Key Operational Variables in Mechanical Vapor Compression for Zero Liquid Discharge Processes: Performance and Efficiency Evaluation

Abstract

1. Introduction

| Year | Refs. | Data Source | Number of Effects | Boiling Temp (°C) | Compressor Vapor Temp (°C) | CR | Feed Flow (kg/s) | Evaporation Flow (kg/s) | Feed Composition Solute/Solution (ppm) | Energy Demand (kWh/m3 Evaporated) |

|---|---|---|---|---|---|---|---|---|---|---|

| 2015 | [16] | Real data | Single effect | 56 | — | 1.27 | — | 0.0015–0.005 | 2000 | 120.87 |

| 2016 | [25] | Real data | 2 | 76–81 | 124–135 | 3 | — | 50 (m3/day) | — | — |

| 2016 | [17] | Real data | Single effect | 70–110 | 115 | 1.15–1.65 | — | 0.028–0.083 | — | — |

| 2017 | [20] | Simulated data | 1–12 | 60 | 96 | 1.44 | 2.78 | — | 30,000–300,000 | — |

| 2017 | [22] | Simulated data | Single effect | 55–95 | — | — | — | — | 30,000–57,000 | 9.5–20 |

| 2017–2018 | [19,26] | Simulated data | 2–6 | 40–77 | 72 | 1.35 | 70 | 35 | 35,000 | 7.67–11.36 |

| 2018 | [27] | Simulated data | 1–14 | 75–90 | — | 1.40–2 | — | 5–1000 (m3/day) | 160,000–200,000 | — |

| 2019 | [28,29] | Simulated data | 2–10 | 50–60 | 156 | 1.85 | 39.29 | 14.53 | 36,000 | 11.75–17 |

| 2020 | [23] | Real/simulated data | Single effect | 72 | 92 | 3 | — | 0.00028 | — | 75 |

| 2020 | [30] | Simulated data | Single effect | 60 | — | 1.35 | 10–58 | 7.5–42.5 | 35,000 | — |

| 2020 | [31] | Simulated data | Single effect | 60 | 141 | 2.13 | 10.74 | 7.44 | 68,000 | 37.7 |

| 2021 | [24] | Simulated data | Single effect | 63 | 81 | 1.26 | — | 500 (m3/day) | — | 20–150 a |

| 2022 | [32] | Real/simulated data | Single effect | 95 | — | 2.5 | — | 0.11 | 400,000–500,000 | — |

| 2023 | [33] | Real/simulated data | Single effect | 88 | — | 1.25–1.71 | — | 0.058–0.089 | Co2+ 103.9 Sr2+ 83.9 Cs+ 57.8 | — |

| 2023 | [18] | Real/simulated data | Single effect | 90–105 | — | 1.3–3.5 | — | 0.11 | — | — |

| 2023 | [34] | Simulated data | Single effect | 63 | 67–81 | 1.25–2.4 | 10–60 | 9.88–13.52 | 40,000 | — |

| 2023 | [35] | Simulated data | 7 | 52–61 | 92 | 1.5 | 6.76 | 1 | — | — |

| 2024 | [36] | Simulated data | Single effect | 75–55 | 1.15–1.5 | 1 | 0.5 | — | — | 20.64–36.06 b |

