Simulation of Snow and Ice Melting on Energy-Efficient and Environmentally Friendly Thermally Conductive Asphalt Pavement

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

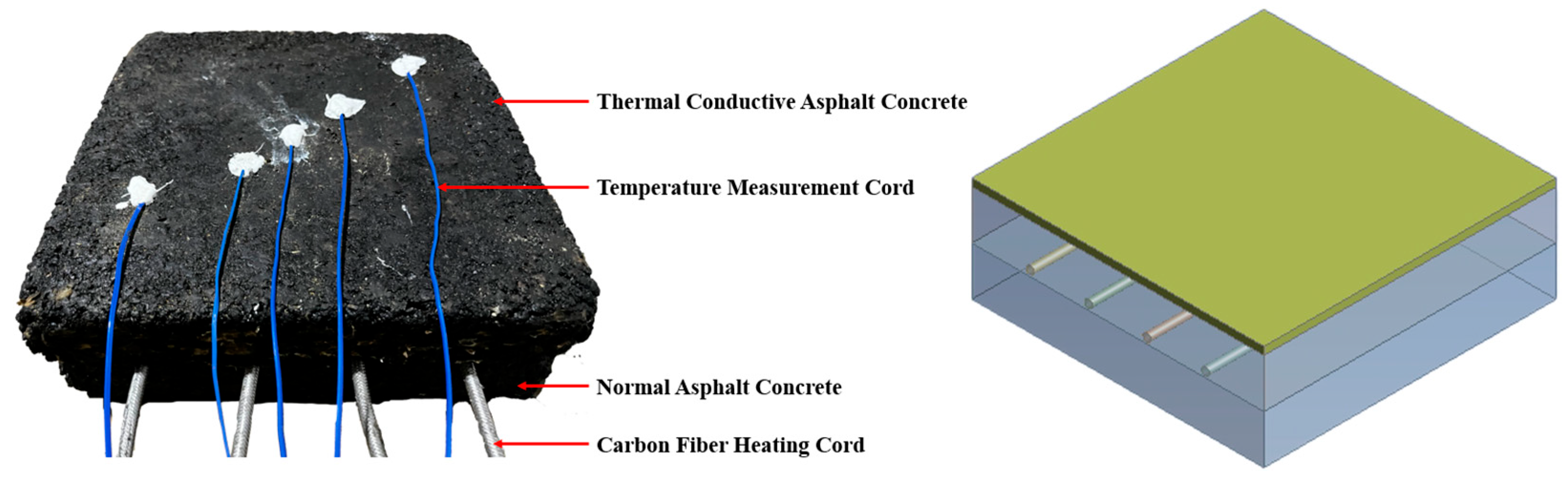

