Abstract

Global supply chains face increasing disruptions from cyber threats, geopolitical instability, extreme weather events, and a range of economic, social, and environmental sustainability challenges. As these disruptions intensify, enhancing Supply Chain Resilience (SCR) has become a strategic priority. This study investigates how Distributed Ledger Technology (DLT) can contribute to SCR by mitigating vulnerabilities and strengthening key capabilities within global supply chains. A qualitative research approach is employed, utilizing expert evaluations to examine DLT’s impact on supply chain vulnerabilities and capabilities. Five workshops were conducted with 25 industry professionals from logistics, IT, procurement, and risk management. Experts examined how DLT could address disruptions stemming from supplier instability, poor traceability, and regulatory and environmental pressures, while highlighting its potential to drive ethical sourcing and environmentally responsible practices. The structured discussions were guided by theoretical frameworks and expert evaluations were synthesized into two analytical matrices illustrating DLT’s influence on SCR. The findings reveal that the contribution of DLT to SCR and sustainability is highly context-dependent, with its effectiveness hinging on how it is embedded within governance structures and aligned with the interplay of complementary technologies. Building on these insights, the study presents the DLT-LFL (Distributed Ledger Technology–Learning Feedback Loop) framework, which integrates sensing, decision-making, adaptation, and predictive learning from distributed operational data, allowing supply chains to better anticipate disruptions, adjust processes dynamically, and continuously strengthen resilience and sustainable practices. The study also develops a practical checklist to assess how effective DLT applications and their integration with predictive and AI-driven analytics reduce vulnerabilities, strengthen capabilities, mitigate risks, and support adaptive decision-making.

1. Introduction

Global supply chains are under increasing strain due to geopolitical instability, cyber threats, extreme weather events, and sudden demand shocks [1]. According to a McKinsey report, supply chain disruptions lasting one month or longer occur every 3.7 years on average, with financial losses often amounting to 45% of annual EBITDA (Earnings Before Interest, Taxes, Depreciation, and Amortization) over a decade [2]. The 2021 semiconductor shortage, the 2023 Suez Canal disruptions, and cyberattacks targeting logistics firms all underscore the urgent need for greater supply chain resilience (SCR)—the ability to anticipate, withstand, and recover from disruptions while maintaining operational efficiency [3].

While platforms like TradeLens have been discontinued due to governance and profitability challenges, the need for decentralized, transparent, and tamper-proof supply chain solutions remains critical. Distributed Ledger Technology (DLT) continues to be recognized as a powerful tool to enhance traceability, security, and coordination across global supply chains [4,5]. By enabling real-time, immutable data sharing, DLT can help reduce fraud, improve operational efficiency, and build trust among supply chain participants. Despite the hurdles faced by early initiatives, companies like Walmart and Nestlé have successfully leveraged DLT to trace contaminated food sources within seconds rather than days, preventing costly recalls and mitigating public health risks. As supply chain vulnerabilities persist, the focus now shifts to scalable and resilient DLT applications that can overcome governance barriers while delivering long-term value [6].

Beyond logistics, cybersecurity threats have become a significant challenge for supply chains. According to a recent report, supply chain cyberattacks have surged by over 400%, with businesses generating over $50 million in revenue being two-and-a-half times more likely to experience such incidents [7]. These attacks often exploit vulnerabilities in software, hardware, and data-sharing networks, particularly those of third-party suppliers with weaker security controls. The financial impact is substantial; projections indicate that by 2025, software supply chain attacks could cost the global economy up to $60 billion. To mitigate these risks, DLT solutions offer a decentralized and cryptographic framework that can eliminate single points of failure and secure transaction records against tampering, thereby enhancing the overall security and resilience of supply chains [8,9].

This paper explores how and in which particular dimensions DLT can enhance SCR by providing greater visibility, security, and efficiency in global trade networks. It investigates the key benefits of DLT-driven solutions in mitigating disruptions caused by geopolitical risks, cyber threats, and demand fluctuations. Ultimately, we seek to answer the following question:

How do distributed ledger-based technologies impact supply chain resilience, and what factors determine their effectiveness in mitigating disruptions?

Therefore, this paper first provides a brief overview of the concepts of SCR and DLT before outlining the applied methods and presenting the key findings. It contributes to the resilience literature and capability theory by introducing the DLT-LFL framework, which integrates sensing, decision-making, adaptation, and predictive learning to advance both resilience and sustainability in supply chains. The paper also offers actionable guidance for practitioners on how to evaluate and implement DLT and complementary technologies to maximize their impact. It concludes with a discussion on future implications for both theory and practice.

