1. Introduction

The papermaking industry is one of the largest in the world, and it accounts for an energy consumption equivalent to 4% of total global demand [

1]. Wood fibers are the most used materials in papermaking [

2], covering 35% of the currently available tree supply; nevertheless, paper consumption has grown 400% in the past 40 years [

3], inducing an interest in non-wood plants and agricultural residues as alternative sources of fibers [

4].

Non-wood materials account for 5–7% of global pulp production and cannot fully replace fiber production from wood sources [

5]. Nonetheless, they can work towards reducing the industry’s dependency on wood fibers [

6], whilst also solving the problem of agricultural waste disposal [

7]. Currently, these residues are either burned or left on the fields, resulting in local environmental impacts [

5]. Implementing waste materials for papermaking can reduce production costs [

8], as well as energy and chemical requirements [

9], and it may offer high-quality fibers that can be blended with common ones to produce paper with specific characteristics like that used for writing and printing, or even tissue paper [

7,

10].

The increase in global paper consumption and the consumer demand for eco-friendly alternatives have also opened the door for a revival of the craft handmade paper industry as a sustainable alternative. In the 2000 years that paper has been part of human civilization, its production has evolved to depend on high-end equipment, which requires substantial amounts of water and generates a great amount of hazardous waste [

1], and with the appearance of sustainability trends such as the circular economy and green chemistry [

11], craft paper offers a way to combine art and science to create a manufacturing process that consumes up to 50% less energy and 75% less water [

8,

12].

Traditionally, artisanal or craft paper has been produced by blending different types of fibers, such as hemp, jute, and those from cloth rags [

12], and it offers a variety of socially responsible products attractive to the modern consumer, as although its production might be a laborious process [

13], it results in high-quality paper that can even surpass machine-made paper in terms of tearing, bursting, and tensile strength [

1]. One such potential fiber source for papermaking is fique (

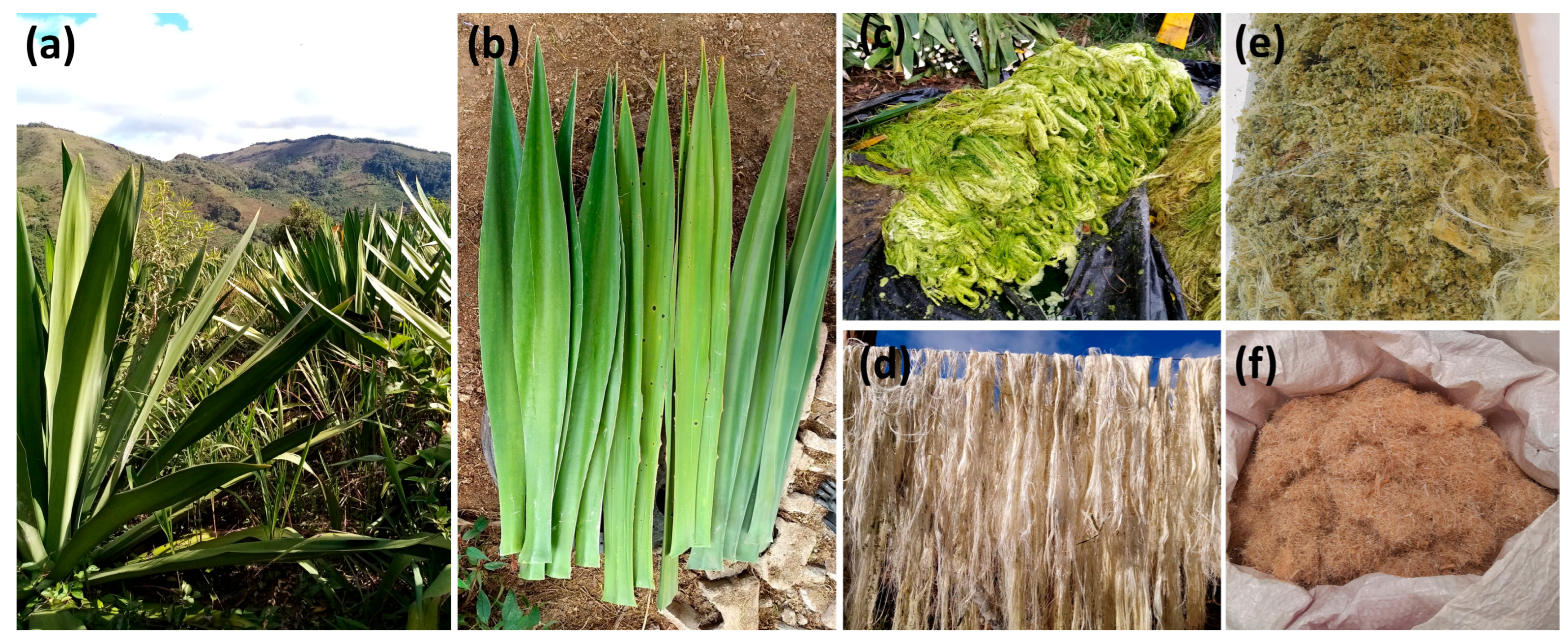

Furcraea spp.). Originating in the Andes region of South America, it is one of Colombia’s most representative plants [

14]. As seen in

Figure 1a,b, fique is a leaf-based plant like abaca or agave, which is cultivated for its long, sturdy, and white fibers that offer great resistance for ropes and textiles [

13]. They are also commonly used to produce Colombia’s emblematic coffee sacks [

7].

Fique’s raw fibers, as shown in

Figure 1c, are usually obtained from manual leaf decortication, and after being washed and dried, as presented in

Figure 1d, they only constitute 4–5% of the leaf’s total weight [

11]. With an average plant yield of 1 kg of long fiber per year (up to 6 kg) [

13], fique production generates substantial and underutilized lignocellulosic byproducts, which include pulp or bagasse (

Figure 1e), obtained from leaf decortication, and short fibers or tow (

Figure 1f), obtained from carding and combing. These byproducts represent 17% and 8–10% of the leaf’s weight, respectively, with the rest being moisture in the form of fique juice [

7,

11]. Therefore, utilizing this waste material could provide significant societal benefits while creating value-added products that contribute to self-sustainability [

15]. This is particularly relevant in Colombia’s Antioquia department, where the fique-producing sector is predominantly composed of single-mother households. Here, the production of craft handmade fique paper can significantly improve crop profitability and foster socioeconomic development in the region.

The reported chemical analysis of fique fibers demonstrates a chemical profile consistent with other non-woods suitable for papermaking, including sugarcane [

16], yielding the following composition: 55.78% cellulose, 18.58% hemicellulose, and 14.23% lignin [

17]. Nonetheless, there are few published articles on the fique pulping process for papermaking and its mechanical properties, as most papers examining fique center on textile and composite material applications [

17,

18,

19,

20,

21].

Previous research highlights the potential of fique for tissue paper applications and craft paper production [

7,

13]. However, the latter studies remain limited and lack the depth of more comprehensive investigations, largely due to insufficient characterization of raw materials and constraints related to paper formation and testing. Although fique has long been associated with papermaking [

22], the informal and/or artisanal nature of these processes has resulted in limited scientific documentation and standardization—an issue that this study addresses through its science-driven approach.

It is well established that paper quality depends primarily on the raw materials and processes utilized in its production [

5]. Accordingly, this paper will focus on the characterization and analysis of fique fibers and bagasse to evaluate their potential within the pulp and paper industry. Pulp properties, such as density, tearing strength, and tensile strength, are explored here, aiming to develop and standardize a mechanical and chemical-free process to produce handmade fique paper both from fiber and from a combination of fiber and bagasse, which has not been thoroughly explored in previous studies. Additionally, a systematic and rigorous analysis of the environmental benefits of using fique waste in the production of handmade paper, based on the application of a Life-Cycle Assessment (LCA) [

23], is conducted to provide information on the sustainability claims often associated with handmade paper production from agricultural waste.

LCA enables the environmental impacts associated with each stage of a product’s life cycle to be quantified, from the sourcing of raw materials to their final disposal [

24]. In this sense, recycling fique as an alternative fiber offers an important environmental benefit. As an agricultural byproduct, its exploitation avoids burning or decomposition in situ, which would release greenhouse gases such as methane and CO

2 [

25]. In addition, processing fique can demand less water, energy, and chemicals compared to wood-based cellulose, leading to a smaller overall ecological footprint [

26]. From a circular economy perspective, valorization of fique in these applications would not only decrease pressure on forest resources but also foster sustainable production chains in rural communities, transforming what was once considered to be waste into a valuable resource [

27]. Consequently, an LCA not only supports sustainability claims but also provides a quantitative framework for comparing these benefits with those of other papermaking methods. Therefore, this study aims to determine whether handmade paper produced from fique residues can achieve a reduction in energy use and environmental impacts (such as GHG emissions and water use) compared to craft handmade paper based on aquatic plant fibers, as assessed through LCA.

2. Materials and Methods

2.1. Materials

Raw materials were obtained from rural zones of Amalfi, in the Antioquia department of Colombia. Fique tow fibers were reduced in size in a RESTCH cutting mill SM 100 (Haan, Alemania) with an internal sieve of 4 mm. Fresh fique bagasse was dried in the Sun for two days and then taken to a tower dryer, with air at 60 °C, to remove as much moisture as possible. Long fiber bundles from the dried bagasse were extracted, weighed, cut in a cutting mill, and reintegrated into the dried bagasse.

The reagents used for morphological analysis were hydrogen peroxide and glacial acetic acid from Sigma Aldrich (Darmstadt, Alemania), and Gram safranin from Bioquigen (Bogotá D.C., Colombia).

The paper formation process incorporated several additives and reagents: a dry-strength agent (MATHVAR), wet-strength agent (Resin RH SCI 20), and sizing agent (Mathsize 9020), all supplied by Mathiesen (Medellín, Colombia). Natural dyes—specifically orange (NARANJA LQ 2) and green (VERDE LQ6)—from the Novacolor Nat line were provided by Colorquimica (La Estrella, Colombia).

