Calibration of Building Performance Simulations for Zero Carbon Ready Homes: Two Open Access Case Studies Under Controlled Conditions

Abstract

1. Introduction

1.1. Limitations of Existing Calibration Research

1.2. Purpose and Contribution of This Study

1.3. Research Questions

- 1.

- How can a standardised, evidence-based DTS workflow be created for calibrating the whole-house HTC of homes?

- 2.

- To what extent does that workflow reproduce measured HTC, and how does its accuracy compare with SAP design calculations?

- 3.

- What approaches to modelling roof ventilation, ground temperature and sub-floor voids are most accurate?

2. Materials and Methods

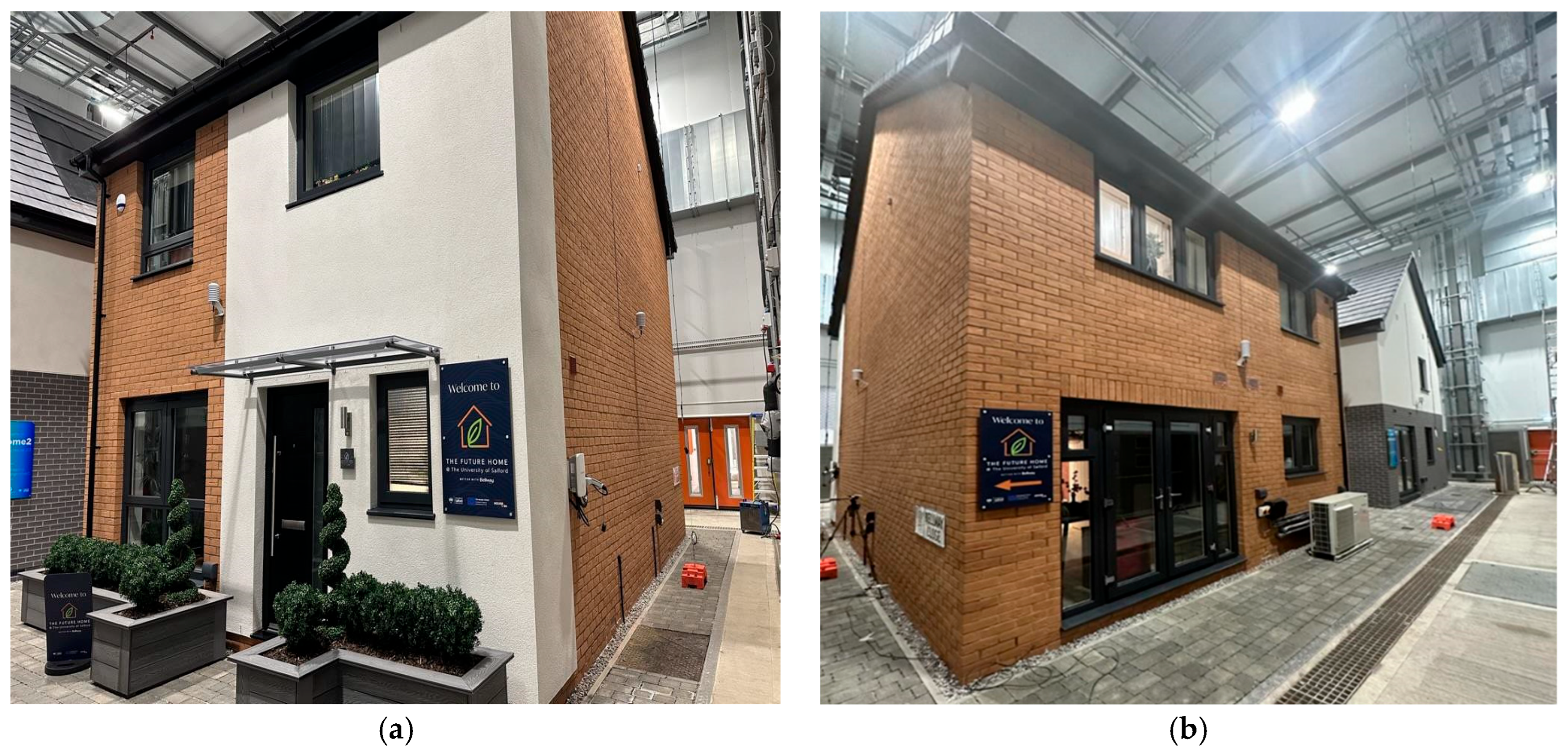

2.1. Introduction to Case Studies

2.2. DTS and SAP Models

2.3. Geometric Modelling

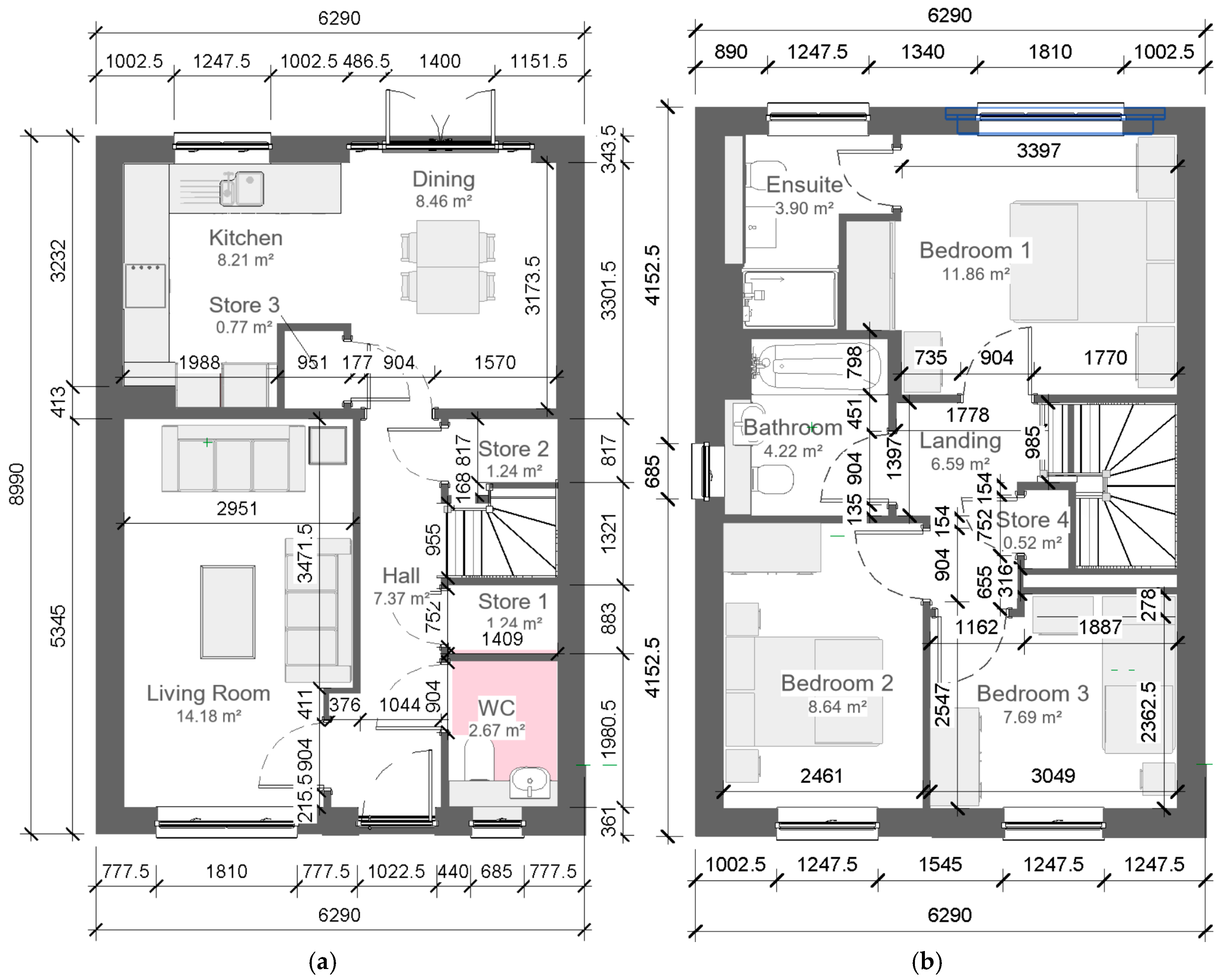

2.3.1. Floor Plans and General Description

2.3.2. Differences in Floor Area and Ceiling Heights Between DTS and SAP

2.3.3. Definition of Zones, Blocks, Surfaces and Loft Hatch

2.4. Construction Details

2.4.1. U-Values

2.4.2. Thermal Bridging Inputs

2.4.3. Roof Ventilation, Ground Temperature and Sub-Floor Voids

2.5. Weather File Adjustments—Controlled Chamber Conditions

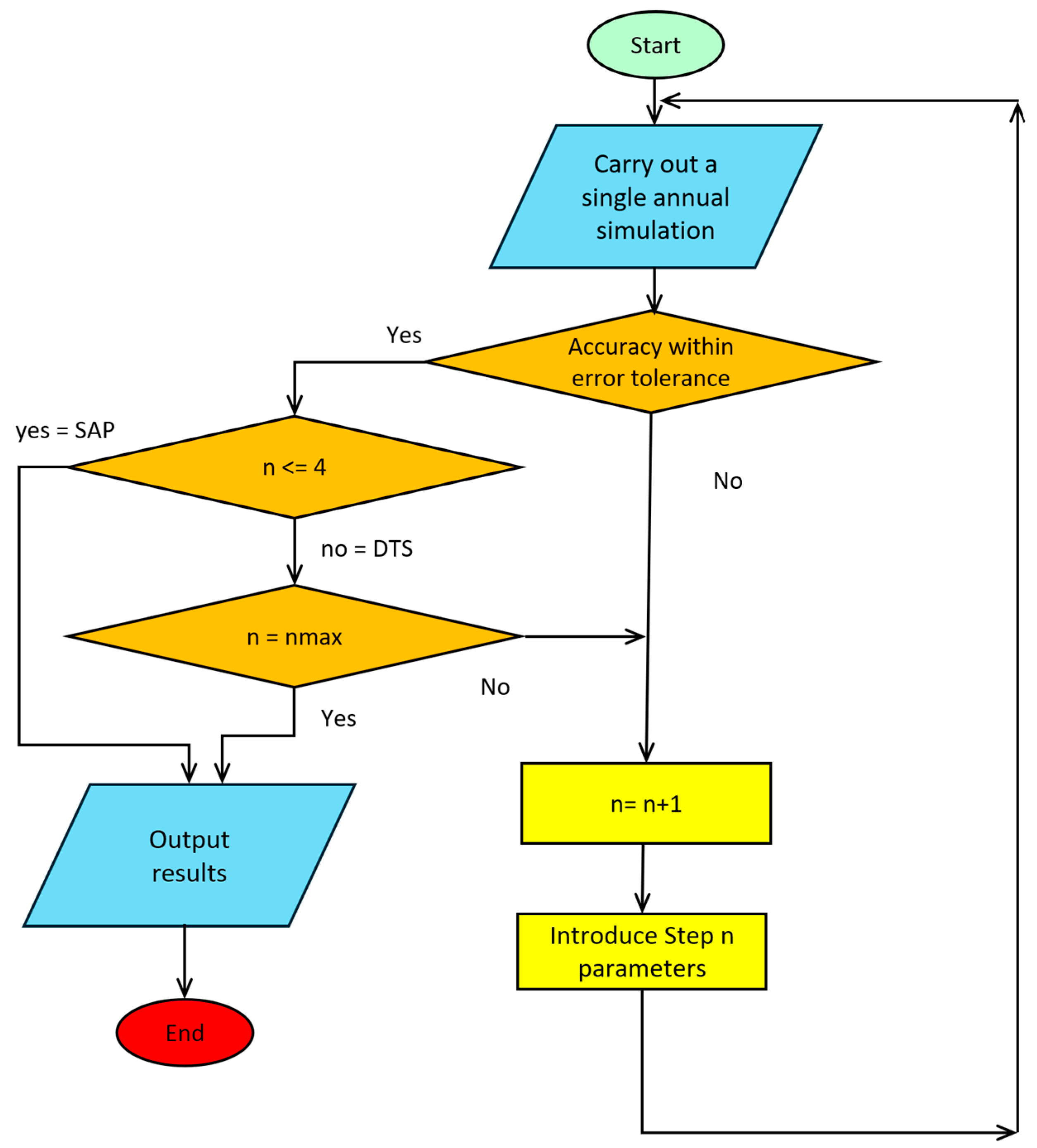

2.6. Development of Calibration Procedure

