1. Introduction

Digital transformation (DT) in business is associated with the adoption of new information technologies, that significantly reshape and enhance business processes. Verhoef et al. [

1] highlight that digitally driven companies have outpaced numerous traditional firms within their industry. Despite the clear and substantial impact of DT on companies, academic attention to these advancements and technologies has been relatively limited and has only begun to grow in recent years [

2].

At the same time, the literature shows a growing interest on sustainability issues [

3]. This shift is driven by the increased attention of international organizations, such as the United Nations and the European Union, on environmental concerns, but also on the well-being of the society as a whole. In this context, companies strive to develop supply chains that are not only environmentally sustainable, but also socially and economically sustainable. As a result, the integration of information technologies, when aligned with sustainable development, benefits all members of a digital supply chain [

4].

To further explore these issues, this study examines how the combination of digital transformation, organizational context, and sustainable development contributes to the formulation of sustainable strategies in third-party logistics (3PL) companies. Specifically, the study investigates whether digitalization can develop internal capabilities that, in turn, enhance business performance and sustainable outcomes. This study extends the research of [

5] by adopting and enhancing their proposed theoretical framework, which forms the basis for the quantitative analysis. Additionally, it addresses specific research gaps, deriving from the analysis of the literature.

Notably, there is little research demonstrating how the digitization of companies contributes to sustainability in supply chains and increases business performance [

6]. For instance, Demir et al. [

7] proposed a model to assess the readiness and maturity of smart and sustainable supply chains, emphasizing the structural preparation of organizations for technology adoption. Similarly, Gunduz et al. [

8] developed a hybrid BWM-QFD model that matches SCM functions with smart and sustainable tools. Singh et al. [

9] demonstrated that digital transformation enhances sustainable performance through resource integration, highlighting the mediating role of internal capabilities. However, their study is conceptual and does not examine how these dynamics unfold within logistics contexts such as 3PL. While all those studies advance the understanding of digital and sustainable alignment, they remain focused on assessment frameworks rather than providing empirical evidence of performance or strategic outcomes. In contrast, this study examines the measurable impact of DT and sustainability on business capabilities and performance in a real-world context—thus providing a practical contribution to both scholarship and practice.

Furthermore, most research examining IT-supported sustainable development within supply chain companies, primarily focuses on the economic and environmental pillar, rather than on the social one [

10]. For instance, Birkel and Müller [

10] conducted a systematic review of Industry 4.0 and found a minimal focus on social issues such as labor equity, workforce well-being, or stakeholder inclusion. Similarly, Schulz and Flanigan [

11] noted that many firms pursue sustainability for competitive advantage, while neglecting their social responsibilities. Additionally, Mohaghegh et al. [

12], in their comprehensive review of digitalized supply chains, emphasized the need for empirical studies that integrate all three dimensions of sustainability. They noted that most existing studies are fragmented, focusing either on economic outcomes or environmental performance, with limited consideration of social factors. This oversight is critical, particularly for 3PL companies, which operate at multiple levels of the supply chain and directly influence working conditions and community outcomes. This study addresses these issues by explicitly including social sustainability indicators in the conceptual framework and evaluating their interaction with digital and organizational factors.

The main research question that this study addresses is: how do digital transformation, organizational context and sustainability orientation interacts within 3PL companies? While many studies have explored these elements independently, this research seeks to empirically examine their interrelationships within a unified framework. This central inquiry fills a notable gap in the literature by integrating all three sustainability pillars within the digital transformation discourse in the logistics sector.

This study makes several original contributions to the literature. First, it examines the above concepts and how they interact. Second, the study pays attention on third-party logistics (3PL) companies, an underrepresented sector in sustainability and DT research. Third, the validation of a comprehensive conceptual framework that links IT resources, human capital, supply chain processes, and sustainability orientation to capabilities and strategy outcomes is going to offer a novel empirical perspective that extends previous conceptual models [

5]. Last but not least, the specific inclusion of the social pillar of sustainability marks a critical addition to the discourse.

In conclusion, there is a lack of empirical studies that simultaneously investigate how digital transformation, organizational context, and sustainable practices (across all three sustainability pillars) influence business capabilities and strategic development—especially within 3PL companies. The objective of this research is to address the above research gap by conducting a quantitative analysis, with the use of questionnaires, on 3PL companies, which operate in Greece. This survey is timely as global supply chains deal with complexity, technological disruption and regulatory pressures to become more transparent and sustainable. The findings of this study validate the developed conceptual framework and research hypotheses, and highlight that adopting new technologies along with sustainable practices can help companies improve their performance, while also benefiting society and the environment.