2.2. Specimen Preparation

2.3. Thermal Property Testing

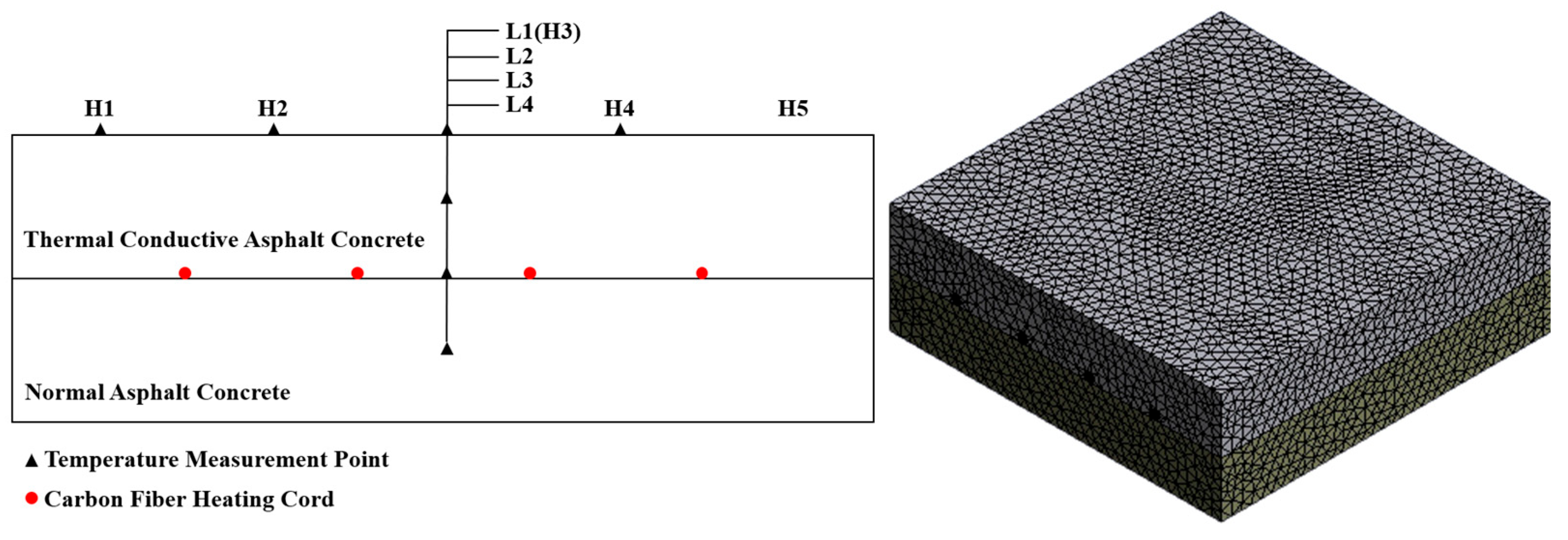

2.4. Simulation Model Creation

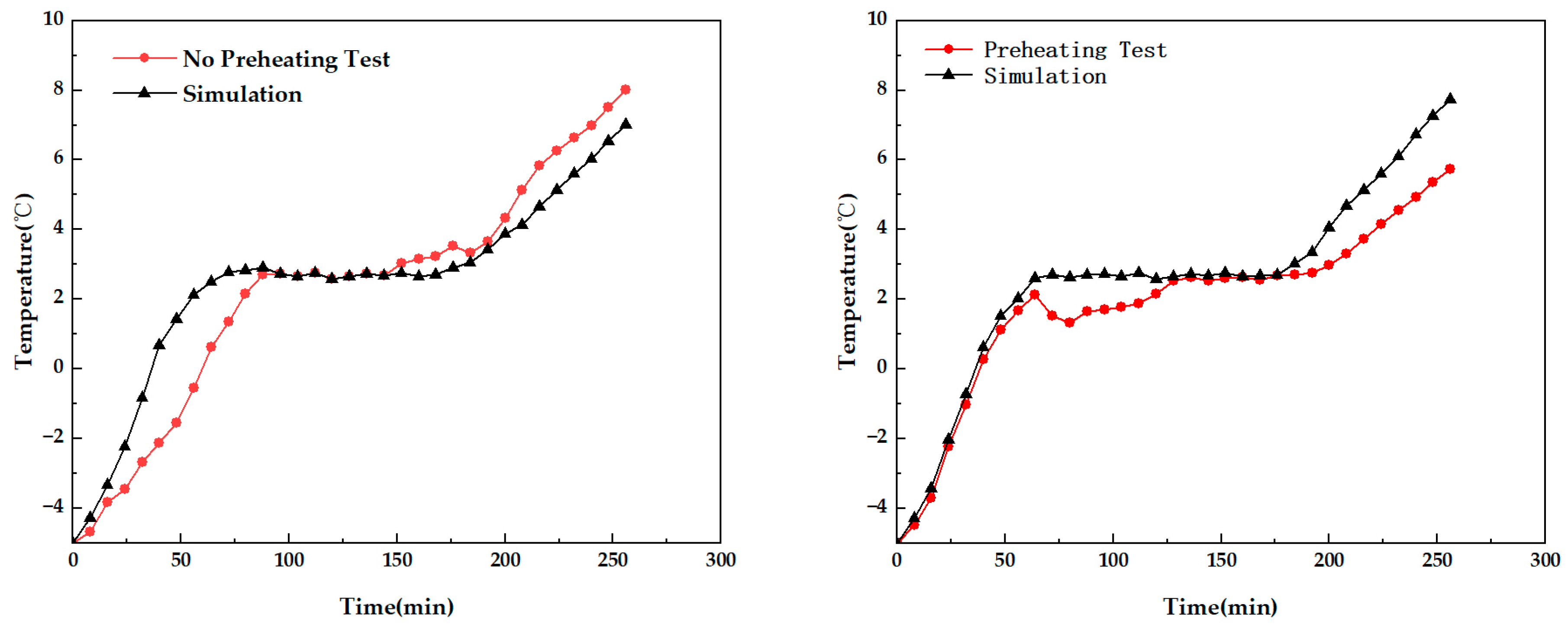