3. Results

4. Discussion

5. Conclusions

- Incorporating as-built U-values and air permeability rates significantly improved model accuracy, with their relative impact varying between the two houses.

- The calibrated DTS models achieved remarkably low performance gaps of 0.5% for TFH and 0.6% for eHome2, falling within the uncertainty range of aggregate heat loss test measurements.

- DTS models outperformed SAP calculations in accuracy, supporting the UK’s planned transition to more dynamic assessment methods.

- Modelling sub-floor voids in suspended floor constructions substantially affected HTC predictions, indicating lower heat loss than previously assumed.

- Roof ventilation rates had minimal impact on HTC for these highly insulated homes, but may be more significant for older, less insulated buildings.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| FHS | Future Homes Standard |

| HTC | Heat Transfer Coefficient |

| DTS | Dynamic Thermal Simulation |

| SAP | Standard Assessment Procedure |

| TFH | The Future Home in Energy House Labs Environmental Chamber 1 developed in collaboration between Bellway Homes and the University of Salford |

| eHome2 | Experimental house in Energy House Labs Environmental Chamber 1 developed in collaboration between Barratt Developments, Saint-Gobain, and the University of Salford |

| PTT | Point Thermal Transmittance |

| LoD | Level of Detail |

| HEM | Home Energy Model |

| EPC | Energy Performance Certificate |

| HFP | Heat Flux Plates |

| USIR | University of Salford Institutional Repository |

References

- Home Energy Model: Future Homes Standard Assessment. Available online: https://www.gov.uk/government/consultations/home-energy-model-future-homes-standard-assessment (accessed on 30 September 2024).

- HM Government. The Future Homes and Buildings Standards: 2023 Consultation; Department for Levelling Up, Housing and Communities: London, UK, 2023. [Google Scholar]

- HM Government. Climate Change Act 2008; Statute Law Database; HM Government: London, UK, 2008. [Google Scholar]

- Johnston, D.; Miles-Shenton, D.; Farmer, D. Quantifying the Domestic Building Fabric ‘Performance Gap. Build. Serv. Eng. Res. Technol. 2015, 36, 614–627. [Google Scholar] [CrossRef]

- HM Government BEIS. SAP 10.2: The Government’s Standard Assessment Procedure for Energy Rating of Dwellings; BRE Garston: Watford, UK, 2023. [Google Scholar]

- BS EN 17887-1:2024; Thermal Performance of Buildings. In Situ Testing of Completed Buildings. Data Collection for Aggregate Heat Loss Test (Part 1). BSI: London, UK, 2024.

