Port Sustainability and Probabilistic Assessment of Ship Moorings at Port Terminal Quays

Abstract

1. Introduction

2. Evaluation of Ship Berthing Time in Ports and Analysis of Sustainable Port Literature

3. Theoretical Basis for the Probability of Ship Berthing at Sustainable Ports

3.1. Steps of Research Methodology

3.2. Mathematical Model

- -

- The technical capacity of the port or terminal to process a specific amount of cargo is known;

- -

- The parameters of the port or terminal infrastructure are known to allow the acceptance of a ship with maximum parameters;

- -

- The performance of the terminal loading equipment is consistent with the ship’s optimal moored time capabilities;

- -

- The hydro-meteorological conditions and the time during which ships cannot enter or leave the port, and when the operation of the terminal loading equipment is limited, are known;

- -

- Other important factors are possible that may limit the entry of ships into and exit from the port, as well as the operation of the terminal equipment, such as the waiting time of ships until passenger and passenger–cargo ships with priority enter the port, the time of technical maintenance of the loading equipment, and other similar factors.

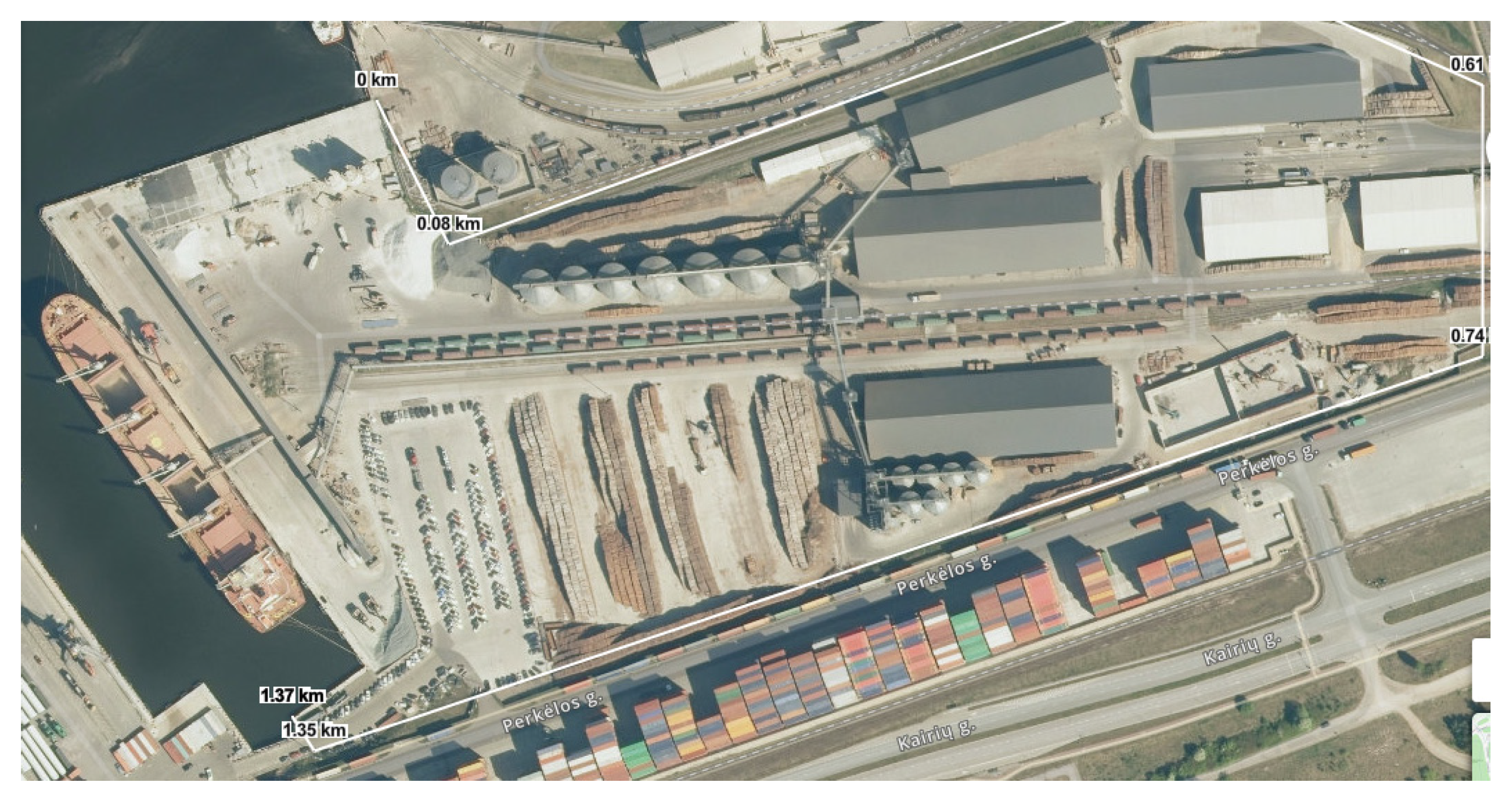

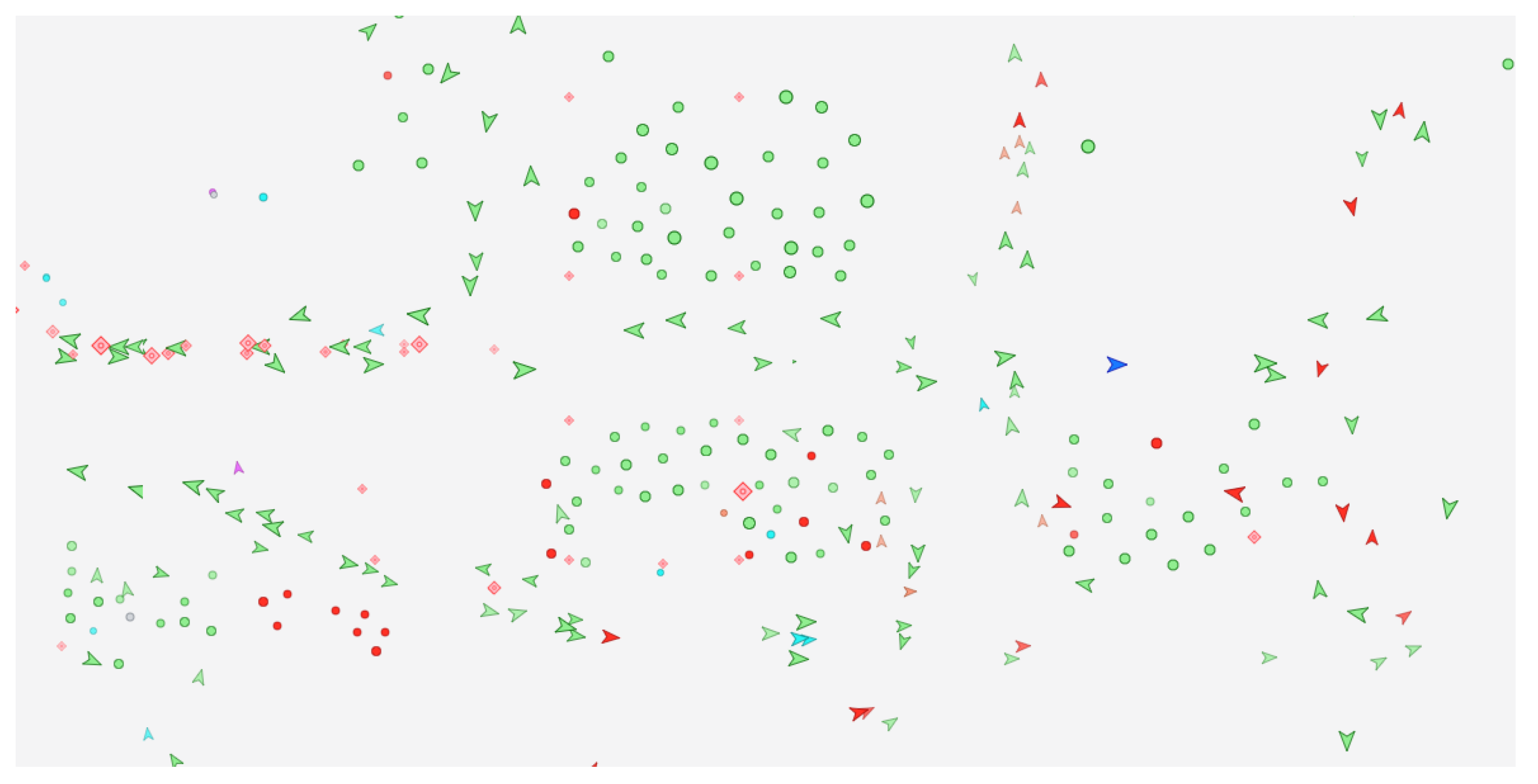

