1. Introduction

Quality assurance represents the deliberate and systematic actions taken by a company to reduce the likelihood of errors and enhance the quality of its products and services. In modern supply chains, quality cannot be limited to production; it must be implemented across all logistics processes that directly influence product integrity and customer satisfaction. From inbound material handling to final delivery, logistics is a critical enabler of quality, ensuring that components, assemblies, and finished goods move accurately, safely, and efficiently through each stage of the value chain [

1]. This interconnectedness highlights that defect prevention—at the heart of quality assurance—depends as much on logistics precision and reliability as on manufacturing controls [

2]. Despite a common misconception that quality assurance and quality control are interchangeable, they serve distinct but complementary purposes where quality control focuses on identifying defects, whereas quality assurance emphasizes preventing them throughout the entire operational process, including logistics [

3].

For many years, logistics has been pivotal in supporting and enhancing overall business operations, and its role in quality assurance is increasingly recognized. By ensuring the correct, timely, and traceable flow of goods, services, information, and finances from suppliers to end consumers, logistics directly influence product and service quality at every touchpoint [

4]. Warehousing is a key logistics operation contributing 15% to 40% of the logistics costs [

5]. Hence, optimizing warehousing processes can increase the company’s profits. Warehouse reception process is one of the critical bottlenecks in logistics management since it is the first process in warehouse operations; however, it is not receiving enough investigation in the warehousing literature, making it an interesting topic of research [

6]. Any disruption, delay, or inaccuracy in logistics can introduce quality risks—such as damaged goods, incorrect quantities, or compromised traceability—into the supply chain. However, traditional warehousing operations often include non-value-added activities that contribute to inefficiencies and potential quality issues. For the automotive industry, warehousing is even more critical due to the large number of components, as an automobile has about 25,000 parts [

7]; hence, warehousing should be optimized to facilitate subsequent operations. The purpose of this study is to minimize such inefficiencies, with a specific focus on optimizing the reception workflow in an automotive company warehouse. To achieve this, the potential of Artificial Intelligence (AI)-driven logistics was explored through a quantitative case study on replacing conventional barcode scanning with advanced GenAI-based recognition systems. By enhancing both the speed and accuracy of inbound logistics, such innovations contribute not only to operational efficiency but also to higher overall quality assurance, higher process reliability, continuous improvement, and reduced operational costs. In addition, the study assesses employee engagement and system adaptability for the AI-driven transformation.

In this context, logistics becomes not only a means of material flow but also a strategic platform for embedding quality assurance principles across the entire supply chain. Various strategies, tools, and best practices are employed within logistics operations to proactively prevent defects and disruptions. For instance, logistics organizations implement quality management systems, monitor key process variables, and leverage data collection and analysis to detect anomalies and prevent quality issues before they affect downstream operations [

8]. In the automotive industry, where supply chain complexity and precision requirements are especially high, these methodologies should be applied rigorously across all logistics segments. However, many logistics processes—such as order processing, inventory management, and transportation—still rely on manual methods that are inherently slow and error-prone [

9]. This challenge becomes particularly critical during peak operational periods when labor shortages can lead to processing backlogs, delayed shipments, and increased risk of errors. Moreover, labor-intensive tasks such as sorting and material handling not only drive up costs but also introduce variability that can compromise quality [

10]. Addressing these challenges through AI-enhanced logistics is therefore a promising pathway to achieving both higher efficiency and improved quality assurance.

The potential of using AI-enabled techniques and Generative Artificial Intelligence (GenAI) in supply chains has been addressed by recent works [

11,

12]. However, there is a lack of applied research in this direction, with almost no available research on warehousing operations. Identifying this research gap highlights the contribution of this study.

Building on this understanding, an analysis of recent literature on AI integration in production and logistics reveals several key elements that are critical for achieving both operational excellence and robust quality assurance. When planning to implement AI tools within logistics processes, companies must consider four foundational pillars: people, clear ethical guidelines, transparency, and continuous monitoring.

Figure 1 illustrates this foundation.

Each of these elements directly supports the goal of delivering higher quality outcomes through more resilient and intelligent logistics operations as follows:

People

The successful deployment of AI technologies depends on the ability of employees to adapt to new workflows and collaborate effectively with intelligent systems. In logistics, AI-driven process optimization not only improves resource efficiency but also reduces repetitive tasks, thereby enhancing working conditions and supporting the development of a more skilled and adaptable workforce [

13]. This should be the key message shared with the labor and employees to avoid resistance to change which is a key challenge in digital transformation [

14].

Clear ethical guidelines

The second critical element is the establishment of clear ethical guidelines, particularly in the context of complex, global supply chains. Such guidelines ensure that AI tools support responsible and transparent logistics operations while upholding the rights and interests of all stakeholders, including employees, customers, suppliers, and partners. In this way, ethical AI contributes to a “cleaner” supply chain, both in terms of environmental impact and social responsibility [

15].

Transparency

In traditional logistics processes, the inability to track goods in real time can lead to a lack of visibility and an increased risk of quality failures. AI-powered logistics solutions address this gap by providing real-time data and predictive insights that enable more accurate and timely decision-making. Transparent feedback loops ensure that critical quality information is communicated effectively across all levels of the supply chain, empowering personnel to maintain consistent quality standards [

16].

Continuous monitoring

Continuous monitoring, enabled by AI and machine learning, plays a key role in sustaining high levels of quality assurance. Advanced monitoring systems can detect potential defects, deviations, and inefficiencies in real time, allowing for rapid corrective actions and ongoing process optimization [

17,

18]. Such systems are particularly valuable in logistics environments where dynamic variables—such as supplier variability, transportation delays, or fluctuating demand—can otherwise compromise quality and performance.

By focusing on those four key elements, organizations can systematically evaluate and enhance logistics operations using AI-driven technologies. This monitoring and optimization process not only improves the efficiency and resilience of supply chain activities but also elevates quality assurance across all logistics touchpoints. Real-time data analytics, predictive modeling, and automated feedback loops enable logistics teams to proactively identify bottlenecks, detect anomalies, and implement corrective measures before they escalate into quality failures. In this way, AI becomes a powerful enabler of both operational excellence and consistent quality outcomes. Furthermore, the ability to continuously assess logistics performance through intelligent systems allows organizations to adapt dynamically to demand variability, supply disruptions, and external risks, all while maintaining high-quality service standards.

Leveraging advanced analytics, machine learning, and real-time data processing, Reception AI offers unprecedented visibility into the inbound flow of goods—a critical phase where quality risks often originate. By enabling automated recognition of labels, verification of product attributes, and validation of quantities during the reception process, AI minimizes human error and ensures that only correctly identified and compliant materials proceed to the subsequent production stages. Moreover, Reception AI supports proactive logistics management by predicting potential bottlenecks and suggesting optimal routing, inventory management, and scheduling strategies. This shift from traditional, reactive logistics models to proactive, data-driven decision-making not only streamlines operations but also safeguards the quality and integrity of materials throughout the supply chain [

19]. Furthermore, Reception AI facilitates a deeper and more comprehensive analysis of the complex interactions within global supply chains. Beyond improving the immediate reception process, AI-powered systems can simulate and assess the potential impacts of external factors—such as geopolitical disruptions, regulatory changes, or supplier sustainability practices—on supply chain performance and quality outcomes [

20]. By analyzing these multidimensional risks, Reception AI enables logistics and quality managers to proactively devise mitigation strategies, ensuring greater resilience and alignment with long-term sustainability goals. For example, AI can evaluate the implications of shifting consumer demands or environmental standards on inventory policies, transportation routes, and supplier selection. This capability empowers decision-makers to implement logistics strategies that uphold stringent quality and compliance standards in an increasingly volatile global environment [

21,

22]. As global supply chains face increasing uncertainty and complexity, Reception AI emerges as a cornerstone technology for achieving more responsive, resilient, and sustainable logistics networks.

The scope of this study is to operationalize these concepts by introducing an automated AI-driven process aimed at optimizing the reception workflow within Bosch’s automotive logistics operations in Romania. Specifically, the objective is to reduce reception time, improve process accuracy, and support continuous improvement and waste reduction—core principles of lean manufacturing. While significant progress was made in minimizing total handling time through the introduction of Reception AI, several quality challenges were identified during implementation, including: (1) label recognition errors; (2) system recognition failures; and (3) enterprise resource planning (ERP) system integration issues. This paper aims to demonstrate how the strategic application of AI elements—grounded in the four key pillars of people, ethical guidelines, transparency, and continuous monitoring—can further enhance logistics performance and elevate quality assurance. In addition, the study assesses employee engagement and system adaptability, recognizing that human factors remain essential to the success of any AI-driven transformation [

23]. The case study under consideration explores how these AI principles, combined with established best practices—such as clear objectives, proper security measures, risk assessment, and the emerging concept of value-driven operations—can create a sustainable, high-performance logistics environment. Together with key performance indicators (KPIs) relevant to the automotive industry, these elements form the foundation of this investigation [

24].

The remainder of this paper is structured as follows: in

Section 2, the reception process is described, and the proposed AI-based system is presented. In

Section 3, the results of the case study at Bosch Automotive manufacturing facility in Blaj, Romania, are presented to assess the performance of the proposed framework.

Section 4 provides discussion and insights based on the study findings. Finally, in

Section 5, conclusions, limitations, and future work are presented.

