Toward Green Manufacturing: A Heuristic Hybrid Machine Learning Framework with PSO for Scrap Reduction

Abstract

1. Introduction

2. Literature Review

2.1. Scrap Forecasting

2.2. Hybrid Algorithms

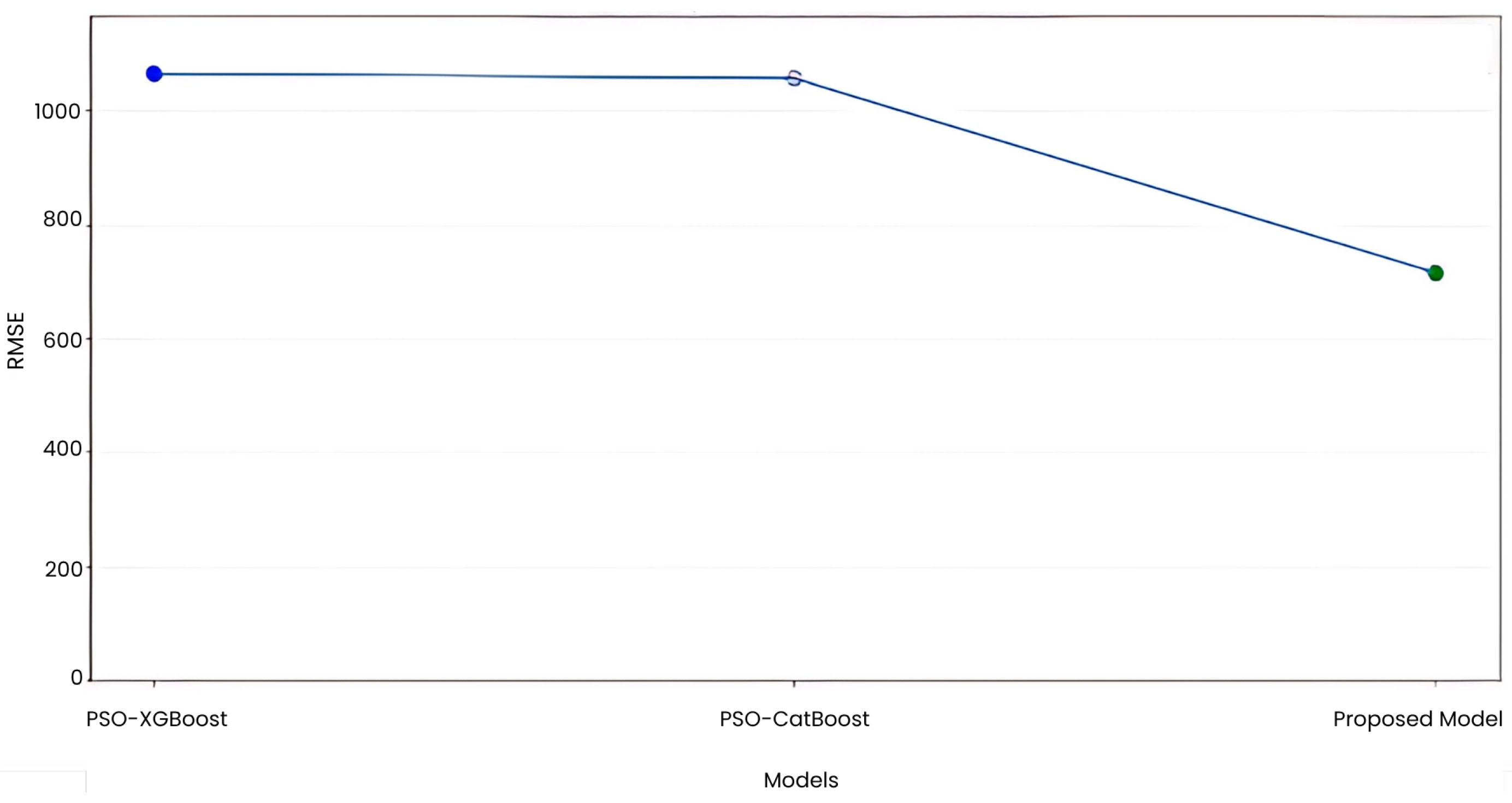

3. Exploratory Data Analysis, Data Preprocessing, and Machine Learning Foundations

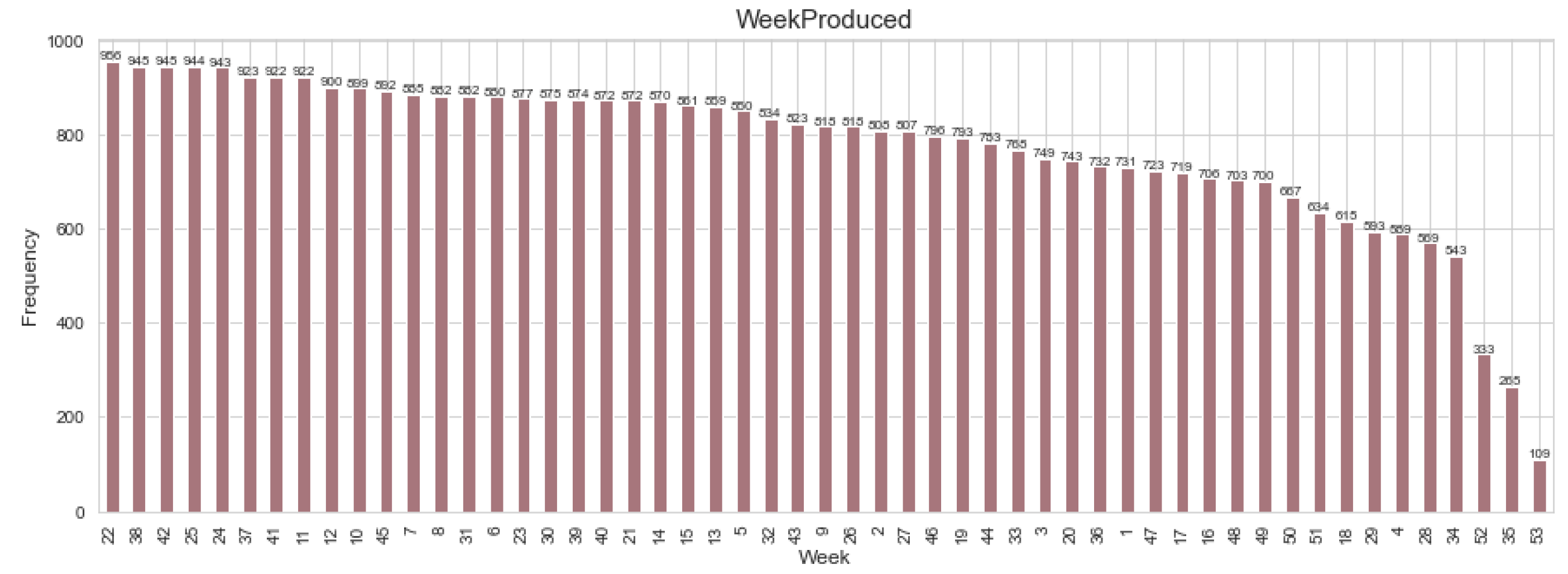

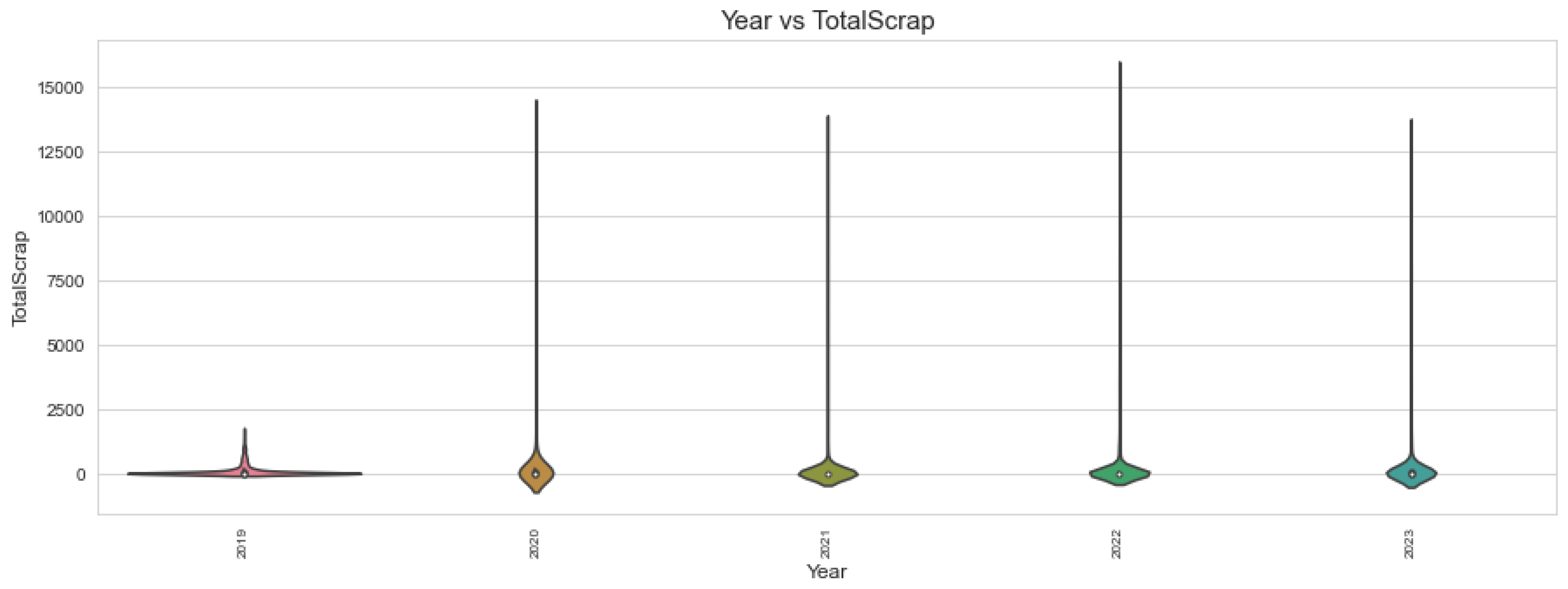

3.1. Exploratory Data Analysis (EDA)

3.2. Data Preprocessing

3.3. Machine Learning (ML)

4. Proposed Hybrid Weighted–Stacked Ensemble (HWSE) Framework

4.1. CatBoost Algorithm

4.2. XGBoost Algorithm

4.3. Proposed Method

| Algorithm 1: HWSE for scrap prediction. |

Input: Dataset D with numeric features , categorical features , and target variable y Output: Final predictions , model performance (RMSE) Step 1: Input the Dataset Load dataset D. Step 2: Separate Features Numeric features Categorical features Step 3: Train Base Models Train XGBoost on : Train CatBoost on : Step 4: Optimize Weights with PSO Run Particle Swarm Optimization to find that minimize validation RMSE, subject to: , Step 5: Weighted Averaging Step 6: Create Stacking Dataset Step 7: Train Meta-Model Train (Ridge, Lasso, or GBM) on Z: Step 8: Blend Predictions , where Step 9: Evaluate Model Evaluate using Root Mean Squared Error (RMSE): Step 10: Benchmark with Baselines Train and evaluate: XGBoost, CatBoost, AdaBoost, LightGBM, GBM, Weighted Averaging, Stacked Ridge, Stacked Lasso, PSO–XGBoost, PSO–CatBoost. Compare RMSE values with the proposed model. |