2. Theoretical Background

2.1. Supply Chain Resilience

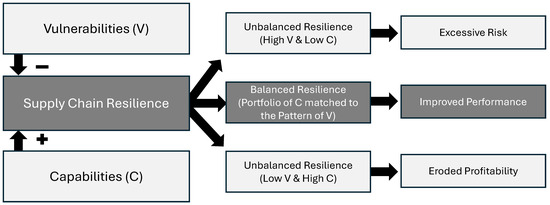

SCR has evolved from Supply Chain Risk Management (SCRM), which aims to safeguard business continuity by identifying and mitigating deviations from organizational goals [10]. SCRM follows a phased approach, addressing both internal and external supply chain risks to minimize overall vulnerability [11,12]. However, traditional risk management often falls short in assessing and responding to unpredictable disruptions [13]. SCR compensates for these shortcomings by emphasizing adaptability, defined as the supply chain’s ability to prepare for, respond to, and recover from unexpected events while maintaining operational continuity and control [14,15]. To assess the impact of DLT on SCR, the concept of “vulnerabilities” is used—disruptions affecting products, services, or resources, stemming from internal or external changes [16]. To counteract these vulnerabilities, supply chains must develop “capabilities”, which refer to the attributes necessary for resilience and long-term survival [17]. Capabilities enable organizations to anticipate, mitigate, and adapt to disruptions. They help prevent disruptions, reduce their impact, and facilitate post-disruption recovery. According to Kotzab et al. (2015), capabilities are defined as attributes necessary for performance or achievement, while in the supply chain context, they are described as features that enable an organization to anticipate and overcome disruptions [17]. Ultimately, a resilient supply chain is achieved by balancing capabilities and vulnerabilities, mitigating excessive risk and improving profitability for long-term performance (see Figure 1) [15].

Figure 1.

Supply Chain Resilience Framework (Pettit et al., 2010, [15]).

2.2. Blockchain-Based Data Exchange in Supply Chains

DLT solutions promise to enable end-to-end traceability. Products can be tracked from their origin to the final consumer, with all relevant historical data securely stored and accessible in real time [18]. This increased visibility improves operational efficiency and helps businesses identify bottlenecks, mitigate disruptions, and optimize logistics [19]. Furthermore, the immutable nature of DLT records strengthens data integrity, reducing the risk of counterfeit goods and fraudulent activities. Every transaction recorded on the ledger is verifiable, making it more difficult for malicious actors to introduce falsified products into the supply chain. Beyond traceability, DLT facilitates secure and trusted data exchange across independent stakeholders, fostering collaboration between suppliers, manufacturers, and distributors [20]. Real-time customer feedback, for example, allows for more accurate demand forecasting, reducing excess inventory and enhancing responsiveness to market fluctuations [21]. Smart contracts further streamline operations by automating contractual obligations, eliminating intermediaries, and ensuring compliance with predefined conditions. By integrating DLT into supply chains, companies not only strengthen their traditional risk management approaches but also enhance supply chain resilience. DLT addresses previously hidden risks, such as counterfeit goods and cybersecurity threats, by providing verifiable data and reducing single points of failure [22].

3. Methodology

To assess the impact of Distributed Ledger Technology (DLT) on Supply Chain Resilience (SCR), a qualitative research approach was employed, focusing on expert evaluations of key factors that influence both “Vulnerabilities” and “Capabilities” within supply chains. These factors were derived from existing theoretical frameworks in the literature as described above and used to guide discussions during workshops with industry experts. The workshops aimed to explore how DLT could address specific vulnerabilities and enhance the capabilities of organizations in managing supply chain disruptions (see Table 1).

Table 1.

Workshop Iterations and Participants.

The workshops were conducted with a diverse group of professionals from different sectors of supply chain management, including logistics, IT, procurement, and risk management. Each workshop consisted of structured discussions around the theoretical concepts of “Vulnerabilities” and “Capabilities” in the context of SCR. The experts were tasked with evaluating the potential impact of DLT on these factors, drawing on their practical experience and expertise in managing real-world supply chain issues. For each vulnerability, the experts assessed how DLT could either mitigate or exacerbate the issue. Similarly, for each capability, the experts discussed how DLT could improve the flexibility, visibility, efficiency, and other characteristics required to enhance supply chain resilience.