2. Materials and Methods

The present case study was conducted at the Bosch Automotive manufacturing facility in Blaj, Romania—an integral part of Bosch’s global production network specializing in electronic modules and sensor components for the automotive industry. The Blaj plant operates at high production volumes, manufacturing an average of 14,000 parts per day, with a takt time of 6 s per unit, underscoring the critical importance of precise and efficient internal logistics. Furthermore, the facility manages the entire logistics chain in-house, from supplier coordination to direct delivery to customers, without relying on intermediate warehouses or subcontractors for logistics processes. This end-to-end responsibility further elevates the importance of maintaining streamlined, error-free logistics operations to support continuous flow and on-time delivery in a highly dynamic production environment. Given these operational demands, the reception process was selected as a key focus area for improvement through GenAI integration. The primary objective of the research was to evaluate the impact of implementing an AI-based image recognition system in the goods reception process. The study aims to quantify changes in processing time, operational costs, and process reliability by comparing performance indicators before and after implementing GenAI. The research employed a quasi-experimental, within-subjects design, where the same logistics workflows were observed under two conditions: conventional reception (manual barcode scanning) and GenAI-enhanced reception (automated visual recognition).

Data was collected over a three-month period between February and April 2024. A total of ten reception cycles were selected, five under the manual system and five under the GenAI system. The sample size reflects the constraints of conducting experiments in a live automotive facility, where extended testing could disrupt production. To ensure validity, all runs were performed under identical conditions, and a within-subjects design was applied, making each cycle directly comparable. The Wilcoxon Signed-Rank Test, appropriate for small samples, was used to confirm statistically significant results, while complementary analyses (value stream mapping and factorial modelling) were used to support the robustness and generalizability of the findings. Each cycle involved the reception of a standardized batch of ten pallets containing automotive components from a consistent supplier. To ensure comparability, all reception activities were conducted during the same work shift, within the same warehouse area, and under identical operating conditions. Operational time measurements were recorded using synchronized digital timekeeping devices, while cost data were extracted directly from the company’s ERP system (SAP), based on predefined standard cost allocations per handling unit. The study focused on key logistics performance indicators, namely total processing time per reception cycle, cost per pallet, rate of identification errors, and system response time for SAP feedback loops. The technical configuration of the AI-enhanced reception system consisted of four industrial-grade Omron cameras (20 megapixels each), complemented by eight high-intensity Light Emitting Diode (LED) panels to ensure consistent lighting conditions. These devices were mounted to capture high-resolution images of both sides of two pallets simultaneously. Captured images were processed locally via an Omron controller and then transmitted to the InTrack cloud platform (hosted on Microsoft Azure) for further analysis. The cloud-based system performed image decoding, barcode reading, and Optical Character Recognition (OCR) processing, with all relevant data transferred automatically to the SAP Q99/P99 systems through secure web services.

Statistical evaluation of the collected data was carried out through a twofold approach. First, a factorial experimental model was employed to examine the influence of multiple operational factors and their interactions on the Time Scanning process, using a structured design of experiments with three factors and replicates. This approach enabled the identification of optimal factor combinations for process efficiency. In parallel, the Wilcoxon Signed-Rank Test was applied to assess paired sample differences, chosen due to the non-parametric characteristics of the data and the limited sample size. Statistical significance was evaluated at a threshold of

p < 0.05. All data processing and analysis were conducted using Minitab Statistical Software version 22.2.2 [

25]. To minimize the influence of potential confounding variables, the research protocol ensured that the same team of logistics personnel performed all reception tasks in both experimental conditions. Furthermore, label design, packaging structure, and delivery documentation were standardized across all test runs. This methodological rigor allowed for a clear and reliable comparison between traditional and AI-enhanced reception workflows, supporting valid conclusions on the effectiveness of the proposed technological intervention. The methodology used has been validated through previous works that compared conventional and AI-based and assessed warehousing processes through value stream mapping, factorial experimental design, and statistical validation using the Wilcoxon Signed-Rank Test [

26,

27,

28,

29,

30].

2.1. Logistics Processes

At the Blaj plant, Bosch has been actively involved in digitalizing logistics processes, including the automation of warehouse facilities, real-time tracking of material flows, integration of Internet of Things (IoT) devices for inventory management, and implementing digital tools to optimize workforce allocation and logistics planning. The plant also utilizes data analytics and GenAI to enhance efficiency and support continuous improvement in supply chain operations. The main logistics processes of the company are classified into three categories as seen in

Figure 2.

2.1.1. Supplier Logistics

Procurement planning aims at optimizing material flow and minimizing supply disruptions. Suppliers are carefully selected based on quality, cost, and delivery performance criteria [

31]. Key suppliers for Bosch Automotive in Blaj include established global companies renowned for their reliability, adherence to stringent quality standards, and timely deliveries. Material requirements planning (MRP) systems automate procurement based on production schedules and inventory levels, effectively streamlining the entire procurement process.

Inbound Control Planning optimizes deliveries to production facilities by defining precise delivery windows to prevent dock congestion. It coordinates transportation for efficient routes and cost-effective lead times. Supplier performance is monitored for on-time delivery, quality, and responsiveness to disruptions. Compliance and documentation ensure regulatory adherence, minimizing risks and delays.

Inbound Control Operative involves the physical handling, inspection, and verification of incoming materials. Receiving and unloading processes ensure the efficient unloading of materials using automated systems where possible. Quality control and inspection is through both random and systematic quality checks to ensure compliance with specifications. Inventory management organizes materials in designated warehouse zones, utilizing warehouse management systems (WMS) to track stock levels and optimize storage efficiency [

2,

32]. Material flow optimization ensures the quick and efficient movement of materials from the warehouse to production lines, reducing handling times and storage costs [

33].

Material requirements and forecast planning are essential for production continuity and avoiding stock shortages or excess inventory. This process involves analyzing past consumption patterns, predicting future material needs, and integrating these insights into procurement and production schedules.

Vendor Evaluation focuses on assessing suppliers based on their adherence to delivery schedules and overall reliability. KPIs such as lead time compliance, defect rates, and responsiveness to urgent demands are monitored continuously. Maintaining strong supplier relationships and implementing corrective actions when performance deviates from agreed benchmarks contribute to a more stable and efficient supply chain.

Early warning processes and goods in transit monitoring aim to mitigate potential disruptions by tracking shipments in real-time and identifying risks before they impact production. Advanced tracking technologies, such as Global Positioning System (GPS) for robots and IoT sensors in cameras, enable logistics teams to monitor the movement of goods, detect delays, and take proactive measures to minimize their effects. This approach ensures greater supply chain transparency and responsiveness to unforeseen challenges (shortages, out-of-stock situations, and longer lead times for components, which impact resilience and recovery processes) [

21].

2.1.2. Production Logistics

Supply chain capacity and demand coordination involve aligning supply chain capacity with demand forecasts. Bosch uses historical data, market trends, and customer orders to predict the required demand for automotive components. Bosch optimizes inventory levels by balancing just-in-time practices with safety stock, ensuring smooth production flow without excess inventory.

Pacemaker operative identifies the “pacemaker” of the production process, which is the point that dictates the overall pace of production. Bosch adjusts the pace of upstream and downstream processes to synchronize with the pacemaker, ensuring that materials flow consistently. Managing cycle times at each operation is essential to match the pacemaker’s output, and buffer zones are established to protect against potential disruptions or variations in upstream or downstream operations, ensuring continuous production.

Production planning involves developing a detailed production plan by first creating a production schedule based on the forecasted customer demand and available capacity. The schedule must remain flexible to adapt to fluctuations in demand or unexpected delays. Resource allocation is an essential part of the planning process, as Bosch ensures that all necessary materials, labor, and machinery are available at the right time to avoid production delays. This careful planning allows for maximum efficiency and reduces the likelihood of bottlenecks.

Production Control Planning and Operative Bosch focuses on smooth production operations during the production process. This involves monitoring the production schedule in real-time, ensuring that all processes are running on track and that materials are available for uninterrupted manufacturing. Bosch closely monitors KPIs like on-time delivery, production efficiency, and quality control. Any disruptions or delays are addressed promptly, with adjustments made to the production schedule or resource allocation as needed. Additionally, Bosch ensures that production operations comply with quality standards and regulatory requirements, minimizing risks and delays.

2.1.3. Customer Planning

Forecast planning in Bosch uses advanced forecasting tools and techniques to identify potential fluctuations in demand, allowing the company to prepare for peak periods or market shifts. The goal of forecast planning is to create a reliable demand projection that aligns production and supply chain operations with anticipated customer needs.

Customer order planning moves into customer order planning, where specific customer orders are integrated into the production schedule. This process involves confirming the availability of required components, determining production timelines, and aligning resources to fulfill customer orders on time. Bosch closely coordinates with sales teams and customers to ensure that orders are accurately captured and that any customization or special requirements are clearly understood. During this phase, Bosch works to optimize inventory management, ensuring that the right parts and products are available to meet customer orders while maintaining cost efficiency. By integrating both forecasted demand and actual customer orders, Bosch can efficiently balance production capacity with customer expectations, ensuring high levels of customer satisfaction and timely delivery.

2.2. Reception Process Overview in Bosch Factory in Blaj, Romania

The reception process at the Bosch factory in Blaj, Romania, is a structured and systematic approach to ensure the proper handling, inspection, and storage of incoming raw materials and packaging. This process is crucial for maintaining supply chain efficiency, quality control, and compliance with internal and external standards. By integrating internal process optimization (Bosch Production System (BPS), SAP-Based Digital Logistics and Inventory Management, and quality audits) with global compliance standards, Bosch ensures high performance, safety, and sustainability in its logistics and manufacturing operations [

34,

35]. The main components of the reception system in the logistics warehouse may be seen in

Figure 3, which illustrates key areas of the process: (a) Warehouse, (b) Reception area, (c) Shipping preparation, and (d) Packaging boxes. These elements provide a comprehensive visual representation of the logistics workflow, ensuring clarity on material handling and storage operations.

