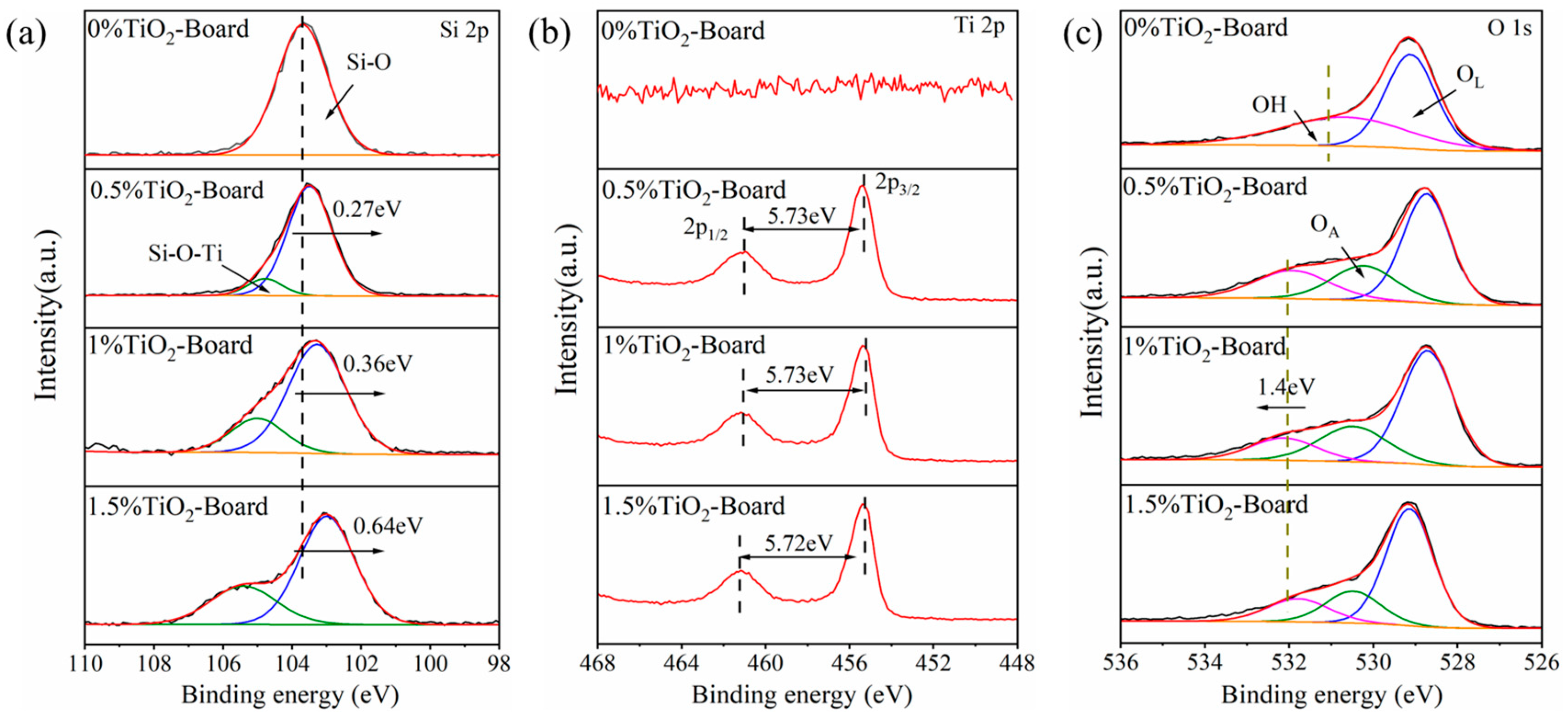

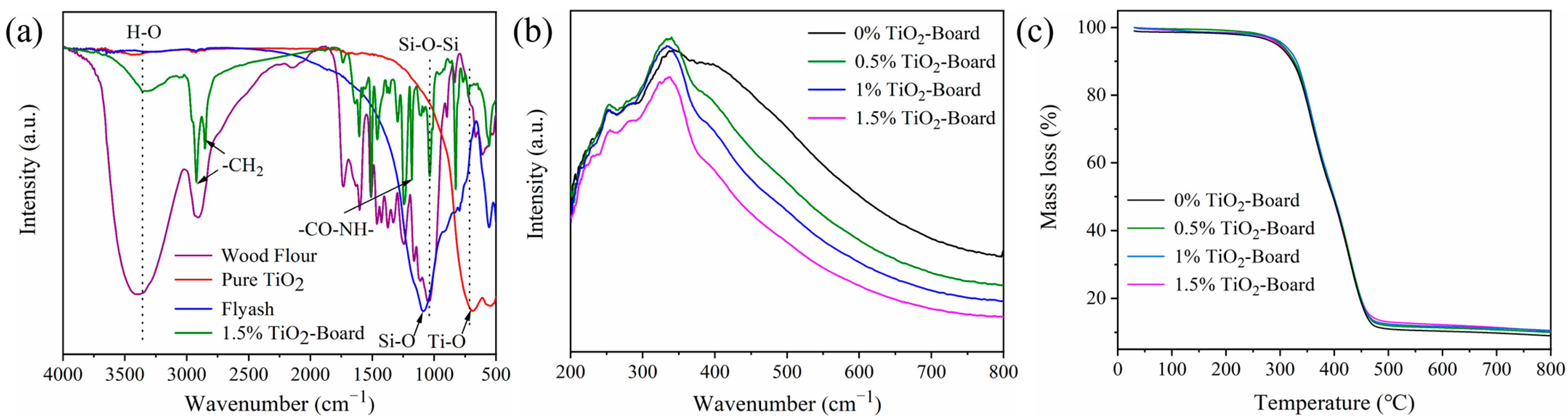

3.1. Analysis of Structure and Performance of Wood Flour-Based Composite Materials

3.2. The Application of Wood Powder-Based Composites in the Design of Outdoor Garden Benches

3.2.1. Design Analysis

- (1)

- Seat design:

- (2)

- Seat leg design:

- (3)

- Connection method:

