Abstract

Vertical farming offers one potential sustainable solution to food production in cities as populations increase and available farmland decreases. However, the large-scale adoption of vertical farms is still impeded by high energy requirements and costs. This research attempts to assess how energy optimization strategies that improve the sustainability and feasibility of vertical farming systems are applied systematically. Following the PRISMA guidelines, a systematic review of 52 articles published between 2014 and early 2024 was conducted on four major academic databases: ScienceDirect, Scopus, Web of Science, and Google Scholar. These reviews revealed that some modern technologies like high-efficiency LED lights, smart HVAC control, and IoT-based smart irrigation systems provided great advancements in reducing electricity consumption. However, even with these innovations, energy savings were heavily impacted by factors such as crop variety, climate, facility layout, system design, and geography. Other critical factors like high upfront spending, limited access to qualified personnel, inconsistent reporting standards, and a lack of real-world data further impede widespread adoption of the technology. This review emphasizes the need for multidisciplinary longitudinal field studies, standardized metric definitions, strategic integration of renewable resources, and supplementary training for operators. These analyses provide a foundation which can assist policymakers, researchers, and investors in developing energy-efficient, low-cost, and eco-friendly vertical farming systems.

1. Introduction

Vertical farming has emerged as a forward-looking answer to rapid urban growth, shrinking farmland, and the urgent need for greener food systems. Cities like Singapore now showcase how stacked gardens can boost local vegetable supplies and lighten environmental footprints. Rooftop farms planned for the city’s public housing alone could lift harvest volumes by 700%, satisfying more than a third of demand while cleverly using scarce land [1]. Seeking to make production smoother and cheaper, Singapore and similar metropolises are quickly rolling out high-tech growing methods such as hydroponics, aeroponics, and aquaponics. Despite these advancements, challenges such as limited available land, regulatory complexity, and other operational barriers persist. Innovative startups—including Plenty, AeroFarms, and Bowery Farming—are advancing enabling technologies for space- and resource-efficient production, leveraging automation and data analytics to control growing conditions and maintain a steady supply of high-quality produce [2,3]. National initiatives worldwide increasingly promote smart agriculture and urban sustainability. For instance, South Korea has launched major plans to commercialize convergence technologies and implement vertical smart farms, even in unconventional locations such as subway stations [4,5]. However, the adoption of AI, big data, and other advanced technologies in agriculture remains limited in both scope and effectiveness [6]. Similarly, China’s use of artificial intelligence and plant factories with artificial lighting is promising, yet hindered by climate variability and a fragmented landscape of smallholder farms [7,8].

In Sweden, integrating controlled environment agriculture (CEA) with cultural and educational initiatives has fostered innovative urban food systems, but significant challenges remain regarding greenhouse gas emissions and skilled labor shortages [9,10]. Urban agriculture policies in cities such as New York and London have sought to address space constraints and infrastructure gaps, though progress is tempered by policy limitations and persistent skepticism toward new farming models [11,12]. In Budapest researchers are actively examining how IoT-enabled smart farming systems can operate within city settings, highlighting the ongoing demand for hands-on studies that fine-tune these fledgling technologies [13,14]. A consistent observation across these investigations is that vertical farms still consume a lot of energy, mainly because of the heat and light needed to keep crops growing. Indeed, recent estimates show that it takes between 10 and 18 kilowatt-hours to grow one kilogram of lettuce in a stacked system—a figure that dwarfs the less-than-1 kilowatt-hour needed for traditional field production. Such a gulf makes it clear that any sustainable future for controlled-environment agriculture hinges on smarter lighting, sharper climate controls, and a reliable mix of renewable power. Even so, key knowledge gaps persist. Most urgently, the field still lacks large-scale, real-world data and agreed-upon benchmarks to judge whether specific energy-saving measures really work. Many current studies overlook the practical integration of renewable energy and rarely address solutions accessible to small-scale operators. Additionally, workforce training and public acceptance are underexplored, ultimately constraining the real-world sustainability and scalability of vertical farming systems.

To bridge these gaps and establish a foundation for further progress, this review systematically evaluates current energy optimization strategies employed in vertical farming, critically examining their inherent limitations. Furthermore, it delineates prospective research directions by integrating technological innovations, operational practices, and policy frameworks, thereby contributing to the development of scalable and energy-efficient vertical farming systems. This review aims to systematically synthesize current research on energy efficiency and optimization in vertical farming, focusing on technological innovations, smart energy management, and sustainability practices. The objective is to identify strategies that reduce energy consumption without compromising productivity, providing a framework for sustainable vertical farming development. The following key research questions guide this review:

- How can energy optimization strategies improve sustainability in vertical farming?

- How do smart irrigation systems contribute to energy efficiency in vertical farming?

- What are the main barriers to adopting advanced energy solutions in vertical farming?

The structure of this paper is as follows. First, it presents an overview of how vertical farming can help address food security challenges in urban areas. The next section outlines the review’s methodology. This is followed by a summary of key studies, focusing on energy use and smart irrigation in vertical farming. The paper then analyzes the main challenges in applying energy-saving strategies, including issues related to advanced models and system complexity. Finally, the study highlights the potential of smart energy systems to improve sustainability in vertical farms and offers suggestions for future research and policymaking.

2. Materials and Methods

To address the research questions and synthesize evidence on energy optimization in vertical farming, this review employed the PRISMA framework for systematic reviews.

