1. Introduction

In recent decades, photovoltaic (PV) technology has experienced significant growth due to the increasing demand for renewable energy. However, with this growth, the amount of waste from PV panels is also increasing, which poses a serious environmental problem [

1,

2,

3]. Waste management in PV systems is mainly related to hazardous waste generated from the improper handling of used panels, which are often disposed of illegally or left onsite. Another problem is the export of used panels into developing countries. Panels with low usability are often sold or donated for further use in counties with lower waste management standards [

4].

Typically, PV panels are laminated with polymeric materials such as ethylene vinyl acetate (EVA) or polyolefin (POE), which complicate their efficient recycling. Standard methods for recycling these panels involve energy-intensive processes such as thermal delamination at high temperatures (450–600 °C), chemical etching, and mechanical shredding [

1,

5], which produce hazardous waste. Although the theoretical recycling efficiency of panels laminated with EVA or POE can reach up to 90%; in reality, owing to material contamination (e.g., glass dust with silicon cell fragments), it reaches significantly lower values, often only approximately 15%.

In response to these shortcomings, alternative methods for lamination of PV panels are emerging, with one of the most promising being a technology based on the use of polydimethylsiloxane (PDMS) gels. The use of PDMS gels offers several advantages over traditional polymers, including high UV resistance, chemical neutrality, and significantly lower degradation of PV panels over their lifetime [

6,

7,

8].

On the other hand, the refractive index of PDMS does not match the index of the PV panel front glass as closely as the EVA does. Therefore, because of the refractive index mismatch, the output power of the laminated PDMS panels could be reduced by approximately −0.1% and up to −0.3% compared with that of the laminated EVA panels. However, the transmittance of the PDMS is very high. Using equal solar cells, the output power of PDMS laminated PV panels is approximately +0.5% and up to +1.5% higher [

8] than that of EVA laminated panels. Therefore, the positive effect of high PDMS transmittance substantially outperforms the negative effect of refractive index mismatch.

Another significant advantage of PDMS gels is the ease of mechanical delamination of the panels at room temperature without the need for thermal or chemical processes. This property allows for significantly more efficient and environmentally friendly recycling of PV panel components, which is a step toward fulfilling the principles of circular economy. PDMS laminated panels can be delaminated faster, are cleaner, and have significantly lower energy consumption, leading to a reduction in the overall carbon footprint and hazardous waste production.

The literature also highlights that the long-term reliability of PV panels depends on the quality of the materials and encapsulation technologies used, with technologies using PDMS among the best in terms of reliability [

6,

7,

8]. The annual degradation rate of panels laminated with PDMS has been monitored for a long time and has extremely low values ranging from −0.15% to −0.22%, which leads to up to three times lower waste production than that for conventional EVA laminated panels with greater degradation.

Thus, PDMS gel-based technologies are becoming increasingly attractive for the PV industry because of a combination of environmental, economic, and technical advantages, especially in terms of low degradation rates [

6,

8]. This approach thus contributes significantly to achieving more sustainable development in the renewable energy sector.

2. Background of the Study

The lifetime (reliability) of photovoltaic generators depends mainly on the quality of the encapsulation technology. The low quality of encapsulation technology results in a very substantial increase in the quantity of photovoltaic generator waste.

Photovoltaic waste management is a critical environmental and societal issue that requires a complex approach [

3]. Unfortunately, instead of responsible recycling, we often encounter illegal practices such as the disposal of panels in landfills or leaving them at the installation site [

9].

Damaged PV panels are declared as dangerous waste and thus very large amounts of dangerous waste need to be recycled urgently. A new recycling method could solve this problem. There are many recycling methods, such as expensive high-temperature (450–600 °C) EVA melting and evaporation in inert atmospheres [

1]. However, chemical etching is time-consuming and environmentally dangerous [

1], and the most popular/relevant methods are simple milling/crushing of the front glass and burning of the encapsulant and the back sheet polymer film, as described elsewhere [

1]. EVA/POE laminated PV panels can be recycled with an ideal recycling efficiency of approximately 90% [

1]. In reality, the aluminum frames and polymer J-boxes are recycled (remelted), whereas the remaining glass is crushed and burned in industrial furnaces. The reason for this is that glass processing companies are not very interested in the glass grit from PV panels because it contains parts of broken c-Si wafers and the rest of the metallic busbars. The glass represents about ~80% of the weight of PV panels Therefore, only 15% of the PV panel’s weight is recycled [

10]. This article does not intend to cover all the existing recycling methods in detail.

