Sustainable Strategies for Raspberry Production: Greenhouse Gas Mitigation Through Biodegradable Substrate Additives in High Tunnels

Abstract

1. Introduction

2. Methods

- Bulk density was determined using gravimetric analysis (ratio of the fresh mass of the solids to the volume of the substrate)

- Moisture content was determined using gravimetric analysis (oven-drying to measure weight loss)

- Angle of repose was determined using the fixed funnel method

- Coefficient of friction was determined using a direct shear test

- Porosity was determined using the water absorption test

- Compressibility was determined using confined compression

Life Cycle Assessment Methodology

3. Results and Discussion

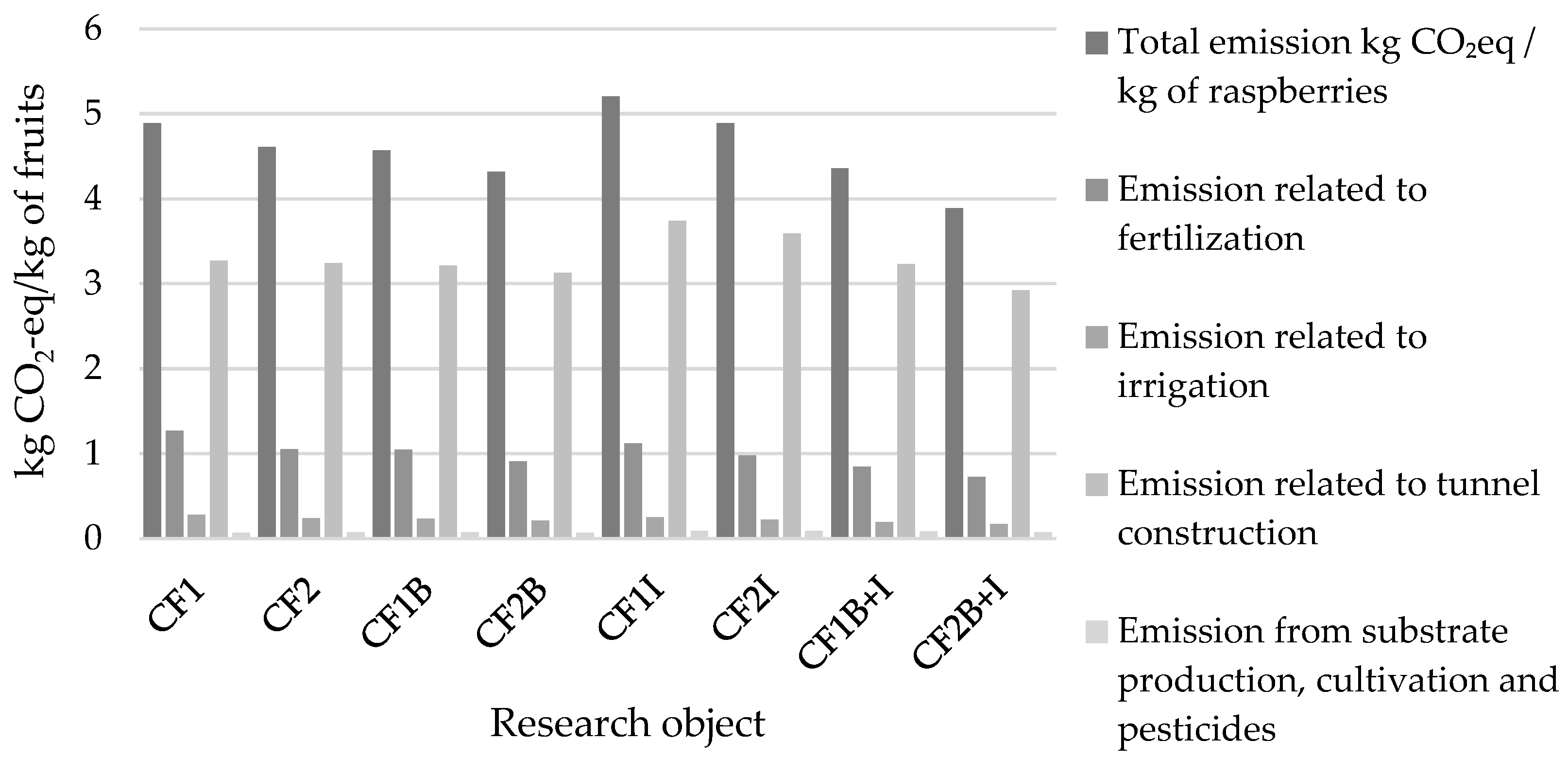

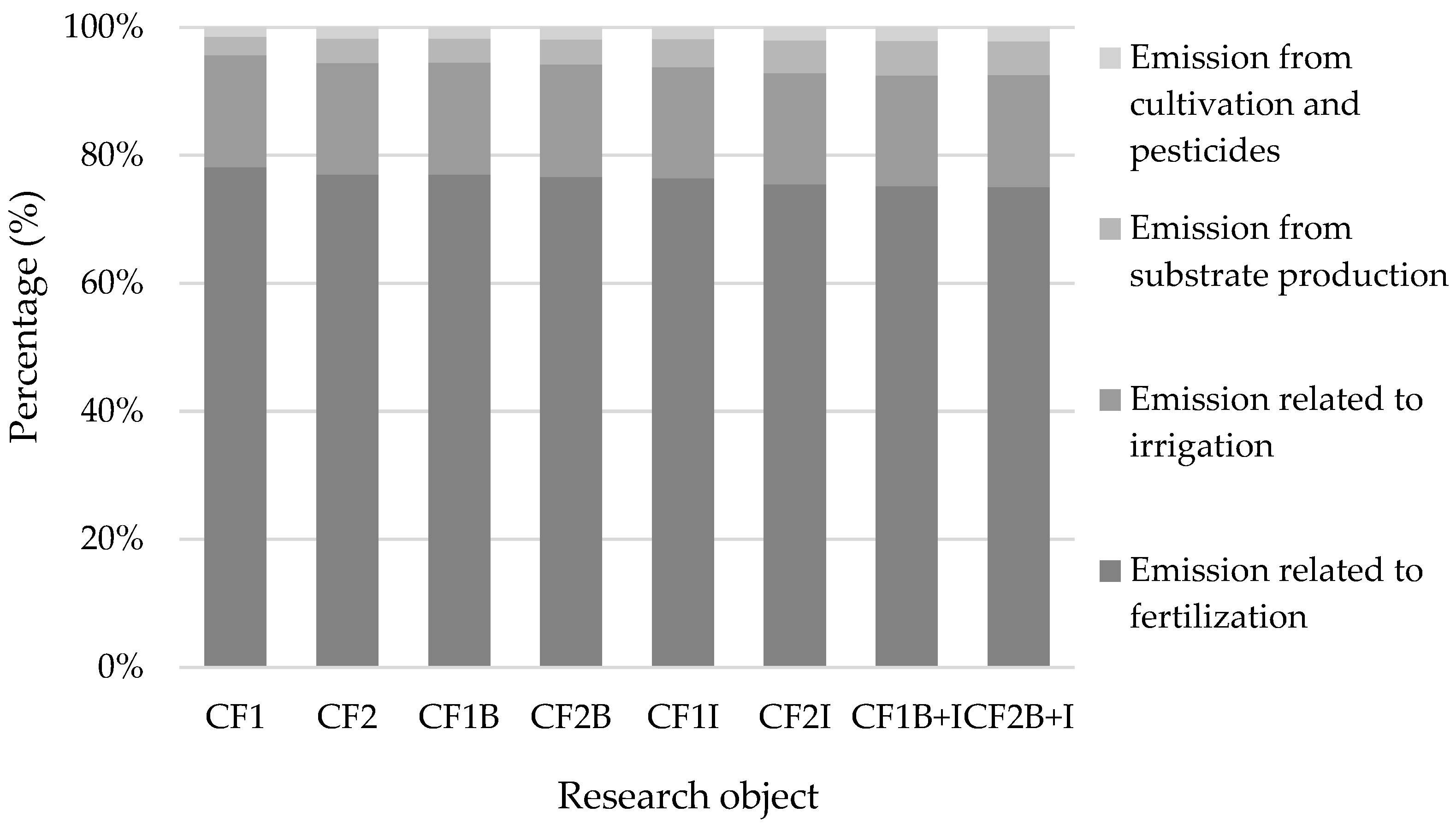

3.1. Analysis of GHG Emissions Related to Raspberry Production

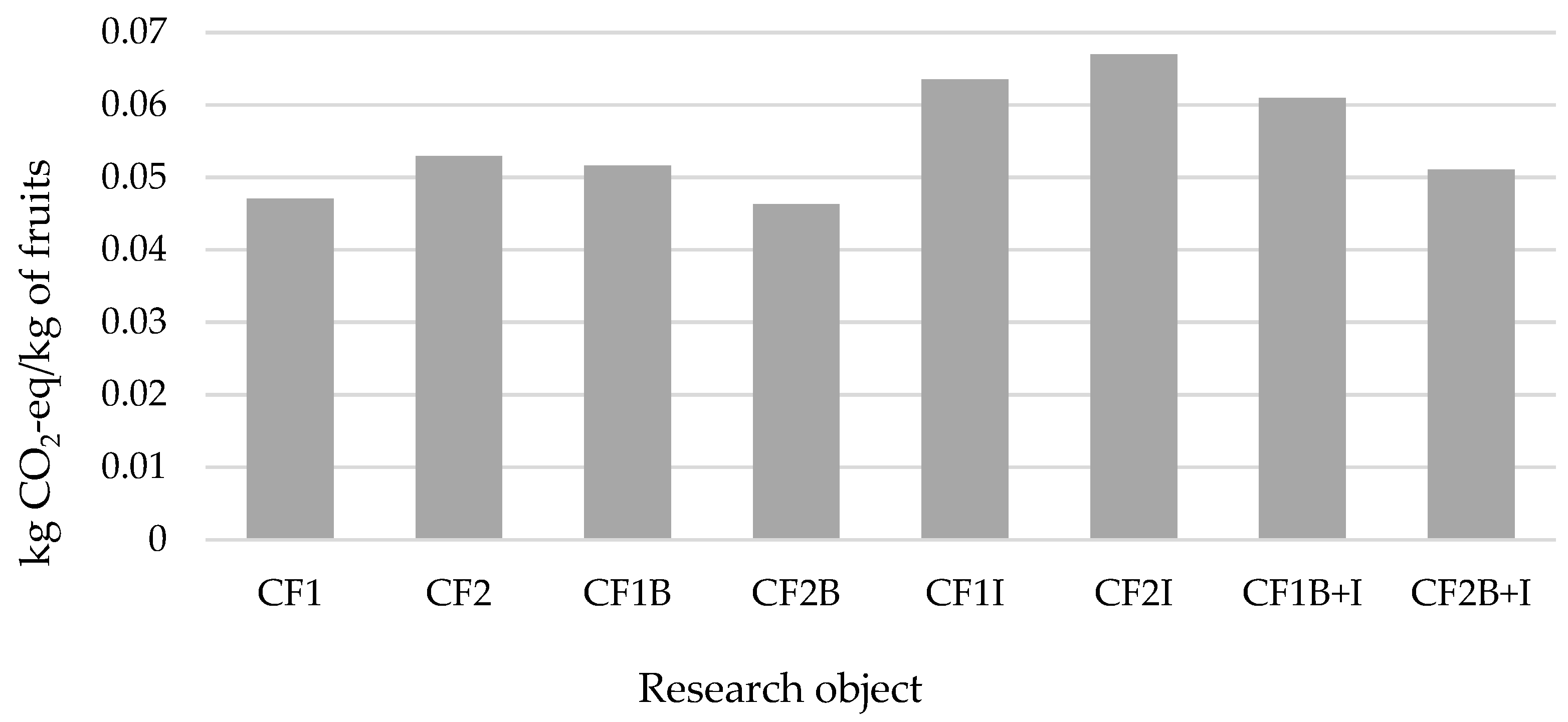

3.2. Emissions Related to Substrate Production

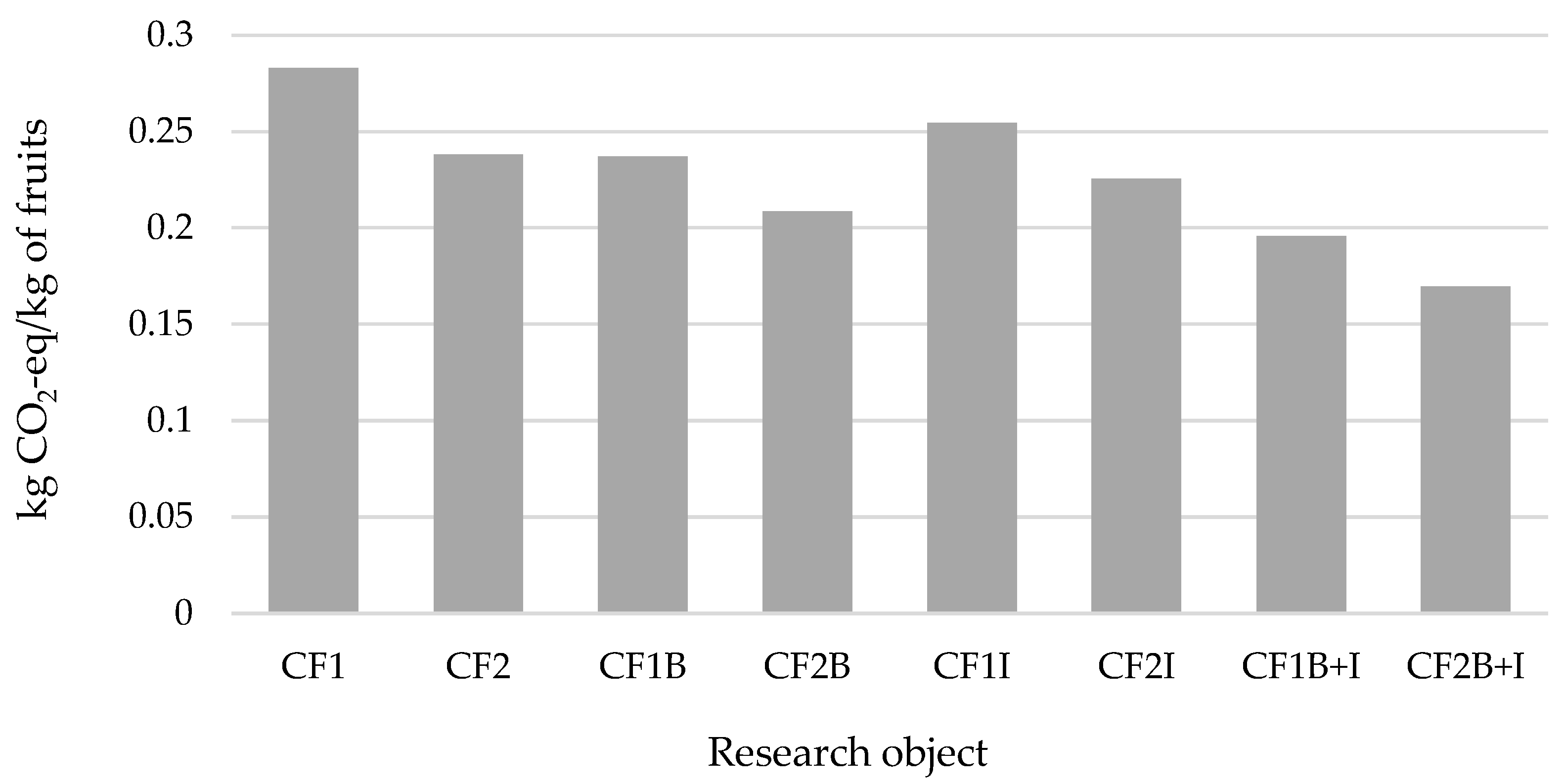

3.3. Emissions from Irrigation

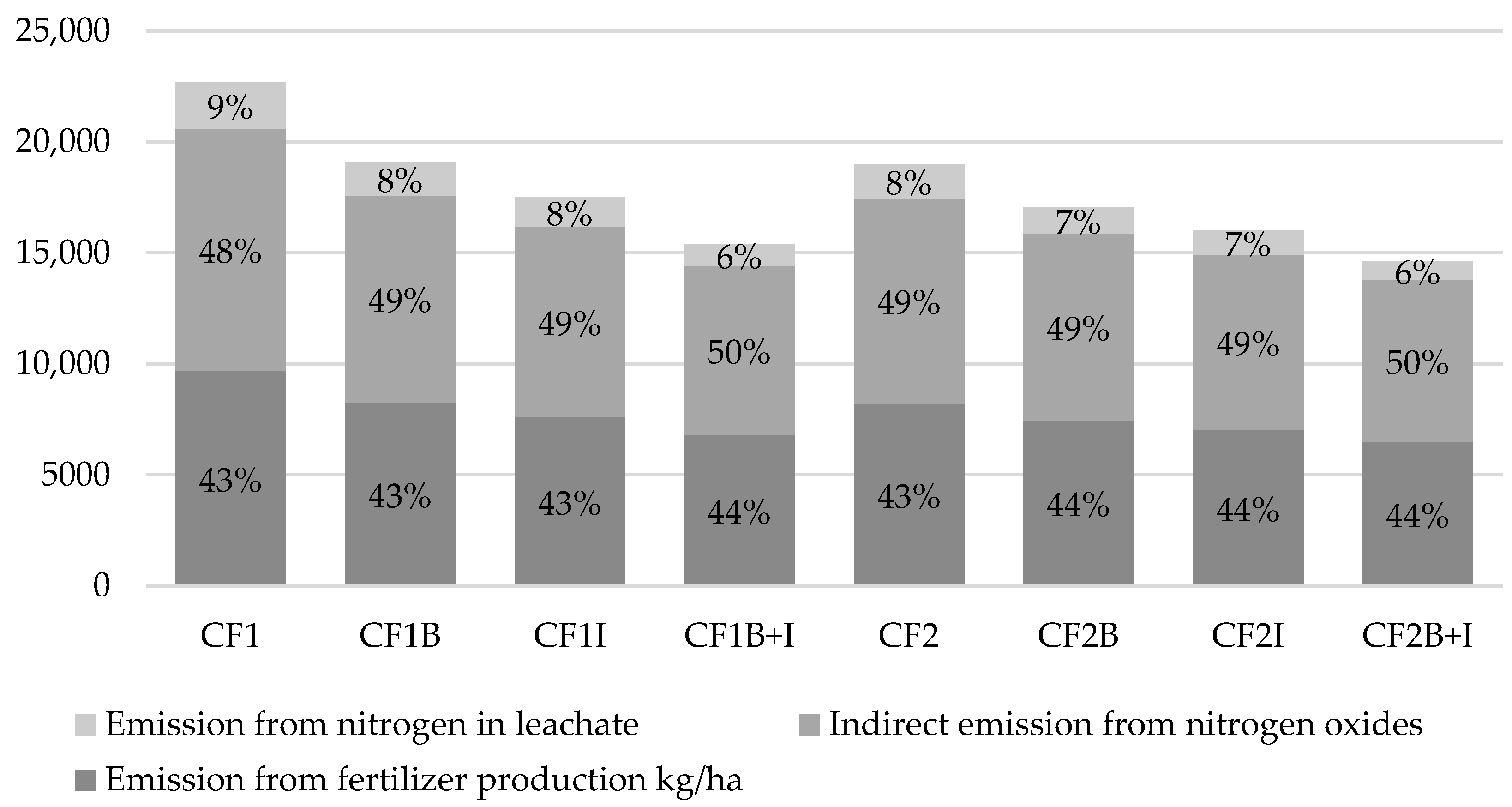

