Abstract

This study explores a conceptual framework for integrating Artificial Intelligence (AI) into Enterprise Resource Planning (ERP) systems, emphasising its transformative potential in highly automated industrial environments, often referred to as ‘dark factories’, where operations are carried out with minimal human intervention using robotics, AI, and IoT. These lights-out manufacturing environments demand intelligent, autonomous systems that go beyond traditional ERP functionalities to deliver sustainable enterprise operations and supply chain management. Drawing from secondary data and a comprehensive review of existing literature, the study identifies significant gaps in current AI-ERP research and practice, namely, the absence of a unified adoption framework, limited focus on AI-specific implementation challenges, and a lack of structured post-adoption evaluation metrics. In response, this paper proposes a novel integrated conceptual framework that combines the Technology–Organisation–Environment (TOE) framework, the Technology Acceptance Model (TAM), and the Information Systems (IS) Success Model. The model incorporates industry-specific dark factors, such as AI autonomy, human–machine collaboration, operational agility, and sustainability, by optimising resource efficiency, enabling predictive maintenance, enhancing supply chain resilience, and supporting circular economy practices. The primary research aim of the current study is to provide a theoretical foundation for further empirical research on the input of AI-ERP systems into autonomous industry settings. The framework provides a robust theoretical foundation and actionable guidance for researchers, technology leaders, and policy-makers navigating the integration of AI and ERP in sustainable enterprise operations and supply chain management.

1. Introduction

The rapid growth of the digital economy has heightened the need for intelligent business systems that can effectively address the increasing complexity of business processes [1]. AI has come a long way since it was a novelty, a futuristic idea rather than a revolution that transforms the way companies work within the framework of financial, manufacturing, logistics, and healthcare industries [2]. The same can be said about ERP systems, which were initially designed to centralise and streamline data transfer, are now being modified to become independent, AI-assisted platforms that provide increased efficiency, decision-making capabilities, and operational flexibility [3]. ERP systems are end-to-end software designed to integrate all business functions on a single platform, encompassing finance, human resources, supply chain management, and customer relationships [4]. They offer a comprehensive platform to store and manage information and processes, thereby assisting organisations in enhancing productivity, ensuring data consistency, reducing operational costs, and facilitating collaboration among departments [5].

Sustainability has now entered the system-level design constraint of the operation of enterprises, as opposed to being a target to meet [6]. The supply chain bottlenecks associated with this approach include energy intensity, material loss, variability-related waste, and transportation-generated carbon waste [7]. Researchers point out that AI-enabled ERP is the most appropriate backing to coordinate sustainability at scale to cover procurement, production planning, quality, distribution and returns in dark-factory environments where sensing, robotics and advanced analytics are in continuous operation [8]. AI-ERP can optimise recipes and schedules to lower energy and scrap, introduce predictive maintenance to extend the life of assets, reduce transport miles through dynamic network construction and load pooling, and enable circular flows where materials are tracked to repair, remanufacture and recycle [9]. Presenting AI-ERP in such a way automatically applies the problem of the research to the sphere of sustainable enterprise operations and supply chain management [10,11].

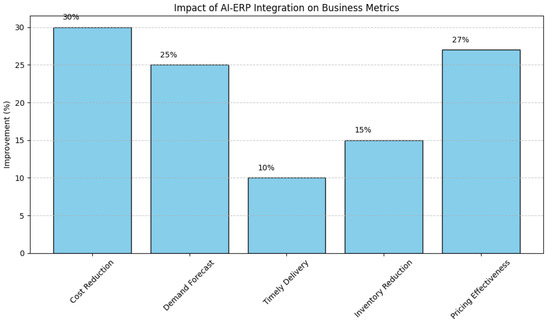

ERP systems leveraging AI can also enhance production management, strengthen supply chain resilience, and monitor material cycling to support recycling and reuse, aligning closely with circular economy principles [12,13]. Figure 1 shows that the latest investigations indicate that the adoption of AI-ERP can lead to a 30% reduction in operating costs for small and medium-sized enterprises (SMEs) or enhance demand forecasts by 15–35%, among other significant benefits [14]. Companies such as Unilever have already demonstrated concrete benefits, including a 10% improvement in the timely delivery of orders and a 15% reduction in inventory expenses, by utilising AI-powered ERP technologies [12]. In addition, real-time AI insights have improved financial decision-making, with companies noting a 27% increase in pricing effectiveness and a 33% increase in data accuracy [15]. Moreover, 62.5% of users of a Korean company reported an increase in the efficiency of their work process due to the integration of AI in ERP [16].

Figure 1.

Business Benefits from AI-ERP Integration. Percentage improvements in key operational metrics due to AI-ERP integration across global SMEs. Data derived from secondary literature and case reports [12,14,15].

Nevertheless, customary ERP has its drawbacks, including the complexity of its features and modules, hardware and software compatibility issues, and the inability to integrate and synchronise data [17,18] smoothly. The common adoption of infrastructure was missing, and there was a lack of attention to the implementation peculiarities of the AI space [19]. Moreover, there is a lack of comprehensive frameworks that focus on the AI-ERP adoption within the frame of sustainability. Since previous studies tend to overlook the interaction among technological preparedness, organisational adaptation, external pressure, and the consequences of post-adoption, the specificities of AI, such as algorithmic transparency, human–machine collaboration, or even the shortage of skills, are poorly explored in the existing literature on ERPs [17].

In order to address these gaps, this work will provide a proposed integrated conceptual framework, a synthesis of the TOE, the TAM and the IS Success Models with sustainability as a fundamental dimension. The structure was based on the autonomy of AI, interdisciplinary collaboration between humans and robots, and flexibility of operation in order to keep the most crucial environmental, economic, and social sustainability goals in sight. In order to direct this study, the following research questions are posed:

- What are the critical factors influencing the adoption of AI-ERP systems in dark factory settings?

- How can existing theoretical frameworks, such as TOE, TAM, and IS Success Models, be integrated to create a unified framework for AI-ERP adoption?

- What strategies can organisations implement to mitigate risks and enhance the stability and effectiveness of AI-ERP systems post-adoption?

By addressing these questions, the study’s primary goal is to provide a theoretical premise upon further empirical research related to the input of AI-ERP systems into an autonomous industry setting.

- To analyse the impact of AI on ERP functionalities in dark industry settings

- To synthesise TOE, TAM, and IS Success Models into an integrated framework for AI-ERP adoption

- To provide actionable strategies for organisations navigating AI-ERP implementation

This research work is both theoretical and practical in nature. Academically, it involves broadening the scope of existing frameworks to a complex and evolving technical environment. In practice, it provides a guideline to organisations on how to reduce risks, enhance system performance, and align the intended AI-ERP adoption with their strategic intentions. Although this framework was primarily based on advanced manufacturing settings, it can also be applied to other industries, such as healthcare and retail, where success increasingly depends on AI-driven ERP systems.

2. Literature Review

2.1. Overview of Previous Studies

Current trends suggest that incorporating AI into ERP systems is a significant driving force for improved operations, informed decision-making based on data, and enhanced competitiveness [20,21]. However, despite the valuable theoretical knowledge, the literature on highly automated systems (i.e., dark factories) underrepresents the practical applications of AI-ERP. To address this gap, the section presents real-life case scenarios and examples that demonstrate the groundbreaking nature of AI-ERP systems in these environments.

In addition, Unilever has been demonstrating the impact of AI-driven ERP systems in its intelligent factories. Implementing a predictive analytics system and automation based on AI enabled Unilever to decrease the number of timely order deliveries by 10% and reduce inventory costs by 15% [22]. On the same note, Siemens Amberg Electronics Plant, which is widely regarded as an example of Industry 4.0 practices, applies AI-ERP to plan production timetables, minimise power usage, and strengthen the supply chain [23]. The above instances underscore the ability of AI-ERP systems to provide quantifiable business at the dark factory.

The ERP systems that helped Foxconn organise the lights-out production plants and use robotics and IoT to perform most tasks without human intervention are also another striking example. Adopting AI-ERP has empowered Foxconn to perform predictive maintenance (saves 20% downtime), as well as enhance material tracking to facilitate the practice of the circular economy [24]. The presented case examples provide support for the implementation of AI-ERP within the context of sustainability, including resource efficiency and waste minimisation.