2.2. Morphological and Chemical Characterization of Fique Fibers

A modified Franklyn maceration method was used to isolate cellulose fibers and cellular elements [

28]. A 1:1 solution of glacial acetic acid and hydrogen peroxide (40 Vol.) was added to the material, which was then placed in a water bath at 60 °C for 48 h. Constant agitation was applied during the final six hours to ensure complete dispersion of the macerated material. The macerated material was filtered, washed, and suspended in distilled water. The fibers were then subjected to the following characterization techniques:

2.2.1. Fiber Morphology and Cellular Elements

Fiber dimensions were measured by light microscopy to understand the potential of fique for papermaking. For high-contrast photos, macerated elements were stained with safranin. Photos were taken using a Nikon eclipse CI optical microscope. Fiber length and internal/external diameters were measured from macerated tow. To measure length, a Petri dish containing a stained sample of fiber suspension was prepared and then oven-dried at 40 °C for 4 h. ImageJ software (ver.1.53e) was used for measurement, and Statgraphics 19 was used for data analysis. The significance level for confidence intervals was established at 5%. Fiber length distribution was estimated based on over 200 fiber measurements. Fiber diameter and lumen distributions were measured based on over 100 fiber measurements.

For fiber classification, three derived values were calculated from the mean values of the fiber properties measured: the Runkel ratio (RR), slenderness ratio (SR), and flexibility coefficient (FC) [

29]. These were calculated as follows:

Cellular element photos were taken from macerated bagasse; these photos utilized both bright-field and dark-field illumination.

2.2.2. X-Ray Diffraction

For a structural analysis, macerated tow fibers were used for X-ray diffraction (XRD) crystallography. A sample of the fiber suspension was cast into dried films and subsequently analyzed by X-ray diffraction using a Empyrean diffractometer, model 2012, from Malvern Panalytical (Malvern, UK). Intensity was measured via standard reflection over an angle 2θ of 5° to 60°, with a step size of 0.026° and 51.128 s per step. The diffractometer operated with a Cu anode radiation source, generating a wavelength of 1.542 Å at 45 kV, 40 mA, and a Kα1/Kα2 relation of 0.5. OriginPro 2024 software was utilized for data analysis.

The crystallinity index (CrI) was calculated using the Segal method [

30], in which CrI is calculated using the following equation:

where I

200 is the maximum intensity of the (200) crystalline peak, and I

AM is the minimum between the (110) and (200) peaks, which represents Segal’s indicator for the amorphous contribution [

31].

The d-spacings between the crystal planes (D) and apparent crystal size (ACS) were calculated using Bragg’s law and Scherrer’s formula, respectively [

31]:

where θ is the angle between the plane and the incident beam, λ is the X-ray wavelength, and FWHM is the full width at half-maximum height of the crystalline peak [

31].

2.2.3. Attenuated Total Reflectance Infrared Spectroscopy (ATR-FTIR)

Infrared spectra were measured on a Nicolet 6700 series spectrometer equipped with a single-reflection ATR and type IIA diamond crystal Thermo Scientific (Waltham, MA, USA). A total of 32 scans were made in the 4000–400 cm−1 range, with a 4 cm−1 resolution.

Characteristic bands were analyzed, and the Iα cellulose fraction was calculated through the method of Imai T. et al. [

32], using the following equation:

where A

750 and A

710 are the intensities of the 750 and 710 cm

−1 peaks, respectively, and k is the adsorption coefficient ratio between the peaks, usually 0.16 [

33].

2.3. Pulp Preparation

Pulp for paper formation was made from two different raw material sources: pure tow fiber (fiber pulp), and a mixture of fique bagasse and tow fiber at a mass ratio of 70/30 to achieve a 50% fiber content (BTM pulp). Before pulping, each material was soaked in water for at least 12 h.

Pulping was performed by mechanically processing the wet material through an electric grain grinder, utilizing a 1 hp single-phase AC motor. The grinder was selected due to its ease of acquisition on the market and low cost, allowing it to be located in rural facilities and operated in parallel to increase production scale. Pulp was obtained after repeatedly passing the material through the mill, and water was added to prevent halting and overheating. The pulp obtained was filtered using a 100-mesh sieve to remove excess water and fines from the mechanical pulping process [

34,

35]. The pulping yield was determined as the ratio of the dry mass of pulp greater than 100 mesh to the initial dry mass.

Three drainability measurements of pulp were obtained using a Canadian Standard Freeness Tester for each pass through the mill, following the TAPPI T-227 test procedure [

36]. Statistical analysis of the experimental data was performed using multifactorial Analysis of Variance (ANOVA) to evaluate the effects of the processing steps (1 to 5 steps), material type (fiber or BTM pulp), and their interaction on pulp drainability. For the ANOVA, the normality of residuals was verified using the Shapiro–Wilk test, and the homogeneity of variances was assessed using Levene’s test. Where ANOVA indicated significant effects, Least Significant Difference (LSD) tests were conducted for pairwise comparisons. Statistical analysis was performed at a 5% significance level using Statgraphics 19.

2.3.1. Additives and Dyes

Additives were used to evaluate potential improvements in the properties and characteristics of paper made from tow fiber pulps. A recommended dosage of 4 g/kg of dry-strength agent and 10 g/kg of wet-strength and sizing agents was applied. Considering that the pulp with 50% fiber should have worse properties, an extra 20% supplementary additives was used: 4.8 g/kg of dry-strength agent, and 12 g/kg each of wet-strength and sizing agents. For their incorporation, water was added to each pulp to achieve a consistency of 3–4%. At this point, the respective additives were introduced into the mixture.

To assess the effects of dyeing on pulp properties, as dyed craft paper should boost commercial appeal, 30 g batches of dry pulp were dyed with the orange and green dyes following the Innato dyeing procedure for basic colorants [

37]. Once the dyeing process was finalized, the pulp was washed through a 100-mesh screen to remove dye residues, and the respective paper agents were added.

Statistical analysis of the experimental data was performed using multifactorial Analysis of Variance (ANOVA) to evaluate the effects of material type (fiber and BTM pulp), pulp treatment (no additives, with additives, green-dyed, and orange-dyed), and their interaction on pulp handsheet properties. For the ANOVA, the normality of residuals was verified using the Shapiro–Wilk test, and the homogeneity of variances was assessed using Levene’s test. Where ANOVA indicated significant effects, Least Significant Difference (LSD) tests were conducted for pairwise comparisons. A significance level of α = 0.05 was used.

2.3.2. Standardized Pulp Handsheet Formation

To obtain properties comparable to those reported in the literature, pulp handsheets were prepared using a standardized handsheet former. They were then couched and dried on metallic plates and rings, following the standard test method TAPPI T-205, with a target grammage of 150 g/m

2. Couching must withdraw the most moisture possible, so three absorbent paper sheets and a metallic plate were placed above the sheets on the former before a metal rolling pin was rolled over them 10 times. This procedure was repeated before taking the formed sheets for drying [

38].

2.3.3. Physical Properties of the Pulp Handsheets

The measured pulp handsheet properties were grammage, paper caliper, tensile strength, and bursting strength. These were determined according to the standard test method TAPPI T-220 [

39].

2.3.4. Field-Emission Scanning Electron Microscopy (FESEM)

For a further analysis of the pulping process, pulp handsheet surface morphology was observed through a Thermo Scientific Apreo 2S Microscope (Waltham, MA, USA). Micrographs were obtained for both sides of handsheets made with 2, 3, 4, and 5 steps through the grain mill.

2.4. Craft Handmade Paper Formation

Paper sheets were formed according to the methodology of Caby Belto (2012) [

40] to evaluate the effects of the craft process on paper properties. Briefly, two wooden molds and deckles with a 30-mesh wire screen were used to form paper sheets approximately A4 (33.3 × 22.1 cm) and A6 (14.8 × 10.1 cm) in size. The formation was performed at a consistency of 6 g/L, with a depth of 10 cm. Once the sheet was formed, the deckle was separated from the mold, and absorbent paper was placed over the fresh sheet. Then, the mold was flipped over a flat surface, and water was removed with a sponge. At this point, the sheets adhered to the absorbent paper and were taken off the mold screen. Later, the sheets were air-dried while still adhering to the hanging absorbent paper. Finally, the dried craft handmade paper was peeled off the absorbent paper and hot-pressed manually to produce flat, uniform sheets.

Craft Paper Physical Properties

The same properties from

Section 2.3.3 were taken to assess paper quality. The paper caliper was measured following the TAPPI T-411 standard method. Tensile strength was measured using the ASTM D828 method. Bursting strength was measured according to ISO 2759 standards.

2.5. Environmental Analysis

A Life-Cycle Assessment (LCA) was conducted using the CML methodology (Centre for Environmental Life-Cycle Assessment) to evaluate the environmental impacts of obtaining handmade paper from fique lignocellulosic residues. Three alternatives were studied in the production of handmade paper: (i) fique fiber with additives, (ii) fique fiber without additives, and (iii) aquatic weed fibers as described by Emmclan et al. (2018) [

6]. The study adopted a “gate-to-gate” approach, covering the stages of pulp acquisition, paste formation, and sheet production. The primary objective was to quantify key environmental indicators (such as water footprint, greenhouse gas emissions, and potential impacts on ecosystems) associated with the valorization of fique agro-industrial residues.

The functional unit selected was 1 sheet of handmade paper produced from fique residues, allowing for a standardized comparison of environmental performance. The LCA was conducted in two main phases: the Life-Cycle Inventory (LCI) and the Life-Cycle Impact Assessment (LCIA). During the inventory phase, data were collected on resource use associated with fiber extraction, retting, pulping, and manual paper production.

The LCIA phase involved translating the LCI data into quantitative environmental impact indicators. The CML baseline methodology, originally developed by Guinée et al. (2002) and updated in 2016, was used to evaluate 11 mid-point environmental impact categories: climate change, acidification, eutrophication, human toxicity, freshwater and marine ecotoxicity, terrestrial ecotoxicity, photochemical oxidant formation, ozone depletion, and abiotic depletion (fossil fuels and minerals) [

41]. The software OpenLCA v2.1 was used for modeling and impact assessment, applying the CML 2001 method in conjunction with the ELCD 3.2 database by GreenDelta [

42].

The following assumptions were considered in this study:

The energy consumed in the paper production process reflects the Colombian national energy matrix for 2021, composed of 81.82% hydroelectricity, 11.1% natural gas, 5.4% coal, 1.07% oil, 0.44% solar, and 0.08% wind energy.

For the chemical inputs used, the ELCD 3.2 database from GreenDelta was utilized to approximate their compositions, combining them with water to adjust their concentration. When it was not possible to identify the active component, it was assumed to be a generic organic compound.

