1. Introduction

At the core of sustainable economic development worldwide is the pressing need to reduce energy consumption and transition from fossil fuels to renewable energy sources. These priorities have driven intensified efforts to develop efficient energy conversion systems, including new units and adaptations of existing ones, to be fueled by various kinds of solid fuels, including low-grade biogenic materials [

1,

2]. This, in particular, applies to small-scale combined heat and power units, underpinning distributed energy systems fed by locally available resources [

3]. Thermally efficient heat exchangers as the basic components of such systems largely contribute to their efficiency [

4,

5,

6,

7], and thereby reducing the fuel consumption and leading to overall energy savings that lie behind the economic and society sustainability goals. Therefore, much of the research in this area focuses on heat transfer enhancement [

8].

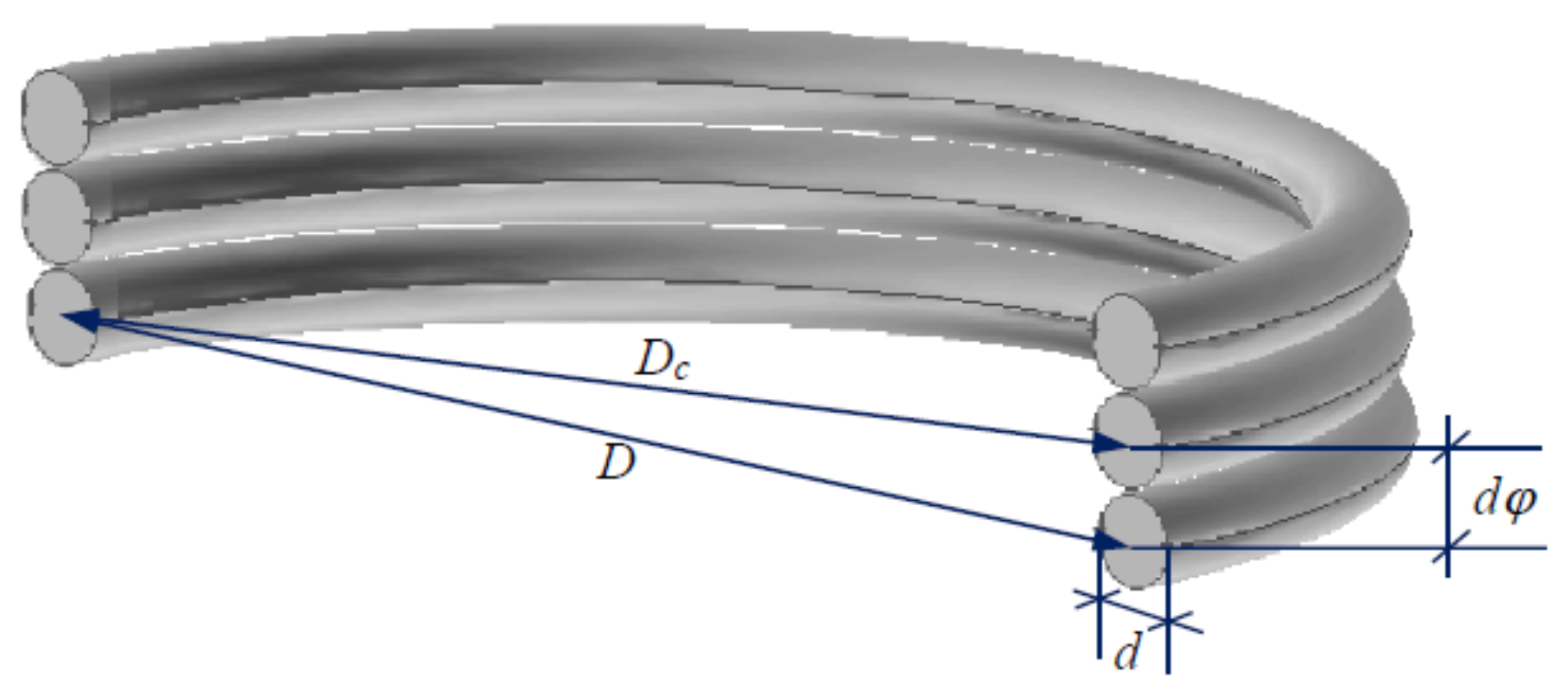

Helically coiled tubes are considered to be among the most beneficial solutions for thermal units since they offer high heat transfer rates, higher compared to straight tubes, particularly in the case of laminar flows [

9,

10]. With this, they feature not only higher effectiveness than other tube-type heat exchanger geometries but also large heat exchange surface area-to-volume ratios that translate into their compactness. Owing to these features, they have been widely used for decades in various industrial applications, such as heat recovery systems [

11,

12], thermal energy storage systems [

13], refrigeration and air conditioning installations [

14,

15,

16], as well as chemical and food industry [

17].

There are numerous works available devoted to the analysis of thermal and flow characteristics of helically coiled type heat exchangers, including both experimental examination and numerical calculations. The latter are essential since the performance of a heat exchanger is always a question of the thermophysical properties of working fluids, the exchanger design, as well as the enhancement technique to be used, either active or passive. Considering the time and cost involved in the experimental work, calculations can considerably improve the design and optimization of these devices.