2.5. Simulation Model Validation

3. Results and Discussion

3.1. Influence of Thermal Conductivity on Heating Rate

3.2. Influence of Heating Cord Power on De-Icing Time

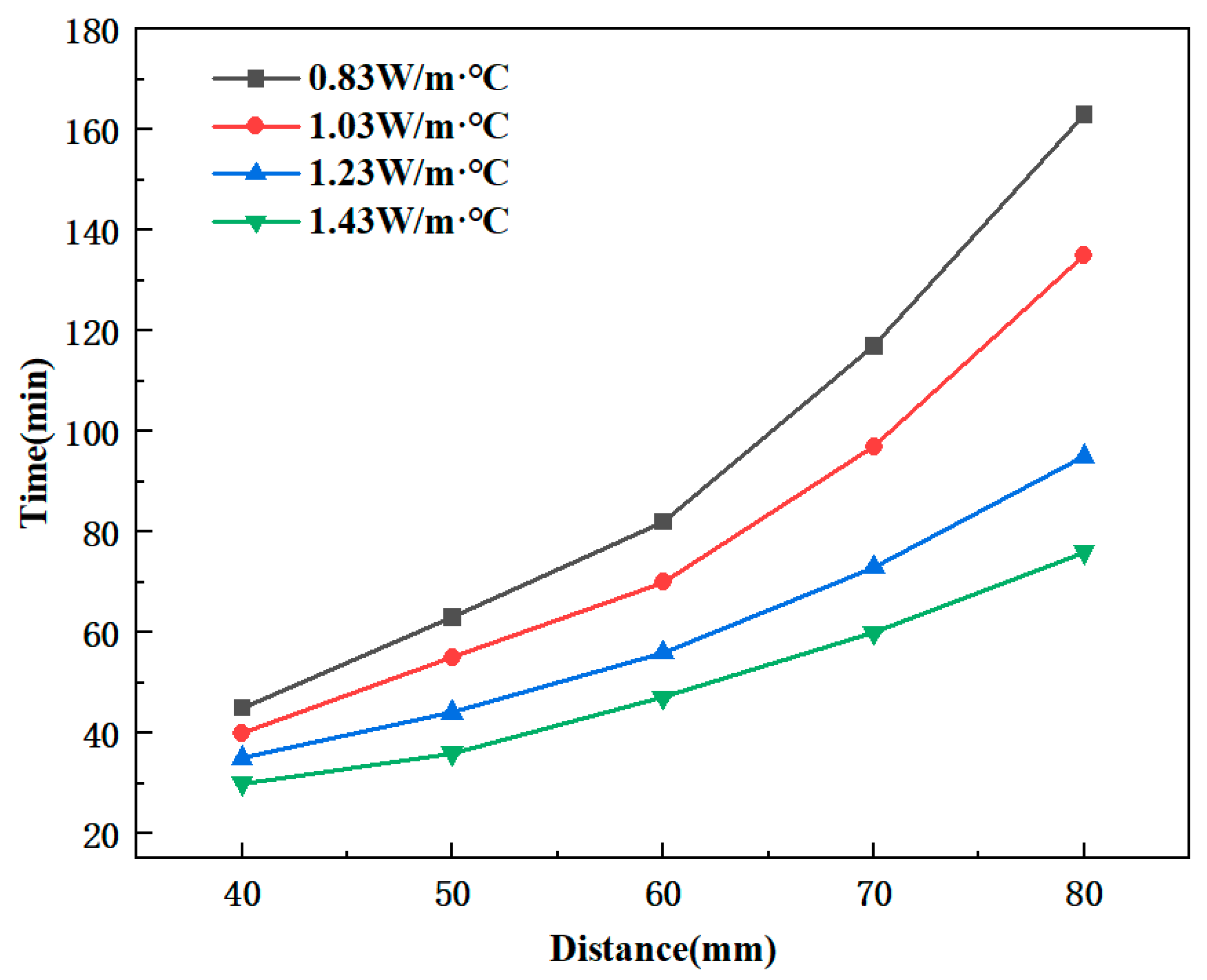