3. Theoretical Framework and Hypotheses Development

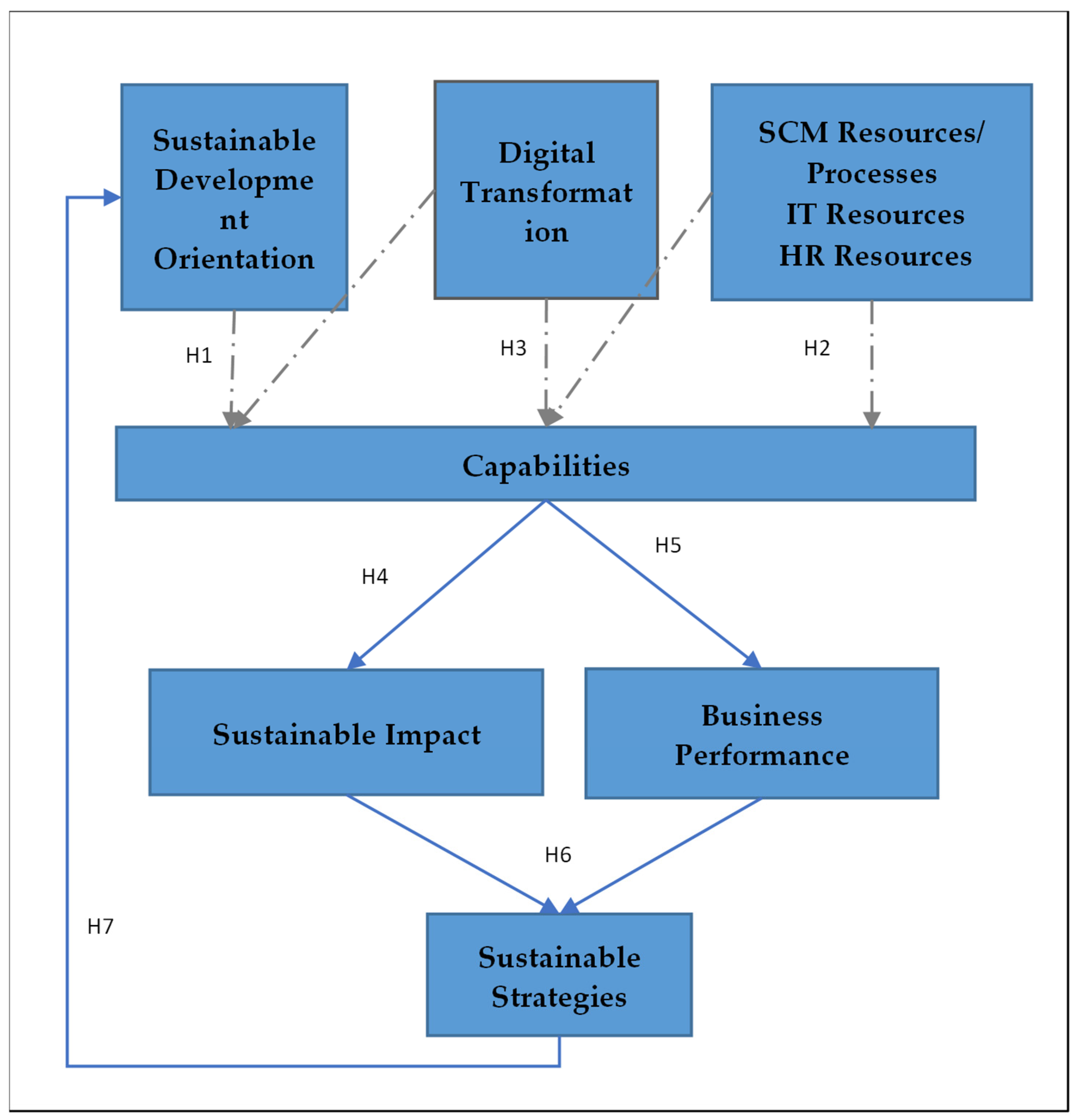

Based on the literature review presented in

Section 2, the following hypotheses were developed to examine the relationships between DT, sustainability orientation, organizational resources, capabilities, performance, and strategies. The hypotheses are grounded in established theoretical perspectives and prior empirical findings, but tested here within the 3PL context to validate their relevance and interconnections.

The integration of cutting-edge technologies such as Internet of Things (IoT), Blockchain and Artificial Intelligence emerges as a key mechanism [

60], which leads to increased growth opportunities for businesses, while allowing for a positive impact on the economy, environment and society. SSCM uses all available resources (such as IT systems, skilled human resources, logistics infrastructure, financial capital, and collaborative supplier relationships) within the supply chain with environmental awareness [

61]. The integration of digital technologies and sustainability policies promotes the seamless and continuous flow of information throughout the supply chain, enabling real-time data exchange and enhancing knowledge transfer. This, in turn, enables companies to make informed decisions instantly [

62]. Therefore, the company’s focus on Digital Transformation along with its orientation towards Sustainable Development has a measurable impact on business capability development.