4.4. Advantages of the Proposed Framework

5. Case Study: Scrap Prediction in the Aerospace Manufacturing Industry

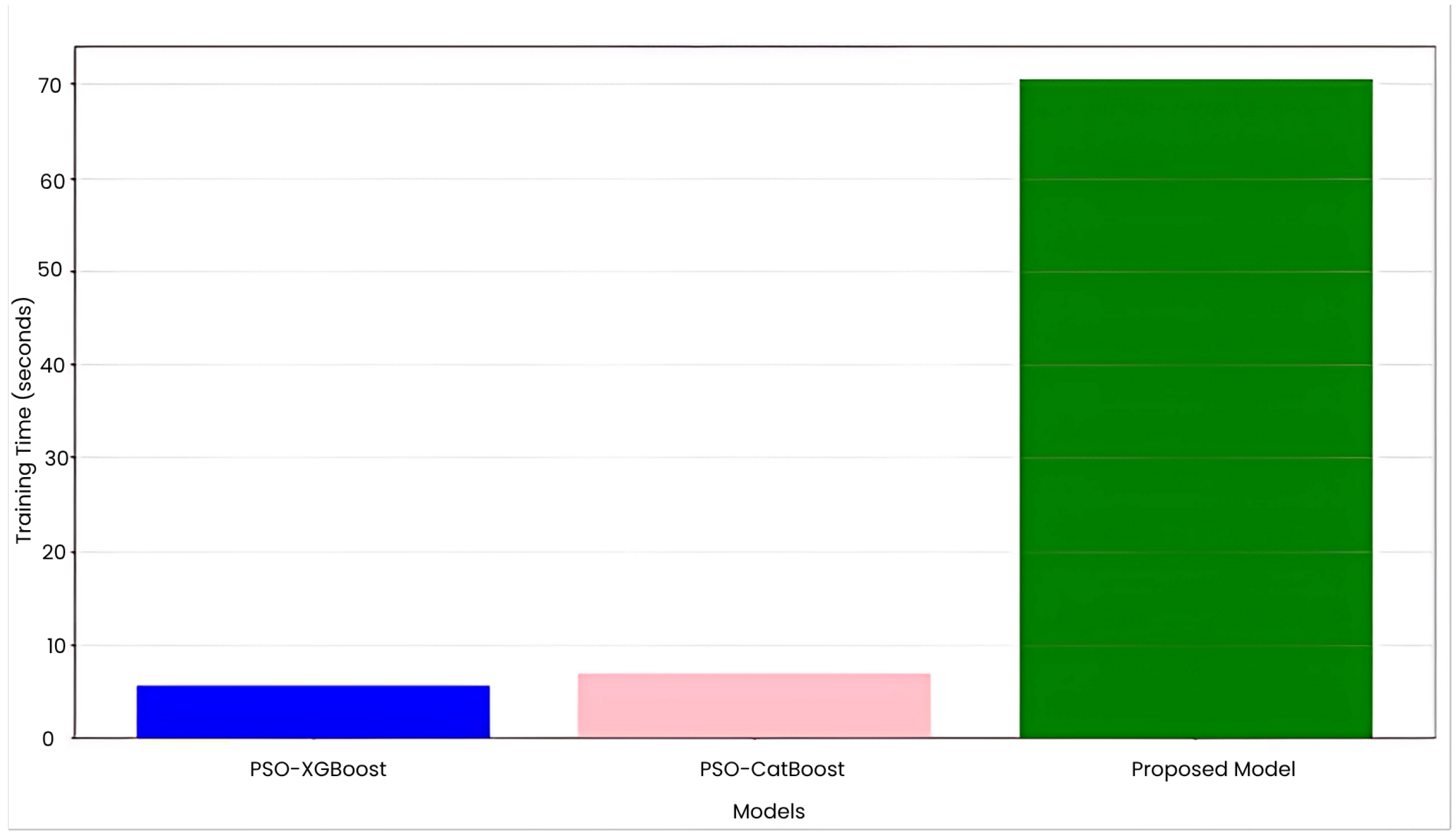

6. Results and Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CatBoost | Categorical Boosting |

| EDA | Exploratory Data Analysis |

| ML | Machine Learning |

| PSO | Particle Swarm Optimization |

| RMSE | Root Mean Squared Error |

| XGBoost | Extreme Gradient Boosting |

References

- Heydarbakian, S.; Spehri, M. Interpretable Machine Learning to Improve Supply Chain Resilience, An Industry 4.0 Recipe. IFAC-PapersOnLine 2022, 55, 2834–2839. [Google Scholar] [CrossRef]

- dos Santos, P.H.; de Carvalho Santos, V.; da Silva Luz, E.J. Towards robust ferrous scrap material classification with deep learning and conformal prediction. Eng. Appl. Artif. Intell. 2025, 140, 109724. [Google Scholar] [CrossRef]

- Sahoo, K.; Samal, A.K.; Pramanik, J.; Pani, S.K. Exploratory Data Analysis Using Python. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 4727–4735. [Google Scholar] [CrossRef]

- Manyika, J.; Chui, M. Big Data: The Next Frontier for Innovation, Competition, and Productivity; McKinsey Global Institute: San Francisco, CA, USA, 2011; Available online: www.mckinsey.com/mgi (accessed on 17 November 2024).