A sensitivity analysis was conducted on the best-performing alternative, craft handmade paper from fique tow fiber without additives, to explore the robustness of the environmental results and identify opportunities for improvement. Two scenarios were evaluated independently:

3. Results and Discussion

3.1. Morphological and Chemical Characterization of Fique Fibers

3.1.1. Fiber Morphology and Cellular Elements

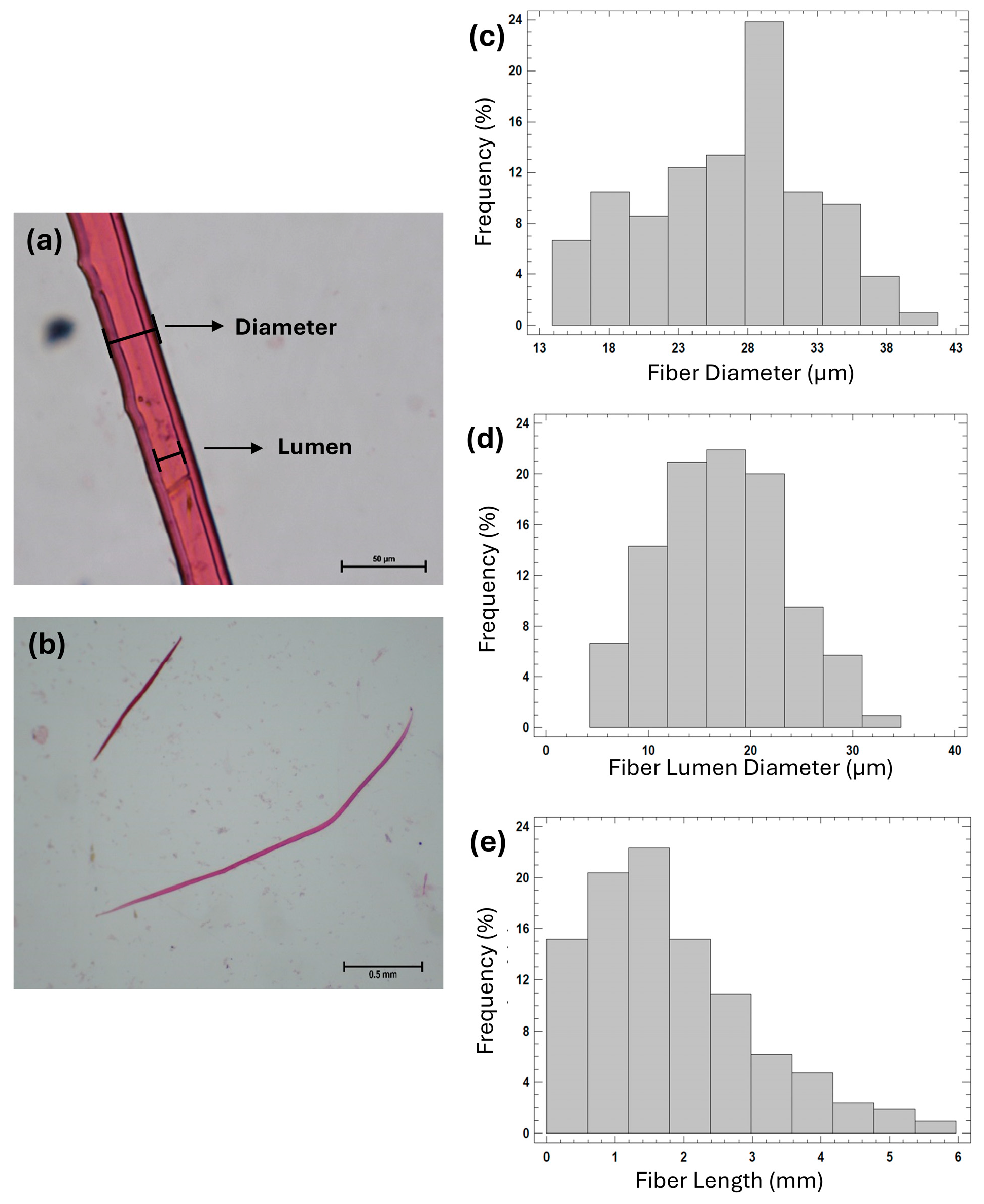

Fique tow fibers were completely separated through the maceration process. Diameter measurements were taken for three segments of 36 distinct fibers.

Figure 2a shows a fiber where the cell walls are visible; the diameter and lumen (internal diameter) are indicated. The results show a mean fiber diameter of 26.5 ± 1.2 μm, a mean lumen of 17.4 ± 1.2 μm, and a mean cell wall thickness (calculated as the difference in diameters) of 4.5 ± 0.2 μm. Both diameters displayed a normal distribution, as presented in

Figure 2c,d.

The mean length observed was 1.83 mm ± 1.64, with fibers ranging from 0.25 mm to 5.96 mm, a difference exemplified in

Figure 2b. Fiber length presented an asymmetric distribution, as shown in

Figure 2e. These results coincide with R. Kumar’s (2022) [

7] fique residue analysis, which showed a mean fiber length of 1.8 mm and a mean fiber width of 22.9 μm, while differing slightly in the length-weighted mean fiber length, with a reference value of 2.3 mm, whilst the obtained value was 2.62 mm. However, other reports show a wider distribution for fique fiber length, with a vastly different fiber diameter and cell wall thickness of 9.22 μm and 1.94 μm, respectively [

13].

Most fibers are centered around the mean length, for which the paper obtained is expected to be uniform in appearance. Nonetheless, the presence of long fibers (>2 mm) could cause flocculation, which, in turn, results in poor paper sheet formation [

43]. Accordingly, fique tow fibers, as reported by their dimensions, are shown to be comparable to some benchmark pulps in the market, such as northern bleached softwood fibers [

7].

The derived values obtained here are shown in

Table 1. In general, the most desirable non-wood fibers must have a slenderness ratio greater than 60, a Runkel ratio less than 1.00, and a flexibility coefficient ranging from 50 to 75 [

6]. Based on the Runkel ratio, fique fibers can be classified as grade III, corresponding to a good pulp quality able to produce high-density paper with elevated tearing, tensile, and bursting strengths, as well as good writing properties [

10]. A high slenderness ratio, though it is only necessary to surpass a value of 33 for papermaking [

44], may allow for fiber interweaving during the pulping process [

43]. Concurrently, the flexibility coefficient is related to paper strength, as higher flexibility provides better fiber bonding in paper sheets [

6]. As a whole, this makes fique tow an excellent candidate for papermaking.

Based on the reference values, fique fibers showed great similarity to

E. grandis, one of the most common eucalyptus species used for commercial papermaking [

49], with approximately equal Runkel and flexibility coefficients. This means that fique fibers should be able to produce commercial-grade pulps similar to those obtained from hardwoods, making them suitable for the manufacture of tissue or printing paper. With the benefit of a higher slenderness ratio and the presence of long fibers in the range of those from softwoods (2.5–4 mm), fique fibers can be used as a “reinforcement material” in different types of paper, like offset paper, or even medium-density fiberboard [

50], which has been produced from fique after a steam explosion pretreatment, with promising results [

18]. However, the pulp properties would not be as good as those obtained from fiber sources like sugarcane bagasse or

P. kesiya, which have a better Runkel ratio and flexibility coefficient [

45,

48].

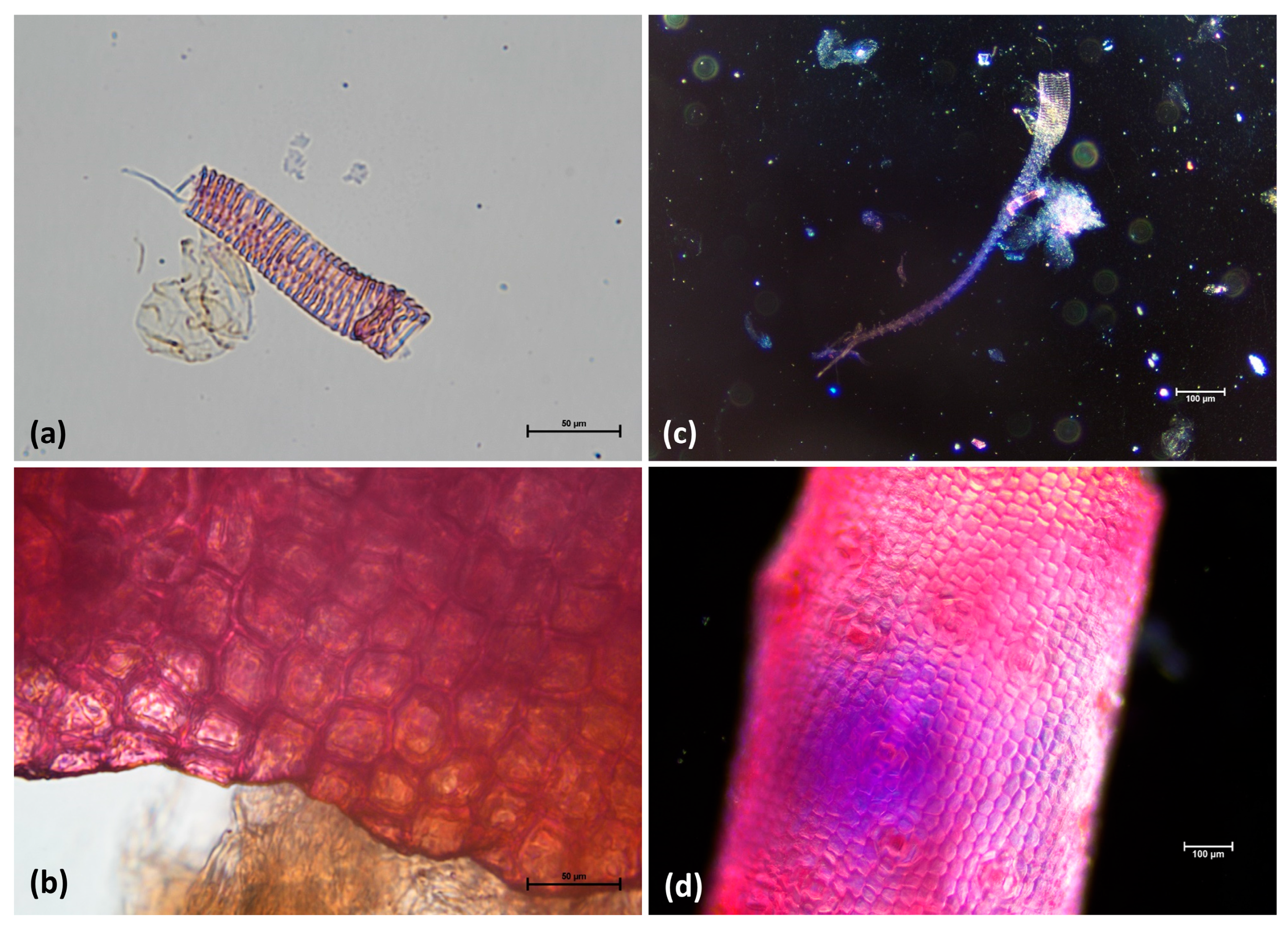

Plant cell debris was not found in the macerated tow. Fique bagasse contained some cellular elements, such as parenchyma cells and pitted vessels, but for the most part it was composed of epithelial cells from the leaf area of the plant, which present a similar configuration to other members of the

agavoideae subfamily like

Agave fourcroydes Lem. [

51]. Some of these elements are shown in

Figure 3.