- Beizaee, A. Measuring and Modelling the Energy Demand Reduction Potential of Using Zonal Space Heating Control in a UK Home. Ph.D. Thesis, Loughborough University, Loughborough, UK, 2016. [Google Scholar]

- Bou-Saada, T.E.; Haberl, J.S. An Improved Procedure for Developing Calibrated Hourly Simulation Models. In Proceedings of the Building Simulation 1995: 4th Conference of IBPSA, Madison, WI, USA, 14–16 August 1995; pp. 475–484. [Google Scholar]

- Coakley, D.; Raftery, P.; Keane, M. A Review of Methods to Match Building Energy Simulation Models to Measured Data. Renew. Sustain. Energy Rev. 2014, 37, 123–141. [Google Scholar] [CrossRef]

- Georgiou, G.; Eftekhari, M.; Eames, P. Calibration and Validation of Residential Buildings: 8 Case Studies of Detached Houses; IBPSA: Las Cruces, NM, USA, 2013. [Google Scholar]

- Marini, D.; Webb, L.H.; Diamantis, G.; Buswell, R.A. Exploring the Impact of Model Calibration on Estimating Energy Savings Through Better Space Heating Control. In Proceedings of the Building Simulation and Optimization: Second Conference of IBPSA-England Conference, UCL, London, UK, 10–11 June 2014. [Google Scholar]

- Mustafaraj, G.; Marini, D.; Costa, A.; Keane, M. Model Calibration for Building Energy Efficiency Simulation. Appl. Energy 2014, 130, 72–85. [Google Scholar] [CrossRef]

- Yoon, J.; Lee, E.J.; Claridge, D.E. Calibration Procedure for Energy Performance Simulation of a Commercial Building. J. Sol. Energy Eng. Trans. ASME 2003, 125, 251–257. [Google Scholar] [CrossRef]

- Reddy, T. Literature Review on Calibration of Building Energy Simulation Programs: Uses, Problems, Procedures, Uncertainty and Tools. ASHRAE Trans. 2006, 112, 226–240. [Google Scholar]

- Gillich, A.; Saber, E.M.; Mohareb, E. Limits and Uncertainty for Energy Efficiency in the UK Housing Stock. Energy Policy 2019, 133, 110889. [Google Scholar] [CrossRef]

- De Wilde, P.; Tian, W. Towards Probabilistic Performance Metrics for Climate Change Impact Studies. Energy Build. 2011, 43, 3013–3018. [Google Scholar] [CrossRef]

- Srivastav, A.; Tewari, A.; Dong, B. Baseline Building Energy Modeling and Localized Uncertainty Quantification Using Gaussian Mixture Models. Energy Build. 2013, 65, 438–447. [Google Scholar] [CrossRef]

- Kumbaroglu, G.; Madlener, R. Evaluation of Economically Optimal Retrofit Investment Options for Energy Savings in Buildings. Energy Build. 2012, 49, 327–334. [Google Scholar] [CrossRef]

- Tian, W.; Heo, Y.; de Wilde, P.; Li, Z.; Yan, D.; Park, C.S.; Feng, X.; Augenbroe, G. A Review of Uncertainty Analysis in Building Energy Assessment. Renew. Sustain. Energy Rev. 2018, 93, 285–301. [Google Scholar] [CrossRef]

- Kershaw, T.; Eames, M.; Coley, D. Assessing the Risk of Climate Change for Buildings: A Comparison between Multi-Year and Probabilistic Reference Year Simulations. Build. Environ. 2011, 46, 1303–1308. [Google Scholar] [CrossRef]

- Jenkins, D.P.; Gul, M.; Patidar, S.; Banfill, P.F.G.; Gibson, G.; Menzies, G. Designing a Methodology for Integrating Industry Practice into a Probabilistic Overheating Tool for Future Building Performance. Energy Build. 2012, 54, 73–80. [Google Scholar] [CrossRef]

- Gaetani, I.; Hoes, P.-J.; Hensen, J.L.M. A Stepwise Approach for Assessing the Appropriate Occupant Behaviour Modelling in Building Performance Simulation. J. Build. Perform. Simul. 2020, 13, 362–377. [Google Scholar] [CrossRef]

- Yu, J.; Chang, W.-S.; Dong, Y. Building Energy Prediction Models and Related Uncertainties: A Review. Buildings 2022, 12, 1284. [Google Scholar] [CrossRef]

- Pan, Y.; Zhu, M.; Lv, Y.; Yang, Y.; Liang, Y.; Yin, R.; Yang, Y.; Jia, X.; Wang, X.; Zeng, F.; et al. Building Energy Simulation and Its Application for Building Performance Optimization: A Review of Methods, Tools, and Case Studies. Adv. Appl. Energy 2023, 10, 100135. [Google Scholar] [CrossRef]

- Belazi, W.; Ouldboukhitine, S.-E.; Chateauneuf, A.; Bouchair, A. Uncertainty Analysis of Occupant Behavior and Building Envelope Materials in Office Building Performance Simulation. J. Build. Eng. 2018, 19, 434–448. [Google Scholar] [CrossRef]

- Johnston, D.; Miles-Shenton, D.; Wingfield, J.; Farmer, D.; Bell, M. Whole House Heat Loss Test Method (Coheating); Leeds Metropolitan University: Leeds, UK, 2012. [Google Scholar]

- Parker, J.; Farmer, D.; Johnston, D.; Fletcher, M.; Thomas, F.; Gorse, C.; Stenlund, S. Measuring and Modelling Retrofit Fabric Performance in Solid Wall Conjoined Dwellings. Energy Build. 2019, 185, 49–65. [Google Scholar] [CrossRef]