- Shahul Hammed, S.; Karthikeyan, M.P.; Raj, R.P.; Preethi, C.; Haripriya, K.; Kathiravan, A. Scrap Management using E-com Online Machine Learning Iscrap Algorithm. In Proceedings of the International Conference on Sustainable Computing and Smart Systems (ICSCSS), Coimbatore, India, 14–16 June 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 356–360. [Google Scholar] [CrossRef]

- Shi-Ming Huang, S.-M.H.; Shi-Ming Huang, Y.-Y.L. Machine Learning Improves Environmental Sustainability: A Teaching Case of Prediction about Scrapping Inventory. Int. J. Comput. Audit. 2023, 5, 4–31. [Google Scholar] [CrossRef]

- Schäfer, M.; Faltings, U.; Glaser, B. DOES—A Multimodal Dataset for Supervised and Unsupervised Analysis of Steel Scrap. Sci. Data 2023, 10, 26–62. [Google Scholar] [CrossRef]

- Abdou, K.; Schaaf, N.; Struckmeier, F.; Braun, J.; Bhat Keelanje Srinivas, P.; Ottnad, J.; Huber, M.F. Nestability: A Deep Learning Oracle for Nesting Scrap Prediction in Manufacturing Industry. Resour. Conserv. Recycl. 2024, 205, 107540. [Google Scholar] [CrossRef]

- Pentland, A.S. The Data-Driven Society. Sci. Am. 2013, 309, 78–83. [Google Scholar] [CrossRef]

- Ohashi, T. Feature Extraction for Machine Learning to Detect Floating Scrap During Stamping Using Accelerometer. J. Adv. Mech. Des. Syst. Manuf. 2024, 18, JAMDSM0052. [Google Scholar] [CrossRef]

- Verleysen, M.; François, D. The Curse of Dimensionality in Data Mining and Time Series Prediction. In Computational Intelligence and Bioinspired Systems; Cabestany, J., Prieto, A., Sandoval, F., Eds.; Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2005; Volume 3512. [Google Scholar] [CrossRef]

- Gelman, A. Exploratory Data Analysis for Complex Models. J. Comput. Graph. Stat. 2004, 13, 755–779. [Google Scholar] [CrossRef]

- Rey, J.; Apelt, S.; Trauth, D.; Mattfeld, P.; Bergs, T.; Klocke, F. Highly Iterative Technology Planning: Processing of Information Uncertainties in the Planning of Manufacturing Technologies. Prod. Eng. 2019, 13, 361–371. [Google Scholar] [CrossRef]

- Schmitt, J.; Bönig, J.; Borggräfe, T.; Beitinger, G.; Deuse, J. Predictive Model-Based Quality Inspection Using Machine Learning and Edge Cloud Computing. Adv. Eng. Inform. 2020, 45, 101101. [Google Scholar] [CrossRef]

- Wuest, T.; Irgens, C.; Thoben, K.D. An Approach to Monitoring Quality in Manufacturing Using Supervised Machine Learning on Product State Data. J. Intell. Manuf. 2014, 25, 1167–1180. [Google Scholar] [CrossRef]

- Huynh, N.-T. Online Defect Prognostic Model for Textile Manufacturing. Resour. Conserv. Recycl. 2020, 161, 104910. [Google Scholar] [CrossRef]

- Franceschini, F.; Galetto, M.; Genta, G.; Maisano, D.A. Selection of Quality-Inspection Procedures for Short-Run Productions. Int. J. Adv. Manuf. Technol. 2018, 99, 2537–2547. [Google Scholar] [CrossRef]

- Galetto, M.; Verna, E.; Genta, G. Effect of Process Parameters on Parts Quality and Process Efficiency of Fused Deposition Modeling. Comput. Ind. Eng. 2021, 156, 107238. [Google Scholar] [CrossRef]

- García, S.; Ramírez-Gallego, S.; Luengo, J.; Benítez, J.M.; Herrera, F. Big Data Preprocessing: Methods and Prospects. Big Data Anal. 2016, 1, 9. [Google Scholar] [CrossRef]

- Li, D.; Zhi, B.; Schoenherr, T.; Wang, X. Developing Capabilities for Supply Chain Resilience in a Post-COVID World: A Machine Learning-Based Thematic Analysis. IISE Trans. 2023, 55, 1256–1276. [Google Scholar] [CrossRef]

- Chen, Y.M.; Chen, T.Y.; Li, J.S. A Machine Learning-Based Anomaly Detection Method and Blockchain-Based Secure Protection Technology in Collaborative Food Supply Chain. Int. J. e-Collab. 2023, 19, 1–16. [Google Scholar] [CrossRef]

- Schroeder, M.; Lodemann, S. A Systematic Investigation of the Integration of Machine Learning into Supply Chain Risk Management. Logistics 2021, 5, 62. [Google Scholar] [CrossRef]

- Pennekamp, J.; Glebke, R.; Henze, M.; Meisen, T.; Quix, C.; Hai, R.; Gleim, L.; Niemietz, P.; Rudack, M.; Knape, S.; et al. Towards an Infrastructure Enabling the Internet of Production. In Proceedings of the 2019 IEEE International Conference on Industrial Cyber Physical Systems (ICPS), Taipei, Taiwan, 6–9 May 2019; IEEE: New York, NY, USA, 2019; pp. 31–37. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Wang, L.; Nee, A.Y.C. Digital Twins and Cyber–Physical Systems toward Smart Manufacturing and Industry 4.0: Correlation and Comparison. Engineering 2019, 5, 653–661. [Google Scholar] [CrossRef]