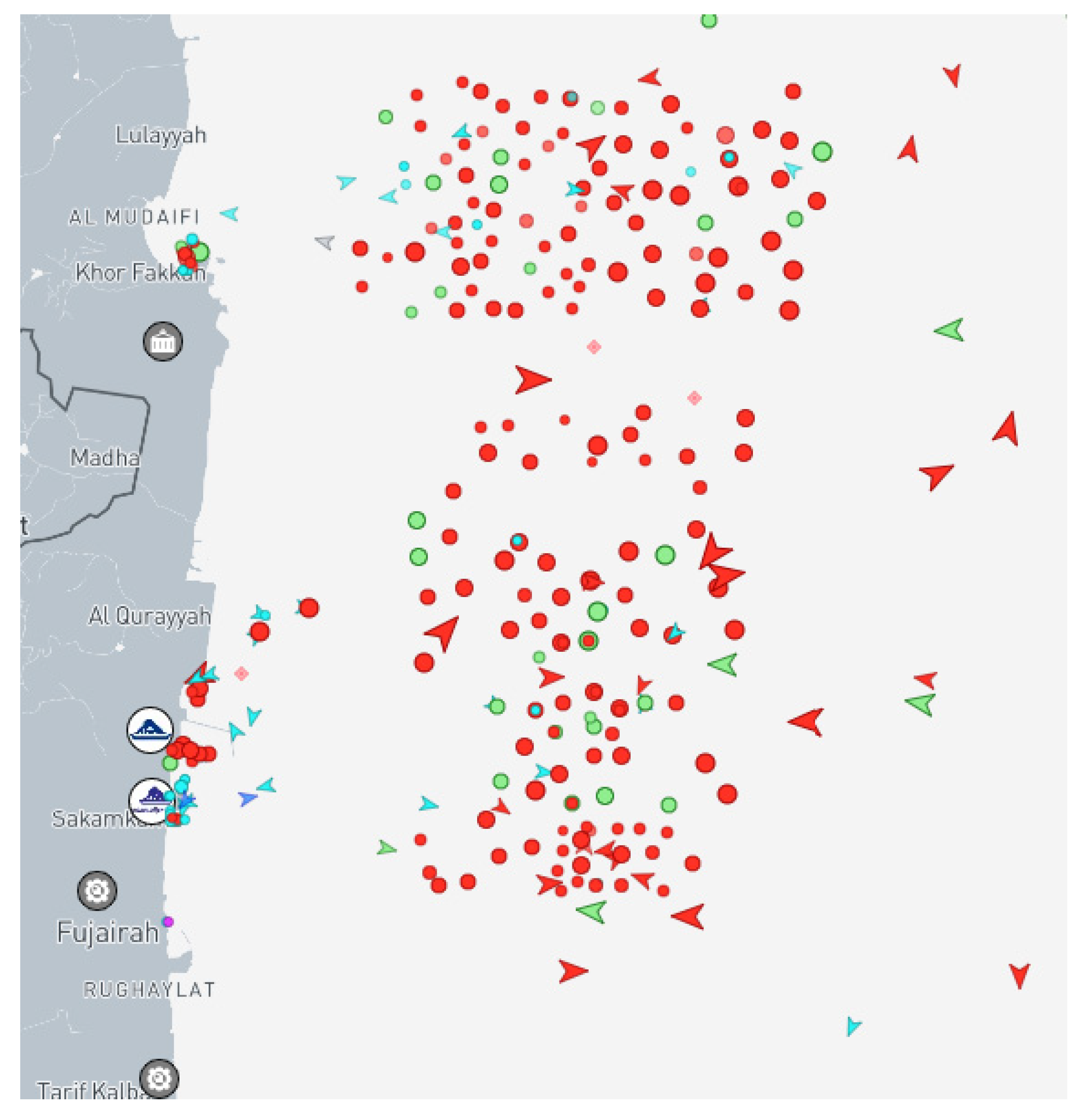

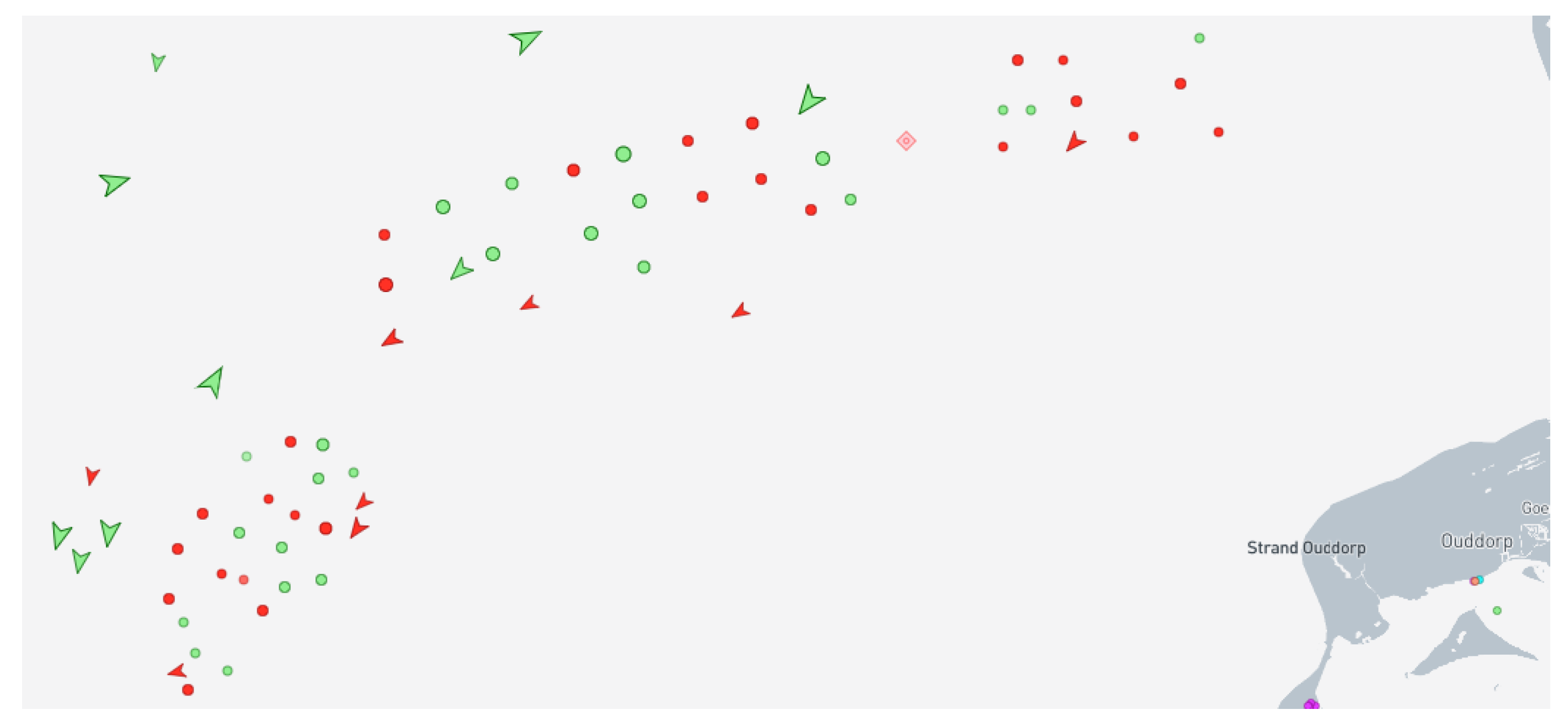

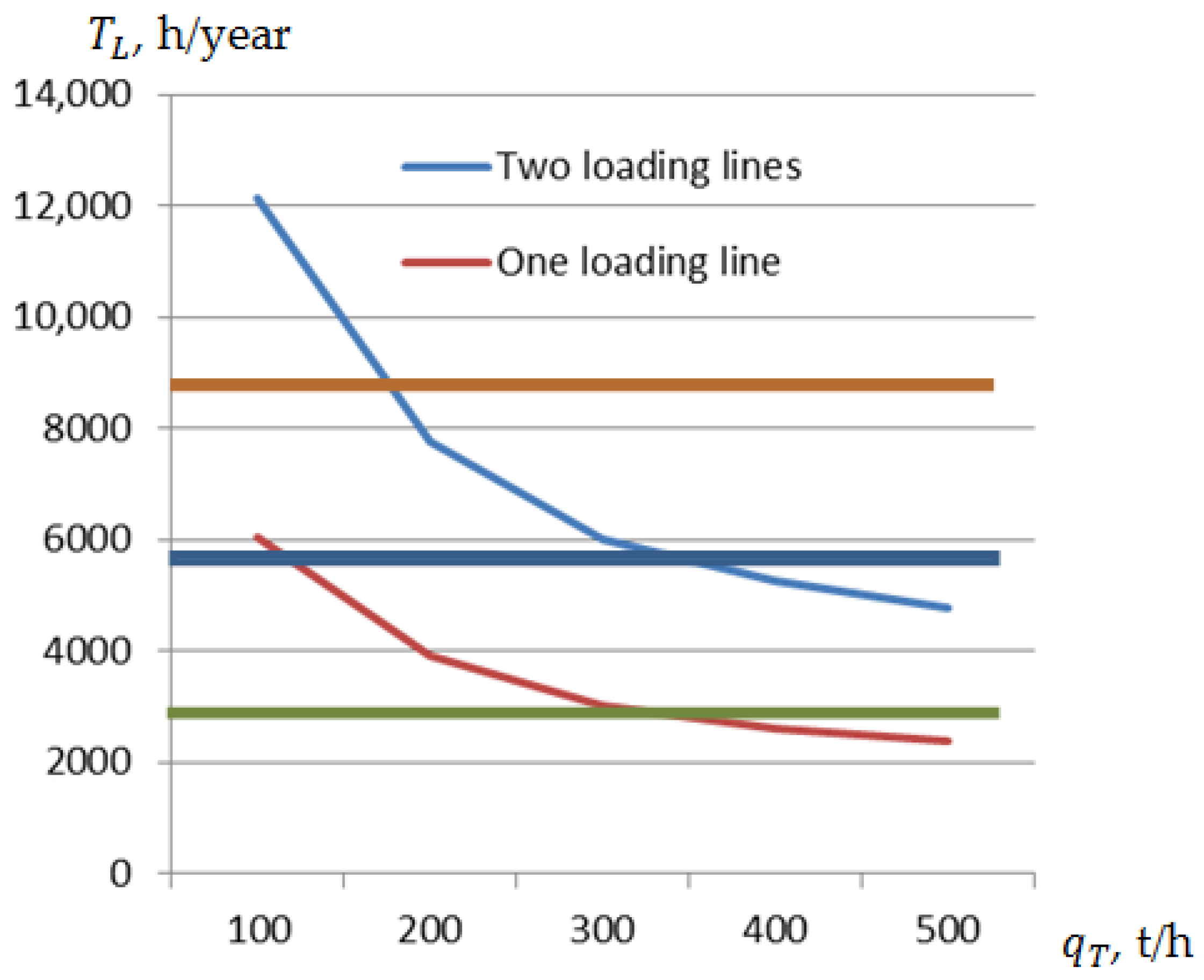

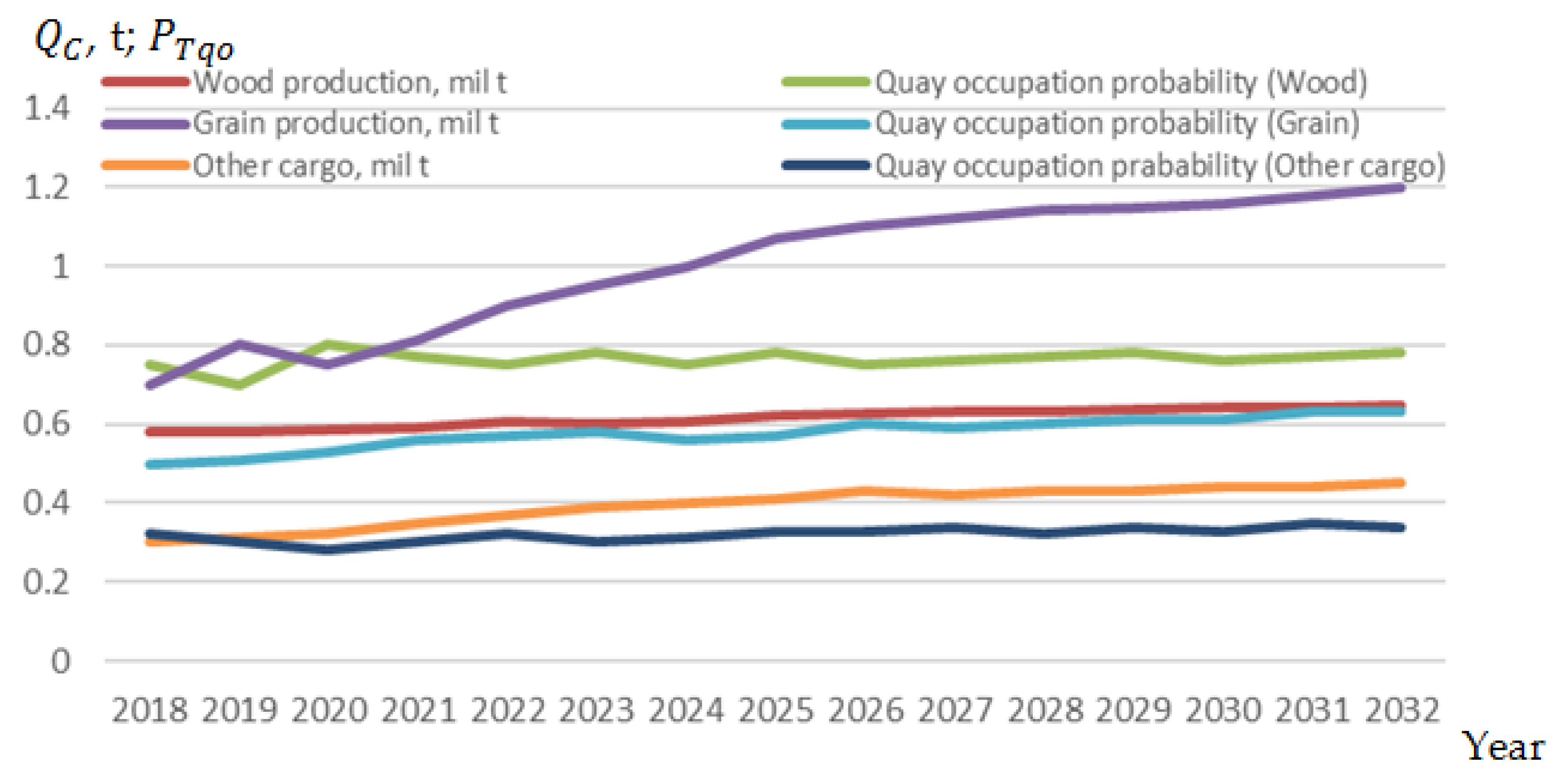

4. Case Study: Assessing Port Berths Occupied by Ships to Create Sustainable Ports

- -

- Using one shift and loading up to two ships at the berths for the same cargo flow—0.998;