PV panels laminated with solid-state polydimethylsiloxane (PDMS) have been tested previously [

8], but methods for recycling them have not been evaluated. A technology for generating PV panels laminated with very soft gels of polydimethylsiloxane (PDMS) was developed several years ago [

11]. In addition to having a high maximum operation temperature of up to +250 °C [

11] and a relative temperature index (RTI) of +150 °C, the PDMS is resistant to ultraviolet radiation. Unlike EVA and other cheap encapsulants, PDMS is a neutral material that does not produce corrosive agents such as acetic acid during the aging process and is very suitable for new complex advanced solar cell structures that are very sensitive to corrosion [

12].

Our recent experiments revealed that recycling solar PV panels (glass/glass) laminated with very soft gels of polydimethylsiloxane (PDMS) is more effective than recycling traditional solar PV panels (glass/TPT laminated with ethylene vinyl acetate (EVA) or polyolefin (POE)).

3. Methods

PV panels laminated with soft PDMS gels were manufactured via a previously developed and described innovative technology [

11].

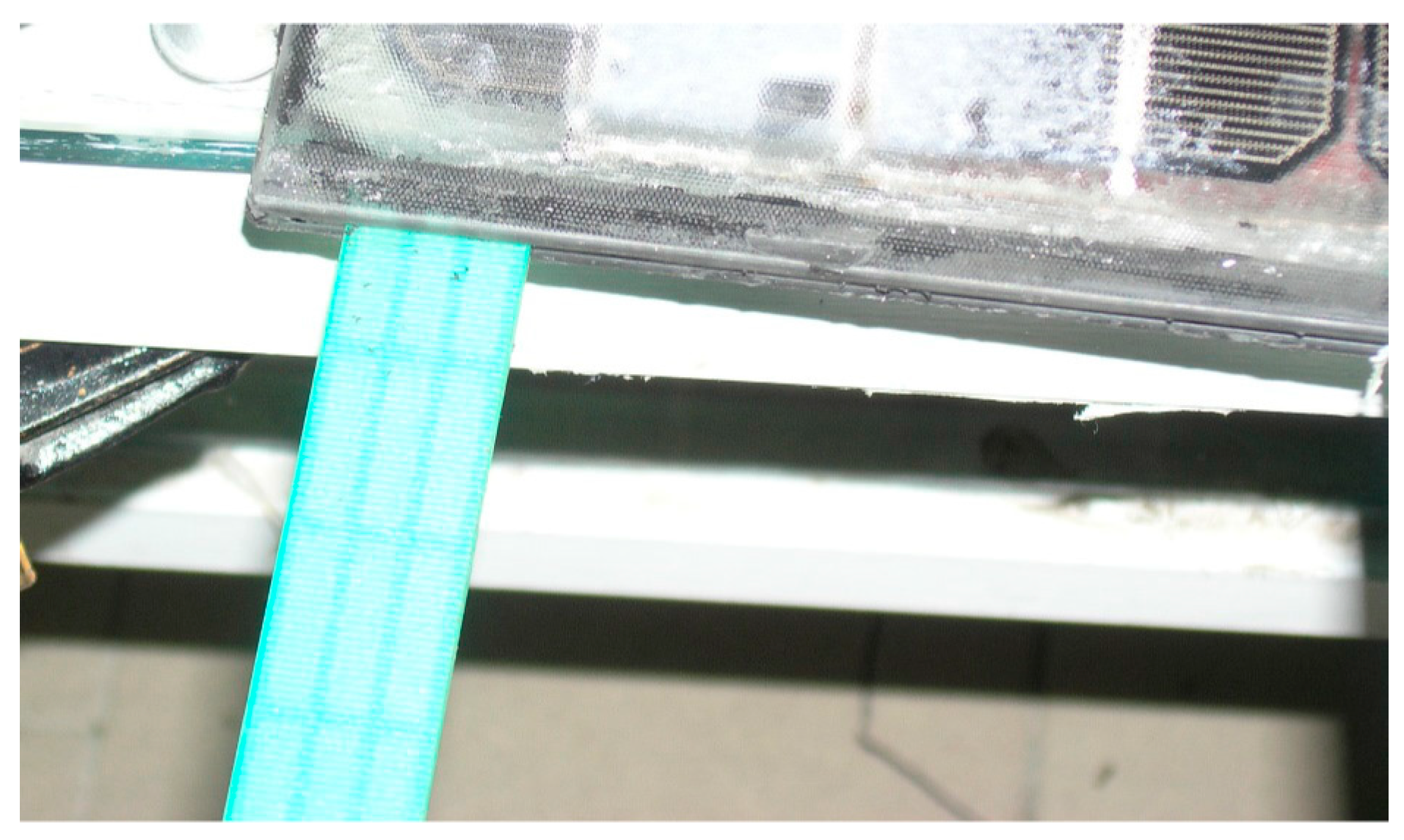

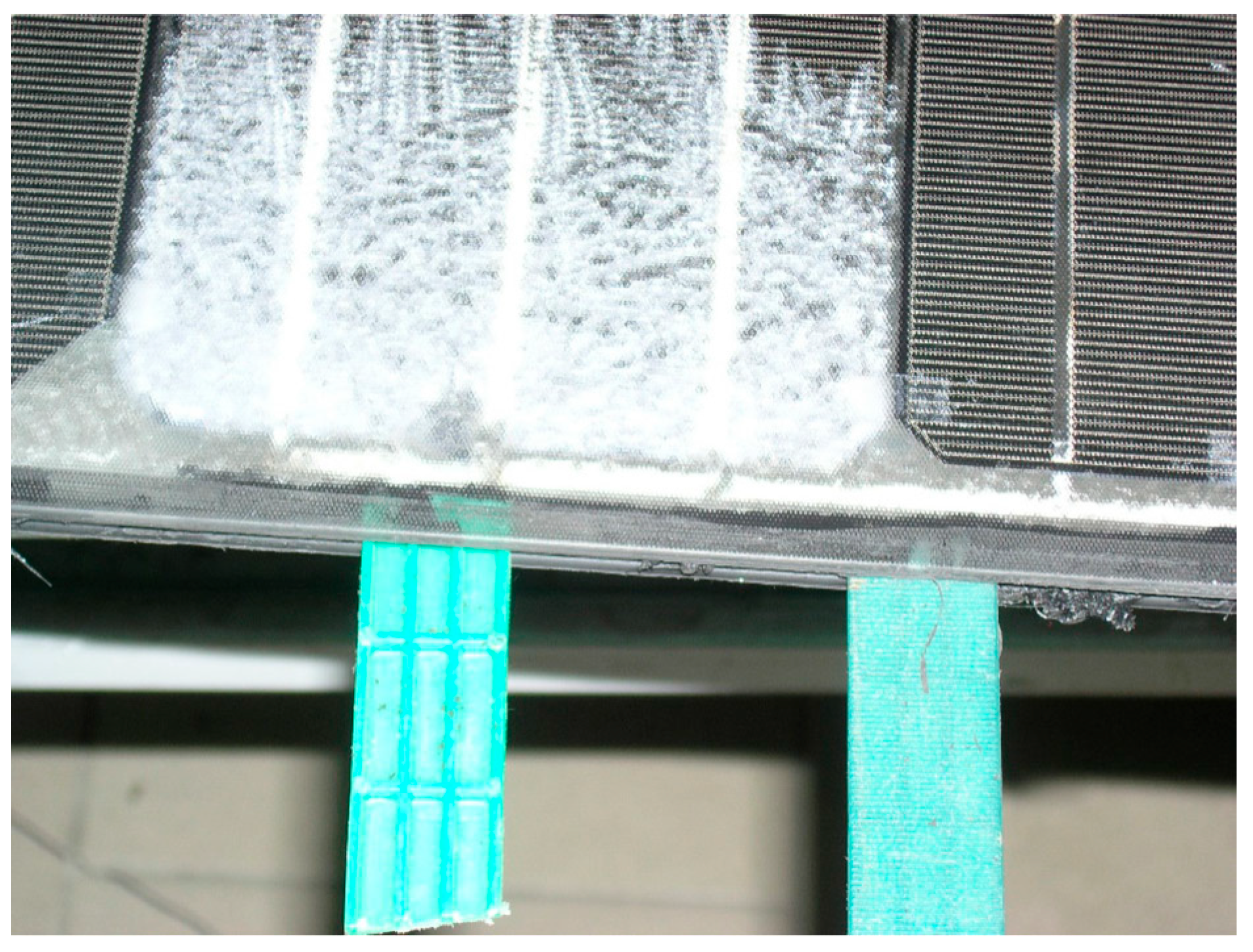

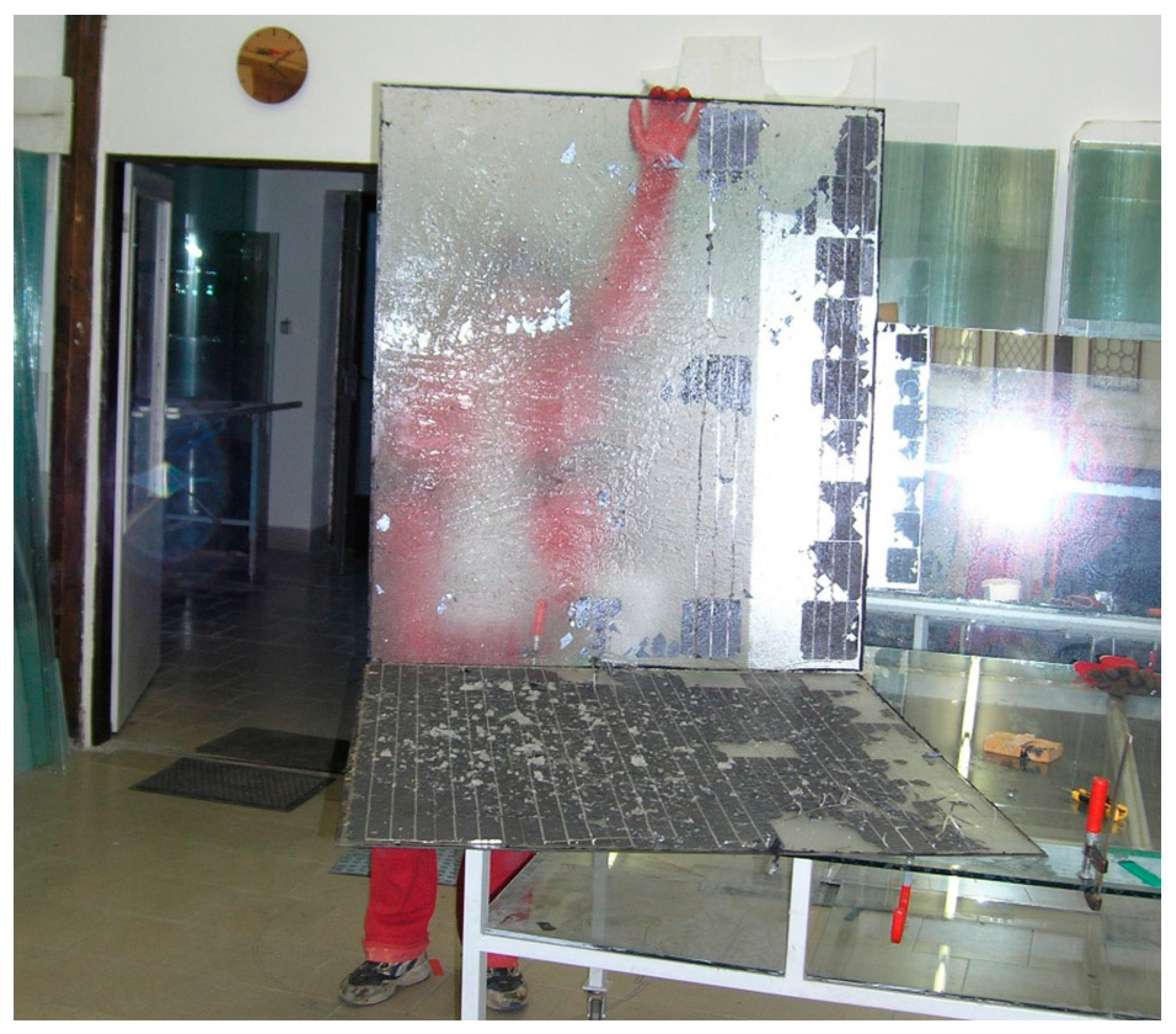

These PV panels can be easily mechanically delaminated at room temperature, as shown in

Figure 1,

Figure 2,

Figure 3,

Figure 4,

Figure 5 and

Figure 6, which is their main advantage over typical PV panels laminated with solid EVE/POE polymers [

1]. PV panel delamination is the most important process influencing the effectiveness of PV panel recycling. The reproducibility of the process was verified by the disassembly and recycling of 1 + 7 identical PV modules laminated with soft PDMS gels. We attempted fast (4 min) delamination with the first pretesting module. However, the upper glass sheet was broken because of the extreme mechanical load.