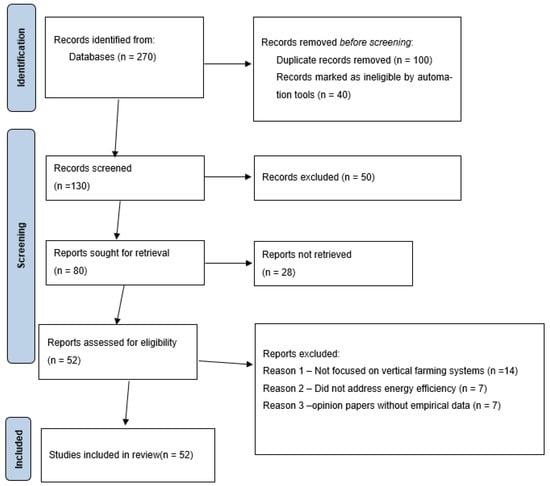

The systematic search identified a total of 270 records from databases. Before screening, 100 duplicate records and 40 records deemed ineligible by automation tools were removed, leaving 130 records for screening. Of these, 50 records were excluded, and 80 reports were sought for retrieval. However, 28 reports could not be retrieved, resulting in 52 reports assessed for eligibility. During eligibility assessment, 14 reports were excluded for not focusing on vertical farming systems, 7 for not addressing energy efficiency, and 7 as opinion papers without empirical data. Ultimately, 52 studies were included in the review. A comprehensive search was conducted across four major academic databases—ScienceDirect, Scopus, Web of Science, and Google Scholar—to ensure broad and relevant coverage. The initial search strategy focused on identifying studies related to energy challenges and solutions in vertical farming, using keywords such as “vertical farming,” “energy optimization,” “energy efficiency,” and “sustainability.”

Figure 1 illustrates the PRISMA flow diagram used in the systematic review process. It visually represents the steps taken to identify, screen, and select relevant studies for inclusion in the final analysis.

Figure 1.

Review process flow.

2.1. Eligibility Criteria

Studies were eligible for inclusion if they (1) focused on energy optimization and/or efficiency in vertical farming within the context of sustainable agriculture, (2) were published in peer-reviewed journals between January 2014 and March 2024, (3) were written in English, and (4) provided full-text access with sufficient methodological detail.

Exclusion criteria included duplicate records, books, conference proceedings, non-peer-reviewed industry/government reports, studies loosely related to vertical farming without energy-related analysis, and studies lacking quantitative or qualitative data on energy use or sustainability impacts. Studies were grouped into thematic categories (e.g., technological innovations, renewable integration, energy management systems, circular economy practices) during synthesis.

2.2. Information Sources

The literature search was conducted in the following databases: ScienceDirect, Scopus, Web of Science, Google Scholar, IEEE Xplore, and SpringerLink. Searches were completed on: ScienceDirect (10 March 2024), Scopus (12 March 2024), Web of Science (13 March 2024), Google Scholar (14 March 2024), IEEE Xplore (15 March 2024), and SpringerLink (15 March 2024). Reference lists of included studies were also screened to identify additional eligible records.

2.3. Search Strategy

Search strings were adapted to each database but maintained consistent Boolean logic. The core query was:

(“vertical farming” OR “plant factory” OR “indoor farming”) AND (“energy optimization” OR “energy efficiency” OR “power management” OR “sustainable energy” OR “energy-saving” OR “renewable energy”) AND (“sustainability” OR “sustainable agriculture” OR “sustainable farming” OR “smart agriculture”)

2.4. Selection Process

All retrieved records were exported to EndNote for duplicate removal. Two reviewers independently screened titles and abstracts against the eligibility criteria. Full texts of potentially relevant studies were retrieved and assessed independently by both reviewers. Disagreements were resolved through discussion; if unresolved, a third reviewer acted as arbiter. No automation tools were used for screening or selection.

Table 1 categorizes the reviewed literature into focus areas and sub-themes relevant to urban agriculture, vertical farming, smart technologies, sustainability, policy, and emerging innovations. References are provided for each sub-theme to guide further study.

Table 1.

Thematic analysis—References by Focus Area.

3. Vertical Farming Background

Vertical farming relies heavily on advanced actuator systems to achieve precise control over key environmental conditions. These actuators regulate devices responsible for managing airflow, lighting, and irrigation, thereby creating optimal environments for plant growth. By automating the operation of pumps and valves within irrigation systems, actuators minimize resource waste and ensure that plants receive consistent and appropriate hydration [25,41,49]. This technological foundation is central to maximizing both resource efficiency and crop yields in vertical farming.

3.1. Smart Systems for Energy Optimization

Building on this background, the following section reviews core energy optimization strategies that enable sustainable operation and address the substantial energy demands inherent in these systems.

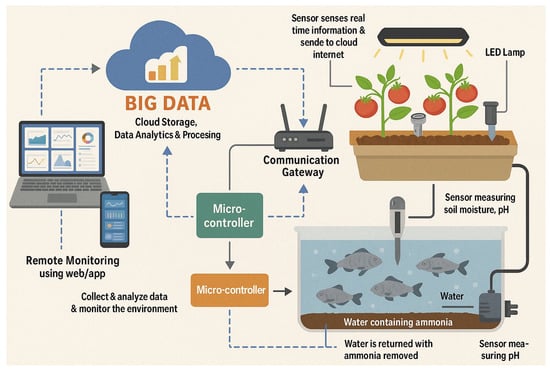

Figure 2 illustrates a smart aquaponic vertical farming system enhanced by Internet of Things (IoT) technologies for real-time monitoring and automated control. The system integrates multiple sensors to measure critical parameters such as soil moisture, pH, water temperature, and ammonia levels. Data collected from these sensors are transmitted via a communication gateway to a microcontroller, which processes the signals and relays them to a cloud platform for storage, analytics, and decision-making.

Figure 2.

Schematic representation of implementation of IoT in vertical farming. (Adapted from Sowmya et al. [40]).

The cloud-based system facilitates remote monitoring through web or mobile applications, enabling users to track environmental conditions and system performance in real time. An LED lighting system supports photosynthesis, while a pump circulates nutrient-rich water from the fish tank to the grow tray. The return flow, post-filtration, ensures efficient water reuse and nutrient delivery. This closed-loop configuration exemplifies sustainable resource use, optimizing energy, water, and nutrient cycles.

