Towards Sustainable Greenhouse Design: A Numerical Study on Temperature Control in Multi-Span Hoop Structures

Abstract

1. Introduction

1.1. Shape

1.2. Cladding Material

1.3. Ventilation

1.4. Spans

2. Materials and Methods

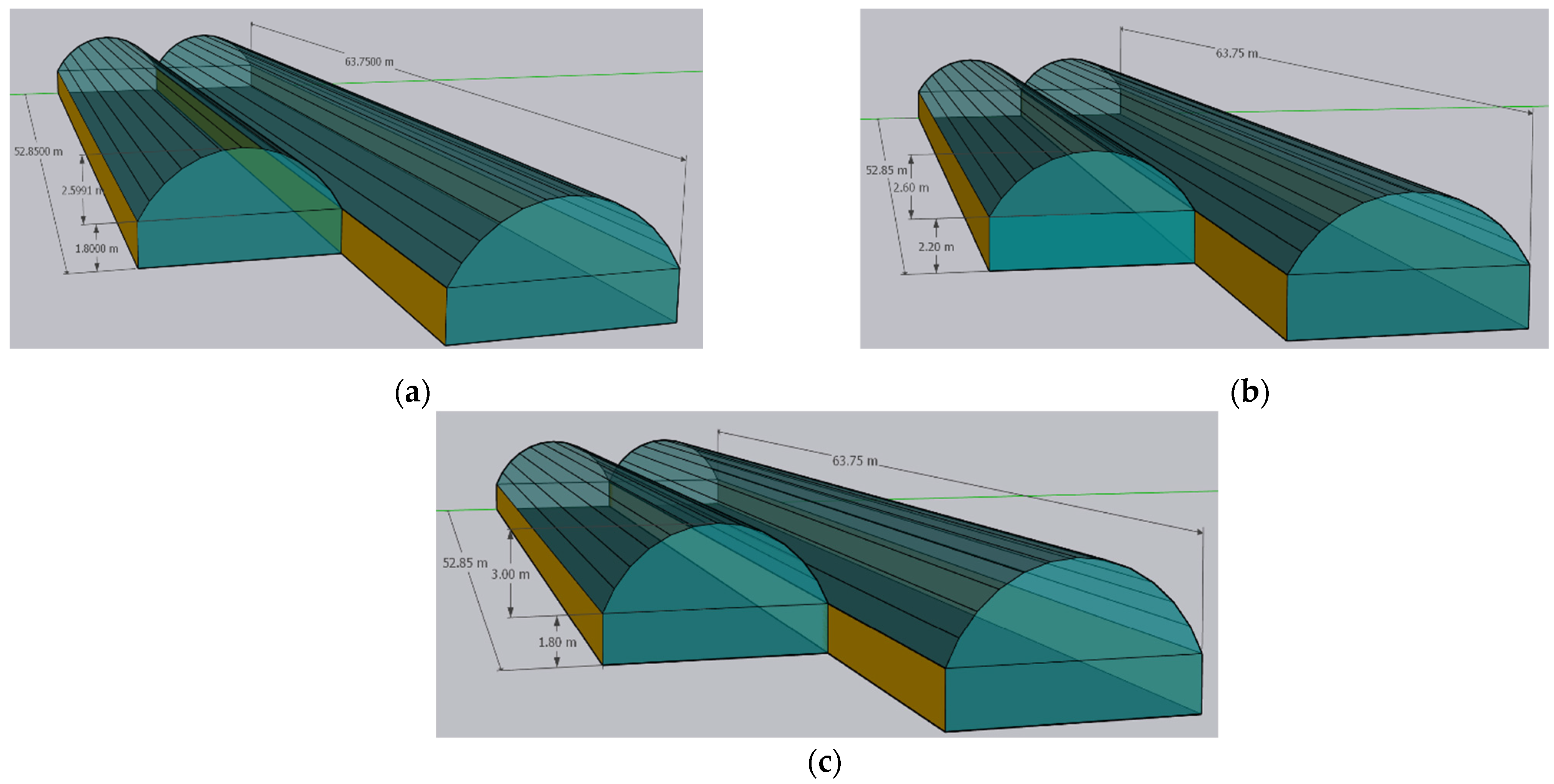

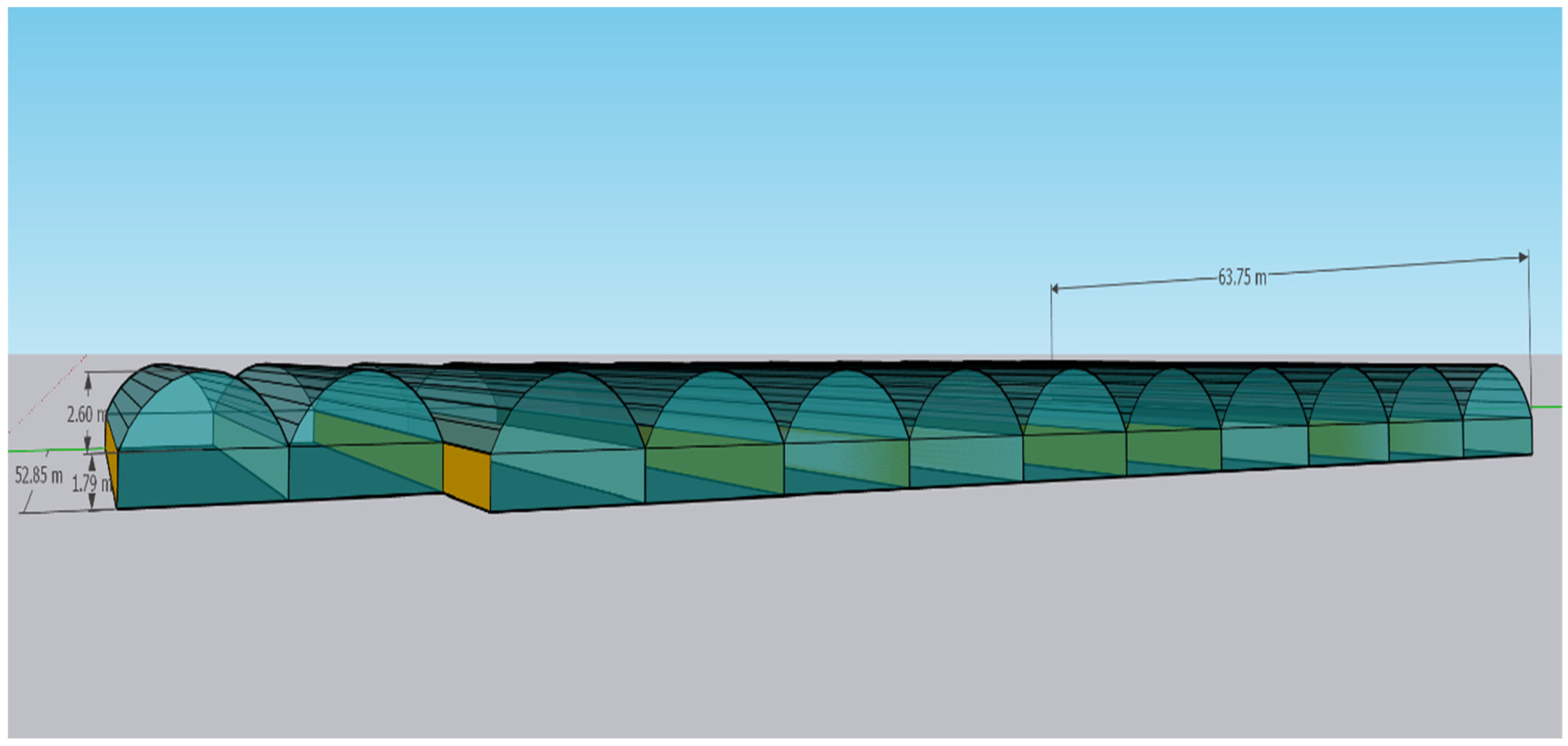