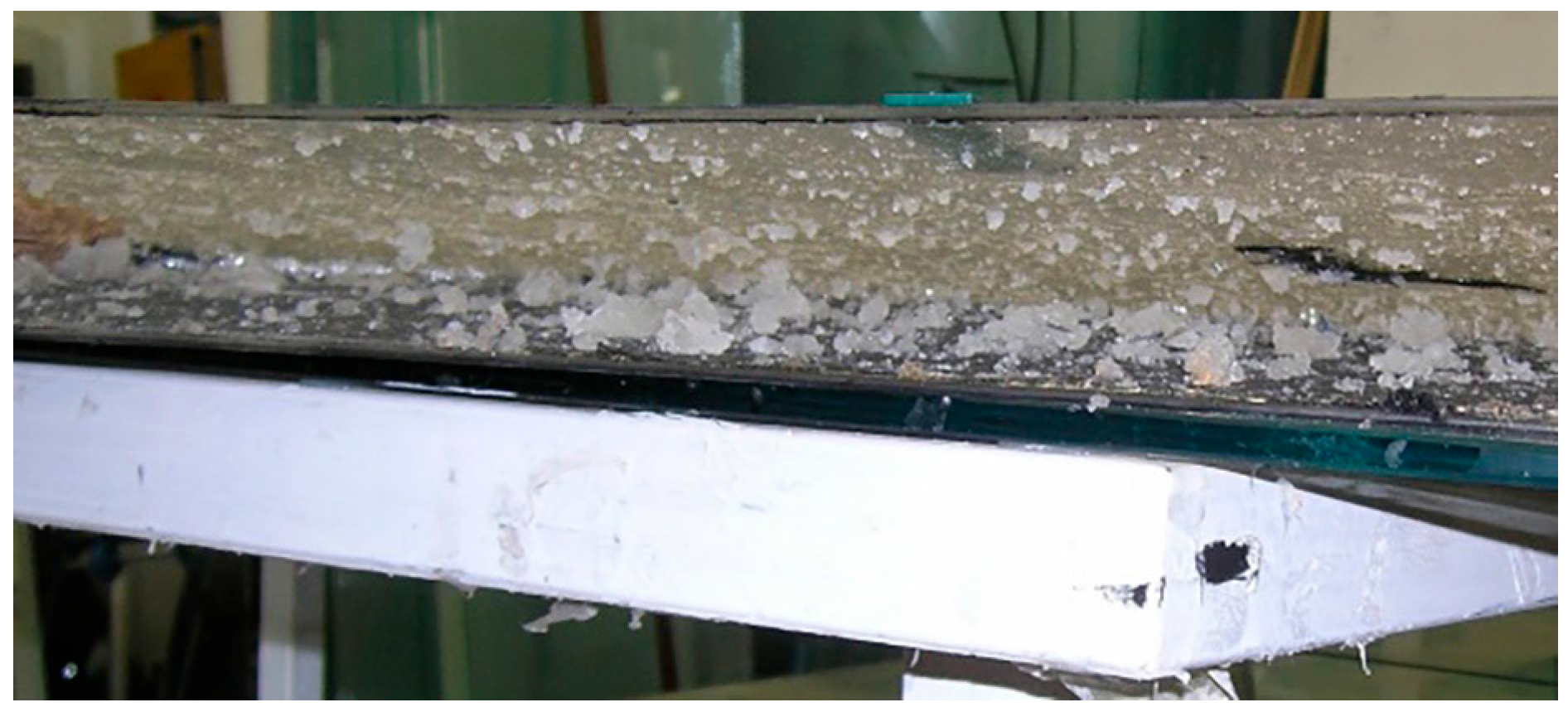

Each of the remaining 7 modules underwent the same disassembly procedure with 16 min of delamination. The overall efficiency of the glass sheet separation process was 93.75% (15 glass sheets were successfully extracted from a total of 16 glass sheets). The 160 W c-Si bifacial glass/glass PV panels were disassembled. Both the hardened and tempered 3 mm thin glass sheets were 124 × 106 cm2 in size. The disassembly of PV panels with sizes of 196 × 99 cm2 (350 Wp) and 172 × 113 cm2 (400 Wp), i.e., 2 square meters, was also successfully evaluated. The total disassembly time after manual processing was 22 min. The optimum delamination speed between 4 min and 16 min will be evaluated in future studies.

