Performance Evaluation of Stress-Absorbing Layer Mixtures Incorporating High-Content Oil-Rich RAP Fine Aggregate

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Samples

2.2.1. Preparation of Binder

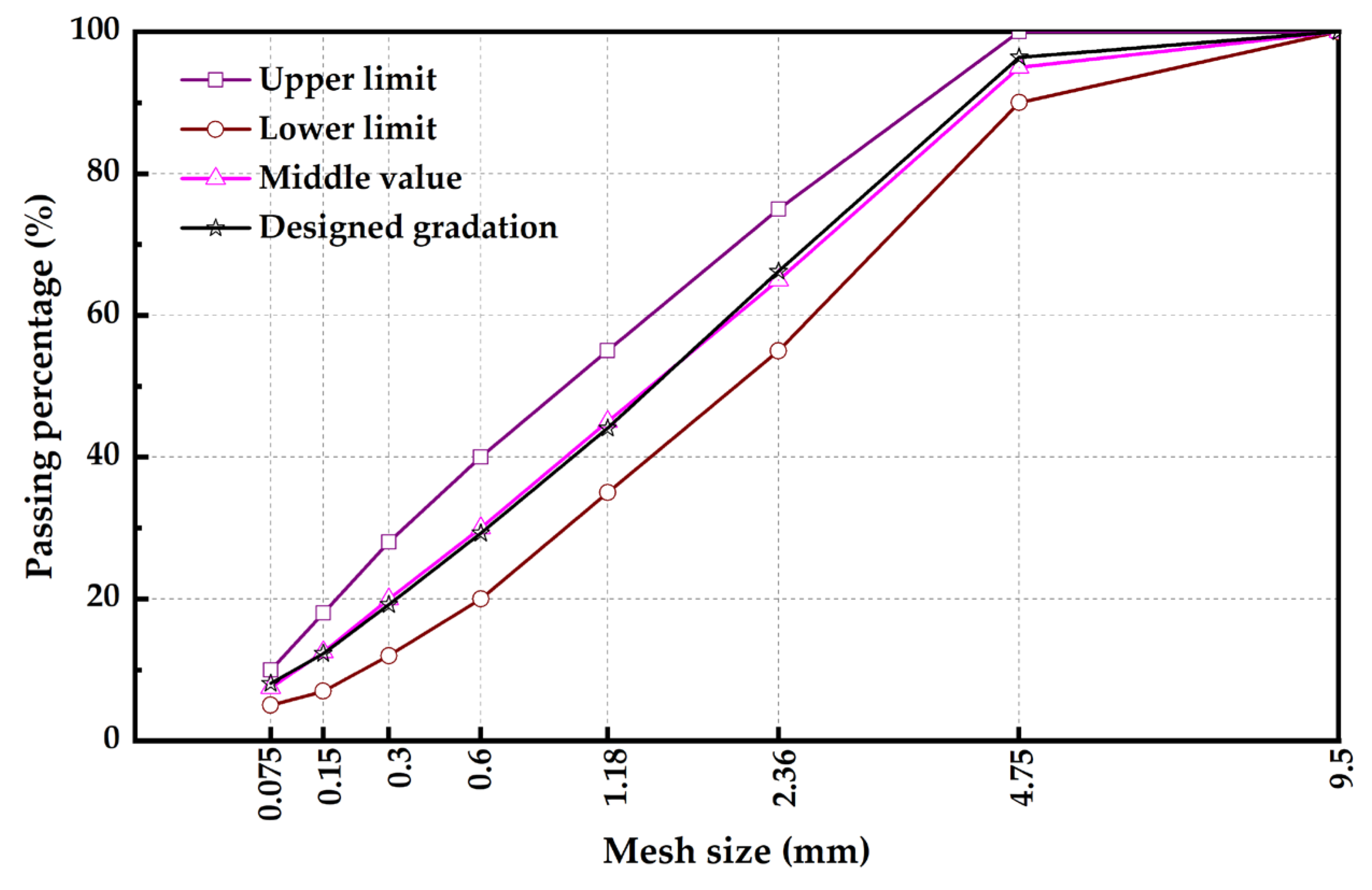

2.2.2. Preparation of SAL Mixtures

2.3. Test Methods

2.3.1. Recycled Asphalt Binder Test

Temperature Scanning Test

Linear Amplitude Scanning Test

BBR Test

2.3.2. SAL Mixture Test

Overlay Test

Road Performance Test

Pearson Correlation

