Machine Learning-Aided Supply Chain Analysis of Waste Management Systems: System Optimization for Sustainable Production

Abstract

1. Introduction

- Explore whether the stochastically perturbed kinetic system converges to a stable equilibrium or exhibits metastable saddle behavior [5] under stochastic perturbations. Convergence to a stable equilibrium will point to a resilient economic SCN while a saddle point will point to probabilistically unreliable SCNs.

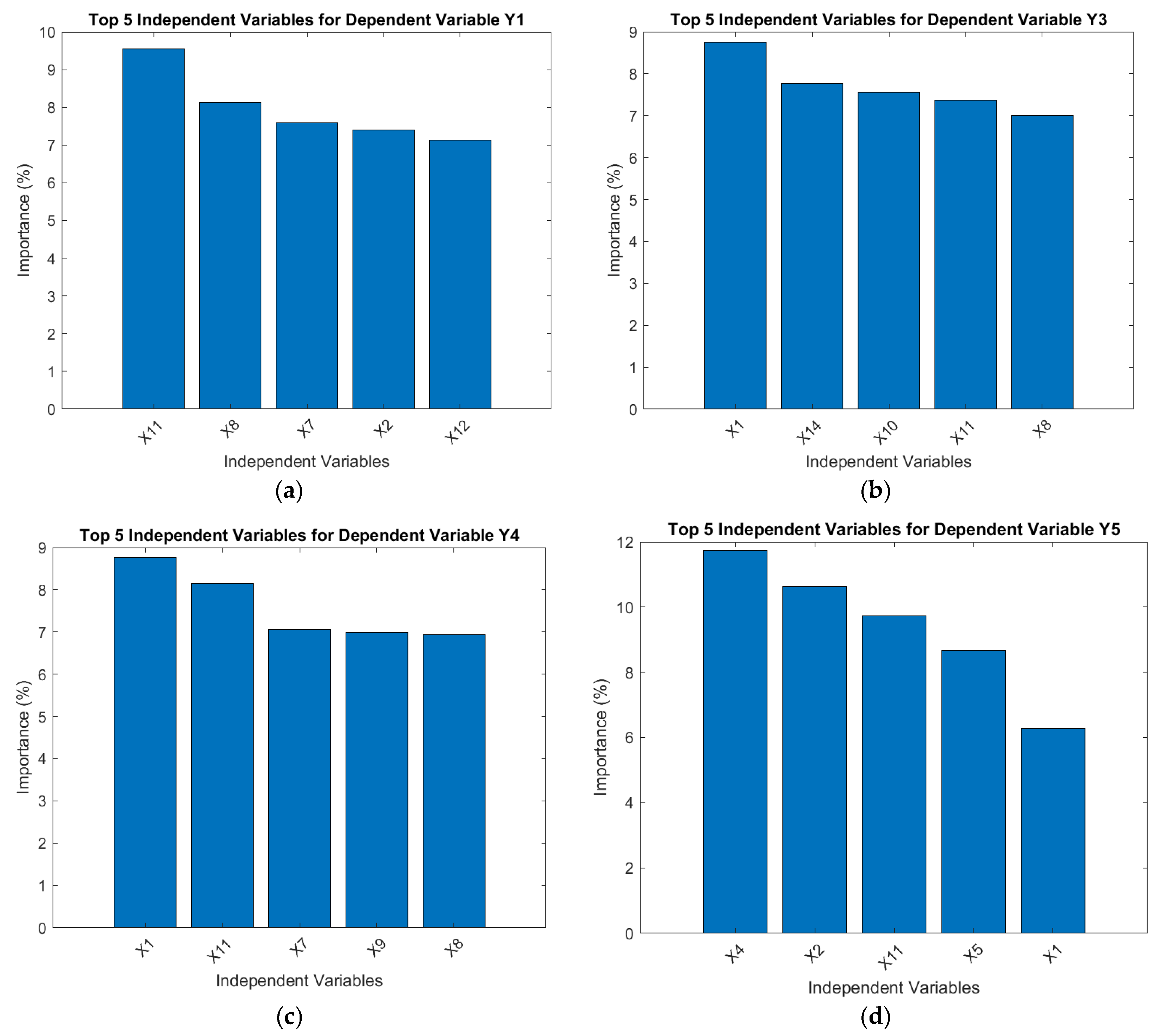

- Extract embedded and latent features using established Machine and Deep Learning algorithms (Deep Neural Network and Random Forest). This will identify the key variables within the e-waste supply chain network from a much wider set of potential contributors. The eventual minimalist model will use these key variables only.

- Generate and analyze four alternative scenarios beyond the base case (original dataset). This will allow us to design and predict parametric spaces within which the system will converge to a resilient SCN (point 1 above).

2. Methodology

2.1. Baseline Model

- Introduction of stochasticity via Monte Carlo simulations in quasi-static variables.