- Marshall, A.; Fitton, R.; Swan, W.; Farmer, D.; Johnston, D.; Benjaber, M.; Ji, Y. Domestic Building Fabric Performance: Closing the Gap between the in Situ Measured and Modelled Performance. Energy Build. 2017, 150, 307–317. [Google Scholar] [CrossRef]

- Glew, D.; Collet, M.; Fletcher, M.; Hardy, A.; Jones, B.; Miles-Shenton, D.; Morland, K.; Parker, J.; Rakhshanbabanari, K.; Thomas, F.; et al. Demonstration of Energy Efficiency Potential (DEEP) Report 2.00 Case Studies Summary; Technical Report; Department for Energy Security and Net Zero and Department of Business, Energy and Industrial Strategy: London, UK, 2024. [Google Scholar]

- Farmer, D.; Henshaw, G.; Tsang, C.; Roberts, B.; Fitton, R.; Swan, W. DEEP Report 5.01 Salford Energy House Fabric Performance Testing; Department for Energy Security and Net Zero: London, UK, 2024. [Google Scholar]

- Jankovic, L.; Henshaw, G.; Tsang, C.; Zhang, X.; Fitton, R.; Swan, W. Heat Transfer Coefficient of a Building: A Constant with Limited Variability or Dynamically Variable? Energies 2025, 18, 2182. [Google Scholar] [CrossRef]

- Kolbe, T.H. Representing and Exchanging 3D City Models with CityGML. In 3D Geo-Information Sciences; Springer: Berlin/Heidelberg, Germany, 2009; pp. 15–31. [Google Scholar] [CrossRef]

- Gerrish, T.; Ruikar, K.; Cook, M.; Johnson, M.; Phillip, M. Using BIM Capabilities to Improve Existing Building Energy Modelling Practices. Eng. Constr. Archit. Manag. 2017, 24, 190–208. [Google Scholar] [CrossRef]

- Allen, E.A.; Pinney, A.A. Standard Dwellings for Modelling Details of Dimensions, Construction and Occupancy Schedules; Building Research Establishment: Watford, UK, 1990. [Google Scholar]

- Taylor, S.; Allinson, D.; Firth, S.; Lomas, K. Dynamic Energy Modelling of UK Housing: Evaluation of Alternative Approaches. In Proceedings of the 13th Conference of International Building Performance Simulation Association, Chambery, France, 25–28 August 2013; pp. 745–752. [Google Scholar]

- Monien, D.; Strzalka, A.; Koukofikis, A.; Coors, V.; Eicker, U. Comparison of Building Modelling Assumptions and Methods for Urban Scale Heat Demand Forecasting. Future Cities Environ. 2017, 3, 2. [Google Scholar] [CrossRef]

- Purdy, J.; Beausoleil-Morrison, I. The Significant Factors in Modelling Residential Buildings. In Proceedings of the 7th International Conference of the International Building Performance Simulation Association, Rio de Janeiro, Brazil, 13–15 August 2001; pp. 207–214. [Google Scholar]

- DesignBuilder Software Ltd. DesignBuilder; Version 7.3.0.044; DesignBuilder Software Ltd.: Stroud, UK, 2024. [Google Scholar]

- Tsang, C.; Fitton, R.; Zhang, X.; Henshaw, G.; Hernandez, H.D.; Farmer, D.; Allinson, D.; Dagli, M.; Jankovic, L.; Swan, W. Dataset for Article: “Calibration of Building Performance Simulations for Zero Carbon Ready Homes: Two Open Access Case Studies in Controlled Conditions”; School of Science, Engineering & Environment, University of Salford: Salford, UK, 2025. [Google Scholar]

- Fitton, R.; Diaz, H.; Farmer, D.; Henshaw, G.; Sitmalidis, A.; Swan, W. Bellway Homes “The Future Home” Baseline Performance Report; ERDF & Innovate: Salford, UK, 2024. [Google Scholar]

- Fitton, R.; Diaz, H.; Farmer, D.; Henshaw, G.; Sitmalidis, A.; Swan, W. Saint Gobain & Barratt Developments “eHome2” Baseline Performance Report; ERDF & Innovate: Salford, UK, 2024. [Google Scholar]

- Physibel. TRISCO, Version 14.0w; Physibel: Maldegem, Belgium, 2020. [Google Scholar]

- Sanders, C.; Haig, J.; Rideout, N. Airtightness of Ceilings. Energy Loss and Condensation Risk; BRE: Watford, UK, 2016. [Google Scholar]

- Allinson, D. Evaluation of Aerial Thermography to Discriminate Loft Insulation in Residential Housing. Available online: https://eprints.nottingham.ac.uk/10284/ (accessed on 30 September 2024).

- Burch, D.M. Infrared Audits of Roof Heat Loss. ASHRAE Trans. 1980, 86 Pt 2, 209–226. [Google Scholar]

- EnergyPlus. EnergyPlus Weather Data. Available online: https://energyplus.net/weather (accessed on 6 June 2025).