The total automatic line disassembly time is estimated to be approximately 15 min.

The room-temperature disassembly process entails the following steps:

- (1)

The aluminum frame was removed manually within 2 min.

- (2)

The polymer J-box was removed manually within 1 min.

- (3)

The slow (approximately 10 mm/min) penetration of high-density polyethylene (HDPE) wedges between the front and rear glasses was performed within 16 min.

- (4)

The front and rear glass sheets were separated manually within 1 min.

- (5)

Soft PDMS gel clusters were collected via a vacuum exhauster within 2 min.

The above-described room-temperature mechanical delamination process, i.e., the new recycling method, is very simple and clean (involving neither burning nor chemical etching) when compared with the delamination of typical PV panels laminated with solid EVA/POE polymers [

5]. The work on a new automatic PV panel delamination line based on the “manual” delamination test results will be finished soon.

4. Results and Discussion

The first two delamination steps, i.e., frame removal and J-box removal, are identical for both the PDMS laminated and standard EVA/POE laminated panels. Both the aluminum frames and polymer J-boxes are not suitable for direct reuse and must be remelted.

The first difference between the two delamination processes is pertaining to the glass. For PDMS laminated PV panels, after delamination, the two glass sheets can be reused in many industrial applications. The glass from EVA/POE laminated panels is usually crushed by milling, creating a large amount of dangerous glass grit. Glass grit represents a high health risk (silicosis), even under strict safety regulations.

The recycling/remelting of glass grit consumes a large amount of energy: melting requires approximately 75–85% of the energy needed for glass production [

13]. This results in substantial differences in energy [MJ] consumption between EVA/POE laminated panel recycling and PDMS laminated PV panel recycling. According to material thermal data handbooks, the energy needed for the remelting of PV panel components is presented in

Table 1. The total remelting energy required for the EVA laminated panels is ~280 MJ (110 MJ + 170 MJ), which is more than two times greater than that for the PDMS laminated panels, as shown in

Table 1. Therefore, if glass remelting can be avoided, the carbon footprint would be substantially reduced. The direct reuse of both the front and rear glass is environmentally sustainable when compared with the existing EVA/POE technology. After successful disassembly, the glass can be directly reused (without remelting) in several ways: (A) For greenhouses or industrial building windows, the remaining highly transparent and environmentally neutral PDMS thin film can be brushed off mechanically. (B) For rear glasses of new glass/glass PV panels, the PDMS thin film in the reused glass must be completely removed using chemical solvents.

The second difference between the two delamination processes pertains to the encapsulating polymers.

Figure 6 shows clusters of PDMS with ultrapure optical quality in delaminated PDMS panels that can be easily collected by a vacuum extractor and recycled into consumer silicone/siloxane rubber products. A proven industrial process involving the room-temperature polymerization of PDMS by an electron beam can be used for this purpose. The solar cells can be easily separated from soft PDMS clusters. On the other hand, separating solar cells embedded in a solid EVA/POE polymer layer is difficult. Moreover, thermal (burning) or chemical (etching) methods represent environmental risks.

The silicone solar cells separated from both the PDMS polymer and the EVA/POE polymer can be reused, for instance, in the production of metallurgical-grade silicone. This means that the rest of the solar cells (including buss bars) cannot be directly reused, but they can be remelted in industrial furnaces for the production of metallurgical-grade silicone.

PV panels laminated with very soft PDMS gels can be easily delaminated/disassembled at room temperature. Two glass sheets of PV panel laminates can be easily mechanically separated via polymer wedges at room temperature (without etching or burning). This enables environmentally sustainable recycling. A comparison of the recycling processes of EVA/POE laminated and PDMS laminated panels is shown in

Table 2.

The new recycling method leads to negligible direct emissions of hazardous waste (

Table 2). All the components of laminated PV panels are mechanically separated at room temperature and all PV panel components are recycled according to the standard methods (with the best practice being mainly remelting); their details are provided in

Table 2.