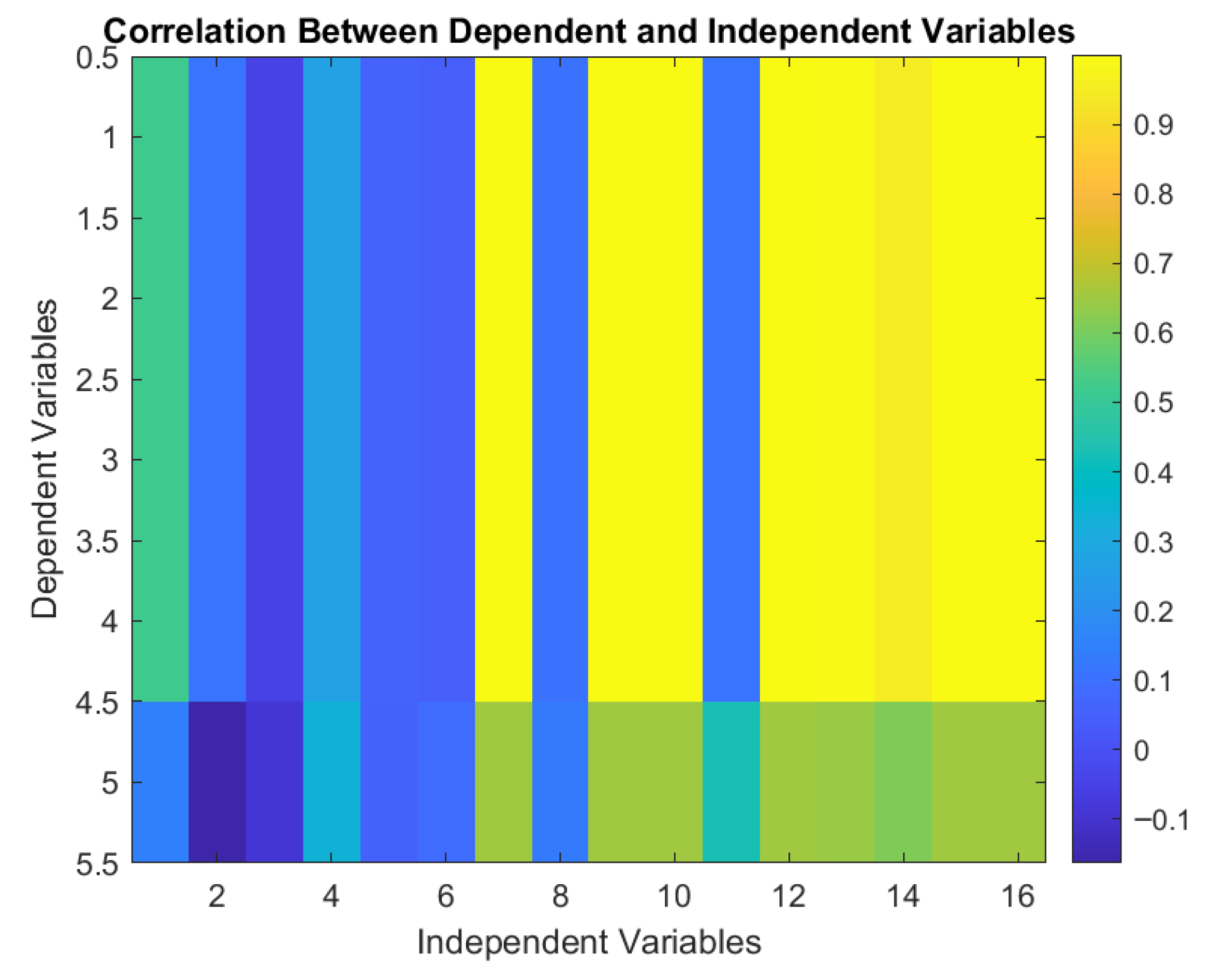

- Application of Machine Learning (ML) to assess the sensitivity and relevance of individual features.

- Exploring multiple simulation scenarios to test the robustness of the originally observed equilibria.

2.2. Dataset Management

2.3. Data Preprocessing

- VCO2 = Volume of CO2 generated

- EC = Energy Consumption in the processes involved

- Wp = Water used due to the processes involved

- Ww = Wastewater generated in the process

- N1 = Number of laborers

- N3 = Number of awareness activities, e.g., adaptation to information, invisible e-waste, repair substituting new

- N4 = Number of recycled products sold

- N5 = Number of operations involved

- N7 = Number of Logistics involved

- N8 = Number of waste materials sent for Treatment, Storage and Disposal Facility (TSDF)