Additionally, an example of AI-ERP integration in a highly automated environment can be found at BMW’s Regensburg Plant. The bot will enhance operational agility, improve the transportation fleet, reduce carbon emissions, and maximise profit through the use of AI algorithms to optimise logistics [25]. Such practical applications demonstrate the importance of AI-ERP systems in achieving sustainability and operational efficiency in dark factories.

However, Ibrahim et al. propose that existing studies on AI are often based on standard theoretical frameworks that fail to recognise AIs’ special complexities, such as the presence of algorithmic bias, ethical considerations and the high cost of implementation [26]. Furthermore, Tornatzky and Fleischer’s [27] TOE Framework is widely used to assess readiness to adopt new technologies based on technological, organisational and environmental indicators. In addition, Awa and Ojiabo applied TOE while exploring ERP adoption in Nigerian organisations, where technological infrastructure and top management support play important roles in influencing the outcome [28]. Na et al. expand on their work by demonstrating how their research highlights the need to align internal capabilities with external pressures, such as compliance and competition [19]. However, they caution that companies with AI infrastructures can become overly complex, potentially creating obstaclesdue to stringent data privacy rules and security standards.

Using the Technology Acceptance Model (TAM), Chatterjee et al. observed that it is effective in predicting the adoption intent of AI-ERP [2]. Nevertheless, TAM does not focus on ethical issues, which are essential to establishing trust, including algorithmic transparency and fairness in interface design [17]. The IS Success Model also assesses performance following adoption using measures such as the quality of the system, accuracy of information, and satisfaction with the information [29]. According to William and Tjhin, having quality systems and accurate data is a key step in ensuring that AI-ERP deployments guarantee the maximum ROI. As Pokala notes, it is also important to establish continuous oversight and feedback to maintain long-term stability [30,31].

There have been promising efforts towards the integration of TOE, TAM and IS frameworks. The proposed framework of Jo and Bang offers predictive power across various organisations, having been applied comprehensively in ERP adoption [16]. Huong et al. applied this method to the finance industry and demonstrated that integrated models minimise the risks of implementation and maximise decision-making [32]. Na et al. used similar frameworks on construction companies and paid much attention to the importance of context and workers’ behaviour in the adoption of AI [19].

However, Al-Salti and Al-Momani still believe that integrated models have an insufficiently mentioned operational side [33]. Their study emphasises the importance of robust data practices, adaptable AI applications, and comprehensive employee training to optimise AI-ERP outcomes. This integrative approach is echoed by Jo and Bang, who argue that a holistic methodology is needed, as it differs from previous research works that have only examined specific dimensions of adoption without considering how they can be integrated with the system [2,16,28].

To study ERP adoption, Jo and Bang combined TOE, TAM, and IS to create a single model, demonstrating its predictive power across various organisations [16]. In addition, Huong et al. extended this approach to the finance sector to demonstrate how integrated models can reduce implementation risks and make optimal decision-making [33]. Na et al., meanwhile, applied explanatory frameworks to construction firms and considered the influence of contextual pressures and worker behaviour on AI adoption [19]. These studies suggest that general adjustments are needed for these industry sectors.

2.2. Challenges in AI-ERP Implementations in Industrial Sectors

AI-ERP faces significant challenges due to algorithmic bias, threats to data security, risks to employee adaptation, and the resulting impacts on system stability. Bias in the algorithm is the most common factor that leads to poor decisions; it may be systematic, such as the creation of an inefficient production schedule, or random, like an inefficient choice of inventory [13]. Bad AI applications can lead to inaccurate predictions in the distribution of activities and resources, thus interfering with supply chains [9]. In addition to accuracy, transparency, and regulatory compliance, recurring monitoring and retraining, as well as the use of explainable artificial intelligence (XAI) techniques, are inalienable [34].

There is another critical issue connected with data security. Artificial intelligence-tailored ERPs are highly susceptible to hacking, data loss, and cyberattacks, including ransomware [7]. Encryption, multi-factor authentication, periodic auditing, and real-time monitoring of deviations can be implemented in a way that addresses these risks [13]. No regulation should be disregarded (General Data Protection Regulation, GDPR, and the California Consumer Privacy Act, CCPA) because it would be punishable to face any fines and damage both the reputation and business [35].

The resistance of employees to using AI-ERP, stemming from concerns about job security or a lack of skills, is another source of risk [3]. The issue should be addressed through open communication, leadership development, rewards, and specialised training sessions [16,26]. The case of labour deficiency in automated industries highlights the need for an industry-academia relationship.

These risks, including algorithmic errors, data breaches, and staff resistance, may impact the business and hinder long-term performance, rendering systems less reliable [31]. Companies should invest in training, cybersecurity, change management, and cost-saving balancing [12]. Ongoing, continuously observed feedback systems and mechanisms are essential to adapting to new risks and achieving measurable results [14].

Proactive mitigation requires risk management measures, such as real-time performance monitoring and machine learning, which detect anomalies and facilitate cross-sector cooperation [16,26]. Legal and ethical factors, such as fairness, transparency, and accountability, must also be incorporated into the AI-ERP design to align with social values and regulations [7,13]. By considering such issues, the integration of AI-ERP systems is effective and sustainable.

2.3. Sustainability Contributions of AI-ERP in Dark-Factory Supply Chains

To achieve sustainability, previous research emphasises the importance of AI-ERP-based systems in promoting environmental, economic, and social aspects, thereby supporting current initiatives in sustainable enterprise activities and supply chain management [6]. One of the most significant areas of focus in the contemporary industrial setting is environmental sustainability; this is an area where organisational entities continue experiencing pressure to minimise their environmental impact. The optimisation using AI is a central factor in the realisation of this, as it can help optimise production, including reducing energy use and material waste [36]. Additionally, the AI-enabled predictive maintenance model can foresee malfunctions by assessing potential issues in advance, thereby reducing downtime and prolonging equipment lifespan, which helps conserve resources [7]. Moreover, AI-ERP technologies enable more efficient monitoring and control of materials, thereby supporting a more closed-loop approach that guides supply chains toward more sustainable activities through recycling and reuse [9]. Such abilities are not only used to improve performance in operations; they also establish organisations as being good custodians of the environment.

Another aspect in which AI-ERP systems are likely to show high potential is economic sustainability. These systems have been proven to assist organisations in minimising costs and maximising profitability by increasing supply chain transparency and resilience [8]. The optimisation of logistics processes by AI-ERP will result in reduced fuel usage in transportation processes and a minimal carbon footprint [10]. Also, with the help of real-time data analytics offered by AI-ERP systems, more demand could be predicted and thus prevent overproduction and related expenses [11]. Small- and medium-sized enterprises (SMEs) can particularly benefit from these economic advantages, which offer cost savings and improved efficiency, ultimately influencing their long-term viability and competitiveness.

Social sustainability is vital since AI-ERP systems enhance safer working conditions in highly automated workplace environments, such as dark factories. By reducing human exposure to hazardous work through mechanisation, the organisation helps to mitigate the symptoms of workplace injuries and improve the overall health of employees [3]. For instance, robotics and AI-driven systems can handle hazardous processes, such as heavy lifting or exposure to hazardous chemicals, thereby ensuring that human workers are not placed at risk [26]. Furthermore, AI-ERP frameworks enable a more profound understanding between humans and machines, and are reliable and flexible to integrate into the workforce [37]. This transition not only optimises the safety scene but also enables employees to focus on more significant activities, leading to increased job satisfaction and organisational morale.

By considering environmental, economic, and social aspects, the AI-ERP systems provide comprehensive coverage of sustainability. These systems not only optimise resource consumption and minimise waste but also improve the efficiency of the supply chain, lower costs, and create safer working environments. By incorporating sustainability into the main functions of artificial intelligence-based enterprise resource planning (AI-ERP) systems, organisations can make their business measurable and sustainable on a global scale, thereby achieving sustainability in businesses [36]. This strategy can reflect the potential of an AI-ERP to produce a more sustainable and resilient future across industries worldwide.

2.4. Theoretical Foundations

To investigate AI-ERP adoption in dark industry environments, this study draws on three well-established theoretical models: TOE, TAM, and the IS Success Model, each offering a unique lens for understanding different phases and dimensions of integration [16].

2.4.1. TOE Framework

The TOE framework was introduced by Tornatzky and Fleischer [27]. The TOE framework examines how an organisation’s technological capabilities, internal structure, and external environment influence the adoption of innovation. Awa and Ojiabo demonstrated the relevance of their work in ERP contexts, noting that cloud infrastructure, leadership alignment, and market pressures drive successful technology uptake [28]. However, it lacks focus on individual user behaviour and post-implementation success metrics, leaving gaps in understanding how employees interact with AI-driven systems and ensuring long-term operational efficiency [17].