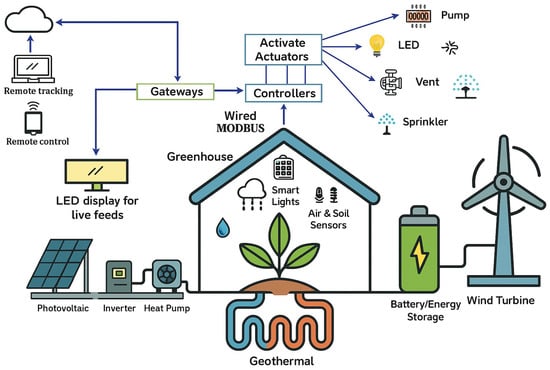

Another Smart System for Energy Optimization is schematic of integrating RESs in a smart GH; Figure 3 presents a conceptual model of a smart greenhouse system that integrates renewable energy technologies and Internet of Things (IoT)-enabled automation to enhance energy efficiency and sustainability. The system utilizes multiple renewable energy sources, including photovoltaic solar panels, geothermal heating, and wind turbines, to power critical greenhouse operations. These energy sources are connected to an inverter, heat pump, and battery energy storage unit to ensure stable and efficient energy supply. Inside the greenhouse, environmental conditions such as temperature, humidity, and soil moisture are monitored using air and soil sensors. These data are transmitted via gateways and processed by central controllers through a wired MODBUS communication protocol. The controllers activate specific actuators—including pumps, heaters, sprinklers, and LED lights—based on real-time sensor inputs to maintain optimal growing conditions. Remote monitoring and control are facilitated through a cloud-connected platform that enables users to access system data and adjust parameters via mobile or web applications. This integrated approach supports precision agriculture by optimizing resource use, reducing energy waste, and enabling autonomous operation under varying climatic conditions.

Figure 3.

A schematic of integrating RESs in a smart GH (Adapted from Jamshidi et al. [8]).

3.2. Life Cycle Assessment of Energy Use in Vertical Farming Systems

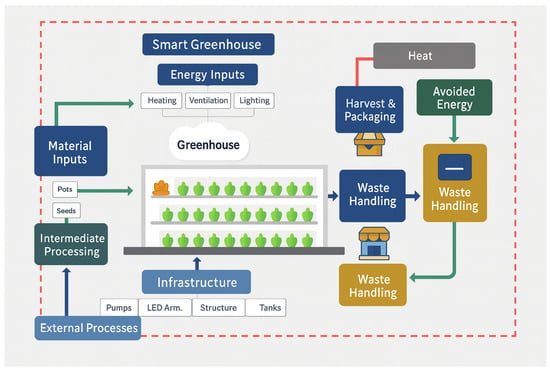

Vertical farming—the cultivation of crops in stacked layers or on vertically inclined surfaces—has emerged as a promising solution to food insecurity in urban environments. Despite its notable advantages, vertical farming is characterized by substantial energy requirements, prompting ongoing research into strategies for optimizing energy use without compromising productivity. The advent of “Vertical Farming 2.0” marks a significant technological advancement, defined by the integration of advanced automation, artificial intelligence, sensor networks, and real-time environmental controls. These innovations enable the precise regulation of light, temperature, humidity, and CO2 levels, allowing crops to be cultivated under optimal, energy-efficient conditions while minimizing waste [50]. A particularly effective approach for reducing energy consumption involves synchronizing LED lighting schedules with off-peak electricity hours, thereby lowering operational costs and enhancing crop yields [33]. Beyond on-farm technological improvements, vertical farms are increasingly collaborating with municipal infrastructure to harness organic waste, capture CO2, and utilize surplus local energy, thus supporting regional sustainability and cost reduction [51]. Flexibility in energy use, such as adjusting operations according to real-time electricity prices or renewable energy availability, further increases operational efficiency [16]. Renewable energy-rich farms now employ solar panels and wind turbines alongside AI and IoT tools that automatically swap loads between the grid and on-site generation, fine-tuning power use to current supply and market tariff signals [30]. Achieving low-power draw remains a core requirement for the long-term financial and planetary viability of vertical horticulture. Integrating hydroponics or aquaponics within a circular economy model then enables precise nutrient recycling while cutting downstream organic waste [17]. Further gains materialize through next-generation LED lighting and crop biostimulants such as spirulina phycocyanin, both of which lift produce quality and allow milder climate settings, curbing the burden on energy-hungry controls [28,29]. To quantify the overall gains, researchers performed a life-cycle assessment on a typical facility yielding around 185,000 plants, equivalent to close to 5500 kg of edibles each year. The cradle-to-gate life-cycle assessment covered every operational stage, including cultivation, energy use, material transport, and local distribution, and centered on leafy greens and herbs while also accounting for on-farm waste management practices [35]. Figure 3 lays out the LCA findings and thereby supplies a comprehensive view of the energy-consumption pattern seen in contemporary vertical farms. With that background in place, the next section turns to the enduring obstacles that still hinder both the broad uptake and the meaningful execution of energy-saving techniques across vertical-farming systems. Figure 4 illustrates a comprehensive life cycle assessment (LCA) framework for vertical farming systems, outlining the flow of materials, energy, and processes from input to end-use. The system boundary, indicated by the red dashed line, captures all stages within the vertical farm’s operational lifecycle. Material inputs such as pots, seeds, growing medium, fertilizers, water, and packaging are transported into the farm and contribute directly to plant cultivation. Supporting this process is the infrastructure backbone, which includes pumps, LED lighting systems, structural components, electronics, and nutrient tanks. These components enable controlled environmental conditions necessary for optimal crop growth. Energy inputs—comprising heating, ventilation, lighting, and pumping—are central to maintaining the internal climate and are among the most energy-intensive operations. Once crops are cultivated, they move to the harvest and packaging stage, where they are prepared for retail and distribution. Simultaneously, waste handling processes manage byproducts such as unused plant material and packaging waste. The system also accounts for heat recovery and avoided energy, where excess heat and energy are recaptured for reuse, contributing to improved energy efficiency. External processes, including intermediate processing and supply logistics, are represented outside the system boundary and connect the vertical farming unit to broader industrial networks. This LCA model enables the identification of high-impact stages within the production cycle and supports the development of strategies for reducing energy consumption, minimizing waste, and enhancing sustainability across the entire vertical farming operation.

Figure 4.

Life Cycle Assessment for Energy Use in Vertical Farming (Adapted from Martin et al. [36]).