In the literature, two basic methods of thermal calculations for various types of heat exchangers can be found [

18]. The first one utilizes the logarithmic mean temperature difference (LMTD), and the second is the so-called

-NTU method (where

means the heat exchanger effectiveness and NTU is the number of heat transfer units). Both methods are based on steady-state conditions and the energy balance equation between hot and cold fluids. The

-NTU method is particularly helpful when the outlet temperatures of the fluids are not known. It assumes constant heat transfer coefficient and fluid properties, which in the case of thermal oil and complex geometry of the system can give unreasonable results, burdened with an error [

19]. The LMTD method is used if all inlet and outlet temperatures are known and the unknown is the required heat transfer area. This approach eliminates the need for iterative calculations, making it computationally efficient. Furthermore, it assumes that the outlet temperatures of both fluids are already known. If they are not, an iterative procedure is needed, which can complicate the analysis. Similarly to the

-NTU method, in this one, the constant properties are often assumed, which may not hold for systems with large temperature variations [

20].

Various researchers utilize CFD tools to analyze the effects of different factors, such as flow rate and geometrical parameters on the performance of heat exchangers. Tuncer et al. [

21] used CFD to simulate heat transfer and fluid flow inside the shell and helically coiled tube in two configurations, conventional and modified aiming at achieving an exchanger of improved efficiency. Omidi et al. [

22] carried out CFD analysis on flow characteristics and heat transfer in a helical coil with four different lobed cross sections, focusing on the impact of the lobe number, coil diameter, flow parameters, as well as nanoparticles on the performance of a heat exchanger. Abu-Hamdeh et al. [

23] performed CFD simulations to examine heat transfer and pressure drop in the new type helically coiled tube heat exchangers (type named “sector-by-sector”), and the helical coiled tube-in-tube heat exchanges for comparison. In another work, Abu-Hamdeh et al. [

24] using CFD approach investigated the thermal-hydraulic characteristics of a helical micro double-tube heat exchanger, considering configurations with various pitch lengths and number of turns. Recently, Elsaid et al. [

25] studied numerically the thermal-hydraulic performance of the shell and helically coiled tube heat exchanger, covering various tube cross-sections (circular, elliptic, and square). Similar cross-section geometries of coiled tubes were also investigated using CFD calculations by Kurnia et al. [

26], who aimed at evaluating heat transfer performance and entropy generation of laminar flow in the hellically coiled tube under heating and cooling. Haskinks and El-Genk [

27] used CFD to analyze friction pressure losses on the shell side of annular heat exchangers with the concentric helically coiled tubes, considering isothermal flows of liquid sodium, water, and helium gas. The simulation cases involved different HEX configurations, with the number of coils varying from 4 to 16, arriving at the total computation time of order of days, depending on the numerical mesh grid refinement.

It is noteworthy that advanced CFD simulations might be challenging for complex heat exchanger geometry, and time-consuming, and therefore may not be effective in practical use [

28]. The literature review shows the lack of studies related to thermal analysis of helically coiled tube heat exchangers in small and medium-scale units that utilize in-house codes for fast predictions of an exchanger performance serving as a useful tool in the design and verification of preliminary geometry.

Soni and Chiesa [

29] developed a calculation code aimed at the thermal rating of helically coiled heat recovery boilers with parallel coaxial coils fed with flue gases parallelly in a counterflow. Their program is based on a one-dimensional model, allowing the computational domain to be divided longitudinally into subsections to account for geometrical variations. Andrzejczyk and Muszyński [

30] carried out the NTU-based calculations and designed a single-tube helically coiled heat exchanger to eventually experimentally verify the influence of external tube surface modification on the heat transfer coefficient. The authors’ study involved both, the co-current and counter-current, flow configuration. Alimoradi [

31] studied the effect of operational and geometrical parameters on the thermal effectiveness of shell-and-helically coiled tube heat exchangers under steady state. Based on the experimentally validated simulation data on heat transfer in the heat exchanger, he carried out calculations of effectiveness and NTU. Employing the NTU analysis, Panahi and Zamzamian [

32] studied the performance of a shell-and-coiled tube heat exchanger with helical wire inserted as a turbulator. In their investigation, the authors aimed to determine the thermal and frictional performance of the designed exchanger compared to the one without the turbulizing wire. Mirgolbabaei [

33] investigated the thermal performance of vertical helically coiled heat exchangers of different geometrical parameters, including coil pitch and tube diameter, through CFD simulation and

-NTU analysis. Unlike the most common approaches that involve constant temperature or heat flux at the tube wall, he implemented a conjugate boundary condition (a fluid-to-fluid heat transfer), arriving at reasonable predictions for the studied configuration. The authors of the present work, in their previous study [

34], proposed the stationary lumped-cell model to simulate the thermal characteristics of the domestic biomass boiler with an integrated helically coiled tube heat exchanger cooled with thermal oil, designed to operate with the organic Rankine cycle (ORC) power generation system. Good agreement between the calculation results and measurement data was obtained, proving the approach to be reliable in estimating the thermal performance of the helically multi-coiled exchangers.

The goal of this study is to utilize the numerical approach based on a one-dimensional lumped-cell model, similar to the one previously developed, to analyze the thermal performance of a helically coiled multi-tube heat exchanger designed to recover heat from waste biomass combustion flue gases. The calculation results for the three-pipe heat exchanger of heat output of 1.2 MW were validated with the measurements. Next, the calculations were performed to examine the thermal and flow characteristics of a four-pipe exchanger to be designed and determine the required heat exchange surface area for the assumed heat output of 2.2 MW.