2.4.2. TAM Framework

TAM was proposed by Davis [38]. TAM explains individual adoption behaviour based on perceived usefulness (PU) and perceived ease of use (PEOU). Chatterjee et al. and Jo and Bang confirmed that TAM is vital in determining ERP system acceptance, primarily when employees must interact with AI-driven interfaces [16,29]. While TAM addresses the human dimension, it does not capture organisational or environmental readiness, which are critical factors in highly automated settings, such as the dark industry [19].

2.4.3. IS Success Model

The IS Success Model was introduced by DeLone and McLean [29]. This model assesses system success across various dimensions, including system quality, information quality, service quality, user satisfaction, and net benefits. William and Tjhin validated the applicability of this model in AI-ERP environments, particularly for post-deployment analysis, highlighting its role in assessing operational efficiency and ROI [30]. However, ISSM does not guide pre-adoption conditions or user motivation, underscoring the need for a more comprehensive framework that addresses both planning and execution phases [32].

2.4.4. Integration of TOE, TAM, and IS Success Models

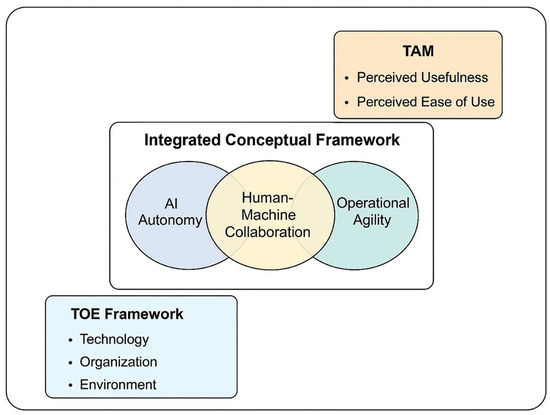

Although these models offer valuable insights individually, none comprehensively address the full AI-ERP lifecycle, particularly within dark industries where autonomy in technology, ethical AI, and dynamic feedback are critical [31]. Figure 2 illustrates that integrating TOE, TAM, and ISSM into a unified framework offers a more comprehensive understanding of adoption readiness, user engagement, and long-term success. This integrated approach enables organisations to address challenges such as data quality, algorithmic bias, cybersecurity risks, and employee resistance, while maximising the potential of AI-ERP systems [26].

Figure 2.

Integrated conceptual framework synthesising TOE, TAM, and IS Success Models to guide AI-ERP adoption, with emphasis on AI autonomy, human–machine collaboration, and operational agility in dark industry environments.

The success of AI-ERP system integration in industrial sectors can be rigorously assessed based on a well-established framework of performance indicators. Empirical metrics can be used to measure the quality of a system; these metrics include system uptime, speed, and scores on integration compatibility [39]. The level of user satisfaction can be measured through Likert-scale surveys, analysis of adoption rates, and employee retention rates [16]. Definite progress and efficiency in operation can be tracked by the changes in cycle time, the enhancement of production precision, waste minimisation, and reduction in costs [26]. Sustainability measures, such as the decrease in CO2 emissions and growth in the recycling rate of materials, can be another key performance metric in a dark-factory environment [7,13].

2.5. Research Hypotheses

The integrative concern of the TOE, TAM, and the model of IS Success, the following research propositions are supported:

H1:

Technological readiness positively influences the perceived usefulness and ease of use of AI-ERP systems (TAM).

H2:

Organisational readiness moderates the relationship between AI-ERP adoption and system success (TOE Framework).

H3:

Environmental pressures significantly impact AI-ERP adoption and effectiveness (TOE Framework).

H4:

Ethical considerations positively influence user acceptance and trust in AI-ERP systems (TAM).

H5:

Data security measures enhance the stability and effectiveness of AI-ERP systems post-adoption (IS Success Model).

H6:

Continuous feedback mechanisms improve the long-term performance of AI-ERP systems (IS Success Model).

2.6. Gaps in Existing Research

The application of AI-ERP is primarily studied in typical industries, with relatively little emphasis on highly autonomous settings, such as dark industries or lights-out manufacturing, which feature a significant dependency on robotics and AI [19]. The settings are novel and present distinct challenges, including real-time data integration, transparency of algorithms, and ethical concerns, which are often overlooked in the recent literature [16].

There is also a gap in the heterogeneous theoretical models applied to the study of the AI-ERP adoption. The current literature typically employs TOE, TAM, or ARE Success models, either independently or in a co-linear combination, in a manner that does not establish an integrating framework encompassing the complete AI-ERP lifecycle, i.e., from pre-adoption preparation to post-adoption assessment [33]. When using the TOE framework, one can assess technological, organisational, and environmental aspects; however, it is not possible to evaluate the behaviour of individual users or measure the success of the system, which is crucial for the thriving of the AI-ERP [17]. On the same note, TAM emphasises user acceptance and does not provide information on organisational fit and pressure of the environment [29].

Additionally, an effective feedback system following the implementation stage is conspicuously missing in the available frameworks. Independent factory settings require the repetition of feedback processes to control an AI-ERP system that evolves after implementation, responding to the new demands of the operational environment without human interference [31]. Such a limitation exposes the organisation to ineffective and inaccurate operations on a dynamic AI-ERP system [30].

Furthermore, existing literature is limited in outlining tools for measuring key attributes of a dark industry execution. For example, only a few previous studies have been conducted on measures related to AI transparency, general indicators of familiarity in human–machine relationships, or controls on tracking regarding rule adherence in confined production settings [9,34]. In addition, the aforementioned gaps highlight the necessity of providing empirical research on the specific assessment tools that should be utilised in the dark factory setting.

Moreover, the application and adoption of AI-ERP depend on geographical, industry, and cultural factors, including opposition to job loss in collectivist cultures and regulatory issues, including the GDPR [26,35]. Developing countries also face infrastructure deficiencies that must be addressed through training the workforce and establishing technology alliances [32]. However, post-implementation feedback systems are essential, and a real-time dashboard and an AI-based feedback portal allow sustained improvement [16]. The operational efficiency is guaranteed by predictive maintenance [12]. Examples of practical tools for creating a dark factory include metrics of AI transparency, user-machine cooperation measures through questionnaires [37], and the use of IoT/blockchain to verify compliance with specific rules [9,35].

Table 1 illustrates that the synergies between these models are an effective way to fill in the gaps in both literature and practice and offer practical data to guide businesses that have to work in complicated industries, such as the dark industry [19]. Such a holistic approach will ensure that AI-ERP systems are not only technically mature but also generally acceptable and able to provide a measure of business value [12].

Table 1.

Integrated Model Combining TOE, TAM, and IS Success for AI-ERP Implementation [19].

Although the impact of AI on implementing an ERP system, as well as adoption and usability, is not well-documented, some scholarly data exist to sufficiently describe its use and related outcomes of sustainability across the supply chains. Prior research has observed the optimisation of current resources and minimisation of waste. However, it seldom incorporates such consequences into an integrated adoption-to-impact logic that addresses context before adoption (TOE), behaviour of adoption (TAM), and after-adoption performance (IS Success) in dark-factory settings [6,36]. This study bridges the methodological gap and explains how AI-ERP is implemented by locating sustainability levers within a single TOE-TAM-IS structure, i.e., energy and material efficiency, predictive maintenance, logistics optimisation, and circular economy tracking [7,9].

3. Methodology

The proposed research is quantitative, based on simulated real-world indicators (i.e., robot density, AI adoption rates, sustainability metrics), and provides structural relationships through regression analyses written in the Google Colab (https://colab.research.google.com, accessed on 19 July 2025), an online platform for Python programming language. Additionally, regression analyses were conducted using libraries such as NumPy (version 1.26.4), pandas (version 2.2.2) and scikit-learn (version 1.5.1). The current research analysed the critical variables that contribute to the adoption and post-adoption success of AI-based ERP systems. Its methodology incorporates theoretical constructs from the TOE framework, the TAM, and the IS Success Model, in an attempt to gain a comprehensive understanding of the use of the AI-ERP system in highly automated environments [16,19].