To ensure the validity and relevance of the findings, the experts were selected for their involvement in DLT projects as well as expertise in supply chain operations, technology integration, or risk management across several industries. This diversity of perspectives was crucial for capturing how DLT interacts with different organizational contexts and supply chain challenges. Workshops, rather than individual interviews, were chosen because they allow for real-time interaction and debate among participants, fostering richer insights, cross-validation of opinions, and the emergence of shared or contrasting viewpoints [23]. This format also made it possible to test ideas collectively and identify consensus or divergence on how DLT could be applied to specific vulnerabilities and capabilities, which would have been less evident in isolated interviews [24].

In total, five workshops were conducted, with a collective group of 25 industry experts providing feedback and evaluations. Their insights were noted in writing, then aggregated, analyzed, and presented in two matrices that display the evaluation of DLT’s impact on SCR-related vulnerabilities and capabilities. To ensure academic rigor in developing the matrices, the study followed the guidelines proposed by Mostyn [25]. Two authors were directly involved in the coding process, first independently coding a subset of workshop transcripts to identify preliminary themes. We initially identified 14 themes related to vulnerabilities and 12 related to capabilities, which were iteratively refined through joint discussion and consolidation to produce the final coding scheme. Regular peer debriefings were used to resolve discrepancies and enhance consistency (for more details, see Appendix A) [26]. The discussions were mainly focused on specific supply chain issues, such as connectivity, supplier disruptions, external stressors, and cybersecurity risks, as well as on more general aspects like flexibility, collaboration, and market positioning. In cases of uncertainty, specific statements were shared with workshop participants to confirm whether particular categorizations or interpretations had been accurately understood. The results from these workshops provide a comprehensive overview of the factors contributing to SCR and how DLT may influence them, which is captured in the DLT-LFL framework and the accompanying checklist, both of which were shared with selected workshop participants for review and validation.

4. Findings

To explore how DLT can influence supply chain resilience in practice, the following section presents the findings from the expert workshops and introduces the DLT-LFL framework, which synthesizes these insights into a structured model for enhancing both resilience and sustainability in supply chains. The first matrix evaluates the impact of DLT on supply chain vulnerabilities, outlining the specific DLT applications that address each challenge and the integration hurdles that may limit their effectiveness. Insights from the first three workshops provide an understanding of how DLT interacts with these vulnerabilities in real-world scenarios (see Table 2). The second matrix focuses on supply chain capabilities, describing how DLT applications can enhance operational flexibility, visibility, efficiency, and other key resilience-related capabilities, along with the integration hurdles that may constrain their adoption (see Table 3).

Table 2.

DLT-Impact on Vulnerabilities.

Table 3.

DLT-Impact on Capabilities.

How to read the tables: Each table lists specific DLT applications in the first column and their corresponding integration hurdles in the second column. The impact of each DLT application on the respective vulnerability (Table 2) or capability (Table 3) is indicated using a scoring system from 0 to 3 points, where 0 represents no impact and 3 indicates a strong positive influence. These scores were established through structured discussions with workshop participants, who assessed the potential effectiveness of each application based on their practical experience. The scoring reflects a consensus evaluation among the experts, capturing both the potential of the technology and the constraints arising from real-world implementation challenges.

4.1. Cybersecurity, Data Integrity, and Fraud Prevention

Cybersecurity and fraud are persistent challenges across industries, particularly in pharmaceuticals, logistics, and trade finance, where supply chain integrity is critical [22]. Experts from Workshop 1 emphasized that cryptographic encryption and immutable ledger records inherent to public blockchains could significantly enhance data security and fraud prevention. Similarly, Workshop 3 participants noted that DLT’s verification mechanisms and product provenance tracking offer substantial advantages in fraud prevention, particularly for high-value goods and financial transactions. However, scalability challenges and integration issues with legacy systems were identified as major obstacles by blockchain developers in Workshop 2. Additionally, compliance officers from Workshop 3 highlighted regulatory gaps, especially in jurisdictions with stringent data protection laws such as GDPR, which complicates broader implementation. Another challenge emphasized in all three workshops was the need for cross-organizational trust frameworks that not only rely on blockchain (particularly private blockchains) but are seamlessly integrated with public blockchains and other technologies.