3. Results

3.1. Step I—Three-Pipe HCHE Case

The developed calculation method was first applied to the real test case of the HCHE composed of three tube coils. It is assumed that each of them consists of different numbers of coil segments, as is presented in

Table 4. The table includes the input computation parameters, i.e., the geometry dimensions, media mass flow rates, the oil temperature at the HE outlet and the flue gas composition.

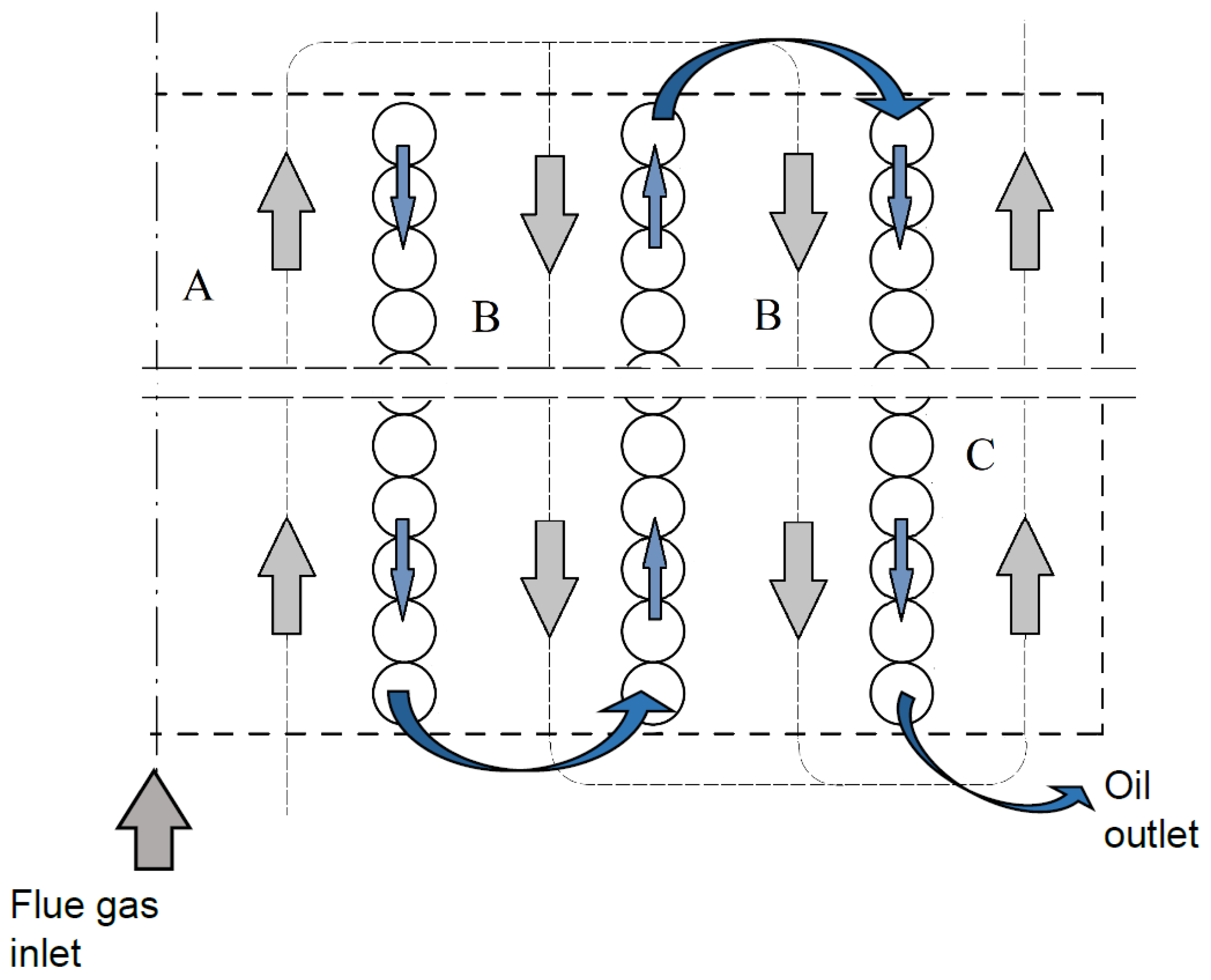

The half cross-sectional view of the exchanger, showing the flow directions of the hot fluid (flue gas) and the cold fluid (thermal oil), is schematically displayed in

Figure 4. As shown in the figure, due to the differing flow characteristics across the specific sections of the heat exchanger, the heat exchanger volume was divided into three general zones for calculation purposes:

zone A—flue gas flow in the inner coil core,

zone B—covering flue gas annular flow in the volume between the inner and outer coil,

zone C—comprising flue gas annular flow in the volume between the outer coil and the wall.

Following such an approach, a heat exchanger is considered a counterflow type.

To check whether the required thermal output of the heat exchanger is obtained, the calculations utilize the mass flow rates of fluids and the inlet flue gas temperature (see values with star, shown in

Table 4). It shall be mentioned that the flow rate of flue gas is a value resulting from the general thermal balance for given oil parameters and assumed inlet/outlet temperature difference on the hot side.