H1. The company’s focus on Digital Transformation and the orientation towards Sustainable Development positively influence the development of Capabilities.

The combination of information technology in supply chains with supply chain processes and the human factor, that is the combination of IT, skilled HR and SCM resources can provide companies with unique capabilities, such as sustainability capabilities and competitive advantage [

47]. This combination forms a dynamic framework that fosters a culture of innovation and responsiveness [

63]. Companies that successfully integrate these elements are able to adapt quickly to market changes, provide superior products and services, and deal with complexities with agility [

64].

H2. The integration of Information Technology together with SCM processes and Human Factor skills positively influence the development of Capabilities.

The following hypothesis asserts that supply chain processes and resources combined with the company’s Digital Transformation orientation will also lead to the development of capabilities within the company. The integration of new digital technologies helps to improve visibility across the supply chain network thus further increasing the company’s capabilities, enabling continuous adaptation and increased customer satisfaction [

65].

H3. The combination of Supply Chain Processes and a focus on Digital Transformation positively influence the development of Capabilities.

The capabilities that have arisen from the supply chain environment play a key role in enhancing the outcomes resulting from the adoption of sustainable practices. The integration of advanced technologies facilitates more informed decision-making aligned with environmental responsibility [

66]. Environmental impact is a critical aspect of the supply chain, and its development can lead the company to sustainability outcomes in a number of ways.

Reducing the carbon footprint [

67].

Stakeholder relations [

68].

Long-term cost savings [

69].

In this context, supply chain capabilities such as real-time visibility, data analytics and collaboration platforms have proven to be crucial to achieving sustainable impact. Data analytics tools allow companies to analyze vast amounts of data to identify opportunities to reduce waste, improve energy efficiency and sustainable procurement practices [

70].

By leveraging these capabilities, companies can optimize their supply chain processes, reduce resource consumption, minimize environmental risks, and ultimately achieve better results from adopting sustainable practices [

71]. Moreover, these capabilities enable companies to demonstrate transparency and accountability in their sustainability efforts, enhancing their brand reputation and value among consumers, investors and other stakeholders [

72]. Therefore, the capabilities developed by the combination of sustainable practices, Digital Transformation and SCM resources have an impact on all pillars of business sustainability [

5].

H4. The capabilities developed positively affect the company’s Sustainable Impact.

Based on the survey [

73], the supply chain capabilities and information technology capabilities are capable to directly and indirectly affect business performance. In the context of supply chain management, business performance refers to the effectiveness and efficiency of a company’s supply chain operations. It involves assessing how well the company is able to manage and optimize its processes.

The business performance of a supply chain is particularly important as it directly affects the overall success of the firm. Factors such as, enhanced reputation and image [

74], strategic supplier relationships [

75], improved efficiency [

76], optimized inventory management [

74], data-driven decision-making [

77] influence the development of performance.

H5. The capabilities arising from the use of Information Technology, lead to an increase in Business Performance.

The synergy between the resulting business performance and the achieved sustainable impact is crucial for the formulation and execution of sustainable supply chain management strategies. This holistic approach enables businesses to align environmental, social and economic considerations, promoting resilience, innovation and long-term success in the context of sustainable supply chain management. According to [

73] supply chain management sustainable strategies have become a modern element of a firm’s strategy. These strategies, as described in the research of [

78], act as drivers for continuous improvement, ensuring that sustainability remains central to the company’s future.

H6. The resulting Business Performance and the Sustainable Impact lead to the development of Sustainable Strategies.

The success of a company depends on its “SCM” practices and policies and related strategy [

79], including sustainable practices. This, in turn, necessitates companies to reevaluate and potentially adopt new strategies, harnessing emerging technologies [

80]. By implementing sustainable strategies, firms not only enhance their position in the market, but also contribute to achieving broader sustainable development goals in their industry. Redefinition of the sustainable policies requires companies to engage in continuous assessments of the environmental, social, and economic impacts of their operations, thus promoting a culture of continuous improvement [

81]. In this way, the company ensures that it remains at the forefront of sustainable practices by incorporating the latest innovations and best practices into its operations. This process not only ensures the company’s compliance with environmental regulations and challenges, but also puts it in an active position to promote innovations that will contribute to long-term and integrated sustainable goals. According to Yu et al. [

82], this process is essential to maintain a company’s competitiveness in the modern market.

H7. The Sustainable Strategies developed lead to a redefinition of the company’s sustainable policies.