- ASHRAE. ASHRAE Handbook Fundamentals; ASHRAE Standard: Atlanta, GA, USA, 2018. [Google Scholar]

- Anderson, B.; Kosmina, L. Conventions for U-Value Calculations (BR443 2019); BRE: Watford, UK, 2020. [Google Scholar]

- ISO 9869-1:2014; Thermal Insulation—Building Elements—In-Situ Measurement of Thermal Resistance and Thermal Transmittance Part 1: Heat Flow Meter Method. International Organization for Standardization: Geneva, Switzerland, 2014.

- ATTMA. ATTMA Technical Standard L1. Measuring the Air Permeability of Building Envelopes (Dwellings); Air Tightness Testing and Measurement Association: Northampton, UK, 2010. [Google Scholar]

- Roberts, B.M.; Allinson, D.; Diamond, S.; Abel, B.; Bhaumik, C.D.; Khatami, N.; Lomas, K.J. Predictions of Summertime Overheating: Comparison of Dynamic Thermal Models and Measurements in Synthetically Occupied Test Houses. Build. Serv. Eng. Res. Technol. 2019, 40, 512–552. [Google Scholar] [CrossRef]

- Jack, R.; Loveday, D.; Allinson, D.; Lomas, K. First Evidence for the Reliability of Building Co-Heating Tests. Build. Res. Inf. 2018, 46, 383–401. [Google Scholar] [CrossRef]

- DOE (U.S. Department of Energy). EnergyPlus, Version 9.4.0 Documentation; DOE (U.S. Department of Energy): Washington, DC, USA, 2020. [Google Scholar]

- Integrated Environmental Solutions Ltd. IES Virtual Environment; Version 2024; Integrated Environmental Solutions Ltd.: Glasgow, UK, 2024; Available online: https://iesve.com/ (accessed on 1 October 2024).

- Thermal Energy System Specialists, LLC. TRNSYS: Transient System Simulation Tool; Madison, WI, USA, 2024; Available online: https://www.trnsys.com/ (accessed on 1 October 2024).

- Lomas, K.J.; Eppel, H.; Martin, C.J.; Bloomfield, D.P. Empirical Validation of Building Energy Simulation Programs. Energy Build. 1997, 26, 253–275. [Google Scholar] [CrossRef]

- Met Office. Met Office Integrated Data Archive System (MIDAS) Land and Marine Surface Stations Data (1853–Current); Met Office: Exeter, UK, 2019. [Google Scholar]

- Allinson, D.; Roberts, B.M.; Lomas, K.; Loveday, D.; Gorse, C.; Hardy, A.; Thomas, F.; Miles-Shenton, D.; Johnston, D.; Glew, D.; et al. Technical Evaluation of SMETER Technologies (TEST) Project; Loughborough University: Loughborough, UK, 2022. [Google Scholar]

- Liu, B.; Vu-Bac, N.; Zhuang, X.; Rabczuk, T. Stochastic Multiscale Modeling of Heat Conductivity of Polymeric Clay Nanocomposites. Mech. Mater. 2020, 142, 103280. [Google Scholar] [CrossRef]

- Liu, B.; Penaka, S.R.; Lu, W.; Feng, K.; Rebbling, A.; Olofsson, T. Data-Driven Quantitative Analysis of an Integrated Open Digital Ecosystems Platform for User-Centric Energy Retrofits: A Case Study in Northern Sweden. Technol. Soc. 2023, 75, 102347. [Google Scholar] [CrossRef]

- Liu, B.; Liu, P.; Lu, W.; Olofsson, T. Explainable Artificial Intelligence (XAI) for Material Design and Engineering Applications: A Quantitative Computational Framework. Int. J. Mech. Syst. Dyn. 2025, 5, 236–265. [Google Scholar] [CrossRef]

- Liu, B.; Wang, Y.; Rabczuk, T.; Olofsson, T.; Lu, W. Multi-Scale Modeling in Thermal Conductivity of Polyurethane Incorporated with Phase Change Materials Using Physics-Informed Neural Networks. Renew. Energy 2024, 220, 119565. [Google Scholar] [CrossRef]

| Level | Thermal Zone | TFH Floor Area (m2) | eHome2 Floor Area (m2) |

|---|---|---|---|

| Ground Floor | Kitchen & Dining | 17.04 | 13.87 |

| Living Room | 14.42 | 17.75 | |

| WC | 2.78 | 3.40 | |

| Store 1 | 1.07 | 1.87 | |

| Store 2 | 1.34 | n/a * | |

| Store 3 | 0.70 | n/a * | |

| Hall | 12.92 | 12.08 | |

| First Floor | Bedroom 1 | 12.00 | 12.02 |

| Bedroom 2 | 9.02 | 9.86 | |

| Bedroom 3 | 8.23 | 7.66 | |

| Ensuite | 3.87 | 3.43 | |

| Bathroom | 4.50 | 4.44 | |

| Store 4 | 0.60 | 0.57 | |

| Total | 88.49 | 86.84 |

| Construction | Layer | Material | Thickness (mm) | Conductivity (W/mK) |

|---|---|---|---|---|

| External wall (TFH) | 1 | Brick outer leaf | 102.5 | 0.77 |

| 2 | Slightly ventilated cavity | 50 | R = 0.71 | |

| 1R 1 | Render | 20 | 1.0 | |

| 2R 1 | Blockwork, 6.7% bridging with standard aircrete | 100 | 0.15 (0.88) | |

| 3 | Oriented Strand Board (OSB) | 9 | 0.13 | |

| 4 | Mineral fibre insulation, 15% bridging with timber frame | 89 | 0.035 (0.12) | |