3.4. Fertilization-Related Emissions

4. Conclusions

- Modifying the composition of the substrate in raspberry cultivation under cover can bring about positive environmental effects in the form of reduced greenhouse gas emissions associated with the production of dessert raspberries. The study demonstrated a nearly 40% reduction in greenhouse gas emissions compared to the control treatment.

- The factors that had the most significant influence on the level of greenhouse gas emissions were water and nutrient use efficiency.

- The air–water properties of the substrate are critically important for both the environmental and economic efficiency of soilless plant production under cover.

- The best environmental and production outcomes were achieved with a substrate mixture composed of coconut fiber, biochar, and a wood industry isolate.

- The parameter that has had the most significant impact on greenhouse gas emissions is the construction and operation of tunnels. Optimizing raspberry production technology in the context of environmental costs should also focus on changes to tunnel design, the use of alternative building materials, and extending tunnel operating life.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Granatstein, D.; Kupferman, E. Sustainable Horticulture in Fruit Production. Acta Hortic. 2006, 767, 295–308. [Google Scholar] [CrossRef]

- Carlsson-Kanyama, A.; Ekström, M.P.; Shanahan, H. Food and Life Cycle Energy Inputs: Consequences of Diet and Ways to Increase Efficiency. Ecol. Econ. 2003, 44, 293–307. [Google Scholar] [CrossRef]

- Cuadra, M.; Björklund, J. Assessment of Economic and Ecological Carrying Capacity of Agricultural Crops in Nicaragua. Ecol. Indic. 2007, 7, 133–149. [Google Scholar] [CrossRef]

- Frey, S.; Barrett, J. Our Health, Our Environment: The Ecological Footprint of What We Eat. In Proceedings of the International Ecological Footprint Conference, Cardiff, UK, 8–10 May 2007. [Google Scholar]

- Garnett, T. Fruit and Vegetables & UK Greenhouse Gas Emissions: Exploring the Relationship. In Food and Climate Research Network; University of Surrey: Guildford, UK, 2006. [Google Scholar]