The rationale for these hypotheses derives from the synthesis of literature discussed in

Section 2. Prior studies demonstrated partial links between DT, sustainability, and organizational outcomes (e.g., [

1,

47]), but failed to empirically integrate these elements into a unified framework within the context of 3PLcompanies. By drawing on these gaps, our hypotheses test how resources (IT, HR, SCM) and orientations (DT, sustainability) interact to develop capabilities, which in turn influence performance, sustainability impact, and strategy formulation. This methodological approach ensures consistency between the literature review and the empirical model.

The theoretical framework, presented below, advances prior research by explicitly integrating digital transformation, sustainable development, and organizational resources within the underexplored 3PL sector. Unlike earlier conceptual models that focused mainly on economic or environmental outcomes, this study incorporates the social dimension of sustainability and empirically validates the role of capabilities. Thus, it provides a distinctive contribution by demonstrating how these interrelated factors jointly shape sustainable strategies and business performance. The concepts analyzed in this section and the hypotheses identified are presented in

Figure 1.

According to the above conceptual framework, companies develop and use their supply chain, HR and IT resources, in order to make their processes more effective and efficient. The combination of these resources with the Digital Transformation and Sustainable Development policies can create specific business capabilities. These capabilities, resulting from the combination of resources [

83] and policies can play a pivotal role in increasing economic performance, reducing the environmental footprint of the supply chain, enhancing social value and increasing the sustainable impact. Companies are taking advantage of these new capabilities not only to increase their business performance [

84] and sustainable impact, but also to develop new sustainable strategies to improve their sustainable policies, further leverage their resources and strengthen their market position.

5. Results

The variables that emerged from the questionnaire were many and it was necessary to group them. In order to reduce the number of variables, factor analysis was carried out using the SPSS statistical software [

93]. The factor analysis resulted in the 10 variables presented in

Table 2.

To examine whether the variables follow the normal distribution, a Kolmogorov–Smirnov (KS) analysis was also performed. The KS test is arguably the best-known normality test [

94]. This test involves comparing the “Asymp. Sig” value with sig = 0.05 for a 5% significance level. If it is less than this, the hypothesis that the variable does not follow a normal distribution is accepted, otherwise it is rejected. The results from the KS test are presented below in

Table 3.

The Kolmogorov–Smirnov test results in

Table 2 indicate that most variables follow an approximately normal distribution, as their significance values are above the 0.05 threshold (e.g., SCM Processes, Focus on DT, Capabilities, Business Performance). However, some variables such as HR Skills (

p = 0.002), IT Level (

p = 0.001), and Sustainable Development Orientation (

p = 0.000) deviate from normality. This mixed outcome justifies the use of both parametric and non-parametric tests in subsequent analyses, ensuring robustness in hypothesis testing. Overall, the test confirms that the dataset is suitable for regression and correlation analyses, though results should be interpreted with caution for the variables that deviate from normality.

Correlation analysis was performed between the variables of the research hypotheses (via SPSS) in order to investigate whether these hypotheses are valid and therefore whether the theoretical framework is well structured. The Spearman correlation coefficient is a statistical measure of the strength of a monotonic relationship between paired data [

95]. In a sample, it is given by rs and its value is in the closed interval −1 < =rs < =1 [

77]. As a general rule, a value greater than 0.3 is acceptable for correlation [

96], (p. 1204).

The correlation matrix in

Table 4 shows several strong and statistically significant relationships among the key constructs. Notably, Capabilities (M05) exhibit very strong positive correlations with IT Level (M04, rs = 0.811,

p < 0.001), Focus on DT (M02, rs = 0.773,

p < 0.001), and HR Skills (M03, rs = 0.659,

p < 0.001). These results confirm the hypothesized interdependencies between organizational resources, digital transformation, and capability development. Additionally, Sustainable Strategies (M08) strongly correlate with Sustainable Impact (M10, rs = 0.693,

p < 0.001), highlighting their mutual reinforcement. Business Performance (M07) shows moderate but significant correlations with Capabilities (M05, rs = 0.387,

p < 0.05), further supporting the model. These correlations provide initial empirical validation for the proposed hypotheses and justify proceeding with regression analysis.

The current hypotheses are tested through regression analysis. These tests are valid, when the dependent variable is following the normal distribution [

97]. The significance level is commonly assigned specific values such as 0.10, 0.05, and 0.01. In practice, the 5 percent significance level, denoted as α = 0.05, has emerged as the most frequently used [

98]. As similar surveys (such as: [

99,

100]) have used the significance level of 5%, the same level of significance is also used in this research.

The Variance Inflation Factor (VIF) and Tolerance are two closely related indicators for diagnosing collinearity in multiple regression. The first index should be less than 10 and the second should be greater than 0.2 [

101].

For any two observations the residuals should be uncorrelated (or independent). This assumption can be tested by the Durbin–Watson test, which tests serial correlations between errors. The result of the test can range between 0 and 4 with a value of 2 meaning that the residuals are uncorrelated and a value below one meaning that the residuals are correlated [

101].

