Repurposing EoL WTB Components into a Large-Scale PV-Floating Demonstrator

Abstract

1. Introduction

2. Materials and Methods

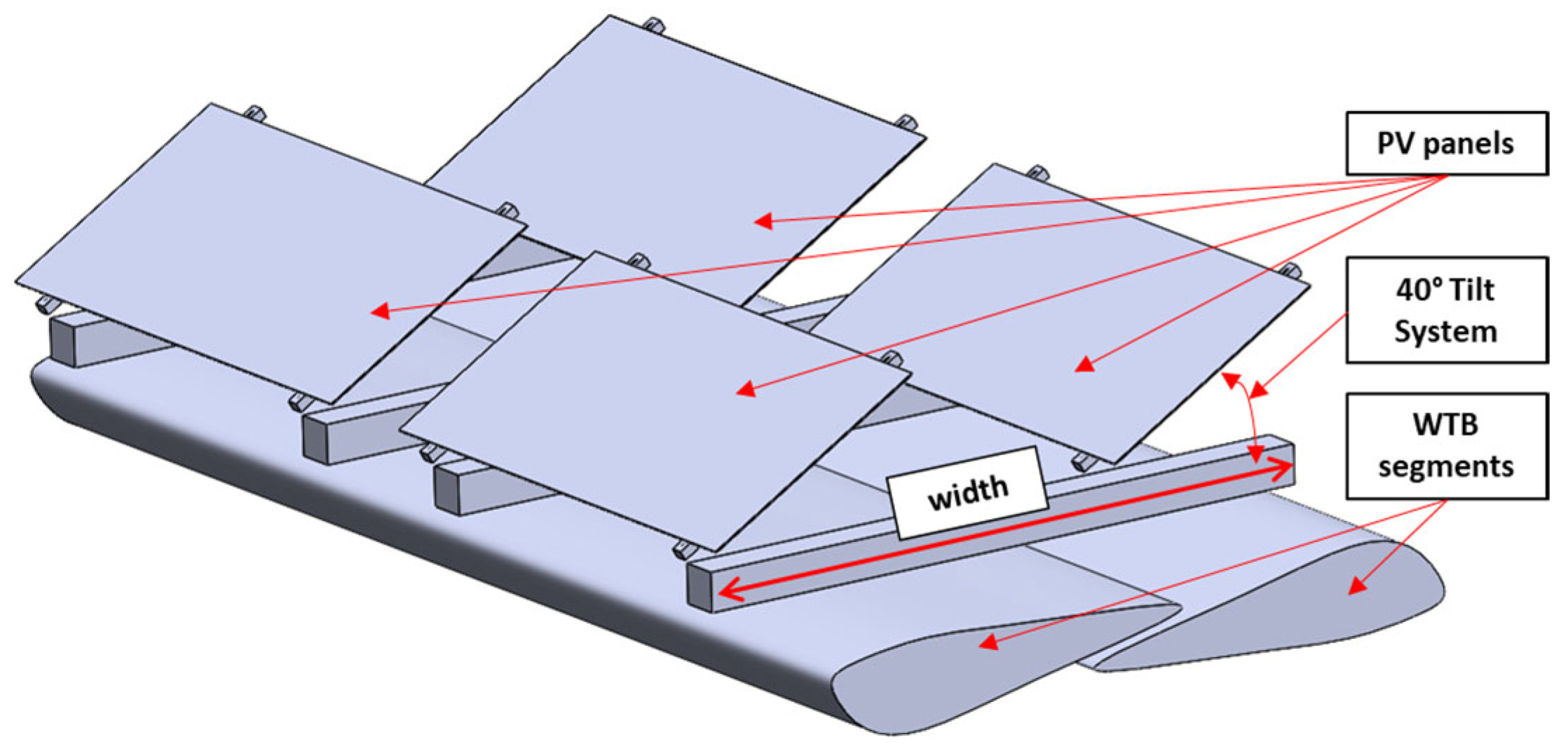

2.1. PV-Floating Demonstrator Design for Circularity

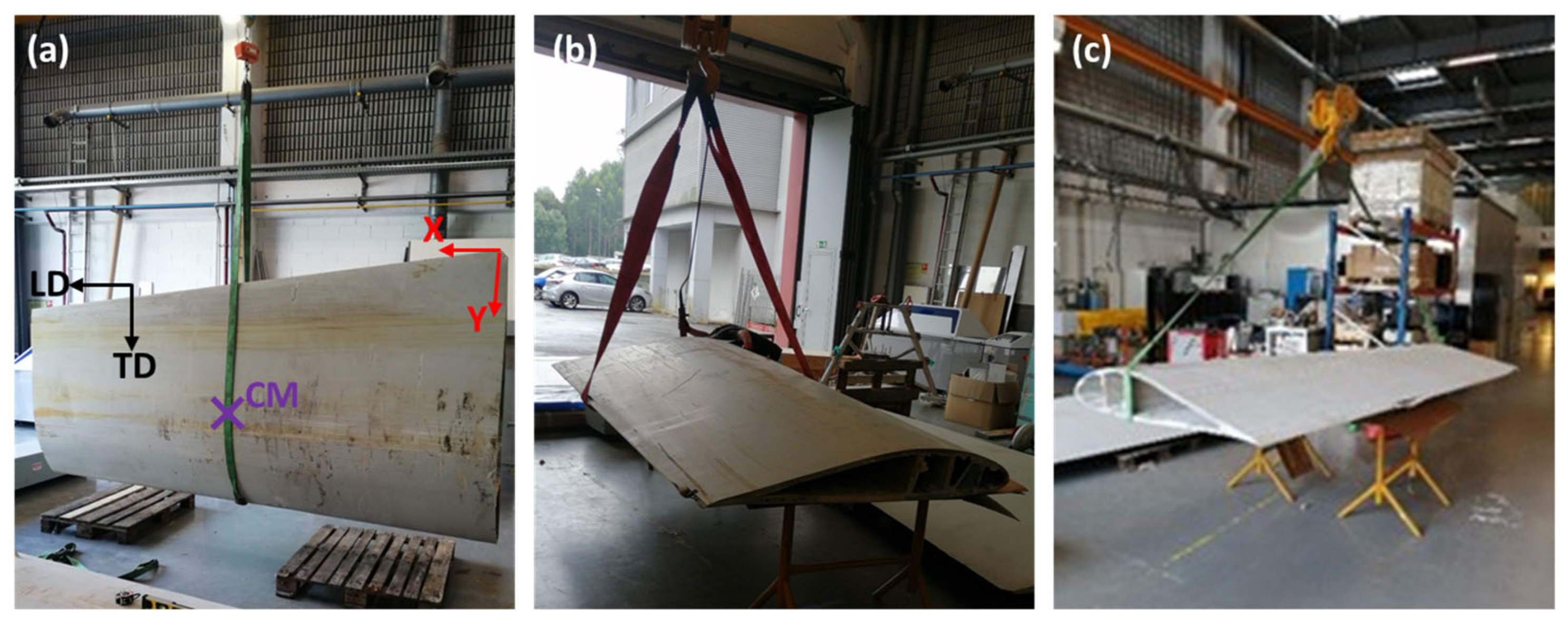

2.1.1. Material Sourcing from an EoL Enercon E66 WTB