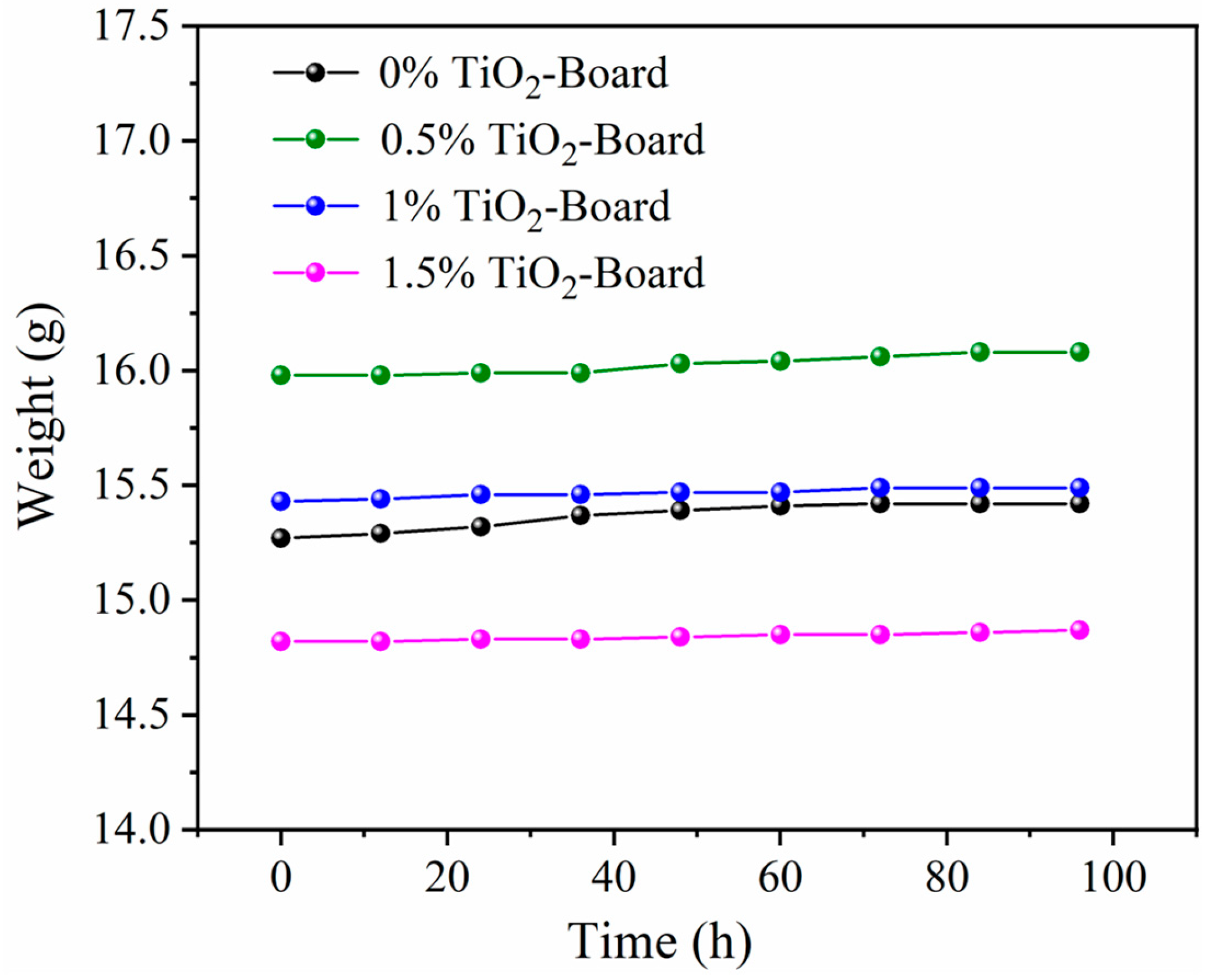

3.2.2. Seat Performance Analysis

- (1)