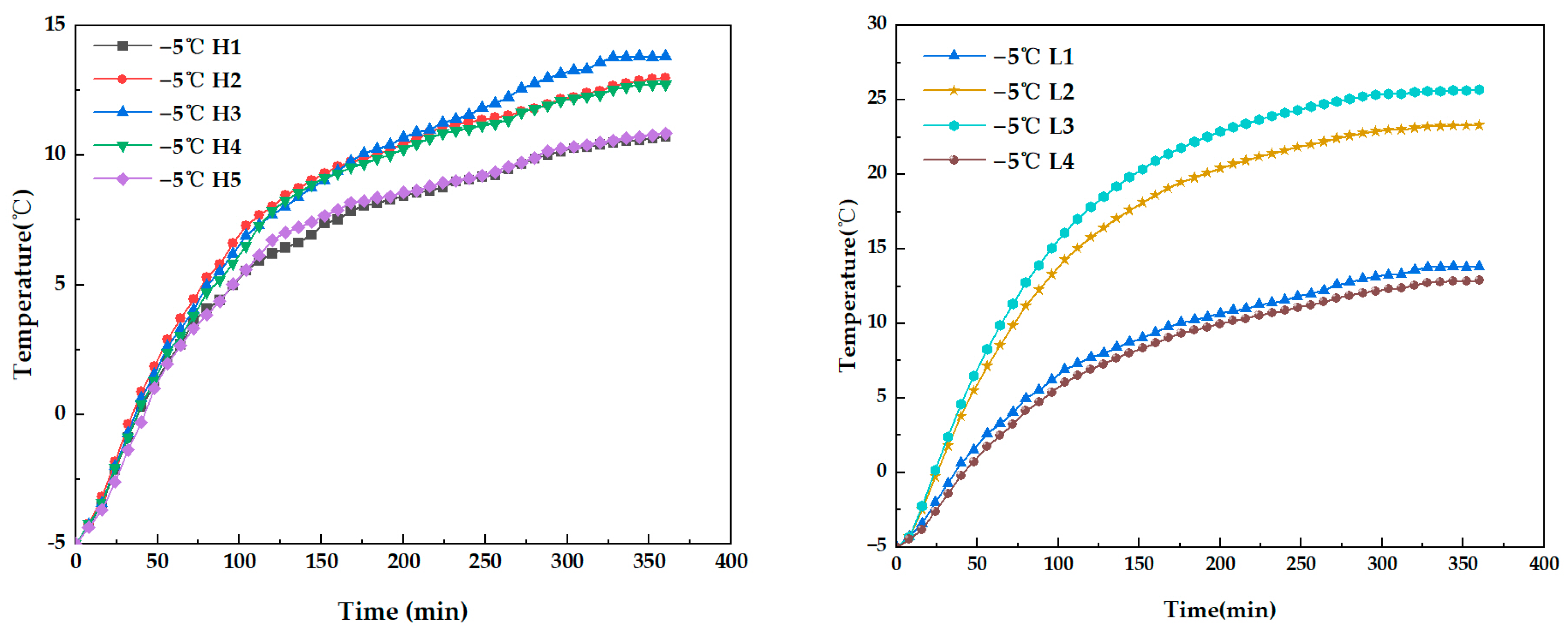

3.3. Influence of Heating Cord Spacing on Thermal Performance

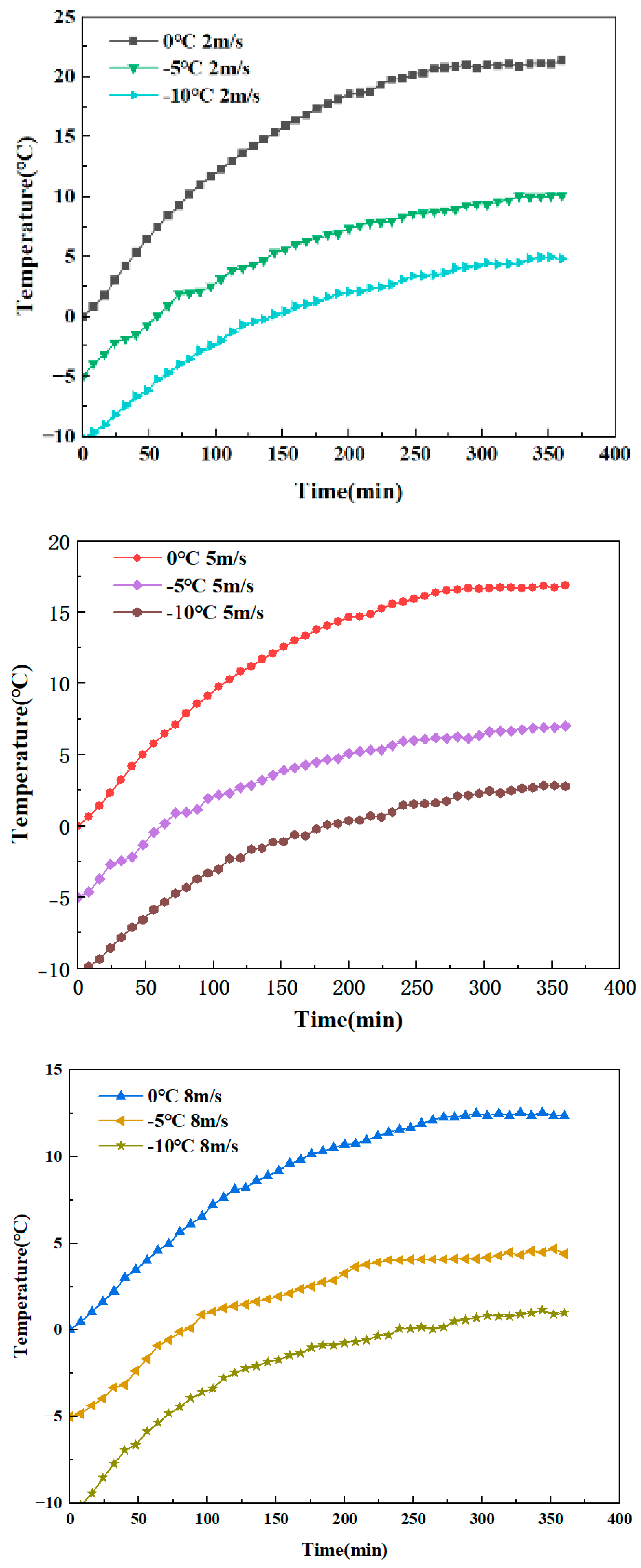

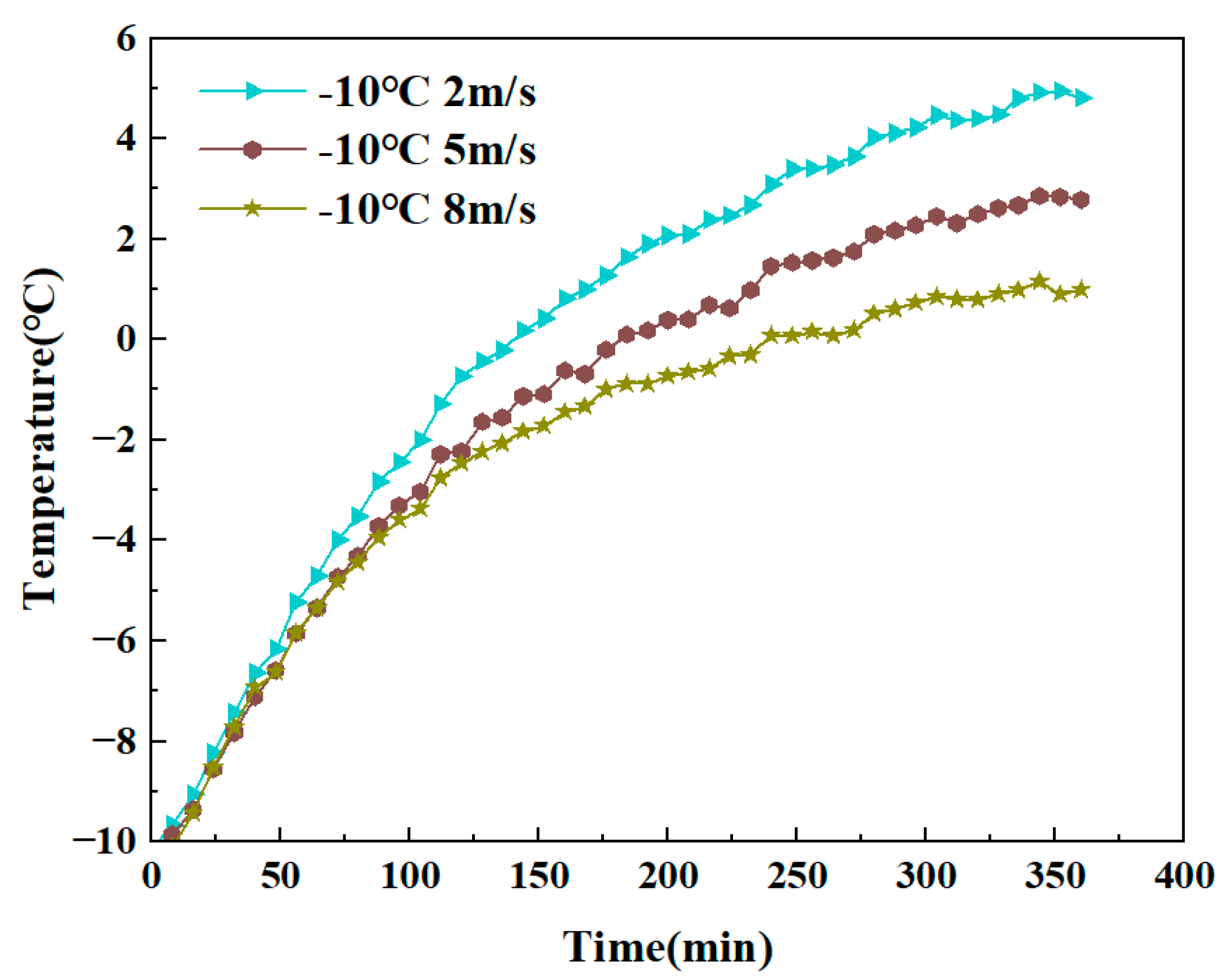