A simulated scenario was developed using 200 firm-level data from an intensive technology sector over four years (2020–2023) [40]. The process of data generation occurred in a systematic manner, where the density of the robot population was provided as a normally distributed variable with a mean value of 310 robots per 10,000 workers and anchored on the International Federation of Robotics data; the cost decrease and sustainability were the percentage changes that were ordered based on the case reports available publicly [22,40]. Additionally, random noise was added to ensure the synthetic data presents realistic scenarios. Sensitivity analysis and cross-validation of differing parameter assumptions, along with robustness checks against limited real-world data, were used [41]. All simulations were carried out using Python libraries NumPy and Pandas, ensuring reproducibility.

The lack of firm-level microdata on AI-ERP adoption necessitates the adoption of synthetic data. However, these studies consider both organisational and individual aspects of AI-ERP adoption, including financial performance and acceptance, as well as various practical implementation obstacles [16,29]. However, only 25% of the variance in user satisfaction remains explained by the OLS regression model. To further investigate the relationship between all these interdependencies, future studies should be more comprehensive than OLS and include structural equation modelling (SEM) or partial least squares SEM (PLS-SEM) [26,40]. Moreover, future studies may focus on gathering data over longer timeframes or primary data, such as firm-level microdata on AI-ERP use, to enhance the validity x and generalizability of empirical studies.

4. Findings

4.1. Proposed Conceptual Framework for AI-ERP in the Dark Industry Era

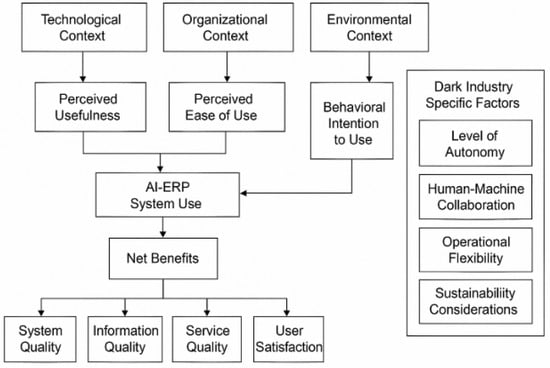

An integrated model is suggested in this study: the TOE, TAM and IS Success Model, supplemented by industry-specific factors. The structure of the model is shown in Figure 3.

Figure 3.

Proposed Integrated Framework for AI-ERP in the Dark Industry Era (adapted from [27]; and modified from [16,19]).

In Figure 3, the proposed conceptual framework is adapted and synthesised from the TOE model [27], TAM [38], and the IS Success Model [29], extended with contextual elements of AI-driven “dark industry” [16,19]. The provided conceptual framework presents a systematic approach for organisations implementing AI-based ERP systems efficiently, including the dark factor of industry-specificities, such as autonomy, human–machine collaboration, operational flexibility, and sustainability [19]. A significant aspect of the framework is that it supports constant feedback mechanisms to ensure its acceptance by users. Insights gathered from end-user interviews can help organisations enhance the design and usability of AI-ERP systems, reinforcing their understanding of the benefits of AI products and addressing potential resistance [16]. Such an iterative process also makes AI-ERP systems not only technically sound but also user-friendly and employee-friendly, allowing them to become widely adopted.

The adoption and application of this paradigm should proceed in phases: pilot implementation, and a fully functioning environment in which IoT-enabled robotics and supply chains have already been integrated for complete Line-of-Business Deployment [9]. Evaluation focuses on dark industry dimensions, such as AI autonomy, measured by decision accuracy, latency, and the level of human override and human–machine collaboration, measured by the reduction in error and the efficiency of the task [9,26]. In addition to system quality, service quality, and user satisfaction, these indicators can form the comprehensive KPI package for monitoring post-adoption outcomes in terms of efficiency, cost reduction, and decision-making [30].

4.2. Application of Integrated Framework

There is a transformative potential in the incorporation of AI into ERP systems in business activities. Nevertheless, there always seem to be problems that accompany implementation, such as technological barriers, organisational resistance, and environmental restrictions. To address these issues, a formal framework should be employed to critically evaluate the implementation of AI-ERP [28]. The model enables organisations to be technologically ready by measuring their infrastructure to integrate AI within ERP systems. It can be used to highlight the possibility of and feasibility of integrating AI-based analytics, machine learning models, or even cloud computing within the current ERP system prior to the implementation [19]. An example is a manufacturing company that can use this framework to assess the capability of its data infrastructure to enable predictive analytics needed to optimise its supply chain.

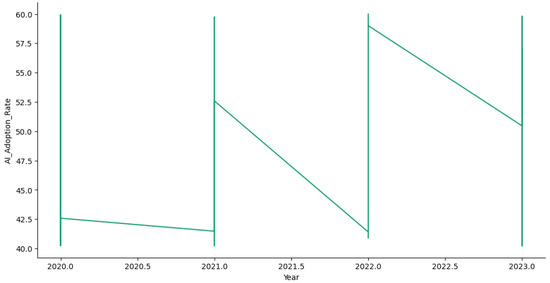

Figure 4 depicts the AI adoption rate from 2020 to 2023. The AI adoption rate started at a high level in 2020, reflecting early enthusiasm and investment in AI-driven solutions. There was a noticeable decline in the adoption rate between 2020 and 2023, with significant fluctuations observed in 2021 and 2022. This suggests that while initial interest was strong, ongoing challenges such as implementation complexities, data quality issues, and workforce readiness may have impacted sustained adoption. By 2023, the adoption rate has stabilised at a slightly lower level compared to 2020, indicating that organisations are adapting to these challenges but have not yet regained the initial momentum.

Figure 4.

Trend in AI Adoption Rate Over Years.

To understand the effectiveness and acceptance among employees of AI-ERP integration, an organisation can use the TAM to assess the perceived ease of use and perceived usefulness of the implemented new technology [37]. For instance, a healthcare company utilising ERP systems can leverage advanced AI to automate various processes across multiple departments, including patient management, predictive admission and discharge, AI-driven diagnostics, and automated billing and payment processing. Then, how employees perceive the value of usefulness and ease of operation can be measured through the TAM [16].

The primary goal of an organisation in integrating AI-ERP systems is to achieve the system’s effectiveness through user satisfaction, system quality and business impact. The TOE, TAM, and IS Success models collectively measure the success of implementing new technology [16]. For example, in the context of a manufacturing company implementing AI-ERP systems to optimise supply chain forecasting and production planning, TOE will assess technological readiness, such as AI-driven infrastructure, along with organisational readiness, including employee skill adoption and environmental factors, such as regulatory compliance [18]. TAM will help evaluate the perceived usefulness of technologies like AI-driven predictive analytics for decision-making. Finally, IS success will be measured by system quality, including the accuracy of real-time analytics and user satisfaction, to determine the level of trust employees have in AI capabilities [18]. All these models can be unified to suppress the challenges of implementing AI in ERP systems, providing a holistic assessment view of different aspects that stimulate the adoption of new technologies.

4.3. Application of AI-ERP Across Industries Using an Integrated Framework

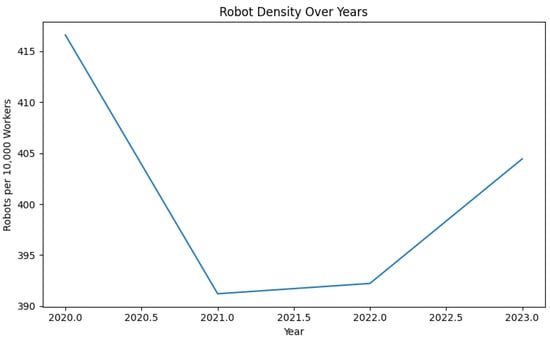

AI integration into ERP systems has garnered significant attention in recent years across various industries, with high adoption potential due to the increasing complexity of business operations and the need for real-time, data-driven decision-making. Manufacturers evaluate the adoption capability of AI-ERP systems based on technological readiness and organisational structure using the TOE framework. As shown in Figure 5, robot density experienced a significant decline in 2021, followed by a steady recovery through 2022 and 2023. While not consistently increasing over the full period, the upward trend since 2021 suggests renewed investment in automation and AI-integrated manufacturing systems, supporting the technological readiness construct within the TOE framework.

Figure 5.

Increasing robot density in industrial firms (2020–2023), showing the technological advancement driving AI-ERP adoption in dark industries.