4.1. Very Low Degradation Rate of Encapsulated Pdms Pv Panels/Generators

The very low degradation rate of the PDMS laminated PV panels/generators impacts the recycling process of laminated PV panels [

6,

7,

8] (see

Table 3). These investigations were performed at very separate areas (USA, Japan, Europe) in natural conditions for very long period of time (26–30 years). A very similar low annual degradation rates in the range of −0.15% to −0.22% were measured. Recent studies indicate that a higher annual degradation rate of EVA laminated PV panels, ranging from −0.7% to −4.9%, is more realistic [

14,

15,

16,

17,

18]. V As the degradation rate of EVA laminated PV panels is significantly higher, more panels need to be replaced over the same time period, leading to increased waste. For example, if a PV panel is replaced (repowering) after 10 years [

19] instead of 30 years, one would indeed need three panels for the same duration, resulting in 3 times more waste.

Recent studies [

1,

20] have indicated that the PV panel degradation rate influences the number of PV panels recycled in a given year. For example, in the year 2024, the number of PV panels to be recycled in a higher degradation rate scenario (“early loss”) is approximately 4 times higher than that in the lower degradation rate scenario (“regular loss”) [

20]. Both theoretical calculations were based on a PV panel lifetime of 30 years. However, in real life, very frequent repowering (installation of new PV panels, etc.) of PV power plants, i.e., after only 10 years [

19], produces even more PV panel waste (see

Table 4). However this article does not intend to perform detailed study of PV panel degradation rates.

Recently, PV panel recycling companies in many countries have registered a surge in the quantity of PV panels to be recycled.

PV waste production can be significantly reduced (~114 times) via PDMS soft gel lamination technology due to its unique synergistic combination of a low degradation rate (reduction in PV waste production) and high recycling efficiency (see

Table 4). If low-degrading PDMS laminated PV panels with very high recycling efficiency are widely accepted soon, the dangerous PV panel waste quantity could be substantially reduced after 2035.

As shown in

Table 4, the estimated waste quantity for the “repowering” scenario involving conventional EVA-laminated panels is approximately 40.0 megatonnes. With 90% recycling efficiency (final waste quantity is 10% only of the initial quantity) the final waste quantity is 4.0 megatonnes. Whereas estimated waste quantity for the “regular-loss” scenario using PDMS-laminated panels is 1.75 megatonnes with recycling efficiency 98% (final waste quantity is 2% only of the initial quantity), it is only 0.035 megatonnes. This corresponds to a waste quantity ratio of approximately 114 to 1. The substantial reduction is due to the unique synergistic combination of a low degradation rate (which limits the number of end-of-life panels) and high recycling efficiency. If low-degrading PDMS laminated PV panels are widely adopted, the amount of hazardous PV waste could be significantly reduced after 2035.

4.2. Low Costs of the New Recycling Method

The cost of recycling standard photovoltaic (PV) panels is approximately 0.7–0.9 USD/kg. These costs can be reduced by using the new recycling method. In

Table 1, energy consumption is reduced by more than a factor of 2. In addition, the environmental and personal safety costs are significantly reduced because the direct hazardous waste generation is substantially reduced, as shown in

Table 2. The resulting recycling price could also be reduced by more than two-fold.

This cost reduction could contribute to enhancing the economic sustainability of recycling processes while supporting a wider implementation of circular economy principles in the field of renewable energy. Moreover, such technology helps minimize the environmental impact of processing waste from renewable energy sources [

20]. Beyond the economic aspects, the environmental impact is equally crucial for assessing sustainability. Therefore, we further focused on a detailed carbon footprint analysis to evaluate the advantages of PDMS technology in terms of energy demand and greenhouse gas emissions.

4.3. Carbon Footprint Analysis

The carbon footprint is a key indicator of environmental performance. For a typical crystalline silicon photovoltaic module of the first tier (≈1 × 2 m, ≈400 W, ≈24 kg), the manufacturing carbon footprint is approximately 144 kg CO

2-eq [

21], which is consistent with more recent assessments for c-Si modules [

22]. This value includes the energy and materials required for the production of cells, glass, frame, and backsheet within the “cradle-to-gate” system boundary.

An encapsulant layer made of polydimethylsiloxane (PDMS) with a thickness of 1 mm and the same surface area (≈2 kg) contributes about 12.53 kg CO

2-eq [

23], whereas an EVA/POE layer of identical size contributes approximately 6 kg CO

2-eq. Replacing EVA/POE with PDMS therefore increases the per-module manufacturing The carbon footprint only slightly—from ≈144 to ≈150 kg CO

2-eq (≈+4%). Importantly, this substitution does not alter the electrical output of the module, ensuring that the comparison remains consistent with respect to the “functional unit.”