3.4. Influence of Wind Speed and Ambient Temperature on Asphalt Concrete

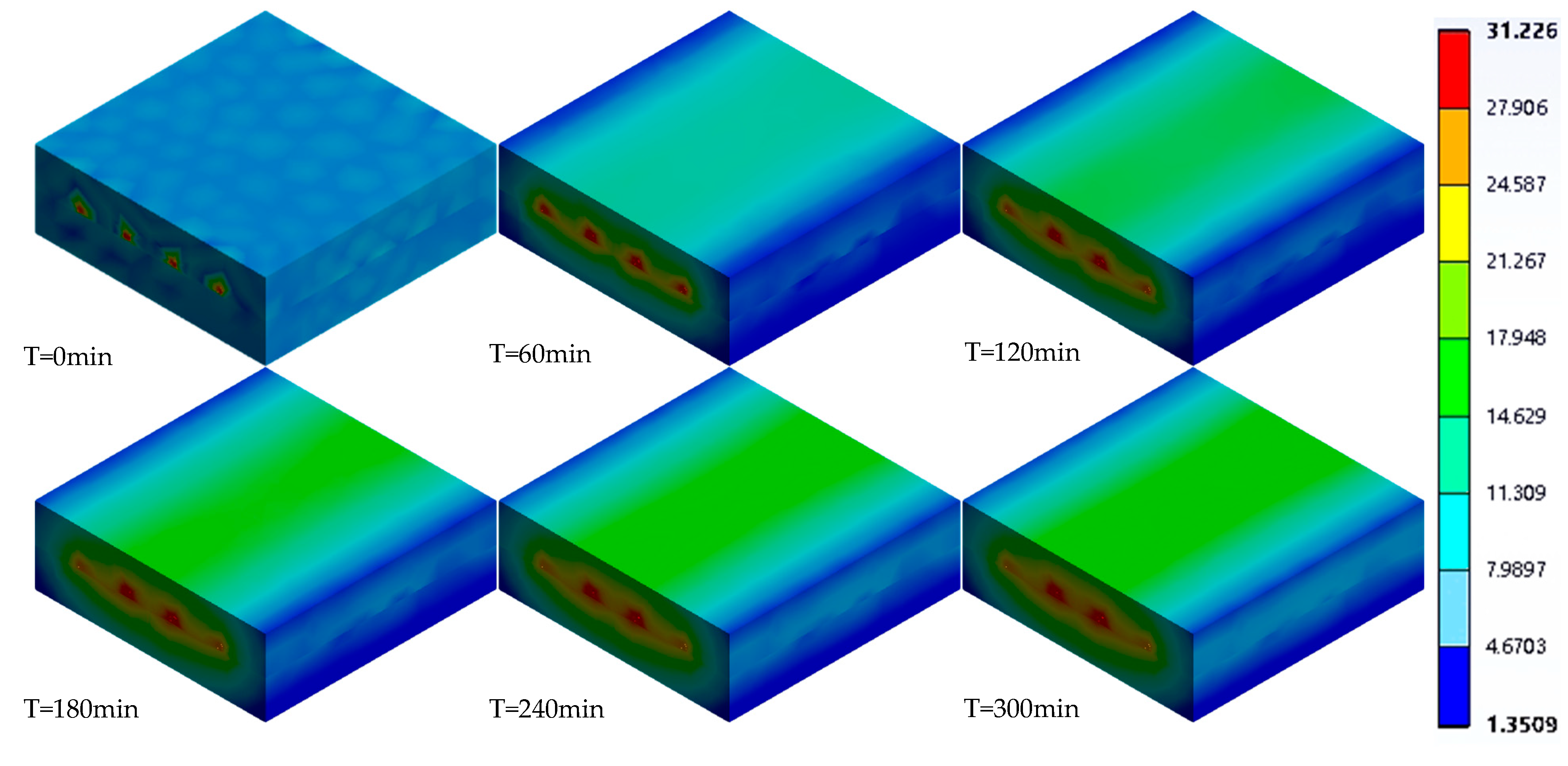

3.5. Internal Temperature Distribution of Asphalt Concrete

4. Conclusions

- (1)