- N9 = Number of Taxes to be paid

- F1 = Unit cost for CO2 recovery

- F2 = Unit cost of energy used

- F3 = Unit cost for water used

- F4 = Unit cost of wastewater treatment

- F5 = Salary of one labor

- F6 = Average cost of awareness activity

- F7 = Unit revenue earned from product sold

- F8 = Unit cost of each operation

- F10 = Unit cost of logistics

- F11 = Unit cost for disposal in TSDF

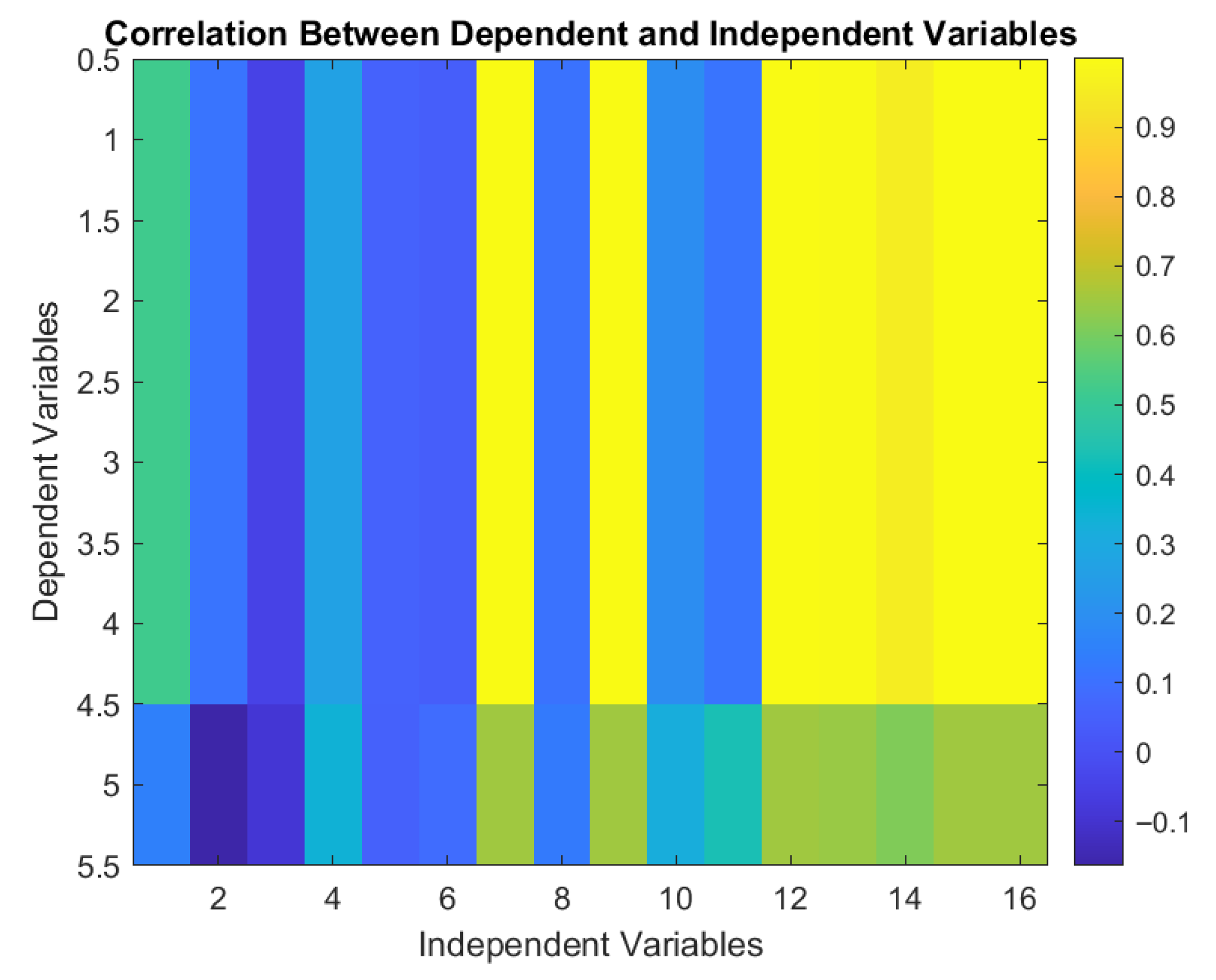

2.4. Variable Behavior Analysis

2.5. Monte Carlo Simulation (MCS)

Monte Carlo for E-Waste SCN

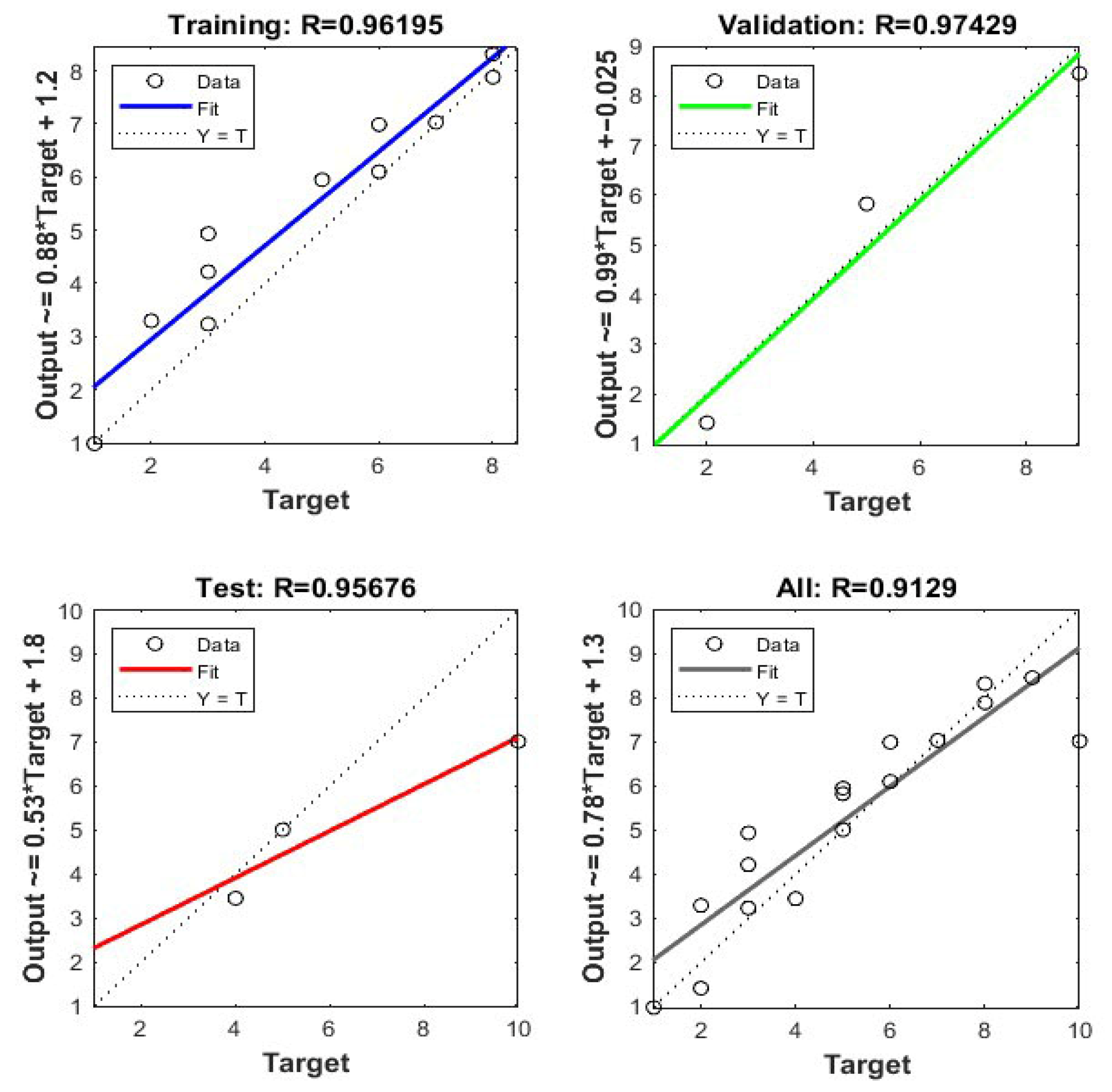