2.4. Environmental Benefit Assessment

3. Results and Discussion

3.1. Performance Analysis of Asphalt Binder

3.1.1. High-Temperature Properties

3.1.2. Fatigue Properties

3.1.3. Low-Temperature Properties

3.2. Performance Analysis of SAL Mixtures

3.2.1. Anti-Cracking Performance Analysis

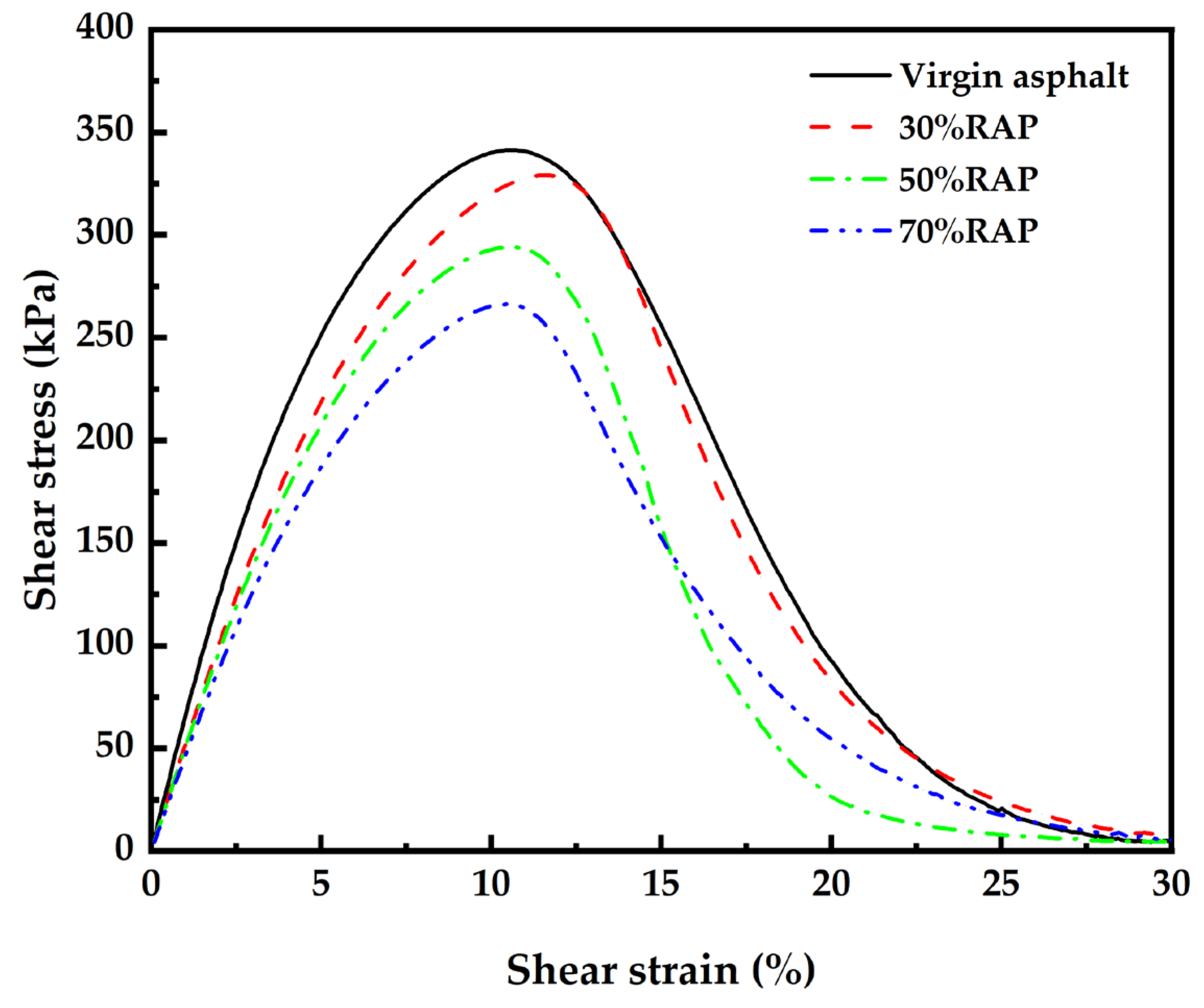

3.2.2. High-Temperature Performance Analysis

3.2.3. Low-Temperature Crack Resistance Analysis

3.2.4. Water Stability Performance Analysis

3.2.5. Fatigue Performance Analysis