The physical properties of Therminol 66 ([

45]) were adopted for calculations. The composition of flue gas, presented in

Table 4, was determined based on the global reaction of the fuel combustion, given its chemical composition.

The flue gas temperature at the inlet to the heat exchanger was assumed adiabatic,

, which equals approximately 1150 °C. Additionally, the outlet oil temperature

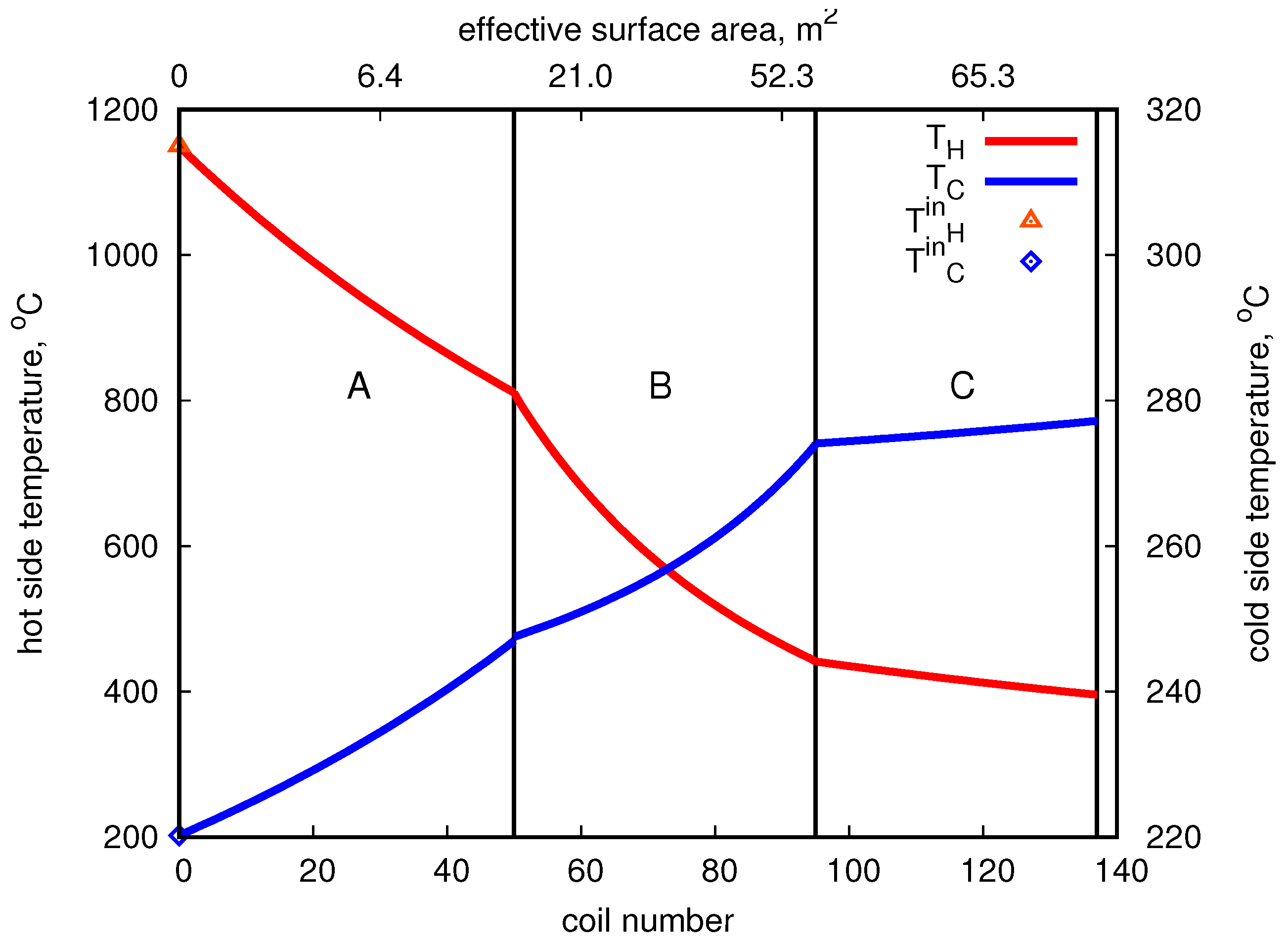

was set to the upper limit of 280 °C. The lower limit for the outlet flue gas temperature was set to 350 °C. The predicted temperature changes of fluids are depicted in

Figure 5. In the figure, the input temperatures are also marked (points).

As observed, the temperature gradients for both fluid flows are the greatest in the first (A) and second (B) sections and significantly decrease in the outer coil (C). The total heat transfer surface area

A amounts to 226

, which in accordance with the aforementioned analysis comes down to the effective heat exchange surface area of

. The heat efficiencies of the subsequent sections are approximately 520 kW, 530 kW, and 65 kW, respectively, which gives the total capacity of ca. 1100 kW. The detailed data are presented in

Table 5.

As seen, the total temperature decrease of flue gases exceeds 750 degrees. Consequently, the total increase of thermal oil temperature reaches nearly 57 °C.