- Rashidov, N.; Chowaniak, M.; Niemiec, M.; Mamurovich, G.S.; Gufronovich, M.J.; Gródek-Szostak, Z.; Szeląg-Sikora, A.; Sikora, J.; Kuboń, M.; Komorowska, M. Assessment of the Multiannual Impact of the Grape Training System on GHG Emissions in North Tajikistan. Energies 2021, 14, 6160. [Google Scholar] [CrossRef]

- Gerbens-Leenes, P.W.; Nonhebel, S.; Ivens, W.P.M.F. A Method to Determine Land Requirements Relating to Food Consumption Patterns. Agric. Ecosyst. Environ. 2002, 90, 47–58. [Google Scholar] [CrossRef]

- Hanson, E.; Von Weihe, M.; Schilder, A.C.; Chanon, A.M.; Scheerens, J.C. High Tunnel and Open Field Production of Floricane- and Primocane-Fruiting Raspberry Cultivars. Hort. Technol. 2011, 21, 412–418. [Google Scholar] [CrossRef]

- Clark, M.; Springmann, M.; Rayner, M.; Scarborough, P.; Hill, J.; Tilman, D.; Harrington, R. Estimating the Environmental Impacts of 57,000 Food Products. Proc. Natl. Acad. Sci. USA 2022, 119, e2120584119. [Google Scholar] [CrossRef]

- Bradish, C.M.; Perkins, P.; Fernandez, G.E.; Ma, G. Comparison of Health-Beneficial Secondary Metabolites in Red Raspberry Grown under Field and High Tunnel Production Systems. In Proceedings of the 2012 ASHS Annual Conference, Miami, FL, USA, 31 July–3 August 2012. [Google Scholar]

- Wróblewska, W.; Pawlak, J.; Paszko, D. Economic Aspects in the Raspberry Production on the Example of Farms from Poland, Serbia, and Ukraine. J. Hortic. Res. 2019, 27, 71–80. [Google Scholar] [CrossRef]

- Menegat, S.; Ledo, A.; Tirado, R. Greenhouse Gas Emissions from Global Production and Use of Nitrogen Synthetic Fertilizers in Agriculture. Sci. Rep. 2022, 12, 14490. [Google Scholar] [CrossRef]

- Kongshaug, G. Energy Consumption and Greenhouse Gas Emissions in Fertilizer Production. In Proceedings of the IFA Technical Conference, Marrakech, Morocco, 28 September–1 October 1998; pp. 1–18. [Google Scholar]

- IPCC. Climate Change 2014: Synthesis Report. Contribution of Working Groups I, II, and III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Pachauri, R.K., Meyer, L.A., Eds.; IPCC: Geneva, Switzerland, 2014; Available online: https://www.ipcc.ch/report/ar5/syr/ (accessed on 28 June 2025).

- Komorowska, M.; Niemiec, M.; Sikora, J.; Suder, M.; Gródek-Szostak, Z.; Atilgan, A.; Ovcharuk, O.; Lach, Ł.; Kusa, R.; Duda, J. Strategies for Managing Corn Residue Crop in the Context of Greenhouse Gas Emissions. Environ. Sci. Pollut. Res. 2024, 31, 60189–60205. [Google Scholar] [CrossRef]

- Cerutti, A.; Beccaro, G.L.; Bosco, S.; De Luca, A.I.; Falcone, G.; Fiore, A.; Iofrida, N.; Giudice, A.L.; Strano, A. Life Cycle Assessment in the Fruit Sector. In Life Cycle Assessment in the Agri-Food Sector; Notarnicola, B., Salomone, R., Petti, L., Renzulli, P., Roma, R., Cerutti, A., Eds.; Springer: Cham, Switzerland, 2015; pp. 333–388. [Google Scholar] [CrossRef]

- Rose, D.C.; Keating, C.; Morris, C. Understanding how to influence farmers’ decision-making behaviour: A social science review. Agric. Syst. 2016, 149, 165–176. [Google Scholar] [CrossRef]

- Bradish, C.M.; Yousef, G.G.; Ma, G.; Perkins-Veazie, P.; Fernandez, G.F. Anthocyanin, Carotenoid, Tocopherol, and Ellagitannin Content of Red Raspberry Cultivars Grown Under Field or High Tunnel Cultivation in the Southeastern United States. J. Amer. Soc. Hort. Sci. 2015, 140, 163–171. [Google Scholar] [CrossRef]

- Klerkx, L.; Rose, D. Dealing with the game-changing technologies of Agriculture 4.0: How do we manage diversity and responsibility in food system transition pathways? Glob. Food Secur. 2020, 24, 100347. [Google Scholar] [CrossRef]

- Carlen, C.; Ançay, A.; Christ, B. Optimization of the Root Environment for Raspberry Production on Substrate. Acta Hortic. 2020, 1277, 283–286. [Google Scholar] [CrossRef]

- Campbell, B.M.; Thornton, P.; Zougmoré, R.; van Asten, P.; Lipper, L. Sustainable intensification: What is its role in climate smart agriculture? Curr. Opin. Environ. Sustain. 2014, 8, 39–43. [Google Scholar] [CrossRef]

- Pretty, J.; Benton, T.G.; Bharucha, Z.P.; Dicks, L.V.; Flora, C.B.; Godfray, H.C.J.; Goulson, D.; Hartley, S.; Lampkin, N.; Morris, C.; et al. Global assessment of agricultural system redesign for sustainable intensification. Nat. Sustain. 2018, 1, 441–446. [Google Scholar] [CrossRef]

- Qiu, C.; Gaudreau, L.; Nemati, R.; Gosselin, A.; Desjardins, Y. Primocane Red Raspberry Response to Fertigation EC, Types of Substrate and Propagation Methods. Eur. J. Hortic. Sci. 2017, 82, 72–80. [Google Scholar] [CrossRef]

- Huang, L.; Gu, M. Effects of Biochar on Container Substrate Properties and Growth of Plants—A Review. Horticulturae 2019, 5, 14. [Google Scholar] [CrossRef]

- Sikora, J.; Niemiec, M.; Tabak, M.; Gródek-Szostak, Z.; Szeląg-Sikora, A.; Kuboń, M.; Komorowska, M. Assessment of the Efficiency of Nitrogen Slow-Release Fertilizers in Integrated Production of Carrot Depending on Fertilization Strategy. Sustainability 2020, 12, 1982. [Google Scholar] [CrossRef]

- Tian, Y.; Sun, X.; Li, S.; Wang, H.; Wang, L.; Cao, J.; Zhang, L. Biochar Made from Green Waste as Peat Substitute in Growth Media for Calathea rotundifolia cv. Fasciata. Sci. Hortic. 2012, 143, 15–18. [Google Scholar] [CrossRef]

- Méndez, A.; Cárdenas-Aguiar, E.; Paz-Ferreiro, J.; Plaza, C.; Gascó, G. The Effect of Sewage Sludge Biochar on Peat-Based Growing Media. Biol. Agric. Hortic. 2016, 33, 40–51. [Google Scholar] [CrossRef]

- Grasselly, D.; Hamm, F.; Quaranta, G.; Vitrou, J. Carbon Footprint of Coconut Fibre (Coir) Substrates. Infos-Ctifl 2009, 249, 55–59. [Google Scholar]

- Heuvel, J.E.V.; Proctor, J.T.; Sullivan, J.A. Trellising System and Cane Density Affect Yield and Fruit Quality of Red Raspberry. Hort. Sci. 2000, 35, 1215–1219. [Google Scholar] [CrossRef]