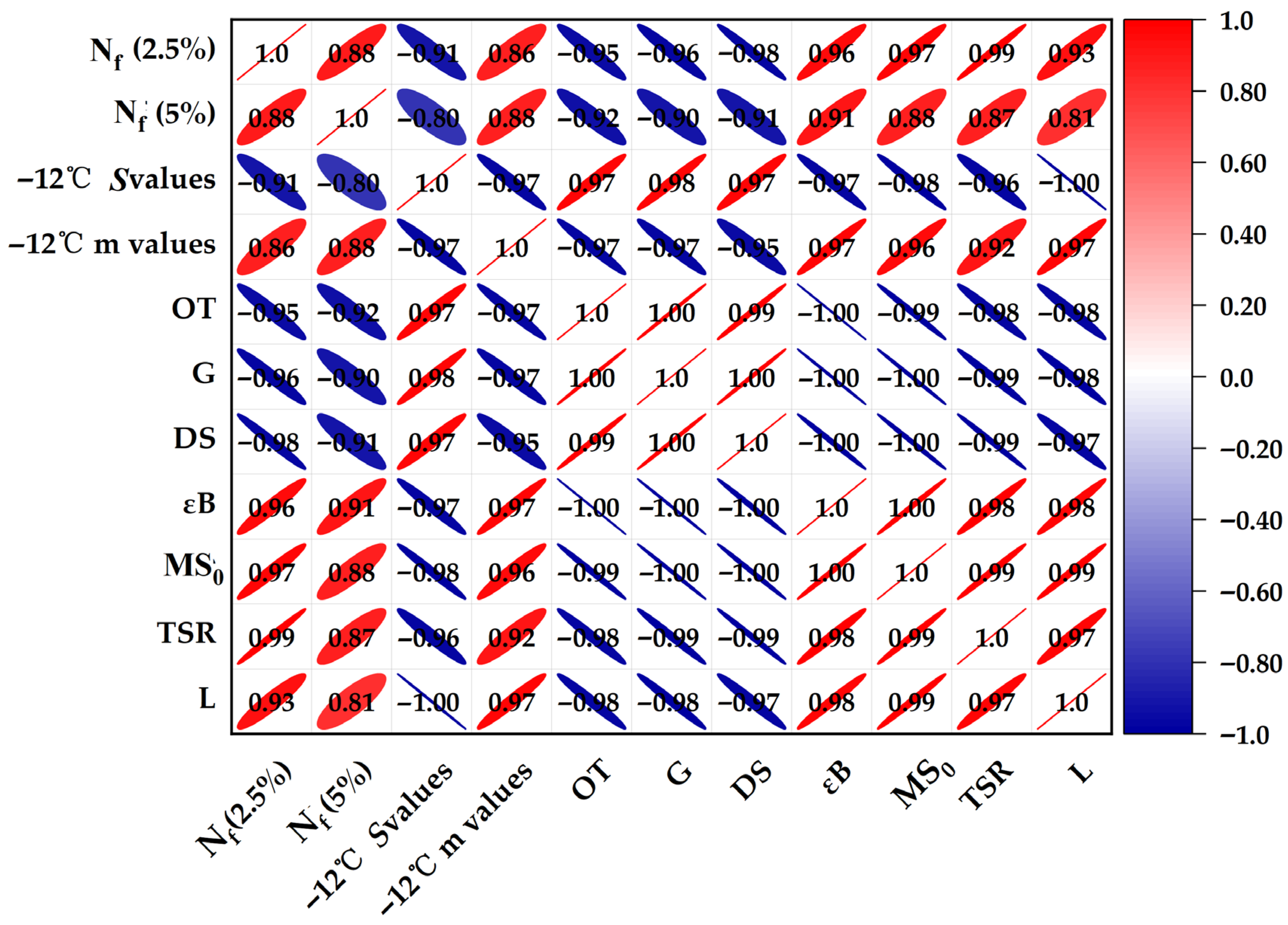

3.3. Correlation Analysis

3.4. Environmental Impact Analysis

4. Conclusions

- (1)

- Binder Performance Modification: The introduction of O-RAP effectively modifies the rheological properties of the asphalt binder, shifting its behavior toward greater rigidity and elasticity. Critically, this enhancement in high-temperature performance is achieved without adversely affecting the low-temperature performance grade, confirming the binder’s suitability for use in varied climates.