4.2. Supply Chain Interdependence and Disruptions

Supply chains rely on highly interconnected global networks, making them prone to disruptions caused by supplier failures, demand fluctuations, and external shocks [10]. Supply chain managers and procurement specialists from Workshop 1 noted that DLT facilitates decentralized data sharing, reducing reliance on intermediaries and improving supply chain visibility. Additionally, Workshop 2′s logistics consultants emphasized that smart contracts could automate compliance checks and streamline supplier verification, enhancing reliability. Despite these benefits, complex coordination and insufficient governance approaches among multiple stakeholders remain significant challenges. Participants from Workshop 2 explained that without standardized protocols, different DLT implementations may not be interoperable, leading to fragmentation rather than improved coordination. Similarly, Workshop 3′s participants noted that high implementation costs and a need for further education challenge, especially small- and medium-sized enterprises (SMEs), in integrating DLT solutions, limiting the overall effectiveness of these technologies in addressing widespread disruptions.

4.3. Regulatory and External Stressors

Legal and regulatory uncertainties pose considerable risks for businesses considering DLT adoption [6]. While DLT offers audit trails and compliance monitoring, the absence of clear global legal frameworks hinders implementation. This concern was echoed by participants in Workshops 1 and 2, as they noted evolving regulations around data privacy and smart contract enforceability introduce risk, particularly for multinational supply chains. Additionally, while DLT can optimize logistics and inventory tracking, it does not address physical constraints such as shortages in raw materials or disruptions in production capacity. Supply chain managers from Workshop 1 pointed out that while DLT improves coordination long-term, the actual resolution of supply chain bottlenecks still requires investments in infrastructure and supplier diversification.

4.4. Operational Resilience and Information Transparency

The decentralized nature of DLT enhances operational resilience by reducing single points of failure, ensuring that supply chain networks remain functional even in the face of localized IT disruptions [10,27]. Participants from Workshop 3 highlighted that decentralization improves disaster recovery capabilities, as data is distributed across multiple nodes rather than stored in a single vulnerable location. This is particularly relevant in industries like automotive manufacturing, where just-in-time production models rely on real-time data coordination across multiple suppliers. For example, automotive companies leveraging blockchain-based supplier networks can maintain operational continuity even if one node in the network experiences downtime, preventing cascading failures across the supply chain.

4.5. Enhancing Operational Flexibility and Resource Efficiency

Workshop participants in Workshops 4 and 5 noted that DLT-driven automation—particularly through smart contracts—enables dynamic adjustments in workflows, reducing delays in procurement and order fulfillment, especially when combined with agentic AI in the future. In industries with complex supplier networks, such as automotive manufacturing, smart contracts can trigger automatic order modifications based on real-time data, ensuring efficient adjustments to fluctuating demand. However, many firms face resistance to change, as existing centralized Enterprise Resource Planning (ERP) systems are deeply embedded in supply chain operations and sometimes lack openness for DLT backends. Additionally, while process automation and streamlined documentation reduce administrative overhead, high initial deployment costs and scalability issues have hindered broader adoption, particularly in industries with thin margins, like retail logistics.

4.6. Improving Supply Chain Visibility and Proactive Risk Management

One of the most widely recognized benefits of DLT adoption is its ability to enhance supply chain visibility through real-time data sharing and decentralized tracking [6]. Workshop discussions highlighted how pharmaceutical companies leverage blockchain-based serialization systems to monitor drug distribution, reducing counterfeit risks and ensuring regulatory compliance. However, challenges remain in achieving data standardization across global supply chain partners, as interoperability between different DLT platforms is still evolving. Similarly, predictive analytics integrated with DLT-backed data and federated learning could enable proactive risk management, helping companies anticipate supply chain disruptions before they escalate. Federated learning, which allows multiple stakeholders to train machine learning models on decentralized data without sharing sensitive information, was highlighted in workshop discussions as a promising approach to enhancing predictive capabilities. In the logistics sector, this combination could enable firms to detect potential bottlenecks caused by geopolitical risks or supplier failures without exposing proprietary operational data.

4.7. Strengthening Supply Chain Resilience and Collaborative Cooperation

The decentralized and immutable nature of DLT fosters stronger data exchange mechanisms, which in turn enhance supply chain resilience [27]. Participants highlighted examples in the food industry, where companies use blockchain to create transparent audit trails, allowing for rapid identification of contamination sources and minimizing product recalls. However, achieving true resilience through DLT requires overcoming regulatory inconsistencies across jurisdictions, making implementation complex for multi-national organizations. Workshop participants from the pharmaceutical and healthcare industries noted that reducing disputes over contract terms and shipment discrepancies is the biggest motivator for blockchain projects. Nonetheless, governance difficulties remain a critical challenge. By aligning DLT applications with standardized operational protocols and shared data governance rules, organizations can systematically reduce cross-partner inefficiencies, improve coordination, and accelerate collective response to disruptions, thereby strengthening both resilience and collaborative capabilities across the supply chain.