2.1.2. Geometrical Characterization of EoL WTB Segments

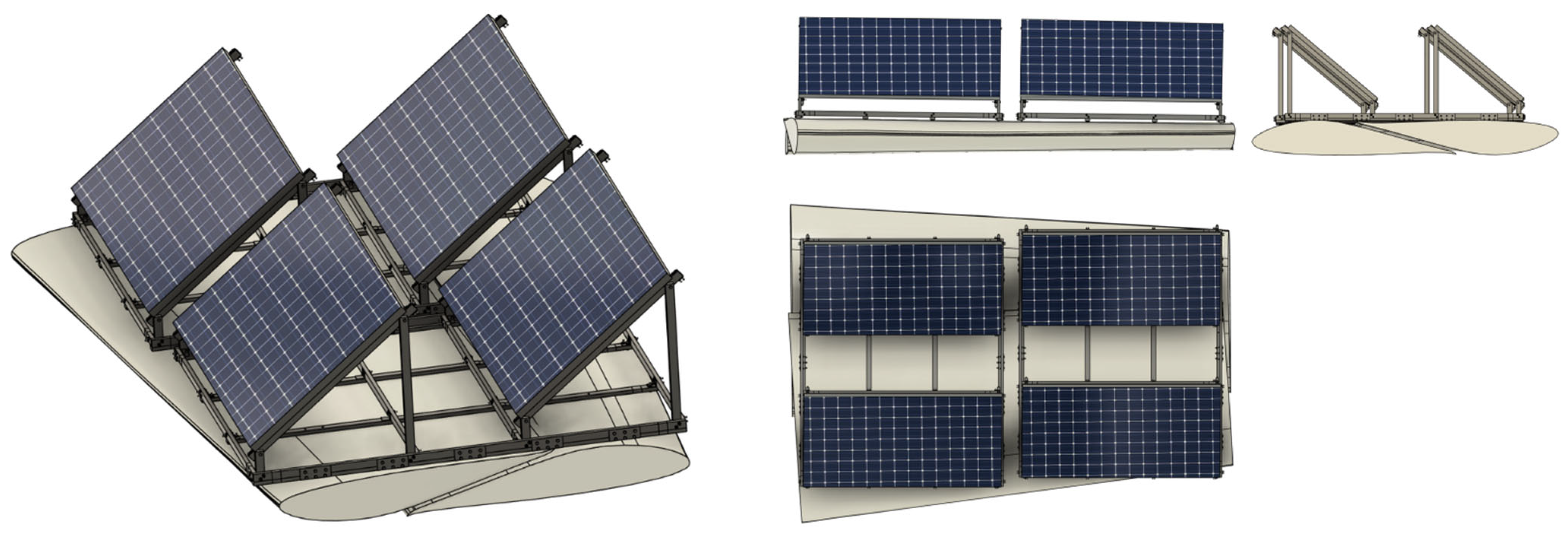

2.1.3. Design Steps and Support Integration

2.2. Demonstrator Assembly

2.2.1. Repair Methods to Ensure WTB Segments Floatability

2.2.2. PV-Floating Demonstrator Assembly

2.3. Experimental Setup and Testing Methodology

2.4. Numerical Simulation for Further Optimization of the Design