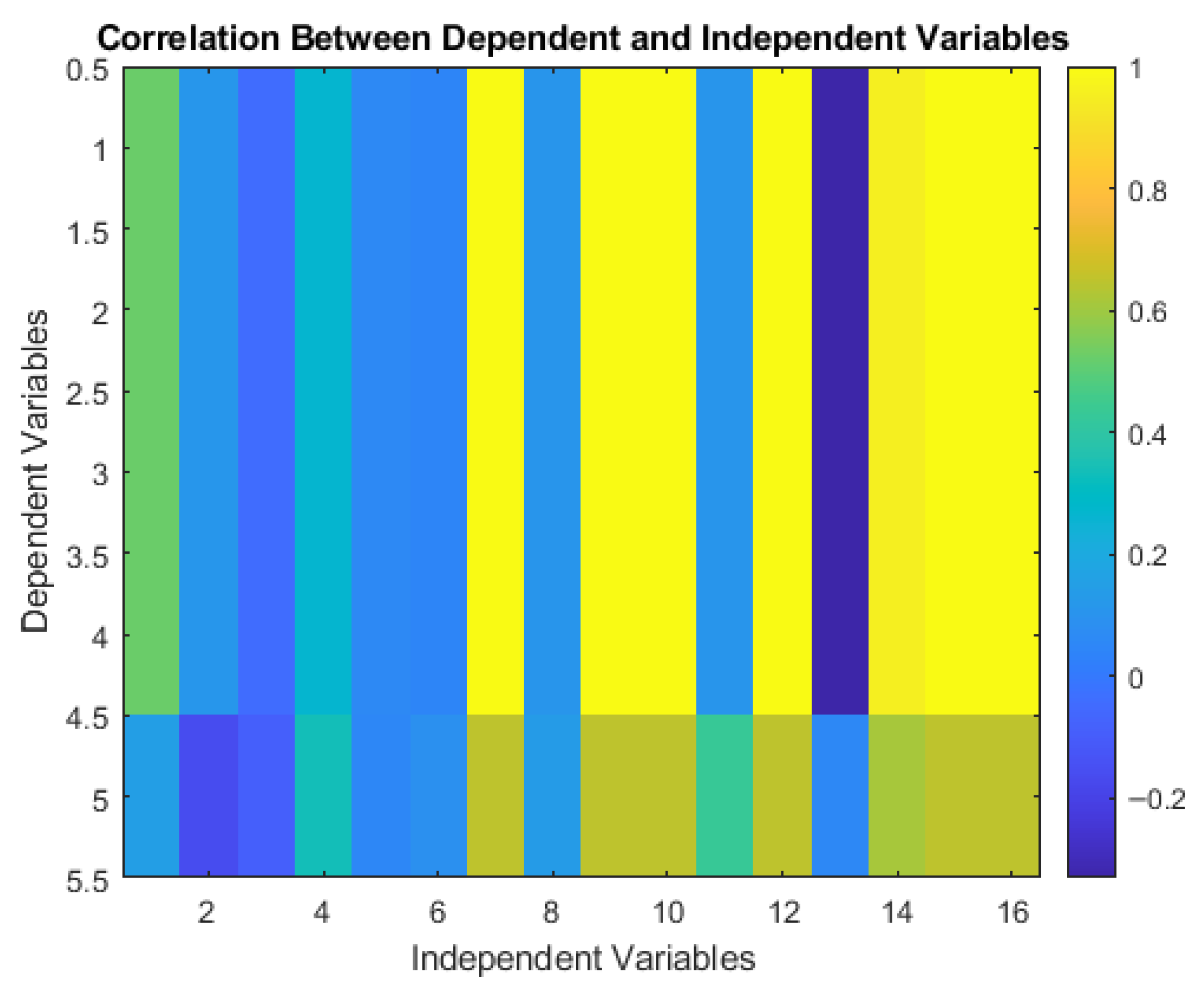

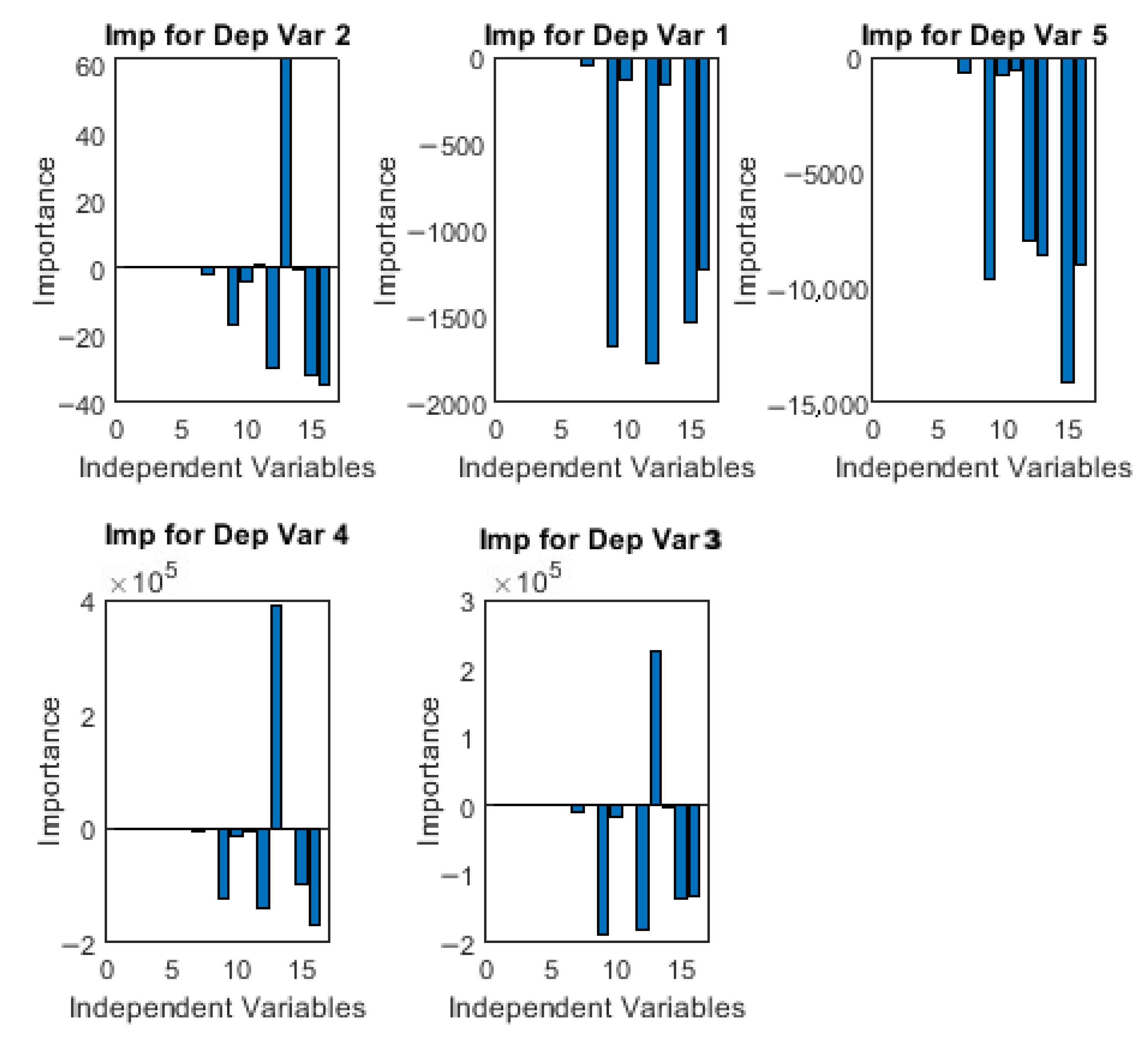

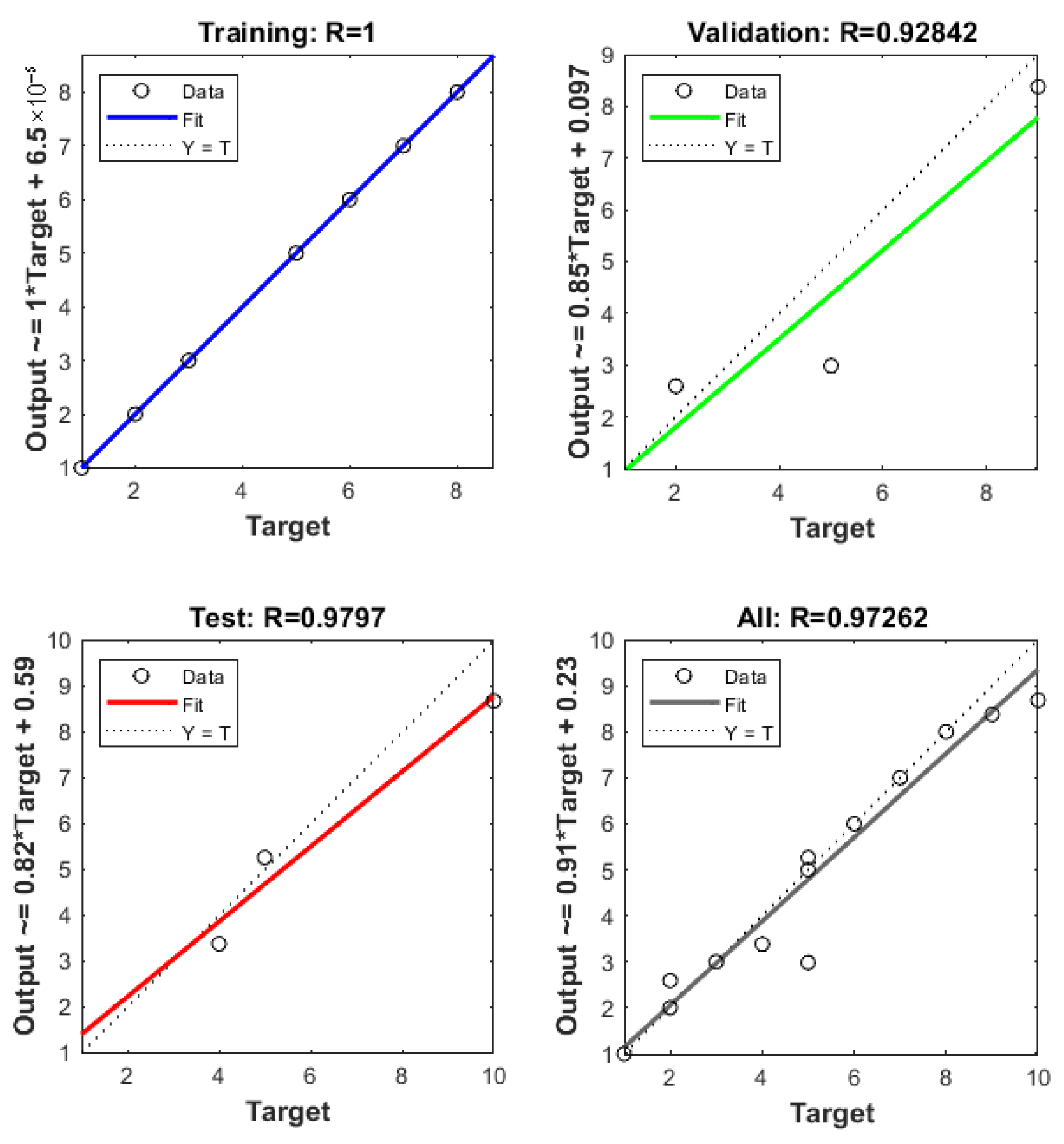

2.6. Machine Learning Framework

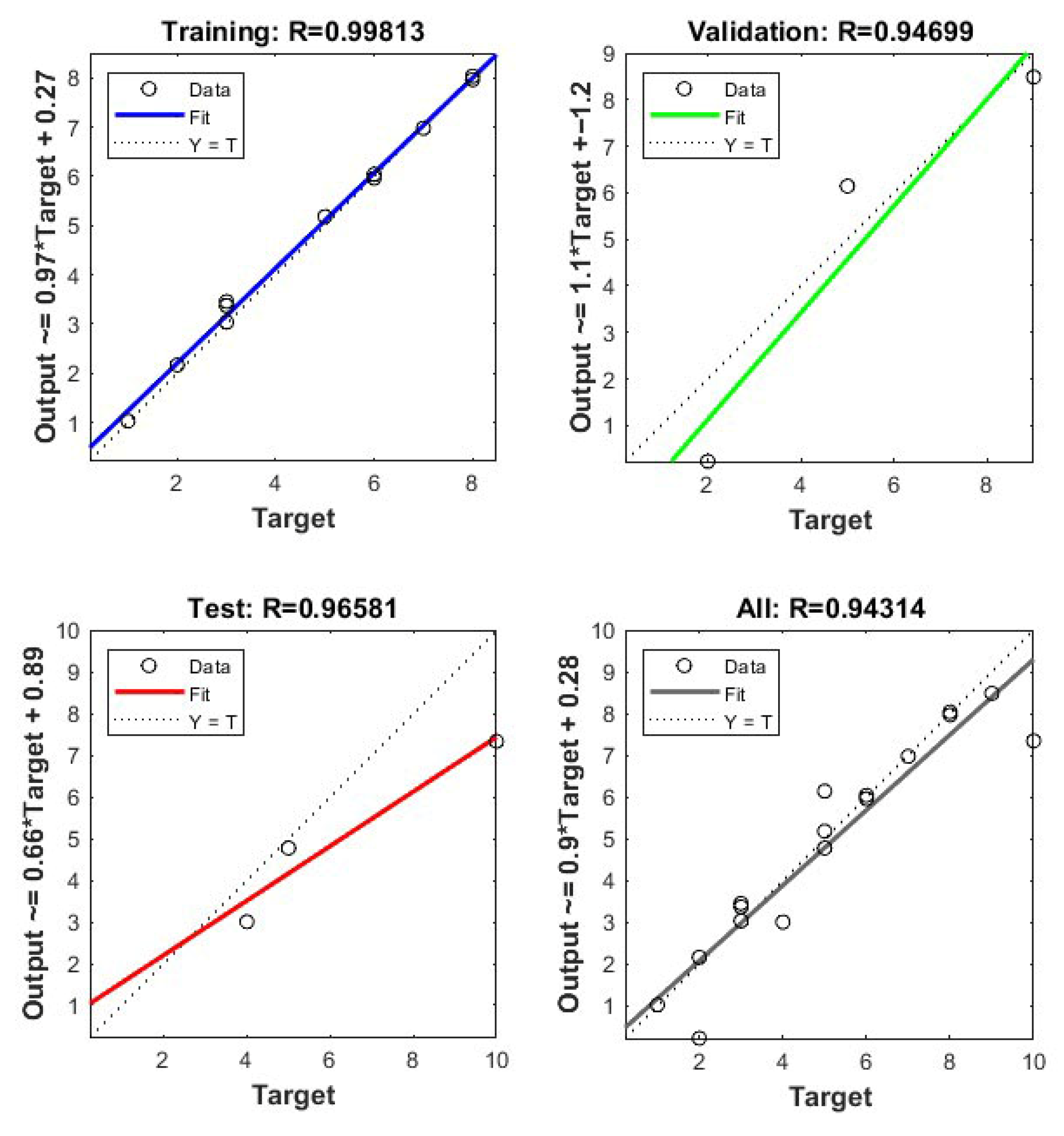

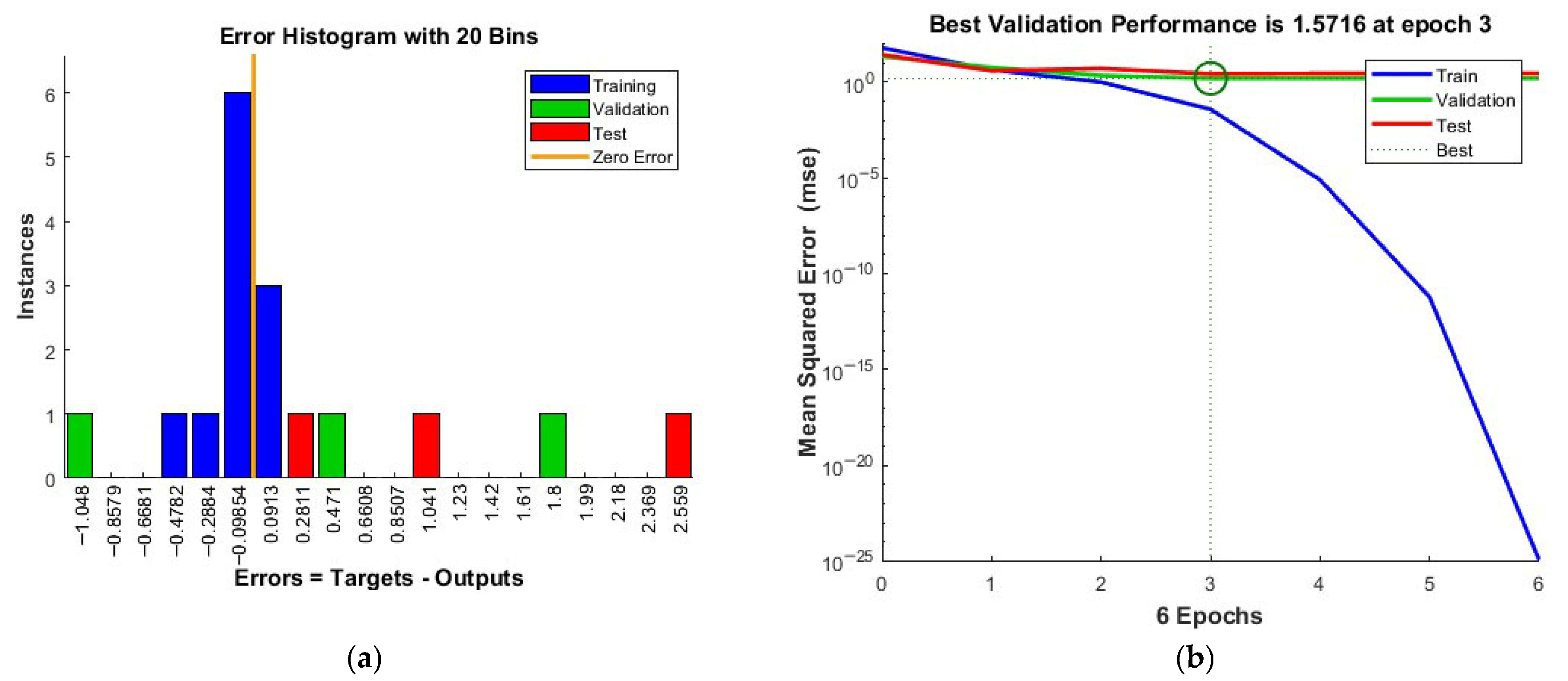

- Feedforward Neural Network (FNN)

- b.