2.1. Greenhouse Structure and Design

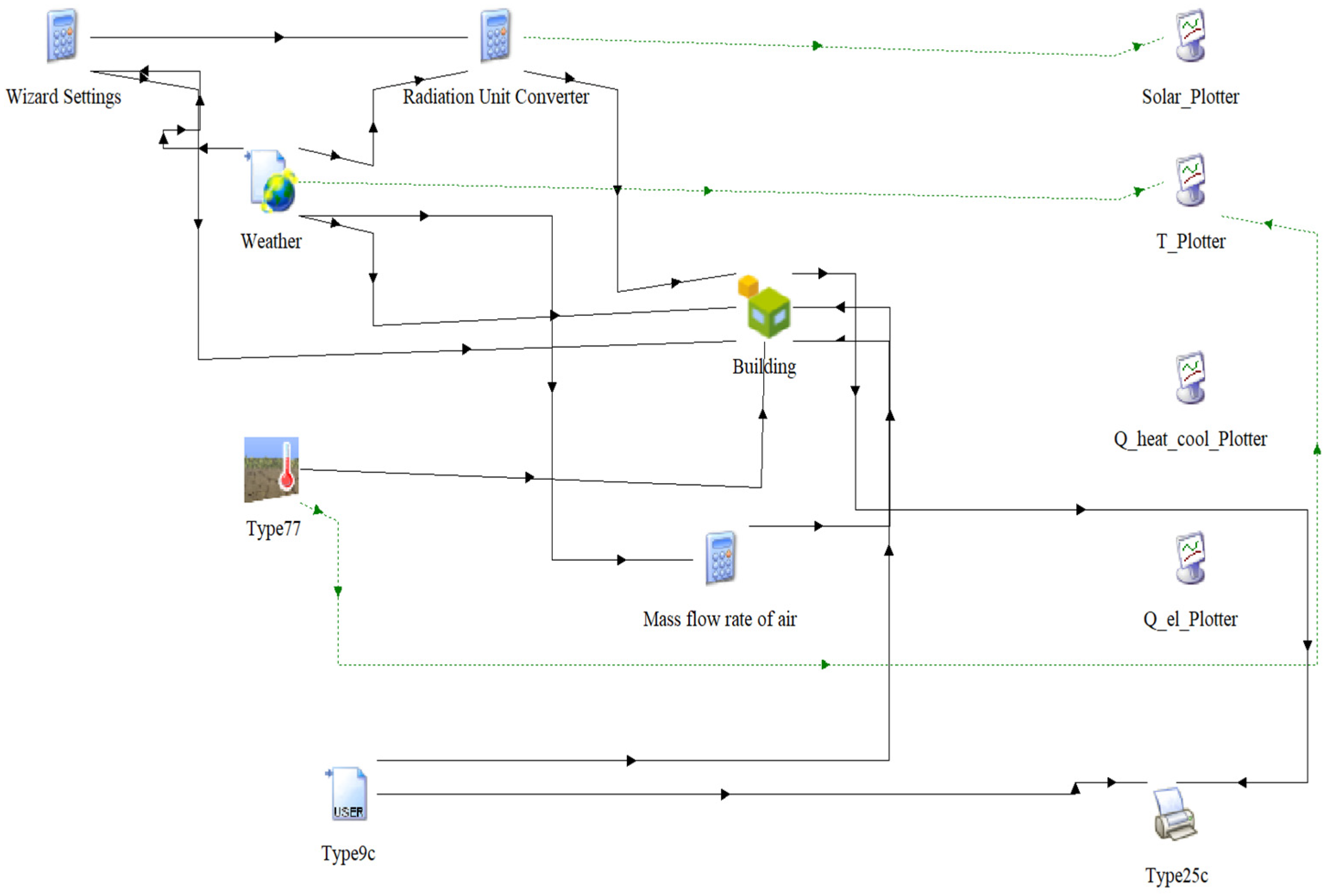

2.2. TRNSYSModel

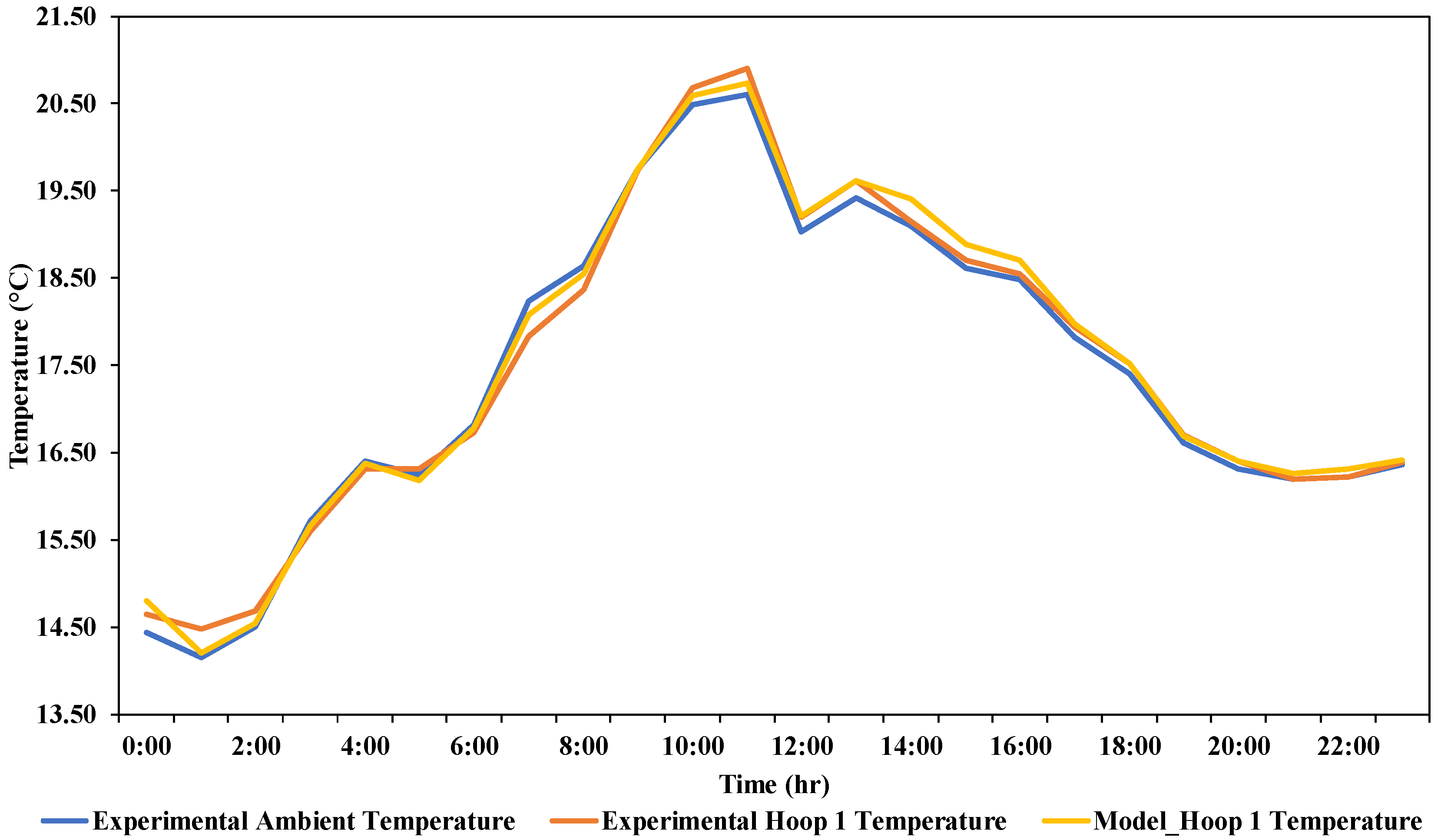

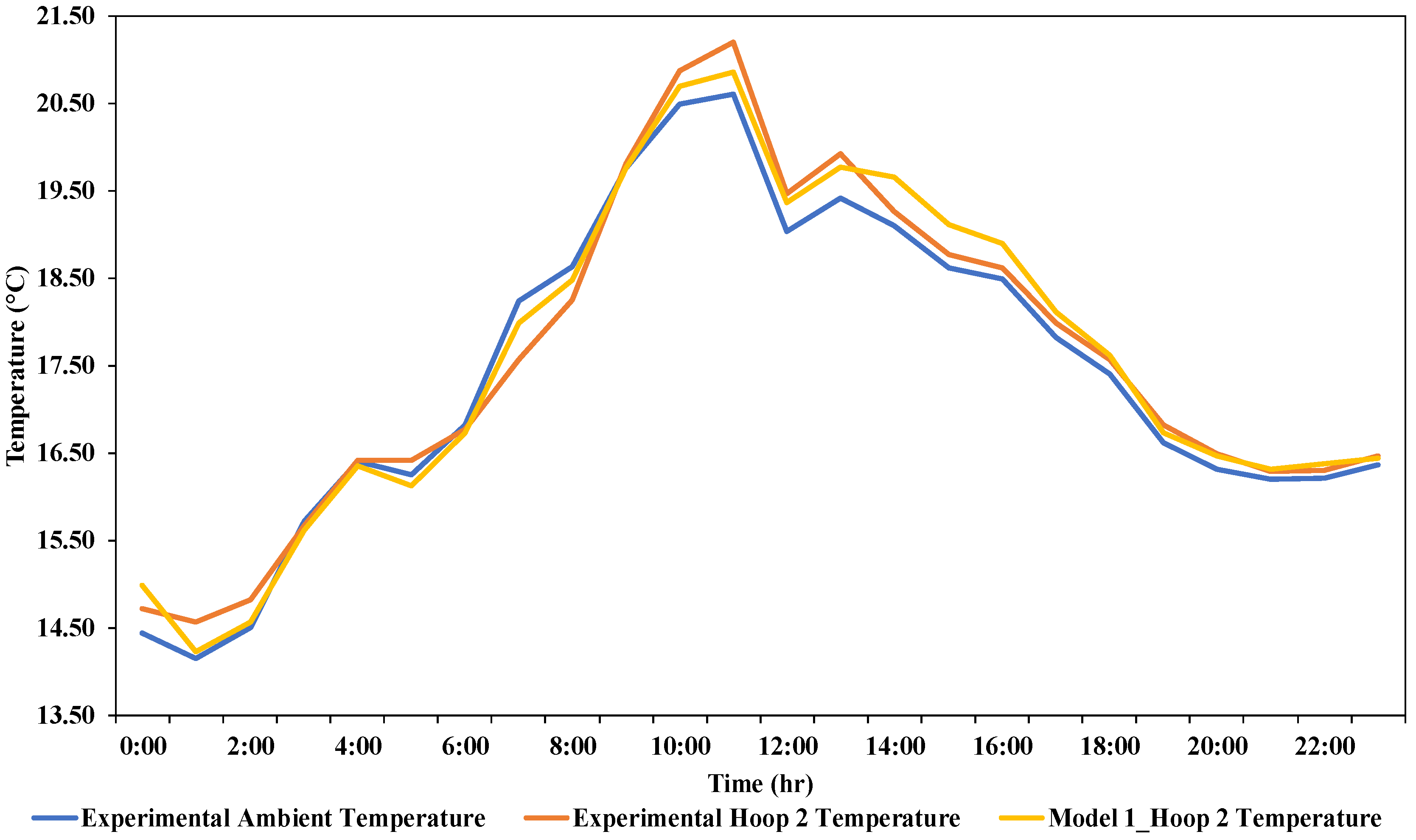

3. Model Validation

Error Analysis

4. Results and Discussion

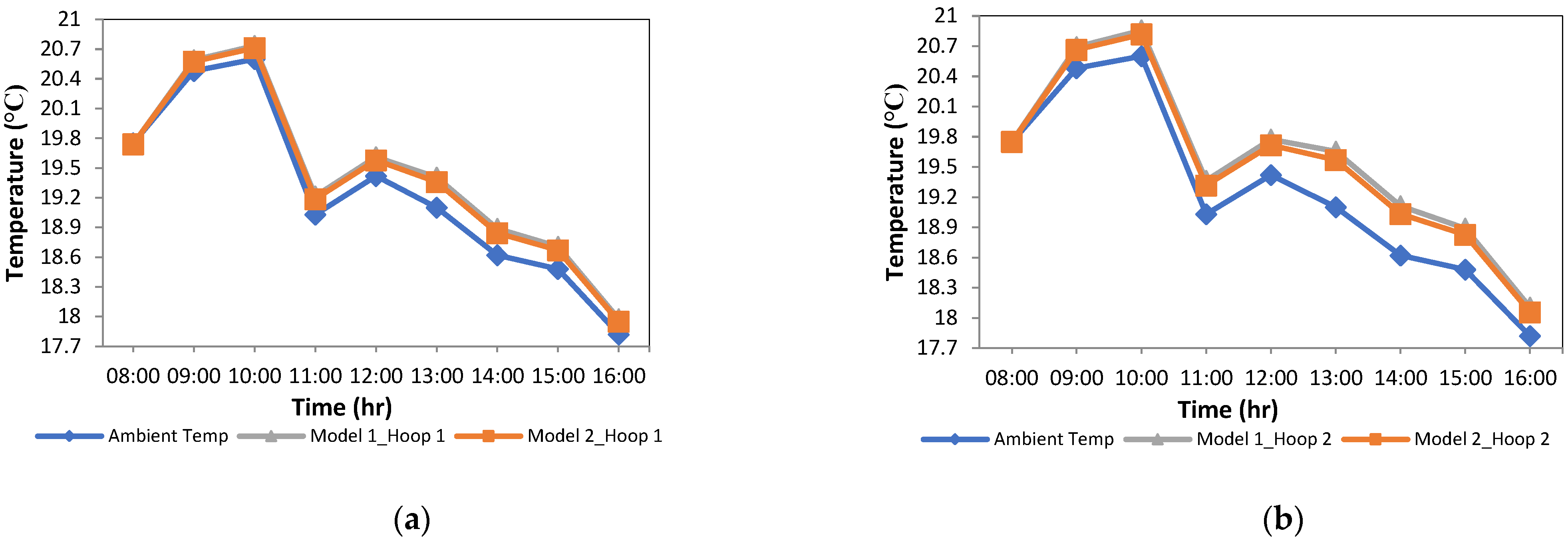

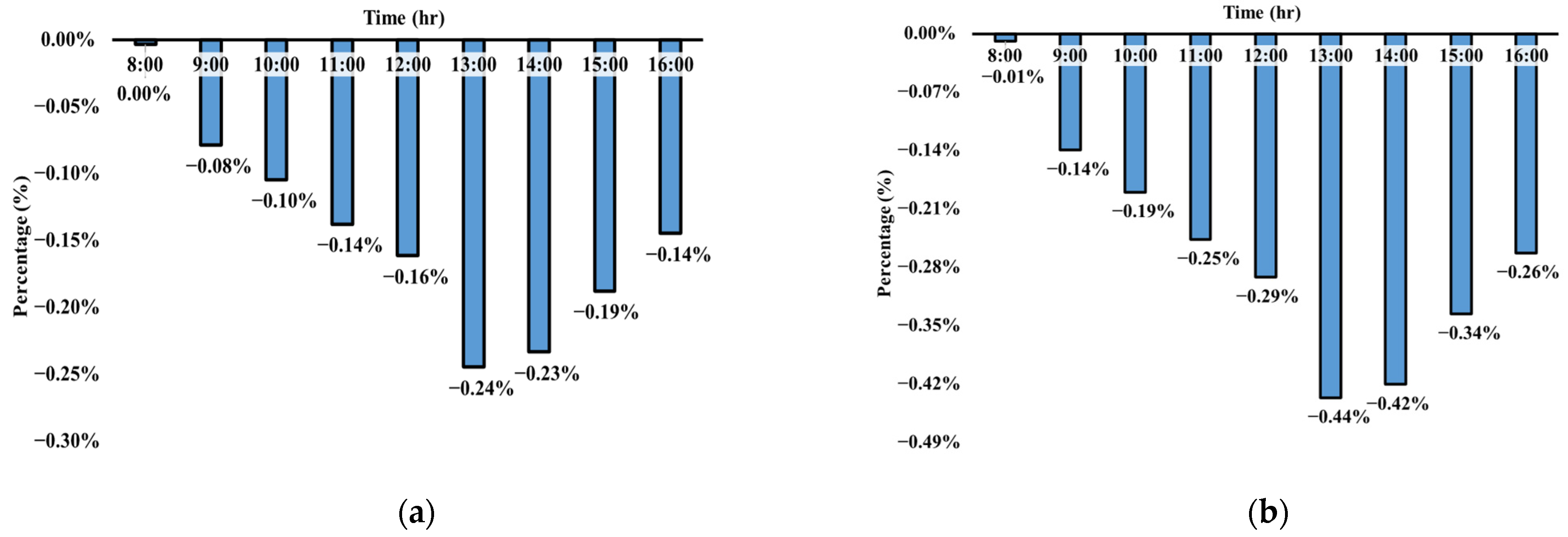