The presence of these cellular elements in fique bagasse is generally considered to be undesirable for papermaking, as they can influence paper’s mechanical resistance and surface properties [

13]. Nonetheless, when in low proportions, they act as a filler and, in some cases, as “formation aids”, keeping long fibers from knotting and decreasing the drainability of the fiber suspension [

12]. Since fiber bundles were calculated to be about 28% of the dried bagasse weight, blending with a more fibrous material is required to make resistant paper from it, but it could be used to help with the expected formation issues due to fique’s long fibers.

3.1.2. X-Ray Diffraction Analysis

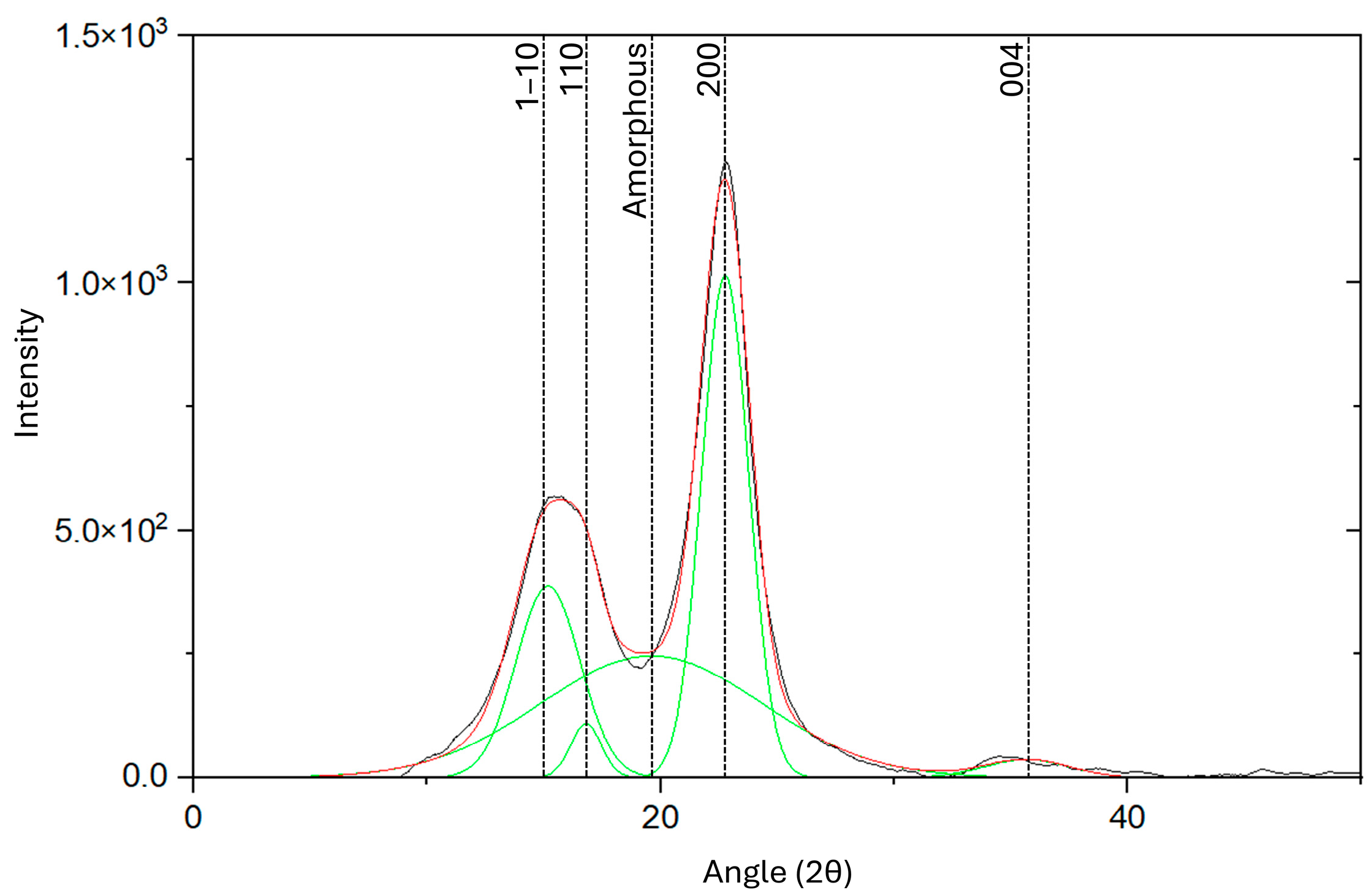

The XRD pattern in

Figure 4 shows the (1–10), (110), (200), and (040) crystallographic planes characteristic of cellulose I, located at 2θ = 15.2°, 16.9°, 22.9°, and 34.6°, respectively [

52].

Table 2 shows the results obtained for fique tow fiber crystallinity. The maceration functioned as a delignification process, increasing the fibers’ crystallinity, which surpassed the reported Segal value of 73.2% for delignified fique fibers/tow [

11]. This is also higher than the Segal crystallinity for bleached cellulose pulp from

Agave tequilana leaves (48.43% to 49.88%) [

53]. A high crystallinity, associated with a higher crystallite size, implies increased density, tensile strength, and hardness of the fibers, with a decrease in dye sorption, chemical reactivity, and flexibility [

54].

In general, pulps used for papermaking usually have a structural crystallinity between 60% and 70% [

55]. This would imply that paper obtained from fique tow fibers might present as a dense material with high stiffness, making it a potential packing material. Water retention value and fiber swellability are also associated with crystallinity, as water does not penetrate the crystalline domains of cellulose, reducing water uptake by the cell wall [

56]. The effect of the refining process on crystallinity should also be considered: in the initial phase of refining, the amorphous regions of cellulose are mostly affected, which increases crystallinity; later, the opposite happens [

55]. Thus, certain properties of the paper associated with the crystallinity index might change partially due to the effect of the degree of pulping.

The d-spacings and crystallite sizes for the different crystalline planes were obtained from the peak deconvolution values; d-spacings are associated with cellulose types and structural allomorphism, and the results obtained for the 1–10, 110, and 200 planes are similar to the previously reported values of 0.58, 0.53, and 0.39 nm in wood fibers—values characteristic of cotton–ramie (Iβ-dominant)-type cellulose [

31,

57]. Fique tow fibers show a decrease in the 1–10 and 200 crystallite sizes but an increase in the 110 crystallite size compared to those of bleached kraft

E. grandis fibers (with a similar Segal crystallinity of 74.9%), with sizes of 3.78, 3.83, and 2.37 nm, respectively [

58]. Crystallite size affects fibers’ thermal degradation, as they may act as barriers to heat transfer, increasing thermal stability [

59], which means that fique fibers could produce pulps with greater thermal stability—something that could be exploited for specific applications, although this would have to be further studied in detail.

3.1.3. Attenuated Total Reflectance Infrared Spectroscopy (ATR-FTIR)

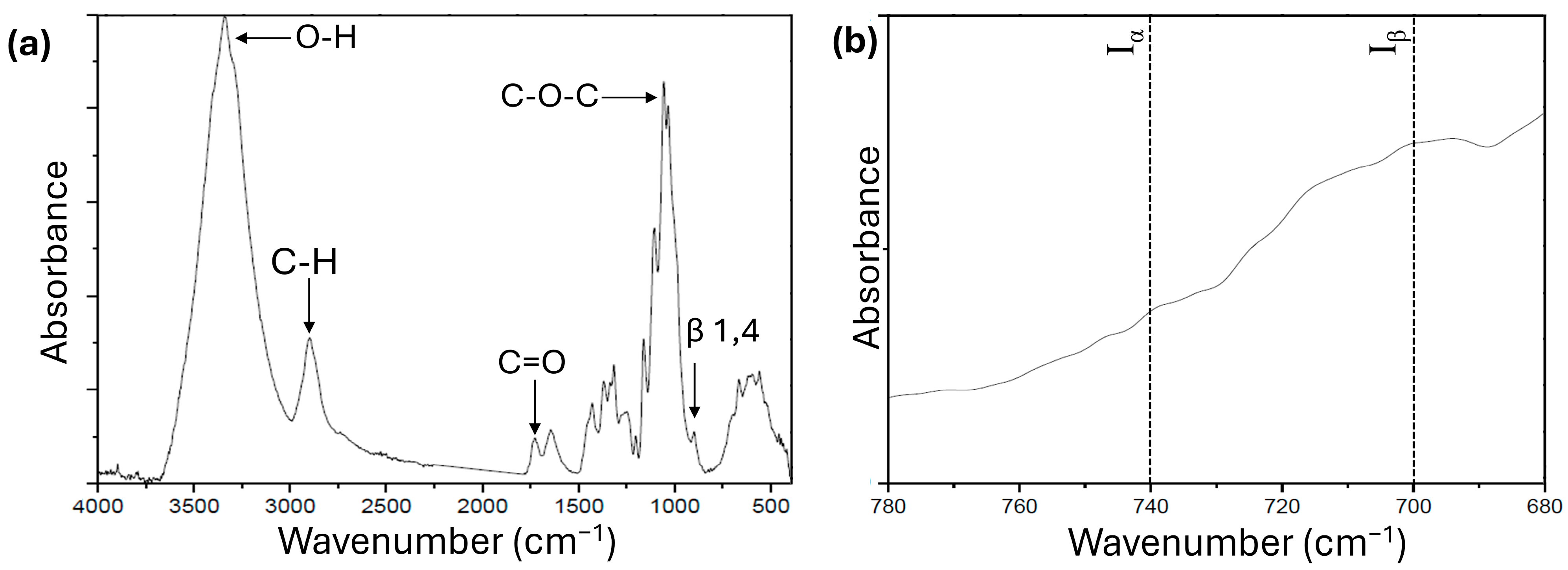

The FTIR spectra of the macerated fique tow fibers, as shown in

Figure 5a, have characteristic bands corresponding to their lignocellulosic components, mainly cellulose and hemicellulose. This aligns with the typical spectra of cellulose from other non-wood materials like barley straw, which presents some characteristic peaks at 3411, 2900, 1640, 1378, 1321, 1273, 1208, 1164, 1120, 1067, 1023, and 898 [

5].