2.5. Life Cycle Assessment Methodology and Scope

2.5.1. Goal and Scope Definition

2.5.2. Life Cycle Inventory (LCI)

3. Results

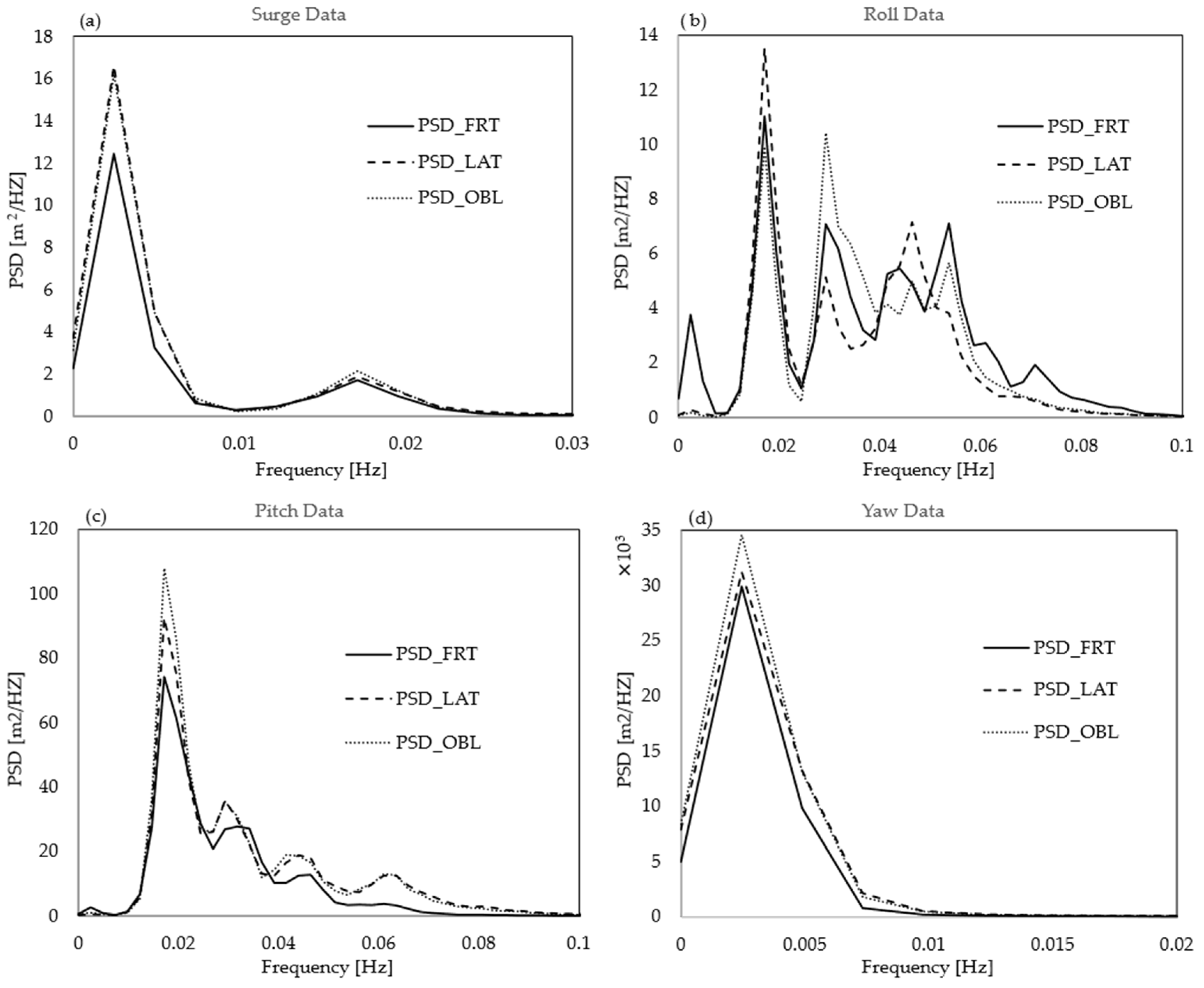

3.1. Experimental Results of Buoyancy and Wave Tests

3.2. Numerical Simulation Results of the Environmental Conditions of the Demonstrator

- (i)