- Chen, M.K.; Tai, T.W.; Hung, T.Y. Component Selection System for Green Supply Chain. Expert Syst. Appl. 2012, 39, 5687–5701. [Google Scholar] [CrossRef]

- Sardar, S.K.; Sarkar, B.; Kim, B. Integrating Machine Learning, Radio Frequency Identification, and Consignment Policy for Reducing Unreliability in Smart Supply Chain Management. Processes 2021, 9, 247. [Google Scholar] [CrossRef]

- Pavlyshenko, B.M. Machine-Learning Models for Sales Time Series Forecasting. Data 2019, 4, 15. [Google Scholar] [CrossRef]

- Tirkolaee, E.B.; Sadeghi, S.; Mooseloo, F.M.; Vandchali, H.R.; Aeini, S. Application of Machine Learning in Supply Chain Management: A Comprehensive Overview of the Main Areas. Math. Probl. Eng. 2021, 1476043. [Google Scholar] [CrossRef]

- El-Kenawy, E.S.M.; Khodadadi, N.; Mirjalili, S.; Abdelhamid, A.A.; Eid, M.M.; Ibrahim, A. Greylag Goose Optimization: Nature-Inspired Optimization Algorithm. Expert Syst. Appl. 2024, 238, 122147. [Google Scholar] [CrossRef]

- El-Kenawy, E.S.M.; Rizk, F.H.; Zaki, A.M.; Elshabrawy, M.; Ibrahim, A.; Abdelhamid, A.A.; Khodadadi, N.; ALmetwally, E.M.; Eid, M.M. iHow Optimization Algorithm: A Human-Inspired Metaheuristic Approach for Complex Problem Solving and Feature Selection. J. Artif. Intell. Eng. Pract. 2024, 1, 36–53. [Google Scholar] [CrossRef]

- El-Kenawy, E.S.M.; Ibrahim, A. Football Optimization Algorithm (FbOA): A Novel Metaheuristic Inspired by Team Strategy Dynamics. J. Artif. Intell. Metaheuristics 2024, 8, 21–38. [Google Scholar] [CrossRef]

- Alexopoulos, K.; Catti, P.; Kanellopoulos, G.; Nikolakis, N.; Blatsiotis, A.; Christodoulopoulos, K.; Kaimenopoulos, A.; Ziata, E. Deep Learning for Estimating the Fill-Level of Industrial Waste Containers of Metal Scrap: A Case Study of a Copper Tube Plant. Appl. Sci. 2023, 13, 2575. [Google Scholar] [CrossRef]

- Knott, A.L.; Stauder, L.; Ruan, X.; Schmitt, R.H.; Bergs, T. Potential of prediction in manufacturing process and inspection sequences for scrap reduction. CIRP J. Manuf. Sci. Technol. 2023, 44, 55–69. [Google Scholar] [CrossRef]

- de Souza, L.G.P.; Vasconcelos, G.A.V.B.; Costa, L.A.R.; Francisco, M.B.; de Paiva, A.P.; Ferreira, J.R. Roughness prediction using machine learning models in hard turning: An approach to avoid rework and scrap. Int. J. Adv. Manuf. Technol. 2024, 133, 4205–4221. [Google Scholar] [CrossRef]

- Schorr, S.; Möller, M.; Heib, J.; Fang, S.; Bähre, D. Quality Prediction of Reamed Bores Based on Process Data and Machine Learning Algorithm: A Contribution to a More Sustainable Manufacturing. Procedia Manuf. 2020, 43, 519–526. [Google Scholar] [CrossRef]

- Galetto, M.; Genta, G.; Maculotti, G.; Verna, E. Defect Probability Estimation for Hardness-Optimised Parts by Selective Laser Melting. Int. J. Precis. Eng. Manuf. 2020, 21, 1739–1753. [Google Scholar] [CrossRef]

- Schmidt, C.; Hocke, T.; Denkena, B. Deep Learning-Based Classification of Production Defects in Automated-Fiber-Placement Processes. Prod. Eng. 2019, 13, 501–509. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, Y. Scrap Steel Price Forecasting with Neural Networks for East, North, South, Central, Northeast, and Southwest China and at the National Level. Ironmak. Steelmak. 2023, 50, 1683–1697. [Google Scholar] [CrossRef]

- Daigo, I.; Murakami, K.; Tajima, K.; Kawakami, R. Thickness Classifier on Steel in Heavy Melting Scrap by Deep-Learning-Based Image Analysis. ISIJ Int. 2023, 63, 197–203. [Google Scholar] [CrossRef]

- Chen, S.; Kaufmann, T. Development of Data-Driven Machine Learning Models for the Prediction of Casting Surface Defects. Metals 2022, 12, 1. [Google Scholar] [CrossRef]

- Polat, T.K. Forecasting of Production and Scrap Amount Using Artificial Neural Networks. Emerg. Mater. Res. 2022, 11, 345–355. [Google Scholar] [CrossRef]

- Díaz-Romero, D.; Sterkens, W.; Van den Eynde, S.; Goedemé, T.; Dewulf, W.; Peeters, J. Deep Learning Computer Vision for the Separation of Cast- and Wrought-Aluminum Scrap. Resour. Conserv. Recycl. 2021, 172, 105685. [Google Scholar] [CrossRef]