The 1429 cm

−1 band is attributed to the CH

2 symmetric bending of hemicellulose [

60], the peak at 1248 cm

−1 corresponds to typical C-O-C vibrations in lignin [

61], and the peak at 1033 cm

−1 is linked to C-O-C at the pyranose ring of cellulose [

31]. Lastly, the band around 898 cm

−1 corresponds to the β-glycosidic linkages characteristic of the D-glucopyranose in cellulose [

11,

53].

Ovalle-Serrano et al. analyzed the IR spectra of fique fibers, tow, and pulp, with no major differences from the ones obtained here [

11]. Among the characteristic peaks, the absorption band around 3342 relates to molecular OH stretching vibration, whose presence in cellulose allows for hydrogen bonds to emerge and fibers to attach in paper formation [

31]. The 2900 cm

−1 bands are attributed to C-H stretching vibration and symmetric tension, as well as intermolecular OH stretching vibration [

5]. The bands at 1726 cm

−1 relate to C-O tension from acetyl and ester groups of hemicellulose, as well as possible C=O stretching of aromatic compounds in the remaining lignin [

53], which is further reflected around the peak at 1644 cm

−1 corresponding to C=C stretching [

17,

61].

A spectrum extension between the 680 nm and 780 nm wavelengths is shown in

Figure 5b; this figure shows the bands corresponding to the I

α and I

β crystalline allomorphs of cellulose, which presented a 10 cm

−1 deviation to the right of their expected positions at 750 and 710 cm

−1, respectively [

33]. For the macerated fique fibers, I

α was calculated to be 5.9%, demonstrating the prevalence of cellulose in its I

β form, which was expected not only from the crystalline planes obtained in the XRD spectra but also from it being the main component of cellulose in higher plants, with proportions varying depending on the cellulose source [

60].

3.2. Pulp Preparation

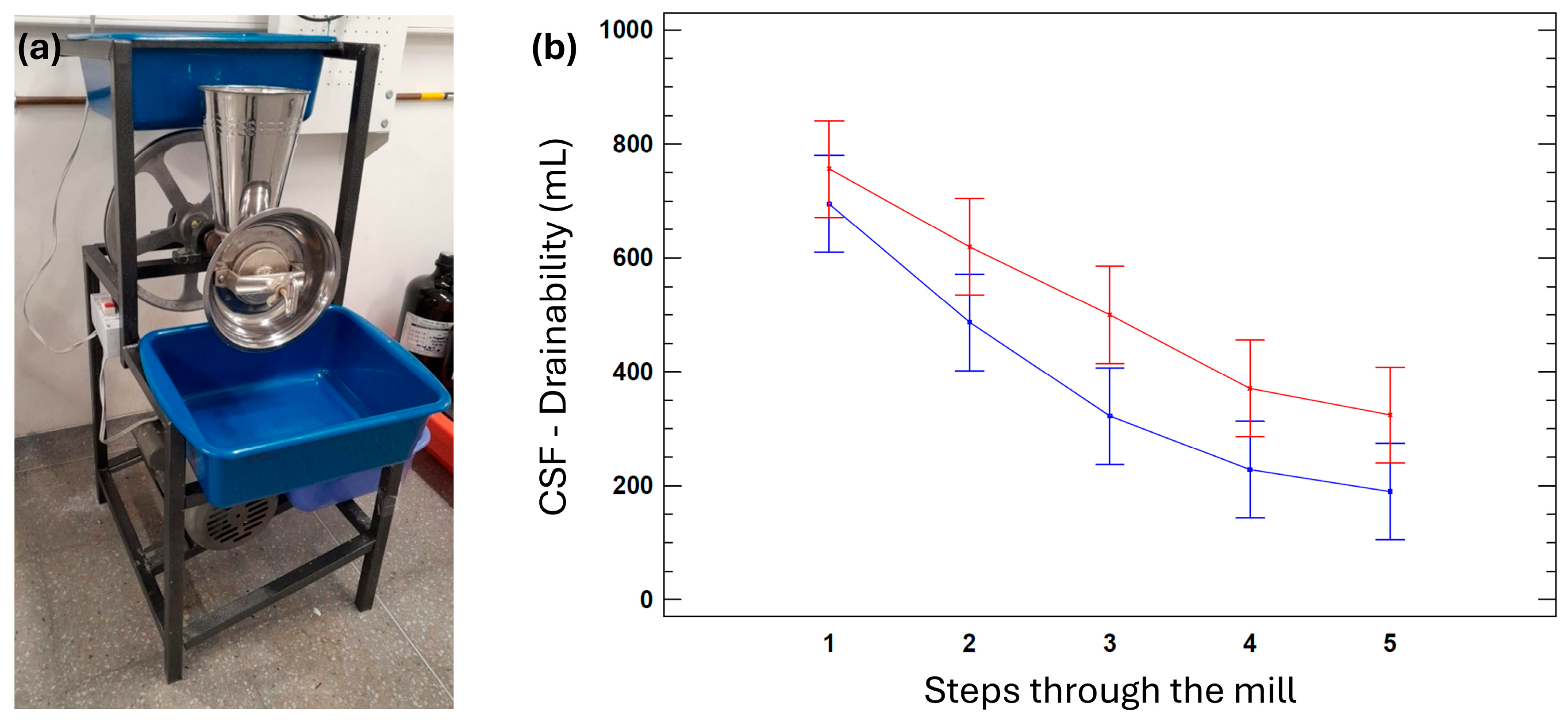

The electric grain mill used to emulate a single-disk refiner is shown in

Figure 6a. This mill could be used in rural areas, while also aiming to be low-cost, making it suitable for potential implementation in a craft paper production process. The pulping of the material resulted in tow fiber separation and fibrillation, with a screened pulp yield of approximately 78% for tow fiber pulp and 52% for the bagasse–tow mixture (BTM) pulp (using a 100-mesh sieve). This yield is lower than that of usual mechanical wood pulping, with yields as high as 95% [

62]. The lower yield is probably caused by greater fines generation and material loss during the screening process, as well as the 50% of the BTM mixture that is composed of non-fibrous material.

Pulps produced from fique tow fiber and BTM showed a significant decrease in drainability as they passed through the grain mill. The results of the applied multifactorial ANOVA (

Table S1) and its validations (

Tables S2–S4) are presented in the

Supplementary Materials. Statistical tests showed a statistically significant difference between the two types of material analyzed and the different steps through the mill. As shown in

Figure 6b, the drainability value of tow fiber pulp decreased from 695 to 190 mL in a five-step milling process, while that of BTM reduced from 756 to 324 mL. These results align with typical drainability values for unbleached softwood kraft pulps, which can go from 750 mL when unrefined to 600–250 mL when refined [

61].

It was expected that the BTM pulp would have lower drainability due to cellular elements acting as fines, which can become stuck in the pores between fibers and reduce water flow. Instead, tow fiber pulp presented higher compaction, with slower drainage and a more pronounced decrease in drainability, indicating faster refining. This compaction may be explained by a higher quantity of polar fines production from fibers. The pronounced reduction in the drainability may also be partially explained by fique’s low lignin content, as lignin has been associated with resistance to refining. Pulps with a low kappa number have been reported to exhibit a lower degree of drainability [

61].

3.2.1. Standardized Pulp Handsheet Formation

To obtain results comparable to other reported values, pulp quality was evaluated from standardized handmade paper sheets.