- To mitigate high IRF values near the connection bolts of the WTB segments, a higher number of bolts should be introduced to distribute the load more evenly. Additionally, the use of Class 12.9 Hex Bolts is recommended, as internal stresses in the bolts can be high (see Figure S3)).

- (ii)

- Plastic end caps connecting the side and bottom spar cap beams could be added for additional reinforcement purposes.

- (iii)

- If less lateral flexibility in the solar panel structure is desired, lowering the height could save material, increase more rigidity, and offer less contact area for additional wind loads in aquatic conditions.

- (iv)

- A lower height combined with wider spar cap beams could also reduce bending stresses in the corner beams.

3.3. LCA of Repurposed Floating Demonstrator

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ACP | ANSYS Composite PrepPost |

| AP | Acidification Potential |

| CC | Climate Change Potential |

| CE | Circular Economy |

| CFRP | Carbon fibre-reinforced polymer |

| CM | Centre of Mass |

| CT | Human Toxicity Potential |

| DoF | Degrees of Freedom |

| EoL | End-of-life |

| ET | Freshwater Ecotoxicity Potencial |

| FE | Freshwater Eutrophication Potential |

| FR | Fossils Resource Use Potential |

| FRP | Fibre-reinforced polymer |

| GFRP | Glass fibre-reinforced polymer |

| GLO | Global |

| HMDS | Hexamethyldisilazane |

| IR | Ionizing Radiation Potential |

| IRF | Inverse Reserve Factor |

| LCA | Life Cycle Assessment |

| LCI | Life Cycle Inventory |

| LD | Longitudinal direction |

| LU | Land Use Potential |

| ME | Marine Eutrophication Potential |

| MR | Metals Resource Use Potential |

| NT | Non-Cancer Human Toxicity Potential |

| OD | Ozone Depletion Potential |

| OF | Photochemical Ozone Formation Potential |

| PM | Particulate Matter Potential |

| PSD | Power Spectral Density |

| Pt | Points |

| PT | Portugal |

| PV | Photovoltaic |

| RER | Europe |

| RoW | Rest of World |

| TD | Transverse direction |

| TE | Terrestrial Eutrophication Potential |

| TRL | Technology Readiness Level |

| UD | Unidirectional |

| WP | Wave Probe |

| WTB | Wind turbine blade |

| WU | Water Use Potential |

References

- Mishnaevsky, L.; Branner, K.; Petersen, H.N.; Beauson, J.; McGugan, M.; Sørensen, B.F. Materials for Wind Turbine Blades: An Overview. Materials 2017, 10, 1285. [Google Scholar] [CrossRef] [PubMed]

- Beauson, J.; Laurent, A.; Rudolph, D.P.; Pagh Jensen, J. The complex end-of-life of wind turbine blades: A review of the European context. Renew. Sustain. Energy Rev. 2022, 155, 111847. [Google Scholar] [CrossRef]

- Pyrzowski, Ł.; Sabik, A.; Kluska, J.; Zembrzuski, J. Stiffness assessment of the laminate recovered from end-of-life wind turbine blade. Compos. Struct. 2024, 348, 118439. [Google Scholar] [CrossRef]

- Gopalraj, S.K.; Kärki, T. A review on the recycling of waste carbon fibre/glass fibre-reinforced composites: Fibre recovery, properties and life-cycle analysis. SN Appl. Sci. 2020, 2, 433. [Google Scholar] [CrossRef]

- Lahuerta, F.; Gesto, D.; Prieto, C.; Johst, P.; Kucher, M.; Mozas, E.; Gracia, O.; Böhm, R.; Bielsa, J.M. Decommissioning Inventory for Wind Turbine Blades Installed Until 2022 in Europe. Mater. Circ. Econ. 2023, 5, 16. [Google Scholar] [CrossRef]

- Liu, P.; Barlow, C.Y. Wind turbine blade waste in 2050. Waste Manag. 2017, 62, 229–240. [Google Scholar] [CrossRef]

- Potting, J.; Hekkert, M.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain. Available online: https://www.pbl.nl/sites/default/files/downloads/pbl-2016-circular-economy-measuring-innovation-in-product-chains-2544.pdf (accessed on 25 January 2023).