2. Methods

2.1. Preliminaries

2.2. Operating Conditions

3. Case Study

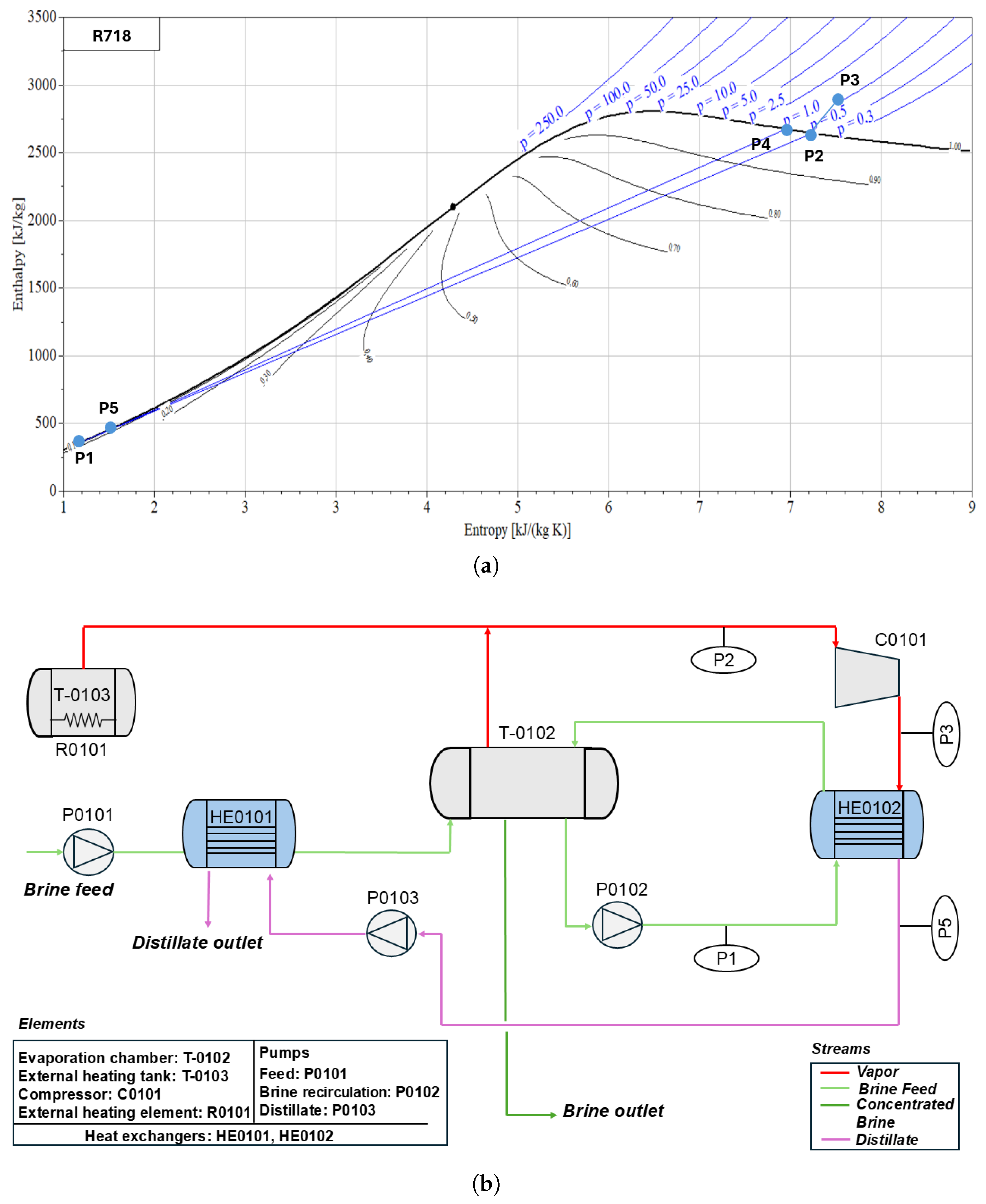

3.1. System Description

3.2. Scenario Definitions

4. Results and Discussion

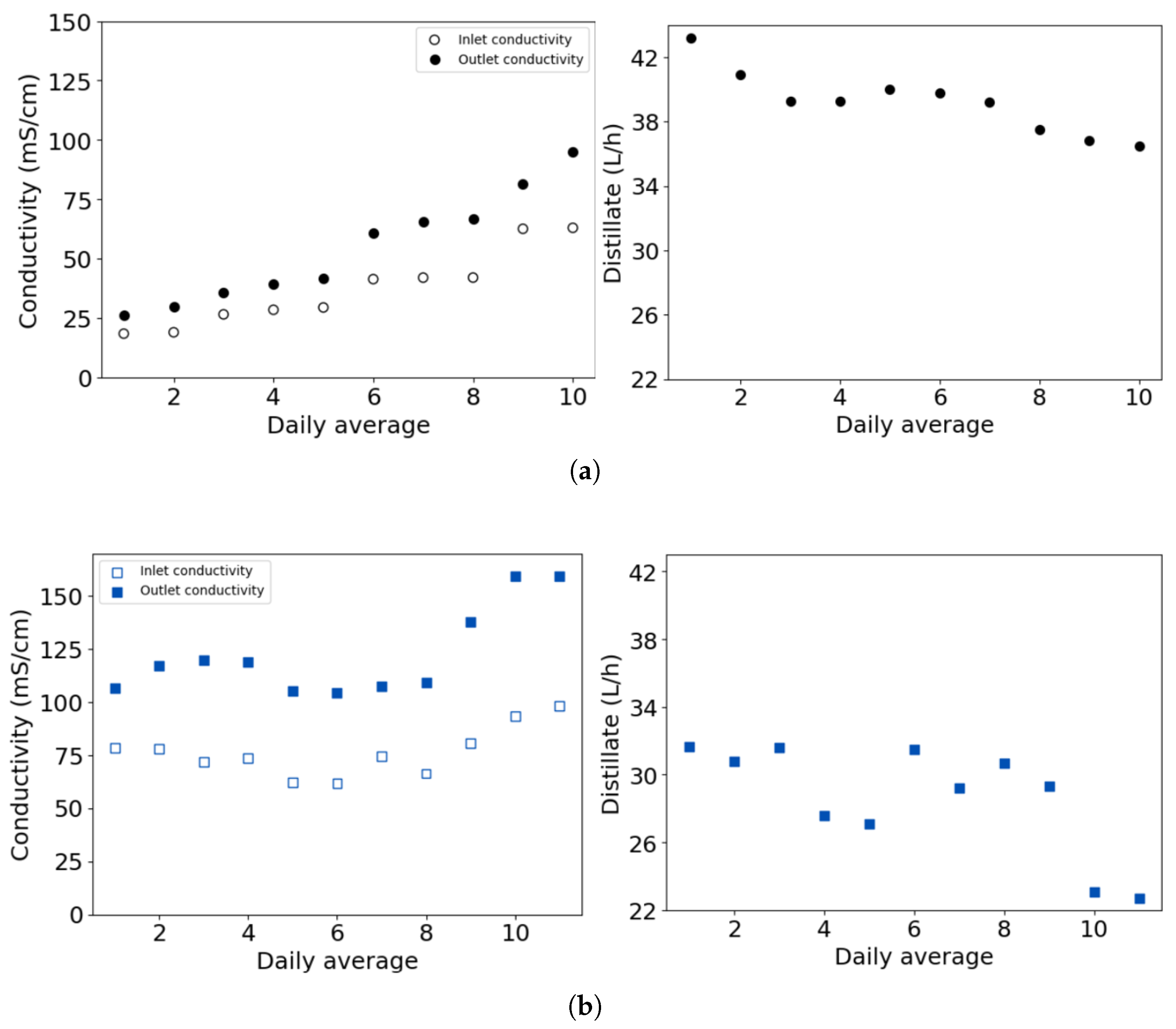

4.1. Results

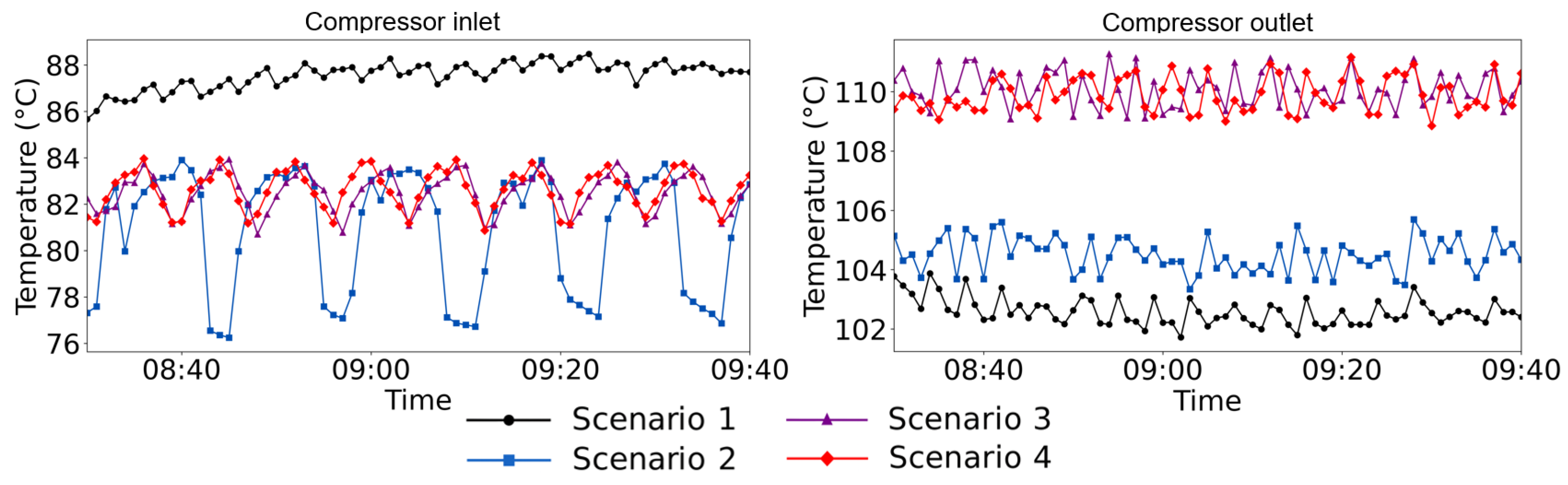

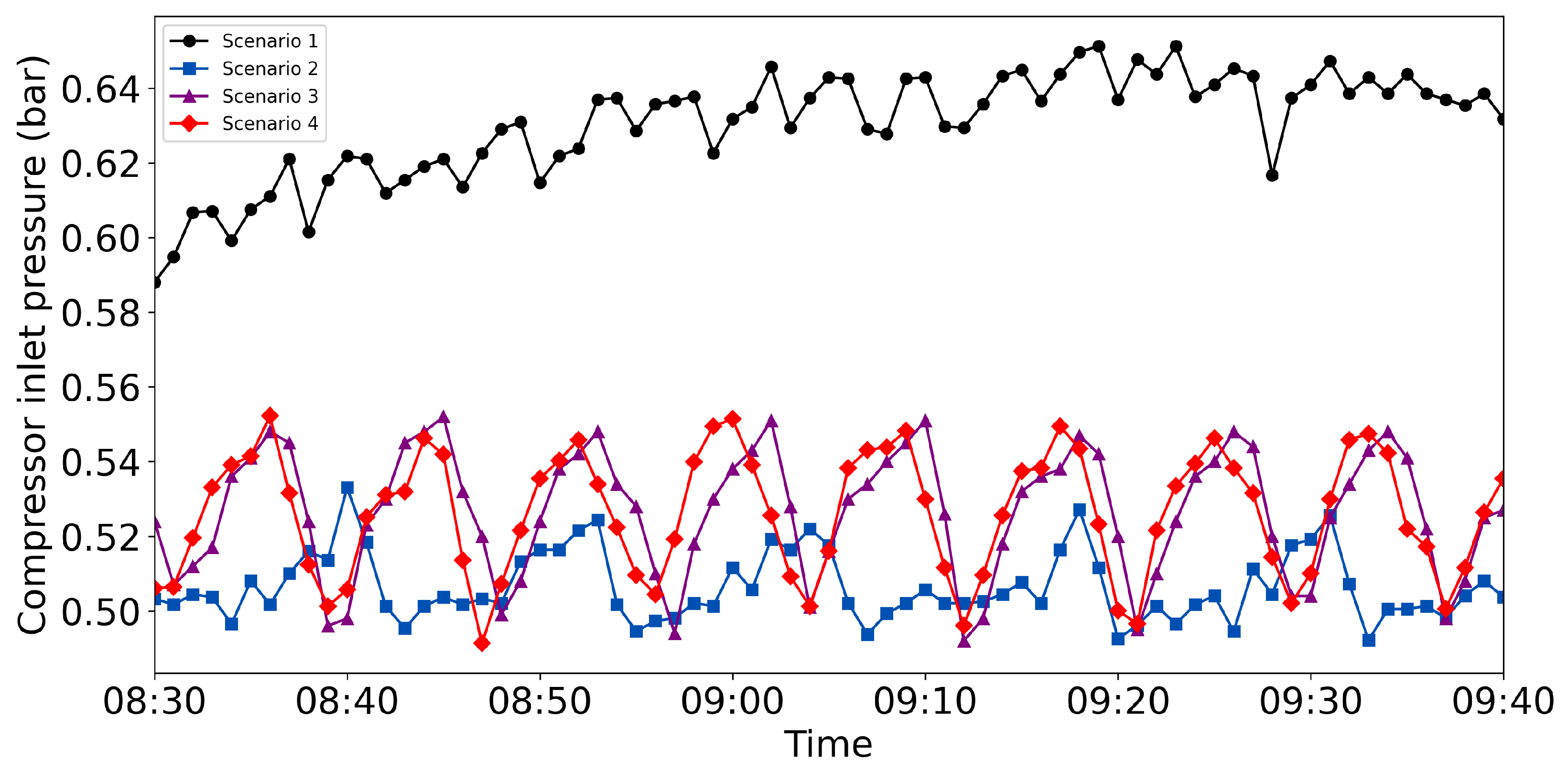

4.2. Temperature and Pressure Analysis

4.3. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CR | Compression ratio |

| HDH | Humidification–dehumidification |

| HNO3 | Nitric acid |

| H-S | Enthalpy–entropy |

| MD | Membrane distillation |

| MEE | Multi-effect evaporation |

| MED | Multi-effect distillation |

| MSF | Multi-stage flash evaporation |

| MVC | Mechanical vapor compression |

| P | Pressure |

| RES | Renewable energy sources |

| RO | Reverse osmosis |

| T | Temperature |

| TVC | Thermal vapor compression |

| ZLD | Zero Liquid Discharge |

References

- The Global Desalination and Water Reuse Community (IDRA). The Global Desalination and Water Reuse Community. 2024. Available online: https://idrawater.org/ (accessed on 1 September 2025).