To determine the acceptance level of new technology, manufacturers assess employees’ perception towards the AI-driven ERP system, whether they find it user-friendly or not [12]. The hospital industry can decide to implement AI-ERP systems after analysing regulatory policies, infrastructure capabilities and financial constraints through TOE analysis. TAM can determine whether professionals are willingly adopting AI-ERP to streamline patient management and reduce administrative burdens. For instance, Mondal and Bhuiyan demonstrated the effectiveness of machine learning in early intervention and personalised treatment for chronic diseases [42]. Their study highlights how predictive models can analyse patient data to identify risk factors and recommend tailored interventions, showcasing the versatility and impact of AI in addressing complex challenges across industries. The IS Success model will enhance data security, flawless patient records and real-time analytics, impacting improved healthcare outcomes, resource allocation, predictive inventory supplies management and cost reductions [43].

AI-ERP can be leveraged by assessing technological compatibility, organisational preparedness, and market trends. This can be used to build a marketing strategy using Machine learning algorithms and Internet of Things (IoT) or facial recognition tools to analyse consumer behaviours, which can be understood through TOE [44]. Internal stakeholders’ acceptance motive can be understood using the TAM for AI-ERP systems to gain customer insights and adjust prices in real-time based on demand. The IS Success model will play a pivotal role in ensuring data accuracy and system quality, thereby improving sales forecasting and delivering superior customer service, ultimately enhancing profitability and customer satisfaction [31].

4.4. Integrating TOE, TAM, and IS Success Model in Business Settings

After analysing the existing functionalities of each model, none of the models provides holistic integrated solutions for AI-ERP systems adoption. In this case, a comprehensive AI-ERP framework will be the most justifying solution, combining the TOE framework, incorporating macro-level influences, the TAM for micro-level determinants and the IS Success model for post-implementation success evaluation, offering a holistic perspective that can be applied in current business settings [16]. However, the model must comprise processes that can be adapted to suit specific regulatory, cultural, and market requirements, thereby avoiding irrelevance and incompetence in other industries and regional contexts.

The regulatory compliance that organisations should undertake to implement the framework requires them to address local regulations through effective data governance, which includes the GDPR or CCPA [13,34]. Methods and plans for change management and leadership services should be adapted to the cultural peculiarities of a specific area to eliminate opposition to automation [26]. When competing in a market, it is necessary to take into account the application of AI-ERP systems to support supply networks and carry out predictive maintenance [9].

Pre-Adoption Phase (TOE Framework), where organisations assess technological feasibility by examining AI infrastructure, cybersecurity, cloud computing, organisational readiness. They also evaluate leadership and financial support, as well as market demand, regulatory constraints in a business environment to shape strategic decisions and understand the implementation possibility [19,35]. Moreover, the density of robot parameters is used to measure technological development, providing information on the level of automation in use in the organisation [40]. These tools help align the technology aspects of the organisation with its strategic direction, leading to easier integration in the preparation phase.

Adoption Decision Phase (TAM), emphasis shifts to the acceptance by the user and perceived ease of use. User Interface (UI) and User Experience (UX) test platforms are used to evaluate the intuitive and operational quality of AI-ERP interfaces. Additionally, these employee training simulations are used to measure user acceptance and learning skills through e-learning systems and simulated use cases [16]. These methodologies ensure that its employees are adequately prepared for the adoption of AI-ERP systems, and thus, during their implementation, resistance is mitigated [26].

In the post-adoption phase of the IS Success Model, monitoring and evaluating the system performance continue. Key Performance Indicators (KPIs) are used to measure success in many different dimensions. Information quality is examined through predictive accuracy and (re)training of the AI models for their relevance and accuracy [12]. User satisfaction is monitored using surveys, Net Promoter Scores (NPS), and AI-driven sentiment analysis, which helps provide actionable feedback for system improvement [33].

However, ethical and social issues should also be solved in a well-organised way. Strict rules and regulations will also place AI-ERP systems within the realm of technological ethics [11]. It is through these additions that the structure becomes more flexible and ethical, thereby enhancing user trust and comfort in the system.

Table 2 outlines the phases of AI integration into ERP systems: Pre-Adoption, Adoption, and Post-Adoption, along with specific modules, their purposes, and actionable steps for IT organisations to support each phase.

Table 2.

Comprehensive Framework for AI-ERP Integration across Phases.

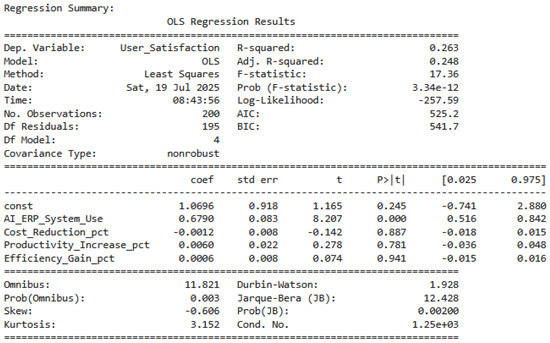

4.5. Regression Analysis: Predicting User Satisfaction

In highly automated industrial procedures, such as those in dark factories, regression analysis attempts to identify factors that influence user satisfaction with AI-ERP systems [19]. The highest impact on the successful implementation of AI-ERP has been user satisfaction, as the adoption process of an AI-ERP system is closely tied to the level of user satisfaction [16]. This study used the Ordinary Least Squares (OLS) regression model to analyse the influence of user satisfaction on other important variables such as AI_ERP_System_Use, Cost_Reduction_pct, Productivity_Increase_pct and efficiency_Gain_pct. The selection of these variables is connected to the fact that they are relevant in terms of the TOE, TAM, and the IS Success Models, which revolve around the aspects of technological readiness, user acceptance, and success beyond adoption [26].

The sample size comprises 200 firm-based observations in an intensive technology industry over four years (2020–2023) [40]. The dependent variable is User Satisfaction, which indicates the amount of satisfaction with the AI-ERP system among users. The independent variables list encompasses several aspects of AI-ERP implementation, including system utilisation, cost savings, productivity maximisation, and efficiency. The results suggest that persistent interaction with the AI-ERP system has a significant impact on user satisfaction, reinforcing the need for functional and user-centric solutions. The ensuing implications are thus to improve AI-driven interfaces, which are expected to promote user adoption and reduce resistance [31,35].

Moreover, addressing implementation obstacles and thereby reducing cost burdens and poor data quality requires the emergence of leadership sponsorship, accompanied by well-organised and effective training programmes, to ensure that users understand the benefits and operational characteristics inherent in AI-ERP systems [45]. Such measures have dual benefits: they increase user satisfaction while driving the overarching success of AI-ERP adoption by balancing technological capabilities with institutional needs.

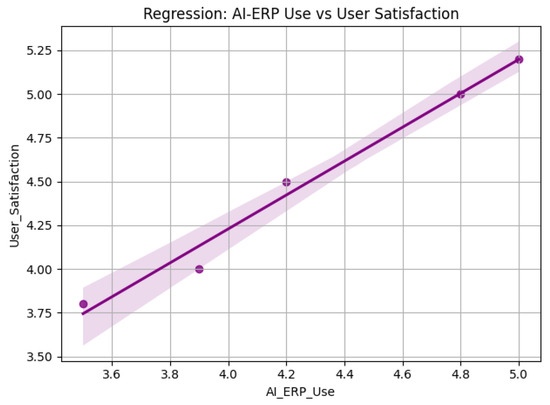

The results, as shown in Figure 6, indicate that the use of AI-ERP systems has a statistically significant positive effect on user satisfaction (β = 0.679, p < 0.001). This confirms that consistent and meaningful engagement with the AI-ERP system is a strong predictor of satisfaction, supporting Objective 3 of the study, which aims to determine how system use contributes to post-adoption outcomes.

Figure 6.

OLS Regression Summary—Predicting User Satisfaction.

Moreover, the OLS regression model explains only 25% of the variance in user satisfaction (adjusted R2 = 0.248), indicating that it has a weak explanatory power with subsequent variables removed. In addition, significant elements of ethical considerations, cultural variations, and workforce preparedness ought to be taken into account. Explainable AI (XAI) methods can be used to measure ethical factors, such as the transparency of the algorithms [34]. Cultural differences can be estimated using cross-cultural surveys [26], whereas workforce readiness may be estimated using skill gap analysis [30]. Professional approaches, such as structural equation modelling (SEM) or partial least squares SEM (PLS-SEM), should be employed in future research to elucidate complex interdependencies [26,39].