- The accuracy of the calculation model was validated through experiments using TCAC specimens with the same dimensions as those in the simulation tests under identical working conditions. The on-site snow and ice melting test on thermal conductive asphalt concrete pavement and the finite element numerical simulation tests showed good agreement in both experimental data results and variation trends; however, it is impossible to simulate the effect of ice melting into water on asphalt pavement temperature. Through the Pearson correlation analysis of the finite element simulation test data and the field snow and ice melting test data, it can be seen that the correlation coefficient R between numerical simulations and field measurements reaches 0.98 in the preheated test. For the non-preheated test, this coefficient measures 0.93. Both values exceed 0.9, demonstrating significant correlation (p < 0.01) between simulation and experimental outcomes.

- (2)

- The specimens’ rate of heating is positively connected with the thermal conductivity of the TCAC under identical external conditions. In comparison to the asphalt concrete specimen with a thermal conductivity of 0.83 W/(m·K), the heating rates of the specimens with thermal conductivities of 1.03, 1.23 W/(m·K), and 1.43 W/(m·K) are 117.6%, 139.2%, and 163.1%, respectively. This implies that, by properly adding thermal conductive fillers for modification, the overall thermal conductivity of asphalt concrete can be successfully increased, creating a three-dimensional continuous heat transport network inside the concrete.

- (3)

- Increasing carbon fiber heating cord power sharply shortens TCAC surface temperature rise time to the snow melting threshold; a rise from 900 to 1800 W/m2 cuts it from 78 to 23 min. Cord laying spacing also affects TCAC with 0.83 and 1.03 W/(m·°C) thermal conductivity; time rises notably over 60 mm spacing. At 1.23 and 1.43 W/(m·°C), TCAC shows a linear spacing time relation, revealing a threshold effect.

- (4)

- Heated for the same duration, the TCAC’s ultimate stable temperature correlates negatively with wind speed and positively with ambient temperature. Both factors correlate negatively with the TCAC heating rate. The time for the ice melting to begin follows rules: a constant wind brings a longer time at lower temperatures (24 min at 0 °C and 230 min at −10 °C in 5 m/s, an 858% increase in time). A constant temperature means a longer time at higher winds (60 min at 2 m/s and 120 min at 8 m/s at −5 °C, doubling the time).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Autelitano, F.; Rinaldi, M.; Giuliani, F. Winter highway maintenance strategies: Are all the sodium chloride salts the same? Constr. Build. Mater. 2019, 226, 945–952. [Google Scholar] [CrossRef]

- Gao, Y.; Xu, Y.; Zeng, W.; Fang, Z.; Duan, K.; Pei, G.; Zhou, W. Salt-frost resistance and mechanism analysis of super-hydrophobic pavement cement concrete for different deicing salts. Road Mater. Pavement Des. 2020, 22, 1908–1929. [Google Scholar] [CrossRef]

- Yang, J.; Zhu, X.; Li, L.; Ling, H.; Zhou, P.; Cheng, Z.; Su, A.; Du, Y. Prefabricated flexible conductive composite overlay for active deicing and snow melting. J. Mater. Civ. Eng. 2018, 30, 2473. [Google Scholar] [CrossRef]

- Ma, T.; Geng, L.; Ding, X.; Zhang, D.; Huang, X. Experimental study of deicing asphalt mixture with anti-icing additives. Constr. Build. Mater. 2016, 127, 653–662. [Google Scholar] [CrossRef]

- Wu, S.; Pan, P.; Chen, M.; Zhang, Y. Analysis of characteristics of electrically conductive asphalt concrete prepared by multiplex conductive materials. J. Mater. Civ. Eng. 2013, 25, 871–879. [Google Scholar] [CrossRef]

- Ma, T.; Ding, X.H.; Wang, H.; Zhang, W. Experimental study of high-performance deicing asphalt mixture for mechanical performance and anti-icing effectiveness. J. Mater. Civ. Eng. 2018, 30, 2369. [Google Scholar] [CrossRef]

- Peng, C.; Yu, J.; Zhao, Z.; Dai, J.; Fu, J.; Wang, W. Effects of a sodium chloride deicing additive on the rheological properties of asphalt mastic. Road Mater. Pavement Des. 2016, 17, 382–395. [Google Scholar] [CrossRef]

- Arabzadeh, A.; Notani, M.A.; Zadeh, A.K.; Nahvi, A.; Sassani, A.; Ceylan, H. Electrically conductive asphalt concrete: An alternative for automating the winter maintenance operations of transportation infrastructure. Compos. Part B 2019, 173, 106985. [Google Scholar] [CrossRef]

- Notani, M.A.; Arabzadeh, A.; Ceylan, H.; Kim, S.; Gopalakrishnan, K. Effect of carbon-fiber properties on volumetrics and ohmic heating of electrically conductive asphalt concrete. J. Mater. Civ. Eng. 2019, 31, 04019200. [Google Scholar] [CrossRef]