4.8. Customer Loyalty, Information Security, and Organizational Adaptability

From a consumer perspective, DLT enhances customer loyalty and satisfaction through provenance tracking, enabling customers and end consumers to verify product authenticity and ethical sourcing [27]. This is particularly valuable in industries like luxury goods and organic food, where customers demand transparent supply chain records. However, participants noted that low consumer awareness of DLT’s benefits limits its impact on purchasing decisions, and integration challenges with existing customer service platforms slow adoption.

Information security remains one of DLT’s strongest capabilities, as tamper-proof records and cryptographic security mechanisms protect against fraud and cyber threats. In industries with sensitive intellectual property, such as automotive and pharmaceuticals, workshop participants emphasized the value of strict access controls in preventing unauthorized alterations.

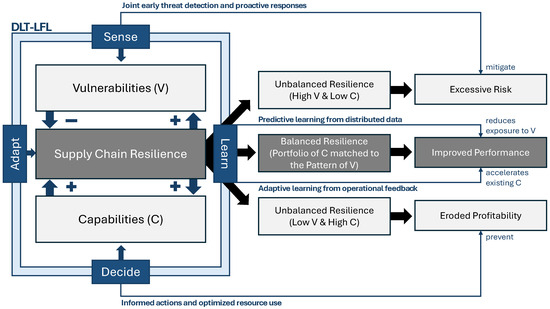

Building on Pettit et al.’s foundational resilience framework and based on the findings of the research process, this study proposes the DLT-LFL (Distributed Ledger Technology—Learning Feedback Loop) Framework for Supply Chain Resilience (Figure 2). Synthesizing theoretical and empirical insights from DLT projects, the DLT-LFL introduces a dynamic, four-step loop: Sense, Decide, Adapt, and Learn, operationalizing DLT’s potential beyond just isolated use cases. Rather than treating the technology as a static tool, the framework suggests its use in an iterative, expanding, and self-reinforcing process. Data gathered through interconnected IoT devices inform decentralized decisions; these decisions trigger coordinated adaptations across supply chain partners; and the outcomes of these adaptations are continuously fed back into predictive learning mechanisms that refine subsequent sensing and decision-making. In this way, the framework links vulnerabilities and capabilities over time and allows both researchers and practitioners to re-design DLT solutions and evaluate their contributions to supply chain resilience with each iteration. For small and medium-sized enterprises in particular, the framework offers a structured pathway to test lightweight, lower-cost DLT applications for their specific needs, compare outcomes against industry benchmarks or best practices, and build resilience incrementally while avoiding large upfront investments.

Figure 2.

DLT-LFL (Distributed Ledger Technology Learning Feedback Loop) for Supply Chain Resilience.

In the Sense phase, DLT-based traceability systems and real-time monitoring IoT sensors and tools support joint early threat detection and proactive responses, thereby helping mitigate excessive risks arising from vulnerabilities. Workshop 4 on the Sense phase: “Real-time data feeds would let us flag anomalies instantly, instead of waiting for a quarterly audit to reveal the problem.” In the Decide phase, autonomous smart contracting and decentralized decision-support systems enable data-driven actions and optimized resource allocations, preventing eroded profitability by strengthening operational capabilities. Workshop 5 on the Decide phase: “In automotive, we repeat thousands of the same component orders each month—automating those with smart contracts saves days of paperwork and removes human error.” Adaptation emerges as the central resilience mechanism, where both vulnerabilities and capabilities are continuously adjusted in response to disruption signals—guided by the evolving state of the system and reinforced through feedback from resilience outcomes. Workshop 1 on the Adapt phase: “Even if it’s not real-time adaptation, but when sudden raw material shortages occur, and the DLT-platform shifts production schedules and sourcing priorities in hours instead of weeks, this keeps our output on track and is a drastic change of the current state”. Finally, the Learn phase is driven by predictive learning through decentralized approaches—such as federated learning—which reduces exposure to vulnerabilities, while adaptive learning from operational feedback loops accelerates capability development. Workshop 5 on the Learn phase: “Through federated learning, our demand forecasting model was trained on shipment […] and sales data from [multiple] suppliers without any of them sharing raw files—the algorithm travelled to their data, learned patterns, and sent back only the trained parameters. That way, we improved predictions for seasonal peaks without exposing sensitive commercial information.”