Figure 7 shows the positive linear relationship between AI-ERP system usage and user satisfaction based on firm-level regression analysis (n = 200). This figure includes charts likely showing trends over time for these metrics and potentially breakdowns of investments or returns by category, offering a concise overview of the financial performance. Each purple dot represents a single firm’s observed values. The solid purple line is the fitted regression line, indicating that higher AI-ERP adoption is associated with greater user satisfaction. The light purple shaded region represents the 95% confidence interval around the regression line, reflecting statistical precision.

Figure 7.

Regression: AI-ERP Use vs. User Satisfaction.

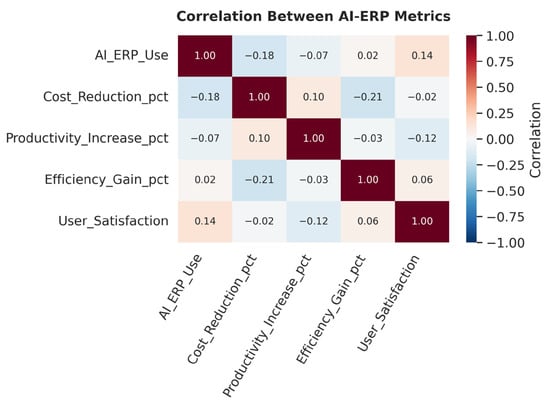

Furthermore, multicollinearity was considered the source of the insignificance of the coefficient variables, such as Cost_Reduction, Productivity_Increase, and Efficiency_Gain. Although no Variance Inflation Factor (VIF) diagnostics were performed, additional appropriate tools took care of redundancy among predictors, like the correlation matrix (Figure 8). The correlation matrix was obtained to identify highly correlated independent variables (e.g., cost reduction and productivity increase). Strongly intercorrelated variables were eliminated or merged in order to decrease redundancy [46,47]. Moreover, a refinement of the model was performed using stepwise variable selection methods, ensuring that overlapping explanatory variables did not affect the standard errors and inverted estimates of coefficients [48,49].

Figure 8.

Correlation Between AI-ERP Metrics. Correlation matrix showing interrelationships between AI-ERP system usage, productivity, cost reduction, efficiency, and user satisfaction.

The Durbin–Watson statistic (~1.93) confirms the absence of autocorrelation, and the residuals passed normality checks (Jarque–Bera = 0.002), ensuring model validity. Further diagnostic tests were carried out to assess the reliability of the model, which included the Breusch–Pagan test. This test found no significant cases of heteroskedasticity, indicating that the variance of the residuals can be constant throughout the observations [50].

Furthermore, external validity was restricted by the use of simulated regressions in the study. To address this, future research should incorporate field experiments and control groups to demonstrate what happens independently of dark factories in real-life settings. Generalisability can be improved by using case studies based on industries that have adopted AI-ERP systems to validate the systems [36] empirically. Additionally, they would enable more dynamic simulation in operational settings, bridging the gap between theory and practice by utilising more advanced simulation methods, such as agent-based modelling or digital twins [9]. Lastly, the simulated trends were compared to scarce real-world data using energy-saving and wastage rates to ensure the observed trends were in line with the simulated trends [40].

5. Discussion

The incorporation of AI in Medicare, the green economy and different industrial sectors has emerged during the last few decades. For Instance, AI applications, including CNN-Transformer based models (e.g., BERT version 1.0), XGBoost (version 2.1.0) framework, Explainable AI, Neural Networks, have been successfully applied in bridging the gaps between traditional finance and Blockchain ecosystems, medicare fraud detection, customer interaction models and enhancing digital payment security [34,35,51,52]. Therefore, this study presents a potentially improved theoretical framework for integrating AI into the ERP system, oriented explicitly towards industrial automation in a new environment known as the dark industry [16]. The suggested framework leverages the synergy of three existing models: TOE, TAM, and the IS Success Model, and integrates industry-specific factors, including autonomy, human–machine collaboration, flexibility, and sustainability [19]. The framework can present an entire plan for deploying AI-ERP in highly profitable, highly automated settings, using pre-adoption readiness, user acceptance, and post-adoption performance as its key metrics.

The framework is based on the TOE dimensions context: technological, organisational, and environmental. The resultant readiness to technology, such as the infrastructure and AI-related capacities, affects the perceived usefulness of the system to the users. Organisational policies, training programmes, and leadership alignment govern the perceived ease of use. In contrast, the behavioural intentions to adopt the AI-ERP systems are established by the environment, such as regulatory pressure and market competitiveness [17]. These TAM elements are discharged into practical system utilisation, which is the central point of the framework. Industry-specific advantages, such as the flexibility to work in unstructured environments and the collaboration between AI and humans, are more dark enablers that contribute to user adoption and the system’s capabilities [53].

Following the adoption, the indicators of post-adoption success are measured using the IS Success Model, which reflects the quality of systems, the quality of information, the quality of services, and user satisfaction [29]. The measures will provide continuous feedback regarding the advancement and expansion of AI-ERP implementation as part of the innovative factory environment [31]. The framework enables the consideration of the complexity of AI-ERP integration and the specifics of current industrial paradigms, without neglecting the impact of pre-adoption factors and the consequences of post-adoption implementations [32].

The findings of the study present practical guidelines to practitioners of the industry, policy-makers, and researchers. Practically, using the integrated TOE–TAM–IS model keeps practitioners on the right track for a holistic evaluation approach to technological, organisational, and environmental readiness [16]. Making AI modules user-friendly and focusing on their positive aspects, including predictive analytics and automation, will lead to increasing user acceptance, and their resistance levels will be minimised [29]. The system performance and user satisfaction could be measured and presented in the form of Key Performance Indicators (KPIs) to ensure the success of post-adoption. The best way to resolve implementation obstacles, including expense and poor information quality, is to build leadership support, strong training facilities, and clearly communicate the benefits of AI-ERPs [44].

The results indicate that the results of AI-ERP adoption differ greatly across regional and sectoral settings. Organisations should utilise context-sensitive mechanisms to enhance adaptability. Accordingly, the automotive industry tends to concentrate on robotics and predictive maintenance, whereas the retail industry promotes data management and purchase anticipation. European companies, in their part, need GDPR-aligned controls, and Asia-Pacific companies have to adjust to having centralised supply chains and disparate digital maturity levels [7,17]. Incorporating these layers of adaptation into the integrated model can provide alignment with regulatory, cultural, and infrastructural situations, which leads to successful adoption.

Policy-makers and industry actors should strive to implement specific ethical principles, data security practices, and data management policies tailored to autonomous industrial environments [13]. Stimulating cross-sector cooperation and benchmarking projects will help accelerate AI-ERP innovation. In contrast, training programmes and investments in workforce training can help mitigate the skills deficiency in AI, robotics, and ERP integration [26].

The future research will be instrumental in promoting the applicability of the framework. It will enhance its generalizability by utilising empirical testing, case studies, and quantitative research across various industries, including manufacturing, healthcare, retail, and dark industries [17]. Regional and sectoral differences must also be explored to appreciate the performance of the framework after adjusting it to different regulatory, cultural, and infrastructural environments [1]. The exploration of the longevity consequences of AI-ERP implementation on operational efficiency, cost reduction capabilities, strategic decision-making processes, and sustainability will reveal lasting value and identify areas for intervention to achieve better outcomes [12].

6. Conclusions

The study determines that the effective implementation of AI-ERP throughout the model cannot involve a series of individual applications; instead, it requires a comprehensive approach that encompasses technical readiness, organisational dynamics, environmental support, user behaviour, and ongoing system evaluation. The various challenges of AI-ERP adoption manifest in different ways, even in highly industrial environments where autonomy, real-time decision-making, and human–machine interaction are of vital importance, such as in dark factories.

The framework suggested in this paper is the only one that fits the emergence of dark industry settings, due to the synergistic blend of the three pillars of TOE, TAM, and the IS Success Model. Its combination with industry-specific variables, such as automation, the ability to respond flexibly to changing needs, sustainability, and ethical concerns, makes it relevant in the fast-developing industrial environment.

In addition, by combining TOE, TAM, and IS Success models, a single perspective emerges to assess the readiness of the AI-ERP, the dependence on user acceptance, and long-term success. The practice will enable organisations to address pressing issues such as data quality, algorithm fairness, cybersecurity threats, and employee resistance, while also maximising the benefits of AI-based ERP systems. Scholars can make essential contributions to the development of this framework by testing the primary constructs through empirical measures, examining the input process, and addressing local differences in adoption processes. Such attempts will streamline the framework, making it more applicable across various sectors and situations.