- (2)

- Mixture Performance and Trade-offs: The use of O-RAP in SAL mixtures presents a definable performance trade-off. While it significantly enhances high-temperature stability and rutting resistance, it concurrently increases mixture brittleness, leading to reductions in low-temperature crack resistance, moisture stability, and fatigue life. Nonetheless, a viable incorporation threshold of up to 70% O-RAP has been established, as mixtures at this level continue to meet standard performance specifications, successfully balancing recycling goals with functional requirements.

- (3)

- System-Level Correlation: The strong correlation between binder Nf and key mixture properties underscores that binder-level performance is a reliable predictor of mixture behavior. The identified negative correlation between Nf and the mixture’s rutting resistance reveals a critical performance contradiction that must be actively managed during the material design phase to optimize overall pavement durability.

- (4)

- Demonstrated Environmental Efficacy: The integration of O-RAP provides substantial and quantifiable environmental benefits. The 70% O-RAP mixture achieves an approximate 70% reduction in virgin material consumption and a net carbon emission reduction of 26.29 kg CO2-eq per ton, establishing high-content O-RAP recycling as a powerful strategy for decarbonizing pavement construction.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mariyappan, R.; Palammal, J.; Balu, S. Sustainable use of reclaimed asphalt pavement (RAP) in pavement applications—A review. Environ. Sci. Pollut. Res. 2023, 30, 45587–45606. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, L.; Xu, L.; Zhou, S.; Luo, B.; Ding, K. In-situ investigation on dynamic response of highway transition section with foamed concrete. Earthq. Eng. Eng. Vib. 2025, 24, 547–563. [Google Scholar] [CrossRef]

- Su, Y.; Luo, B.; Luo, Z.; Xu, F.; Huang, H.; Long, Z.; Shen, C. Mechanical characteristics and solidification mechanism of slag/fly ash-based geopolymer and cement solidified organic clay: A comparative study. J. Build. Eng. 2023, 71, 106459. [Google Scholar] [CrossRef]

- Ding, X.; Luo, B.; Zhou, H.; Chen, Y. Generalized solutions for advection–dispersion transport equations subject to time- and space-dependent internal and boundary sources. Comput. Geotech. 2025, 178, 106944. [Google Scholar] [CrossRef]

- Hasheminezhad, A.; Ceylan, H.; Kim, S. Sustainability promotion through asphalt pavements: A review of existing tools and innovations. Sustain. Mater. Technol. 2024, 42, e01162. [Google Scholar] [CrossRef]

- Yin, P.; Liu, F.; Li, Z.; Pan, B.; Liu, T. Evaluation on the adhesion property of recycled asphalt based on the multi-scale experiments. Buildings 2024, 14, 2365. [Google Scholar] [CrossRef]

- Gao, Y.; Yu, X.; Zhang, H.; Xia, Q.; He, P.; Xiao, K. Mechanisms for improving the adhesion of oil-rich RAP fine aggregate asphalt mortars to aggregates. Constr. Build. Mater. 2024, 435, 136785. [Google Scholar] [CrossRef]

- Zhao, X.; Ma, B. Microstructure in adhesion development process and strength formation mechanism in early stage of cold recycled mixture with emulsified asphalt. Adv. Civ. Eng. 2024, 2024, 7940655. [Google Scholar] [CrossRef]

- Shi, X.; Mukhopadhyay, A.; Zollinger, D. Sustainability assessment for portland cement concrete pavement containing reclaimed asphalt pavement aggregates. J. Clean. Prod. 2018, 192, 569–581. [Google Scholar] [CrossRef]

- Lei, B.; Yang, W.; Guo, Y.; Wang, X.; Xiong, Q.; Wang, K.; Li, W. Interfacial adhesion between recycled aggregate and asphalt mastic filled with recycled concrete powder. Case Stud. Constr. Mater. 2024, 20, e02721. [Google Scholar] [CrossRef]

- Wang, T.; Zhao, X.; Zheng, L.; Mao, C.; Wang, L.; Falchetto, A.; Guo, D. Hot in-place recycled asphalt mixtures: RAP analysis, compaction characteristics and field evaluation. Sustainability 2024, 16, 1064. [Google Scholar] [CrossRef]