To test the hypotheses, the correlation of the variables is first examined, and a regression analysis is performed. All the results from the regression analyses are presented on

Appendix A.

| H1 | HA: The company’s focus on Digital Transformation (M02) and the orientation towards Sustainable Development (M06) positively influence the development of Capabilities (M05). |

According to the Spearman correlation coefficient, there is a positive correlation of variables M02 and M05 and it is equal to rs = 0.773 and it is strong, as well as variables M06 and M05 and it is equal to rs = 0.581 and it is moderate.

Therefore, using multiple regression will determine the extent to which the independent variables will influence the dependent variable (M05). The model explained a substantial proportion of variance in satisfaction (Adjusted R2 = 0.784, F = 55.445, p < 0.000). Among the predictors, FocusOnDT emerged as the strongest determinant (β = 0.717, p < 0.000), followed by SDOrientation (β = 0.279, p < 0.05). The fixed term does not exert a significant effect on the dependent variable (as sig = 0.809 > 0.05).

Therefore, the analysis continues with the “Remove” method. In the case of the “Remove” method, a variable to be removed due to significance must be determined. This method cannot be used alone, but in combination with the first ‘Enter’ method. Essentially, certain variables must be eliminated based on their smallest contribution to the overall variance.

For this purpose, a regression is performed again using the subtraction procedure. Among the predictors, FocusOnDT emerged as the strongest determinant (β = 0.875,

p < 0.000), followed by SDOrientation (β = 0.760,

p < 0.00). The fixed term has been excluded.

The independent variables are now statistically significant relative to the dependent variable for a 5% significance level, and the constant term has been removed. Therefore, H1 is accepted.

| H2 | HA: The level of Information Technology (M04) together with SCM Processes (M01) and Human Factor skills (M03) positively influence the development of Capabilities (M05). |

According to Spearman correlation coefficient, there is a strong positive correlation (equal to rs = 0.659) between variables M05 and M04, as well as a very strong positive correlation (equal to rs = 0.811) with variable M03 and a strong positive correlation (rs = 0.665) with variable M01.

Therefore, the use of multiple regression can determine the function of the above relationship. The model explained a substantial proportion of variance in satisfaction (Adjusted R

2 = 0.769, F = 43.162,

p < 0.000). Among the predictors, ITLevel emerged as the strongest determinant (β = 0.748,

p < 0.000), but the other independent variables “HRSkills” and “SCM_Processes” are not highly significant, while the constant term is not significant with respect to the variable [

102]. Therefore, regression is performed again by the “Remove” procedure.

The independent variables are now statistically significant relative to the dependent variable at a 5% significance level, and the constant term has been removed. Therefore, H2 is accepted.

| H3 | HA: Supply Chain Processes (M01) together with the focus on Digital Transformation (M02) have a positive impact on the development of Capabilities (M05). |

According to Spearman correlation coefficient, there is a strong positive correlation (equal to rs = 0.665) between variables M01 and M05 and between variables M05 and M02, which is equal to rs = 0.773.

Therefore, multiple regression can be used to determine the function of the above relationship. The model explained a substantial proportion of variance in satisfaction (Adjusted R2 = 0.687, F = 42.768, p < 0.000). Among the predictors, FocusOnDT emerged as the strongest determinant (β = 0.667, p < 0.000). On the other hand, the other variable and the fixed term do not exert a significant effect on the dependent variable (as sig > 0.05).

Therefore, one independent variable remains statistically significant, while the other as well as the constant term do not exert a significant effect on the dependent variable. For this purpose, a regression is performed again using the subtraction procedure and the following function is obtained:

The independent variables are now statistically significant relative to the dependent variable for a 5% significance level, and the constant term has been removed. Therefore, H3 is also accepted.

| H4 | The capabilities developed (M05) positively affect the company’s Sustainable Impact (M10). |

According to Spearman correlation coefficient, there is a positive correlation between variable M05 and variable M10, which is mediocre and equal to rs = 0, 365. The model explained a substantial proportion of variance in satisfaction (Adjusted R2 = 0.158, F = 2.831, p < 0.016). The predictor, Capabilities emerged as the only one and strong determinant (β = 4.036, p < 0.016) and the fixed term exerts a significant effect on the dependent variable (as sig > 0.025).