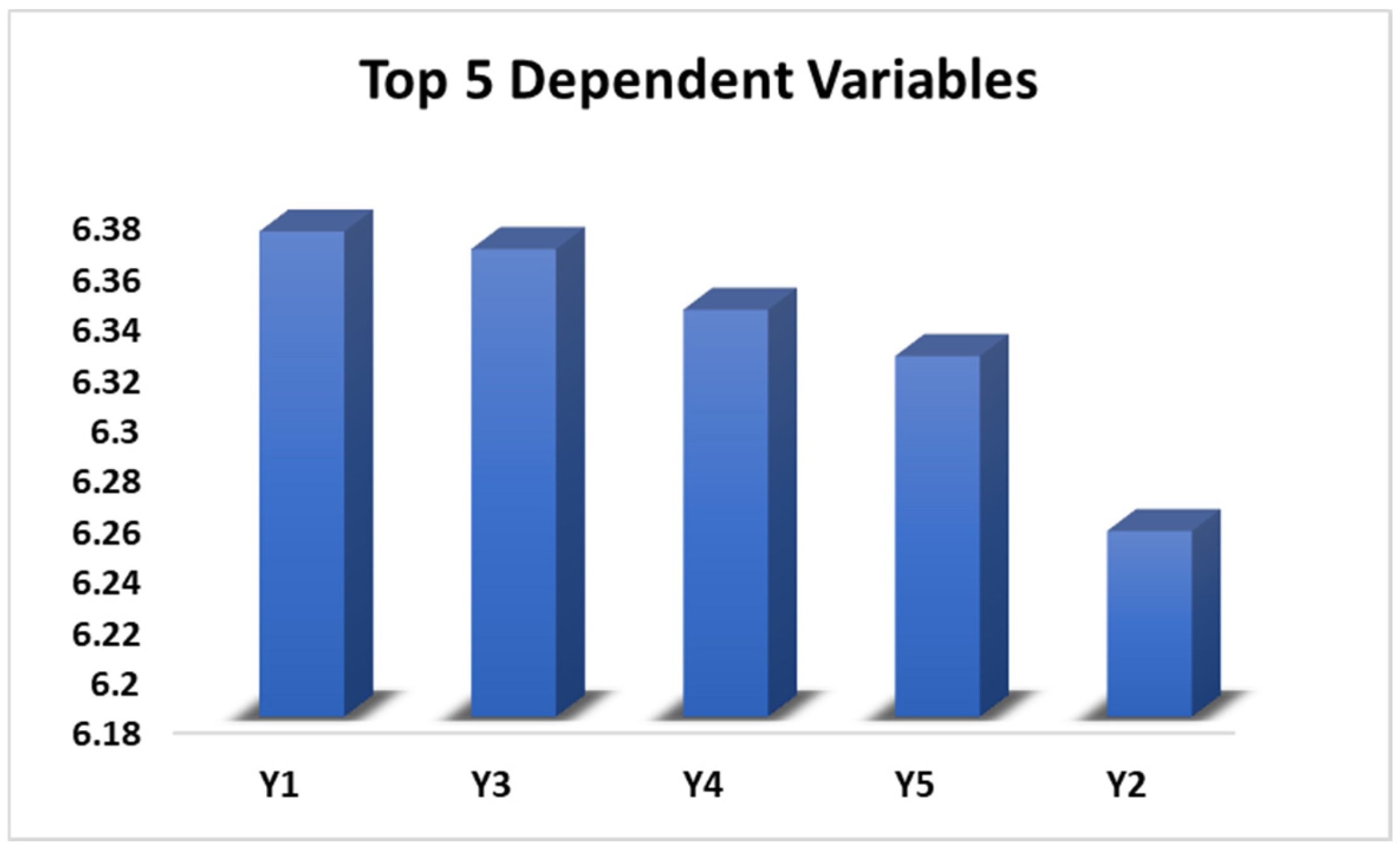

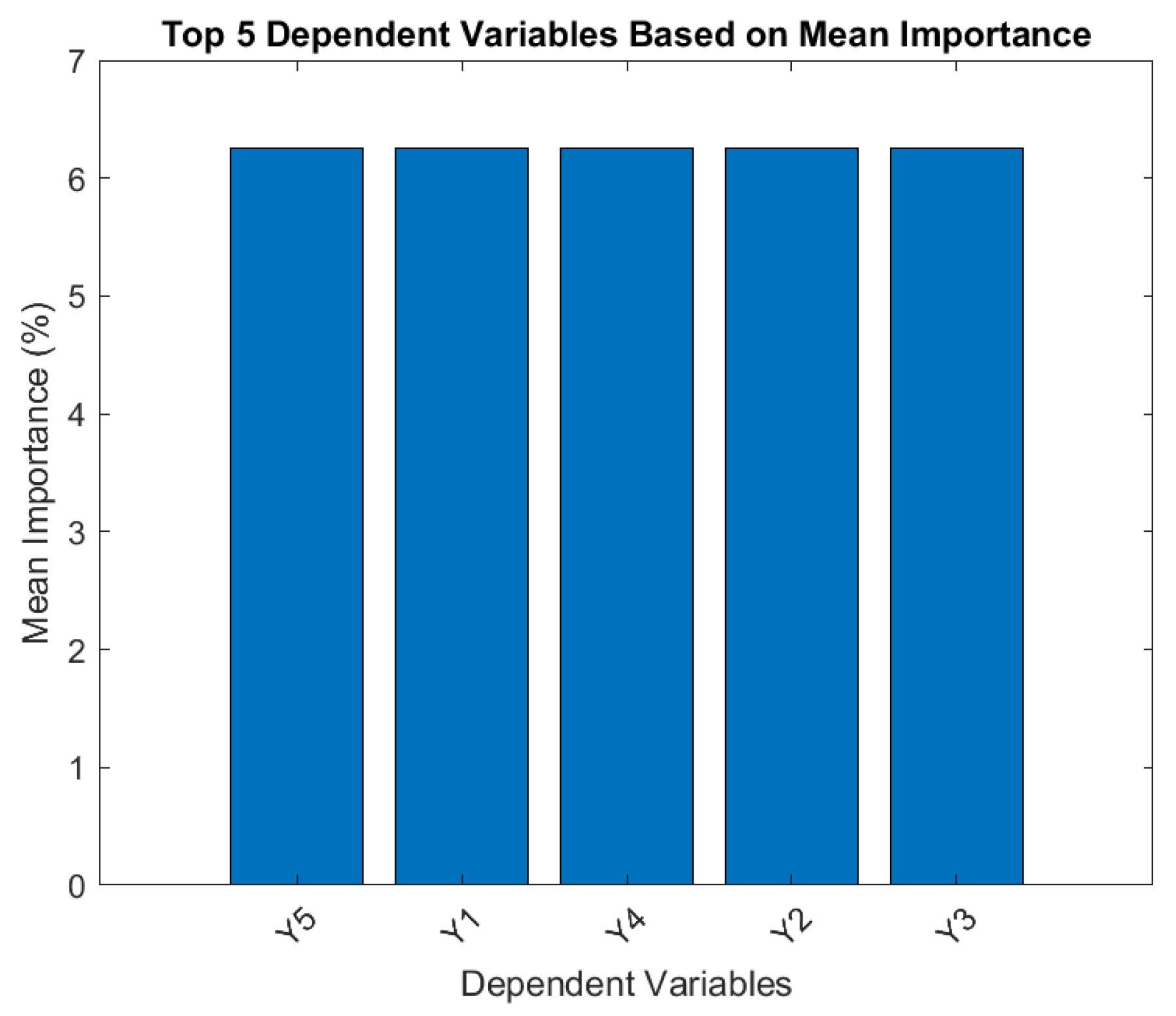

- Random Forest Network (RFN)