- -

- Using two shifts and loading up to two ships at the berths for the same cargo flow—0.793;

- -

- Using three shifts and loading up to two ships at the berths for the same cargo flow—0.621.

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Valentine, V.F.; Benamara, H.; Hoffmann, J. Maritime transport and international seaborne trade. Marit. Policy Manag. 2013, 40, 226–242. [Google Scholar] [CrossRef]

- Duru, O. The Origin and Consistency of the Ton–Mile Metric in the Shipping Economics. Logistics 2017, 1, 3. [Google Scholar] [CrossRef]

- Santos, T.A. Sustainable Port Operations: Pollution Prevention and Mitigation Strategies. Sustainability 2025, 17, 4798. [Google Scholar] [CrossRef]

- Review of Maritime Transport 2021. United Nations Conference on Trade and Development, New York. 2021. Available online: https://unctad.org/system/files/official-document/rmt2021_en_0.pdf (accessed on 25 August 2025).

- Liu, C.; Yu, Y.; Ye, W.; Xu, S.; Qu, B.; Yang, P. Energy management strategy and software design for shore power DC microgrid system. In Proceedings of the 2023 IEEE Transportation Electrification Conference and Expo, Asia-Pacific (ITEC Asia-Pacific), Chiang Mai, Thailand, 28 November–1 December 2023; pp. 1–7. [Google Scholar]

- Maksimavičius, R. Some Elements of the Ro-Ro Terminals. Transport 2004, 19, 75–81. [Google Scholar] [CrossRef]

- Potential of Container Terminal Operations for RoRo Terminals. Available online: https://www.researchgate.net/publication/383223973_Potential_of_Container_terminal_operations_for_RoRo_terminals (accessed on 25 August 2025).

- Notteboom, T. Roro shipping vs. trucking: Revisiting the impact of low-sulphurmarine fuel use on cost competitiveness of routing options in north Europe. WMU J. Marit. Aff. 2020, 19, 399–426. [Google Scholar] [CrossRef]

- Gülmez, Y.; Tapaninen, U.P. Predicting cargo handling and berthing times in bulk terminals: A neural network approach. Case Stud. Transp. Policy 2025, 19, 101351. [Google Scholar] [CrossRef]

- Barasa, L.; Malau, A.G.; Sumali, B. Effect of Berthing Time and Berth Output on Conventional Donation Utilization at PT Pelindo II Palembang Branch. Int. Rev. Manag. Mark. 2019, 9, 6–17. [Google Scholar] [CrossRef]

- UNCTAD. International Maritime Trade and Port Traffic; UNCTAD: Geneva, Switzerland, 2019; pp. 1–25. [CrossRef]

- Connor, E.O.; Evers, N.; Vega, A. Port performance from a policy perspective—A systematic review of the literature. J. Ocean Coast. Econ. 2019, 6, 3. [Google Scholar] [CrossRef]

- Munim, Z.H.; Saeed, N. Seaport competitiveness research: The past, present and future. Int. J. Shipp. Transp. Logist. 2019, 11, 533–557. [Google Scholar] [CrossRef]

- Weerasinghe, B.A.; Perera, H.N.; Bai, X. Optimizing container terminal operations: A systematic review of operations research applications. Marit. Econ. Logist. 2023, 26, 307–341. [Google Scholar] [CrossRef]

- Clark, X.; Dollar, D.; Micco, A. Port efficiency, maritime transport costs, and bilateral trade. J. Dev. Econ. 2004, 75, 417–450. [Google Scholar] [CrossRef]

- Munim, Z.H.; Schramm, H.-J. The impacts of port infrastructure and logistics performance on economic growth: The mediating role of seaborne trade. J. Shipp. Trade 2018, 3, 1–19. [Google Scholar] [CrossRef]

- Paulauskas, V. LNG Transportation and Storage; Klaipeda University Publish House: Klaipėda, Lithuania, 2017; 304p. (In Lithuanian) [Google Scholar]

- Olba, X.B.; Daamen, W.; Vellinga, T.; Hoogendoorn, S.P. Multi-criteria evaluation of ship traffic for port assessment: A case study of the Port of Rotterdam. Case Stud. Transp. Policy 2019, 7, 871–881. [Google Scholar] [CrossRef]

- Port of Shanghai. Available online: https://en.wikipedia.org/wiki/Port_of_Shanghai (accessed on 25 August 2025).