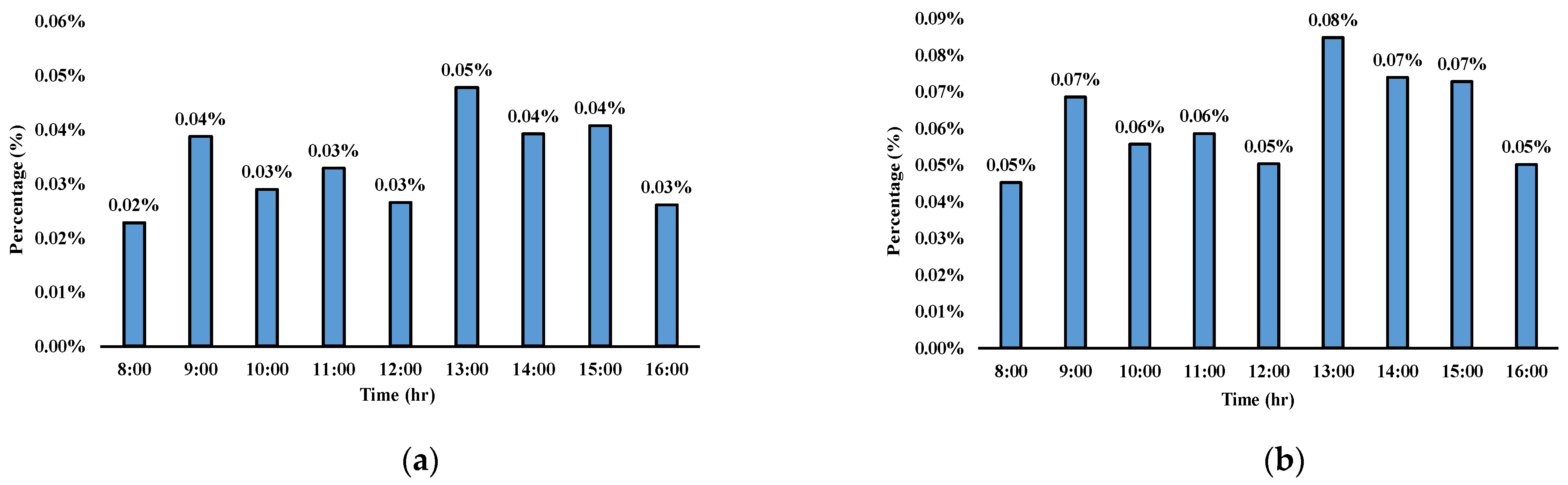

4.1. Greenhouse Height Increment

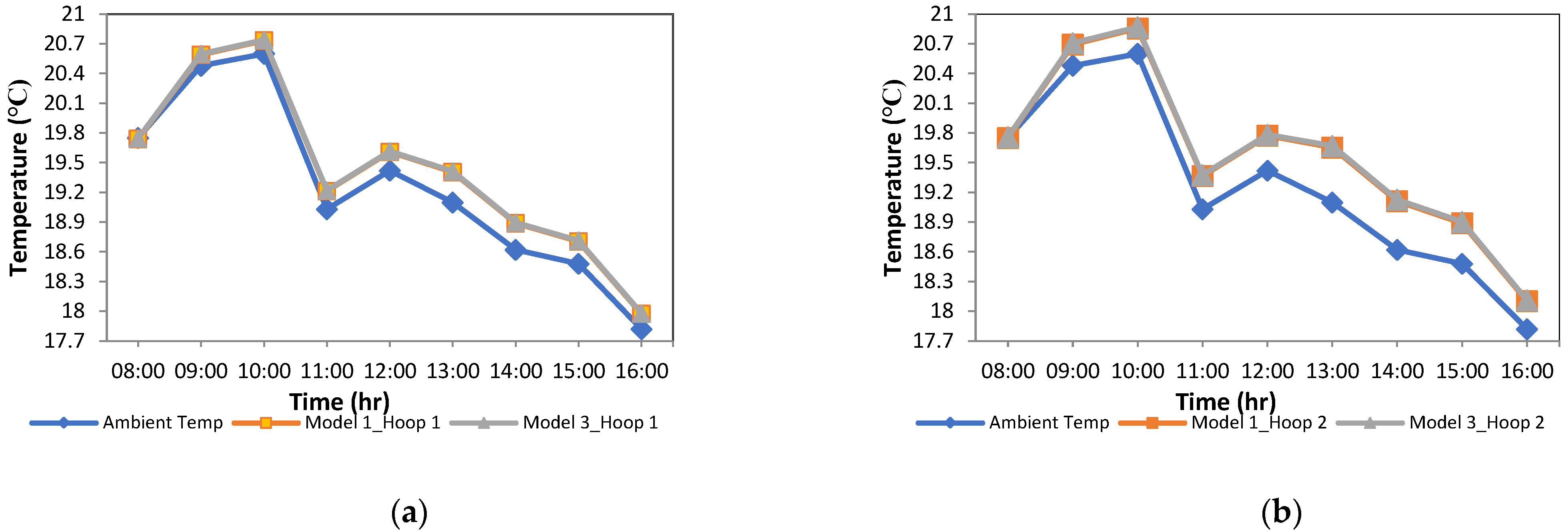

4.2. Greenhouse Arch Height Increment

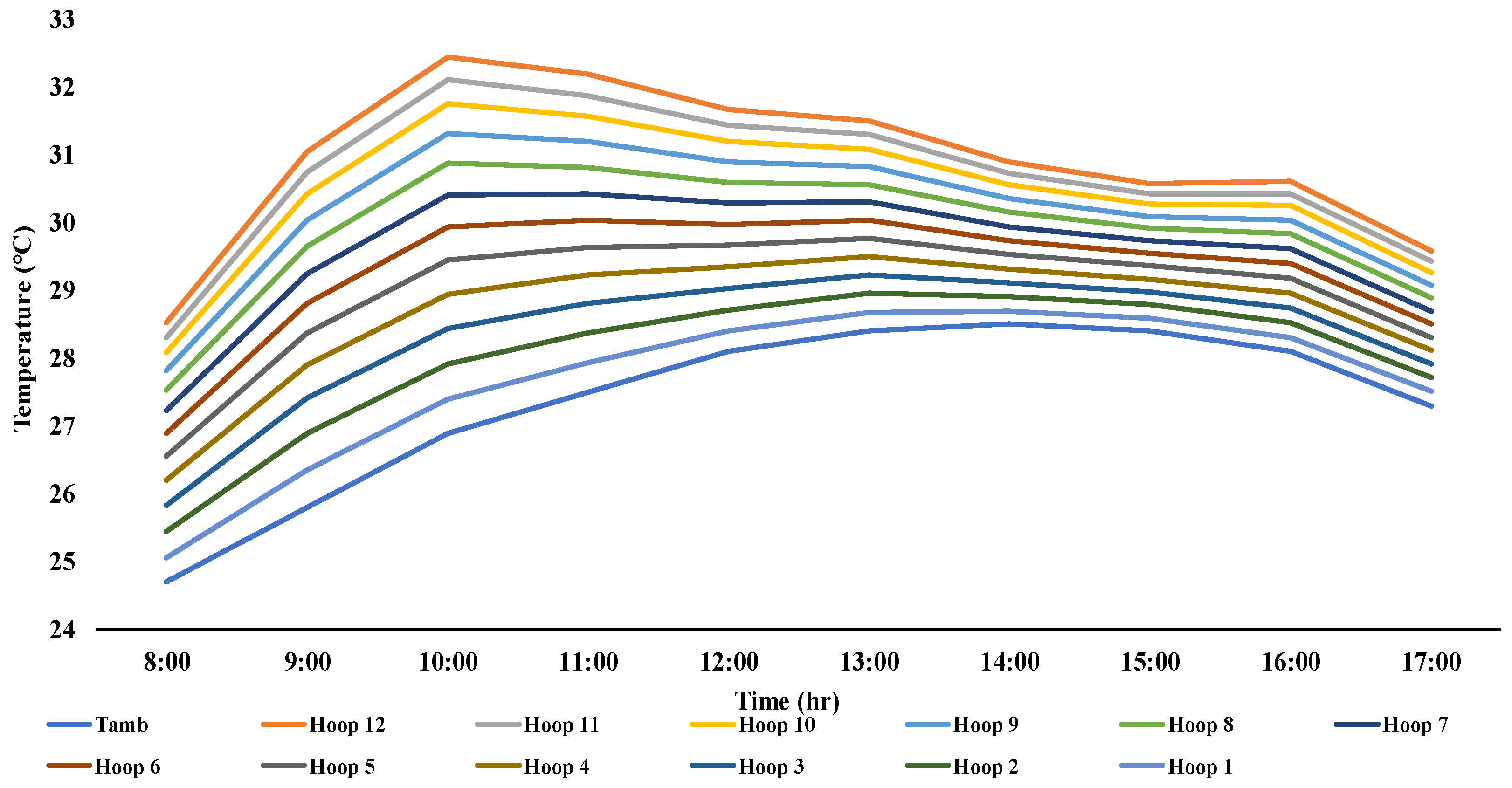

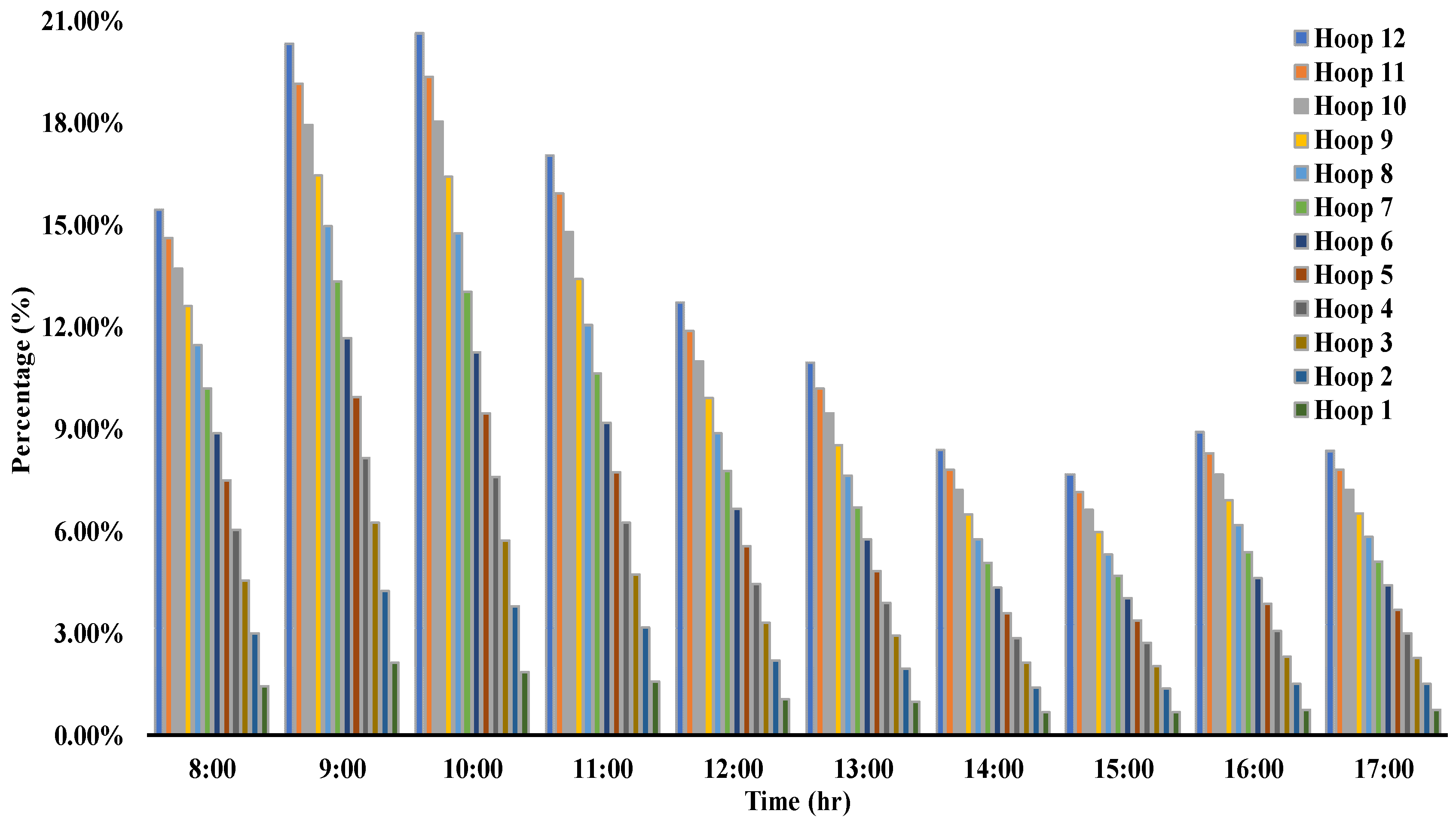

4.3. Greenhouse with Increased Span Numbers

5. Conclusions

- The investigation showed that when the height of the greenhouse structure was increased by 0.40 m from the Model 1 design to the Model 2 design of the greenhouse structure, the maximum decrease in temperature was 0.39% and 0.62% for Hoop 1 and Hoop 2 structures, respectively.

- The results showed that upon increasing the arch height of the greenhouse structure from Model 1 to Model 3 by 0.40 m, the temperature inside the hoop structures 1 and 2 increased by 0.09% and 0.15%, respectively. This rise in temperature was caused by the increase in solar radiation transmittance and heat accumulation due to the arch height increment.