3. Results and Discussions

3.1. Case 1: Benchmark Dataset

3.2. Case 2: Perturbation in F4

3.3. Case 3: Perturbation in F7

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kavil, Y.N.; Alshemmari, H.; Alkasbi, M.M.; Alelyani, S.S.; Orif, M.I.; Al-Farawati, R.K. Electronic waste and environmental diplomacy: How GCC E-waste management interfaces with the Stockholm Convention. J. Hazard. Mater. Adv. 2025, 17, 100610. [Google Scholar] [CrossRef]

- Campana, P.; Censi, R.; Ruggieri, R.; Amendola, C. Smart Grids and Sustainability: The Impact of Digital Technologies on the Energy Transition. Energies 2025, 18, 2149. [Google Scholar] [CrossRef]

- Choi, W.H.; Pae, K.P.; Kim, N.S.; Kang, H.Y.; Hwang, Y.W. Feasibility study of closed-loop recycling for plastic generated from waste electrical and electronic equipment (WEEE) in South Korea. Energies 2023, 16, 6358. [Google Scholar] [CrossRef]

- Bhatnagar, B.; Dixit, V. Resilient supply chains: Advancing technology integration with pre-and post-disruption technology roadmap. J. Enterp. Inf. Manag. 2025. [Google Scholar] [CrossRef]

- Debnath, B.; El-Hassani, R.; Chattopadhyay, A.K.; Kumar, T.K.; Ghosh, S.K.; Baidya, R. Time evolution of a supply chain network: Kinetic Modeling. Phys. A Stat. Mech. Appl. 2022, 607, 128085. [Google Scholar] [CrossRef]

- Goldstein, H.; Poole, C.P.; Safko, J. Classical Mechanics; Pearson Education: London, UK, 2011; ISBN 978-813175891. [Google Scholar]

- Mohamed-Iliasse, M.; Loubna, B.; Abdelaziz, B. Machine learning in supply chain management: A systematic literature review. Int. J. Supply Oper. Manag. 2022, 9, 398–416. [Google Scholar]

- Pasupuleti, V.; Thuraka, B.; Kodete, C.S.; Malisetty, S. Enhancing supply chain agility and sustainability through machine learning: Optimization techniques for logistics and inventory management. Logistics 2024, 8, 73. [Google Scholar] [CrossRef]

- Zhu, J.; Wu, Y.; Liu, Z.; Costa, C. Sustainable optimization in supply chain management using machine learning. Int. J. Manag. Sci. Res. 2025, 8, 1–8. [Google Scholar] [CrossRef]

- Lin, S.W.; Lu, W.M. Using inverse DEA and machine learning algorithms to evaluate and predict suppliers’ performance in the apple supply chain. Int. J. Prod. Econ. 2024, 271, 109203. [Google Scholar] [CrossRef]

- Yan, H.; Wang, Z.; Bo, S.; Zhao, Y.; Zhang, Y.; Lyu, R. Research on image generation optimization based deep learning. In Proceedings of the International Conference on Machine Learning, Pattern Recognition and Automation Engineering, Singapore, 7–9 August 2024; pp. 194–198. [Google Scholar]

- Zhao, Q.; Hao, Y.; Li, X. Stock price prediction based on hybrid CNN-LSTM model. Appl. Comput. Eng. 2024, 104, 110–115. [Google Scholar] [CrossRef]

- Wang, T.; Cai, X.; Xu, Q. Energy market price forecasting and financial technology risk management based on generative AI. Appl. Comput. Eng. 2024, 116, 29–34. [Google Scholar] [CrossRef]

- Fatorachian, H.; Kazemi, H.; Pawar, K. Digital technologies in food supply chain waste management: A case study on sustainable practices in smart cities. Sustainability 2025, 17, 1996. [Google Scholar] [CrossRef]

- Farshadfar, Z.; Mucha, T.; Tanskanen, K. Leveraging Machine Learning for Advancing Circular Supply Chains: A Systematic Literature Review. Logistics 2024, 8, 108. [Google Scholar] [CrossRef]

- Debnath, B.; Chattopadhyay, A.K.; Kumar, T.K. An economic optimization model of an e-Waste supply chain network: Machine learned kinetic modelling for sustainable production. Sustainability 2024, 16, 6491. [Google Scholar] [CrossRef]

- Leong, W.Y.; Wong, K.Y.; Anjomshoae, A. A systematic literature review of aggregate production planning (APP): Social and economic perspectives. J. Ind. Eng. Manag. 2025, 18, 48–71. [Google Scholar] [CrossRef]

- Srivastava, S.K.; Shrivastava, R. Modeling for Copper Recovery from E-Waste by Using Machine Learning Technique: An Approach for the Circular Economy. Curr. Anal. Chem. 2025. [Google Scholar] [CrossRef]

- Johnson, M.; Khatoon, A.; Fitzpatrick, C. Application of AI and Machine Vision to improve battery detection and recovery in E-Waste Management. In Proceedings of the 2022 International Conference on Electrical, Computer, Communications and Mechatronics Engineering (ICECCME), Maldives, Maldives, 16–18 November 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–6. [Google Scholar]

- Gao, J.; Adjei-Arthur, B.; Sifah, E.B.; Xia, H.; Xia, Q. Supply chain equilibrium on a game theory-incentivized blockchain network. J. Ind. Inf. Integr. 2022, 26, 100288. [Google Scholar] [CrossRef]

- de Carvalho Freitas, E.S.; Xavier, L.H. System dynamics applied to the e-waste value chain: A brazilian case study. Ecol. Model. 2025, 506, 111139. [Google Scholar] [CrossRef]

- Mun, J. Case Studies in Certified Quantitative Risk Management (CQRM): Applying Monte Carlo Risk Simulation, Strategic Real Options, Stochastic Forecasting, Portfolio Optimization, Data Analytics, Business Intelligence, and Decision Modeling; IIPER: Dublin, CA, USA, 2016; ISBN 978-1734497328. [Google Scholar]

- Bruni Prenestino, F.; Barbierato, E.; Gatti, A. Robust Synthetic Data Generation for Sequential Financial Models Using Hybrid Variational Autoencoder–Markov Chain Monte Carlo Architectures. Future Internet 2025, 17, 95. [Google Scholar] [CrossRef]

- Singh, A.; Goel, A.; Chauhan, A.; Singh, S.K. Sustainability of Electronic Product Manufacturing through E-Waste Management and Reverse Logistics. Sustain. Futures 2025, 9, 100490. [Google Scholar] [CrossRef]