2.3. New vs. Old Receiving Process

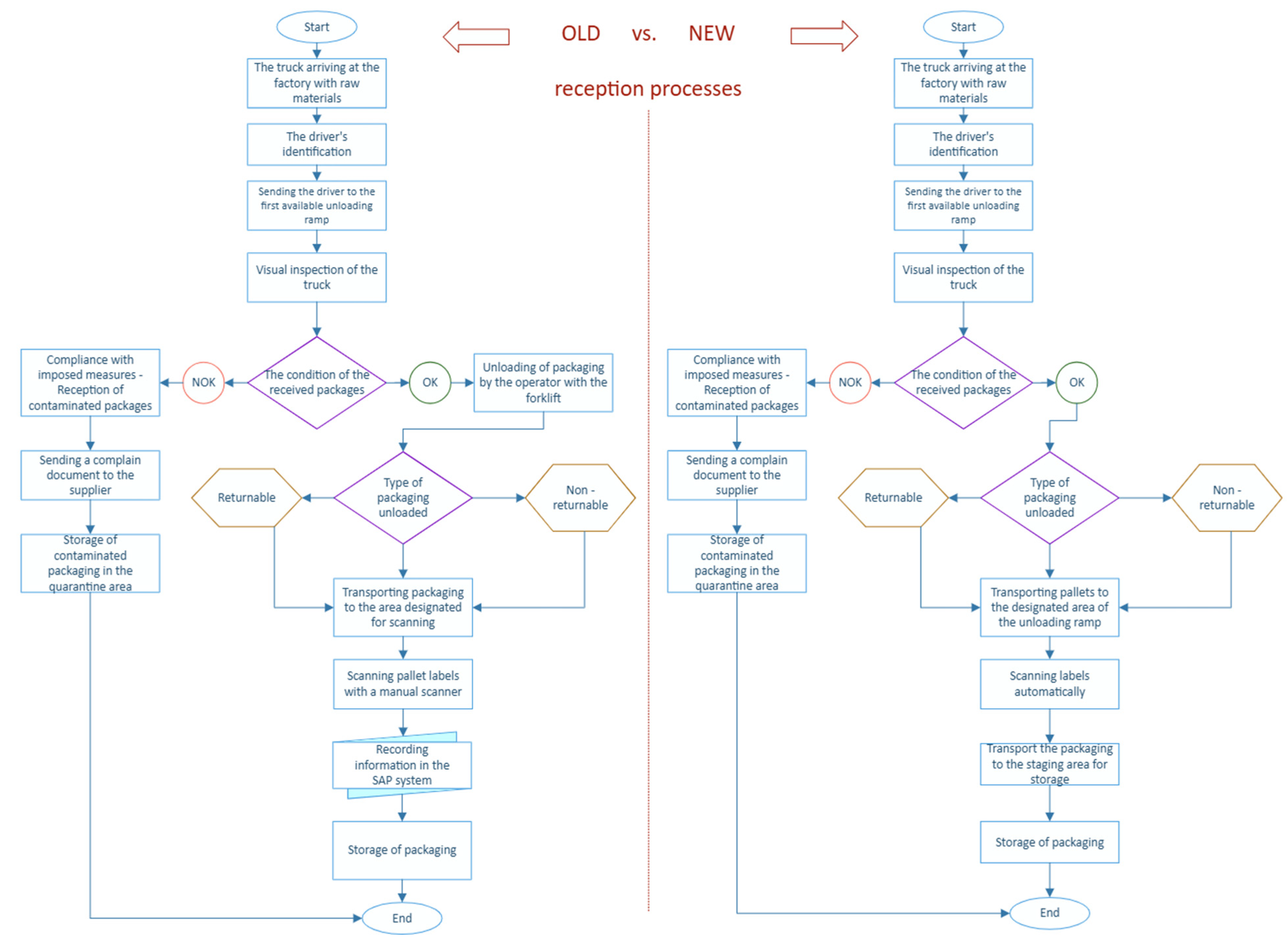

The process begins when a truck carrying raw materials arrives at the factory premises. The first step is the driver’s identification, followed by directing the driver to the first available unloading ramp. A visual inspection of the truck is conducted to assess the condition of the shipment before further handling. A key decision point in the process is the inspection of the packages received. If the condition of the packages is deemed non-compliant (NOK), corrective measures are taken. These include receiving contaminated packages under imposed measures, sending a complaint document to the supplier, and storing contaminated packaging in a quarantine area to prevent potential risks to production. These specific steps may be seen in

Figure 4.

If the received packages pass inspection and are classified as compliant (OK), the unloading process is carried out using forklifts. At this stage, a distinction is made between returnable and non-returnable packaging. For returnable packaging, the materials are transported to a designated scanning area, where pallet labels are scanned using a manual scanner. The scanned data is then recorded in the SAP system, ensuring traceability and inventory management. The packaging is subsequently stored in the appropriate location. For non-returnable packaging, after unloading, it follows specific storage procedures as per Bosch’s internal logistics guidelines. This structured reception process ensures smooth supply chain operations by integrating quality checks, digital tracking, and compliance measures. By leveraging SAP for data recording and monitoring, Bosch maintains high standards of accuracy and efficiency in its inbound logistics at the Blaj facility. The new process introduces automatic scanning of labels instead of manual scanning, improving efficiency. The transportation flow has changed, with pallets being moved directly to the designated unloading ramp area before storage, rather than first being scanned separately. The step for recording information in the SAP system has been removed or automated.

3. Results

3.1. Business Model for Cleaner Logistics and Supply Chain

While AI is changing many fields including supply chain management, it creates both big possibilities and tough ethical problems [

36]. Hence, prior to adopting AI in production operations, it is necessary to develop a model that integrates various factors together to ensure sustainable and ethical implementation.

This Cleaner Logistic and Supply Chain Model integrates key concepts for a more sustainable and ethical supply chain as illustrated in

Figure 5. The model presented was developed by the authors based on direct observations of the company’s processes during factory visits and data collection. It reflects the specific operational context of the company.

A detailed breakdown of each element present in the diagram is presented below.

3.1.1. Leadership and Mindset

Leadership and mindset are foundational to embedding sustainability across logistics operations [

37]. Strong leadership cultivates a sustainability-oriented culture, encourages innovation, and ensures ethical responsibility at all organizational levels. Leadership that exemplifies environmental values creates long-term commitment and motivates cross-functional teams to adopt and sustain green practices; this involves:

Promoting sustainability is a strategic priority;

Driving behavioral changes through awareness and accountability;

Investigating training on green practices, such as ethical sourcing, resource efficiency, and regulatory compliance;

Setting clear goals and leading decarbonization initiatives (e.g., through energy-efficient technologies and waste reduction strategies).

3.1.2. Implementation and Monitoring

Effective implementation and monitoring allow for continuous improvement and ensure accountability throughout the supply chain. This component ensures that sustainability goals translate into measurable action. It includes:

Establishing KPIs aligned with environmental, social, and governance (ESG) targets,

Utilizing advanced data systems for real-time monitoring and performance tracking,

Conducting periodic audits and evaluations to refine strategies,

Enabling adaptive measures based on insights from analytics and operational feedback.

3.1.3. Principles for Cleaner Logistics

The operational foundation of a sustainable logistics system is built on several key principles that guide performance and environmental responsibility. Fault prevention plays a critical role by ensuring early detection of inefficiencies and enabling proactive measures to address them before they escalate [

38]. Flexibility is equally important, allowing logistics operations to remain agile in response to evolving regulations and shifting market demands. Standardization contributes to overall efficiency by streamlining procedures, ensuring consistent quality, and minimizing unnecessary resource use and waste [

39]. Transparency strengthens trust among stakeholders by promoting open communication about sourcing practices, logistics processes, and environmental impact. Finally, continuous improvement is essential for long-term sustainability, as it encourages organizations to constantly evaluate performance, integrate innovation, and evolve through feedback and strategic adjustments. Together, these principles support not only environmental progress but also the operational excellence needed in modern logistics systems.

3.1.4. Ethical Guidelines

Ethical guidelines serve as the moral and regulatory foundation for sustainable logistics, ensuring that all business activities are conducted in a responsible and conscientious manner. They emphasize the importance of fair labor conditions and environmentally sound practices, reinforcing commitment to human rights and ecological integrity throughout the supply chain. Integrity must be upheld across every stage—from sourcing raw materials to production and transportation—ensuring that operations remain transparent and accountable. These guidelines also require alignment with both international frameworks and local compliance standards, promoting consistency and legality in all logistics decisions. Furthermore, ethics are embedded into procurement strategies and partner selection processes, ensuring that collaborators share the same commitment to sustainability and fairness [

36]. These guiding values support all other aspects of the logistics model and steer organizations toward socially responsible decision-making.

3.1.5. Collaboration and Partnerships

Sustainable logistics is inherently a collective effort that cannot be achieved in isolation. The complexity and interconnectedness of modern supply chains require a high level of cooperation among diverse actors to ensure that environmental and social objectives are fully integrated into logistics practices. Collaboration fosters both scalability and consistency in implementing green strategies, allowing individual initiatives to align with broader sustainability goals. Engaging stakeholders—such as suppliers, customers, regulatory authorities, and non-governmental organizations—is essential for co-designing practical and inclusive sustainability solutions. This engagement helps identify common challenges, align priorities, and develop strategies that are feasible and beneficial for all parties involved. By involving a wide range of contributors, companies can ensure that their sustainability efforts are both comprehensive and contextually relevant.