- Stability Test

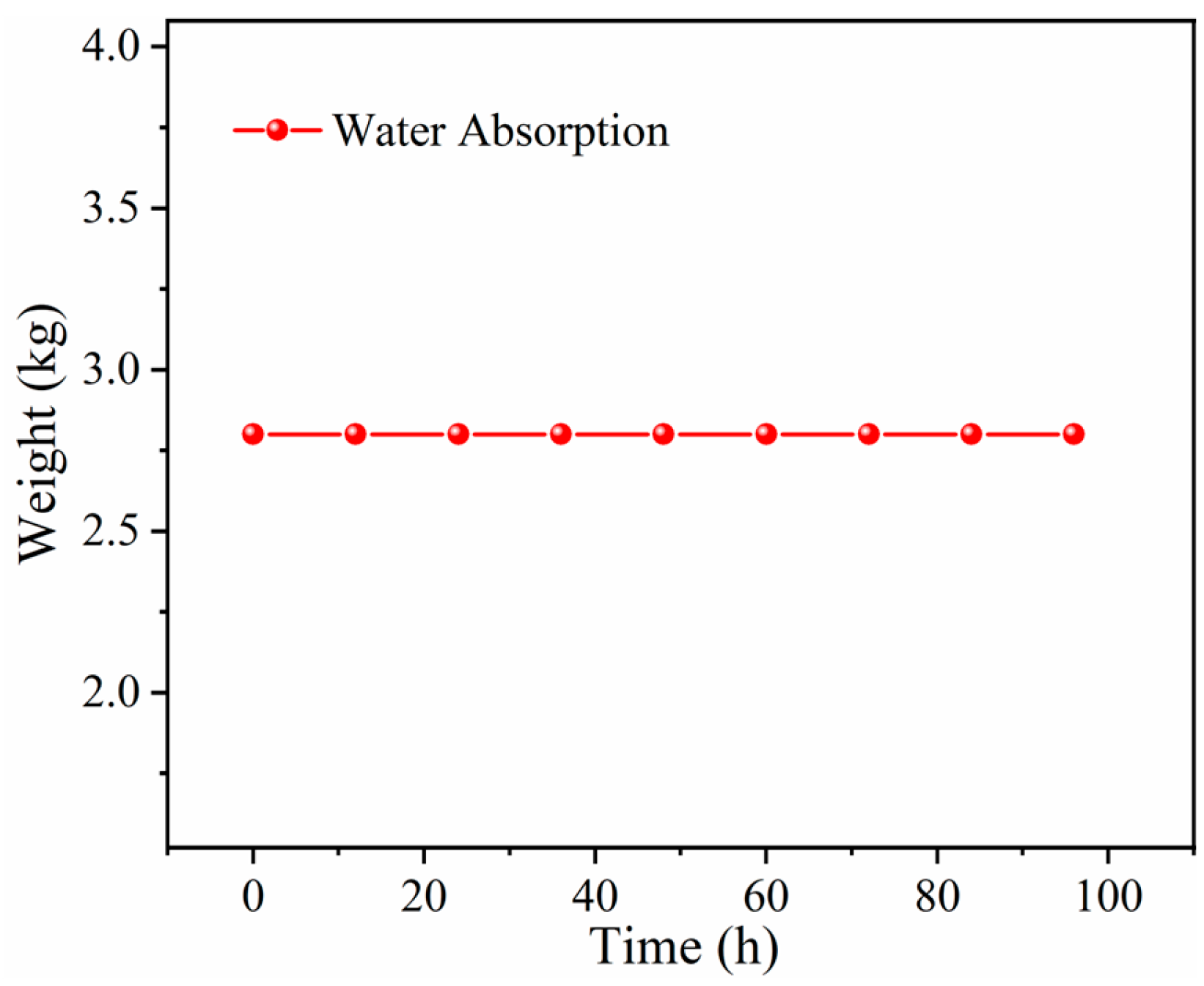

- (2)

- Safety Performance Test—Harmful Substance Detection

4. Conclusions

- (1)

- Structural strength and stability: Mechanical Strength: Scanning electron microscopy (SEM) and X-ray photoelectron spectroscopy (XPS) tests revealed that the composite material exhibited exceptional performance across all criteria when the TiO2 content reached 1.5%. As the TiO2 content increased to 1.5%, more stable Si-O-Si and Si-O-Ti bonds were formed, enhancing the material’s structural strength and dimensional stability.

- (2)

- UV Resistance and hydrophobicity: As the amount of TiO2 added increased, a large amount of reactive free radicals (OA) were generated and the free -OH groups in the composite material decreased, effectively improving the UV resistance and moisture penetration inhibition of composite materials. The surface water contact angle gradually increased, reaching 100.6° for the 1.5% TiO2-Board, significantly improving its hydrophobicity. This enhanced waterproof characteristic will increase the application potential of outdoor seating in humid and rainy environments.

- (3)