- The study showed that the increase in span numbers in a greenhouse from 2 to 12, had a significant increase in temperature inside the hoop structures. This temperature difference inside the hoop structures is observed in the comparison of Model 1 and Model 4 designs. The Model 4 design showed that the maximum temperature difference between Hoop 1 and Hoop 12 structure was 17 °C.

- The findings from the study identify that increasing the span numbers of a multi-span greenhouse has a significant effect on the temperature levels of the hoop structures. Therefore, introducing ventilation could be a suitable solution to maintain the temperature inside the hoop structures at the required levels.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| PAR | Photosynthetically Active Radiation |

| TPE | Thermal polyethylene |

| PVC | polyvinylchloride |

| 3L | Three layers |

| EVA | Ethylene vinyl acetate |

| UV | ultraviolet |

| IR | infrared |

| RMS | Root mean square |

References

- Angioni, A.; Porcu, L.; Dedola, F. Determination of famoxadone, fenamidone, fenhexamid and iprodione residues in greenhouse tomatoes. Pest Manag. Sci. 2012, 68, 543–547. [Google Scholar] [CrossRef]

- Jin, C.; Mao, H.; Chen, Y.; Shi, Q.; Wang, Q.; Ma, G.; Liu, Y. Engineering-oriented dynamic optimal control of a greenhouse environment using an improved genetic algorithm with engineering constraint rules. Comput. Electron. Agric. 2020, 177, 105698. [Google Scholar] [CrossRef]

- Sabir, N.; Singh, B. Protected cultivation of vegetables in global arena: A review. Indian J. Agric. Sci. 2013, 83, 123–135. [Google Scholar]

- Shamshiri, R.R.; Jones, J.W.; Thorp, K.R.; Ahmad, D.; Man, H.C.; Taheri, S. Review of optimum temperature, humidity, and vapour pressure deficit for microclimate evaluation and control in greenhouse cultivation of tomato: A review. Int. Agrophys. 2018, 32, 287–302. [Google Scholar] [CrossRef]

- Bo, Y.; Zhang, Y.; Zheng, K.; Zhang, J.; Wang, X.; Sun, J.; Wang, J.; Shu, S.; Wang, Y.; Guo, S. Light environment simulation for a three-span plastic greenhouse based on greenhouse light environment simulation software. Energy 2023, 271, 126966. [Google Scholar] [CrossRef]

- Benni, S.; Tassinari, P.; Bonora, F.; Barbaresi, A.; Torreggiani, D. Efficacy of greenhouse natural ventilation: Environmental monitoring and CFD simulations of a study case. Energy Build. 2016, 125, 276–286. [Google Scholar] [CrossRef]

- Cemek, B.; Demir, Y.; Uzun, S.; Ceyhan, V. The effects of different greenhouse covering materials on energy requirement, growth and yield of aubergine. Energy 2006, 31, 1780–1788. [Google Scholar] [CrossRef]

- Choab, N.; Allouhi, A.; El Maakoul, A.; Kousksou, T.; Saadeddine, S.; Jamil, A. Review on greenhouse microclimate and application: Design parameters, thermal modeling and simulation, climate controlling technologies. Sol. Energy 2019, 191, 109–137. [Google Scholar] [CrossRef]

- Gupta, M.J.; Chandra, P. Effect of greenhouse design parameters on conservation of energy for greenhouse environmental control. Energy 2002, 27, 777–794. [Google Scholar] [CrossRef]

- Maraveas, C.; Karavas, C.-S.; Loukatos, D.; Bartzanas, T.; Arvanitis, K.G.; Symeonaki, E. Agricultural greenhouses: Resource management technologies and perspectives for zero greenhouse gas emissions. Agric. For. 2023, 13, 1464. [Google Scholar] [CrossRef]

- Singh, M.C.; Singh, J.P.; Singh, K.G. Development of a microclimate model for prediction of temperatures inside a naturally ventilated greenhouse under cucumber crop in soilless media. Comput. Electron. Agric. 2018, 154, 227–238. [Google Scholar] [CrossRef]

- Singh, R.; Bhagoria, J.; Narayanan, R. Experimental Analysis of Thermo-Hydraulic Performance of Quadratic Duct with Artificial Roughness on a Single Broad Heated Surface of the Absorber Plate of Solar Air Heater. Case Stud. Therm. Eng. 2025, 72, 106415. [Google Scholar] [CrossRef]

- Achour, Y.; Ouammi, A.; Zejli, D. Technological progresses in modern sustainable greenhouses cultivation as the path towards precision agriculture. Renew. Sustain. Energy Rev. 2021, 147, 111251. [Google Scholar] [CrossRef]

- Allali, F.E.; Fatnassi, H.; Demrati, H.; Molina-Aiz, F.D.; Gourdo, L.; Errami, Y.; Wifaya, A.; Aharoune, A. CFD-based optimization of direct evaporative cooling systems for Canarian greenhouses in semi-arid regions. Energy Build. 2024, 323, 114767. [Google Scholar] [CrossRef]

- Hosny, K.M.; El-Hady, W.M.; Samy, F.M. Technologies, protocols, and applications of Internet of Things in greenhouse farming: A survey of recent advances. Inf. Process. Agric. 2024, 12, 91–111. [Google Scholar] [CrossRef]

- Johnston, N.L.; Narayanan, N.R.; Moola, N.M.R. CFD investigation on key design parameters of a Hoop-Type greenhouse. CFD Lett. 2023, 15, 59–66. [Google Scholar] [CrossRef]

- Brækken, A.; Sannan, S.; Jerca, I.O.; Bădulescu, L.A. Assessment of heating and cooling demands of a glass greenhouse in Bucharest, Romania. Therm. Sci. Eng. Prog. 2023, 41, 101830. [Google Scholar] [CrossRef]

- Alshenaifi, M.A.; Sharples, S.; Abuhussain, M.A.; Alotaibi, B.S.; Aldersoni, A.A.; Abdelhafez, M.H.H. Integrating a passive downdraught evaporative cooling tower into a Saudi house—The impact of climatic conditions on PDEC performance. Build. Environ. 2023, 242, 110497. [Google Scholar] [CrossRef]

- Muhie, S.H. Novel approaches and practices to sustainable agriculture. J. Agric. Food Res. 2022, 10, 100446. [Google Scholar] [CrossRef]

- Trepanier, M.-P.; Gosselin, L. Sensitivity analysis of lamp model parameters in energy and yield simulations of greenhouse. Biosyst. Eng. 2024, 239, 158–172. [Google Scholar] [CrossRef]

- Li, J.; Zhai, Z.; Li, H.; Ding, Y.; Chen, S. Climate change’s effects on the amount of energy used for cooling in hot, humid office buildings and the solutions. J. Clean. Prod. 2024, 442, 140967. [Google Scholar] [CrossRef]

- Carnie, J.-T.; Hardalupas, Y.; Sergis, A. Decarbonising building heating and cooling: Designing a novel, inter-seasonal latent heat storage system. Renew. Sustain. Energy Rev. 2024, 189, 113897. [Google Scholar] [CrossRef]

- Di Martino, M.; Namany, S.; Mahmood, F.; Al-Ansari, T.; Linke, P.; Pistikopoulos, E.N. Food-energy-water nexus considerations in optimal greenhouse farming systems design and operation. Appl. Energy 2025, 379, 124900. [Google Scholar] [CrossRef]

- Hosseini Monjezi, P.; Taki, M.; Abdanan Mehdizadeh, S.; Rohani, A.; Ahamed, M.S. Prediction of greenhouse indoor air temperature using artificial intelligence (AI) combined with sensitivity analysis. Horticulturae 2023, 9, 853. [Google Scholar] [CrossRef]

- Wu, H.; West, S.R. Co-optimisation of wind and solar energy and intermittency for renewable generator site selection. Heliyon 2024, 10, e26891. [Google Scholar] [CrossRef]