| 5 | PIR insulation board | 40 | 0.022 | |

| 6 | Service void, 11.8% bridging with wooden battens | 25/38 2 | R = 0.67 (0.292) | |

| 7 | Gypsum plasterboard | 15 | 0.19 | |

| External wall (eHome2) | 1 | Weberwall brick slip finishing system | 15 | 0.72 |

| 1R 1 | Webersill TF finish coat and Weberend LCA rapid base coat | 7.5 | 0.72 | |

| 2 | BG glassroc x | 12.5 | 0.1865 | |

| 3 | Ventilated cavity | 25 | R = 0.71 | |

| 4 | Oriented Strand Board | 9 | 0.13 | |

| 5 | TFR35 Insulation, 8.8% bridging with flange | 47 | 0.035 (0.13) | |

| 6 | TFR35 Insulation, 1.7% bridging with flange | 151 | 0.035 (0.13) | |

| 7 | TFR35 Insulation, 8.8% bridging with flange | 47 | 0.035 (0.13) | |

| 8 | Oriented Strand Board | 9 | 0.13 | |

| 9 | Service void with 8.8% bridging with wooden battens | 35 | R = 0.67 (0.269) | |

| 10 | BG Gyproc Wallboard | 15 | 0.19 | |

| Loft ceiling (TFH) | 1 | Knauf insulation loft roll | 400 | 0.044 |

| 2 | Knauf insulation loft roll, 9% bridging with wooden battens | 100 | 0.044 (0.13) | |

| 3 | BG Gyproc Wallboard | 15 | 0.19 | |

| Loft ceiling (eHome2) | 1 | Isover Spacesaver roof insulation | 300 | 0.044 |

| 2 | Isover Spacesaver roof insulation, 9% bridging with wooden battens | 100 | 0.044 (0.13) | |

| 3 | BG Gyproc Wallboard | 15 | 0.19 | |

| Unoccupied pitched roof | 1 | Concrete tiles (roofing) | 10 | 1.5 |

| 2 | Air gap | 10 | R = 0.15 | |

| 3 | Roofing Felt | 5 | 0.19 | |

| Internal partitions | 1 | Gypsum plasterboard | 15 | 0.19 |

| 2 | Air gap | 100 | R = 0.15 | |

| 3 | Gypsum plasterboard | 15 | 0.19 | |

| Ground floor | 1 | 450 mm NUG375 + 75 mm Screed | 450 | 0.058 |

| Internal floor (TFH) | 1 | Caberdek chipboard floor | 22 | 0.13 |

| 2 | Air gap 300 mm | 300 | R = 0.23 | |

| 3 | Gypsum plasterboard | 15 | 0.19 | |

| Internal floor (eHome2) | 1 | Caberdek chipboard floor | 22 | 0.13 |

| 2 | Oriented Strand Board | 15 | 0.13 | |

| 3 | Air gap 254 mm | 254 | R = 0.23 | |

| 4 | BG Gyproc wallboard | 15 | 0.19 | |

| External door | 1 | Painted Oak | 35 | 0.19 |

| Parameter | TFH | eHome2 | Future Homes Standard |

|---|---|---|---|

| Brick external wall U-value (W/m2K) | 0.18 | 0.13 | 0.18 |

| Rendered external wall U-value (W/m2K) | 0.17 | 0.13 | 0.18 |

| Loft ceiling U-value (W/m2K) | 0.09 | 0.11 | 0.11 |

| Ground floor U-value (W/m2K) | 0.11 | 0.11 | 0.13 |

| Windows U-value (W/m2K) | 1.20 | 1.20 | 1.20 |

| Windows Solar Heat Gain Coefficient (-) | 0.51 | 0.51 | / |

| French door U-value (W/m2K) | 1.40 | / | 1.20 |

| External door U-value (W/m2K) | 1.00 | 1.20 | 1.00 |

| Air infiltration rate @ 50 Pa (m3/hm2) | 2.50 | 3.00 | 5.00 |

| Internal partition U-value (W/m2K) | 1.89 | 1.89 | / |

| Internal floor U-value (W/m2K) | 1.34 | 1.16 | / |

| Internal door U-value (W/m2K) | 2.82 | 2.82 | / |

| Thermal Bridging Inputs | TFH | eHome2 |

|---|---|---|

| Roof-Wall (W/mK) | 0.059 | 0.066 |

| Wall–ground floor (W/mK) | 0.190 | 0.151 |

| Wall–wall (corner) (W/mK) | 0.040 | 0.046 |

| Wall–floor (Int–not ground floor) (W/mK) | 0.060 | 0.062 |

| Lintel above window or door (W/mK) | 0.050 | 0.060 |

| Sill below window (W/mK) | 0.030 | 0.092 |

| Jamb below window (W/mK) | 0.050 | 0.044 |

| Parameter | Value |

|---|---|

| Dry-Blub Temperature | 5.2 and 5.3 °C |

| Dew Point Temperature | 2.16 and 2.31 °C |

| Relative Humidity | 81% |

| Atmospheric Pressure | 101,325 Pa |

| Horizontal Infrared Radiation Intensity from Sky | 269.59 and 269.87 W/m2 |

| Global Horizontal Radiation | 0 Wh/m2 |

| Direct Normal Radiation | 0 Wh/m2 |

| Diffuse Horizontal Radiation | 0 Wh/m2 |

| Wind Speed | 0.2 m/s |

| Total Sky Cover | 0 |

| Opaque Sky Cover | 0 |

| Snow Depth | 0 cm |

| Liquid Precipitation Depth | 0 cm |

| Building Fabric Parameter | TFH Design | TFH As-Built | eHome2 Design | eHome2 As-Built |

