Structure-from-Motion Photogrammetry for Density Determination of Lump Charcoal as a Reliable Alternative to Archimedes’ Method †

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Collection

2.2. Archimedes’ Method

2.3. Photogrammetry

2.3.1. Image Acquisition

2.3.2. 3D Modeling and Volume Estimation of Charcoal Samples

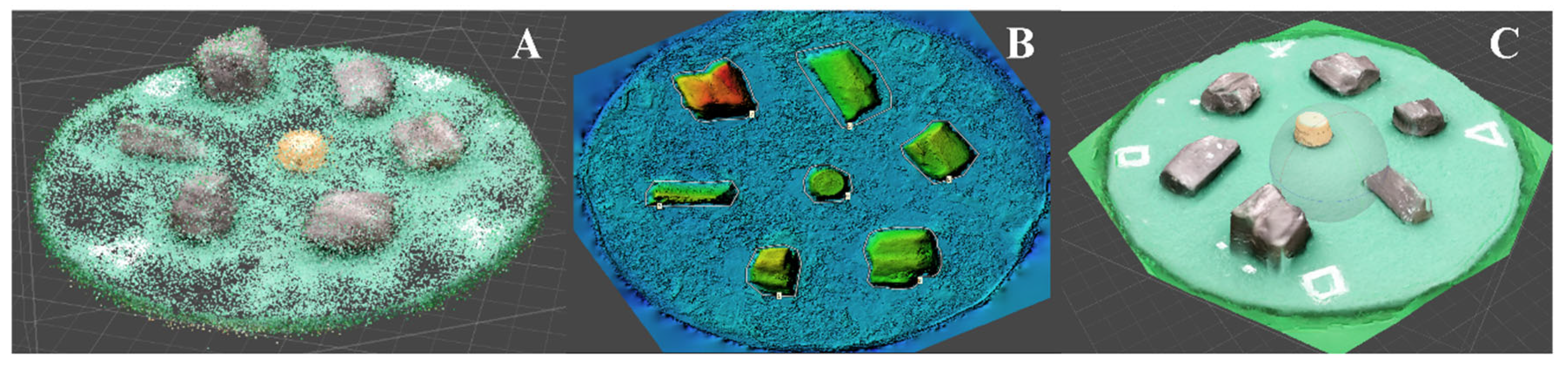

- Photo alignment and sparse point cloud generation: Images were aligned through automatic feature detection and matching, allowing estimation of internal and external camera parameters. This produced a sparse point cloud through triangulation (Figure 2A). As previously mentioned, manual markers were placed on predefined visual targets during sample preparation to enhance alignment accuracy.

- Dense point cloud generation: A dense point cloud was computed using multi-view stereo (mvs) algorithms, which interpolated additional points based on image overlap to enhance spatial resolution.

- Model cleaning and orientation: Erroneous or noisy points were manually removed from the dense cloud. The model was then aligned with the reference plane.

- Digital Elevation Model (DEM) and mesh construction: A DEM was generated from the dense point cloud (Figure 2B). The uniform coloration of the DEM base was used to verify correct orientation. A polygonal mesh was then built using Delaunay triangulation, producing a continuous 3D surface (Figure 2C). Original photographs were projected onto the mesh to create a high-resolution texture, highlighting surface details and improving visual realism.