- Wang, H.; Xie, B.; Li, C. Review on operation control of cold thermal energy storage in cooling systems. Energy Built Environ. 2025, 6, 509–523. [Google Scholar] [CrossRef]

- Castro, R.; Silva, P.; Pires, L. Advances in solutions to improve the energy performance of agricultural greenhouses: A comprehensive review. Appl. Sci. 2024, 14, 6158. [Google Scholar] [CrossRef]

- Narayanan, R.; Parthkumar, P.; Pippia, R. Solar energy utilisation in Australian homes: A case study. Case Stud. Therm. Eng. 2021, 28, 101603. [Google Scholar] [CrossRef]

- Sedaghat, A.; Kalbasi, R.; Narayanan, R.; Mehdizadeh, A.; Soleimani, S.M.; Malayer, M.A.; Al-Khiami, M.I.; Salem, H.; Hussam, W.K.; Sabati, M.; et al. Integrating solar PV systems for energy efficiency in portable cabins: A case study in Kuwait. Sol. Energy 2024, 277, 112715. [Google Scholar] [CrossRef]

- Sethi, V.P. On the selection of shape and orientation of a greenhouse: Thermal modeling and experimental validation. Sol. Energy 2009, 83, 21–38. [Google Scholar] [CrossRef]

- Çakır, U.; Şahin, E. Using solar greenhouses in cold climates and evaluating optimum type according to sizing, position and location: A case study. Comput. Electron. Agric. 2015, 117, 245–257. [Google Scholar] [CrossRef]

- Sun, W.; Wei, X.; Zhou, B.; Lu, C.; Guo, W. Greenhouse heating by energy transfer between greenhouses: System design and implementation. Appl. Energy 2022, 325, 119815. [Google Scholar] [CrossRef]

- Baxevanou, C.; Fidaros, D.; Bartzanas, T.; Kittas, C. Yearly numerical evaluation of greenhouse cover materials. Comput. Electron. Agric. 2018, 149, 54–70. [Google Scholar] [CrossRef]

- Geoola, F.; Kashti, Y.; Levi, A.; Brickman, R. Quality evaluation of anti-drop properties of greenhouse cladding materials. Polym. Test. 2004, 23, 755–761. [Google Scholar] [CrossRef]

- Cemek, B.; Demir, Y. Testing of the condensation characteristics and light transmissions of different plastic film covering materials. Polym. Test. 2005, 24, 284–289. [Google Scholar] [CrossRef]

- Babaghayou, M.; Mourad, A.-H.I.; Lorenzo, V.; Chabira, S.; Sebaa, M. Anisotropy evolution of low density polyethylene greenhouse covering films during their service life. Polym. Test. 2018, 66, 146–154. [Google Scholar] [CrossRef]

- Seven, S.A.; Tastan, Ö.F.; Tas, C.E.; Ünal, H.; Ince, İ.A.; Menceloglu, Y.Z. Insecticide-releasing LLDPE films as greenhouse cover materials. Mater. Today Commun. 2019, 19, 170–176. [Google Scholar] [CrossRef]

- Guo, Y.; Zhao, H.; Zhang, S.; Wang, Y.; Chow, D. Modeling and optimization of environment in agricultural greenhouses for improving cleaner and sustainable crop production. J. Clean. Prod. 2021, 285, 124843. [Google Scholar] [CrossRef]

- Briscoe, B.J.; Galvin, K.P. The effect of surface fog on the transmittance of light. Sol. Energy 1991, 46, 191–197. [Google Scholar] [CrossRef]

- Taki, M.; Rohani, A.; Rahmati-Joneidabad, M. Solar thermal simulation and applications in greenhouse. Inf. Process. Agric. 2018, 5, 83–113. [Google Scholar] [CrossRef]

- Gruda, N.; Bisbis, M.; Tanny, J. Impacts of protected vegetable cultivation on climate change and adaptation strategies for cleaner production–a review. J. Clean. Prod. 2019, 225, 324–339. [Google Scholar] [CrossRef]

- McCartney, L.; Orsat, V.; Lefsrud, M.G. An experimental study of the cooling performance and airflow patterns in a model Natural Ventilation Augmented Cooling (NVAC) greenhouse. Biosyst. Eng. 2018, 174, 173–189. [Google Scholar] [CrossRef]

- Li, A.; Huang, L.; Zhang, T. Field test and analysis of microclimate in naturally ventilated single-sloped greenhouses. Energy Build. 2017, 138, 479–489. [Google Scholar] [CrossRef]

- Espinoza, K.; Lopez, A.; Valera, D.L.; Molina-Aiz, F.D.; Torres, J.A.; Pena, A. Effects of ventilator configuration on the flow pattern of a naturally-ventilated three-span Mediterranean greenhouse. Biosyst. Eng. 2017, 164, 13–30. [Google Scholar] [CrossRef]

- Kacira, M.; Sase, S.; Okushima, L. Effects of side vents and span numbers on wind-induced natural ventilation of a gothic multi-span greenhouse. Jpn. Agric. Res. Q. JARQ 2004, 38, 227–233. [Google Scholar] [CrossRef]

- Li, X.; Ma, J.; Zheng, L.; Chen, J.; Sun, X.; Guo, X. Optimization of the regulated deficit irrigation strategy for greenhouse tomato based on the fuzzy borda model. Agriculture 2022, 12, 324. [Google Scholar] [CrossRef]

- Baeza, E.J.; Pérez-Parra, J.J.; Montero, J.I.; Bailey, B.J.; López, J.C.; Gázquez, J.C. Analysis of the role of sidewall vents on buoyancy-driven natural ventilation in parral-type greenhouses with and without insect screens using computational fluid dynamics. Biosyst. Eng. 2009, 104, 86–96. [Google Scholar] [CrossRef]

- Asgari, N.; McDonald, M.T.; Pearce, J.M. Energy modeling and Techno-Economic feasibility analysis of greenhouses for tomato cultivation utilizing the waste heat of cryptocurrency miners. Energies 2023, 16, 1331. [Google Scholar] [CrossRef]

- Klein, S.A.; Beckman, W.A.; Mitchell, J.W.; Duffie, J.A.; Duffie, N.A.; Freeman, T.L.; Mitchell, J.C.; Braun, J.E.; Evans, B.L.; Kummer, J.P.; et al. TRNSYS 16—Mathematical Reference (Vol. 5). Available online: http://sel.me.wisc.edu/trnsys (accessed on 15 July 2020).

- Solar Energy Laboratory; Univ. of Wisconsin-Madison; TRANSSOLAR Energietechnik GmbH; CSTB—Centre Scientifique et Technique du Bâtiment; TESS—Thermal Energy System Specialists, LLC; TRANSSOLAR Energietechnik GmbH. TRNSYS 16—Multizone Building Modeling with Type56 and TRNBuild. In TRNSYS 16 (Vol. 6). Available online: https://sel.me.wisc.edu/trnsys/user18-resources/downloads/trnsys16-manuals.zip (accessed on 17 July 2020).