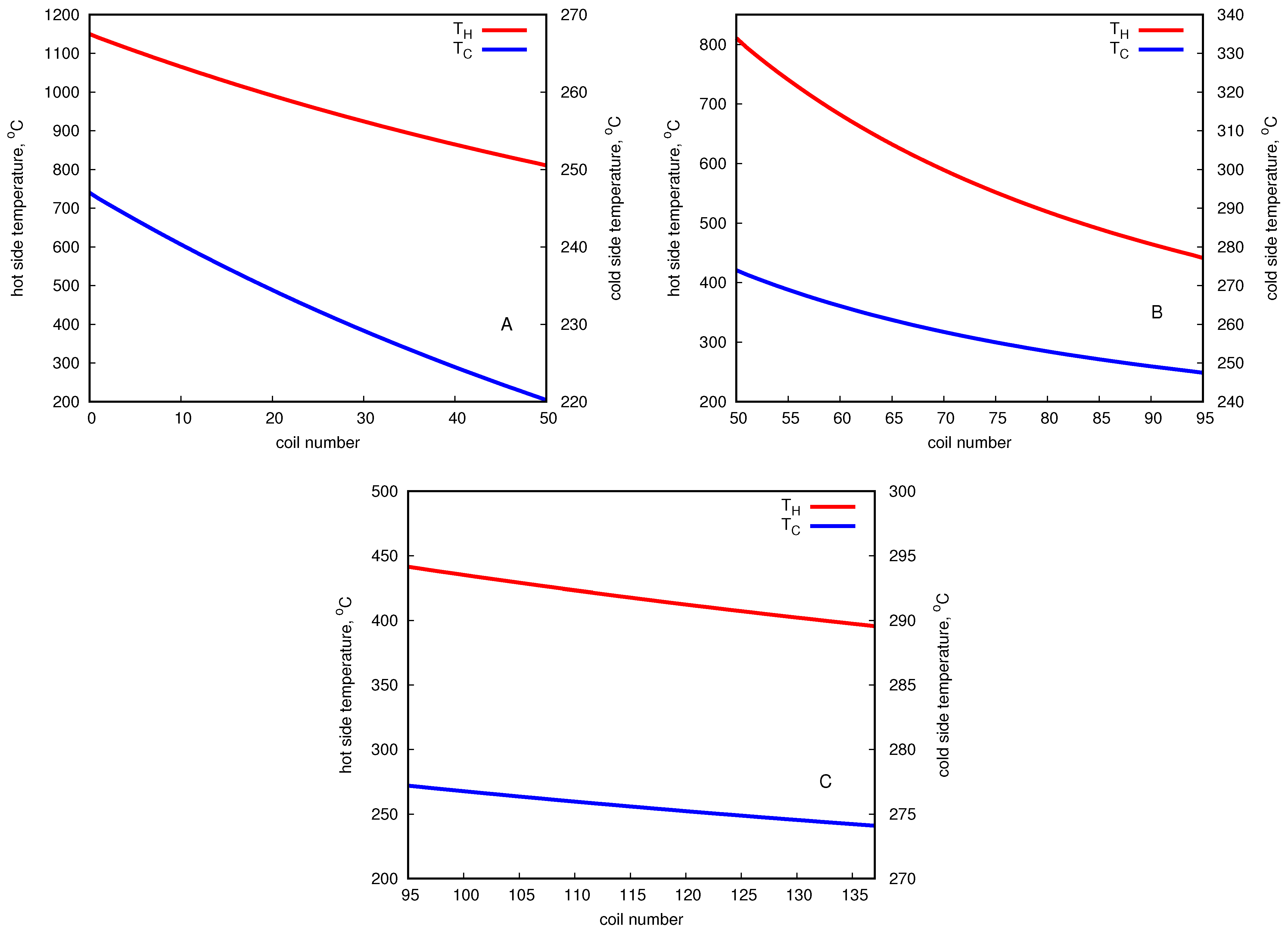

Figure 6 presents the graphs of temperature distribution on the hot and cold sides in A, B and C sections, which are the variation curves typical for the counter-current type of heat exchanger, as assumed in the computations.

3.2. Step II—Four-Pipe HCHE Case

This stage aimed at predicting the thermal performance of a heat exchanger of a similar helically coiled type design but with an additional tube (outer) and a given thermal capacity. Likewise, in this case, four different flow sections within the heat exchanger were taken into consideration, as demonstrated in

Figure 7:

zone A—flue gas flow in the inner coil core,

zone B—covering flue gas annular flow in the volume between the inner and the third coil,

zone C—annular flow delineated by the third and fourth coils,

zone D—involving flue gas flow between the fourth (outer) coil and the exchanger wall.

The half cross-sectional view of the exchanger with marked flow directions of the hot fluid (flue gas) and the cold fluid (thermal oil) is schematically demonstrated in

Figure 7. It is clearly seen that in such a case, the exchanger is considered in terms of a mixed type, i.e., as counter-current in sections A, B and C, and as co-current in section D. Thereby, the determined flue gas temperature at the outlet of the exchanger is averaged between sections A and B.

Thermal and flow parameters, assumed for the calculations are presented in

Table 6. The mass flow rate on the cold side (thermal oil) is determined based on the design heat exchanger capacity and outlet/inlet temperature difference of the cooling fluid, whereas the flow rate of exhaust gas is calculated from the general energy balance assuming the thermal oil parameters and the flue gas temperature decrease. The flue gas composition taken was the same as in the case of a 3-pipe HCHE (see

Table 4). Similarly, the physical properties of Therminol 66 ([

45]) were adopted for calculations.