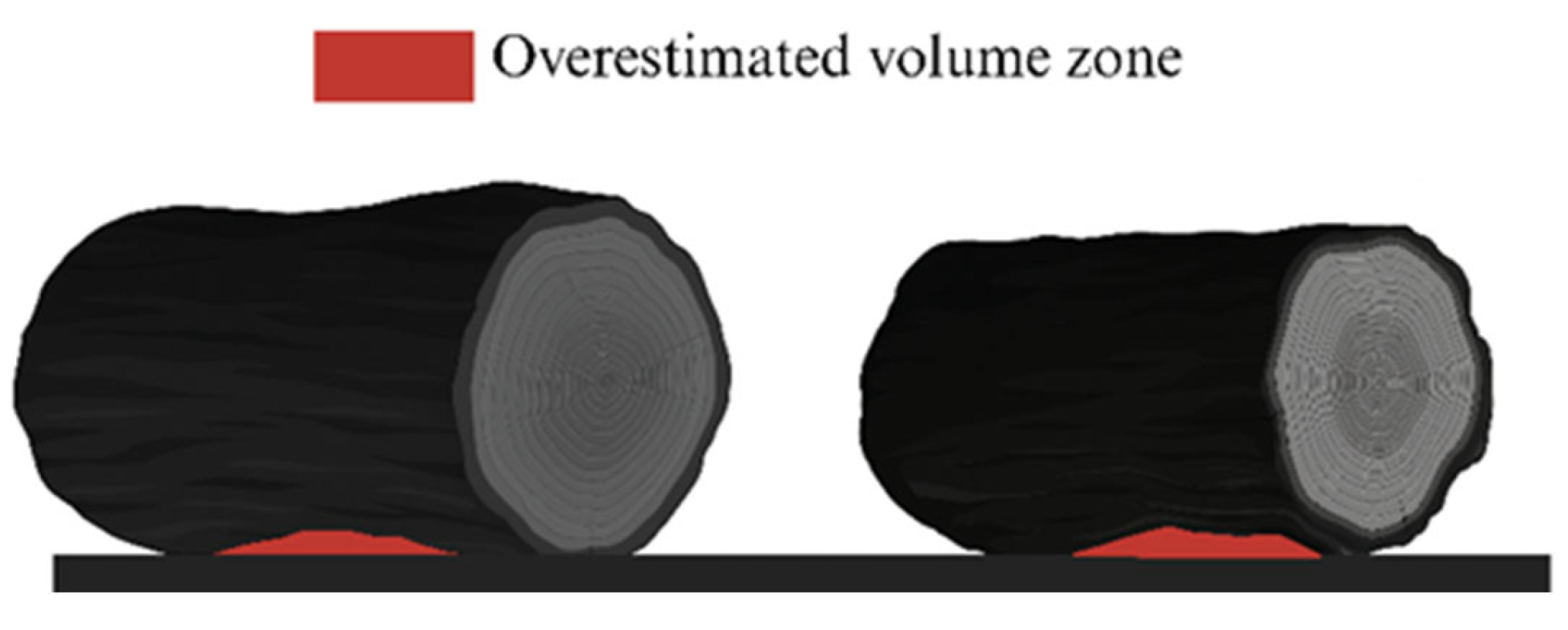

- Volume estimation: To calculate volumes, polygonal regions were drawn around each charcoal fragment. Using the “Measure” tool in Metashape, volumes were computed relative to a best-fit plane, which minimizes irregularities in the base surface. The obtained volume was used for apparent density calculation.