Sharing data, resources, and best practices is another critical component of effective collaboration. Transparent information exchange allows stakeholders to benchmark performance, identify areas for improvement, and replicate successful approaches. Resource sharing, such as joint investments in green infrastructure or collaborative logistics platforms, enhances efficiency and reduces costs, creating mutual advantages that support long-term sustainability. Building long-term partnerships rooted in shared responsibility and mutual benefit is key to achieving sustained progress. These partnerships are based on trust, aligned values, and a commitment to continuous improvement. By fostering enduring relationships, companies and their partners can work together to innovate, overcome barriers, and accelerate the transition toward a cleaner, more resilient logistics ecosystem.

3.1.6. Sustainability Growth

Sustainability growth refers to embedding long-term environmental goals into business development. Sustainability growth ensures that businesses remain resilient and competitive while protecting planetary resources through various practices including:

Integrate practices such as carbon-neutral transport, eco-packaging, and circular economy models;

Reinvest in innovation to scale low-impact logistics solutions;

Balance profitability with environmental performance and social impact.

3.1.7. The Role of Data

At the center of this model is data—the driving force behind insight, integration, and intelligence. With accurate, accessible data, organizations can measure progress, report impact, and adapt proactively. Data enables:

Evidence-based decision-making across all components,

Real-time visibility of logistics flows and emissions,

Predictive capabilities for risk and demand planning,

Evaluation of Return on Investment (ROI) for sustainability investments.

3.2. Integration of GenAI in the Reception Process

The integration of GenAI in the reception process at Bosch Automotive Romania demonstrates a leap forward in warehouse efficiency, real-time monitoring, and data accuracy. Leveraging high-resolution imaging, intelligent communication between hardware and software, and dynamic data dashboards, GenAI ensures that reception operations are executed with minimal human intervention while maximizing precision and traceability.

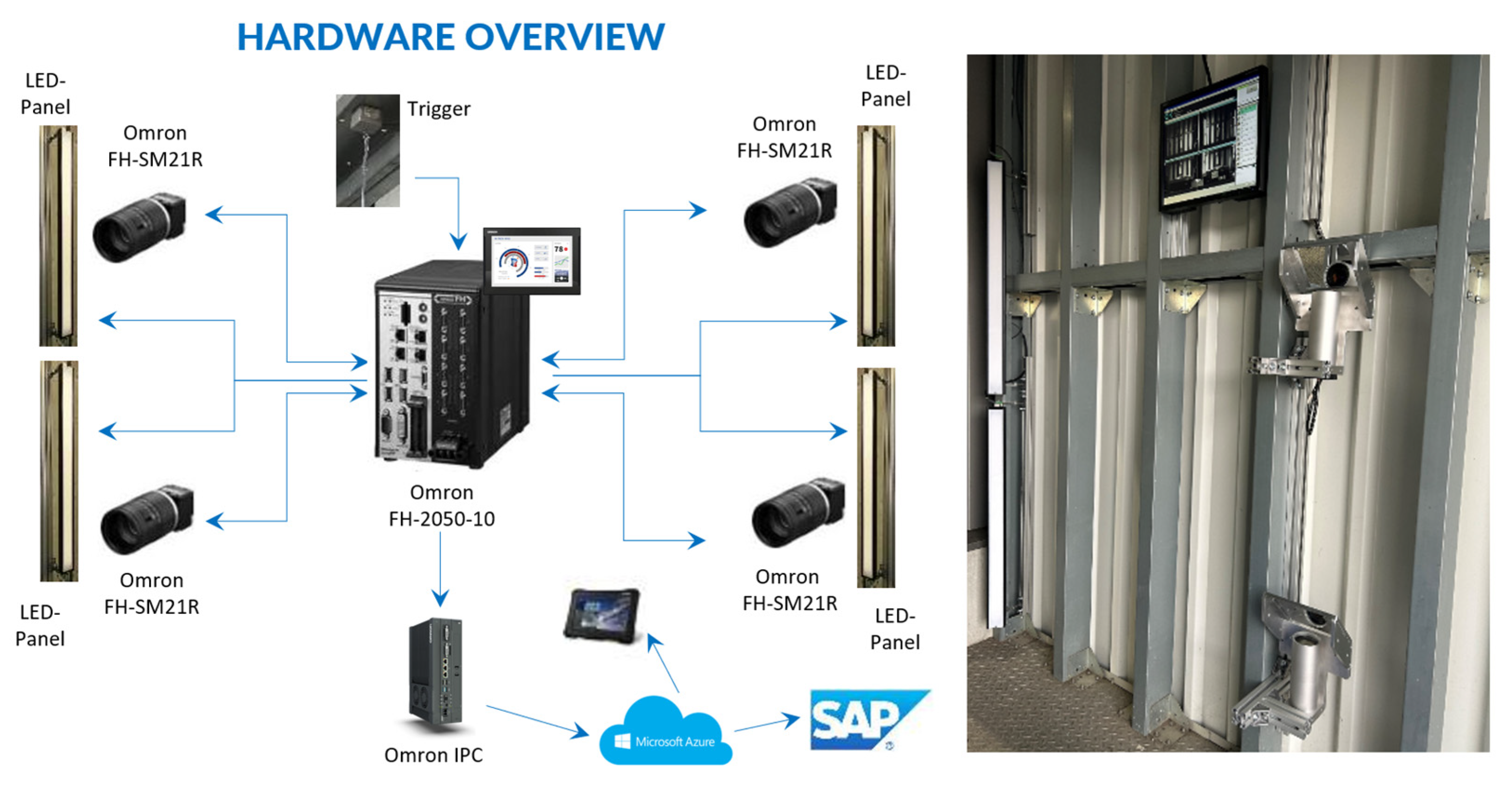

3.2.1. Visual Capture System Overview

Within the framework of implementing an AI-driven reception process at Bosch Automotive, a key technological pillar is the high-resolution visual capture system. This system plays a foundational role in enabling accurate, automated identification and verification of incoming goods by leveraging advanced industrial imaging technologies. The setup includes four Omron industrial cameras, each with a resolution of 20 megapixels, strategically positioned to simultaneously capture detailed visual data from two full sides of two pallets. The cameras are arranged to monitor four specific quadrants—left-top, left-bottom, right-top, and right-bottom—thereby ensuring full visual coverage of all palletized materials, including labels, barcodes, and physical configurations.

To guarantee consistent image quality regardless of environmental conditions, the system is complemented by eight high-intensity LED lighting panels. These provide uniform, high-lumen illumination, effectively minimizing visual noise caused by shadows or reflective surfaces. As a result, the visual data acquired is optimized for downstream image recognition processes, facilitating high-precision GenAI-based analysis and decision-making within the reception workflow.

Figure 6 shows the hardware components of the proposed system.

The purpose of the image process is multifold:

Automatic identification of boxes and labels,

Verification of pallet configuration,

Detection of missing or misplaced items,

Real-time documentation and traceability.

The visual data acquired on the shopfloor is processed in real time through the Omron control unit, which performs initial filtering and formatting of the information. Subsequently, this preprocessed data is securely transmitted to the InTrack cloud platform, hosted on Microsoft Azure, where advanced analytical algorithms extract and structure relevant logistical parameters. This automated recognition and validation mechanism eliminates the need for manual inspections, enhancing both speed and accuracy in the reception process. By enabling seamless integration with ERP environments, it lays the groundwork for end-to-end digitalization of inbound logistics, significantly improving traceability, consistency, and operational efficiency.

3.2.2. Data Flow Architecture and System Integration

The AI-enhanced reception infrastructure is underpinned by a tightly integrated system architecture comprising high-resolution Omron imaging units (20 MP), synchronized LED illumination, and a centralized control module. Operating as a cohesive IoT network, these components enable multi-angle acquisition and real-time processing of pallet-related visual data with high spatial accuracy. Once captured, the visual input undergoes preliminary processing within the local Omron controller before being transmitted to the InTrack cloud environment, hosted on Microsoft Azure. Within this platform, the unstructured visual input is algorithmically transformed into structured digital records. This facilitates the automated validation of incoming goods and the immediate tracking of reception events.

Sensor-based decision logic embedded in the control system allows for autonomous execution of key verification steps. The system communicates bidirectionally with enterprise resource planning environments—specifically SAP Q99 and P99—through standardized web service interfaces. This direct integration eliminates the need for manual data entry, significantly reducing latency and the risk of human error. By providing real-time data synchronization and system-wide visibility, the architecture enhances operational responsiveness and ensures traceability in high-throughput logistics scenarios. It represents a critical enabler for process automation, quality assurance, and scalable digital transformation in warehouse reception workflows.

Figure 7 shows the Identification and process.

Post-data capture, the system interfaces with Power BI dashboards and dedicated production/ramp monitors, offering live visualization of reception statuses and anomalies. These dashboards aggregate data from the AI image recognition system, InTrack cloud, and ERP systems. Monitors located on the shopfloor and unloading ramps display real-time logistics KPIs (such as pallet verification status, discrepancies, or loading schedules). These interfaces provide clear, actionable insights to warehouse operators and supervisors, enabling data-driven decisions and proactive quality management. Through this intelligent monitoring setup, GenAI significantly enhances visibility, accountability, and operational control across the reception process, ensuring compliance with Bosch’s high quality and efficiency standards.