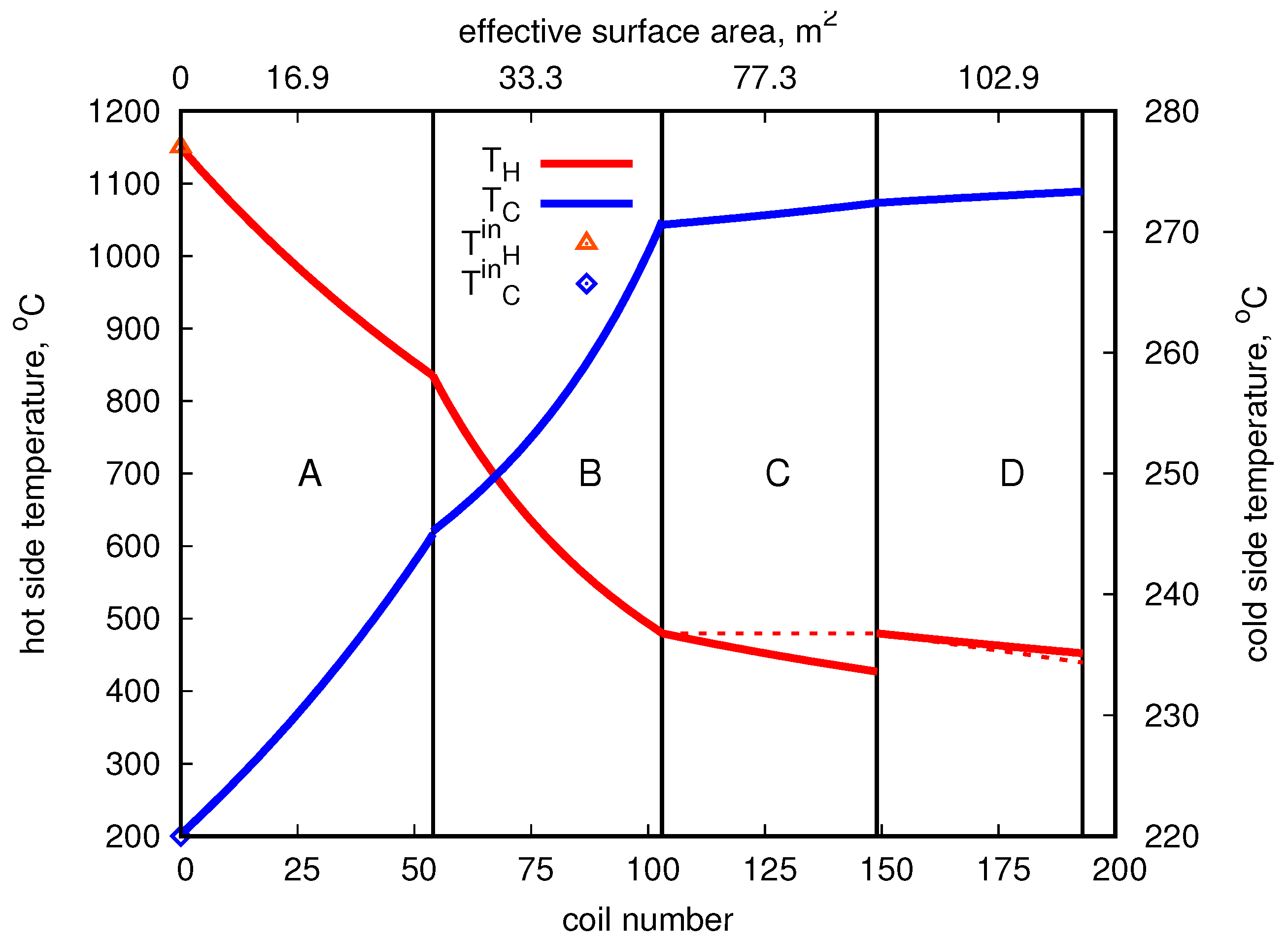

Like in the previous case, the temperature limits were adopted. For oil, it was set not higher than 280 °C, and for flue gas not lower than 350 °C. The flue gas temperature at the inlet into the exchanger was assumed at 1150 °C. The input temperature (points) and the temperature changes of the fluids are shown in

Figure 8.

The results reveal that the most intensive heat transfer, as expected, occurs in the first two sections (A and B). One should note that the dashed line in section C in

Figure 8 corresponds also with the inlet flue gas temperature in section D, wherein, contrary to sections A–C, the co-current flow is considered (see

Figure 7). In addition, owing to the mixed type heat exchanger (counter-current/co-current), at the outlet from the exchanger, the flue gas temperature is taken as an average between the outlet temperatures from sections C and D (

Figure 8, dashed line in section D).

The total coil surface area

A amounts to 350

, but the effective heat exchange surface area is over three times lower and it equals to

. The heat duties of the respective sections are approximately 890 kW, 950 kW, 67 kW and 36 kW, which gives the total capacity of ca. 1945 kW. The detailed data are presented in

Table 7.

As seen, the total temperature decrease of the exhaust gases exceeds 710 degrees, which with the analyzed flow and geometrical parameters gives over 50 °C increase in oil temperature.