2.4. Economic Evaluation

2.5. Statistical Analysis

3. Results and Discussion

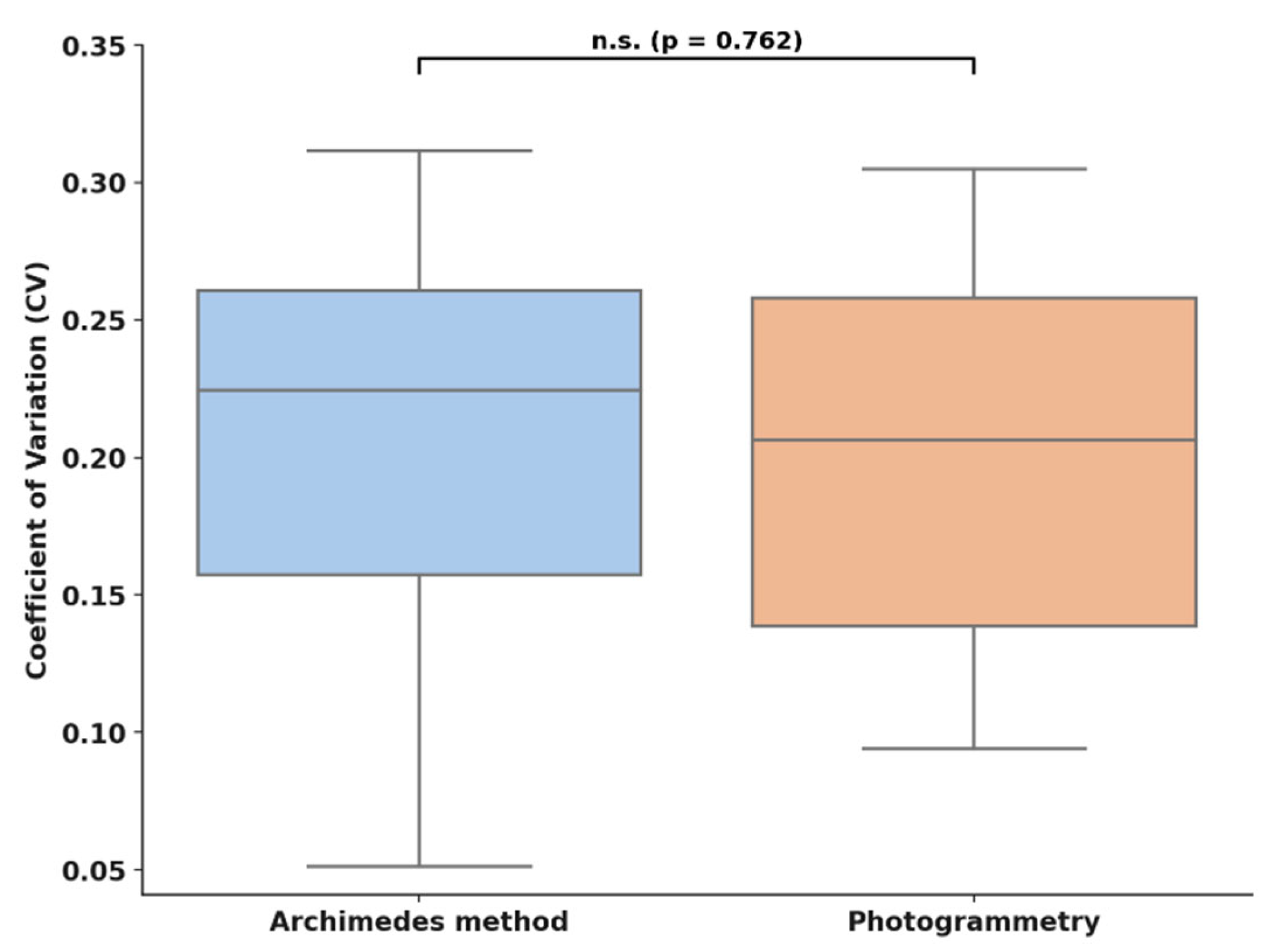

3.1. Apparent Density Values

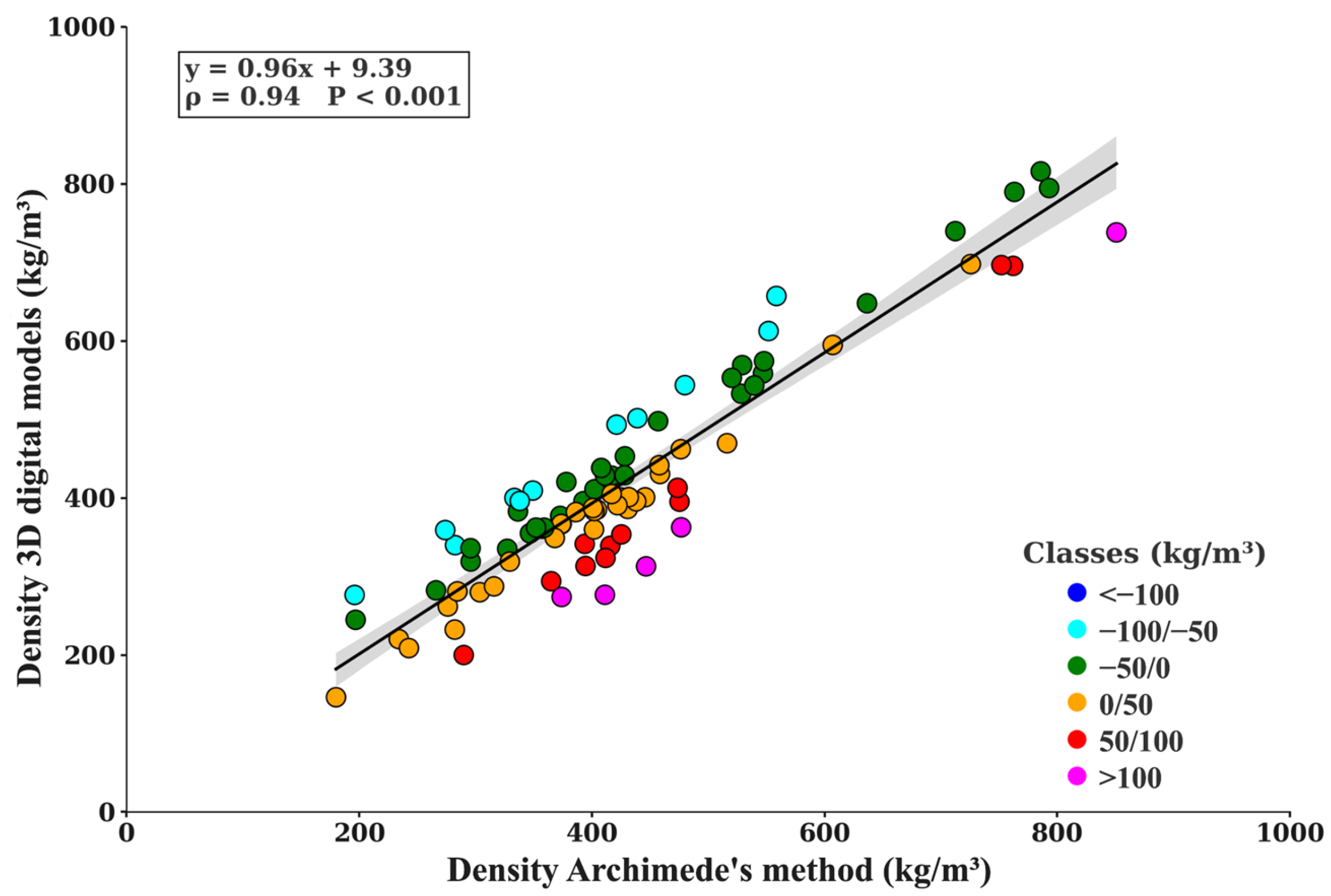

3.2. Statistical Agreement and Method Comparison Between Photogrammetry and Archimedes’ Method

3.3. Operational and Economic Comparison of Archimedes’ Method and Photogrammetry

3.3.1. Operational and Technical Comparison

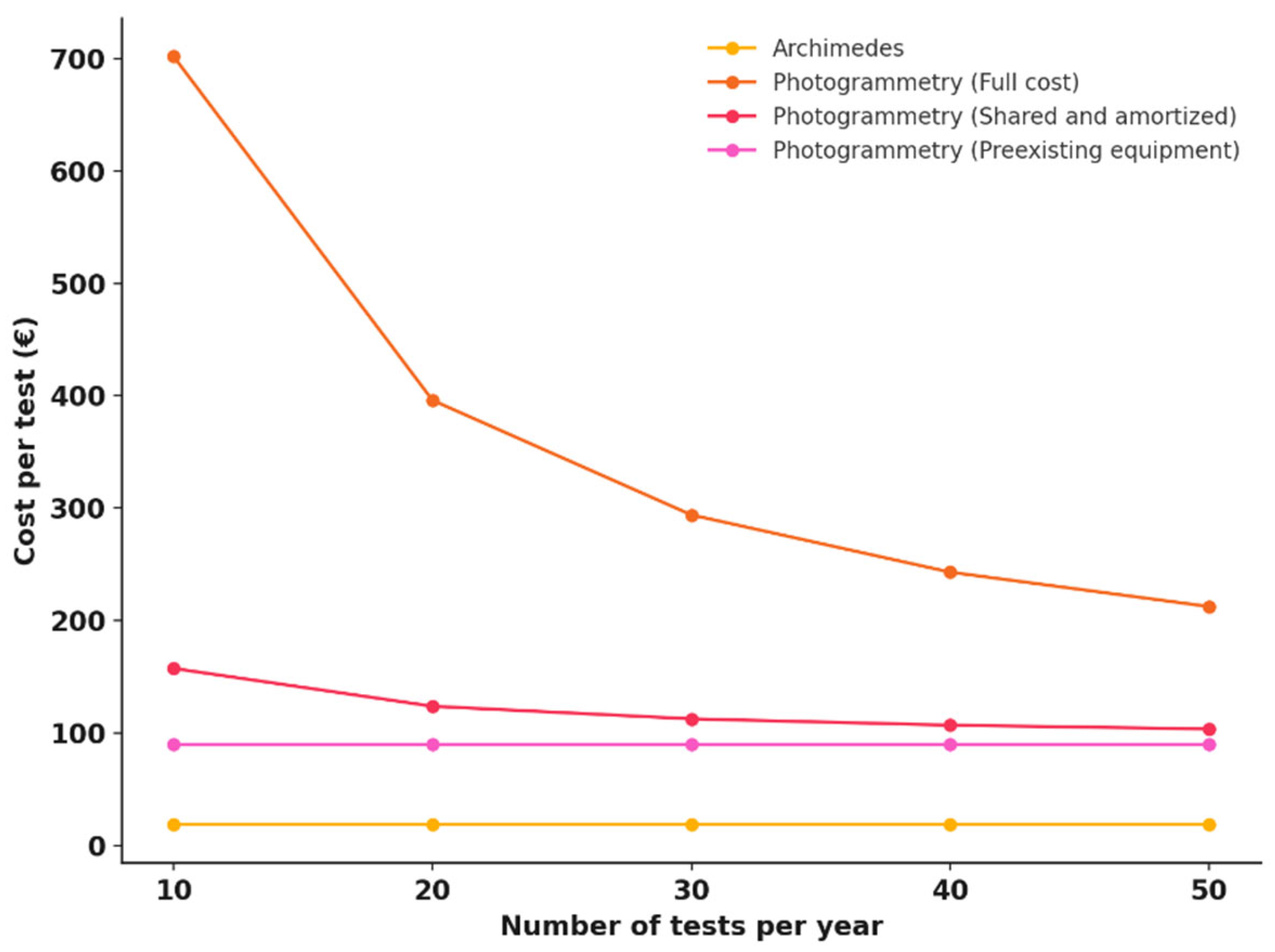

3.3.2. Economic Evaluation and Applicability

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| SfM | Structure from motion |