- Dale, A.; Pirgozliev, S.; King, E.M.; Sample, A. Scheduling Primocane-Fruiting Raspberries (Rubus idaeus L.) for Year-Round Production in Greenhouses by Chilling and Summer-Pruning of Canes. J. Hortic. Sci. Biotechnol. 2005, 80, 346–350. [Google Scholar] [CrossRef]

- Sønsteby, A.; Myrheim, U.; Heiberg, N.; Heide, O.M. Production of High Yielding Red Raspberry Long Canes in a Northern Climate. Sci. Hortic. 2009, 121, 289–297. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; EU Policy Framework on Biobased, Biodegradable and Compostable Plastics; COM(2022) 682 Final; European Commission: Brussels, Belgium, 2022. [Google Scholar]

- Niemiec, M.; Komorowska, M.; Atilgan, A.; Abduvasikov, A. Labelling the Carbon Footprint as a Strategic Element of Environmental Assessment of Agricultural Systems. Agric. Eng. 2024, 28, 235–250. [Google Scholar] [CrossRef]

- Sangaré, M.; Nemati, M.R.; Fortin, J.P. Beneficial Effect of Coconut Fiber and Peat on the Physical Quality of Nursery Substrates. Acta Hortic. 2013, 1013, 175–180. [Google Scholar] [CrossRef]

- Antle, J.M.; Valdivia, R.O. Modelling the supply of ecosystem services from agriculture: A minimum-data approach. Aust. J. Agric. Resour. Econ. 2006, 50, 1–15. [Google Scholar] [CrossRef]

- Hutsol, T.; Kutyrev, A.; Kiktev, N.; Biliuk, M. Robotic Technologies in Horticulture: Analysis and Implementation Prospects. Agric. Eng. 2023, 27, 113–133. [Google Scholar] [CrossRef]

- Ilari, A.; Toscano, G.; Boakye-Yiadom, K.A.; Duca, D.; Pedretti, E.F. Life Cycle Assessment of Protected Strawberry Productions in Central Italy. Sustainability 2021, 13, 4879. [Google Scholar] [CrossRef]

- Pan, S.Y.; He, K.H.; Lin, K.T.; Fan, C.; Chang-Tang, C. Addressing Nitrogenous Gases from Croplands Toward Low-Emission Agriculture. npj Clim. Atmos. Sci. 2022, 5, 43. [Google Scholar] [CrossRef]

- Mohammadzadeh, P.; Shahgholi, G.; Szymanek, M.; Tanaś, W. Analysis of Energy Indicators of Dry Farming Wheat Production in Northwest of Iran. Agric. Eng. 2024, 28, 37–49. [Google Scholar] [CrossRef]

- De Beus, N.; Carus, M.; Barth, M. Carbon footprint and sustainability of different natural fibres for biocomposites and insulation material-study providing data for the automotive and insulation industry. Carbon Footpr. Nat. Fibres 2019, 56. Available online: https://eiha.org/media/2019/03/19-03-13-Study-Natural-Fibre-Sustainability-Carbon-Footprint.pdf (accessed on 28 June 2025).

- Soto-Barrera, V.C.; Begambre-González, F.; Vellojín-Muñoz, K.E.; Fernandez-Hoyos, D.F.; Torres-Bejarano, F.M. Life Cycle Assessment of Biocomposite Production in Development Stage from Coconut Fiber Utilization. Sustainability 2025, 17, 8338. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14041:1998; Environmental Management—Life Cycle Assessment—Goal and Scope Definition and Inventory Analysis. International Organization for Standardization: Geneva, Switzerland, 1998.

- PN-EN 13041:2002; Soil Improvers and Growing Media–Determination of Physical Properties–Dry Bulk Density, Air Capacity, Water Capacity, Shrinkage and Total Porosity. Polish Committee for Standardization: Warsaw, Poland, 2002.

- Notarnicola, B.; Tassielli, G.; Renzulli, P.A.; Monforti-Ferrario, F.; Sala, S. Environmental impacts of food consumption in Europe. J. Clean. Prod. 2017, 140, 753–765. [Google Scholar] [CrossRef]

- European Commission-Joint Research Centre-Institute for Environment and Sustainability. International Reference Life Cycle Data System (ILCD) Handbook—General Guide for Life Cycle Assessment—Detailed Guidance; EUR 24708 EN; Publications Office of the European Union: Luxembourg, 2010; Available online: https://eplca.jrc.ec.europa.eu/uploads/ILCD-Handbook-General-guide-for-LCA-DETAILED-GUIDANCE-12March2010-ISBN-fin-v1.0-EN.pdf (accessed on 28 June 2025).

- IPCC. Summary of the Revised 1996 IPCC Guidelines for National Greenhouse Gas Inventories. In The Additions and Revisions to the Reference Manual of the IPCC Guidelines Were Accepted by the IPCC at Its Twelfth Session (Mexico City, 11–13 September 1996); IPCC: Geneva, Switzerland, 1996. [Google Scholar]

- Houghton, J.T.; Meira Filho, L.G.; Lim, B.; Treanton, K.; Mamaty, I.; Bonduki, Y.; Griggs, D.J.; Callender, B.A. Revised 1996 IPCC Guidelines for National Greenhouse Gas Inventories; IPCC: Geneva, Switzerland, 1996. [Google Scholar]

- Garg, A.; Kazunari, K.; Pulles, T. IPCC Guidelines for National Greenhouse Gas Inventories. 2020. Available online: https://www.ipcc-nggip.iges.or.jp/public/2006gl/pdf/2_Volume2/V2_1_Ch1_Introduction.pdf (accessed on 26 March 2020).

- Wood, S.; Cowie, A. Review of Greenhouse Gas Emission Factors for Fertiliser Production; Research and Development Division, State Forests of New South Wales; Cooperative Research Centre for Greenhouse Accounting: Sydney, Australia, 2004. [Google Scholar]

- Novoa, R.; Tejeda, H. Evaluation of the N2O emissions from N in plant residues as affected by environmental and management factors. Nutr. Cycl. Agroecosyst. 2006, 75, 29–46. [Google Scholar] [CrossRef]

- IPCC. 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2019; Available online: https://www.ipcc.ch/report/2019-refinement-to-the-2006-ipcc-guidelines-for-national-greenhouse-gas-inventories/ (accessed on 27 June 2025).

- IPCC. IPCC Guidelines for National Greenhouse Gas Inventories, Volume 4: Agriculture, Forestry and Other Land Use; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2006. [Google Scholar]

- IPCC. The Intergovernmental Panel on Climate Change (IPCC) Will Participate in the 21st Conference of the Parties (COP 21) to the United Nations Framework Convention on Climate Change (UNFCCC) in Paris, Starting on Monday, 30 November, 2015; IPCC: Geneva, Switzerland, 2015. [Google Scholar]

- Forster, P.; Ramaswamy, V.; Artaxo, P.; Berntsen, T.; Betts, R.; Fahey, D.W.; Haywood, J.; Lean, J.; Lowe, D.C.; Myhre, G.; et al. Changes in Atmospheric Constituents and in Radiative Forcing. In Climate Change 2007: The Physical Science Basis. Contribution of Working Group I to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Solomon, S., Qin, D., Manning, M., Chen, Z., Marquis, M., Averyt, K.B., Tignor, M., Miller, H.L., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2007; Available online: https://www.ipcc.ch/site/assets/uploads/2018/02/ar4-wg1-chapter2-1.pdf (accessed on 27 June 2025).