3.2.3. Data Flow Architecture and System Integration

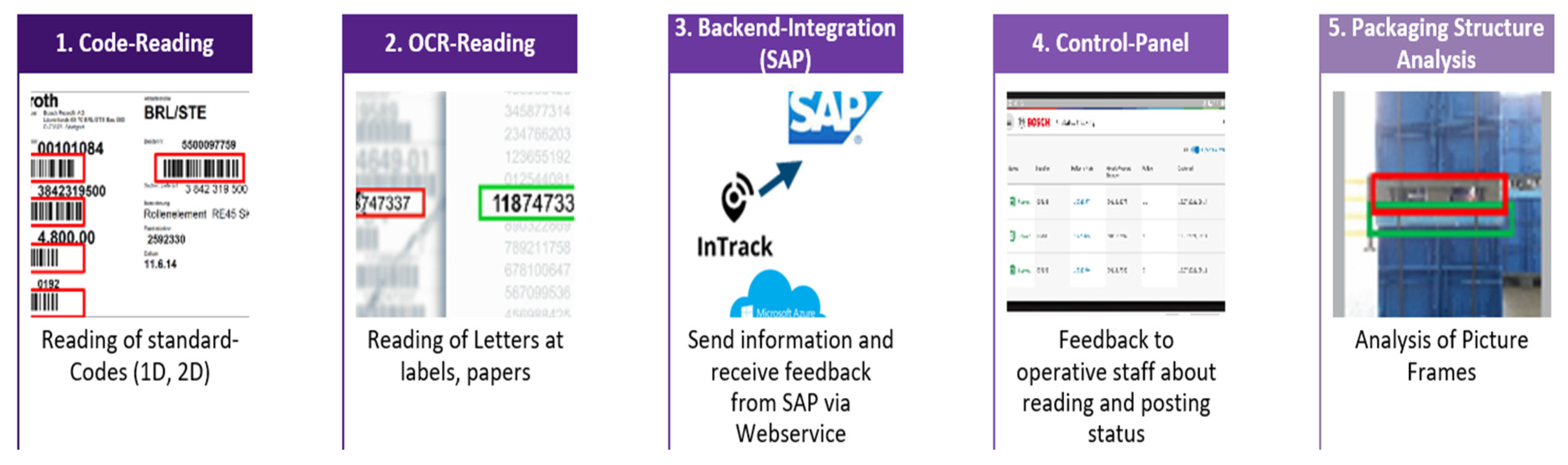

The image processing workflow is a central pillar of the GenAI-based reception system implemented at Bosch Automotive. It involves a multi-stage visual recognition pipeline that uses industrial imaging, OCR, barcode scanning, and deep integration with backend systems to automate and validate inbound logistics operations. This process includes five stages as shown in

Figure 8.

Code-Reading

High-resolution cameras capture standard barcodes (1D and 2D) on labels attached to delivered goods. These include material numbers, internal batch codes, quantities, and delivery identifiers. The system accurately decodes both linear and matrix codes under varied lighting conditions using AI-enhanced image recognition.

OCR-Reading

In addition to barcodes, the system applies OCR to extract alphanumeric data from labels, delivery notes, and printed documents. This ensures redundancy in data capture and improves recognition in cases where barcodes are damaged or missing.

Backend-Integration (SAP)

All extracted data is processed and transmitted via web services to SAP (Q99/P99) systems through the InTrack platform, hosted on Microsoft Azure. The system verifies the data against delivery expectations and automatically triggers feedback mechanisms based on the match/mismatch status.

Control Panel

Operators receive real-time feedback via a centralized control dashboard. This interface displays the reading results, posting statuses, and alerts for any discrepancies. It ensures that staff can monitor and intervene only when necessary, supporting exception-based management rather than manual inspections.

Packaging Structure Analysis

AI algorithms also analyze the physical layout and packaging structure of the pallet, identifying issues such as incorrect stacking, missing containers, or damage. By comparing the actual image frame to expected structural patterns, the system flags abnormalities for further review.

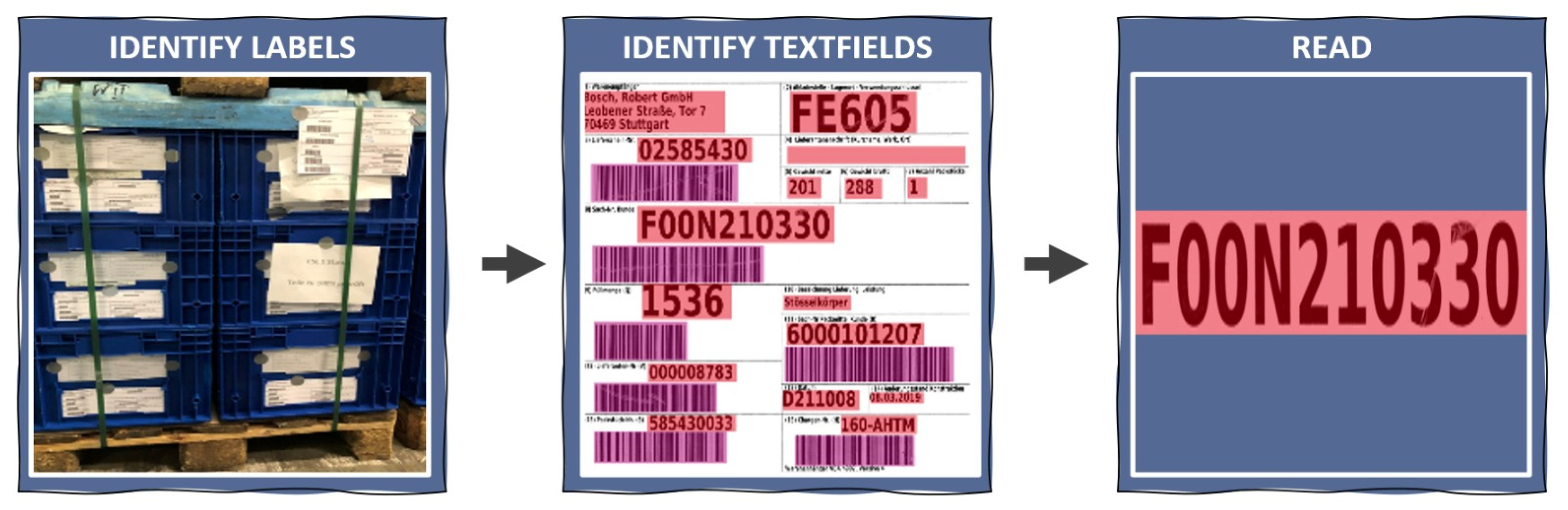

3.3. Operationalization of GenAI in Reception Workflows

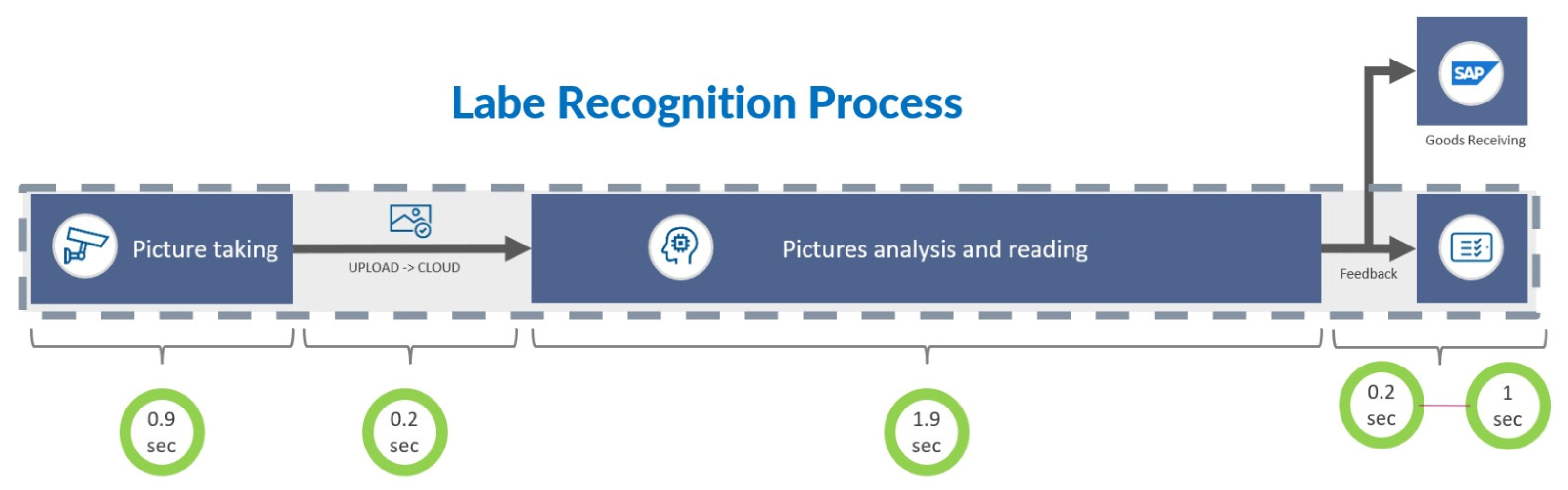

Introducing GenAI elements into the reception process of warehousing management can significantly enhance efficiency, accuracy, and overall operations. One illustrative example is the Label Recognition Process, which demonstrates how automation, cloud computing, and enterprise system integration can streamline goods receiving as shown in

Figure 9.

The process begins with the automatic capture of label images using cameras or visual sensors. This initial picture-taking step, which lasts approximately 0.9 s, ensures that each incoming package or product is visually recorded. Next, the image is uploaded to a cloud platform in just 0.2 s, enabling remote and scalable processing. In the cloud, the system performs picture analysis and reading using AI-based tools such as OCR or machine learning models. This is the most time-intensive phase, taking 1.9 s, and involves extracting relevant information from the label—such as barcodes, product codes, or delivery information.