- Prado de Nicolás, A.; Molina-Garcia, A.; García-Bermejo, J.T.; Vera-García, F. Desalination, minimal and zero liquid discharge powered by renewable energy sources: Current status and future perspectives. Renew. Sustain. Energy Rev. 2023, 187, 113733. [Google Scholar] [CrossRef]

- International Desalination Association (IDA). Desalination at a Glance; IDA: Alexandria, VA, USA, 2011. [Google Scholar]

- Panagopoulos, A.; Haralambous, K.J.; Loizidou, M. Desalination brine disposal methods and treatment technologies—A review. Sci. Total Environ. 2019, 693, 133545. [Google Scholar] [CrossRef] [PubMed]

- United Nations. The 17 Goals. 2015. Available online: https://sdgs.un.org/goals (accessed on 2 September 2025).

- Cui, Y.; Jiang, J.; Fu, T.; Liu, S. Feasibility of using Waste Brine/Seawater and Sea Sand for the Production of Concrete: An Experimental Investigation from Mechanical Properties and Durability Perspectives. Sustainability 2022, 14, 13340. [Google Scholar] [CrossRef]

- Panagopoulos, A.; Giannika, V. Decarbonized and circular brine management/valorization for water & valuable resource recovery via minimal/zero liquid discharge (MLD/ZLD) strategies. J. Environ. Manag. 2022, 324, 116239. [Google Scholar] [CrossRef]

- Reig, M.; Casas, S.; Gibert, O.; Valderrama, C.; Cortina, J. Integration of nanofiltration and bipolar electrodialysis for valorization of seawater desalination brines: Production of drinking and waste water treatment chemicals. Desalination 2016, 382, 13–20. [Google Scholar] [CrossRef]

- Sanchis-Carbonell, J.; Carrero-Ferrer, I.; Sáez-Fernández, A.; Pedro-Monzonís, M.; Campíns-Falcó, P.; Montiel, V. Towards a zero liquid discharge process from brine treatment: Water recovery, nitrate electrochemical elimination and potential valorization of hydrogen and salts. Sci. Total Environ. 2024, 926, 172060. [Google Scholar] [CrossRef]

- del Villar, A.; Melgarejo, J.; García-López, M.; Fernández-Aracil, P.; Montano, B. The economic value of the extracted elements from brine concentrates of Spanish desalination plants. Desalination 2023, 560, 116678. [Google Scholar] [CrossRef]

- Panagopoulos, A. Techno-economic assessment of zero liquid discharge (ZLD) systems for sustainable treatment, minimization and valorization of seawater brine. J. Environ. Manag. 2022, 306, 114488. [Google Scholar] [CrossRef]

- Tong, T.; Xu, L.; Horseman, T.; Westerhoff, P.; Xu, P.; Yao, Y.; Zhang, X.; Alghanayem, R.; Lin, S. Brine management with zero and minimal liquid discharge. Nat. Rev. Clean Technol. 2025, 1, 185–200. [Google Scholar] [CrossRef]

- De Nicolas, A.P.; Molina-Garcia, A.; Vera-Garcia, F.; Garcia-Bermejo, J.T. Sustainable Zero Liquid Discharge for Desalination and Denitrification Processes: Desirows Life European Project. In Proceedings of the 2022 IEEE International Conference on Environment and Electrical Engineering and 2022 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Prague, Czech Republic, 28 June–1 July 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Calleja-Cayon, P.; Molina-Garcia, A.; Vera-Garcia, F. Mechanical vapor compression and renewable energy source integration into desalination process LIFE-Desirows case example. Therm. Sci. 2024, 28, 4395–4405. [Google Scholar] [CrossRef]

- Shamet, O.; Antar, M. Mechanical vapor compression desalination technology—A review. Renew. Sustain. Energy Rev. 2023, 187, 113757. [Google Scholar] [CrossRef]

- Li, Y.; Wu, H.; Liang, X.; Rong, C.; Chen, H. Experimental study of waste concentration by mechanical vapor compression technology. Desalination 2015, 361, 46–52. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, C.; Zhang, Z.; Yang, L.; Lin, W. Study on mechanical vapor recompression system with wet compression single screw compressor. Appl. Therm. Eng. 2016, 103, 205–211. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, Z.; Tong, L.; Yang, J.; Wang, L.; Li, X.; Zhang, Y.; Xu, P.; Yu, Z.; Zhang, J. Experimental research and model optimization of a novel mechanical vapor compression evaporation system driven by Roots steam compressor. Int. J. Refrig. 2023, 150, 185–199. [Google Scholar] [CrossRef]

- Jamil, M.A.; Zubair, S.M. Design and analysis of a forward feed multi-effect mechanical vapor compression desalination system: An exergo-economic approach. Energy 2017, 140, 1107–1120. [Google Scholar] [CrossRef]