Ultimately, the proposed model can enable organisations to achieve success in the era of Industry 4.0 and beyond, thanks to enhanced operational efficiency, reduced costs, and informed strategic decision-making. It also provides businesses with relevant practical plans to manage it through the pre-adoption planning, implementation, and post-adoption examination in an orderly manner. This study helps to fill the gaps in the literature. It provides actionable advice, enabling the successful integration of AI-ERP systems and allowing organisations to unlock their potential in highly automated settings. Although this research emphasises the contribution of AI-ERP to the sustainable industrial change, its application can be maximised by applying the guidelines for adapting it. The organisations are expected to align their implementation needs with regulatory demands, assess the capacity of their workforce to handle processes, and positivise ethics-by-design, including the explainability of algorithms, fairness inspections, and human-in-the-loop controls. To address social barriers like resistance and skill gaps, a systematic change management approach and/or a system of consecutive training is necessary. This study has limitations. The use of simulated data limits empirical generalizability, and the model only explains a portion of the variation in user satisfaction, suggesting that there are unexplored factors, including environmental pressures and employee competencies. Differences in sector and culture are observed but not verified empirically. The framework should be supported by future studies that utilise case studies and innovative techniques (e.g., SEM, PLS-SEM) across various industries and areas.

Author Contributions

M.S.I.: Conceptualisation, Methodology, Writing—Final manuscript preparation. M.I.I.: Data collection, writing-Primary draft preparation. A.Q.M.: Literature review, Data collection. M.T.H.K.: Conceptualisation, Methodology development, manuscript editing and overall supervision. N.D.: Data collection, Writing—Reviewing and Scientific Editing. N.M.: Conceptualisation, Methodology, Supervision. All authors have read and agreed to the published version of the manuscript.

Funding

This study did not receive any funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Publicly available datasets were analyzed in this study. This data can be found here: https://ifr.org/ifr-press-releases/news/global-robot-density-in-factories-doubled-in-seven-years, accessed on 15 August 2025.

Acknowledgments

The authors would like to thank Khadeza Yesmin Lucky and Shariful Haque, for their assistance in literature review, data collection and primary draft preparation. We also want to thank Fatema for her constructive feedback on the conceptualisation, writing and its successful publication.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Mohammed, I.A. AI and machine learning in predictive analytics for supply chain optimisation in the global economy. In Multidisciplinary Research Nexus: Ideas for the Modern World; San International Scientific Publications: Tamil Nadu, India, 2025; Volume 18, pp. 146–153. [Google Scholar] [CrossRef]

- Chatterjee, S.; Rana, N.P.; Dwivedi, Y.K.; Baabdullah, A.M. Understanding AI adoption in manufacturing and production firms using an integrated TAM-TOE model. Technol. Forecast. Soc. Change 2021, 173, 121007. [Google Scholar] [CrossRef]

- Adenekan, T.K. Challenges in integrating AI with ERP systems: A comparative study of industry practices. Int. J. Manag. Entrep. Res. 2025, 6, 1607–1624. [Google Scholar]

- Zhong, R.Y.; Newman, S.T.; Huang, G.Q.; Lan, S. Big data for supply chain management in the service and manufacturing sectors: Challenges, opportunities, and future perspectives. Comput. Ind. Eng. 2025, 101, 572–591. [Google Scholar] [CrossRef]

- Hrischev, R.; Shakev, N. Artificial intelligence in ERP systems. Eng. Sci. 2023, 1, 3–15. [Google Scholar] [CrossRef]

- Dumitru, V.F.; Ionescu, B.; Rîndașu, S.-M.; Barna, L.-E.; Crîjman, A.-M. Crîjman. Implications for sustainability accounting and reporting in the context of the automation-driven evolution of ERP systems. Electronics 2023, 12, 1819. [Google Scholar] [CrossRef]

- Kumar, A.N.P.; Bogner, J.; Funke, M.; Lago, P. Balancing progress and responsibility: A synthesis of sustainability trade-offs of AI-based systems. In Proceedings of the 2024 IEEE 21st International Conference on Software Architecture Companion (ICSA-C), Hyderabad, India, 4–8 June 2024; pp. 207–214. [Google Scholar] [CrossRef]

- Issa, J.; Abdulrahman, L.M.; Abdullah, R.M.; Sami, T.M.G.; Wasfi, B. AI-powered sustainability management in enterprise systems based on cloud and web technology: Integrating IoT data for environmental impact reduction. J. Inf. Technol. Inform. 2024, 3, 154. [Google Scholar]

- Samuels, A. Examining the integration of artificial intelligence in supply chain management from Industry 4.0 to 6.0: A systematic literature review. Front. Artif. Intell. 2025, 7, 1477044. [Google Scholar] [CrossRef]

- Mhaskey, S.V. Integration of artificial intelligence (AI) in enterprise resource planning (ERP) systems: Opportunities, challenges, and implications. Int. J. Comput. Eng. Res. Trends 2024, 11, 1–9. [Google Scholar] [CrossRef]

- Barna, L.E.L. The impact of using artificial intelligence and ERP systems in the work of accounting professionals and auditors. Ann. Univ. Oradea Econ. Sci. Ser. 2024, 33, 1. [Google Scholar] [CrossRef]

- Singh, V. AI-driven ERP evolution: Enhancing supply chain resilience with neural networks and predictive LSTM models. Eur. J. Adv. Eng. Technol. 2025, 12, 47–52. [Google Scholar] [CrossRef]

- Dai, J.; Wang, L.; Zhang, H. Data integration challenges in IoT-enabled manufacturing systems. J. Ind. Inform. 2018, 14, 123–135. [Google Scholar]

- Madaki, A.S.A.; Ahmad, K.; Singh, D.; Alshurideh, M.T.; Alzoubi, M.R.; Falaki, N.; Alzyoud, M. Understanding theories and models of information technology integration implementation in non-western organisations: Elaborating the TOE model in Nigeria’s public sector. In Intelligence-Driven Circular Economy: Regeneration Towards Sustainability and Social Responsibility; Springer: Cham, Switzerland, 2025; pp. 17–36. [Google Scholar] [CrossRef]

- Yathiraju, N. Investigating the use of an artificial intelligence model in an ERP cloud-based system. Int. J. Electr. Electron. Comput. 2022, 7, 1–26. [Google Scholar] [CrossRef]

- Jo, H.; Bang, Y. Understanding continuance intention of enterprise resource planning (ERP): TOE, TAM, and IS success model. Heliyon 2023, 9, e21019. [Google Scholar] [CrossRef]

- Al-Mashaqbeh, I.A. Digital Transformation in Management Accounting: Shaping Corporate Strategies—A Case Study Based on Swedish Service-Related Firms. Master’s Thesis, University of Gothenburg, Gothenburg, Sweden, 2024. Available online: https://gupea.ub.gu.se/handle/2077/82968 (accessed on 15 August 2024).

- Bertram, Y. Intelligent ERP: The General Concept and a System Assessment. Master’s Thesis, Universidade NOVA de Lisboa, Lisbon, Portugal, 2022. Available online: http://hdl.handle.net/10362/142295 (accessed on 15 August 2025).

- Na, S.; Heo, S.; Han, S.; Shin, Y.; Roh, Y. Acceptance model of artificial intelligence (AI)-based technologies in construction firms: Applying the technology acceptance model (TAM) in combination with the technology–organisation–environment (TOE) framework. Buildings 2022, 12, 90. [Google Scholar] [CrossRef]

- Niropam Das, H.R.; Siddiqa, K.B.; Barikdar, C.R.; Hassan, J.; Bhuiyan, M.M.R.; Mahmud, F. The strategic impact of business intelligence tools: A review of decision-making and ambidexterity. Membrane Technol. 2025, 1, 542–553. [Google Scholar] [CrossRef]

- Barua, A.; Karim, F.; Islam, M.M.; Das, N.; Sumon, F.I.; Rahman, A.; Debnath, P.; Karmakar, M.; Khan, A. Optimising energy consumption patterns in southern California: An AI-driven approach to sustainable resource management. J. Ecohumanism 2025, 4, 2920–2935. [Google Scholar] [CrossRef]

- International Federation of Robotics (IFR). World Robotics Report 2023; IFR: Frankfurt, Germany, 2023; Available online: https://ifr.org/img/worldrobotics/2023_WR_extended_version.pdf (accessed on 15 August 2025).