- Klabunde, M.; Schumacher, T.; Strohmaier, M.; Lemmerich, F. Similarity of neural network models: A survey of functional and representational measures. ACM Comput. Surv. 2025, 57, 242. [Google Scholar] [CrossRef]

- Imani, M.; Beikmohammadi, A.; Arabnia, H.R. Comprehensive analysis of random Forest and XGBoost performance with SMOTE, ADASYN, and GNUS under varying imbalance levels. Technologies 2025, 13, 88. [Google Scholar] [CrossRef]

- Nweje, U.; Taiwo, M. Leveraging Artificial Intelligence for predictive supply chain management, focus on how AI-driven tools are revolutionizing demand forecasting and inventory optimization. Int. J. Sci. Res. Arch. 2025, 14, 230–250. [Google Scholar] [CrossRef]

- Debnath, B.; Chattopadhyay, A.K.; Kumar, T.K. Cleaner Production in Multivariate Supply Chain Networks: Sustainable Business Future Through a “Roll of Dice”. In Circular Economy and Sustainable Development: A Necessary Nexus for a Sustainable Future; Springer International Publishing: Cham, Switzerland, 2024; pp. 655–674. [Google Scholar]

- Bach, A. Boltzmann’s probability distribution of 1877. Arch. Hist. Exact Sci. 1990, 41, 1–40. [Google Scholar] [CrossRef]

- Hayati, M.; Ganji, S.M.S.A.; Shahcheraghi, S.H.; Khabir, R.R. Optimization of copper recovery from electronic waste using response surface methodology and Monte Carlo simulation under uncertainty. J. Mater. Cycles Waste Manag. 2023, 25, 211–220. [Google Scholar] [CrossRef]

- Metropolis, N.; Rosenbluth, A.W.; Rosenbluth, M.N.; Teller, A.H.; Teller, E. Equation of state calculations by fast computing machines. J. Chem. Phys. 1953, 21, 1087–1092. [Google Scholar] [CrossRef]

- Frain, J.C. An Introduction to Matlab for Econometrics; TEP Working Paper, No. 0110; Department of Economics, Trinity College: Dublin, Ireland, 2010. [Google Scholar]

- Aggarwal, C.C. Neural Networks and Deep Learning: A Textbook; Springer: Berlin/Heidelberg, Germany, 2018; ISBN 78-3319944630. [Google Scholar]

- Wang, J.; Swartz, C.L.; Huang, K. Deep learning-based model predictive control for real-time supply chain optimization. J. Process Control 2023, 129, 103049. [Google Scholar] [CrossRef]

- Jin, S.; Sun, X. Deep Neural Network Fusion Model for Accurate Logistics Demand Prediction of Agricultural Products. J. Circuits Syst. Comput. 2025. [Google Scholar] [CrossRef]

- Nikabadi, M.S.; Hajihoseinali, A. E-Waste recycling system in closed loop supply chain. Int. J. Sys. Dyn. Appl. 2018, 7, 26. [Google Scholar] [CrossRef]

- Fuji, T.; Ito, K.; Matsumoto, K.; Yano, K. Deep multi-agent reinforcement learning using dnn-weight evolution to optimize supply chain performance. In Proceedings of the 51st Hawaii International Conference on System Sciences, Hilton Waikoloa Village, HI, USA, 3–6 January 2018. [Google Scholar]

- Vairagade, N.; Logofatu, D.; Leon, F.; Muharemi, F. Demand forecasting using random forest and artificial neural network for supply chain management. In Computational Collective Intelligence, Proceeding of the 11th International Conference, ICCCI 2019, Hendaye, France, 4–6 September 2019; Proceedings Part I 11; Springer: Cham, Switzerland, 2019; pp. 328–339. [Google Scholar]

- Breiman, L. Random Forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Farazi, M.Z.R. Building Agile Supply Chains with Supply Chain 4.0: A Data-Driven Approach to Risk Management. Am. J. Eng. Technol. 2025, 7, 21–34. [Google Scholar] [CrossRef]

- Sharma, M.; Shah, J.K.; Joshi, S. Modeling enablers of supply chain decarbonisation to achieve zero carbon emissions: An environment, social and governance (ESG) perspective. Environ. Sci. Pollut. Res. 2023, 30, 76718–76734. [Google Scholar] [CrossRef]

- Debnath, B.; Chowdhury, R.; Ghosh, S.K. Sustainability of metal recovery from E-waste. Front. Environ. Sci. Eng. 2018, 12, 1–12. [Google Scholar] [CrossRef]

- Ma, Y.; McLaughlan, M.; Zhang, N.; Li, J. Novel feasible path optimisation algorithms using steady-state and/or pseudo-transient simulations. Comput. Chem. Eng. 2020, 143, 107058. [Google Scholar] [CrossRef]

- Rawlings, J.B.; Ekerdt, J.G. Chemical Reactor Analysis and Design Fundamentals, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2009; p. 18. [Google Scholar]

- Fogler, H.S. Elements of Chemical Reaction Engineering, 5th ed.; Prentice Hall: Hoboken, NJ, USA, 2016; p. 574. ISBN 978-0-13-388751-8. [Google Scholar]

| Dependent Variables | ||

|---|---|---|

| Variable | Mean | Standard Deviation |

| VCO2 | 1.575 | 0.238 |

| Ec | 0.0095 | 0.0053 |

| Ww | 82.5 | 9.014 |

| Wp | 77.5 | 9.014 |

| N3 | 4.5 | 2.739 |

| Independent Variables | ||

| N1 | 29.33 | 11.832 |

| N4 | 4.333 | 2.146 |

| N5 | 6.0 | 0.816 |

| N7 | 2.667 | 1.155 |

| N8 | 2.667 | 1.155 |

| N9 | 2.0 | 0.816 |

| F1 | 14,250 | 2752.6 |

| F2 | 34.167 | 9.072 |

| F3 | 1,575,000 | 45,984 |

| F4 | 609,796 | 4249 |

| F5 | 108,778 | 2540 |

| F6 | 171,667 | 45,038 |

| F7 | 4,500,000 | 250,551 |

| F8 | 4600 | 545.9 |

| F10 | 269,474 | 62,339 |

| F11 | 174,000 | 38,720 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ng, Z.W.; Debnath, B.; Chattopadhyay, A.K. Machine Learning-Aided Supply Chain Analysis of Waste Management Systems: System Optimization for Sustainable Production. Sustainability 2025, 17, 8848. https://doi.org/10.3390/su17198848

Ng ZW, Debnath B, Chattopadhyay AK. Machine Learning-Aided Supply Chain Analysis of Waste Management Systems: System Optimization for Sustainable Production. Sustainability. 2025; 17(19):8848. https://doi.org/10.3390/su17198848

Chicago/Turabian StyleNg, Zhe Wee, Biswajit Debnath, and Amit K Chattopadhyay. 2025. "Machine Learning-Aided Supply Chain Analysis of Waste Management Systems: System Optimization for Sustainable Production" Sustainability 17, no. 19: 8848. https://doi.org/10.3390/su17198848

APA StyleNg, Z. W., Debnath, B., & Chattopadhyay, A. K. (2025). Machine Learning-Aided Supply Chain Analysis of Waste Management Systems: System Optimization for Sustainable Production. Sustainability, 17(19), 8848. https://doi.org/10.3390/su17198848