- Cheng, L.; Hao, G.; Sun, D.; Zhou, X. Novel conductive wearing course using a graphite, carbon fiber, and epoxy resin mixture for active de-icing of asphalt concrete pavement. Mater. Struct. 2021, 54, 48. [Google Scholar] [CrossRef]

- Chen, M.; Wu, S.; Wang, H.; Zhang, J. Study of ice and snow melting process on conductive asphalt solar collector. Sol. Energy Mater. Sol. Cells 2011, 95, 3241–3250. [Google Scholar] [CrossRef]

- Vo, H.V.; Park, D.W.; Dessouky, S. Simulation of snow melting pavement performance using measured thermal properties of graphite-modified asphalt mixture. Road Mater. Pavement Des. 2015, 16, 696–706. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, Y.; Wei, Z.; Zhang, D. Microwave absorption enhancement of asphalt concrete with SiC-Fe3O4 mixtures modifier. Constr. Build. Mater. 2020, 254, 119209. [Google Scholar] [CrossRef]

- Torres-Machí, C.; Chamorro, A.; Pellicer, E.; Yepes, V.; Videla, C. Sustainable pavement management: Integrating economic, technical, and environmental aspects in decision making. Transp. Res. Rec. 2015, 2523, 56–63. [Google Scholar] [CrossRef]

- Wen, X.; Wang, H.; Yang, J. Electrical conductivity and rheological properties of asphalt binder containing graphite. In Proceedings of the COTA International Conference of Transportation Professionals, Nanjing, China, 6–8 July 2019; pp. 964–974. [Google Scholar]

- Liu, X.; Wu, S. Study on the graphite and carbon fiber modified asphalt concrete. Constr. Build. Mater. 2011, 25, 1807–1811. [Google Scholar] [CrossRef]

- Amani, S.; Kavussi, A.; Karimi, M.M. Effects of aging level on induced heating-healing properties of asphalt mixes. Constr. Build. Mater. 2020, 263, 120105. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, Y.; Zhang, Y.; Feng, S.; Lu, G.; Cao, L. Laboratory and numerical investigation of microwave heating properties of asphalt mixture. Materials 2019, 12, 146. [Google Scholar] [CrossRef]

- Karimi, M.M.; Jahanbakhsh, H.; Nejad, F.M. Energy-based approach to characterize induced heating of asphalt concrete under electromagnetic field. Construct. Build Mater. 2020, 12, 1762–1788. [Google Scholar] [CrossRef]

- Mohammed, A.G.; Ozgur, G.; Sevkat, E. Electrical resistance heating for deicing and snow melting applications: Experimental study. Cold Reg. Sci. Technol. 2019, 160, 128–138. [Google Scholar] [CrossRef]

- Wang, Y.; Jiang, X.; Cheng, G.; Huang, K.; Lu, H.; Li, Y.; Zhou, H.; Huang, B. Electrical and thermal properties of asphalt pavements utilizing electrically conductive geogrids for snow and ice melting. J. Mater. Civ. Eng. 2025, 37, 19163. [Google Scholar] [CrossRef]

- Han, S.; Wei, H.; Jiang, B.; Wang, H.; Chen, J. Numerical and outdoor experimental study on active snow melting of conductive rubber composites in roads. Road Mater. Pavement Des. 2023, 24, 1748–1764. [Google Scholar] [CrossRef]

- Yi, J.; Zhao, R.; Xie, S.; Zhao, H.; Feng, D. Thermal performance of a layered asphalt pavement system for snow melting. Cold Reg. Sci. Technol. 2022, 193, 103419. [Google Scholar] [CrossRef]

- Guo, B. Study on Snow Melting and Deicing Technology of Asphalt Concrete Bridge Deck with Embedded Carbon Fiber Heating Wires. Master’s Thesis, Henan University, Kaifeng, China, 2018. [Google Scholar]

- Zhang, W.; Dong, S.; Song, Z.; Ding, S.; Yi, J.; Han, B. Snow-melting performance and application method of stainless steel wires-modified conductive asphalt concrete based on electrothermal conversion. Appl. Therm. Eng. 2025, 269, 126066. [Google Scholar] [CrossRef]

- Karimi, M.M.; Jahanbakhsh, H.; Jahangiri, B.; Nejad, F.M. Induced heating-healing characterization of activated carbon modified asphalt concrete under microwave radiation. Constr. Build. Mater. 2018, 178, 254–271. [Google Scholar] [CrossRef]

- Liu, Q.T.; Li, B.; Schlangen, E.; Sun, Y.H.; Wu, S.P. Research on the Mechanical, Thermal, Induction Heating and Healing Properties of Steel Slag/Steel Fibers Composite Asphalt Mixture. Appl. Sci. 2017, 7, 1088. [Google Scholar] [CrossRef]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

- JTG 3432-2024; Test Methods of Aggregate for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2024.

- Gustafsson, S.E. Transient plane source techniques for thermal conductivity and thermal diffusivity measurements of solid materials. Rev. Sci. Instrum. 1991, 62, 797–804. [Google Scholar] [CrossRef]

- ISO 22007-2: 2022; Plastics-Determination of Thermal Conductivity and Thermal Diffusivity. International Organization for Standardization: Geneva, Switzerland, 2022.