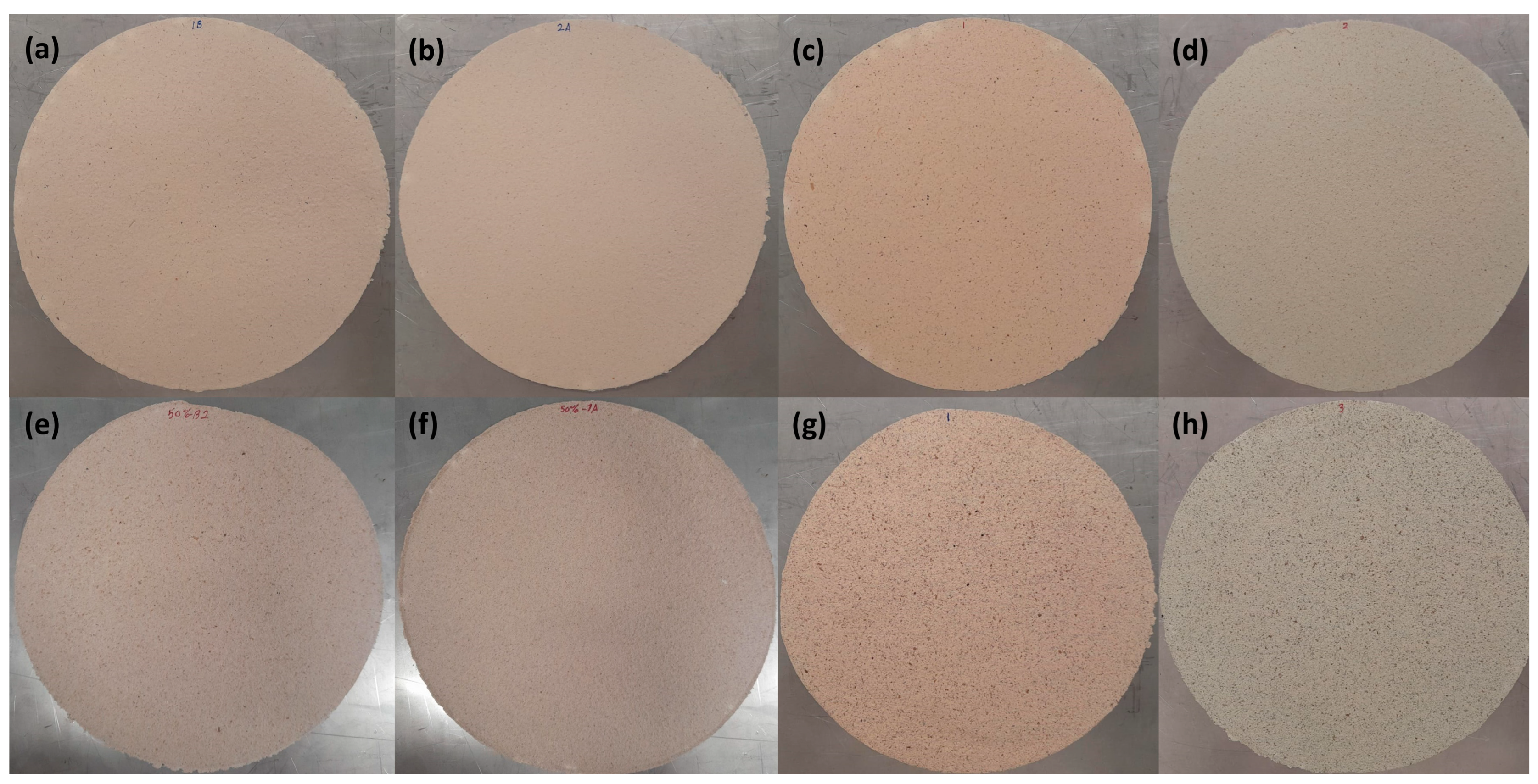

Figure 7 presents photographs of the different sheets produced. Upon drying, the handsheets had a polished surface on the plate-sided face. Tow fiber pulp paper had a uniform and lighter appearance, while BTM pulp paper had a dotted appearance and a lower dye sorption, making it look grayer. Both pulps created an opaque paper and seemed to have good resistance, although from paper couching it was noticed that BTM had a lower wet resistance and required greater attention. Green-dyed handsheets showed a greater change in color with a lesser amount of dye, making dye compatibility an important property to consider when a colored pulp is wanted.

The dotted appearance of the BTM sheets was most likely due to their cellular elements surfacing during paper formation, which also resulted in a light shedding of fines from the dry paper. This seems to be reduced by the use of additives. The effect of the pulping degree (milling steps) on paper appearance resulted in increased paper uniformity and whiteness. Mechanical pulping is considered to be a high-yield process, eliminating the use of chemicals; therefore, lignin remains in the fibers, and the lightening of the color may be attributed to the release of lignin-rich components from the lamellae as the fibers’ exterior cell walls become detached [

63]. In paper processed with two passes through the mill, a considerable number of fiber bundles were visible. These bundles gradually decreased as the number of passes increased. Additionally, other elements present in the raw tow showed signs of disaggregation, resulting in a smoother paper surface.

Table 3 presents the results of several multifactorial ANOVAs at a significance level of 0.05, evaluating the effects of pulp type (tow fiber pulp and BTM pulp) and treatment (no additives, with additives, green-dyed, and orange-dyed) on three physical-mechanical properties of the formed sheets (tensile index, bursting index, and density). The experimental results showed that both factors had a statistically significant effect on all physical-mechanical properties evaluated.

Properties obtained from paper handsheets, along with reference values, are shown in

Table 4. LSD charts (

Figures S1–S3) and ANOVA validations (

Tables S5–S13) are presented in the

Supplementary Materials. The maximum tensile index obtained was 13.01 N m/g for the tow fiber handsheets with additives, with the lowest being 7.62 N m/g for the green-dyed BTM sheets. The highest value for burst index was 1.42 kPa m

2/g for tow fiber handsheets without additives, with a lower bound of 0.71 kPa m

2/g, again for the green-dyed BTM handsheets. Inversely, BTM handsheets with no additives were the densest, with 0.38 g/cm

3, whilst the lowest density of 0.24 g/cm

3 was for the green-dyed tow fiber handsheets. Tow fiber pulp sheets’ greater tensile and burst indices can be attributed to a greater amount of interweaving and bonding, whilst BTM paper’s higher density is likely due to the presence of fine non-fibrous material acting as filler, along with a lower cellulose content [

64]. On the other hand, the multiple comparison analysis showed the existence of two statistically different groups: One group consisted of leaves with dyes, which had lower and statistically similar values in the mechanical properties. The other group was composed of handsheets without dyes, which had better or higher values in these properties but were statistically similar to each other.

The mechanical pulping used in this work resulted in pulps with lower resistance compared to benchmark wood pulps obtained through chemical processes, like those of eucalyptus and pine, whose tensile and burst indices surpass 40 N m/g and 3 kPa m

2/g. Still, the burst index was near the range of 0.8–1.2 kPa m

2/g, which has been reported to be common for promising raw materials [

5]. This means that despite the differences between wood and fique pulps, as well as the processes used, high-quality pulps can be obtained from fique’s lignocellulosic residues if a 50% fiber content is guaranteed, although the lower bound for acceptable property values is unknown.

The efficacy of additives is uncertain, as they had no effect on the mechanical properties measured, although they may influence other paper properties. On the other hand, the dyeing process had a major effect on handsheet strength, likely caused by a degradation of fibers in a hydrolysis process favored by a high temperature and the addition of acetic acid, so other tests like water retention and folding endurance could give a deeper insight into pulp quality. Therefore, based on the physical properties results of using additives and dyes, it was decided to make the craft handmade papers only with pulp resulting from the pulping of the fique tow.

3.2.2. Field-Emission Scanning Electron Microscopy (FESEM)

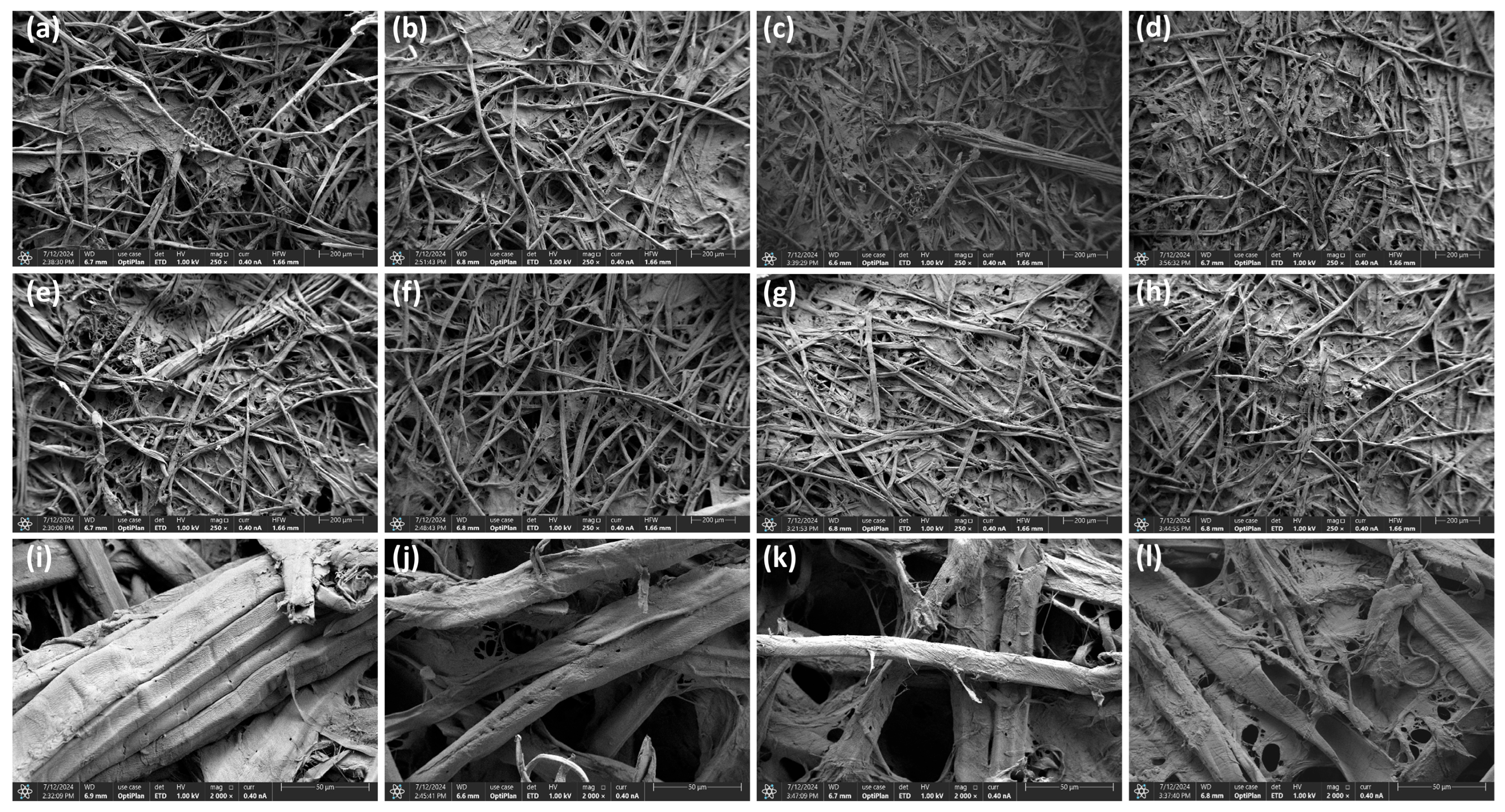

FESEM micrographs helped to assess the efficacy of the pulping process for refining by means of surface morphology analysis;

Figure 8a–h illustrate the changes in both sides of the tow fiber handsheets’ surface from a two-step to a five-step milling process. Initially, the presence of fiber bundles and other elements is notable, with a lower amount of fiber bonding and a generally rougher aspect. Upon refining, a uniform surface is achieved, disaggregating fiber bundles present in the raw material into individual fibers, but also generating some degree of deformation in the form of fiber torsion, bending, and fracturing.