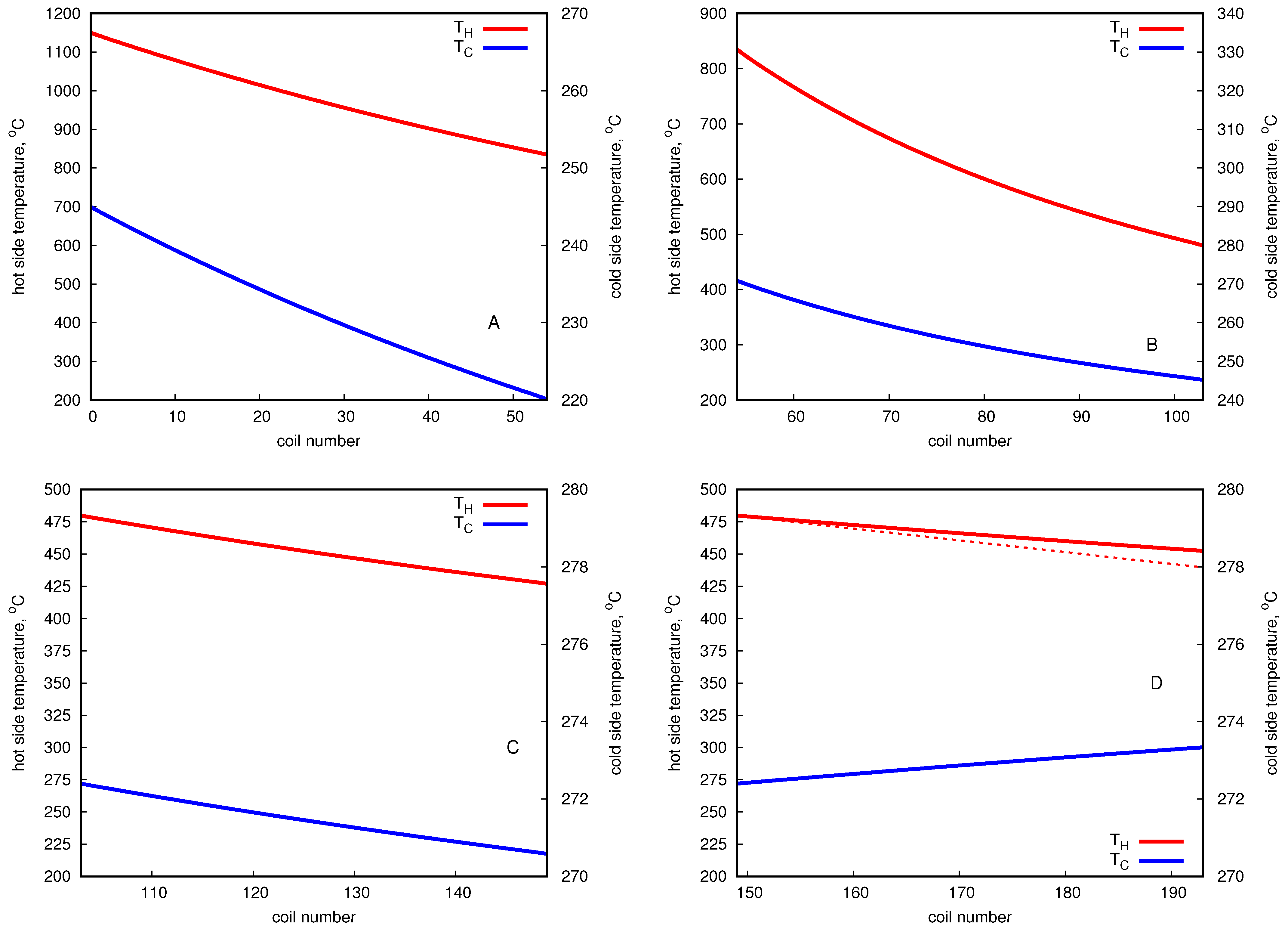

In

Figure 9, the graphs for temperature distribution at each section are presented. The first three sections (A, B and C) represent the counter-current type of heat exchanger, and the last one (D) is a co-current type of heat exchanger.

In analyzed cases, the assumption of heating the thermal oil to 280 °C was almost achieved. One should note that another important aspect in the design of exchangers with such a type of coolant must be accounted for. Namely, the protection of the device in case of unexpected significant changes in parameters (e.g., temperature and pressure), beyond the range of operating parameters of both the working fluid (oil) and the installation itself, which may result, for example, in a fire of the installation. It is, therefore, necessary to equip it with an automation system, taking into account different factors. In the case of no or too little oil flow through the heat exchanger, the differential pressure switch on the oil inlet and outlet should be used. The safety valve is widely accepted to prevent excessive pressure increase, while a thermostat prevents the maximum temperature from being exceeded. Moreover, in an open system with an expansion tank, the oil level in the tank should be controlled. In this case, a float sensor may be used to disallow the system leakage.