3.3. Model-Based Energy Optimization in Vertical Farming

Optimization in vertical farming increasingly relies on advanced modeling and simulation techniques to navigate the complexities of sustainable production. By employing coupled heuristic approaches, vertical farms are able to fine-tune critical variables such as water use, radiation, and temperature throughout the growth cycle, thereby maximizing yield while minimizing energy consumption [52]. The adoption of sophisticated optimization tools—such as the P-Graph Framework—enables vertical farms to address multifaceted operational challenges by formulating and solving complex problems. These methods support the identification of strategies that are both economically and energetically optimal, guiding farms toward more sustainable and cost-effective operations. This emphasis on computational optimization highlights the growing importance of data-driven decision-making in contemporary vertical farming. The upcoming section reviews concrete obstacles—engineering, organizational, and economic—that can limit how far and how quickly these cutting-edge optimization methods can actually be used in the field. Table 2 lists several energy-saving practices for vertical farms, including smart sensors, spectral lighting, and system coupling, clearly showing how each one cuts power use and boosts overall sustainability.

Table 2.

Model-Based Energy Optimization in Vertical Farming.

3.4. Optimizing Water and Energy Use Through Intelligent Irrigation Systems

Integrating advanced energy-conservation strategies with smart irrigation systems is pivotal for boosting the efficiency of vertical farms. Smart irrigation uses sensors, automation, and IoT to fine-tune both water and power consumption, directly addressing two key hurdles in sustainable agriculture. Central to this setup is the automated water-delivery network, guided by probes that track soil moisture, weather trends, and plant-growth phases. It applies exactly what each crop needs when it needs it, cutting down both over- watering and wasted resource. By curbing excessive pumping, the system also slashes unwanted energy use and trims operating costs [32,36].

Real-time updates to the irrigation schedule, based on live soil and climate data, close the efficiency gap that plagues many conventional approaches. Integration with IoT permits round-the-clock surveillance and self-correcting operation, sparing growers from constant manual checks and lifting accuracy still higher [24,39]. In this way, automation not only streamlines management but also shields the system from human error and guarantees uniform water distribution across the growing cycle. Energy-saving sensors and microcontrollers substantially cut power use, delivering precise data that guides resource decisions without draining the system [44]. A key benefit of smart irrigation lies in its capacity to stop crops from being overwatered, a process that trims the energy needed to pull water from wells, treat it, and move it around, ultimately saving both energy and water while softening many side effects on the environment [23,42,54]. Because these tools keep soil moisture within a narrow, target range they can also cut the number of watering events, letting plants grow steadily while freeing energy for other critical tasks in the farm [22,44]. Taken together, these advantages show that smart irrigation is vital to making vertical farms precise, efficient, and kinder to the planet. The next section therefore turns to the hurdles—hardware costs, limited data-sharing, and knowledge gaps—that still slow the broad rollout of energy-optimizing systems across the industry. To build upon the broad energy optimization strategies outlined in the previous table, it is important to recognize how these overarching approaches are complemented by targeted interventions within specific subsystems. Irrigation stands out as one of the most critical subsystems in vertical farming, where the adoption of smart technologies further enhances overall energy efficiency and sustainability. Table 3 focuses on smart irrigation systems, detailing their unique contributions and illustrating how they function synergistically with other energy optimization techniques to drive sustainable outcomes in vertical farming operations. Table 3 outlines various smart irrigation strategies in vertical farming and their specific effects on energy efficiency and sustainability. Each approach is briefly described, with supporting references, to demonstrate its role in reducing both energy and resource use.

Table 3.

Smart Irrigation Strategies for Energy Efficiency and Sustainability in Vertical Farming.

4. Challenges in Integrating Energy Optimization Approaches into Vertical Farming

Implementing optimized energy strategies in vertical farming presents significant complexity, particularly when these systems are proposed as solutions for food security. Vertical farming is inherently capital-intensive, requiring substantial upfront investment and ongoing operational expenditures [37]. Reliance on artificial lighting and HVAC (heating, ventilation, and air conditioning) systems contributes to high energy consumption and sustainability concerns [19,52]. The high day-to-day expenses tied to vertical farming, including lighting and climate control, sharpen the financial strain and make it harder for operators to break even [15,19,45]. Adding artificial intelligence, the Internet of Things, and automated equipment can improve yields, yet the price of new hardware and the cost of keeping it running usually outweigh immediate savings [26,29,45]. Dealing with these sophisticated setups also demands trained personnel fluent in both agriculture and tech, and the shortage of such specialists slows broader industry growth [26,29]. Adjusting energy use on the fly during price spikes or when wind and sunlight vary is still a tough puzzle for engineers and managers alike [16,27,50]. Although solar panels and wind turbines cut carbon emissions, their fickle output forces growers to rely on back-up power or battery stores, pulling more money into system design [16,27,50]. Because of the heavy power draw, critics maintain that vertical farms—even those using renewables—must take further steps if they want to claim truly sustainable credentials.

Making vertical farming truly sustainable requires that operators fine-tune energy use without sacrificing either crop quantity or quality [18,37,55]. Widespread doubts about the technology, compounded by limited public experience, slow its adoption, underscoring the urgent need for educational campaigns that clearly explain the system’s benefits [18]. When officials attempt to scale vertical farms as a way to bolster food security in crowded cities, they quickly run into economic and logistical hurdles, because local differences in energy grids, climate, and wealth shape what is practical. For that reason, small-scale studies based in each community are critical; they provide the localized data needed to craft workable solutions and guide larger rollouts [29].

By addressing these interconnected economic, technical, social, and regional challenges, future research and policy initiatives can pave the way for more sustainable, efficient, and widely adopted vertical farming systems. The concluding section summarizes key findings and presents recommendations for advancing the field. Table 4 highlights major challenges to energy efficiency in vertical farming, including high energy demand, costs, and technical complexity. Each challenge is briefly described, along with its specific impacts and supporting references.

Table 4.

Challenges Impacting Energy Efficiency in Vertical Farming.