The independent variable remains statistically significant, as well as the constant term is quite insignificant with respect to the variable. Therefore, the resulting formula is:

Therefore, H4 is accepted.

| H5 | HA: The Capabilities (M05) arising from the use of Information Technology lead to an increase in Business Performance (M07). |

According to Spearman correlation coefficient, there is a negative correlation of variable M05 with variable M07 and it is equal to rs = 0.387 and it is acceptable. The model explained a substantial proportion of variance in satisfaction (Adjusted R2 = 0.148, F = 5.692, p < 0.025). The predictor, Capabilities emerged as the only one determinant (β = 0.408, p < 0.025) and the fixed term exerts a significant effect on the dependent variable (as sig > 0.004).

The independent variable remains statistically significant (sig = 0.025 < 0.05), and the fixed term has a significant effect on the dependent variable (as sig = 0.004).

Therefore, H5 is accepted.

| H6 | HA: The resulting Business Performance (M07) and the Sustainable Impact (M10) lead to the development of Sustainable Strategies (M08). |

According to Spearman correlation coefficient, there is a positive correlation of variables M07 and M08 and it is equal to rs = 0.443 and it is moderate, of variables M10 and M08 and it is equal to rs = 0.693 and it is strong. Therefore, using multiple regression will determine the extent to which the independent variables will influence the dependent variable. The model explained a substantial proportion of variance in satisfaction (Adjusted R2 = 0.383, F = 9.369, p < 0.01). Among the predictors, SDImpactIT emerged as the strongest determinant (β = 0.048, p < 0.016), The other variables and the fixed term do not exert a significant effect on the dependent variable (as sig > 0.05).

The independent variable “SDImpactIT” remain statistically significant, except for the other one (sig = 0.213), but the fixed term also has no significant effect on the dependent variable (as sig = 0.6281 > 0.05). Therefore, the analysis continues with the “Remove” method. In the case of the “Remove” method, a variable to be removed due to significance must be determined

For this purpose, a regression is performed again using the subtraction procedure and the following function is obtained:

The independent variables are now statistically significant relative to the dependent variable for a 5% significance level, and the constant term has been removed. Therefore, the null hypothesis is rejected and HA (that is H6) is accepted.

| H7 | HA: The sustainable strategies (M08) developed lead to a redefinition of the company’s sustainable policies (M09). |

According to Spearman correlation coefficient, there is a positive correlation, equal to rs = 0.614 which is strong. The model explained a substantial proportion of variance in satisfaction (Adjusted R

2 = 0.350, F = 30.497,

p < 0.001). The predictor, SustainableStrategies emerged as the only one determinant (β = 0.557,

p < 0.001) and the fixed term exerts a significant effect on the dependent variable (as sig > 0.000).

The independent variable remains statistically significant (sig = 0.001 < 0.05), as well as the constant term exerts a significant effect on the dependent variable (as sig = 0.000). Therefore, the null hypothesis is rejected and HA (that is H7) is accepted.

In summary the results of the quantitative analysis reveal that all research hypotheses are true and accepted.

| H1 | Μ05 = 0.875 × (Μ02) + 0.760 × (Μ06) | Accepted |

| H2 | M05 = 0.793 × (Μ03) + 0.684 × (Μ04) | Accepted |

| H3 | Μ05 = 0.694 × (Μ01) + 0.822 × (Μ02) | Accepted |

| H4 | M10 = 4.036 × (Μ05) + 21.574 | Accepted |

| H5 | Μ07 = 0.408 × (Μ05) + 2.048 | Accepted |

| H6 | Μ08 = 0.524 × (Μ07) + 0.625 × (Μ10) | Accepted |

| H7 | M09 = 0.557 × (Μ08) + 1.865 | Accepted |

Each research question was operationalized through clearly defined variables (e.g., digital transformation orientation, sustainability impact, IT level), measured via validated items, and tested using SPSS. Statistical evidence demonstrates that all the proposed hypotheses hold true within the sample and thus the main research questions were comprehensively addressed.

6. Discussion

The findings of this survey are in alignment with the findings of previous research. Dao et al. [

47] contend that Information Systems (IS) play a crucial and indispensable role in bolstering sustainable supply chains, as they offer advantages to a company, its partners, and customers. Furthermore, as demonstrated in the analysis of Stroumpoulis and Kopanaki [

5], Digital Transformation (DT) can empower businesses to develop Information Technology (IT) solutions tailored to develop specific sustainable strategies in their supply chain. Moreover, according to Sharma et al. [

103], adopting novel technologies can actively support the advancement of Sustainable SCM initiatives, resulting in optimized economic outcomes, reduced environmental footprints, and enhanced societal contributions.

Moreover, Stroumpoulis and Kopanaki [

5] concluded that DT can make a substantial environmental impact by enabling emissions monitoring and control, as well as facilitating recall and rework processes. They also concluded that DT positively influences the social dimension of SCM by ensuring data accuracy and supplying various stakeholder groups with real-time information, thereby ensuring transparency and traceability throughout the supply chain. Finally, DT can also drive economic sustainability by enhancing operational efficiency, leading to cost reductions, and providing improved insights into financial flows within the supply chain and among trading partners.