- Audsley, E.; Stacey, K.; Parsons, D.J.; Williams, A.G. Estimation of the Greenhouse Gas Emissions from Agricultural Pesticide Manufacture and Use; Cranfield University: Cranfield, UK, 2009. [Google Scholar] [CrossRef]

- Cech, R.; Leisch, F.; Zaller, J.G. Pesticide Use and Associated Greenhouse Gas Emissions in Sugar Beet, Apples, and Viticulture in Austria from 2000 to 2019. Agriculture 2022, 12, 879. [Google Scholar] [CrossRef]

- Lal, R. Soil Carbon Sequestration Impacts on Global Climate Change and Food Security. Science 2004, 304, 1623–1627. [Google Scholar] [CrossRef]

- Audsley, E. Harmonisation of Environmental Life Cycle Assessment for Agriculture; Final Report, Concerted Action AIR3-CT94-2028; European Commission, DG VI Agriculture: Luxembourg, 1997; 139p. [Google Scholar]

- Pretty, J.; Bharucha, Z.P. Integrated Pest Management for sustainable intensification of agriculture in Asia and Africa. Insects 2015, 6, 152–182. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency (EPA). Greenhouse Gas Inventory Guidance: Direct Emissions from Mobile Combustion Sources; EPA: Washington, DC, USA, 2016; p. 27.

- Wang, D.; Ye, W.; Wu, G.; Li, R.; Guan, Y.; Zhang, W.; Wang, J.; Shan, Y.; Hubacek, K. Greenhouse Gas Emissions from Municipal Wastewater Treatment Facilities in China from 2006 to 2019. Sci. Data 2022, 9, 317. [Google Scholar] [CrossRef] [PubMed]

- FAO. Livestock Environmental Assessment and Performance Partnership. In Global Database of GHG Emissions Related to Feedcrops: Methodology; Version 1; FAO: Rome, Italy, 2017. [Google Scholar]

- Smebye, A.B.; Sparrevik, M.; Schmidt, H.P.; Cornelissen, G. Life-Cycle Assessment of Biochar Production Systems in Tropical Rural Areas: Comparing Flame Curtain Kilns to Other Production Methods. Biomass Bioenergy 2017, 101, 35–43. [Google Scholar] [CrossRef]

- Zhao, Q.; Feng, J.; Guo, S.; Yang, S.; Jing, R.; Zhang, X.; Zhou, X.; Li, D. Water-Fertilizer Regulation Improves Yield, Quality, and Water-Fertilizer Use Efficiency of Greenhouse Lettuce by Altering the Bacterial Community in Nutrient Solutions. J. Agric. Food Res. 2025, 21, 101976. [Google Scholar] [CrossRef]

- Boyacı, S.; Kocięcka, J.; Atilgan, A.; Niemiec, M.; Liberacki, D.; Rolbiecki, R. Determination of the Effects of Different Irrigation Levels and Vermicompost Doses on Water Consumption and Yield of Greenhouse-Grown Tomato. Water 2024, 16, 1095. [Google Scholar] [CrossRef]

- Nieto, A.; Gascó, G.; Paz-Ferreiro, J.; Fernández, J.; Plaza, C.; Méndez, A. The Effect of Pruning Waste and Biochar Addition on Brown Peat Based Growing Media Properties. Sci. Hortic. 2016, 199, 142–148. [Google Scholar] [CrossRef]

- Kader, S.; Gratchev, I.; Michael, R.N. Recycled waste substrates: A systematic review. Sci. Total Environ. 2024, 953, 176029. [Google Scholar] [CrossRef] [PubMed]

- International Fertilizer Association (IFA). Energy Efficiency and CO2 Emissions in Ammonia Production 2008–2009: Summary Report; International Fertilizer Association: Paris, France, 2009. [Google Scholar]

- World Resources Institute (WRI). World Resources 2000–2001: People and Ecosystems—The Fraying Web of Life; World Resources Institute: Washington, DC, USA, 2000; Available online: http://pdf.wri.org/world_resources_2000-2001_people_and_ecosystems.pdf (accessed on 28 June 2025).

- Niemiec, M.; Cupiał, M.; Szeląg-Sikora, A. Ocena Efektywności Nawożenia Selera Korzeniowego Nawozami o Spowolnionym Działaniu. Agric. Agric. Sci. Procedia 2015, 7, 177–183. [Google Scholar] [CrossRef]

- FAO. FAOSTAT: Emission Totals; FAO: Rome, Italy; Available online: https://www.fao.org/faostat/en/#data/GT (accessed on 29 October 2022).

| Experimental Variant | Coconut Fiber Substrate Lergo | Coconut Fiber Substrate Ceres | 10% Biochar Amendment | 10% Isolate Amendment |

|---|---|---|---|---|

| CF1 | + | |||

| CF2 | + | |||

| CF1B | + | + | ||

| CF2B | + | + | ||

| CF1I | + | + | ||

| CF2I | + | + | ||

| CF1B + I | + | + | + | |

| CF2B + I | + | + | + |

| Coconut fiber LERGO CF1 | Bulk density | BD [kg/m2] | 95 (5%), 256.3 (35%) |

| Particle density | DE [kg/m2] | 180 | |

| Moisture content | Mar [%] | 35 | |

| Angle of repose | φ [°] | 42–44 | |

| Coefficient of friction | μ | 0.28 | |

| Max. water holding capacity | kg/kg | 0.38 | |

| Porosity | ρ [%] | 47.2 | |

| Compressibility | Y [%] | 65 | |

| Coconut fiber CERES CF2 | Bulk density | BD [kg/m2] | 110 (5%), 290.5 (33%) |

| Particle density | DE [g/cm2] | 170 | |

| Moisture content | Mar [%] | 33 | |

| Angle of repose | φ [°] | 41–42 | |

| Coefficient of friction | μ | 0.26 | |

| Max. water holding capacity | kg/kg | 0.41 | |

| Porosity | ρ | 35.3 | |

| Compressibility | Y [%] | 72 |

| CF1B | Bulk density | BD [kg/m2] | 315.6 |

| Moisture content | Mar [%] | 35 | |

| Angle of repose | φ [°] | 41–43 | |

| Coefficient of friction | μ | 0.29 | |

| Porosity | ρ [%] | 37.3 | |

| Compressibility | Y [%] | 63–64 | |

| CF2B | Bulk density | BD [kg/m2] | 319.3 |

| Moisture content | Mar [%] | 35 | |

| Angle of repose | φ [°] | 42–44 | |

| Coefficient of friction | μ | 0.29 | |

| Porosity | ρ [%] | 41.2 | |

| Compressibility | Y [%] | 64 | |

| CF1I | Bulk density | BD [kg/m2] | 393.5 |

| Moisture content | Mar [%] | 35 | |

| Angle of repose | φ [°] | 40–43 | |

| Coefficient of friction | μ | 0.28 | |

| Porosity | ρ [%] | 34.8 | |

| Compressibility | Y [%] | 64 | |

| CF2I | Bulk density | BD [kg/m2] | 290.5 |

| Moisture content | Mar [%] | 33 | |

| Angle of repose | φ [°] | 40–42 | |

| Coefficient of friction | μ | 0.27 | |

| Porosity | ρ [%] | 31.3 | |

| Compressibility | Y [%] | 69–71 | |

| CF1B + I | Bulk density | BD [kg/m2] | 353.1 |

| Moisture content | Mar [%] | 33 | |

| Angle of repose | φ [°] | 41–43 | |

| Coefficient of friction | μ | 0.27 | |

| Porosity | ρ [%] | 26.8 | |

| Compressibility | Y [%] | 70–73 | |

| CF2B + I | Bulk density | BD [kg/m2] | 438.3 |

| Moisture content | Mar [%] | 33 | |

| Angle of repose | φ [°] | 40–43 | |

| Coefficient of friction | μ | 0.27–0.28 | |

| Porosity | ρ [%] | 24.7 | |

| Compressibility | Y [%] | 70–72 |

| Tank | Type of Fertilizer | Fertilizer Content in the Mixture [%] | Fertilizer Consumption [kg/ha/year] | |