5. Discussion

As detailed in Section 3.1 and Section 3.2, energy optimization strategies for vertical farming—including high-efficiency LED lighting, advanced HVAC controls, and smart irrigation—present promising opportunities for reducing both costs and resource consumption. However, their effective implementation is often complex and highly context-dependent. Energy optimization is widely acknowledged as fundamental to achieving the operational and financial sustainability of vertical farming systems. For example, adopting high-efficiency LED lighting can reduce lighting energy consumption by 30–50% compared to traditional high-pressure sodium (HPS) lamps, as confirmed by commercial-scale trials and modeling studies [7,13]. Ref. [13] reports that replacing high-pressure sodium lamps with LEDs cuts energy expenses by nearly $35,692 each year and trims maintenance costs by an additional $6580, yielding an overall payback period of roughly two to three years under standard operating circumstances. Despite the higher capital investment required, these savings render LED technology economically viable for many operators, though such upfront costs may remain prohibitive for small-scale or under-capitalized farms.

Integrating smart HVAC controls represents another substantial advance in energy-efficient vertical farming. Modeling and field studies suggest that smart, sensor-driven HVAC systems can lower overall energy use by 15–25%, although actual savings depend on climate, facility insulation, and system configuration [44,59]. Although these systems entail significant initial outlays for automation, sensors, and controls, the resulting operational cost reductions often lead to a payback period of three to five years for mid-sized facilities.

Smart irrigation systems—featuring real-time soil moisture sensors, automated valves, and IoT integration—are increasingly used to optimize water and energy consumption [12,25,36]. Empirical studies show that such systems can reduce unnecessary water pumping by 20–30%, directly lowering energy consumption and operating costs. The cost of sensor deployment is typically recovered within one or two growing seasons, especially in regions where water or energy is scarce.

Despite these technological advancements, contradictions and limitations persist in the literature. Reported energy savings from light-emitting diodes (LEDs) or intelligent heating, ventilation, and air-conditioning (HVAC) controls vary markedly between investigations, principally because crop species, environmental parameters, and facility layouts differ [13,44].

Studies based exclusively on simulation routinely inflate estimated savings relative to those measured in operating farms, underscoring the demand for extended, real-world trials. Moreover, many published analyses omit consistent reporting units—such as kilowatt-hours per kilogram—thereby hindering across-study comparison and meta-analysis. Economic questions persist alongside technical ones. While capital-intensive, advanced energy systems usually yield satisfactory returns in large vertical farms, small-scale growers often find the up-front investment prohibitive and the requisite skill scarce, leaving a research void in affordable, broadly applicable optimization techniques. Integrating renewable photovoltaics and wind can further curtail grid reliance, but their inherent intermittency complicates continuous energy supply. Batteries and demand–response schemes address part of the issue, yet field data on their durability and long-run cost-effectiveness remain sparse, limiting confidence in widespread adoption. In locations where powering the farm still means burning a lot of coal or gas, the green promise of vertical agriculture hangs on solid electricity management; sloppy energy use can wipe out the gains from saving soil and redirecting water. Nearly everyone now agrees that a serious education push and skilled workforce are essential. Running these dense, high-tech farms calls for operators who blend deep technical know-how with sharp management instincts. Tailored apprenticeships, step-by-step knowledge-sharing, and partnerships with trade schools are therefore critical if growers are to wield the new tools wisely. Meanwhile, doubts from the public and wavering investors dog the sector, especially fears that the energy crunch will sink the farms economically and ecologically. Openness in reporting, eye-catching pilot farms, and clear, honest outreach can calm skepticism and pave the way for larger-scale deployment.

6. Future Research Directions

Despite notable advances in energy optimization for vertical farming, several unresolved issues require targeted investigation. High operational costs and variability in reported energy savings—highlighted by studies such as [13,44]—underscore the need for research that extends beyond simulations and controlled environments to include large-scale, real-world deployments. Prioritizing field-based, longitudinal studies is essential to rigorously validate the economic and sustainability claims associated with technologies such as LED retrofitting, demand response strategies, and AI-driven environmental controls. There is also a pressing need for comparative research that evaluates the performance of energy optimization methods across diverse facility types, climate conditions, and crop varieties. Particular attention should be given to small-scale and resource-constrained vertical farms, where high upfront costs and skills gaps may inhibit technology adoption. Understanding the scalability and cost-effectiveness of advanced systems in these settings is critical for ensuring broader sustainability and accessibility. Given the technical challenges inherent in integrating renewable energy and storage solutions—especially the intermittency of solar and wind power—future work should focus on developing system-level solutions and enhancing operational resilience. The creation of standardized, universally accepted metrics for energy efficiency and environmental impact is equally important, as current inconsistencies hinder robust cross-study comparisons. A more comprehensive evaluation of the long-term environmental impacts of vertical farming is warranted, particularly in regions that rely on carbon-intensive energy grids. This includes the need for detailed life-cycle assessments and environmental modeling to capture indirect effects and potential trade-offs. Finally, addressing persistent workforce and educational gaps will require research on effective training programs, curriculum development, and knowledge transfer initiatives. Developing a skilled labor force is essential for fully realizing the potential of advanced energy management in vertical farming.

7. Conclusion

This review has demonstrated that the sustainability and operational success of vertical farming are fundamentally dependent on the strategic implementation of energy optimization technologies. While solutions such as LED lighting, smart HVAC systems, and automated irrigation show substantial promise for reducing energy demand and enhancing efficiency, the realized benefits are highly context-dependent, influenced by factors such as farm scale, local energy infrastructure, and available capital. Persistent inconsistencies in the literature—stemming from differences in study design, reliance on simulations, and the lack of standardized metrics—highlight the need for more robust empirical evidence, particularly in real-world settings. A major limitation of this review is that much of the available research is based on short-term or simulated data rather than large-scale, longitudinal field studies. The diversity in methodologies and reporting practices further complicates the ability to draw direct comparisons or synthesize outcomes across studies. In addition, there remains limited insight into the performance and adoption of energy optimization strategies within small-scale or resource-constrained vertical farms, as well as a lack of comprehensive analyses on the integration of renewable energy and storage technologies. To address these gaps, future research should prioritize rigorous, field-based, and longitudinal studies that evaluate the real-world energy and economic impacts of core optimization technologies. Comparative investigations across farm sizes, crop types, and geographic contexts are recommended, alongside the development of standardized metrics for energy and sustainability reporting. Further, dedicated research is needed to explore practical approaches for integrating renewables, advancing storage solutions, and overcoming the workforce and financial barriers that limit technology adoption—especially for smaller producers.