The use of quantitative analysis and statistical modeling was deliberate for two main reasons. First, it allows the empirical validation of a multi-dimensional conceptual framework that links digital transformation, sustainable development, and organizational context. Unlike case studies or purely qualitative approaches, quantitative analysis provides statistically reliable evidence of causal relationships among constructs. Second, the use of regression and correlation techniques in SPSS ensures robustness by testing hypotheses systematically, controlling for multicollinearity, and assessing model fit with established indicators. This approach is particularly well-suited for examining 3PL companies, where multiple variables such as IT resources, human skills, and sustainability orientation interact simultaneously.

As stated in the first hypothesis, the company’s focus on Digital Transformation, combined with its orientation towards Sustainable Development, will lead to the development of capabilities. Specifically, the integration of cutting-edge technologies is essential [

38] towards this direction. According to Rane et al. [

62], the incorporation of these technologies and sustainability policies promotes seamless and continuous information flow throughout the supply chain, allowing real-time data exchange and enhancing knowledge transmission, leading to increased growth opportunities for businesses while simultaneously positively affecting the economy, the environment, and the society.

Furthermore, the high level of Information Technology and the skills/knowledge of the human factor will propel the company towards the development of capabilities [

47], confirming the second research hypothesis. This combination of Business Processes, Information Technology, and Specialized Human Resources constitutes a dynamic framework capable of fostering a culture of innovation and responsiveness to emerging issues [

63].

Specifically, the company’s focus on digital transformation, along with its supply chain processes and resources, can lead to the development of capabilities, as suggested by the third hypothesis. Through the integration of new technologies, organizations can establish a continuous flow of information throughout the supply chain [

104]. This enables real-time data exchange, allowing companies to make informed decisions promptly. The automation of routine tasks not only improves operational processes but also enhances accuracy and efficiency, reducing the likelihood of errors in critical areas, thus enabling better service management [

65].

The capabilities that have emerged from the supply chain environment improve the impact that has resulted from the adoption of sustainable practices. Specifically, this hypothesis suggests that through streamlined logistics, improved traceability and optimized resource use facilitated by these capabilities, companies can achieve better environmental, social and economic outcomes from their sustainability initiatives [

105].

The sustainable impact resulting from strategic initiatives within the supply chain acts as a catalyst that drives companies towards excellence in Sustainable Development in their industry. Through addressing environmental issues, such as resource consumption, emissions, and waste production, companies not only meet regulatory requirements but also play an active role in promoting sustainability. This commitment includes implementing environmentally friendly practices, optimizing supply chains and transportation for reduced carbon footprint, and adopting innovative technologies to enhance efficiency and reduce environmental pollution [

106]. By continuously improving and focusing on transparency, these companies not only minimize their negative ecological footprint but also contribute positively to the broader socio-environmental landscape [

107]. This approach aligns with modern expectations for corporate social responsibility [

108] and positions companies as key contributors to sustainable development, ensuring the long-term impact of their activities in a dynamic business environment.

The adoption of Digital Transformation involves implementing cutting-edge technologies to enhance visibility, automate workflows, and optimize decision-making. By incorporating these technologies, companies gain flexibility, improve efficiency, and reduce operational costs, ultimately enhancing their economic competitiveness [

109]. The capabilities arising from the use of technology have the potential to significantly improve business performance. By integrating IT tools and systems, companies can streamline operations, improve decision-making processes and enhance overall efficiency. These capabilities allow businesses to access real-time data, optimize resource allocation and automate routine tasks, leading to increased productivity and cost savings [

110].

The combination of increased business performance and sustainable impact is crucial for the development of sustainable strategies in organizations (6th research hypothesis). The elevation of business performance, including improved service quality, enhanced collaboration with partners, and increased operational efficiency, provides a solid foundation for sustainable practices [

111]. This increased performance has a positive impact on both economic and social aspects, contributing to the overall sustainability of the business. This involves the implementation of policies and practices that consider environmental, social, and economic factors, ensuring responsible and ethical business behavior [

78]. Finally, digital transformation, characterized by the integration of innovative technologies, enhances effectiveness, flexibility, and adaptability and further facilitates the implementation of sustainable practices [

112]. Therefore, together, these pillars constitute an integrated and collaborative approach supporting sustainable strategies.

According to Charles and Ochieng [

79] for a company to strengthen its position in its task environment, it should develop and implement Sustainable Strategies. In this way, companies not only enhance their position in the supply chain, but also contribute to achieving broader sustainable development goals within the industry. These strategies serve as a roadmap for continuous improvement, ensuring that sustainability remains a driving force in shaping the future of the company and promoting positive impacts on both the business and the environment.