When normalized to an equal service lifetime, the advantage of PDMS becomes evident. Over 20 years, conventional practice usually requires two EVA-laminated modules (one replacement because of usual repowering), resulting in a cumulative manufacturing CARBON FOOTPRINT of ≈288 kg CO2-eq (144 + 144). In contrast, a single PDMS-laminated module suffices at ≈150 kg CO2-eq. In terms of the carbon footprint per kWh generated, the difference becomes even more pronounced, as the more stable encapsulation reduces the risks of delamination, yellowing, and transmittance losses, thereby limiting performance degradation.

When expressed over the same service horizon, the EVA/POE option thus leads to an increase of approximately +92% in the manufacturing carbon footprint compared to PDMS. These findings are consistent with the process analysis discussed above: PDMS technology combines a modest per-module The carbon footprint with a reduced need for replacements, resulting in a significantly lower cumulative carbon footprint. Furthermore, sensitivity analyses indicate that even when considering variations in the energy mix of manufacturing, or the inclusion of transportation and recycling, the relative advantage of PDMS remains robust.

4.4. Environmental Impact an Life Cycles Assesment

From a life-cycle perspective, encapsulation with PDMS gels yields broader environmental benefits beyond carbon footprint alone. Conventional EVA/POE modules typically generate substantial hazardous outputs during end-of-life processing, including glass grit contaminated with silicon fragments and metals, together with gaseous emissions from polymer combustion or chemical etching [

1,

10]. By contrast, PDMS-based panels can be mechanically delaminated at room temperature, enabling direct reuse of both glass sheets and thereby avoiding most of these impacts; in practice, more than 80% of the module mass can be directly reused [

2]. This shift from “remelt and downcycle” to “retain and reuse” reduces resource extraction, energy demand, and on-site occupational risks [

2,

9].

Considering key impact categories: (i) Resource depletion falls because reusing float glass displaces primary glass production and associated raw materials [

2]. (ii) Water consumption declines when energy-intensive remelting is avoided; glass melting alone requires roughly 75–85% of the energy used for virgin glass production [

13]. (iii) Acidification and eutrophication potentials are lowered because PDMS does not produce acetic acid during aging, and its recycling pathway avoids acid etchants and combustion by-products common to EVA/POE routes [

12]. (iv) Human health and safety improve by minimizing fine glass dust (silicosis risk) and eliminating toxic combustion emissions [

9].

Comparative LCA evidence indicates that these category-level savings outweigh the slightly higher cradle-to-gate footprint of PDMS encapsulant per module [

1,

2,

10]. Sensitivity analyses further show that the advantage persists across electricity mixes, transport distances, and end-of-life scenarios: under coal-intensive manufacturing, fewer replacements amplify avoided emissions; with low-carbon electricity, absolute footprints drop for all options, yet the relative PDMS benefit remains due to extended lifetime and high recycling efficiency [

6,

8,

21,

22]. Normalized per unit electricity, longer-lived PDMS modules reduce life-cycle impacts (including GHGs) on a g/kWh basis because performance degradation and repowering frequency are both curtailed [

19,

21,

22]. Taken together, the results support integrating PDMS pathways into PV circularity policies and standards (e.g., guidance under PVPS and EoL frameworks) and prioritizing designs that maximize component reuse over energy-intensive reprocessing [

19,

20].

5. Conclusions

PV panel lamination/encapsulation technology using very soft polydimethylsiloxane (PDMS) gels is a very effective solution for achieving both beginning-of-life (BOL) low degradation rates and end-of-life (EOL) recycling. PV panels laminated with very soft PDMS gels are much more effective throughout their whole life cycle, from BOL to EOL, compared to the existing PV panels.

Finally, the very low annual degradation rate of encapsulated PDMS PV generators/panels, as shown in

Table 3, reduces the number of PV panels recycled in a given year by at least a factor of 3 (up to 4 times). The replacement of PV power plants after 10 years of operation will increase PV panel waste by ~20-fold in the near future. The final PV waste production can be greatly reduced (~114 times) when PDMS soft gel lamination PV technology is used (see

Table 4) due to its unique synergistic combination of a low degradation rate (reduced PV waste production) and high recycling efficiency.

The developed approaches and technologies comply with the principles of circular economy. This research helps embed sustainability at the core of resource management.