Funding

This paper was funded by the Ministry of Higher Education, Research and Innovation, Sultanate of Oman, Block Funding Program (BFP) No: BFP/RGP/ICT/24/113.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Acknowledgments

The authors gratefully acknowledge the valuable contributions of Mohammed Al-Sarem (College of Computer Science and Engineering, Taibah University, Saudi Arabia; Energy, Industry, and Advanced Technologies Research Center, Taibah University, Saudi Arabia), Fahad Ghabban (College of Computer Science and Engineering, Taibah University, Saudi Arabia; Energy, Industry, and Advanced Technologies Research Center, Taibah University, Saudi Arabia), Ibraheem Shayea (Electronics and Communication Engineering Department, Istanbul Technical University, Türkiye; Department of Intelligent Systems and Cybersecurity, Astana IT University, Kazakhstan), Nasser Tabook (Department of Computer Science, College of Arts and Applied Sciences, Dhofar University, Oman), Rawad Abdulghafor (Faculty of Computer Studies, Arab Open University—Oman), and Mohammad Nassef (Department of Computer Science, Cairo University, Egypt; Department of Computer Science and Artificial Intelligence, University of Jeddah, Saudi Arabia). Their dedicated efforts and collaborative work were instrumental in conducting this research and completing this paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Erekath, S.; Seidlitz, H.; Schreiner, M.; Dreyer, C. Food for future: Exploring cutting-edge technology and practices in vertical farm. Sustain. Cities Soc. 2024, 106, 105357. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Göçer, F.; Uztürk, D. A novel Pythagorean fuzzy set integrated Choquet integral approach for vertical farming technology assessment. Comput. Ind. Eng. 2021, 158, 107384. [Google Scholar] [CrossRef]

- Martin, M.; Weidner, T.; Gullström, C. Estimating the potential of building integration and regional synergies to improve the environmental performance of urban vertical farming. Front. Sustain. Food Syst. 2022, 6, 849304. [Google Scholar] [CrossRef]

- de Jong, A.; Milestad, R.; Bustamante, M.J.; Martin, M. Analyzing the divergence and development of business models for urban farming. Urban Agric. Reg. Food Syst. 2024, 9, e70004. [Google Scholar] [CrossRef]

- Mannan, J.M.; Suguna, S.K.; Dhivya, M.; Parameswaran, T. Smart scheduling on cloud for IoT-based sprinkler irrigation. Int. J. Pervasive Comput. Commun. 2020, 17, 3–19. [Google Scholar] [CrossRef]

- Langendahl, P.-A. The Politics of Smart Farming Expectations in Urban Environments. Front. Sustain. Cities 2021, 3, 691951. [Google Scholar] [CrossRef]

- Ardakani, S.P.; Xie, H.; Liu, X. Smart Technologies for Urban Farming and Green Infrastructure Development: A Taxonomy. In Urban Sustainability; Springer: Singapore, 2022; pp. 379–397. [Google Scholar] [CrossRef]

- Jamshidi, F.; Ghiasi, M.; Mehrandezh, M.; Wang, Z.; Paranjape, R. Optimizing Energy Consumption in Agricultural Greenhouses: A Smart Energy Management Approach. Smart Cities 2024, 7, 859–879. [Google Scholar] [CrossRef]

- Kaya, C. Intelligent Environmental Control in Plant Factories: Integrating Sensors, Automation, and AI for Optimal Crop Production. Food Energy Secur. 2025, 14, e70026. [Google Scholar] [CrossRef]

- Miserocchi, L.; Franco, A. Benchmarking energy efficiency in vertical farming: Status and prospects. Therm. Sci. Eng. Prog. 2025, 58, 103165. [Google Scholar] [CrossRef]

- Lee, D.; Kim, K. National Investment Framework for Revitalizing the R&D Collaborative Ecosystem of Sustainable Smart Agriculture. Sustainability 2022, 14, 6452. [Google Scholar] [CrossRef]

- Saad, M.H.M.; Hamdan, N.M.; Sarker, M.R. State of the art of urban smart vertical farming automation system: Advanced topologies, issues and recommendations. Electron. 2021, 10, 1422. [Google Scholar] [CrossRef]

- Ágoston, G.; Pongrácz, F.; Horváth, K.G.; Bukodi, Z. Vertical farms and smart cities—Identification of common research areas, Tungsram’s experience and vision in Central Europe. In Proceedings of the 2022 Smart City Symposium Prague (SCSP), Prague, Czech Republic, 26–27 May 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Augustine, C.; Balaji, K.; Dharanikumar, S.V.; Anand, A.J. Urban farming: Case study. In Advanced Technologies for Smart Agriculture; River Publishers: Aalborg, Denmark, 2023; pp. 321–338. Available online: https://www.taylorfrancis.com/books/edit/10.1201/9781032628745/advanced-technologies-smart-agricult… (accessed on 5 June 2025).

- Ahamed, M.S.; Sultan, M.; Monfet, D.; Rahman, M.S.; Zhang, Y.; Zahid, A.; Bilal, M.; Ahsan, T.M.A.; Achour, Y. A critical review on efficient thermal environment controls in indoor vertical farming. J. Clean. Prod. 2023, 425, 138923. [Google Scholar] [CrossRef]

- Arabzadeh, V.; Miettinen, P.; Kotilainen, T.; Herranen, P.; Karakoc, A.; Kummu, M.; Rautkari, L. Urban vertical farming with a large wind power share and optimised electricity costs. Appl. Energy 2023, 331, 120416. [Google Scholar] [CrossRef]

- Coon, D.; Lindow, L.; Boz, Z.; Martin-Ryals, A.; Zhang, Y.; Correll, M. Reporting and practices of sustainability in controlled environment agriculture: A scoping review. Envrion. Syst Decis 2024, 44, 301–326. [Google Scholar] [CrossRef]

- Daniels, A.; Fink, M.; Leibold, M.; Wollherr, D.; Asseng, S. Optimal Control for Indoor Vertical Farms Based on Crop Growth. IFAC- Pap. 2023, 56, 9887–9893. [Google Scholar] [CrossRef]