- Ellen MacArthur Foundation. Towards the Circular Economy: Economic and Business Rationale for an Accelerated Transition. Available online: https://emf.thirdlight.com/file/24/xTyQj3oxiYNMO1xTFs9xT5LF3C/Towards%20the%20circular%20economy%20Vol%201%3A%20an%20economic%20and%20business%20rationale%20for%20an%20accelerated%20transition.pdf (accessed on 20 February 2023).

- Johst, P.; Kucher, M.; Schulz, P.; Knorr, A.; Kupfer, R.; Böhm, R. Identification of circular eco-subsystems for end-of-life aviation composite components based on a systematized R6-strategy. J. Phys. Conf. Ser. 2023, 2526, 12055. [Google Scholar] [CrossRef]

- Leahy, P.G. End-of-life Options for Composite Material Wind Turbine Blades: Recover, Repurpose or Reuse? In Proceedings of the 14th SWEDES Conference, Dubrovnik, Croatia, 1–6 October 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Vishnupriya, V.; Meldrum, J.; Kahandawa, R.; Domingo, N.; Shahzad, W.; Shen, X. Closing the Loop: A Comprehensive Review of Circular Repurposing Options for Decommissioned Wind Turbine Blade Materials. Future Cities Environ. 2024, 10, 17. [Google Scholar] [CrossRef]

- Ruane, K.; Soutsos, M.; Huynh, A.; Zhang, Z.; Nagle, A.; McDonald, K.; Gentry, T.R.; Leahy, P.; Bank, L.C. Construction and Cost Analysis of BladeBridges Made from Decommissioned FRP Wind Turbine Blades. Sustainability 2023, 15, 3366. [Google Scholar] [CrossRef]

- Alshannaq, A.A.; Bank, L.C.; Scott, D.W.; Gentry, R. A Decommissioned Wind Blade as a Second-Life Construction Material for a Transmission Pole. Constr. Mater. 2021, 1, 95–104. [Google Scholar] [CrossRef]

- Johst, P.; Seibert, D.; Zschiebsch, W.; Kucher, M.; Carneiro, C.; Araújo, A.; Santos, R.M.; Rodriguez-Ortiz, L.A.; Alexandra Tapia, E.; Böhm, R. Eco-efficient manufacturing: Transforming end-of-life wind turbine blade components into floats for PV-floating systems. MATEC Web Conf. 2024, 401, 5006. [Google Scholar] [CrossRef]

- Rodriguez-Ortiz, L.A.; Suárez, E.A.T.; Muíños-Landín, S.; Boga, D.C.; Araújo, A.; Carneiro, C.; Santos, R.M.; Johst, P.; Böhm, R. Business Guidance on Conformity Assessment of Reuse and Repair for Aeronautics and Wind Energy. In Proceedings of the 14th EASN International Conference on “Innovation in Aviation & Space Towards Sustainability Today & Tomorrow”, Thessaloniki, Greece, 8–11 October 2024; MDPI: Basel, Switzerland, 2025; p. 101. [Google Scholar]

- Delaney, E.L.; Leahy, P.G.; McKinley, J.M.; Gentry, T.R.; Nagle, A.J.; Elberling, J.; Bank, L.C. Sustainability Implications of Current Approaches to End-of-Life of Wind Turbine Blades—A Review. Sustainability 2023, 15, 12557. [Google Scholar] [CrossRef]

- Henao, Y.; Grubert, E.; Korey, M.; Bank, L.C.; Gentry, R. Life Cycle Assessment and Life Cycle Cost Analysis of Repurposing Decommissioned Wind Turbine Blades as High-Voltage Transmission Poles. J. Constr. Eng. Manag. 2024, 150, 05024004. [Google Scholar] [CrossRef]

- Ramaswamy, N.; Joshi, B.; Song, G.; Mo, Y.L. Repurposing Decommissioned Wind Turbine Blades: A Circular Economy Approach to Sustainable Resource Management and Infrastructure Innovation. Renew. Sustain. Energy Rev. 2024, 215, 115629. [Google Scholar] [CrossRef]

- Nagle, A. Sustainability Assessment of the Repurposing of Wind Turbine Blades. Ph.D. Thesis, University College Cork, Cork, Ireland, 2022. [Google Scholar]

- Johst, P.; Kucher, M.; Bühl, M.; Schulz, P.; Kupfer, R.; Schilling, L.; Santos, R.M.; Carneiro, C.; Voigt, P.; Modler, N.; et al. Identification and Environmental Assessments for Different Scenarios of Repurposed Decommissioned Wind Turbine Blades. Mater. Circ. Econ. 2023, 5, 13. [Google Scholar] [CrossRef]