Once the data is extracted, it is sent back to the local system in 0.2 s, where it undergoes validation or triggers specific workflows. The final step involves integration with the SAP system, specifically within the Goods Receiving module, which takes 1.0 s to register the incoming items. In total, the entire label recognition process is completed in approximately 4.2 s, offering a rapid and reliable method to automate goods reception. This not only reduces manual effort and potential human error but also enhances traceability and speeds up downstream warehouse activities. By embedding GenAI-powered recognition and ERP integration into the reception process, warehouses can achieve a higher degree of operational intelligence and responsiveness.

3.3.1. Inventory Management

Effective inventory management plays a critical role in ensuring accurate and timely reception, handling, and storage of goods within warehouse environments. In conventional warehousing systems, the prevalence of manual operations introduces multiple opportunities for process inefficiencies and logistics failures, which can negatively impact the performance of downstream operations. The most frequently encountered errors in traditional workflows include quality-related failures, where damaged or non-conforming goods are accepted due to insufficient verification; quantity discrepancies between ordered and received materials; skipped process steps, particularly during registration or inspection; misclassification or incorrect identification of item types; processing delays that propagate through the supply chain; and label identification errors resulting from inadequate scanning or manual oversight.

3.3.2. Value Stream Mapping

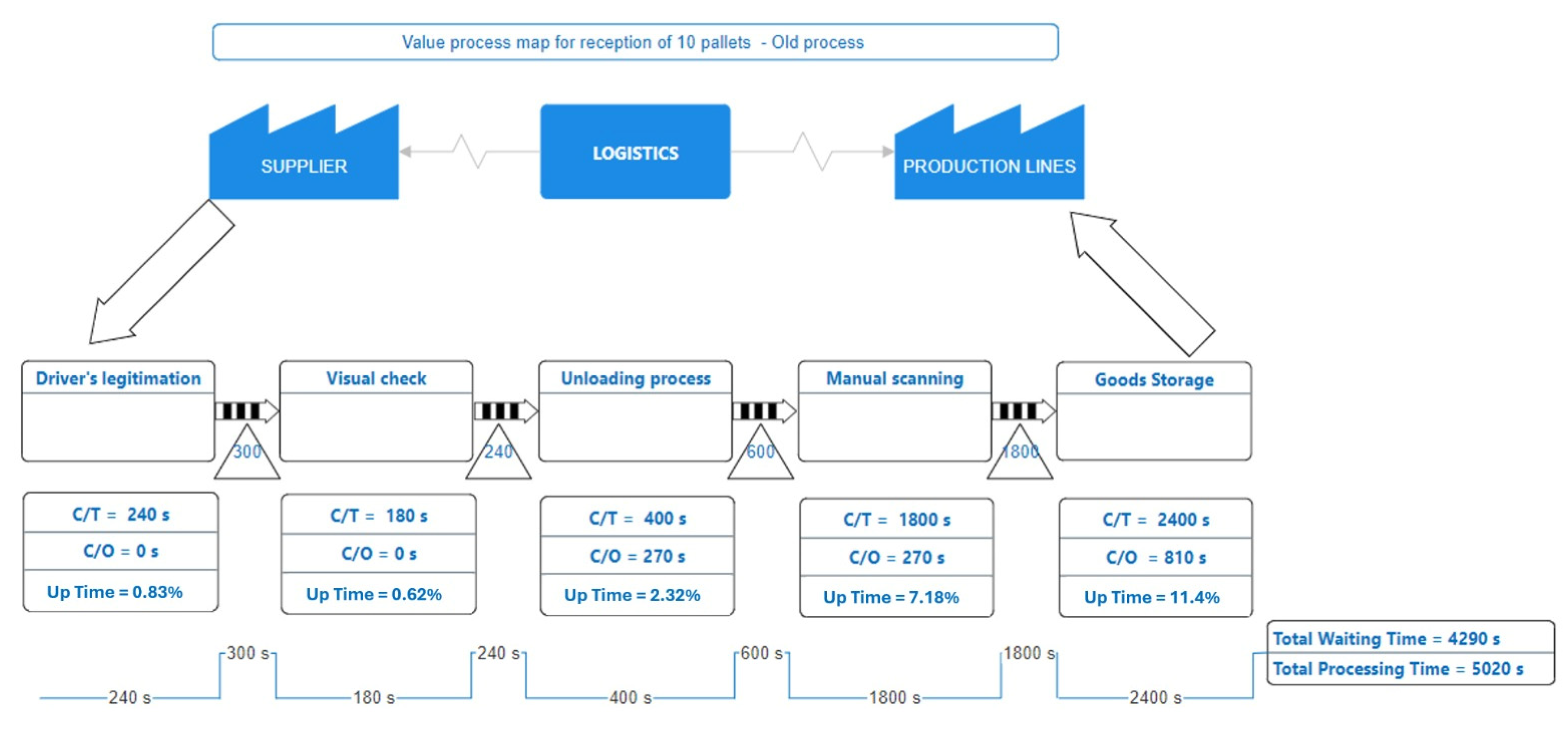

To quantify these inefficiencies, a value stream mapping (VSM) analysis [

29] was conducted on the legacy reception process for a standard batch of ten pallets as shown in

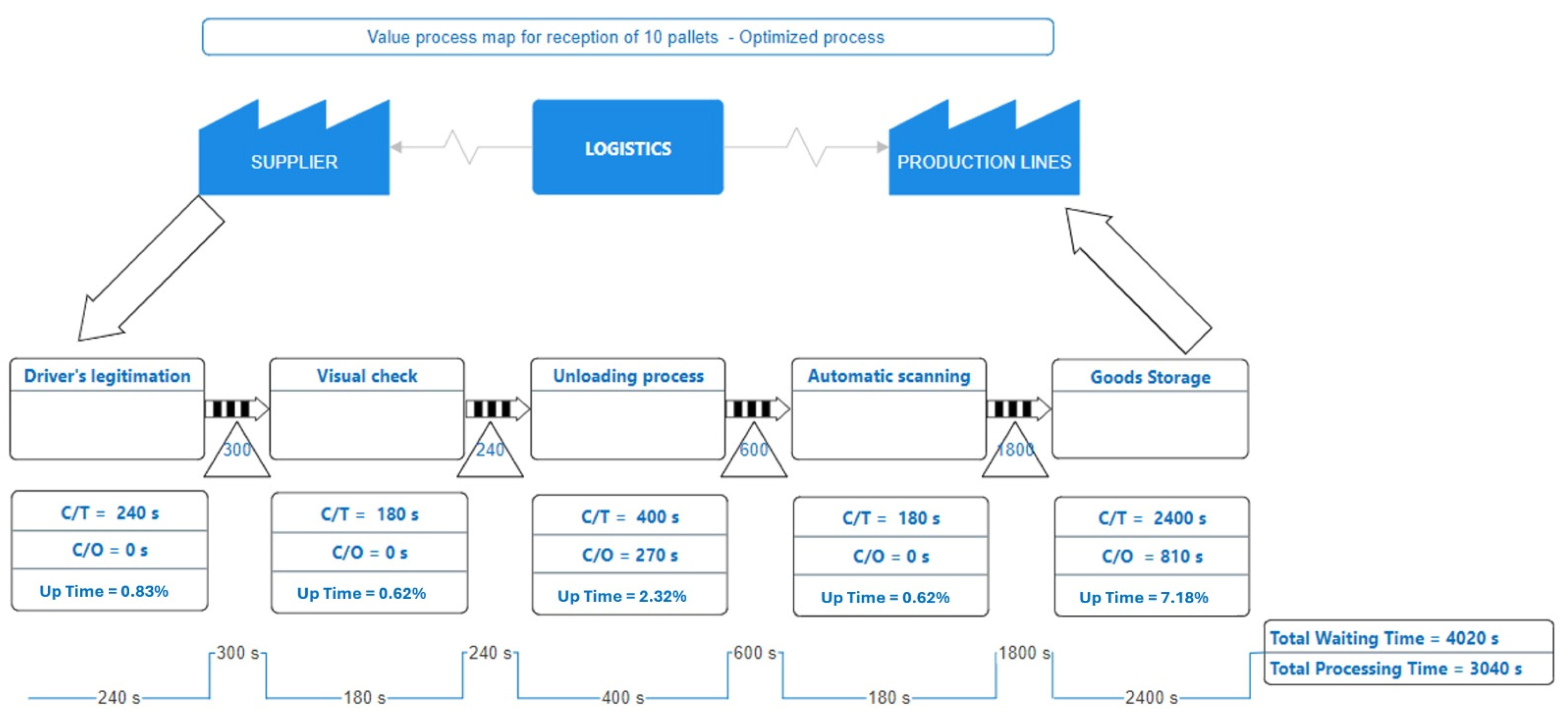

Figure 10. The process consisted of five primary stages: driver identification (240 s), visual inspection (180 s), unloading operations (400 s), manual barcode scanning (1800 s), and goods storage (2400 s). The total processing time amounted to 5020 s, while total waiting time reached 4290 s. Notably, the manual scanning phase represented over 35% of the overall processing time, highlighting it as a major throughput bottleneck and a critical point of failure prone to human error, particularly in label recognition and registration. In contrast, the optimized workflow incorporates artificial intelligence-driven automation to replace manual scanning activities. The revised process is represented in

Figure 11 with maintaining the same preliminary steps—driver identification (240 s), visual inspection (180 s), and unloading (400 s)—but substitutes manual barcode scanning with an automated label recognition system, reducing the scanning duration from 1800 s to only 180 s. The goods storage phase remains unchanged at 2400 s. This optimized model yields a total processing time of 3040 s, marking a 39.5% reduction compared to the legacy process, and a marginal reduction in waiting time to 4020 s.