- Jarimi, H.; Bakar, M.N.A.; Othman, M.; Din, M.H. Bi-fluid photovoltaic/thermal (PV/T) solar collector: Experimental validation of a 2-D theoretical model. Renew. Energy 2016, 85, 1052–1067. [Google Scholar] [CrossRef]

- Tran, B.; Tseng, W.; Chen, C. Climate change impacts on crop yields across temperature rise thresholds and climate zones. Sci. Rep. 2025, 15, 23424. [Google Scholar] [CrossRef]

- Zhang, T.; He, Y.; DePauw, R.; Jin, Z.; Garvin, D.; Yue, X.; Anderson, W.; Li, T.; Dong, X.; Zhang, T.; et al. Climate change may outpace current wheat breeding yield improvements in North America. Nat. Commun. 2022, 13, 5591. [Google Scholar] [CrossRef] [PubMed]

- Fatnassi, H.; Boulard, T.; Benamara, H.; Roy, J.; Suay, R.; Poncet, C. Increasing the height and multiplying the number of spans of greenhouse: How far can we go? Acta Hortic. 2017, 1170, 137–144. [Google Scholar] [CrossRef]

- Kruger, S.; Pretorius, L. Evaluating the Effect of Number of Spans on Heat Transfer in Greenhouses. In Proceedings of the ASME 2019 International Mechanical Engineering Congress and Exposition, Salt Lake City, UT, USA, 11–14 November 2019. [Google Scholar] [CrossRef]

- He, K.; Chen, D.; Sun, L.; Liu, Z.; Huang, Z. The effect of vent openings on the microclimate inside multi-span greenhouses during summer and winter seasons. Eng. Appl. Comput. Fluid Mech. 2015, 9, 399–410. [Google Scholar] [CrossRef]

| Parameter | Experimental | Model 1 | Model 2 | Model 3 | Model 4 |

|---|---|---|---|---|---|

| Short greenhouse structure length | 52.85 m | 52.85 m | 52.85 m | 52.85 m | 52.85 m |

| Long greenhouse structure length | 63.75 m | 63.75 m | 63.75 m | 63.75 m | 63.75 m |

| Greenhouse structure width | 9.5 m | 9.5 m | 9.5 m | 9.5 m | 9.5 m |

| Greenhouse height | 2.8 m | 2.8 m | 3.2 m | 2.8 m | 2.8 m |

| Greenhouse arch height | 2.6 m | 2.6 m | 2.6 m | 3.0 m | 2.6 m |

| Number of spans | 2 | 2 | 2 | 2 | 12 |

| Natural ventilation air inlet | Hoop 2 | Hoop 2 | Hoop 2 | Hoop 2 | Hoop 1 |

| Natural ventilation air outlet | Hoop 1 | Hoop 1 | Hoop 1 | Hoop 1 | Hoop 12 |

| Variables | Values/Range |

|---|---|

| Date of experimental data | 6 August 2020 to 20 August 2020 |

| Data collection duration | 2 Weeks |

| Parameter measured | Temperature |

| Frequency of data collection | 1 min |

| Number of tunnels considered | 2 |

| Data collected | Temperature |

| Category | Component | Description |

|---|---|---|

| Parameters | LUb | Logical unit for reading the *.bui file created by TRNBuild. |

| T*-MODE | Defines whether the star network is recalculated only at start or at each iteration, depending on heat transfer coefficient settings. | |

| Aop | Weighting factor for operative room temperature: Top = Aop × Tair + (1 − Aop) × Tsurf. | |

| Inputs | TRNBuild files | Building description (*.BLD) and transfer function coefficients (*.TRN) are generated and automatically linked. |

| INF file | Provides a list of required inputs and available outputs for proper model connections. | |

| Outputs | Zone air temperatures | Default output includes air temperature values for each zone. |

| Energy demands | Provides sensible energy demands, heating, and cooling loads for zones. | |

| Optional summaries | Users can specify monthly or hourly reports by defining logical unit numbers. |

| Percentage Difference in Temperature with Model 1 | Hoop 1 (Average Difference) | Hoop 2 (Average Difference) | Hoop 1 (Maximum Difference) | Hoop 2 (Maximum Difference) |

|---|---|---|---|---|

| Summer (%) | −0.04296 | −0.07761 | −0.35743 | −0.59551 |

| Autumn (%) | −0.03503 | −0.06325 | −0.27189 | −0.4713 |

| Winter (%) | −0.0279 | −0.05025 | −0.39272 | −0.62729 |

| Spring (%) | −0.04469 | −0.08081 | −0.25239 | −0.39202 |

| Percentage Difference in Temperature with Model 1 | Hoop 1 (Average Difference) | Hoop 2 (Average Difference) | Hoop 1 (Maximum Difference) | Hoop 2 (Maximum Difference) |

|---|---|---|---|---|

| Summer (%) | 0.00138 | 0.00260 | 0.02526 | 0.03518 |

| Autumn (%) | 0.00467 | 0.00864 | 0.05771 | 0.10126 |

| Winter (%) | 0.00748 | 0.01371 | 0.09499 | 0.15388 |

| Spring (%) | 0.00169 | 0.00324 | 0.02088 | 0.03881 |

| S. No | Average Temperature Difference with Ambient Air (°C) | Maximum Temperature Difference with Ambient Air (°C) | ||||||

|---|---|---|---|---|---|---|---|---|

| Summer (8 a.m.–4p.m.) | Autumn (8 a.m.–3 p.m.) | Winter (8 a.m.–3 p.m.) | Spring (8 a.m.–3 p.m.) | Summer (8 a.m.–4 p.m.) | Autumn (8 a.m.–3 p.m.) | Winter (8 a.m.–3 p.m.) | Spring (8 a.m.–3 p.m.) | |

| Hoop 12 | 2.83 | 2.297 | 1.74 | 2.83 | 17.21 | 15.62 | 14.59 | 11.92 |

| Hoop 11 | 2.64 | 2.14 | 1.63 | 2.64 | 16.36 | 14.72 | 14.28 | 11.23 |

| Hoop 10 | 2.46 | 1.95 | 1.52 | 2.45 | 15.46 | 13.79 | 13.91 | 10.50 |

| Hoop 9 | 2.23 | 1.77 | 1.38 | 2.22 | 14.36 | 12.65 | 13.46 | 9.81 |

| Hoop 8 | 2.00 | 1.59 | 1.24 | 1.99 | 13.27 | 11.48 | 12.89 | 9.17 |

| Hoop 7 | 1.76 | 1.4 | 1.09 | 1.76 | 12.12 | 10.23 | 12.16 | 8.41 |

| Hoop 6 | 1.52 | 1.21 | 0.94 | 1.51 | 11.02 | 8.94 | 11.29 | 7.55 |

| Hoop 5 | 1.28 | 1.02 | 0.79 | 1.27 | 9.74 | 7.59 | 10.23 | 6.60 |

| Hoop 4 | 1.03 | 0.82 | 0.64 | 1.02 | 8.27 | 6.26 | 8.94 | 5.52 |

| Hoop 3 | 0.78 | 0.62 | 0.48 | 0.77 | 6.58 | 4.89 | 7.35 | 4.33 |

| Hoop 2 | 0.52 | 0.41 | 0.32 | 0.51 | 4.63 | 3.36 | 5.36 | 3.05 |

| Hoop 1 | 0.25 | 0.20 | 0.15 | 0.25 | 4.63 | 3.36 | 5.36 | 3.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Narayanan, R.; Madas, S.R.; Singh, R. Towards Sustainable Greenhouse Design: A Numerical Study on Temperature Control in Multi-Span Hoop Structures. Sustainability 2025, 17, 8712. https://doi.org/10.3390/su17198712

Narayanan R, Madas SR, Singh R. Towards Sustainable Greenhouse Design: A Numerical Study on Temperature Control in Multi-Span Hoop Structures. Sustainability. 2025; 17(19):8712. https://doi.org/10.3390/su17198712

Chicago/Turabian StyleNarayanan, Ramadas, Sai Ruthwick Madas, and Rohit Singh. 2025. "Towards Sustainable Greenhouse Design: A Numerical Study on Temperature Control in Multi-Span Hoop Structures" Sustainability 17, no. 19: 8712. https://doi.org/10.3390/su17198712

APA StyleNarayanan, R., Madas, S. R., & Singh, R. (2025). Towards Sustainable Greenhouse Design: A Numerical Study on Temperature Control in Multi-Span Hoop Structures. Sustainability, 17(19), 8712. https://doi.org/10.3390/su17198712