- André, A.; Bru, T.; Abbasi, A.G.; Sinha, S.; Nunes, S.; Juntikka, M.; Kazmierczak, K.; Egilsson, N.Ó.; Frid, G.; Sobczyk, M.; et al. A Holistic and Circular Approach for Managing End-of-Service Wind Turbine Blades. Sustainability 2024, 16, 7858. [Google Scholar] [CrossRef]

- Beauson, J.; Brøndsted, P. Wind Turbine Blades: An End of Life Perspective. In MARE-WINT; Ostachowicz, W., McGugan, M., Schröder-Hinrichs, J.-U., Luczak, M., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 421–432. ISBN 978-3-319-39094-9. [Google Scholar]

- Jensen, J.P.; Skelton, K. Wind turbine blade recycling: Experiences, challenges and possibilities in a circular economy. Renew. Sustain. Energy Rev. 2018, 97, 165–176. [Google Scholar] [CrossRef]

- Hau, E. Wind Turbines; Springer: Berlin/Heidelberg, Germany, 2013; ISBN 978-3-642-27150-2. [Google Scholar]

- Ziegler, L.; Gonzalez, E.; Rubert, T.; Smolka, U.; Melero, J.J. Lifetime extension of onshore wind turbines: A review covering Germany, Spain, Denmark, and the UK. Renew. Sustain. Energy Rev. 2018, 82, 1261–1271. [Google Scholar] [CrossRef]

- Joustra, J.; Flipsen, B.; Balkenende, R. Structural reuse of wind turbine blades through segmentation. Compos. Part C Open Access 2021, 5, 100137. [Google Scholar] [CrossRef]

- Calabrò, E. An Algorithm to Determine the Optimum Tilt Angle of a Solar Panel from Global Horizontal Solar Radiation. J. Renew. Energy 2013, 2013, 1–12. [Google Scholar] [CrossRef]

- Alshannaq, A.A.; Respert, J.A.; Bank, L.C.; Scott, D.W.; Gentry, T.R. As-Received Physical and Mechanical Properties of the Spar Cap of a GE37 Decommissioned Glass FRP Wind Turbine Blade. J. Mater. Civ. Eng. 2022, 34, 04022266. [Google Scholar] [CrossRef]

- Johst, P.; Bühl, M.; André, A.; Kupfer, R.; Protz, R.; Modler, N.; Böhm, R. Characterisation of End-of-Life Wind Turbine Blade Components for Structural Repurposing: Experimental and Analytic Prediction Approach. Sustainability 2025, 17, 7783. [Google Scholar] [CrossRef]

- Katnam, K.B.; Comer, A.J.; Roy, D.; Da Silva, L.F.M.; Young, T.M. Composite Repair in Wind Turbine Blades: An Overview. J. Adhes. 2015, 91, 113–139. [Google Scholar] [CrossRef]

- Duong, C.N.; Wang, C.H. Composite Repair: Theory and Design; Elsevier: Amsterdam, The Netherlands, 2007; ISBN 9780080451466. [Google Scholar]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- EN 15978:2011; Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method. European Committee for Standardization: Brussels, Belgium, 2012.

- Krauklis, A. Environmental Aging of Constituent Materials in Fiber-Reinforced Polymer Composites. Ph.D. Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2019. [Google Scholar]

- Bazli, M.; Zhao, X.-L.; Jafari, A.; Ashrafi, H.; Raman, R.S.; Bai, Y.; Khezrzadeh, H. Durability of glass-fibre-reinforced polymer composites under seawater and sea-sand concrete coupled with harsh outdoor environments. Adv. Struct. Eng. 2021, 24, 1090–1109. [Google Scholar] [CrossRef]

- Chen, C.-F. Offshore floating photovoltaic system energy returns assessment—A life cycle energy analysis-based perspective. AIMSE Energy 2023, 11, 540–554. [Google Scholar] [CrossRef]

- Keller, T.; Zand, S.M.; Habibi, T. Composite engineering structures in seawater—Review of durability and environmental performance. Compos. Struct. 2025, 357, 118891. [Google Scholar] [CrossRef]

- Deeney, P.; Nagle, A.J.; Gough, F.; Lemmertz, H.; Delaney, E.L.; McKinley, J.M.; Graham, C.; Leahy, P.G.; Dunphy, N.P.; Mullally, G. End-of-Life alternatives for wind turbine blades: Sustainability Indices based on the UN sustainable development goals. Resour. Conserv. Recycl. 2021, 171, 105642. [Google Scholar] [CrossRef]

- Cromratie Clemons, S.K.; Salloum, C.R.; Herdegen, K.G.; Kamens, R.M.; Gheewala, S.H. Life cycle assessment of a floating photovoltaic system and feasibility for application in Thailand. Renew. Energy 2021, 168, 448–462. [Google Scholar] [CrossRef]

- Kester, J.; Liu, J.; Binani, A. Carbon Footprint Analysis of Floating PV Systems: IEA PVPS Task 12—PV Sustainability Activities. Technical Report. Available online: https://iea-pvps.org/wp-content/uploads/2024/07/IEA-PVPS-T12-29-2024-EXEC-SUMM-Floating-PV-Carbon-Footprint.pdf (accessed on 26 June 2025).