|---|---|---|---|---|

| Brick external wall U-value (W/m2K) | 0.18 | 0.17 | 0.13 | 0.15 |

| Rendered external wall U-value (W/m2K) | 0.17 | 0.17 | 0.13 | 0.16 |

| Loft ceiling U-value (W/m2K) | 0.09 | 0.14 | 0.11 | 0.14 |

| Ground floor PTT-value (W/m2K) | 0.11 | 0.14 | 0.11 | 0.14 |

| Air permeability rate (m3/(h.m2) @ 50 Pa) | 2.50 | 4.00 | 3.00 | 2.81 |

| Internal partition U-value (W/m2K) | 1.89 | 1.28 | 1.76 | 1.28 |

| Internal floor U-value (W/m2K) | 1.34 | 0.73 | 1.16 | 0.73 |

| Internal door U-value (W/m2K) | 2.82 | 2.69 | 2.82 | 2.69 |

| Calibration Step | U-Values | Air Permeability | Additional Modelling Parameters |

|---|---|---|---|

| 1 | Design | Design | - |

| 2 | As-built | Design | - |

| 3 | Design | As-built | - |

| 4 | As-built | As-built | - |

| 5 | As-built | As-built | Added roof ventilation modelling |

| 6 | Added ground modelling | ||

| 7 | Added sub-floor void modelling | ||

| 8 | Combined modelling parameters |

| Calibration Step | Details | TFH DTS (W/K) | TFH SAP (W/K) | eHome2 DTS (W/K) | eHome2 SAP (W/K) |

|---|---|---|---|---|---|

| 1 | Design U-values and air permeability | 76.0 (−6.0%) | 76.3 (−7.2%) | 72.5 (−5.5%) | 73.8 (−3.8%) |

| 2 | As-built U-values and design air permeability | 78.7 (−4.3%) | 78.9 (−4.0%) | 78.2 (2.0%) | 80.7 (5.2%) |

| 3 | Design U-values and as-built air permeability | 80.9 (−1.6%) | 81.7(−0.6%) | 71.9 (−6.3%) | 73.1 (−4.7%) |

| 4 | As-built U-values and air permeability | 83.6 (1.7%) | 84.3 (2.6%) | 77.6 (1.2%) | 80.0 (4.3%) |

| 5 | Step 4 + Added roof ventilation modelling | 83.5 (1.6%) | n/a * | 77.5 (1.0%) | n/a * |

| 6 | Step 4 + Added ground modelling | 87.4 (6.3%) | 81.8 (6.6%) | ||

| 7 | Step 4 + Added sub-floor void modelling | 79.4 (−3.4%) | 73.6 (−4.0%) | ||

| 8 | Step 4 + Combined modelling parameters | 81.8 (−0.5%) | 77.1 (0.5%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsang, C.; Fitton, R.; Zhang, X.; Henshaw, G.; Díaz-Hernández, H.P.; Farmer, D.; Allinson, D.; Sitmalidis, A.; Dgali, M.; Jankovic, L.; et al. Calibration of Building Performance Simulations for Zero Carbon Ready Homes: Two Open Access Case Studies Under Controlled Conditions. Sustainability 2025, 17, 6673. https://doi.org/10.3390/su17156673

Tsang C, Fitton R, Zhang X, Henshaw G, Díaz-Hernández HP, Farmer D, Allinson D, Sitmalidis A, Dgali M, Jankovic L, et al. Calibration of Building Performance Simulations for Zero Carbon Ready Homes: Two Open Access Case Studies Under Controlled Conditions. Sustainability. 2025; 17(15):6673. https://doi.org/10.3390/su17156673

Chicago/Turabian StyleTsang, Christopher, Richard Fitton, Xinyi Zhang, Grant Henshaw, Heidi Paola Díaz-Hernández, David Farmer, David Allinson, Anestis Sitmalidis, Mohamed Dgali, Ljubomir Jankovic, and et al. 2025. "Calibration of Building Performance Simulations for Zero Carbon Ready Homes: Two Open Access Case Studies Under Controlled Conditions" Sustainability 17, no. 15: 6673. https://doi.org/10.3390/su17156673

APA StyleTsang, C., Fitton, R., Zhang, X., Henshaw, G., Díaz-Hernández, H. P., Farmer, D., Allinson, D., Sitmalidis, A., Dgali, M., Jankovic, L., & Swan, W. (2025). Calibration of Building Performance Simulations for Zero Carbon Ready Homes: Two Open Access Case Studies Under Controlled Conditions. Sustainability, 17(15), 6673. https://doi.org/10.3390/su17156673