- Available online: https://www.marinetraffic.com/en/ais/home/centerx:-12.0/centery:24.9/zoom:4 (accessed on 25 August 2025).

- Port of Fujairah. Available online: https://fujairahport.ae/ (accessed on 25 August 2025).

- Port of Rotterdam Authority. Available online: https://www.portofrotterdam.com/en (accessed on 25 August 2025).

- Top 50 Ports in the World. Available online: https://www.worldshipping.org/top-50-ports (accessed on 25 August 2025).

- Tan, C.; He, J. Integrated proactive and reactive strategies for sustainable berth allocation and quay crane assignment under uncertainty. Ann. Oper. Res. 2025, 349, 879–910. [Google Scholar] [CrossRef]

- Song, Y.; Ji, B.; Yu, S.S. Multi-Port Berth Allocation and Time-Invariant Quay Crane Assignment Problem with Speed Optimization. IEEE Trans. Intell. Transp. Syst. 2025, 26, 128–142. [Google Scholar] [CrossRef]

- Zheng, H.; Wang, Z.; Liu, H. The Integrated Rescheduling Problem of Berth Allocation and Quay Crane Assignment with Uncertainty. Processes 2023, 11, 522. [Google Scholar] [CrossRef]

- Chu, L.; Zhang, J.; Chen, X.; Yu, Q. Optimization of Integrated Tugboat–Berth–Quay Crane Scheduling in Container Ports Considering Uncertainty in Vessel Arrival Times and Berthing Preferences. J. Mar. Sci. Eng. 2024, 12, 1541. [Google Scholar] [CrossRef]

- Li, S.; Song, L. Berth Allocation and Quay Crane Assignment Considering the Uncertain Maintenance Requirements. Appl. Sci. 2025, 15, 660. [Google Scholar] [CrossRef]

- Elmi, Z.; Singh, P.; Meriga, V.K.; Goniewicz, K.; Borowska-Stefańska, M.; Wiśniewski, S.; Dulebenets, M.A. Uncertainties in Liner Shipping and Ship Schedule Recovery: A State-of-the-Art Review. J. Mar. Sci. Eng. 2022, 10, 563. [Google Scholar] [CrossRef]

- Gürel, S.; Shadmand, A. A heterogeneous fleet liner ship scheduling problem with port time uncertainty. Cent. Eur. J. Oper. Res. 2019, 27, 1153–1175. [Google Scholar] [CrossRef]

- Port of Antwerp. Available online: https://www.portofantwerpbruges.com/en (accessed on 25 August 2025).

- Port of Yakohama. Available online: https://www.vesseltracker.com/en/Port/Yokohama/Dashboard.html (accessed on 25 August 2025).

- Bregni, S.; Jmoda, L. Improved Estimation of the Hurst Parameter of Long-Range Dependent Traffic Using the Modified Hadamard Variance. In Proceedings of the 2006 IEEE International Conference on Communications (ICC 2006), Istanbul, Turkey, 11–15 June 2006. [Google Scholar]

- Hanqing, J.; Shige, P. Optimal unbiased estimation for maximal distribution. Am. Inst. Math. Sci. 2021, 6, 189–198. [Google Scholar] [CrossRef]

- Jaynes, E.T. Probability Theory the Logic of Science; Cambridge University Press: New York, NY, USA, 2003; 758p. [Google Scholar]

- Paulauskas, V. Logistika; Klaipeda University Publish House: Klaipėda, Lithuania, 2007; 288p. (In Lithuanian) [Google Scholar]

- Alalawin, A.; Arabiyat, L.M.; Alalaween, W.; Qamar, A.; Mukattash, A. Forecasting vehicle’s spare parts price and demand. J. Qual. Maint. Eng. 2021, 27, 483–499. [Google Scholar] [CrossRef]

- Google Maps. Available online: https://www.google.com/maps/@55.7306584,21.1467253,3826m/data=!3m1!1e3?entry=ttu&g_ep=EgoyMDI1MDczMC4wIKXMDSoASAFQAw%3D%3D (accessed on 25 August 2025).