- Yang, C.; Wu, S.; Cui, P.; Amirkhanian, S.; Zhao, Z.; Wang, F.; Zhang, L.; Wei, M.; Zhou, X.; Xie, J. Performance characterization and enhancement mechanism of recycled asphalt mixtures involving high RAP content and steel slag. J. Clean. Prod. 2022, 336, 130484. [Google Scholar] [CrossRef]

- Gaillard, L.; Chazallon, C.; Hornych, P.; Quezada, J.; Geffard, J. Study of the influence of the mastic coating of untreated reclaimed asphalt pavement on the permanent and resilient behavior. J. Test. Eval. 2022, 50, 967–983. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, H.; Barbieri, D.; Lou, B.; Hoff, I. The classification and reutilisation of recycled asphalt pavement binder: Norwegian case study. Case Stud. Constr. Mater. 2022, 17, e01491. [Google Scholar] [CrossRef]

- Pasandín, A.; Pérez, I. The influence of the mineral filler on the adhesion between aggregates and bitumen. Int. J. Adhes. Adhes. 2015, 58, 53–58. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, L.; Yan, B.; Kong, D.; Li, Y.; Wu, S. Diffusionmechanism of rejuvenator and its effects on the physical and rheological performance of aged asphalt binder. Materials 2019, 12, 4130. [Google Scholar] [CrossRef] [PubMed]

- Ai, X.; Cao, J.; Feng, D.; Gao, L.; Hu, W.; Yi, J. Performance evaluation of recycled asphalt mixtures with various percentages of RAP from the rotary decomposition process. Constr. Build. Mater. 2022, 321, 126406. [Google Scholar] [CrossRef]

- Yu, X.; Tang, W.; Li, N.; Jiang, M.; Huang, J.; Wang, D. Refined decomposition: A new separation method for RAP materials and its effect on aggregate properties. Constr. Build. Mater. 2022, 358, 129452. [Google Scholar] [CrossRef]

- Aravindmanikandan, R.; Radhakrishnan, V.; Bharath, G. Effect of RAP dissociation and agglomeration on recycled asphalt binder availability. J. Mater. Civ. Eng. 2024, 36, 04024264. [Google Scholar] [CrossRef]

- Han, L.; Zhang, S.; Zhang, Z.; Gao, T. Mechanical analysis of preventing reflection cracks based on stress absorbing layer. Adv. Civ. Eng. 2022, 2022, 8016215. [Google Scholar] [CrossRef]

- Meng, Y.; Lai, J.; Mo, S.; Fang, G.; Deng, S.; Wei, X.; Yang, F. Investigating the deterioration mechanism of adhesion between asphalt and aggregate interface under acid rain erosion. Appl. Surf. Sci. 2023, 639, 158171. [Google Scholar] [CrossRef]

- Costa, J.; Borges, P.; Santos, F.; Bezerra, A.; Van, W.; Blom, J. Cementitious binders and reclaimed asphalt aggregates for sustainable pavement base layers: Potential, challenges and research needs. Constr. Build. Mater. 2020, 265, 120325. [Google Scholar] [CrossRef]

- Yao, Y.; Yang, J.; Gao, J.; Zheng, M.; Xu, J.; Zhang, W.; Song, L. Strategy for improving the effect of hot in-place recycling of asphalt pavement. Constr. Build. Mater. 2023, 366, 130054. [Google Scholar] [CrossRef]

- Panda, R.; Biswal, D. A systematic review of geo-polymer stabilised reclaimed asphalt pavement (RAP) as a base layer of pavement. Road Mater. Pavement 2025, 26, 231–253. [Google Scholar] [CrossRef]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. China Communications Publishing House: Beijing, China, 2011.

- Gao, Y.; Yu, X.; Xia, Q.; Zhang, H. Evaluation of complex shear modulus of recycled asphalt mortars based on euclidean distance method in the mixing process. Int. J. Pavement Res. Technol. 2024. [Google Scholar] [CrossRef]

- Li, Y.; Tian, G.; Guo, W.; Wei, Z.; Zhou, Z.; Chen, Z.; Huang, X.; Gao, Y. Fatigue resistance of asphalt and asphalt mixture incorporated with high-elasticity anti-rutting additive. Constr. Build. Mater. 2025, 459, 139730. [Google Scholar] [CrossRef]

- AASHTO T313; Standard Method of Test for Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- TEX-248-F; Overlay Test Constr. Div. Texas Department of Transportation (TxDOT): Austin, TX, USA, 2009.