- Application in furniture design: The 1.5% TiO2 composite demonstrated optimal performance in strength, UV resistance, and hydrophobicity, validating its suitability for outdoor furniture and enabling its use for the design of outdoor chairs. Actual testing demonstrated excellent structural stability and waterproof performance. Moreover, safety testing confirmed that the chair’s formaldehyde and phthalate emissions met national safety standards, ensuring its environmental safety for outdoor use.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alam, M.M.; Greco, A.; Rajabimashhadi, Z.; Corcione, C.E. Efficient and environmentally friendly techniques for lignocellulosic biomass processing. Clean. Mater. 2024, 13, 100253. [Google Scholar] [CrossRef]

- Upton, B.M.; Kasko, A. Biomass-Derived Poly(ether-amide)s Incorporating Hydroxycinnamates. Biomacromolecules 2019, 20, 758–766. [Google Scholar] [CrossRef] [PubMed]

- Ralph, J.; Lapierre, C.; Boerjan, W. Lignin structure and its engineering. Curr. Opin. Biotechnol. 2019, 56, 240–249. [Google Scholar] [CrossRef] [PubMed]

- Gioia, C.; Colonna, M.; Tagami, A.; Medina, L.; Sevastyanova, O.; Berglund, L.A.; Lawoko, M. Lignin-Based Epoxy Resins: Unravelling the Relationship between Structure and Material Properties. Biomacromolecules 2020, 21, 1920–1928. [Google Scholar] [CrossRef]