- Iris, C.; Pacino, D.; Røpke, S. Improved formulations and an Adaptive Large Neighborhood Search heuristic for the integrated berth allocation and quay crane assignment problem. Transp. Research. Part E Logist. Transp. Rev. 2017, 105, 123–147. [Google Scholar] [CrossRef]

- Cheimanoff, N.; Fontane, F.; Kitri, M.N.; Tchernev, N. Exact and heuristic methods for the integrated berth allocation and specific time-invariant quay crane assignment roblems. Comput. Oper. Res. 2022, 141, 105695. [Google Scholar] [CrossRef]

- Yu, J.; Tang, G.; Song, X. Collaboration of vessel speed optimization with berth allocation and quay crane assignment considering vessel service differentiation. Transport. Res. E Logist. Transport. Rev. 2022, 160, 102651. [Google Scholar] [CrossRef]

- Yin, D.; Niu, Y.; Yang, J.; Yu, S. Static and Discrete Berth Allocation for Large-Scale Marine-Loading Problem by Using Iterative Variable Grouping Genetic Algorithm. J. Mar. Sci. Eng. 2022, 10, 1294. [Google Scholar] [CrossRef]

- Guo, L.; Zheng, J.; Du, J.; Gao, Z.; Fagerholt, K. Integrated planning of berth allocation, quay crane assignment and yard assignment in multiple cooperative terminals. Transp. Res. Part E Logist. Transp. Rev. 2024, 183, 103456. [Google Scholar] [CrossRef]

- IMO International Convention for the Prevention of Pollution from Ships (MARPOL-73/78). Available online: https://www.imo.org/en/knowledgecentre/conferencesmeetings/pages/marpol.aspx (accessed on 25 August 2025).

- UN 17 Sustainable Development Goals (SDGs). Available online: https://sdgs.un.org/goals (accessed on 25 August 2025).

| Year | Cargo Flow, Thousand Tons | Forecast Coefficient | Factor 1 | Factor‘s Weight | Factor 2 | Factor‘s Weight | Factor 3 | Factor‘s Weight | Factor 4 | Factor‘s Weight | Factor 5 | Factor‘s Weight | Multicriteria Coefficient | Forecast Cargo Flow | = 12) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 580 | ||||||||||||||

| 2 | 580 | 0 | |||||||||||||

| 3 | 585 | 2.5 | |||||||||||||

| 4 | 590 | 3.3 | |||||||||||||

| 5 | 605 | 6.25 | |||||||||||||

| 6 | 600 | 4 | |||||||||||||

| 7 | 608 | 4.7 | |||||||||||||

| 8 | 1.2 | 0.25 | 2.3 | 0.25 | 1 | 0.15 | 1 | 0.2 | 1 | 0.15 | 1.009 | 611 | 623 | ||

| 9 | 2.0 | 0.25 | 4.4 | 0.25 | 1 | 0.15 | 1 | 0.2 | 1 | 0.15 | 1.016 | 615 | 627 | ||

| 10 | 3.1 | 0.25 | 6.5 | 0.25 | 1 | 0.15 | 1 | 0.2 | 0.9 | 0.15 | 1.009 | 618 | 630 | ||

| 11 | 4.3 | 0.25 | 8.2 | 0.25 | 1.1 | 0.15 | 0.95 | 0.2 | 0.9 | 0.15 | 1.007 | 621 | 633 | ||

| 12 | 5.5 | 0.25 | 10.1 | 0.25 | 1.2 | 0.15 | 0.90 | 0.2 | 0.9 | 0.15 | 1.034 | 625 | 637 | ||

| 13 | 6.7 | 0.25 | 12.3 | 0.25 | 1.2 | 0.15 | 0.90 | 0.2 | 1 | 0.15 | 1.058 | 629 | 641 | ||

| 14 | 7.8 | 0.25 | 14.5 | 0.25 | 1.2 | 0.15 | 0.85 | 0.2 | 1 | 0.15 | 1.056 | 632 | 644 | ||

| 15 | 9.0 | 0.25 | 16.7 | 0.25 | 1.2 | 0.15 | 0.85 | 0.2 | 1 | 0.15 | 1.065 | 636 | 648 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paulauskas, V.; Paulauskas, D.; Paulauskas, V. Port Sustainability and Probabilistic Assessment of Ship Moorings at Port Terminal Quays. Sustainability 2025, 17, 8973. https://doi.org/10.3390/su17208973

Paulauskas V, Paulauskas D, Paulauskas V. Port Sustainability and Probabilistic Assessment of Ship Moorings at Port Terminal Quays. Sustainability. 2025; 17(20):8973. https://doi.org/10.3390/su17208973

Chicago/Turabian StylePaulauskas, Vytautas, Donatas Paulauskas, and Vytas Paulauskas. 2025. "Port Sustainability and Probabilistic Assessment of Ship Moorings at Port Terminal Quays" Sustainability 17, no. 20: 8973. https://doi.org/10.3390/su17208973

APA StylePaulauskas, V., Paulauskas, D., & Paulauskas, V. (2025). Port Sustainability and Probabilistic Assessment of Ship Moorings at Port Terminal Quays. Sustainability, 17(20), 8973. https://doi.org/10.3390/su17208973