- Han, D.; He, W.; Yue, C.; Pu, W. Study on desalination of zero-emission system based on mechanical vapor compression. Appl. Energy 2017, 185, 1490–1496. [Google Scholar] [CrossRef]

- Dahmardeh, H.; Akhlaghi Amiri, H.; Nowee, S. Evaluation of mechanical vapor recompression crystallization process for treatment of high salinity wastewater. Chem. Eng. Process. Process Intensif. 2019, 145, 107682. [Google Scholar] [CrossRef]

- Jamil, M.A.; Zubair, S.M. On thermoeconomic analysis of a single-effect mechanical vapor compression desalination system. Desalination 2017, 420, 292–307. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, X.; Liao, R.; Shi, B.; Wu, L.; Liu, K. Experimental study on energy consumption of mechanical vapor recompression evaporation method for recovery of water from oily wastewater. Desalin. Water Treat. 2020, 179, 98–105. [Google Scholar] [CrossRef]

- Farahat, M.A.; Fath, H.E.; El-Sharkawy, I.I.; Ookawara, S.; Ahmed, M. Energy/exergy analysis of solar driven mechanical vapor compression desalination system with nano-filtration pretreatment. Desalination 2021, 509, 115078. [Google Scholar] [CrossRef]

- Shen, J.; Xing, Z.; Zhang, K.; He, Z.; Wang, X. Development of a water-injected twin-screw compressor for mechanical vapor compression desalination systems. Appl. Therm. Eng. 2016, 95, 125–135. [Google Scholar] [CrossRef]

- Jamil, M.A.; Zubair, S.M. Effect of feed flow arrangement and number of evaporators on the performance of multi-effect mechanical vapor compression desalination systems. Desalination 2018, 429, 76–87. [Google Scholar] [CrossRef]

- Ghazi, M.; Faqir, M.; Mada, M.; Essadiqi, E. Thermal analysis and optimization of mechanical vapour compression desalination process driven by renewable energy using genetic algorithm. Desalin. Water Treat. 2018, 135, 25–46. [Google Scholar] [CrossRef]

- Elsayed, M.L.; Mesalhy, O.; Mohammed, R.H.; Chow, L.C. Transient and thermo-economic analysis of MED-MVC desalination system. Energy 2019, 167, 283–296. [Google Scholar] [CrossRef]

- Elsayed, M.L.; Mesalhy, O.; Mohammed, R.H.; Chow, L.C. Performance modeling of MED-MVC systems: Exergy-economic analysis. Energy 2019, 166, 552–568. [Google Scholar] [CrossRef]

- Liu, C.; Bi, M.; Cui, G. Parameter optimization and economic analysis of a single-effect mechanical vapor compression (MVC) distillation system. Desalin. Water Treat. 2020, 201, 75–85. [Google Scholar] [CrossRef]

- Randon, A.; Rech, S.; Lazzaretto, A. Brine Management: Techno-economic Analysis of a Mechanical Vapor Compression Energy System for a Near-Zero Liquid Discharge Application. Int. J. Thermodyn. 2020, 23, 128–137. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, Z.; Tong, L.; Yang, J.; Wang, L.; Song, Y.; Yu, Z.; Zhang, Y.; Zhang, J. A mechanical vapor compression regeneration system of potassium formate solution: Model development, experimental verification and performance prediction. Desalination 2022, 539, 115940. [Google Scholar] [CrossRef]

- Zhang, H.; Tong, L.; Zhang, Z.; Song, Y.; Yang, J.; Yue, Y.; Wu, Z.; Wang, Y.; Yu, Z.; Zhang, J. A integrated mechanical vapor compression enrichment system of radioactive wastewater: Experimental study, model optimization and performance prediction. Energy 2023, 282, 128868. [Google Scholar] [CrossRef]

- Liu, C.; Xu, L.; Wang, Y. Comparative performance evaluation of two compression ways of a singleeffect mechanical vapor compression desalination system. Desalin. Water Treat. 2023, 316, 136–150. [Google Scholar] [CrossRef]

- Rostami, S.; Ghiasirad, H.; Rostamzadeh, H.; Kalan, A.S.; Maleki, A. A wind turbine driven hybrid HDH-MED-MVC desalination system towards minimal liquid discharge. S. Afr. J. Chem. Eng. 2023, 44, 356–369. [Google Scholar] [CrossRef]

- Yang, H.; Yang, C.; Geng, L. A heat pump-driven mechanical vapor compression desalination system and its operating characteristics. Water Resour. Ind. 2024, 32, 100264. [Google Scholar] [CrossRef]

- Gebel, J. Thermal Desalination Processes. In Desalination; Kucera, J., Ed.; Wiley: Hoboken, NJ, USA, 2014; pp. 39–154. [Google Scholar] [CrossRef]

- KAESER KOMPRESSOREN SE. Assembly and Service Manual for Blower Unit; Technical Report; KAESER KOMPRESSOREN SE: Coburg, Germany; Available online: https://au.kaeser.com/download.ashx?id=tcm:166-5944 (accessed on 1 September 2025).