|---|---|---|---|---|

| Type of Mixture | ||||

| Starter 27 April–27 June 2022 | Fruit 28 June–30 September 2022 | |||

| A | Calcium nitrate (15,5% N, 19% Ca) (kg) | 4.9 | 3.5 | 652.42 |

| Ammonium nitrate (34% N) (kg) | 0.8 | 0.0 | 32 | |

| Magnesium nitrate (11% N, 9.4% Mg) (kg) | 1.2 | 1.0 | 178.41 | |

| Potassium nitrate (K 13.4 N%, 38.2 K) (kg) | 0.0 | 1.6 | 208.65 | |

| DTPA chelat (7% Fe) (g) | 0.1 | 0.07 | 13.63 | |

| EDDHA chelat (6% Fe) (g) | 0.06 | 0.1 | 14.94 | |

| B | Monopotassium phosphate (MKP—22.8% P, 28.7% K) (kg) | 1.8 | 1.5 | 267.61 |

| Potassium nitrate (K—13.4 N%, 38.2 K) (kg) | 2.0 | 2.5 | 406.01 | |

| Potassium sulfate (K—41.5%, 18% S) (kg) | 0.2 | 0.5 | 73.20 | |

| Magnesium sulfate (9.8% Mg, 13% S) (kg) | 2.5 | 1.5 | 296.69 | |

| Manganese chelate EDTA (13% Mn) (g) | 0.025 | 0.02 | 3.62 | |

| Manganese sulfate (32% Mn) (g) | 0.020 | 0.022 | 3.54 | |

| Zinc sulfate (23% Zn) (g) | 0.019 | 0.017 | 2.98 | |

| Copper sulfate (25.5% Cu) (g) | 0.0045 | 0.0045 | 0.77 | |

| Borax (11.3% B) (g) | 0.011 | 0.012 | 2.00 | |

| Sodium molybdate (40% Mo) (g) | 0.001 | 0.001 | 0.17 | |

| Date of Procedure | Repellent | Dose [kg or L/ha] | Amount of Water Used [L/ha] | Active Substance | Amount of Active Substance per ha | CO2 Equivalent [kg/kg] | CO2 Equivalent [kg/ha] |

|---|---|---|---|---|---|---|---|

| 13.05 | KristaLeaf Foto | 3 kg | 1000 | 14.2% N; 1.5% P2O5; 7% K2O; | 0.426 kg N; 0.045 kg P2O5; 0.21 kg K2O; | N—1.3 P2O5—0.2 K2O—0.15 | 0.5943 |

| 06.06 | Koromite 10 EC | 1.25 L | 750 |

Milbemektyna

9.3 g/L | 11.63 g 0.0116 kg | 5.10 | 0.059 |

| 10.06 | Pyrus 400 SC | 2 L | 1000 | Pirymetanil—400 g/L (34.3%) | 800 g 0.8 kg | 3.9 | 3.12 |

| 16.06 | Kobe 20 SP | 0.2 kg | 500 | Acetamipryd—200 g/kg (20%) | 40 g/ha 0.04 kg/ha | 15.10 | 0.604 |

| 20.06 | Decis Mega 50EW | 0.25 L | 500 | Deltametryna 50 g/L (4.8%) | 12.5 g/ha 0.0125 kg | 11.70 | 0.1463 |

| 19.07 | Safran 018 EC | 0.5 L | 700 | Abamektyna: 18 g/L | 9 g/ha 0.009 L | 5.10 | 0.459 |

| 17.08 07.09 11.10 | Polyversum WP | 0.6 kg | 2100 | Pythium oligandrum: 106 w 1 g | 0.6 kg/ha | 3.9 | 2.34 |

| 26.08 | Serenade ASO | 8 L | 750 | Bacillus subtilis QST 713—13.96 g/L (1.34%) | 111.68 g 0.1117 kg/ha | 3.9 | 0.436 |

| 23.09 | Julietta | 1000 | Saccharomyces cerevisiae LAS02—961 g/kg (96.1%) | 2.4025 kg/ha | 3.9 | 9.3698 |

| Fertilizer | Emission Coefficient [CO2-eq/kg *] | Amount [kg/ha] | Emission Volume [CO2-eq/ha] | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CF1 | CF2 | CF1B | CF2B | CF1I | CF2I | CF1B + I | CF2B + I | CF1 | CF2 | CF1B | CF2B | CF1I | CF2I | CF1B + I | CF2B + I | ||

| Calcium nitrate | 3.3 | 1247 | 1058 | 1064 | 961 | 979 | 903 | 874 | 835 | 4116 | 3492 | 3512 | 3171 | 3231 | 2982 | 2885 | 2757 |

| Ammonium nitrate | 7.99 | 32.0 | 27.0 | 27.2 | 24.5 | 25 | 23.1 | 22,3 | 21.3 | 254 | 215 | 217 | 196 | 199 | 184 | 178 | 170 |

| Magnesium nitrate | 2.8 | 348 | 295 | 297 | 268 | 273 | 252 | 244 | 233 | 975 | 827 | 831 | 751 | 765 | 706 | 683 | 653 |

| Potassium nitrate | 2.9 | 1311 | 1112 | 1119 | 1010 | 1029 | 950 | 919 | 878 | 3803 | 3227 | 3245 | 2930 | 2985 | 2756 | 2666 | 2548 |

| Iron chelate DTPA | 1.55 | 25.7 | 21.8 | 21.9 | 19.8 | 20.1 | 18.6 | 18 | 17.2 | 39.8 | 33.7 | 33.9 | 30.6 | 31.2 | 28.8 | 27.9 | 26.6 |

| Iron chelate EDDHA | 1.55 | 30.2 | 25.6 | 25.8 | 23.3 | 23.7 | 21.9 | 21.2 | 20.2 | 46.8 | 39.7 | 39.9 | 36.0 | 36.7 | 33.9 | 32.9 | 31.3 |

| Potassium phosphate (I) | 0.4 | 522 | 443 | 445 | 402 | 410 | 378 | 366 | 350 | 208 | 177 | 178 | 161 | 164 | 151 | 146 | 139 |

| Potassium sulfate | 0.12 | 156 | 132 | 133 | 120 | 122 | 113 | 109 | 104 | 18.8 | 15.9 | 16.0 | 14.5 | 14.7 | 13.6 | 13.2 | 12.6 |

| Magnesium sulfate | 0.3 | 554 | 470 | 472 | 427 | 435 | 401 | 388 | 371 | 166 | 141 | 141 | 128 | 130 | 120 | 116 | 111 |