This learning–feedback loop operationalizes DLT’s potential by embedding intelligence, automation, and cross-organizational coordination into the ongoing processes of risk detection, response optimization, and performance adaptation across modern supply chains. The DLT-LFL framework serves as a dynamic analytical lens and tool for evaluating and guiding the design of distributed ledger technologies that enhance supply chain resilience by continuously linking sensing, decision-making, adaptation, and learning processes to evolving vulnerabilities and capabilities. In addition, the framework comes with a practitioner-oriented checklist (Table 4) that can be applied to assess current capabilities, identify resilience gaps, and prioritize interventions. The checklist systematically maps each phase of the DLT-LFL loop to concrete outcomes—risk mitigation, prevention of eroded profitability, reduction in vulnerabilities, and acceleration of capabilities—allowing organizations to evaluate which applications are most effective in their specific context. For small and medium-sized enterprises, the checklist also provides a low-barrier entry point to identify high-impact, resource-efficient DLT interventions, helping them prioritize incremental steps rather than costly full-scale implementations. By following this structured approach, practitioners can not only monitor the impact of solutions over time but also iteratively refine their technology strategies, ensuring they are aligned with operational needs, and continuously improving supply chain resilience and sustainability.

Table 4.

Checklist for Evaluating Supply Chain Resilience Using the DLT-LFL.

- Applying the Checklist

- Rate each criterion: 0 = absent, 1 = partial, 2 = fully implemented.

- Use the analysis questions to guide evaluation and provide evidence for the ratings.

- Identify gaps where risks, vulnerabilities, or capabilities are insufficiently addressed.

- Map described DLT applications to the identified gaps to prioritize interventions.

- Repeat assessments periodically to monitor improvements and maturity progression.

- Document key decisions and rationales for transparency and future review.

- Track which phases (Sense, Decide, Adapt, Learn) show the greatest maturity gaps.

- Adjust criteria or analysis questions as new DLT applications or industry practices emerge.

5. Conclusions

This study contributes to the theoretical understanding of Distributed Ledger Technology (DLT) as a tool for enhancing Supply Chain Resilience (SCR) by addressing both vulnerabilities and capabilities in global trade networks. The analysis of expert evaluations from multiple industry workshops provides empirical evidence for how DLT impacts key resilience factors, such as cybersecurity, data integrity, and operational flexibility. Additionally, this research advances existing theoretical frameworks in the SCR field by moving beyond static lists of vulnerabilities and capabilities, proposing a dynamic, iterative learning–feedback loop that links sensing, decision-making, adaptation, and predictive learning via federated learning. The findings underscore the importance of data standardization, interoperability, and governance as crucial components of DLT’s potential to transform supply chain resilience. To conceptualize these insights, the study proposes the DLT-LFL framework, which structures the contribution of DLT across four iterative phases—sense, decide, adapt, and learn—providing a dynamic model for building resilience.

For practitioners, this research offers actionable insights into how DLT can be strategically leveraged to improve supply chain operations. Industry experts emphasized DLT’s capacity to enhance real-time traceability, fraud prevention, and collaboration. To support immediate application, the study provides a practitioner checklist aligned with the DLT-LFL framework, enabling organizations to evaluate current capabilities, identify resilience gaps, prioritize interventions, and track improvements over time. However, the study is limited by the slow progress of active enterprise blockchain solutions and by the fact that many challenges were collected as practical advice, such as legacy system integration, regulatory compliance, and insufficient governance approaches. These insights can guide organizations in addressing hurdles before advancing DLT integrations. Furthermore, the study is limited by expert opinions and the few industries that participated in the workshops, making the implications particularly relevant for logistics, pharmaceuticals, and automotive sectors, where managing supply chain disruptions is critical for maintaining operational efficiency. The DLT-LFL framework, together with the checklist, can assist practitioners in aligning specific DLT solutions with resilience strategies by identifying where sensing, decision-making, learning, or adaptation processes require support.

In conclusion, DLT offers substantial potential for enhancing SCR by addressing critical vulnerabilities, such as cybersecurity risks, and by strengthening capabilities like collaborative learning, analytics, and decision-making. However, the research also highlights significant challenges, including governance and integration issues, transitions from private to public blockchains and regulatory uncertainties. Looking ahead, further research should focus on scalable, yet decentralized solutions that can accommodate the diverse needs of different industries, while also addressing the evolving regulatory landscape. Additionally, exploring the integration of AI-driven analytics and federated learning with DLT could pave the way for more sophisticated predictive capabilities. Future work could further refine the DLT-LFL framework by validating its applicability across different supply chain contexts and testing how specific DLT applications contribute to resilience-building over time. Research should also apply the checklist, develop quantitative measures, and assess the long-term impact of DLT implementations across different industries. Investigating the integration of complementary technologies such as IoT devices and edge computing, as well as federated learning, along with organizational and governance factors that influence adoption, will provide further guidance for practical implementation.