The implementation of GenAI-based label recognition significantly enhances system throughput by minimizing scanning-related delays and reducing the frequency of identification and classification errors. Additionally, automation ensures higher traceability and consistency in data acquisition, thus improving inventory accuracy and supporting lean logistics principles. In summary, transitioning from manual to GenAI-automated inventory reception processes delivers substantial gains in processing speed, accuracy, and operational resilience. It mitigates key categories of logistics failures—namely quality, quantity, skip, type, time, and identification errors—while enabling a more robust and scalable warehousing infrastructure aligned with Industry 4.0 standards. From

Figure 11, it was observed that the processing time has decreased by 79%.

3.4. Comparative Analysis Before and After GenAI Implementation Using Wilcoxon Signed-Rank Test

To evaluate the impact of GenAI implementation on logistic operations, a Wilcoxon Signed-Rank Test was conducted. This statistical approach was selected due to its robustness in comparing paired, non-normally distributed data, such as the times and costs associated with the reception process before and after GenAI integration.

3.4.1. Reception Time Analysis

The analysis considered reception time data collected from five representative samples.

Table 1 displays the median reception times before (scanner-based) and after (camera-based AI) implementation.

The Wilcoxon Signed-Rank Test indicated a statistically significant reduction in reception times post-AI implementation (Z = −2.023, p < 0.05). Specifically, AI implementation resulted in an average time reduction of approximately 79%, demonstrating significant improvement in operational efficiency.

3.4.2. Operational Costs Analysis

Operational costs were also compared using data aggregated for daily, monthly, and annual scenarios. Results are presented in

Table 2.

The statistical analysis showed significant cost reductions at all measured intervals. Particularly, annual operational savings reached approximately €13,063.68, strongly validating the financial viability of adopting AI-based logistic solutions.

3.4.3. Interpretation and Implications

The substantial reductions in both reception time and operational costs suggest that GenAI implementation significantly enhances logistics performance, confirming the initial hypotheses. These results underline the practical benefits of AI technologies, advocating for their broader adoption in logistics management processes within the automotive industry.

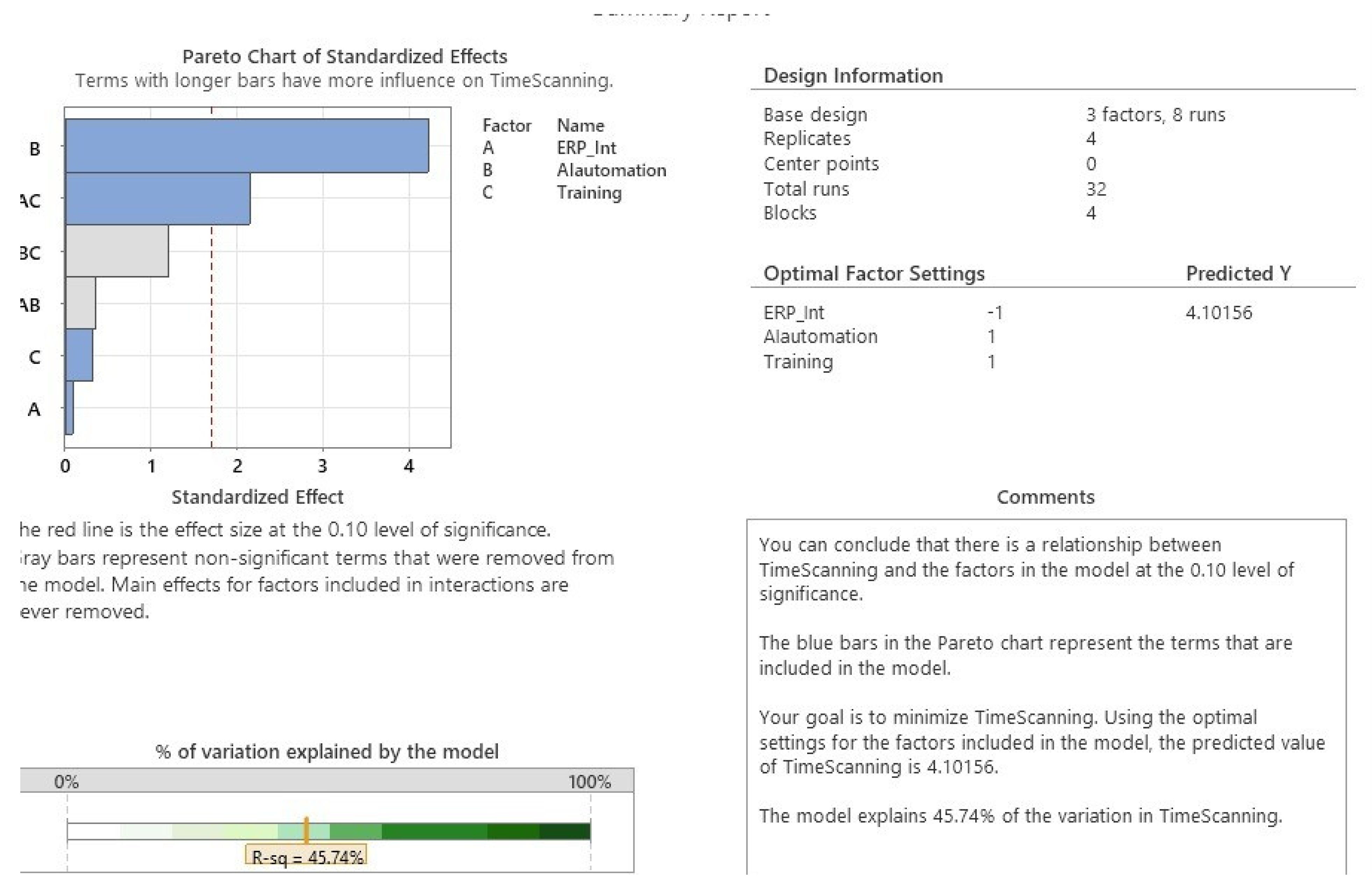

3.5. Predictors of Potential Cost Savings for Companies in the Automotive Industry

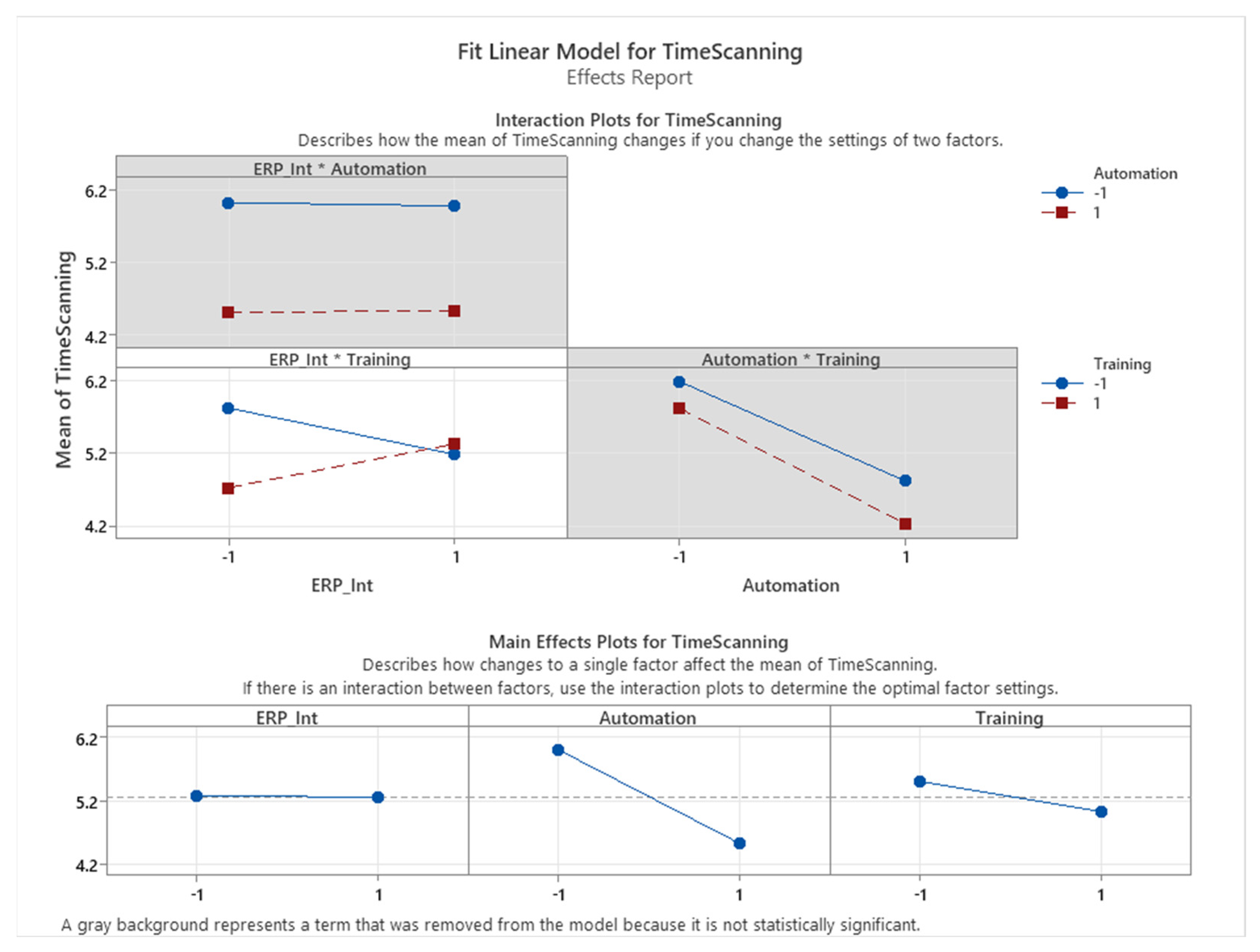

The factorial experimental model focuses on identifying the influence of several operational factors on TimeScanning—a key performance indicator in logistics workflows, directly associated with labor productivity and cost efficiency. The response variable of the model is TimeScanning, which measures the time required to scan an item in warehouse operations. Three explanatory variables were derived directly from the operational context of the reception process: ERP_Int represents the level of ERP system integration (coded as −1 for low and +1 for high), Automation reflects the degree of automation in label recognition and data entry (−1 for manual and +1 for automated), and Training captures personnel skill levels (−1 for basic and +1 for advanced training). These variables were selected as they represent the main controllable factors influencing reception time and cost efficiency in warehousing operations. The linear factorial model was constructed using a two-level full factorial design with interaction terms. Experimental data collected under the different factor combinations were analyzed in Minitab to estimate the coefficients and evaluate factor significance. This approach, consistent with standard design of experiments methodology, enabled us to quantify both main effects and interactions, leading to the estimated mathematical model as a linear factorial model with interaction terms, represented by Equation (1):