- Debdas, S.; Reddy, Y.P.K.; Das, D.; Das, S.; Hazra, S.; Chatterjee, S. Vertical Agriculture in the IoT Era. In Proceedings of the 2023 IEEE 3rd International Conference on Smart Technologies for Power, Energy and Control (STPEC), Bhubaneswar, India, 10–13 December 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Jeongsun, C.; Ji-In, C. Proposal for Improving Underground Smart Farm Spaces in Seoul Metro Stations-Focusing on Sangdo, Dapsimni, Cheonwang, Chungjeong-ro, and Euljiro3-ga Station Sangdo-. Archit. Inst. Korea 2024, 40, 25–33. [Google Scholar] [CrossRef]

- Angotti, T. Urban agriculture: Long-term strategy or impossible dream?: Lessons from prospect farm in brooklyn, New York. Public Health 2015, 129, 336–341. [Google Scholar] [CrossRef]

- Soofi, A.F.; Manshadi, S.D. Carbon-Aware Operation of Resilient Vertical Farms in Active Distribution Networks. IEEE Trans. Smart Grid 2024, 15, 431–443. [Google Scholar] [CrossRef]

- Takagaki, M.; Hara, H.; Kozai, T. Micro- and mini-PFALs for improving the quality of life in urban areas. In Plant Factory, 2nd ed.; Academic Press: Cambridge, MA, USA, 2019; pp. 117–128. [Google Scholar] [CrossRef]

- Awasthi, A.; Rangare, A.; Kaushik, R.; Immanuel, J. Live Demonstration: IoT based smart vertical farming framework with sensor network and mobile application for real-time monitoring. In Proceedings of the 2023 IEEE SENSORS, Vienna, Austria, 29 October–1 November 2023; p. 1. [Google Scholar] [CrossRef]

- Devendiran, R.; Turukmane, A.V.; Sathiyaraj, A.; Srinivasa Rao, P.; Prasad, B.; Pulipati, S. Smart Irrigation: Revolutionizing Water Management in Agriculture for Sustainable Practices and Improved Crop Yield. In Proceedings of the 2023 6th International Conference on Recent Trends in Advance Computing (ICRTAC), Chennai, India, 14–15 December 2023; pp. 651–656. [Google Scholar] [CrossRef]

- Ghiasi, M.; Wang, Z.; Mehrandezh, M.; Paranjape, R. A Systematic Review of Optimal and Practical Methods in Design, Construction, Control, Energy Management and Operation of Smart Greenhouses. IEEE Access 2024, 12, 2830–2853. [Google Scholar] [CrossRef]

- Suhail, A.; Hasteer, N. Use of smart farming techniques to mitigate water scarcity. In Artificial Intelligence and IoT-Based Technologies for Sustainable Farming and Smart Agriculture; IGI-GLOBAL: Hershey, PA, USA, 2021; pp. 140–150. [Google Scholar]

- Nwanojuo, M.A.; Anumudu, C.K.; Onyeaka, H. Impact of Controlled Environment Agriculture (CEA) in Nigeria, a Review of the Future of Farming in Africa. Agriculture 2025, 15, 117. [Google Scholar] [CrossRef]

- Pimentel, J.; Friedler, F. Synthesis of Integrated Vertical Farming Systems with Multiperiodic Resource Availability. Chem. Eng. Trans. 2022, 94, 1039–1044. [Google Scholar] [CrossRef]

- Rathore, T.; Gupta, D.K.; Kumar, N. Smart Irrigation system using IoT. In Proceedings of the 2023 Third International Conference on Secure Cyber Computing and Communications (ICSCCC), Jalandhar, India, 26–28 May 2023; pp. 605–610. [Google Scholar] [CrossRef]

- Reynolds, K.; Gottfried, C.; Thomas, T. Racial equity and the USDA’s Office of Urban Agriculture granting program and urban offices. J. Agric. Food Syst. Community Dev. 2024, 14, 129–139. [Google Scholar] [CrossRef]

- Robbiani, G.; Törn, E. Intermittent Light Scheduling for Energy Cost Reduction in Vertical Farming. IEEE Technol. Soc. Mag. 2024, 43, 81–90. [Google Scholar] [CrossRef]

- Sanjuan-Delmás, D.; Llorach-Massana, P.; Nadal, A.; Ercilla-Montserrat, M.; Muñoz, P.; Montero, J.I.; Josa, A.; Gabarrell, X.; Rieradevall, J. Environmental assessment of an integrated rooftop greenhouse for food production in cities. J. Clean. Prod. 2018, 177, 326–337. [Google Scholar] [CrossRef]

- Wu, W.; Feng, X.; Lu, C. The rise of smart agriculture in China: Current situation and suggestions for further development. Exp. Agric. 2024, 60, e28. [Google Scholar] [CrossRef]

- Milestad, R.; Carlsson-Kanyama, A.; Schaffer, C. The Högdalen urban farm: A real case assessment of sustainability attributes. Food Secur. 2020, 12, 1461–1475. [Google Scholar] [CrossRef]

- Martin, M.; Bustamante, M.J. Growing-Service Systems: New Business Models for Modular Urban-Vertical Farming. Front. Sustain. Food Syst. 2021, 5, 787281. [Google Scholar] [CrossRef]

- Al-Kodmany, K. Mitigating Climate Change: The Potential of Vertical Farming to Feed High-Density Cities. In The Routledge Handbook on Greening High-Density Cities: Climate, Society, and Health, 1st ed.; Routledge: Abingdon, UK, 2024; pp. 50–70. [Google Scholar] [CrossRef]

- Ali, A.; Hussain, T.; Tantashutikun, N.; Hussain, N.; Cocetta, G. Application of Smart Techniques, Internet of Things and Data Mining for Resource Use Efficient and Sustainable Crop Production. Agriculture 2023, 13, 397. [Google Scholar] [CrossRef]

- Takagaki, M.; Hara, H.; Kozai, T. Micro- and Mini-PFALs for Improving the Quality of Life in Urban Areas. In Plant Factory: An Indoor Vertical Farming System for Efficient Quality Food Production; Academic Press: Cambridge, MA, USA, 2015; pp. 91–104. [Google Scholar] [CrossRef]