- Li, J.M.; Zhang, Z.Y.; Zhang, Y.; Sun, F.L.; Wang, D.Y.; Wang, H.; Jin, Z.F. Synergistic effect of lignin and ethylene glycol crosslinked epoxy resin on enhancing thermal, mechanical and shape memory performance. Int. J. Biol. Macromol. 2021, 192, 516–524. [Google Scholar] [CrossRef]

- Zhang, W.L.; Qiu, X.Q.; Wang, C.W.; Zhong, L.; Fu, F.B.; Zhu, J.H.; Zhang, Z.J.; Qin, Y.L.; Yang, D.J.; Xu, C.C. Lignin derived carbon materials: Current status and future trends. Carbon Res. 2022, 1, 14. [Google Scholar] [CrossRef]

- Camargos, H.M.C.; Yang, L.; Jackson, J.C.; Tanganini, I.C.; Francisco, K.R.; Ceccato-Antonini, S.R.; Rezende, C.A.; Faria, A.F. Lignin and Nanolignin: Next-Generation Sustainable Materials for Water Treatment. ACS Appl. Bio Mater. 2025, 8, 2632–2673. [Google Scholar] [CrossRef]

- Suvanjumrat, C.; Chansoda, K.; Chookaew, W. Additive manufacturing advancement through large-scale screw-extrusion 3D printing for precision parawood powder/PLA furniture production. Clean. Eng. Technol. 2024, 20, 100753. [Google Scholar] [CrossRef]

- Candelier, K.; Thevenon, M.F.; Petrissans, A.; Dumarcay, S.; Gerardin, P.; Petrissans, M. Control of wood thermal treatment and its effects on decay resistance: A review. Ann. For. Sci. 2016, 73, 571–583. [Google Scholar] [CrossRef]

- Fan, Y.F.; Zhu, Z.Q.; Luan, J.C.; Liu, Y. Exploring the Application Method of Bamboo Powder in Promoting the Development of Sustainable Outdoor Furniture. Sustainability 2024, 16, 11282. [Google Scholar] [CrossRef]

- Ditommaso, G.; Gaff, M.; Kačík, F.; Sikora, A.; Sethy, A.; Corleto, R.; Razaei, F.; Kaplan, L.; Kubš, J.; Das, S.; et al. Interaction of technical and technological factors on qualitative and energy/ecological/economic indicators in the production and processing of thermally modified merbau wood. J. Clean. Prod. 2020, 252, 119793. [Google Scholar] [CrossRef]

- Zhang, N.; Mao, Y.Q.; Wu, S.S.; Xu, W. Effects of the ball milling process on the particle size of graphene oxide and its application in enhancing the thermal conductivity of wood. Forests 2022, 13, 1325. [Google Scholar] [CrossRef]

- Zelinka, S.L.; Altgen, M.; Emmerich, L.; Guigo, N.; Keplinger, T.; Kymäläinen, M.; Thybring, E.E.; Thygesen, L.G. Review of Wood Modification and Wood Functionalization Technologies. Forests 2022, 13, 1004. [Google Scholar] [CrossRef]

- Hill, C.; Altgen, M.; Rautkari, L. Thermal modification of wood—a review: Chemical changes and hygroscopicity. J. Mater. Sci. 2021, 56, 6581–6614. [Google Scholar] [CrossRef]

- Donath, S.; Militz, H.; Mai, C. Wood modification with alkoxysilanes. Wood Sci. Technol. 2004, 38, 555–566. [Google Scholar] [CrossRef]

- Mosadeghzada, Z.; Ahmad, I.; Daika, R.; Ramli, A.; Jajaludin, Z. Preparation and properties of acacia sawdust/UPR composite based on recycled PET. Malays. Polym. J. 2009, 4, 30–41. [Google Scholar]

- Novosel, A.; Sedlar, T.; Čizmar, D.; Turkulin, H.; Živković, V. Structural reinforcement of bi-directional oak-wood lamination by carbon fibre implants. Constr. Build. Mater. 2021, 287, 123073. [Google Scholar] [CrossRef]

- Mathapati, M.; Amate, K.; Prasad, C.D.; Jayavardhana, M.L.; Raju, T.H. A review on fly ash utilization. Mater. Today Proc. 2022, 50, 1535–1540. [Google Scholar] [CrossRef]