- MSDS—Ficha de Dados de Segurança. Available online: https://media.adeo.com/media/2570120/media.pdf (accessed on 3 July 2025).

- Borgaonkar, A.; McNamara, G. Environmental Impact Assessment of Anti-Corrosion Coating Life Cycle Processes for Marine Applications. Sustainability 2024, 16, 5627. [Google Scholar] [CrossRef]

- Bianco, I. Life Cycle Inventory of Cutting Technologies in the Ornamental Stone Supply Chain. Doctoral Thesis, Politecnico di Torino, Turin, Italy, 2018. [Google Scholar]

- Joteo. Electricity Usage and Cost Calculator. Available online: https://joteo.net/electricity-usage-calculator (accessed on 7 July 2025).

- Zhu, M.; Guo, W.; Ouyang, J.; Wei, C.; Pratomo, E.S.; Mativenga, P.; Li, L. Low carbon high quality simultaneous laser and mechanical hybrid drilling of carbon fibre reinforced polymer composite. CIRP J. Manuf. Sci. Technol. 2023, 46, 1–18. [Google Scholar] [CrossRef]

- Fingersh, L.; Hand, M.; Laxson, A. Wind Turbine Design Cost and Scaling Model. Available online: https://www.nrel.gov/docs/fy07osti/40566.pdf (accessed on 2 February 2023).

- Nagle, A.J.; Delaney, E.L.; Bank, L.C.; Leahy, P.G. A Comparative Life Cycle Assessment between landfilling and Co-Processing of waste from decommissioned Irish wind turbine blades. J. Clean. Prod. 2020, 277, 123321. [Google Scholar] [CrossRef]

- Johst, P.; Lee, S.; Kim, E.; Bae, S.; Böhm, R.; Na, W. Structural integrity assessment of repurposed wind turbine blade composite components with acoustic emission testing and Ib-value analysis. Compos. Part B Eng. 2025, 301, 112490. [Google Scholar] [CrossRef]

- Schindler, A.K.; Duke, S.R.; Galloway, W.B. Co-processing of end-of-life wind turbine blades in portland cement production. Waste Manag. 2024, 182, 207–214. [Google Scholar] [CrossRef] [PubMed]

- Fry, K.L.; Gillings, M.M.; Isley, C.F.; Gunkel-Grillon, P.; Taylor, M.P. Trace element contamination of soil and dust by a New Caledonian ferronickel smelter: Dispersal, enrichment, and human health risk. Environ. Pollut. 2021, 288, 117593. [Google Scholar] [CrossRef]

- Marrugo-Negrete, J.; Pinedo-Hernández, J.; Marrugo-Madrid, S.; Díez, S. Assessment of trace element pollution and ecological risks in a river basin impacted by mining in Colombia. Environ. Sci. Pollut. Res. Int. 2021, 28, 201–210. [Google Scholar] [CrossRef] [PubMed]

- Hayibo, K.S.; Mayville, P.; Pearce, J.M. The greenest solar power? Life cycle assessment of foam-based flexible floatovoltaics. Sustain. Energy Fuels 2022, 6, 1398–1413. [Google Scholar] [CrossRef]

- Verma, R.; Vinoda, K.S.; Papireddy, M.; Gowda, A. Toxic Pollutants from Plastic Waste- A Review. Procedia Environ. Sci. 2016, 35, 701–708. [Google Scholar] [CrossRef]

- Kudzin, M.H.; Piwowarska, D.; Festinger, N.; Chruściel, J.J. Risks Associated with the Presence of Polyvinyl Chloride in the Environment and Methods for Its Disposal and Utilization. Materials 2023, 17, 173. [Google Scholar] [CrossRef]

| Input/Output | Dataset | Amount | Unit | Comment |

|---|---|---|---|---|

| EoL wind turbine components | n.a. | 2 × 300 | kg | - |

| Spar cap beams | n.a. | 97 | kg | - |

| Epoxy putty for surface defects | Created composition | 1.5 | kg | based on [42] |

| Epoxy resin and glass fibres for laminating | Created composition (resin); Glass fibre, market, GLO | 1 L (resin); 400 g (fibre) | L; grams | based on proxy |

| Waterproof maritime-grade paint | Created composition | 14.7 | kg | from [43] |

| Steel (i.e., brackets, plates, bolts, nuts, washers) | Chromium steel 18/8, hot-rolled, market, GLO | 16.7 | kg | - |