The process from fiber bundle separation to fiber defibrillation and rupture can be better observed in

Figure 8i–l. The pulping process should ideally leave fibers separated and with some degree of fibrillation or fiber collapse, without compromising their integrity to the point of breakage. This is readily achieved at five steps through the mill; therefore, any further milling may be unfavorable to paper quality. Nonetheless, this process is not uniform, as fibers in all stages could be found in the four paper sheets evaluated, and micrographs are not a guarantee of certain paper properties; thus, for pulp quality optimization, further testing should be required.

Overall, refining increased the total surface area available for bonding via external fibrillation [

6] and conversion of fibers into ribbons, partially due to fique fibers having thin walls (Runkel < 1) [

48]. The formation of a film-like material surrounding the fibers can also be observed, which was produced by the release of hydrophilic compounds during defibrillation, producing a gelatinous layer that improves fiber bonding [

61]. Some of these compounds may include polysaccharides, extractives, and very fine cellulosic fibrils [

67]. In summary, the effect of pulping on fibers resulted in increased flexibility of the cell wall and bonding area, which improves paper’s density, tearing resistance, and tensile strength [

68].

3.3. Craft Handmade Paper Formation

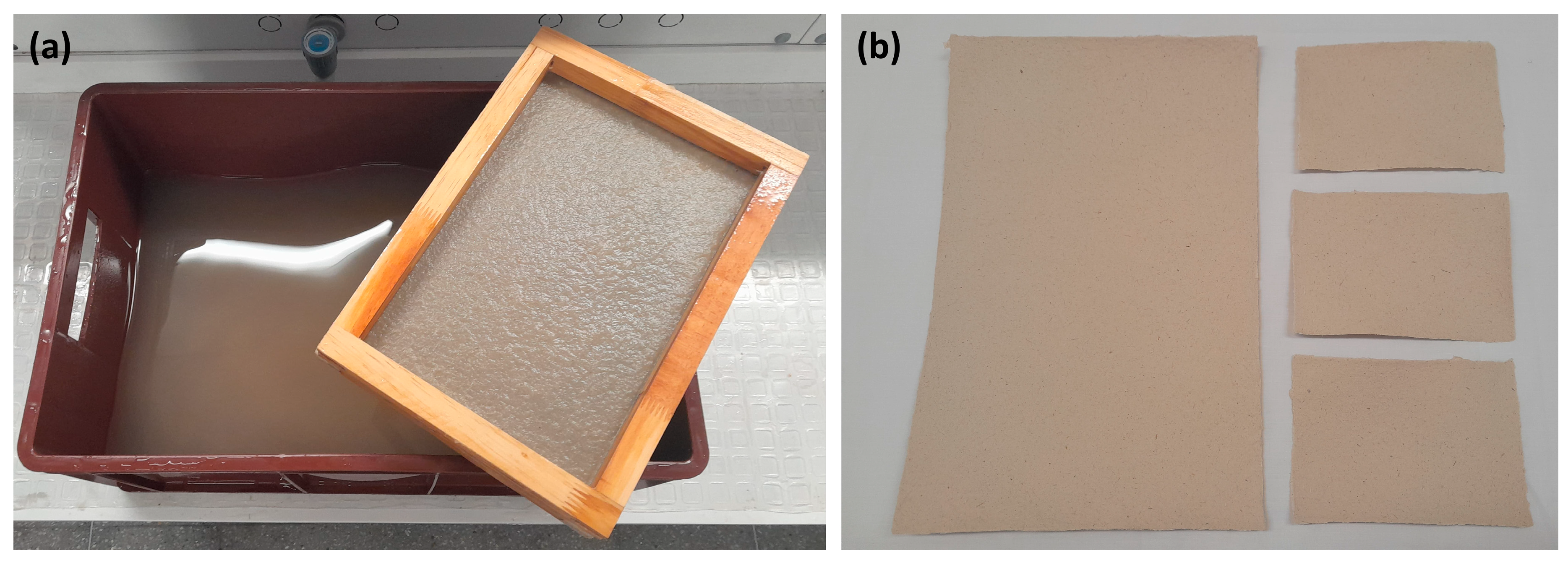

To examine the craft process, paper was formed with the traditional dipping method [

15] (

Figure 9a), and tow fiber pulp was used to make craft handmade paper in two sizes, as shown in

Figure 9b. As anticipated, given the fiber morphology, some flocculation occurred during the formation of craft handmade paper. The resulting craft paper absorbed and retained a significant amount of water, indicating a high degree of pulping. The drying process, which took approximately 18 h overnight, resulted in minimal loss of craft paper shape or curling. The obtained craft handmade paper had grammages between ~60 and ~160 g/m

2.

Similar to standard handsheets, craft handmade paper exhibited a uniform and light appearance. This craft paper had a softer surface, which was further enhanced by hot pressing, and some fiber bundles remained visible. The physical properties of craft handmade paper are presented in

Table 5. The tensile index values are higher than those of standardized handsheets, likely due to the hot pressing of the craft handmade formation, which has been associated with improved properties and increased density [

69]. On the other hand, craft paper showed a decrease in paper density, likely attributed to the use of a lower size mesh compared to that in standard sheet formation, decreasing fines retention and resulting in sheets with a more porous structure.

Commercial craft fique paper produced by a chemi-mechanical pulping has a higher burst index and density, with a lower tensile index—differences that could be associated with production methods but prove that the obtained paper has characteristics resembling those of high-quality paper. Other studies have obtained fique fiber paper made with a chemical pretreatment and other additives, with a burst index that surpasses the results obtained here [

13]. This could also be caused by the mesh used in paper formation, but it also suggests that low uniformity of the pulping method used may be causing a lack of fiber separation or fibrillation, in which case mechanical properties should be measured for sheets at various milling degrees in order to optimize pulp characteristics. A mixture of pulps at various milling degrees could also be beneficial for paper properties.

If these sheets were to be dyed to increase their commercial value, a reduction in paper resistance would also be expected, yet data from pulp handsheets shows that the dyed pulps resembled, and in some cases surpassed, the resistance values for other non-wood materials considered to have high potential for craft papermaking, like pineapple or aquatic weeds (

Cyperus digitatus) [

5,

6].

3.4. Environmental Analysis

Table 6 shows the results for the Life-Cycle Assessment (LCA) evaluating and comparing the environmental performance of the three proposed alternatives in the production of handmade paper: (i) fique fiber with additives, (ii) fique fiber without additives, and (iii) aquatic weed fibers, based on the process described by Emmclan et al. (2018) [

6]. The results were expressed per functional unit of one sheet (9.009 g) produced.

In terms of environmental impact, fique tow fiber generally performs better than aquatic weed fiber. For instance, fique tow fiber contributes less to climate change (2.20 × 10−4 kg CO2 eq/sheet) and acidification (3.21 × 10−4 kg SO2 eq/sheet), meaning that it releases fewer greenhouse gases and acid-forming pollutants per sheet of paper. While these differences might seem small for a single sheet, they can add up significantly in larger production volumes. Even with additives, fique fiber’s impact in these areas remains minimal.

Beyond climate and acidification, fique tow fiber also shows lower impacts across various ecotoxicity categories, including in freshwater, marine, and terrestrial environments. This suggests that it is less harmful to ecosystems. This pattern extends to human toxicity, indicating that fique fiber paper production is less likely to release substances that are harmful to human health. Additionally, fique tow fiber uses significantly less water in its production (0.280 L/sheet, compared to 0.345 L/sheet for aquatic weed fiber), a crucial advantage given global water scarcity. Both fiber types have negligible impacts on material resource depletion (metals/minerals) and ozone depletion.

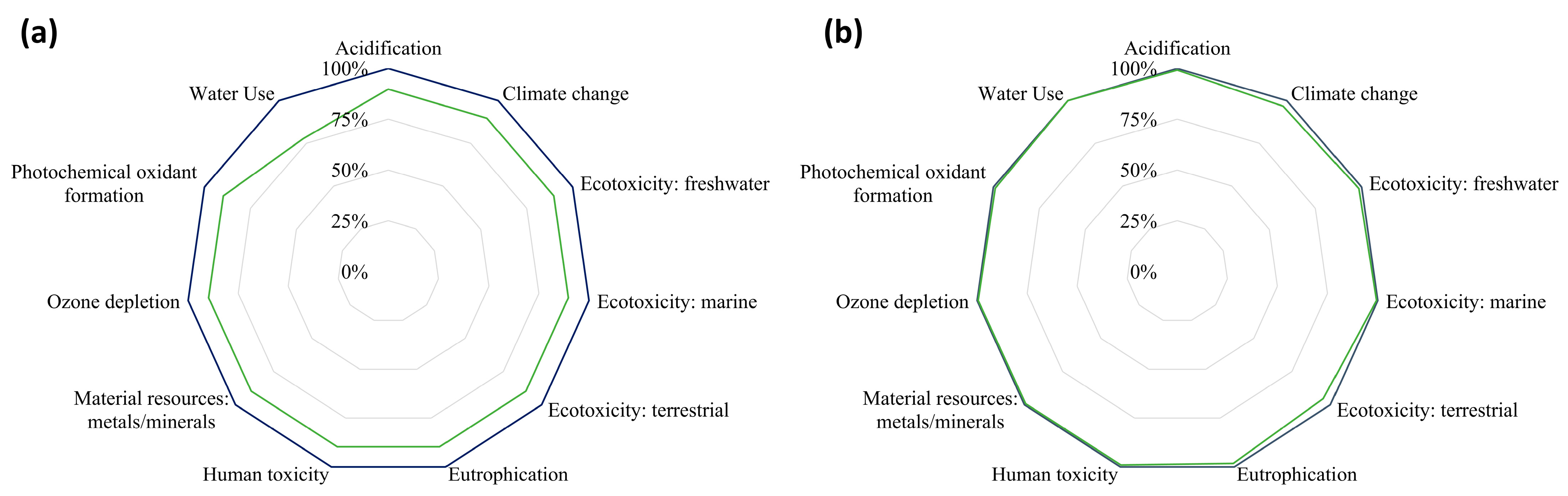

To present a more intuitive and accessible interpretation of the data, complementing the numerical values detailed in

Table 6,

Figure 10 was made as a visual aid to ease the comparison of the environmental impacts associated with handmade paper production using untreated fique fiber versus aquatic weed fiber. Setting the aquatic plant fibers as the 100% reference point, the figure clearly illustrates that paper produced from untreated fique exhibits a lower environmental burden across nearly all evaluated categories.