- Lara, J.R.; Noyes, G.; Holtzapple, M.T. An investigation of high operating temperatures in mechanical vapor-compression desalination. Desalination 2008, 227, 217–232. [Google Scholar] [CrossRef]

- Zhou, Y.; Shi, C.; Dong, G. Analysis of a mechanical vapor recompression wastewater distillation system. Desalination 2014, 353, 91–97. [Google Scholar] [CrossRef]

- Aly, N.H.; El-Figi, A.K. Mechanical vapor compression desalination systems—A case study. Desalination 2003, 158, 143–150. [Google Scholar] [CrossRef]

- Nafey, A.; Fath, H.; Mabrouk, A. Thermoeconomic design of a multi-effect evaporation mechanical vapor compression (MEE–MVC) desalination process. Desalination 2008, 230, 1–15. [Google Scholar] [CrossRef]

- Hernández-Baño, P.; Molina-García, A.; Vera-García, F. Data-Monitoring Solution for Desalination Processes: Cooling Tower and Mechanical Vapor Compression Hybrid System. Sensors 2024, 24, 2909. [Google Scholar] [CrossRef] [PubMed]

| Variable | Range |

|---|---|

| Inlet temperature | 80–90 °C |

| Outlet temperature | 100–130 °C |

| Inlet pressure | >0.5 bar |

| Outlet pressure | 1.05–1.09 bar |

| Component | Concentration Level |

|---|---|

| Calcite, Mg-bearing (CaCO3-Mg) | 54% |

| Aragonite (CaCO3) | 22% |

| Halite (NaCl) | 14% |

| Gypsum (CaSO4 · 2H2O) | 10% |

| Element | Specifications | Action |

|---|---|---|

| Compressor (C0101) | KAESER OMEGA 21B model. Rotatory lobe type compressor | - |

| Evaporation chamber (T-0102) | European Directive 2014/68/EU. Capacity: 88 L | - |

| External steam generation tank (T-0103) | European Directive 2014/68/EU. Capacity: 57 L | - |

| External heating element (R0101) | TOPE company. Power: 13.5 kW | Boiling temperature control |

| Recirculation pump (P0102) | S. ROBUSCHI company. Centrifugal pump. Maximum flow rate: 16,000 L/h | - |

| Cooling pump (P0104) | GAMMA/X. Prominent company. Solenoid-driven diaphragm metering pump | Compressed vapor temperature |

| Venting system | BURKERT company. Angle Seat Valve | |

| Vapor recirculation (FCV0101) | BURKERT company. Straight-seated control valve | Compressed vapor pressure |