- Díaz-Romero, D.J.; Van den Eynde, S.; Sterkens, W.; Eckert, A.; Zaplana, I.; Goedemé, T.; Peeters, J. Real-Time Classification of Aluminum Metal Scrap with Laser-Induced Breakdown Spectroscopy Using Deep and Other Machine Learning Approaches. Spectrochim. Acta Part B At. Spectrosc. 2022, 196, 106519. [Google Scholar] [CrossRef]

- Tsymbal, A.; Puuronen, S. Bagging and Boosting with Dynamic Integration of Classifiers. In Proceedings of the 4th European Conference on Principles of Data Mining and Knowledge Discovery (PKDD), Lyon, France, 13–16 September 2000; Springer: Berlin/Heidelberg, Germany, 2000; pp. 116–125. [Google Scholar]

- Zhang, L.; Janošík, D. Enhanced Short-Term Load Forecasting with Hybrid Machine Learning Models: CatBoost and XGBoost Approaches. Expert Syst. Appl. 2024, 241, 122686. [Google Scholar] [CrossRef]

- Nagassou, M.; Mwangi, R.W.; Nyarige, E. A Hybrid Ensemble Learning Approach Utilizing Light Gradient Boosting Machine and Category Boosting Model for Lifestyle-Based Prediction of Type-II Diabetes Mellitus. J. Data Anal. Inf. Process. 2023, 11, 480–511. [Google Scholar] [CrossRef]

- Kahraman, E.; Hosseini, S.; Taiwo, B.O.; Fissha, Y.; Jebutu, V.A.; Akinlabi, A.A.; Adachi, T. Fostering Sustainable Mining Practices in Rock Blasting: Assessment of Blast Toe Volume Prediction Using Comparative Analysis of Hybrid Ensemble Machine Learning Techniques. J. Saf. Sustain. 2024, 1, 75–88. [Google Scholar] [CrossRef]

- Khan, P.W.; Byun, Y.-C.; Lee, S.-J.; Park, N. Machine Learning-Based Hybrid System for Imputation and Efficient Energy Demand Forecasting. Energies 2020, 13, 2681. [Google Scholar] [CrossRef]

- Qiu, Y.; Zhou, J.; Khandelwal, M.; Yang, H.; Yang, P.; Li, C. Performance Evaluation of Hybrid WOA-XGBoost, GWO-XGBoost and BO-XGBoost Models to Predict Blast-Induced Ground Vibration. Eng. Comput. 2022, 38, 4145–4162. [Google Scholar] [CrossRef]

- Chen, H.; Shen, Q.G.; Skibniewski, M.J.; Cao, Y.; Liu, Y. Dynamic Prediction and Optimization of Tunneling Parameters with High Reliability Based on a Hybrid Intelligent Algorithm. Inf. Fusion 2025, 114, 102705. [Google Scholar] [CrossRef]

- Ahn, J.M.; Kim, J.; Kim, K. Ensemble Machine Learning of Gradient Boosting (XGBoost, LightGBM, CatBoost) and Attention-Based CNN-LSTM for Harmful Algal Blooms Forecasting. Toxins 2023, 15, 608. [Google Scholar] [CrossRef] [PubMed]

- Velleman, P.F. Applications, Basics, and Computing of Exploratory Data Analysis; The Internet-First University Press: Ithaca, NY, USA, 1981; Available online: http://dspace.library.cornell.edu/handle/1813/62 (accessed on 19 November 2024).

- Komorowski, M.; Marshall, D.; Salciccioli, J.; Crutain, Y. Exploratory Data Analysis. In Secondary Analysis of Electronic Health Records; MIT Critical Data, Ed.; Springer: Cham, Switzerland, 2016; pp. 185–203. [Google Scholar] [CrossRef]

- Morgenthaler, S. Exploratory Data Analysis. Wiley Interdiscip. Rev. Comput. Stat. 2009, 1, 33–44. [Google Scholar] [CrossRef]

- Jebb, A.T.; Parrigon, S.; Woo, S.E. Exploratory Data Analysis as a Foundation of Inductive Research. Hum. Resour. Manag. Rev. 2017, 27, 265–276. [Google Scholar] [CrossRef]

- Flury, B.K.; Riedwyl, H. Standard Distance in Univariate and Multivariate Analysis; Taylor & Francis, Ltd.: Abingdon, UK, 1986. [Google Scholar]

- Agresti, A. Categorical Data Analysis, 2nd ed.; Wiley-Interscience: Hoboken, NJ, USA, 2002. [Google Scholar]

- Rencher, A.C. A Review of “Methods of Multivariate Analysis, Second Edition”. IIE Trans. 2005, 37, 1083–1085. [Google Scholar] [CrossRef]

- García, S.; Luengo, J.; Herrera, F. Data Preprocessing in Data Mining; Springer: Cham, Switzerland, 2015; Available online: http://www.springer.com/series/8578 (accessed on 15 December 2024).

- Ramírez-Gallego, S.; Krawczyk, B.; García, S.; Woźniak, M.; Herrera, F. A Survey on Data Preprocessing for Data Stream Mining: Current Status and Future Directions. Neurocomputing 2017, 239, 39–57. [Google Scholar] [CrossRef]

- Chandrasekar, P.; Qian, K. The Impact of Data Preprocessing on the Performance of a Naïve Bayes Classifier. In Proceedings of the International Computer Software and Applications Conference (COMPSAC), Atlanta, GA, USA, 10–14 June 2016; IEEE Computer Society: Washington, DC, USA, 2016; pp. 618–619. [Google Scholar] [CrossRef]

- Alasadi, S.A.; Bhaya, W.S. Review of Data Preprocessing Techniques in Data Mining. J. Eng. Appl. Sci. 2017, 16, 4102–4107. [Google Scholar]