- Li, H.; Wang, H.; Lin, J.; Yang, J.; Yao, Y. Study on the effect of SBS/HVA/CRM composite-modified asphalt on the performance of recycled asphalt mixtures. Polymers 2024, 16, 3226. [Google Scholar] [CrossRef]

- Lu, J.; Wang, G.; Hu, J.; Liu, Z. Fatigue resistance of RCA modified asphalt based on dielectric properties. J. Wuhan Univ. Technol. 2024, 39, 91–101. [Google Scholar] [CrossRef]

- Li, K.; Yan, X.; Wang, Y.; Ai, T.; Niu, Y.; Chen, Y. Design and modification mechanism of a novel high-viscosity thermoplastic polyurethane modified asphalt. Constr. Build. Mater. 2024, 433, 136585. [Google Scholar] [CrossRef]

- Xiao, J.; Liu, X.; Zhang, H.; Bi, Y.; Zhang, J.; Xu, R. A novel application of red mud in improving aging resistance of asphalt. J. Test. Eval. 2023, 51, 2687–2699. [Google Scholar] [CrossRef]

- Gao, Y.; Li, L.; Zhang, Y. Modeling crack propagation in bituminous binders under a rotational shear fatigue load using pseudo J-integral paris’ law. Transp. Res. Rec. 2020, 2674, 94–103. [Google Scholar] [CrossRef]

- Huang, Q.; Chen, X.; Yao, J.; Yu, X.; Yao, D. Comprehensive performance evaluation of asphalt mortar based on multi-Index weighted decision model. J. Test. Eval. 2022, 50, 2866–2882. [Google Scholar] [CrossRef]

- Buechner, J.; Wistuba, M. Assessing creep properties of asphalt binder, asphalt mastic and asphalt mixture. Road Mater. Pavement 2022, 23, 116–130. [Google Scholar] [CrossRef]

- Gao, Y.; Yu, X.; Fan, X.; Zhang, H.; Xia, Q.; Zhou, Z.; Liu, W. Evaluation of adhesion performance and molecular dynamics simulation of SBS–modified asphalt during the field aging. Constr. Build. Mater. 2025, 474, 141116. [Google Scholar] [CrossRef]

- Jia, M.; Zhang, Z.; Yang, N.; Qi, B.; Wang, W.; Huang, Z.; Sun, J.; Luo, F.; Huang, T. Performance evaluation of thermosetting and thermoplastic polyurethane asphalt mixtures. J. Mater. Civ. Eng. 2022, 34, 04022097. [Google Scholar] [CrossRef]

- Jin, J.; Xiao, M.; Liu, S.; Chen, H.; Wen, Z.; Liu, P.; Rao, R.; Qian, G. Investigation of rheological properties and modification mechanism of bio-oil/crumb rubber modified asphalt reinforced by fiber. Constr. Build. Mater. 2024, 455, 139202. [Google Scholar] [CrossRef]

- Fahad, M.; Nagy, R. Finite element modeling and laboratory performance evaluation of lignin, basalt and polyester fiber-reinforced asphalt mixtures. Appl. Sci. 2025, 15, 3953. [Google Scholar] [CrossRef]

- Flores-Ruiz, D.; Montoya-Alcaraz, M.; García, L.; Gutiérrez, M.; Calderón-Ramírez, J. Mitigation strategies based on life cycle assessment for carbon dioxide reduction in asphalt pavements: Systematic review. Sustainability 2025, 17, 695. [Google Scholar] [CrossRef]

- Jaffar, S.; Abid, M.; Khan, S.; Jafri, T.; Rehman, Z.; Tariq, M.; Ng, A. Evaluation of conventional and sustainable modifiers to improve the stiffness behavior of weak sub-grade soil. Sustainability 2022, 14, 2493. [Google Scholar] [CrossRef]

| Properties | Results | Methods |

|---|---|---|

| Ductility (5 cm/min, 5 °C) (cm) | 32.3 | T 0605 [25] |

| Penetration (25 °C, 100 g, 5 s) (0.1 mm) | 53.4 | T 0604 [25] |

| Softening point (Ring & ball) (°C) | 83.0 | T 0606 [25] |

| Dynamic viscosity (135 °C) (Pa·s) | 2.3 | T 0625 [25] |

| Solubility (%) | 99.3 | T 0607 [25] |

| Elastic recovery (25 °C) (%) | 93.4 | T 0662 [25] |

| Density (15 °C, cm) | 1.032 | T 0603 [25] |

| Mesh Size (mm) | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 | Asphalt Content |