Author Contributions

Writing–original draft, T.G. and M.A.G.; Writing–review & editing, T.G. and M.A.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AI | Artificial Intelligence |

| C | Capabilities |

| DLT | Distributed Ledger Technology |

| LFL | Learning Feedback Loop |

| SCR | Supply Chain Resilience |

| SCRM | Supply Chain Risk Management |

| V | Vulnerabilities |

Appendix A

| Initial Code | Consolidated Theme | Type | Example Statement |

| Security Flaws | Cybersecurity & Data Integrity | Vulnerability | “Sometimes we don’t manage to patch security issues fast enough across our supplier network, […] that could compromise our data.” |

| Late supplier shipments | Supplier/Customer Disruptions | Vulnerability | “Unexpected shipment delays force us to reroute inventory at the last minute.” |

| Regulatory reporting gaps | External Stressors (Legal/Regulatory) | Vulnerability | “Compliance requirements differ significantly across countries, […] creating gaps in our reporting.” |

| Predictive inventory planning | Proactive Risk Management | Capability | “Using data from multiple suppliers and in the future ideally also further partners along the way, we anticipate shortages […] before they happen.” |

| Resource optimization | Resource Efficiency | Capability | “Monitoring our stock with the Hyperledger Fabric helps us cut waste and use resources more efficiently.” |

| Collaborative dashboards | Supply Chain Visibility | Capability | “Shared dashboards across partners increase transparency and coordination.” |

References

- World Economic Forum. Leveraging Digital Tools in the Age of Supply Chain Disruption. Available online: https://www.weforum.org/stories/2025/01/supply-chain-disruption-digital-winners-losers/ (accessed on 12 September 2025).

- McKinsey. Tech and Regionalization Bolster Supply Chains, but Complacency Looms. 2024. Available online: https://www.mckinsey.com/capabilities/operations/our-insights/tech-and-regionalization-bolster-supply-chains-but-complacency-looms (accessed on 12 September 2025).

- Joshi, S.; Luong, H.T. Review on supply chain resilience: Phenomena, modelling techniques and framework of resilience building strategies with future research directions. Int. J. Supply Chain. Oper. Resil. 2022, 5, 150–184. [Google Scholar] [CrossRef]

- Deloitte. A Primer on Web3 Adoption for Enterprise. 2025. Available online: https://www2.deloitte.com/us/en/pages/consulting/articles/blockchain-and-web3-adoption-for-enterprises.html (accessed on 12 September 2025).

- Jensen, T.; Hedman, J.; Henningsson, S. How TradeLens Delivers Business Value With Blockchain Technology. MISQE 2019, 18, 221–243. [Google Scholar] [CrossRef]

- Gürpinar, T.; Henke, M.; Ashraf, R. Integrating blockchain technology in supply chain management—A process model with evidence from current implementation projects. In Proceedings of the 57th Hawaii International Conference on System Sciences, Honolulu, HI, USA, 3–6 January 2024; p. 57. [Google Scholar]

- Insurance Business. Supply Chain Cyber Attacks Surge over 400%, Expected to Continue Rising—Cowbell Report. Available online: https://www.insurancebusinessmag.com/us/news/cyber/supply-chain-cyber-attacks-surge-over-400-expected-to-continue-rising--cowbell-report-525369.aspx (accessed on 12 September 2025).

- Große, N.; Leisen, D.; Gürpinar, T.; Forsthövel, R.S.; Henke, M.; ten Hompel, M. Evaluation of (De-)Centralized IT technologies in the fields of Cyber-Physical Production Systems. In Proceedings of the CPSL Conference Proceedings, Stellenbosch, South Africa, 17–20 March 2020. [Google Scholar] [CrossRef]

- Zhou, L.; Diro, A.; Saini, A.; Kaisar, S.; Hiep, P.C. Leveraging zero knowledge proofs for blockchain-based identity sharing: A survey of advancements, challenges and opportunities. J. Inf. Secur. Appl. 2024, 80, 103678. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. A digital supply chain twin for managing the disruption risks and resilience in the era of Industry 4.0. Prod. Plan. Control. 2020, 32, 775–788. [Google Scholar] [CrossRef]