- Adl-Zarrabi, B.; Mirzanamadi, R.; Johnsson, J. Hydronic pavement heating for sustainable ice-free roads. Transp. Res. Procedia 2016, 14, 704–713. [Google Scholar] [CrossRef]

- Pan, P.; Wu, S.; Xiao, Y.; Wang, P.; Liu, X. Influence of graphite on the thermal characteristics and anti-ageing properties of asphalt binder. Constr. Build. Mater. 2014, 68, 220–226. [Google Scholar] [CrossRef]

- Khasawneh, M.A.; Adnan, S.; Mohannad, A.T.; Ahmad, A.M. Effect of aggregate gradation and asphalt mix volumetrics on the thermal properties of asphalt concrete. Case Stud. Constr. Mater. 2023, 18, e01725. [Google Scholar] [CrossRef]

- Demirtürk, D.; Ozturk, H.I.; Guler, M. Investigation of the influence of mixture and microstructural properties on the thermal conductivity of asphalt concrete using the transient heat transfer method. Mater. Struct. 2024, 57, 179. [Google Scholar] [CrossRef]

- Yang, Z.; Hu, E.; Lei, X.; Chen, Z.; Xiong, F.; Zhan, C. Preparation and analysis of carbon fiber-silicon carbide thermally conductive asphalt concrete. Fluid Dyn. Mater. Process. 2024, 20, 705–723. [Google Scholar] [CrossRef]

| Penetration | Softening Point | Ductility | Open Flash Point | Residual Penetration Ratio | Residual Ductility |

|---|---|---|---|---|---|

| 7.3 mm | 47 °C | 58 cm | >300 °C | 67.5% | 8 cm |

| Crushing Value | Los Angeles Abrasion Loss | Water Absorption | Crushing Strength | Slender Flat Particle Content |

|---|---|---|---|---|

| 9.5 MPa | 3.7% | 0.9% | 160 MPa | 4% |

| Tensile Strength | Tensile Modulus | Density | Resistivity | Monofilament Diameter |

|---|---|---|---|---|

| 4825 MPa | 230 GPa | 1.82 g/cm3 | 1.75 × 10−3 W | 7.3 mm |

| Carbon Content | Bulk Density | Diameter | Thermal Conductivity | Appearance |

|---|---|---|---|---|

| 98.5% | 3.18 g/cm3 | 0.073 mm | 270 W/(m·K) | Green powder |

| Sieve Size/mm | 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 |

| Total passing/% | 100 | 95 | 77 | 53 | 37 | 27 | 19 | 14 | 9 | 5 |

| Material | Density (kg/m3) | Thermal Conductivity (W/m·°C) | Specific Heat Capacity (J/kg·°C) |

|---|---|---|---|

| 48 k carbon fiber | 2000 | 60.3 | 712 |

| Ordinary asphalt concrete | 2250 | 0.83 | 1100 |

| TCAC | 2400 | 1.23/1.43/1.03 | 1300 |

| Thermal Conductivity W/(m·K) | Surface Temperature °C | Rising Temperature Rate °C/min |

|---|---|---|

| 0.83 | 6.378 | 0.0632 |

| 1.03 | 8.374 | 0.0743 |

| 1.23 | 10.841 | 0.0880 |

| 1.43 | 13.616 | 0.1034 |

| Power(W/m2) | Time (min) | |

|---|---|---|

| −5 °C | −10 °C | |

| 900 | 78 | 132 |

| 1200 | 51 | 87 |

| 1500 | 38 | 67.5 |

| 1800 | 23 | 54 |

| Case | Ambient Temperature (°C) | Wind Speed (m/s) |

|---|---|---|

| 1 | −5 | 2 |

| 2 | −5 | 5 |

| 3 | −5 | 8 |

| 4 | −10 | 2 |

| 5 | −10 | 5 |

| 6 | −10 | 8 |

| Case | Stable Temperature (°C) | Heating Rate (°C/min) |

|---|---|---|

| 1 | 10.083 | 0.041 |

| 2 | 7.022 | 0.033 |

| 3 | 4.392 | 0.026 |

| 4 | 4.796 | 0.041 |

| 5 | 2.772 | 0.035 |

| 6 | 1.088 | 0.030 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, W.; Ma, Y.; Xi, L.; Huang, H.; Zheng, L.; Chen, Z.; Li, W. Simulation of Snow and Ice Melting on Energy-Efficient and Environmentally Friendly Thermally Conductive Asphalt Pavement. Sustainability 2025, 17, 8190. https://doi.org/10.3390/su17188190

Peng W, Ma Y, Xi L, Huang H, Zheng L, Chen Z, Li W. Simulation of Snow and Ice Melting on Energy-Efficient and Environmentally Friendly Thermally Conductive Asphalt Pavement. Sustainability. 2025; 17(18):8190. https://doi.org/10.3390/su17188190

Chicago/Turabian StylePeng, Wenbo, Yalina Ma, Lei Xi, Hezhou Huang, Lifei Zheng, Zhi Chen, and Wentao Li. 2025. "Simulation of Snow and Ice Melting on Energy-Efficient and Environmentally Friendly Thermally Conductive Asphalt Pavement" Sustainability 17, no. 18: 8190. https://doi.org/10.3390/su17188190

APA StylePeng, W., Ma, Y., Xi, L., Huang, H., Zheng, L., Chen, Z., & Li, W. (2025). Simulation of Snow and Ice Melting on Energy-Efficient and Environmentally Friendly Thermally Conductive Asphalt Pavement. Sustainability, 17(18), 8190. https://doi.org/10.3390/su17188190