These strategies, in turn, will lead the company to redefine its Sustainable Policies continually, updating its goals and policies (7th research hypothesis) [

80]. Companies should engage in continuous assessments of environmental impacts, social impacts, and economic sustainability, promoting a culture of continuous improvement. This situation ensures that the company stays at the forefront of sustainable practices, incorporating the latest innovations and best practices into its activities.

Therefore, the findings of this study offer several practical implications for managers in 3PL companies [

113]. First, managers should recognize that digital transformation and sustainable development are not isolated initiatives but mutually reinforcing drivers of capability building. By investing in advanced IT systems, data analytics, and human resource development, 3PL firms can enhance visibility, responsiveness, and collaboration across the supply chain. Second, the results indicate that capabilities developed through DT and sustainability initiatives directly improve business performance. Managers can therefore justify digital and sustainability investments not only for compliance or reputation purposes but also for measurable economic gains. Third, the study highlights the importance of including the social dimension of sustainability—such as labor equity, employee well-being, and community engagement—when formulating strategies. For managers, this means adopting holistic sustainability approaches that balance economic, environmental, and social priorities to create long-term competitive advantage.

7. Conclusions

This study examined the evolving field of digital transformation (DT) and sustainability in the context of 3PLcompanies. Through the development of a conceptual framework and the identification of research hypotheses, it contributes to a deeper understanding of how technology and sustainability intersect in the contemporary business landscape, providing valuable insights for both professionals and academics. However, due to the fact that the population is small and the response ration acceptable but low, this survey is complementary to a previous qualitative survey [

114], stated that the under examination conceptual framework could lead to business performance and sustainable excellence.

The findings of the quantitative analysis demonstrate that Digital Transformation enhances business processes, augments capabilities, and fosters a stronger orientation toward sustainable policies and development. The conclusions drawn from this study are completely aligned with the empirical evidence and the theoretical arguments presented throughout this paper. Each of the seven hypotheses is statistically supported by the results of multiple and linear regression analysis, with strong and significant relationships validated through robust correlation and factor analyses. The findings confirm the predicted influence of digital transformation and sustainability orientation on capability development and demonstrate the downstream effects on business performance and sustainable strategy formation. These conclusions are well-aligned with existing theories and they are also supported by the literature reviewed, including the conceptual foundation proposed by Stroumpoulis & Kopanaki [

5].

More specifically, the company’s focus on Digital Transformation and the orientation towards Sustainable Development, combined with specific IT, HR and SCM resources positively influence the development of capabilities. The attained capabilities can lead to enhanced business performance and increased sustainable impact. These results drive the development of sustainable strategies leading to the redefinition of sustainable policies.

In light of these findings, it is evident that companies that leverage DT in tandem with sustainable strategies can position themselves favorably within their task environment. Nevertheless, it is imperative for managers to continually redefine and update their sustainable strategies and policies to maintain this advantageous position.

This study addresses the research gap identified in the literature by providing empirical evidence on how DT, sustainability, and organizational context jointly shape business capabilities and strategic development in 3PL firms. While most prior studies emphasized economic or environmental sustainability or remained conceptual, this research explicitly integrates the social dimension and validates the relationships quantitatively in the underexplored 3PL sector. In doing so, it extends the body of knowledge on sustainable supply chain management and demonstrates the measurable impact of DT-driven sustainability on organizational outcomes.

Regarding the theoretical contribution, this research advances the understanding of how digital technologies and sustainability practices interact to build capabilities that improve firm performance. By incorporating the social pillar into the DT–SSCM framework, the study fills a notable gap in the literature and provides a more holistic perspective of sustainability. Furthermore, it empirically validates the mediating role of organizational capabilities, thereby extending resource-based and capability-building theories in the logistics sector.

From a managerial perspective, the results highlight that investments in digital transformation and sustainability initiatives should not be treated separately. Managers in 3PL companies can use these findings to justify digital investments not only for compliance or efficiency but also for direct business performance gains. Moreover, the inclusion of social sustainability signals the need for firms to address workforce well-being, equity, and stakeholder engagement alongside environmental and economic goals. Practically, this means aligning DT initiatives with green technologies, responsible HR practices, and IT systems that enhance transparency and collaboration across the supply chain.

Future research could expand the scope of this study by testing the framework in other sectors and not only in 3PL Companies. To further examine and compare the study’s results, a quantitative analysis needs to be applied in different industries or parts of the supply chain. Moreover, to analyze this phenomenon in depth, a mixed research method [

43] including a qualitative analysis in the form of case studies could also be applied. Conducting additional research to assess the effects of Digital Transformation on various aspects of sustainability performance would be of high value, providing guidance to industry practitioners and academic scholars as they navigate the expected shifts in the business landscape.