- Joshi, A.P.; Patel, B.V. Data Preprocessing: The Techniques for Preparing Clean and Quality Data for Data Analytics Process. Orient. J. Comput. Sci. Technol. 2021, 13, 78–81. [Google Scholar] [CrossRef]

- Zheng, X.; Wang, M.; Ordieres-Meré, J. Comparison of Data Preprocessing Approaches for Applying Deep Learning to Human Activity Recognition in the Context of Industry 4.0. Sensors 2018, 18, 2146. [Google Scholar] [CrossRef]

- Fan, C.; Chen, M.; Wang, X.; Wang, J.; Huang, B. A Review on Data Preprocessing Techniques Toward Efficient and Reliable Knowledge Discovery from Building Operational Data. Front. Energy Res. 2021, 9, 652801. [Google Scholar] [CrossRef]

- Dong, X.L.; Rekatsinas, T. Data Integration and Machine Learning: A Natural Synergy. In Proceedings of the ACM SIGMOD International Conference on Management of Data, Houston, TX, USA, 10–15 June 2018; Association for Computing Machinery: New York, NY, USA, 2018; pp. 1645–1650. [Google Scholar] [CrossRef]

- Alpaydin, E. Introduction to Machine Learning, 3rd ed.; MIT Press: Cambridge, MA, USA, 2014. [Google Scholar]

- Ni, D.; Xiao, Z.; Lim, M.K. A Systematic Review of the Research Trends of Machine Learning in Supply Chain Management. Int. J. Mach. Learn. Cybern. 2020, 11, 1463–1482. [Google Scholar] [CrossRef]

- Ali, M.F.B.M.; Ariffin, M.K.A.B.M.; Supeni, E.E.B.; Mustapha, F.B. An Unsupervised Machine Learning-Based Framework for Transferring Local Factories into Supply Chain Networks. Mathematics 2021, 9, 3114. [Google Scholar] [CrossRef]

- Ben Elmir, W.; Hemmak, A.; Senouci, B. Smart Platform for Data Blood Bank Management: Forecasting Demand in Blood Supply Chain Using Machine Learning. Information 2023, 14, 31. [Google Scholar] [CrossRef]

- Hirata, E.; Lambrou, M.; Watanabe, D. Blockchain Technology in Supply Chain Management: Insights from Machine Learning Algorithms. Marit. Bus. Rev. 2020, 6, 114–128. [Google Scholar] [CrossRef]

- Sharma, N.; Sharma, R.; Jindal, N. Machine Learning and Deep Learning Applications—A Vision. Glob. Trans. Proc. 2021, 2, 24–28. [Google Scholar] [CrossRef]

- Lee, A.; Taylor, P.; Kalpathy-Cramer, J. Machine Learning Has Arrived! Ophthalmology 2017, 124, 1726–1728. [Google Scholar] [CrossRef] [PubMed]

- Sokolova, M.; Lapalme, G. A Systematic Analysis of Performance Measures for Classification Tasks. Inf. Process. Manag. 2009, 45, 427–437. [Google Scholar] [CrossRef]

- Brown, S. Machine Learning, Explained. MIT Sloan School of Management. 2021. Available online: https://mitsloan.mit.edu/ideas-made-to-matter/machine-learning-explained (accessed on 19 October 2024).

- Prokhorenkova, L.; Gusev, G.; Vorobev, A.; Dorogush, A.V.; Gulin, A. CatBoost: Unbiased Boosting with Categorical Features. In Proceedings of the 32nd International Conference on Neural Information Processing Systems (NeurIPS 2018), Montréal, QC, Canada, 3–8 December 2018; Curran Associates, Inc.: Red Hook, NY, USA, 2018; pp. 6639–6649. [Google Scholar]

- Chen, T.; Guestrin, C. XGBoost: A Scalable Tree Boosting System. In Proceedings of the 22nd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, San Francisco, CA, USA, 13–17 August 2016; Association for Computing Machinery: New York, NY, USA, 2016; pp. 785–794. [Google Scholar] [CrossRef]

| Reference | Application Area | Methodology | Key Findings/Contribution |

|---|---|---|---|

| [13] | Production engineering | Uncertainty management | Improved handling of uncertainties in manufacturing planning |

| [14] | Smart factories | ML + Edge Computing | Predictive quality inspection in real-time settings |

| [15] | Manufacturing quality | Supervised ML | Enhanced defect monitoring using product state data |

| [16] | Textile manufacturing | Online ML model | Prognostic defect detection reduced scrap generation |

| [17] | Manufacturing | Decision models | Optimized inspection for short-run productions |

| [36] | Additive manufacturing | ML-based estimation | Accurate prediction of hardness-related defects in SLM |

| [18] | 3D printing (FDM) | Parameter analysis | Identified critical process parameters for efficiency |

| [35] | Machining sustainability | Process data + ML | Scrap reduction via predictive quality analytics |

| [37] | Composite manufacturing | Deep learning | Automated defect detection in fiber placement |

| [38] | Iron & steel industry | ANN | Regional scrap steel price forecasting with high accuracy |

| [39] | Steel recycling | PSPNet (DL) | Visual classification of unwanted materials in scrap |

| [40] | Foundry industry | CatBoost, XGBoost | Boosting algorithms outperform conventional methods in defect prediction |

| [41] | General manufacturing | ANN | Simultaneous prediction of production output and scrap levels |

| [42] | Recycling (Aluminum) | Deep learning CV | High-accuracy classification of aluminum scrap |

| [43] | Recycling (Aluminum) | LIBS + RF/NN | Real-time scrap classification enhances recycling efficiency |