- Annanth, V.K.; Abinash, M.; Rao, L.B. Intelligent manufacturing in the context of industry 4.0: A case study of Siemens industry. J. Phys. Conf. Ser. 2021, 1969, 012019. [Google Scholar] [CrossRef]

- Yaqub, M.Z.; Alsabban, A. Industry-4.0-enabled digital transformation: Prospects, instruments, challenges, and implications for business strategies. Sustainability 2023, 15, 8553. [Google Scholar] [CrossRef]

- Bhavikatta, N.B. AI-Driven Inventory Optimization in Supply Chains: A Comprehensive Review on Reducing Stockouts and Mitigating Overstock Risks. J. Comput. Sci. Technol. Stud. 2025, 7, 1–13. [Google Scholar] [CrossRef]

- Ibrahim, F.; Münscher, J.-C.; Daseking, M.; Telle, N.-T. The technology acceptance model and adopter type analysis in the context of artificial intelligence. Front. Artif. Intell. 2025, 7, 1496518. [Google Scholar] [CrossRef]

- Tornatzky, L.G.; Fleischer, M.; Chakrabarti, A.K. Processes of Technological Innovation; Lexington Books: Lexington, MA, USA, 1990. [Google Scholar]

- Awa, H.O.; Ojiabo, O.U. A model of adoption determinants of ERP within T-O-E framework. Inf. Technol. People 2016, 29, 901–930. [Google Scholar] [CrossRef]

- DeLone, W.H.; McLean, E.R. Information systems success: The quest for the dependent variable. Inf. Syst. Res. 1992, 3, 60–95. [Google Scholar] [CrossRef]

- William, F.; Tjhin, V.U. The evaluation of enterprise resource planning application using information systems success model. J. Manag. Inf. Decis. Sci. 2021, 24, 1–13. [Google Scholar]

- Pokala, P. The integration and impact of artificial intelligence in modern enterprise resource planning systems: A comprehensive review. Int. J. Comput. Eng. Technol. 2024, 15, 79–88. [Google Scholar] [CrossRef]

- Huong, D.T.; Ngoc, L.T.M.; Mai, N.P. Applying the TAM and TOE integrated framework in researching the social media adoption in retail businesses in Vietnam. VNU J. Sci. Econ. Bus. 2020, 36, 1–10. [Google Scholar] [CrossRef]

- Al-Okaily, A.; Al-Okaily, M.; Teoh, A.P. ERP success in Jordanian firms: A conceptual model based on the DeLone and McLean IS Success Model. VINE J. Inf. Knowl. Manag. Syst. 2021, 53, 1025–1040. [Google Scholar] [CrossRef]

- Alam Mozumder, S.; Sakil, M.B.H.; Hasan, R.; Hasan, A.; Fuad, K.M.N.R.; Mridha, M.F.; Islam, R.; Watanobe, Y. Hybrid contrastive learning with attention-based neural networks for robust fraud detection in digital payment systems. IEEE Open J. Comput. Soc. 2025, 6, 1053–1064. [Google Scholar] [CrossRef]

- Alam Mozumder, S.; Hasan, R.; Sakil, M.B.H.; Hasan, A.; Eva, A.A.; Maua, J. AI-driven financial knowledge graphs: Bridging traditional finance and blockchain ecosystems with graph neural networks. In Proceedings of the 2025 International Conference on Electrical, Computer and Communication Engineering (ECCE), Chittagong, Bangladesh, 13–15 February 2025; pp. 1–6. [Google Scholar] [CrossRef]

- Pugna, I.B.; Boldeanu, D.M. The role of ERP systems in driving corporate sustainability. Proc. Int. Conf. Bus. Excel. 2025, 19, 402–412. [Google Scholar] [CrossRef]

- Shabur, A.; Shahriar, A.; Ara, M.A. From automation to collaboration: Exploring the impact of Industry 5.0 on sustainable manufacturing. Discov. Sustain. 2025, 6, 341. [Google Scholar] [CrossRef]

- Davis, F.D. Perceived usefulness, perceived ease of use, and user acceptance of information technology. MIS Q. 1989, 13, 319–340. [Google Scholar] [CrossRef]

- Dwivedi, Y.K.; Hughes, L.; Ismagilova, E.; Aarts, G.; Coombs, C.; Crick, T.; Duan, Y.; Dwivedi, R.; Edwards, J.; Eirug, A.; et al. Artificial intelligence (AI): Multidisciplinary perspectives on emerging challenges, opportunities, and agenda for research, practice and policy. Int. J. Inf. Manag. 2019, 57, 101994. [Google Scholar] [CrossRef]

- Frankfurt. Robot Density in the Manufacturing Industry 2023 Data. IFR International Federation of Robotics. 2024. Available online: https://ifr.org/ifr-press-releases/news/global-robot-density-in-factories-doubled-in-seven-years (accessed on 20 November 2024).

- Fabra-Boluda, R.; Ferri, C.; Ramírez-Quintana, M.J.; Martínez-Plumed, F. Unveiling the robustness of machine learning families. Mach. Learn. Sci. Technol. 2024, 5, 035040. [Google Scholar] [CrossRef]

- Mondal, R.S.; Bhuiyan, M.N.A. Predictive analytics for chronic disease management: A machine learning approach to early intervention and personalised treatment. J. Comput. Anal. Appl. 2024, 33, 4096–4107. Available online: https://eudoxuspress.com/index.php/pub/article/view/2743 (accessed on 30 May 2025).

- Ali, C.S.M.; Zeebaree, S.R.M. Cloud-based web applications for enterprise systems: A review of AI and marketing innovations. Asian J. Res. Comput. Sci. 2025, 18, 427–451. [Google Scholar] [CrossRef]

- Jawad, Z.N.; Balázs, V. Machine learning-driven optimisation of enterprise resource planning (ERP) systems: A comprehensive review. Beni-Suef Univ. J. Basic. Appl. Sci. 2024, 13, 4. [Google Scholar] [CrossRef]

- Kunduru, A.R. Effective usage of artificial intelligence in enterprise resource planning applications. Int. J. Comput. Trends Technol. 2023, 71, 73–80. [Google Scholar] [CrossRef]

- Gujarati, D.N.; Porter, D.C. Basic Econometrics, 5th ed.; McGraw-Hill: New York, NY, USA, 2009. [Google Scholar]

- Chan, J.Y.-L.; Leow, S.M.H.; Bea, K.T.; Cheng, W.K.; Phoong, S.W.; Hong, Z.-W.; Chen, Y.-L. Mitigating the multicollinearity problem and its machine learning approach: A review. Mathematics 2022, 10, 1283. [Google Scholar] [CrossRef]

- Heinze, G.; Wallisch, C.; Dunkler, D. Variable selection—A review and recommendations for the practicing statistician. Biom. J. 2018, 60, 431–449. [Google Scholar] [CrossRef]

- Xi, W.-F.; Jiang, Q.-W.; Yang, A.-M.M. Using stepwise regression to address multicollinearity is not appropriate. Int. J. Surg. 2024, 110, 3122–3123. [Google Scholar] [CrossRef]

- Martin, N. Robust and efficient Breusch-Pagan test-statistic: An application of the beta-score Lagrange multipliers test for non-identically distributed individuals. arXiv 2023, arXiv:2301.07245v1. [Google Scholar]

- Hasan, A.; Alam Mozumder, S.; Hasan, R.; Sakil, M.B.H.; Eva, A.A.; Hasan, N. CAMICS: A context-aware multi-intent conversational system for enhanced AI-driven customer interaction models. In Proceedings of the 2025 International Conference on Emerging Smart Computing and Informatics (ESCI), Pune, India, 5–7 March 2025; pp. 1–6. [Google Scholar] [CrossRef]

- Sakil, M.B.H.; Hasan, A.; Alam Mozumder, S.; Hasan, R.; Opee, S.A.; Mridha, M.F.; Aung, Z. Enhancing Medicare Fraud Detection With a CNN-Transformer-XGBoost Framework and Explainable AI. IEEE Access 2025, 13, 79609–79622. [Google Scholar] [CrossRef]

- Evjemo, L.D.; Gjerstad, T.; Grøtli, E.I.; Sziebig, G. Trends in smart manufacturing: Role of humans and industrial robots in smart factories. Curr. Robot. Rep. 2020, 1, 35–41. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).