- Zygmunt-Kowalska, B.; Pielichowska, K.; Trestka, P.; Ziąbka, M.; Kuźnia, M. The effect of ash silanization on the selected properties of rigid polyurethane foam/coal fly ash composites. Energies 2022, 15, 2014. [Google Scholar] [CrossRef]

- Nayl, A.A.; Abd-Elhamid, A.I.; Aly, A.A.; Bräse, S. Recent progress in the applications of silica-based nanoparticles. RSC. Adv. 2022, 12, 13706–13726. [Google Scholar] [CrossRef]

- Cao, M.T.; Tang, M.W.; Lin, W.S.; Ding, Z.H.; Cai, S.; Chen, H.X.; Zhang, X.X. Facile Fabrication of Fluorine-Free, Anti-Icing, and Multifunctional Superhydrophobic Surface on Wood Substrates. Polymers 2022, 14, 1953. [Google Scholar] [CrossRef] [PubMed]

- Petrillo, M.; Sandak, J.; Grossi, P.; Sandak, A. Chemical and appearance changes of wood due to artificial weathering—Dose–response model. J. Near Infrared Spec. 2019, 27, 26–37. [Google Scholar] [CrossRef]

- Carvalho, P.G.; Naveira, R.I.; Granone, L.I.; Mendive, C.B.; Massa, A.E.; Churio, M.S. A comparative review of natural and synthetic UV filters: Gadusol and benzophenone-3 as representative examples. Environ. Adv. 2023, 13, 100404. [Google Scholar] [CrossRef]

- Racovita, A.D. Titanium dioxide: Structure, impact, and toxicity. Int. J. Environ. Res. Public Health 2022, 19, 5681. [Google Scholar] [CrossRef]

- Cole, C.; Shyr, T.; Ou-Yang, H. Metal oxide sunscreens protect skin by absorption, not by reflection or scattering. Photodermatol. Photoimmunol. Photomed. 2016, 32, 5–10. [Google Scholar] [CrossRef]

- Kaur, R.; Bhardwaj, S.K.; Chandna, S.; Kim, K.H.; Bhaumik, J. Lignin-based metal oxide nanocomposites for UV protection applications: A review. J. Clean. Prod. 2021, 317, 128300. [Google Scholar] [CrossRef]

- Pánek, M.; Šimůnková, K.; Novák, D.; Dvořák, O.; Schönfelder, O.; Šedivka, P.; Kobetičová, K. Caffeine and TiO2 Nanoparticles Treatment of Spruce and Beech Wood for Increasing Transparent Coating Resistance against UV-Radiation and Mould Attacks. Coatings 2020, 10, 1141. [Google Scholar] [CrossRef]

- Ghamarpoor, R.; Fallah, A.; Jamshidi, M. Investigating the use of titanium dioxide (TiO2) nanoparticles on the amount of protection against UV irradiation. Sci. Rep. 2023, 13, 9793. [Google Scholar] [CrossRef]

- Bulcha, B.; Tesfaye, J.L.; Anatol, D.; Shanmugam, R.; Dwarampudi, L.P.; Nagaprasad, N.; Bhargavi, V.L.N.; Krishnaraj, R. Synthesis of zinc oxide nanoparticles by hydrothermal methods and spectroscopic investigation of ultraviolet radiation protective properties. J. Nanomater. 2021, 2021, 8617290. [Google Scholar] [CrossRef]

- Sivakumar, K.; Nalini, A. Benzophenone type UVR filters for various materials: A review. J. Mol. Liq. 2024, 395, 123905. [Google Scholar] [CrossRef]

- Grätzel, M. Photoelectrochemical cells. Nature 2001, 414, 338–344. [Google Scholar] [CrossRef]

- Asahi, R.; Morikawa, T.; Ohwaki, T.; Aoki, K.; Taga, Y. Visible-light photocatalysis in nitrogen-doped titanium oxides. Science 2001, 293, 269–271. [Google Scholar] [CrossRef]

- Khan, S.U.M.; Al-Shahry, M.; Ingler, J.W.B. Efficient Photochemical Water Splitting by a Chemically Modified n-TiO2. Science 2002, 297, 2243–2245. [Google Scholar] [CrossRef] [PubMed]