| [29] | Optimization | GGO metaheuristic | Improved feature selection and constrained optimization |

| [30] | Optimization | iHowOA metaheuristic | Human-inspired search balances exploration and exploitation |

| [31] | Optimization | FbOA metaheuristic | Football-strategy inspired optimization for global search |

| [44] | General ML | Hybrid AdaBoost+Bagging | Early dynamic integration improved classifier accuracy |

| [45] | Energy (Load forecasting) | CatBoost + XGBoost | Hybrid boosting improved short-term load prediction |

| [46] | Healthcare (Diabetes) | LightGBM + CatBoost | Hybrid ensemble reduced overfitting and improved accuracy |

| [47] | Mining | LightGBM + CatBoost | Blast toe prediction supporting sustainable practices |

| [48] | Energy forecasting | Hybrid (CatBoost, XGBoost, RF) | Robust prediction under missing data conditions |

| [49] | Environmental engineering | WOA/GWO + XGBoost | Hybrid models outperform conventional learners in vibration prediction |

| [50] | Construction (Tunneling) | CatBoost + Bayesian Opt. + NSGA-III | High reliability in tunneling parameter optimization |

| [51] | Environmental monitoring | Hybrid boosting + CNN-LSTM | Forecasting harmful algal blooms with strong predictive accuracy |

| Methodology | Scrap/Quality | Energy | Healthcare | Environment | Mining/Construction |

|---|---|---|---|---|---|

| Random Forest (RF) | [42,43] | – | – | – | – |

| Artificial Neural Networks (ANN) | [38,41] | – | – | – | – |

| CatBoost | [40] | [45] | – | – | [50] |

| XGBoost | [40] | [45,48] | – | [49,51] | [50] |

| Hybrid Models | – | [45,48] | [46] | [49,51] | [47,50] |

| Deep Learning (DL) | [37,39] | – | – | – | – |

| Variable | Description |

|---|---|

| General Production Information | |

| Date | The date the product is produced |

| Machine, MachineCode | Machine identity and corresponding code |

| Operator | Worker operating the machine |

| Item, Description | Product code and name |

| LotNumber | Code of the product family |

| WorkingHours | Machine’s total operating hours |

| WorkingSpeed | Operating speed of the machine |

| Amount | Number of produced parts |

| Hit | Number of machine hits |

| Consumption | Energy consumption in kWh |

| SpEnergyConsumption | Specific energy consumption in kWh |

| Scrap-related Variables | |

| FormError, BurrHole, BurrSurface, GradualCut, … | Different types of scrap causes (e.g., form error, surface burr, scratches, mold traces, missing holes, bending/slitting errors, etc.) |

| RawMatScrap, RollEndScrap | Scrap caused by raw material or roll ends |

| TotalNumberScrap, TotalProductionScrap | Total number and amount of scrap parts |

| ProductionScrapRate | Scrap ratio in production |

| TotalEngScrap, TotalScrap | Engineering scrap and overall scrap (kg) |

| Downtime and Failure Variables | |

| MoldFailure, MechanicalFault, ElectricalFault, … | Downtime (minutes) due to different machine or process failures (e.g., pneumatic, hydraulic, transfer, mold change, roll change, machine setting, etc.) |

| PlannedMaintenanceFailure, CleaningError, TrainingError | Downtime due to maintenance, cleaning or training |

| MaterialDelay, ForkliftDelay, RepairDelay, BoxDelay | Downtime due to logistic delays |

| PowerCut, ChiefDecision | Downtime due to external or managerial causes |

| TotalDowntime, TotalNumberStop | Overall downtime and number of stops |

| ModelChange, ModelChangeCount, ModelChangePeriod | Frequency and duration of model changes |

| Variable | Count | Mean | Std | Min | 25% | 50% | 75% | Max |

|---|---|---|---|---|---|---|---|---|

| WorkingHours | 40,748 | 0.0 | 4.5 | 5.75 | 9.0 | |||

| Amount | 40,956 | 6722.6 | 10,249.0 | 0.0 | 580.0 | 2450.0 | 9041.0 | 144,000.0 |

| Hit | 40,940 | 3821.6 | 5083.5 | 0.0 | 400.0 | 1325.0 | 5650.0 | 42,940.0 |

| WorkingSpeed | 57 | 3175.4 | 7280.8 | 20.0 | 28.0 | 33.0 | 40.0 | 46,000.0 |

| FormError | 854 | 28.4 | 122.2 | 2.0 | 2.0 | 5.0 | 16.0 | 3000.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nacar, E.N.; Erdebilli, B.; Eraslan, E. Toward Green Manufacturing: A Heuristic Hybrid Machine Learning Framework with PSO for Scrap Reduction. Sustainability 2025, 17, 9106. https://doi.org/10.3390/su17209106

Nacar EN, Erdebilli B, Eraslan E. Toward Green Manufacturing: A Heuristic Hybrid Machine Learning Framework with PSO for Scrap Reduction. Sustainability. 2025; 17(20):9106. https://doi.org/10.3390/su17209106

Chicago/Turabian StyleNacar, Emine Nur, Babek Erdebilli, and Ergün Eraslan. 2025. "Toward Green Manufacturing: A Heuristic Hybrid Machine Learning Framework with PSO for Scrap Reduction" Sustainability 17, no. 20: 9106. https://doi.org/10.3390/su17209106

APA StyleNacar, E. N., Erdebilli, B., & Eraslan, E. (2025). Toward Green Manufacturing: A Heuristic Hybrid Machine Learning Framework with PSO for Scrap Reduction. Sustainability, 17(20), 9106. https://doi.org/10.3390/su17209106