| Manganese chelate | 2.0 | 6.86 | 5.82 | 5.85 | 5.29 | 5.39 | 4.97 | 4.81 | 4.60 | 13.7 | 11.6 | 11.7 | 10.6 | 10.8 | 9.94 | 9.62 | 9.19 |

| Zinc sulfate | 3.8 | 5.87 | 4.98 | 5.01 | 4.52 | 4.61 | 4.25 | 4.12 | 3.93 | 18.9 | 19.0 | 17.2 | 17.5 | 16.2 | 15.6 | 14.9 | 18.9 |

| Copper sulfate | 3.8 | 1.54 | 1.30 | 1.31 | 1.18 | 1.21 | 1.11 | 1.08 | 1.03 | 5.84 | 4.95 | 4.98 | 4.49 | 4.58 | 4.23 | 4.09 | 3.91 |

| Sodium tetraborate | 4.0 | 4.06 | 3.45 | 3.47 | 3.13 | 3.19 | 2.94 | 2.85 | 2.72 | 16.2 | 13.8 | 13.9 | 12.5 | 12.8 | 11.8 | 11.4 | 10.9 |

| Sodium molybdate | 4.0 | 0.34 | 0.289 | 0.29 | 0.262 | 0.267 | 0.247 | 0.238 | 0.228 | 1.36 | 1.15 | 1.16 | 1.04 | 1.07 | 0.99 | 0.95 | 0.91 |

| Sum | 9683 | 8218 | 8262 | 7464 | 7602 | 7017 | 6788 | 6492 | |||||||||

| Type of Action | Functional Unit | Fuel Consumption [dm3] | Energy Consumption [MJ] | CO2 Emission [kg] |

|---|---|---|---|---|

| Transport of the tunnel elements | ha | 1024 | 41,400 | 3966 |

| Tunnel construction | 2541 | 102,733 | 9840 | |

| Tunnel construction | kWh/Mg | 480,000 | 44,184 |

| Material Used | Operation Time [Years] | Amount of Material Used kg/ha | Emission Coefficient [kg CO2-eq/kg] | GHG Emission [kg CO2-eq/ha/year] |

|---|---|---|---|---|

| Foil | 4 | 1875 | 1.83 | 1125 |

| Steel | 25 | 288,000 | 2.40 | 21,081 |

| Object | GHG Emission [kg CO2-eq/ha] | GHG Emission [kg CO2-eq/kg of Yield] |

|---|---|---|

| CF1 | 87,629 | 4.889 ab* |

| CF1B | 83,381 | 4.572 bc |

| CF1I | 81,504 | 5.202 a |

| CF1B + I | 79,067 | 4.356 cd |

| CF2 | 83,273 | 4.609 bc |

| CF2B | 80,862 | 4.318 cd |

| CF2I | 79,781 | 4.890 ab |

| CF2B + I | 78,039 | 3.891 d |

| Object/ Substrate | Emission Coefficient from Substrate Production [g CO2/kg Substrate] | Mass of Substrate [t/ha] | GHG Emission [kg CO2-eq/ha] | GHG Emission [kg CO2-eq/ha/rok] | GHG Emission [kg CO2-eq/kg of Yield] |

|---|---|---|---|---|---|

| CF1 | 362 | 6.989 | 2529.9 | 843.3 | 0.047 bc* |

| CF1B | 328.3 | 8.600 | 2823.2 | 941.1 | 0.052 bc |

| CF1I | 342.8 | 8.709 | 2985.3 | 995.1 | 0.063 a |

| CF1B + I | 309.1 | 10.729 | 3316.3 | 1105.4 | 0.061 a |

| CF2 | 362 | 7.917 | 2866.0 | 955.3 | 0.053 b |

| CF2B | 328.3 | 7.917 | 2599.2 | 866.4 | 0.046 c |

| CF2I | 340.0 | 9.637 | 3276.8 | 1092.3 | 0.067 a |

| CF2B + I | 256.8 | 11.957 | 3070.5 | 1023.5 | 0.051 bc |

| Object | Amount of Water Used [m3/ha] | Amount of Energy Used [kWh/ha] | Emission Coefficient [CO2-eq/unit] | GHG Emission [CO2-eq/ha] | GHG Emission [kg CO2-eq/kg of Yield] |

|---|---|---|---|---|---|

| CF1 | 2744 | 5487 | 0.9245 | 5073 | 0.283 a* |

| CF1B | 2341 | 4655 | 4304 | 0.237 bc | |

| CF1I | 2154 | 4675 | 4322 | 0.254 ab | |

| CF1B + I | 1923 | 4227 | 3908 | 0.196 de | |

| CF2 | 2328 | 4307 | 3982 | 0.238 bc | |

| CF2B | 2114 | 3975 | 3675 | 0.209 cd | |

| CF2I | 1988 | 3845 | 3555 | 0.225 bcd | |

| CF2B + I | 1838 | 3676 | 3398 | 0.170 e |

| Object | Emissions from Fertilizer Production [CO2-eq/ha] | Indirect Emissions from Nitrogen Oxides [CO2-eq/ha] | Emissions from Nitrogen in Leachate [CO2-eq/ha] | GHG Emissions from Fertilization [CO2-eq/ha] | GHG Emissions from Fertilization [CO2-eq/kg of Yield] |

|---|---|---|---|---|---|

| CF1 | 9695 | 10,893 | 2109 | 22,698 | 1.266 a* |

| CF1B | 8271 | 9293 | 1533 | 19,098 | 1.046 bc |

| CF1I | 7611 | 8551 | 1350 | 17,512 | 1.119 ab |

| CF1B + I | 6795 | 7634 | 964 | 15,393 | 0.848 de |

| CF2 | 8226 | 9242 | 1532 | 19,000 | 1.051 bc |

| CF2B | 7469 | 8392 | 1212 | 17,074 | 0.911 cd |

| CF2I | 7024 | 7892 | 1083 | 15,999 | 0.981 bcd |

| CF2B + I | 6494 | 7297 | 813 | 14,603 | 0.728 e |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Komorowska, M.; Kuboń, M.; Niemiec, M.; Tora, J.; Okręglicka, M.; Wongkaew, A. Sustainable Strategies for Raspberry Production: Greenhouse Gas Mitigation Through Biodegradable Substrate Additives in High Tunnels. Sustainability 2025, 17, 8740. https://doi.org/10.3390/su17198740

Komorowska M, Kuboń M, Niemiec M, Tora J, Okręglicka M, Wongkaew A. Sustainable Strategies for Raspberry Production: Greenhouse Gas Mitigation Through Biodegradable Substrate Additives in High Tunnels. Sustainability. 2025; 17(19):8740. https://doi.org/10.3390/su17198740

Chicago/Turabian StyleKomorowska, Monika, Maciej Kuboń, Marcin Niemiec, Justyna Tora, Małgorzata Okręglicka, and Arunee Wongkaew. 2025. "Sustainable Strategies for Raspberry Production: Greenhouse Gas Mitigation Through Biodegradable Substrate Additives in High Tunnels" Sustainability 17, no. 19: 8740. https://doi.org/10.3390/su17198740

APA StyleKomorowska, M., Kuboń, M., Niemiec, M., Tora, J., Okręglicka, M., & Wongkaew, A. (2025). Sustainable Strategies for Raspberry Production: Greenhouse Gas Mitigation Through Biodegradable Substrate Additives in High Tunnels. Sustainability, 17(19), 8740. https://doi.org/10.3390/su17198740