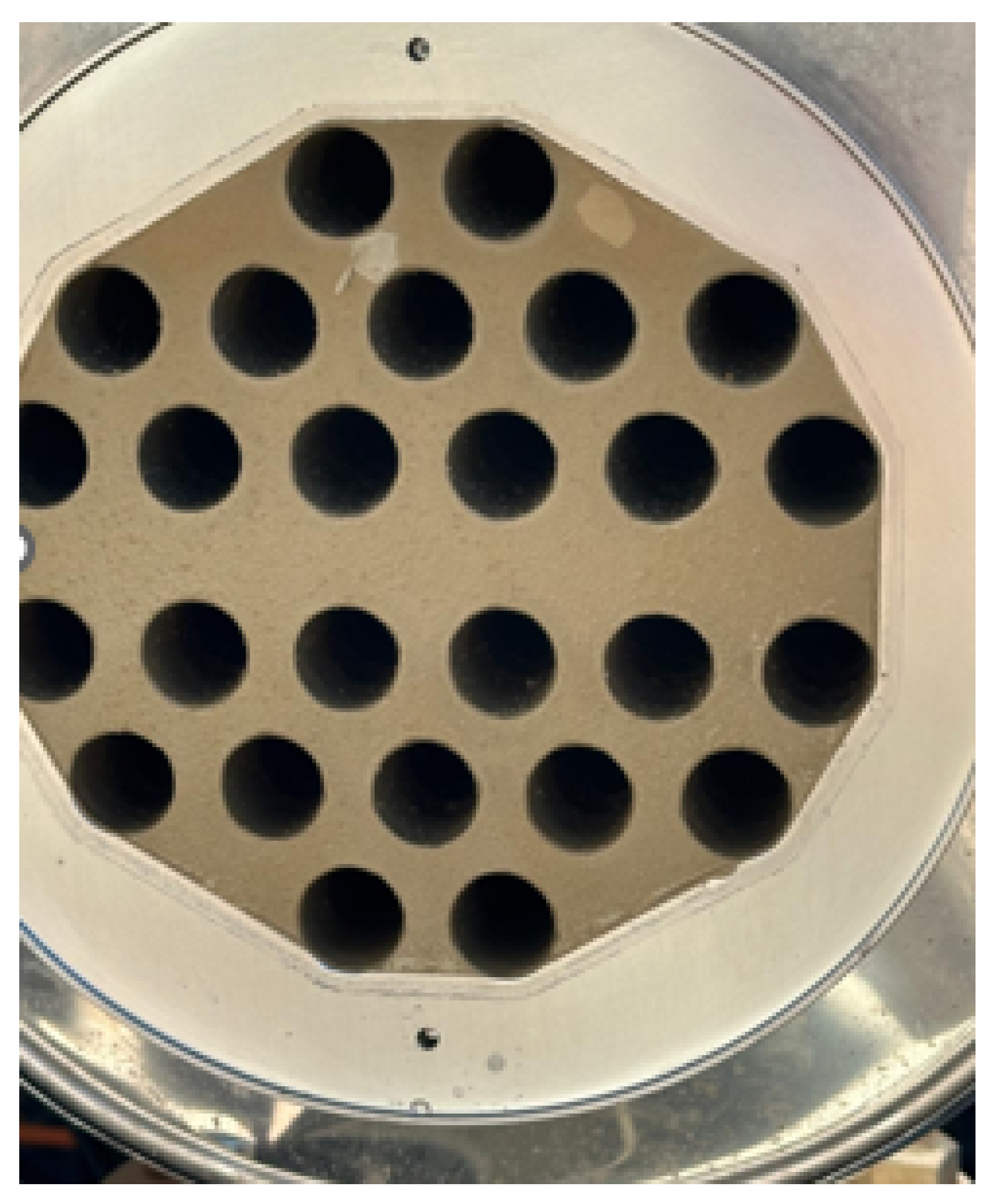

| Heat Exchanger (HE0102) | Shell and tube. Two-pass tube side. One-pass shell side. AISI 316L | - |

| Pre-Heat Exchanger (HE0101) | Double tube. AISI 316 L | - |

| Temperature sensor | TD2251—IFM | Temperatures: Evaporation, outlet and heating tank temperature |

| Pressure sensor | PX3524 and PI2795—IFM | Inlet and Outlet Pressure |

| Scenario | Feed Flow (L/h) | Distillate Flow (L/h) | Consumption (kWh/m3 Feed) | Inlet Temperature (°C) | CR |

|---|---|---|---|---|---|

| Scenario 1 | 85 | 40 | 165 | 87–88 | 1.62 |

| Scenario 2 | 60 | 28 | 214 | 76–83 | 2.10 |

| Scenario 3 | 60 | 32 | 200 | 81–84 | 1.98 |

| Scenario 4 | 70 | 35 | 170 | 82–84 | 1.99 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hernández-Baño, P.; Calleja-Cayón, P.; Vera-García, F.; Molina-García, A. Key Operational Variables in Mechanical Vapor Compression for Zero Liquid Discharge Processes: Performance and Efficiency Evaluation. Sustainability 2025, 17, 9212. https://doi.org/10.3390/su17209212

Hernández-Baño P, Calleja-Cayón P, Vera-García F, Molina-García A. Key Operational Variables in Mechanical Vapor Compression for Zero Liquid Discharge Processes: Performance and Efficiency Evaluation. Sustainability. 2025; 17(20):9212. https://doi.org/10.3390/su17209212

Chicago/Turabian StyleHernández-Baño, Paula, Pablo Calleja-Cayón, Francisco Vera-García, and Angel Molina-García. 2025. "Key Operational Variables in Mechanical Vapor Compression for Zero Liquid Discharge Processes: Performance and Efficiency Evaluation" Sustainability 17, no. 20: 9212. https://doi.org/10.3390/su17209212

APA StyleHernández-Baño, P., Calleja-Cayón, P., Vera-García, F., & Molina-García, A. (2025). Key Operational Variables in Mechanical Vapor Compression for Zero Liquid Discharge Processes: Performance and Efficiency Evaluation. Sustainability, 17(20), 9212. https://doi.org/10.3390/su17209212