- Jin, Q.J.; Shen, Y.S.; Sui, G.R.; Tao, X.J.; Pan, Y.C.; Zhu, S.M. Synergistic catalytic removals of NO, CO and HC over CeO2 modified Mn-Mo-W-Ox/TiO2-SiO2 catalyst. J. Rare Earths 2018, 36, 148–155. [Google Scholar] [CrossRef]

- Qin, J.T.; Li, J.; Liu, F.Y.; Zhang, Z.L.; Jiang, L.X. Improving the Electrochemical Stability of TiMn2 Middle-Layer for Oxygen Evolution Anode in Sulfuric Acid Solution by High-Temperature Nitriding. Adv. Sustain. Syst. 2024, 8, 2400061. [Google Scholar] [CrossRef]

- Yang, J.Y.; Dai, J.F.; Liu, X.H.; Fu, S.Y.; Zong, E.M.; Song, P.A. A lignin-based epoxy/TiO2 hybrid nanoparticle for multifunctional bio-based epoxy with improved mechanical, UV absorption and antibacterial properties. Int. J. Biol. Macromol. 2022, 210, 85–93. [Google Scholar] [CrossRef]

- Wei, W.; Howard-Reed, C.; Persily, A.; Zhang, Y. Standard Formaldehyde Source for Chamber Testing of Material Emissions: Model Development, Experimental Evaluation, and Impacts of Environmental Factors. J. Environ. Sci. Technol. 2013, 47, 14. [Google Scholar] [CrossRef]

- Silva, M.J.; Reidy, J.A.; Samandar, E.; Herbert, A.R.; Needham, L.L.; Calafat, A.M. Detection of phthalate metabolites in human saliva. Arch. Toxicol. 2005, 79, 647–652. [Google Scholar] [CrossRef]

- Rizwan, V.; Ibrahim, S.M.; Zaheer, M.M. Explainable artificial intelligence-based compressive strength optimization and Life-Cycle Assessment of eco-friendly sugarcane bagasse ash concrete. Environ. Sci. Pollut. Res. 2025, 32, 6922–6947. [Google Scholar] [CrossRef]

| Materials | Fly Ash | Wood Flour | TiO2 | Epoxy Resin | Polyamide |

|---|---|---|---|---|---|

| 0% TiO2 | 3 g | 8 g | 0% wt | 22 g | 5 g |

| 0.5% TiO2 | 3 g | 8 g | 0.5% wt | 22 g | 5 g |

| 1.0% TiO2 | 3 g | 8 g | 1.0% wt | 22 g | 5 g |

| 1.5% TiO2 | 3 g | 8 g | 1.5% wt | 22 g | 5 g |

| Experiment | Length (mm) | Width (mm) | Height (mm) |

|---|---|---|---|

| 0 h | 380 | 380 | 500 |

| 12 h | 380 | 380 | 500 |

| 24 h | 380 | 380 | 500 |

| 36 h | 380 | 380 | 500 |

| 48 h | 380 | 380 | 500 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, H.; Gao, Y.; Zhang, K. Exploring the Sustainable Development Strategy of Wood Flour-Based Composite Materials in Outdoor Furniture. Sustainability 2025, 17, 9235. https://doi.org/10.3390/su17209235

Zhou H, Gao Y, Zhang K. Exploring the Sustainable Development Strategy of Wood Flour-Based Composite Materials in Outdoor Furniture. Sustainability. 2025; 17(20):9235. https://doi.org/10.3390/su17209235

Chicago/Turabian StyleZhou, Huidi, Yuqi Gao, and Kaili Zhang. 2025. "Exploring the Sustainable Development Strategy of Wood Flour-Based Composite Materials in Outdoor Furniture" Sustainability 17, no. 20: 9235. https://doi.org/10.3390/su17209235

APA StyleZhou, H., Gao, Y., & Zhang, K. (2025). Exploring the Sustainable Development Strategy of Wood Flour-Based Composite Materials in Outdoor Furniture. Sustainability, 17(20), 9235. https://doi.org/10.3390/su17209235