| Silicone | Silicone product, market, RER | 320 | g | - |

| Cement sawing, for TD cuts (stage C1) | Soft stone cutting using diamond wire technology, created process | 1.06 | m2 | from [44] |

| Surface abrasion with pneumatic orbital sander (stage A5) | Electricity, Compressed air, Waste | 2 × 6 | h | process compiled from various sources |

| Cutting shear web components (stage A5) | Power sawing, with catalytic converter, RER | 1 | h | - |

| Table saw for cutting spar beams (stage A5) | Electricity, high voltage, market, PT | 20 kWh/10 h | KWh, h | from Joteo calculator [45] |

| Drilling holes on steel connections (stage A5) | Steel removed by drilling, computer numerical controlled, RER | 229 | grams steel removed | - |

| Drilling holes on composite (stage A5) | Electricity, high voltage, market, PT | 38 MJ/6 h | MJ, h | from [46] |

| Cutting steel brackets and plates (stage A5) | Power sawing, with catalytic converter, RER | 3 | h | - |

| Inbound transport EoL components (stage A4) | Transport, freight, lorry 16–32 metric ton, EURO4, market, RER | 2310 or 100 | km | actual distance and assumed distance |

| Inbound and Waste transport (other materials) (stage A4 and C2) | Transport, freight, lorry 16–32 metric ton, EURO4, market, RER | 100 | km | Assumed distance |

| Product: Repurposed floating system | n.a. | 6.72 | m2 | Surface area of PV panels |

| EoL treatment: composite structures | Created process | 2 × 300 | kg | Based on stated composition [47] |

| EoL treatment: shredding composite structures | Electricity, high voltage, market, PT | 102 per structure; 0.71 per kg | MJ | from [48] |

| EoL treatment: spar cap beams | Waste polyethylene, treatment, municipal incineration, GLO | 61% × 97 | kg | Based on composition, from [49,50] |

| Waste glass, treatment, municipal incineration, GLO | 39% × 97 | kg | ||

| EoL treatment: coatings | Waste plastic, mixture, treatment, municipal incineration, GLO | 18 | kg | - |

| EoL treatment: steel | Waste reinforcement steel, treatment, recycling, RoW | 16.7 | kg | - |

| Indicator | Conventional Structure A | Conventional Structure B | Repurposed |

|---|---|---|---|

| Weight percentage steel (%) | 3% | 30% | 2% |

| Contribution to CC of steel (%) | 1% | 24% | 8% |

| Weight percentage plastic/WTB parts (%) | 92% | 70% | 95% |

| Contribution to CC of plastic/WTB parts (%) | 55% | 44% | 0% |

| Weight percentage coating (%) | n.a. | n.a. | 3% |

| Contribution to CC of coating (%) | n.a. | n.a. | 8% |

| Total structure weight (per m2) | 12.4 kg | 20.3 kg | 109 kg |

| Contribution to CC of EoL plastic/WTB parts (%) | 38% | 31% | 47% |

| Contribution to CC of WTB/plastic parts inbound transport (%) | <1% | <1% | 26% |

| Contribution to CC of tools (%) | n.a. | n.a. | 5% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moutinho, M.; Rocha, R.; Atteln, D.; Johst, P.; Böhm, R.; Chatzipanagiotou, K.-R.; Stamkopoulou, E.; Koumoulos, E.P.; Araujo, A. Repurposing EoL WTB Components into a Large-Scale PV-Floating Demonstrator. Sustainability 2025, 17, 8717. https://doi.org/10.3390/su17198717

Moutinho M, Rocha R, Atteln D, Johst P, Böhm R, Chatzipanagiotou K-R, Stamkopoulou E, Koumoulos EP, Araujo A. Repurposing EoL WTB Components into a Large-Scale PV-Floating Demonstrator. Sustainability. 2025; 17(19):8717. https://doi.org/10.3390/su17198717

Chicago/Turabian StyleMoutinho, Mário, Ricardo Rocha, David Atteln, Philipp Johst, Robert Böhm, Konstantina-Roxani Chatzipanagiotou, Evangelia Stamkopoulou, Elias P. Koumoulos, and Andreia Araujo. 2025. "Repurposing EoL WTB Components into a Large-Scale PV-Floating Demonstrator" Sustainability 17, no. 19: 8717. https://doi.org/10.3390/su17198717

APA StyleMoutinho, M., Rocha, R., Atteln, D., Johst, P., Böhm, R., Chatzipanagiotou, K.-R., Stamkopoulou, E., Koumoulos, E. P., & Araujo, A. (2025). Repurposing EoL WTB Components into a Large-Scale PV-Floating Demonstrator. Sustainability, 17(19), 8717. https://doi.org/10.3390/su17198717