Figure 12 shows the summary for the fit linear model for TimeScanning and

Figure 13 shows the effects. According to the standardized effects and Pareto chart, the statistically significant terms included in the final model at a 90% confidence level (α = 0.10) are Automation (B), Training (C), and the interaction between ERP_Int and Training (AC). This implies that these factors have a substantial impact on reducing TimeScanning. The optimal settings for minimizing TimeScanning are a low level of ERP integration (−1), a high level of automation (+1), and an advanced level of training (+1). Under these conditions, the predicted TimeScanning value is 3.98063 units of time. The model explains 50.16% of the variation in TimeScanning, which indicates a moderate-to-strong explanatory power. This suggests that around half of the variability in scanning time is driven by the selected factors, while the remainder may be attributed to uncontrolled or unmeasured process noise. In terms of interpretation, Automation (B) is the most influential factor, with higher automation clearly contributing to reduced TimeScanning. Training (C) also demonstrates a significant individual effect, as well-trained staff perform scanning tasks more efficiently. Notably, the interaction between ERP_Int and Training (AC) suggests that high levels of training can offset the disadvantages of a poorly integrated ERP system, a critical insight for cost-sensitive operations.

The residual analysis confirms the validity of the model. Residuals versus fitted values show no obvious patterns, which supports the assumption of linearity and homoscedasticity. The residuals versus observation order indicate stability across experimental blocks, with only a few isolated large residuals that do not significantly distort the model’s conclusions. This factorial modeling approach confirms that automation and training are strategic levers for reducing operational time and thus costs in warehouse environments. Even when ERP systems are not fully integrated, the combination of high automation and adequate staff training can achieve substantial gains in process efficiency. The robustness of the model is validated by the top five alternative solutions, which also yield low predicted TimeScanning values, further reinforcing the reliability of the optimization settings. This analysis provides empirical evidence that investing in warehouse automation and targeted personnel training can serve as reliable predictors of cost reduction in the automotive supply chain.

Within warehouse operations, our case study demonstrated that automation is a critical enabler for reducing logistics-related expenditures. By replacing manual tasks with automated solutions, companies can significantly lower dependency on human labor, streamline workflows, and reallocate operational resources more effectively toward high-demand activities. In the Bosch case, automation of label recognition directly reduced reception time by 79% and generated measurable annual cost savings of over €13,000.

Beyond these case-specific results, previous research has shown that, when integrated with a modern and adaptive Warehouse Management System (WMS), automation can also support improvements in space—such as higher storage density in bins and racks, better use of vertical space, and the elimination of underutilized areas [

2,

31]. In addition, the strategic configuration of the warehouse network plays a fundamental role in controlling logistics costs. The decision regarding warehouse location has long-term implications on both the cost structure and service level performance across the supply chain. Striking an optimal balance between customer proximity and property cost remains a complex but necessary objective, influencing not only inventory and transportation expenses but also delivery reliability and customer satisfaction [

22].

From a managerial perspective, continuous monitoring of warehousing cost drivers—such as labor, facility rent and utilities, material handling equipment, racking systems, and IT infrastructure—is essential. Evidence from prior studies shows that, before implementing cost optimization strategies, organizations must carefully evaluate their potential cascading effects across the entire supply chain, since isolated cost reductions may compromise overall performance if not evaluated within the broader operational context [

34].

4. Discussion

The integration of GenAI-based systems into the reception processes at the Bosch Automotive facility in Blaj has demonstrated clear operational benefits, particularly in terms of processing efficiency, quantifiable error reduction, enhanced data accuracy, and cost reduction. The findings of this study are aligned with existing literature on the digital transformation of logistics and reinforce the viability of implementing AI technologies in complex supply chain environments. Three types of errors were monitored: label misreads, system recognition failures, and ERP integration issues. At the beginning of implementation, these errors were relatively high; however, as the AI system progressively adapted and improved through learning, the error rate decreased drastically. From a performance standpoint, the implementation of automated visual recognition and data integration with ERP systems yielded a significant reduction in total reception time—approximately 79% as verified by the Wilcoxon Signed-Rank Test, alongside a drop in label misreads to below 1% compared to frequent misreads in manual scanning. All errors were logged in the ERP feedback loop and validated against delivery documentation, ensuring reliability of the results. This result confirms that GenAI-based automation can effectively replace manual barcode scanning, which previously represented a major bottleneck in the reception workflow.

Furthermore, the annual operational cost savings, exceeding €13,000, underscore the economic justification for this digital transformation initiative. This reported annual savings represent direct operational savings from reduced reception times and lower handling costs. These figures do not include infrastructure or maintenance expenses related to the AI system. Such costs were considered separately as part of the investment analysis and are not reflected in the operational savings table (

Table 2).

The enhanced system has also proven effective in mitigating common types of logistics failures. Identification, type, and quantity errors were substantially reduced due to the consistent accuracy of the AI-powered imaging and label recognition modules. This automation supports a shift from reactive quality control to proactive quality assurance, consistent with lean manufacturing and Industry 4.0 principles. Despite these positive outcomes, the study also identified limitations associated with the implementation phase. In particular, inconsistencies in label templates posed challenges to automated recognition, leading to occasional scanning failures and SAP integration issues. These findings emphasize the need for standardization across packaging and labeling practices to fully leverage the capabilities of intelligent systems.

Moreover, although the current study focused primarily on quantifiable performance indicators, further research is warranted to assess qualitative factors such as employee adaptability, skill development, and perceptions of AI-enabled workflows. The human factor remains central to the long-term success of digital initiatives, particularly in environments where man-machine collaboration is essential. Previous research suggests that AI technologies not only optimize specific operational metrics but also contribute to broader strategic goals such as sustainability, process transparency, and supply chain resilience [

40,

41,

42]. However, scalability and generalizability must be further investigated through multi-site studies or cross-industry comparisons.

In conclusion, this research highlights the transformative potential of GenAI in reception logistics within the automotive sector. While immediate gains in speed and cost-efficiency are evident, long-term success depends on continuous monitoring, standardization efforts, and organizational readiness for digital integration [

43,

44]. Future work should explore the impact of GenAI adoption across other supply chain nodes, assess return on investment over extended periods, and examine the interplay between AI systems and workforce dynamics in high-volume industrial settings.

The findings of this study extend beyond the specific case of the Bosch Automotive, offering valuable insights for both industry practitioners and policymakers. The demonstrated reduction in reception times and the associated cost savings provide compelling evidence of the potential of scaling AI-driven solutions across warehousing and reception processes in various sectors. For policymakers, such studies shed light on the need for developing regulatory frameworks that enable and guide AI integration into supply chain operations, specifically regulations related to data governance and privacy to create a secure and responsible environment that fosters innovation and sustainability.

5. Conclusions

The integration of generative Artificial Intelligence into warehousing and reception processes significantly enhances efficiency, accuracy, and operational performance within the automotive logistics sector. The present study, conducted at the Bosch Automotive facility in Blaj, Romania, clearly demonstrates these advantages through concrete, measurable outcomes. Empirical analysis revealed substantial improvements in key logistics indicators following AI implementation. Specifically, reception times were dramatically reduced by approximately 79%, validated statistically through the Wilcoxon Signed-Rank Test. Furthermore, significant cost savings were observed across various operational levels—daily, monthly, and annually—highlighting the economic viability and sustainability of investing in advanced AI systems. Moreover, the Cleaner Logistic and Supply Chain Model proposed herein emphasizes strategic leadership, continuous improvement, technological innovation, and sustainability as essential pillars for modern logistics operations. By aligning AI technology with these principles, businesses can proactively enhance environmental responsibility, operational transparency, and long-term efficiency. However, successful AI integration requires addressing specific challenges, such as standardizing labeling templates and managing initial system adaptation issues.

While the findings of this study provide promising results, one limitation is that the analysis is based on a single case study within one facility (Bosch Automotive). Another limitation is covering a limited number of operational cycles, which may not fully capture variations across longer periods or different demand scenarios. Future research should explore expanded applications of AI technologies across other logistic operations across multiple companies and sectors such as retail, pharmaceuticals, and consumer goods and cross-country for larger datasets and further investigate long-term impacts on workforce dynamics and skill requirements. This would provide more insight into the scalability and adaptability of AI-enabled logistics solutions.