Figure 10a illustrates the differences in the environmental profiles between fique tow fiber without additives and aquatic weed fibers for handmade paper production. It can be observed that the process utilized in the present study results in reduced impacts in all key categories, such as acidification, climate change, human toxicity, and all forms of ecotoxicity—a reduction that is likely associated with the elimination of chemicals in the pulping process. In this regard, the fique tow fiber process without additives demonstrates lower impacts, highlighting increased environmental performance, particularly regarding the release of harmful substances into the environment and potential effects on human health.

The fique fiber process also shows lower impacts in terms of photochemical oxidant formation compared to the aquatic weed fiber process. The most notable relative difference is observed in water use: the fique-based process consumes approximately 20–22% less water than the aquatic weed fiber process, representing a significant improvement in water-use efficiency.

Figure 10b, in turn, illustrates the effect of incorporating additives into the fique fiber process. A moderate increase in all environmental impact categories is observed when comparing the additive-enhanced process to the variant without additives. Nevertheless, it is important to emphasize that even with the inclusion of additives, the environmental impacts associated with the fique tow fiber remain considerably lower than those of aquatic weed fibers (as shown by comparing

Figure 10b to

Figure 10a). This suggests that while additives may enhance certain technical properties of the paper, their use slightly increases the environmental burden of the fique-based process.

Sensitivity Analysis

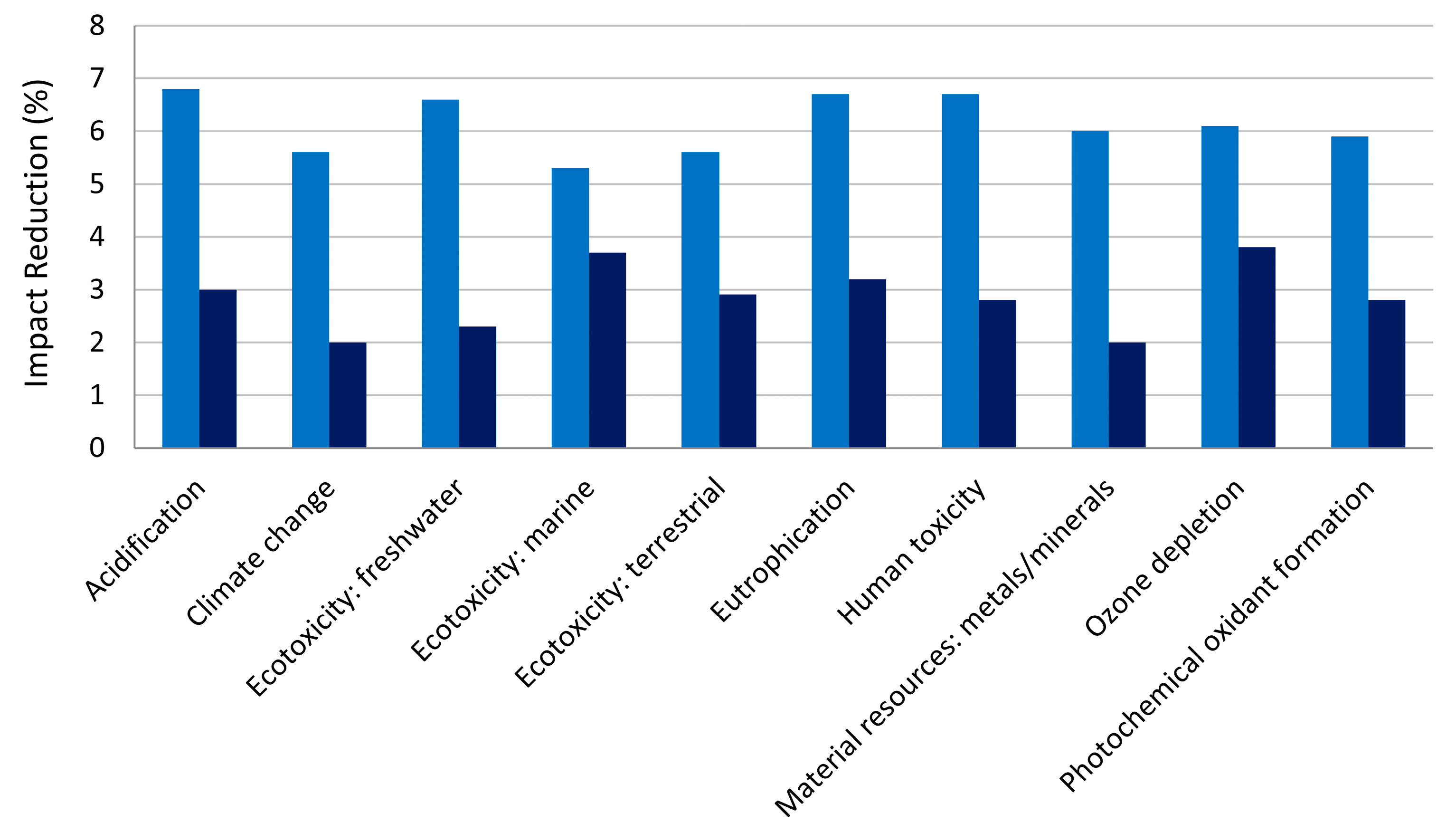

The results, summarized in

Figure 11, show that both variables have a measurable effect on environmental performance across all impact categories. Reducing electricity consumption had the greatest influence, with improvements ranging from −5.3% (marine ecotoxicity) to −6.8% (acidification). In contrast, reducing process waste by 10% resulted in smaller but still relevant reductions, from −2.0% (climate change and material resources) to −3.8% (ozone depletion).

These findings highlight the dominant contribution of electricity use in the life-cycle impacts of the handmade paper process and underscore the potential benefits of cleaner or more efficient energy sources. Nevertheless, waste minimization also plays a meaningful role, particularly in the marine and terrestrial ecotoxicity categories.

3.5. Prospects and Future Research Directions

Recompiling the results obtained for fiber characterization, it is shown that fique meets all quality standards given by derived values, while also having structural characteristics and a composition that give it certain advantages for papermaking over other non-wood materials. This is validated by the obtained handsheet pulp properties being comparable to those of other promising materials, which is surprising due to the pulping process not only being entirely mechanical but also being carried out on a mill that was not designed for it. It is important, then, to acknowledge the previously expressed low uniformity of fiber refining based on milling degree, for which measurements should be obtained at each step through the mill to optimize its pulp properties. The vast differences in the properties obtained for standardized and craft handmade paper should also be further investigated, as this may give insight into crucial variables affecting craft paper quality. Additionally, although bagasse did not seem to impart much to paper’s properties, acting more or less as a filler, papermaking seems to be the right step towards the valorization of fique’s lignocellulosic residues.

To further validate the technical viability and market potential of fique-based craft paper, it would be recommended to study alternative natural dyeing methods and their effects on pulp properties, seeking to minimize the impact on paper quality. Also, the effects of hot-pressing temperature, pressure, and time on the paper’s final mechanical properties are not well understood, and other properties like pulp viscosity and swelling index would provide a deeper understanding of the potential use of fique pulps in industrial applications.

While the present study primarily aimed to define the technical conditions for craft handmade paper production from fique residues, further research should address the quantification of uncertainty and the inclusion of broader sustainability dimensions. Specifically, a Monte Carlo simulation is recommended to evaluate the uncertainty associated with key input variables such as energy mix, water consumption, and additive use. This statistical approach would provide confidence intervals for environmental impact categories and help identify the most influential parameters within the LCA model.

Finally, it should be noted that the results obtained from the experimental section of this paper will be used as the basis for the implementation of a paper workshop in the rural community of Amalfi, Antioquia. Consequently, future research efforts should focus on economic assessments and the development of this technology, with an emphasis on improving its scalability and optimizing its functional performance without compromising the inherent environmental benefits. These future assessments should incorporate socioeconomic indicators, such as potential for local job creation, income generation, gender inclusion, and the affordability and scalability of the proposed process for low-income rural communities, where the indicators would provide a more holistic understanding of the sustainability and replicability of fique-based craft paper production, aligning the valorization strategy with national rural development goals and circular economy principles.

4. Conclusions

Fique fiber shows a high aptitude for papermaking; with a Runkel ratio of 0.52, slenderness ratio of 69.19, and flexibility coefficient of 65.70%, it surpasses other non-woods’ properties and resembles commercial wood fibers from hardwoods. As such, its properties are within the range of the most desirable non-wood fibers and, as it is readily obtainable from underutilized residues, it can be considered to be an ideal raw material for high-quality craft paper.

Craft handmade paper had a tensile and burst index reaching 34.2 N m/g and 1.354 kPa m2/g, respectively. This reconfirms, on a scientific basis, that it is possible to obtain craft paper from fique tow with a uniform appearance, good resistance, good writing properties, and a pale beige color. Also, the pulps obtained displayed high potential for papermaking, with a tensile and burst index as high as 13.0 N m/g and 1.42 kPa m2/g for tow fiber pulp and 11.09 N m/g 1.05 kPa m2/g for bagasse–tow pulp, respectively. This presents an opportunity for fique paper in ornamental applications, as long as a minimum 50% fiber composition is achieved in the pulp raw materials.

In this context, a simple electric grain grinder was shown to be capable of producing high-quality pulps, with drainability measurements as low as 190 mL for tow fiber pulp and 324 mL for bagasse–tow mixture pulp in a five-step milling process. Furthermore, different fiber bundle disaggregation and defibrillation degrees can be obtained depending on the number of times the pulp goes through the mill, which could be used to adjust the paper’s final appearance to meet market expectations.

The additives used did not improve the paper properties measured, and although they may help to create an overall higher-quality paper, their use was not deemed necessary for certain applications. This proves that the production of craft paper using simple and economical refining equipment, and without any chemicals, is technically feasible—an approach that achieves waste valorization in rural communities.

The findings of the Life-Cycle Assessment demonstrate that additive-free fique tow paper outperforms both fique tow paper with additives and other non-wood paper in terms of producing low-impact craft handmade paper. Additionally, its footprint reduction across a wide variety of impact categories, coupled with its origin as an easily accessible and locally sourced agro-industrial byproduct, highlights its enormous potential as a truly eco-efficient and sustainable alternative