- Sowmya, C.; Anand, M.; Indu Rani, C.; Amuthaselvi, G.; Janaki, P. Recent developments and inventive approaches in vertical farming. Front. Sustain. Food Syst. 2024, 8, 1400787. [Google Scholar] [CrossRef]

- Stanghellini, C.; Katzin, D. The dark side of lighting: A critical analysis of vertical farms’ environmental impact. J. Clean. Prod. 2024, 458, 142359. [Google Scholar] [CrossRef]

- Swetha, K.R.; Akash, K.R.; Beerendra, P.N.M.; Manoj, M.R.; Prajwal, B.N.; Thejaswini, H.B. An Automated Irrigation System for Agriculture Using IoT. In Proceedings of the 2023 International Conference on Applied Intelligence and Sustainable Computing (ICAISC), Dharwad, India, 16–17 June 2023; pp. 1–9. [Google Scholar] [CrossRef]

- Brinks, H.; Kool, S.D. Farming with future: Implementation of sustainable agriculture through a network of stakeholders. In Changing European Farming Systems for A Better Future: New Visions for Rural Areas; Wageningen Academic: Wageningen, The Netherlands, 2006; pp. 299–303. [Google Scholar] [CrossRef]

- Diehl, J.A.; Sweeney, E.; Wong, B.; Sia, C.S.; Yao, H.; Prabhudesai, M. Feeding cities: Singapore’s approach to land use planning for urban agriculture. Glob. Food Secur. 2020, 26, 100377. [Google Scholar] [CrossRef]

- Despommier, D. Vertical farms, building a viable indoor farming model for cities’, Field Actions Science Reports. J. Field Actions 2019, Special Issue 20, 68–73. [Google Scholar]

- Kim, S.-J.; Yoe, H. Trend and Standardization of Smart Farm Technology. Korean Inst. Commun. Inf. Sci. 2022, 47, 1965–1973. [Google Scholar] [CrossRef]

- Broad, G.M. Know Your Indoor Farmer: Square Roots, Techno-Local Food, and Transparency as Publicity. Am. Behav. Sci. 2020, 64, 1588–1606. [Google Scholar] [CrossRef]

- Sumalatha, K.; Harshdeep, K. Smart Monitoring and Irrigation Regulation via IoT and Cloud. In Proceedings of the 2024 8th International Conference on I-SMAC (IoT in Social, Mobile, Analytics and Cloud)(I-SMAC), Kirtipur, Nepal, 3–5 October 2024; pp. 88–94. [Google Scholar] [CrossRef]

- Sashika, M.A.N.; Gammanpila, H.W.; Priyadarshani, S.V.G.N. Exploring the evolving landscape: Urban horticulture cropping systems–trends and challenges. Sci. Hortic. 2024, 327, 112870. [Google Scholar] [CrossRef]

- Kim, D.-I.; Kim, H.-J. A Study on Integrating Social Infrastructure through Program Convergence. Archit. Inst. Korea 2024, 40, 91–100. [Google Scholar] [CrossRef]

- Popkova, E.G. Model of Uninterruptible and Highly Efficient Operation of Vertical Farms Based on Alternative Energy in the Interests of Sustainable Agriculture. In Geo-Economy of the Future: Sustainable Agriculture and Alternative Energy: Volume II; Springer: Cham, Switzerland, 2022; pp. 879–884. [Google Scholar] [CrossRef]

- Debdas, S.; Chatterjee, S.; Das, S.; Das, D.; Hazra, S.; Shah, P.B. IoT Edge Based Vertical Farming. In Proceedings of the 2023 World Conference on Communication & Computing (WCONF), RAIPUR, India, 14–16 July 2023; pp. 1–5. [Google Scholar] [CrossRef]

- Xie, S.; Martinez-Vazquez, P.; Baniotopoulos, C. Wind Aerodynamics and Related Energy Potential of Urban High-Rise Vertical Farms. In Proceedings of the 4th International Conference “Coordinating Engineering for Sustainability and Resilience” & Midterm Conference of CircularB “Implementation of Circular Economy in the Built Environment”; CESARE 2024. Lecture Notes in Civil Engineering; Springer: Cham, Switzerland, 2024; Volume 489, pp. 187–196. [Google Scholar] [CrossRef]

- Wijnands, F.G.; Brinks, H.; Schoorlemmer, H.; de Bie, J. Integrated Pest Management Adoption in the Netherlands: Experiences with Pilot Farm Networks and Stakeholder Participation. In Integrated Pest Management; Springer: Dordrecht, The Netherlands, 2014. [Google Scholar] [CrossRef]

- Singh, J.; Neeraj; Srinivas Reddy, P.; Hasan, D.S.; Alsahlanee, A.T.R.; Shaik, N. IoT-Enabled Automated Smart Irrigation System Incorporating Sensor Parameters. In Proceedings of the Fifth Doctoral Symposium on Computational Intelligence; DoSCI 2024; Lecture Notes in Networks and Systems; Springer: Singapore, 2024; Volume 1095, pp. 33–43. [Google Scholar] [CrossRef]

- Sivamani, S.; Bae, N.; Cho, Y. A smart service model based on ubiquitous sensor networks using vertical farm ontology. Int. J. Distrib. Sens. Netw. 2013, 9, 161495. [Google Scholar] [CrossRef]

- Tariq, B.; Amina, B.; Touhami, A.; Khelifa, B.; Chaimaa, S. Greenhouse Irrigation System Based IoT. In Proceedings of the 2024 4th International Conference on Embedded & Distributed Systems (EDiS), BECHAR, Algeria, 3–5 November 2024; pp. 285–290. [Google Scholar] [CrossRef]

- Varia, J.; Kamaleson, C.; Lerer, L. Biostimulation with phycocyanin-rich Spirulina extract in hydroponic vertical farming. Sci. Hortic. 2022, 299, 111042. [Google Scholar] [CrossRef]

- Chowdhury, H.; Asiabanpour, B. A circular economy integration approach into vertical farming with computer-based simulation model for resource optimization and waste reduction. J. Clean. Prod. 2024, 470, 143256. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).