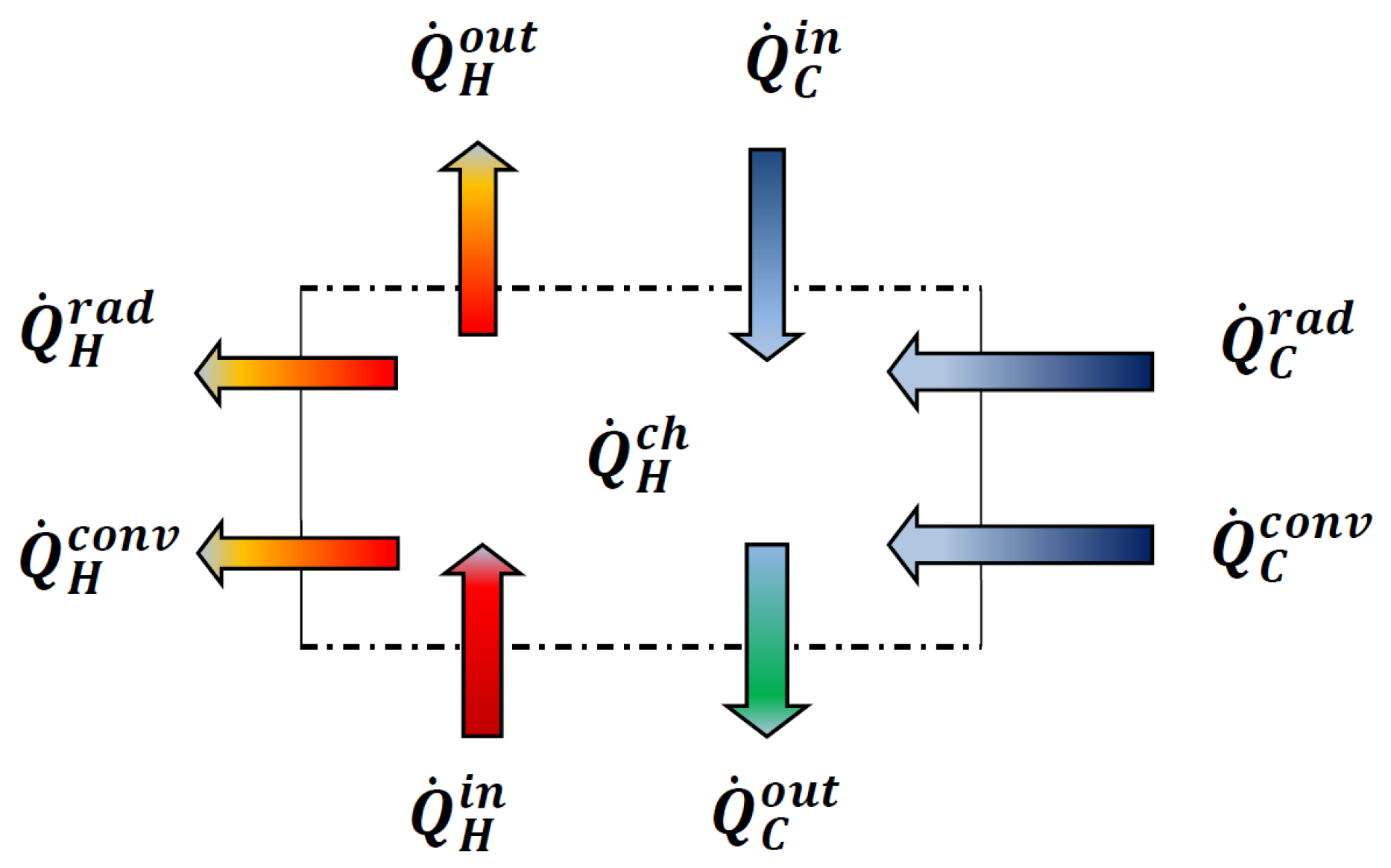

Leaving aside the aforementioned security aspects, it was shown in this paper that the proposed simple and fast mathematical model for determining the thermal and flow performance of helically coiled heat exchangers is a perspective tool for the first step design of heating units. It is a useful tool for geometrically complex systems which are characterized by different types of flow. This approach can be used for analyzing different types of heat exchangers: co-current, counter-current flow, and mixed ones. It is based on a simple stationary energy balance equation between the fluids, taking into account all types of heat transfer (convection, conduction, radiation) whose values depend on the flow parameters and geometry. Moreover, the developed model accounts for temperature-varying physical fluid properties.

4. Conclusions

In this study, the thermal evaluation of helically coiled multi-tube heat exchangers fed with flue gas and cooled with thermal oil was conducted through numerical calculations. To perform the analysis, a one-dimensional multi-section lumped model was developed and implemented in the in-house code.

Two configurations of a concentric helically coiled tube exchanger were analyzed: the three- and four-tube cases. The analysis was conducted in two stages. In the first stage, which covered the calculations for the three-tube case, the developed in-house code was validated with measurement data, showing satisfactory convergence, at about 6% regarding the predicted thermal capacity. In the second stage, the developed methodology was used to determine the thermal performance of a helically coiled tube heat exchanger of larger capacity, other tube dimensions and tube configuration, i.e., four-tube heat exchanger. The thermal power in this case was predicted with an accuracy of less than 12%.

The obtained results demonstrate that the in-house code can serve as an effective design tool when a preliminary heat exchanger geometry is given. It thus comprises an alternative for costly and time-consuming advanced CFD calculations.

Future work should focus on calculating the pressure drop in the system on both sides, the shell side (hot fluid flow) and the tube side (cold fluid flow). This will provide complete information about the thermal and flow characteristics of helically coiled heat exchangers.