|---|---|---|---|---|---|---|---|---|

| Passing rate (%) | 100.0 | 90.9 | 72.2 | 48.8 | 31.7 | 24.9 | 19.5 | 7.0 |

| Properties | Results |

|---|---|

| Appearance | Grainy, uniform, satiation |

| Single mass particle (g) | 0.021 |

| Density (g/cm3) | 0.959 |

| Melt index (190 °C, 2.16 kg, g/10 min) | 7.19 |

| Ash content | 0.102 |

| Parameter | Virgin Asphalt | 30%RAP | 50%RAP | 70%RAP |

|---|---|---|---|---|

| Nf (2.5%) | 1.15 × 1012 | 8.05 × 1011 | 4.57 × 1010 | 4.80 × 109 |

| Nf (5%) | 7.02 × 1011 | 1.54 × 1011 | 9.01 × 109 | 9.32 × 108 |

| Parameter | Virgin Asphalt | 30%RAP | 50%RAP | 70%RAP |

|---|---|---|---|---|

| Test cycles N (Times) | 1200 | 1200 | 1200 | 1200 |

| Load loss rate R (%) | 68.42 | 74.84 | 79.22 | 83.51 |

| The maximum load of the first cycle F (kN) | 1.38 | 1.87 | 2.46 | 3.34 |

| Critical fracture energy Ec (J/m2) | 1.28 | 1.49 | 1.84 | 2.08 |

| Total fracture energy G (J/m2) | 594.31 | 608.53 | 621.54 | 632.28 |

| Component | Virgin Asphalt | 30%RAP | 50%RAP | 70%RAP | |

|---|---|---|---|---|---|

| Material Consumption | O-RAP Used (kg) | 0 | 300 | 500 | 700 |

| Virgin Asphalt (kg) | 70.0 | 49.0 | 35.0 | 21.0 | |

| Virgin Aggregate (kg) | 930.0 | 651.0 | 465.0 | 279.0 | |

| Reduction vs. Baseline | Virgin Asphalt Saved (kg) | - | 21.0 | 35.0 | 49.0 |

| Virgin Aggregate Saved (kg) | - | 279.0 | 465.0 | 651.0 | |

| CO2-eq Emissions (kg) | From Virgin Asphalt | 37.80 | 26.46 | 18.90 | 11.34 |

| From Virgin Aggregate | 4.65 | 3.26 | 2.33 | 1.40 | |

| From O-RAP Processing | 0.00 | 24.00 | 40.00 | 56.00 | |

| Total Emissions | 42.45 | 53.72 | 61.23 | 68.74 | |

| Net Carbon Reduction | - | −11.27 | −18.78 | −26.29 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Y.; Fan, X.; Liu, B.; Gao, Y.; Yu, X.; Tang, W. Performance Evaluation of Stress-Absorbing Layer Mixtures Incorporating High-Content Oil-Rich RAP Fine Aggregate. Sustainability 2025, 17, 9230. https://doi.org/10.3390/su17209230

Zhu Y, Fan X, Liu B, Gao Y, Yu X, Tang W. Performance Evaluation of Stress-Absorbing Layer Mixtures Incorporating High-Content Oil-Rich RAP Fine Aggregate. Sustainability. 2025; 17(20):9230. https://doi.org/10.3390/su17209230

Chicago/Turabian StyleZhu, Yaoting, Xiangyang Fan, Bin Liu, Yuchao Gao, Xin Yu, and Wei Tang. 2025. "Performance Evaluation of Stress-Absorbing Layer Mixtures Incorporating High-Content Oil-Rich RAP Fine Aggregate" Sustainability 17, no. 20: 9230. https://doi.org/10.3390/su17209230

APA StyleZhu, Y., Fan, X., Liu, B., Gao, Y., Yu, X., & Tang, W. (2025). Performance Evaluation of Stress-Absorbing Layer Mixtures Incorporating High-Content Oil-Rich RAP Fine Aggregate. Sustainability, 17(20), 9230. https://doi.org/10.3390/su17209230