- Ulf Paulsson. Supply Chain Risk Management. In Supply Chain Risk: A Reader; Routledge: London, UK, 2004; pp. 79–96. [Google Scholar]

- Schröder, M. Entwicklung einer Methode zur strukturierten Verbesserung des Supply Chain Risikomanagements. In Strukturierte Verbesserung des Supply Chain Risikomanagements; Schröder, M., Ed.; Supply Chain Management; Springer: Fachmedien Wiesbaden, Germany, 2019; pp. 135–218. [Google Scholar] [CrossRef]

- Wildemann, H. Risikomanagement und Rating, 1. Aufl.; TCW, Transfer-Centrum: Munich, Germany, 2006; Volume 25. [Google Scholar]

- Emmanuel-Yusuf, D.; Morse, S.; Leach, M. Resilience and Livelihoods in Supply Chains (RELISC): An Analytical Framework for the Development and Resilience of the UK Wood Fuel Sector. Sustainability 2017, 9, 660. [Google Scholar] [CrossRef]

- Pettit, T.J.; Fiksel, J.; Croxton, K.L. Ensuring Supply Chain Resilience: Development of a Conceptual Framework. J. Bus. Logist. 2010, 31, 1–21. [Google Scholar] [CrossRef]

- Christopher, M.; Peck, H. Building the Resilient Supply Chain. IJLM 2004, 15, 1–14. [Google Scholar] [CrossRef]

- Kotzab, H.; Teller, C.; Grant, D.B.; Friis, A. Supply chain management resources, capabilities and execution. Prod. Plan. Control 2015, 26, 525–542. [Google Scholar] [CrossRef]

- Erukala, S.B.; Tokmakov, D.; Perumalla, A.; Kaluri, R.; Bekyarova-Tokmakova, A.; Mileva, N.; Lubomirov, S. A secure end-to-end communication framework for cooperative IoT networks using hybrid blockchain system. Sci Rep. 2025, 15, 11077. [Google Scholar] [CrossRef] [PubMed]

- Düdder, B.; Fomin, V.; Gürpinar, T.; Henke, M.; Iqbal, M.; Janavičienė, V.; Matulevičius, R.; Straub, N.; Wu, H. Interdisciplinary Blockchain Education: Utilizing Blockchain Technology From Various Perspectives. Front. Blockchain 2021, 3, 578022. [Google Scholar] [CrossRef]

- Große, N.; Guerpinar, T.; Henke, M. Blockchain-Enabled Trust in Intercompany Networks Applying the Agency Theory. In Proceedings of the Blockchain and Internet of Things Conference, Ho Chi Minh City, Vietnam, 8–10 July 2021; pp. 8–14. [Google Scholar] [CrossRef]

- Dujak, D.; Sajter, D. Blockchain Applications in Supply Chain. In SMART Supply Network; Kawa, A., Maryniak, A., Eds.; EcoProduction; Springer International Publishing: Berlin/Heidelberg, Germany, 2019; pp. 21–46. [Google Scholar] [CrossRef]

- Li, L.; Yan, S.; Peng, S.; Hou, P. The interplay of blockchain and channel structure with consideration of cyber-security in a platform supply chain. Transp. Res. Part E Logist. Transp. Rev. 2025, 197, 104045. [Google Scholar] [CrossRef]

- Kitzinger, J. Qualitative research. Introducing focus groups. BMJ 1995, 311, 299–302. [Google Scholar] [CrossRef] [PubMed]

- Halkier, B. Focus groups as social enactments: Integrating interaction and content in the analysis of focus group data. Qual. Res. 2010, 10, 71–89. [Google Scholar] [CrossRef]

- Mostyn, B. The content analysis of qualitative research data: A dynamic approach. In The Research Interview; Brenner, M., Brown, J., Cauter, D., Eds.; Academic Press: London, UK, 1985; pp. 115–145. [Google Scholar]

- Janesick, V.J. Peer Debriefing. In The Blackwell Encyclopedia of Sociology; Ritzer, G., Ed.; John Wiley & Sons, Inc.: New York, NY, USA, 2015. [Google Scholar] [CrossRef]

- Katina, P.F.; Gheorghe, A.V. Blockchain-Enabled Resilience: An Integrated Approach for Disaster Supply Chain and Logistics Management; CRC Press: Boca Raton, FL, USA, 2023; p. 180. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).