| mvs | Multi-view-stereo |

| SDG | Sustainable development goal |

| DEM | Digital elevation model |

| CV | Coefficient of variation |

| MAE | Mean absolute error |

| MAPE | Mean absolute percentage error |

| RMSE | Root mean squared error |

References

- Seboka, Y. Charcoal Production: Opportunities and Barriers for Improving Efficiency and Sustainability. In Bio-Carbon Opportunities in Eastern & Southern Africa. Harnessing Carbon Finance to Promote Sustainable Forestry, Agro-Forestry and Bio-Energy; United Nations Development Programme: New York, NY, USA, 2009; pp. 102–126. [Google Scholar]

- Pyshyev, S.; Miroshnichenko, D.; Malik, I.; Contreras, A.B.; Hassan, N.; ElRasoul, A.A. State of the Art in the Production of Charcoal: A Review. Chem. Chem. Technol. 2021, 15, 61–73. [Google Scholar] [CrossRef]

- Pereira, A.K.S.; Júnior, D.L.; da Silva, Á.M.; Cupertino, G.F.M.; de Souza, E.C.; Delatorre, F.M.; Ucella-Filho, J.G.M.; de Oliveira, P.R.S.; Rodrigues, B.P.; Júnior, A.F.D. How Pyrolysis Conditions Shape the Structural and Functional Properties of Charcoal? A Study of Tropical Dry Forest Biomass. Renew. Energy 2025, 243, 122575. [Google Scholar] [CrossRef]

- Assis, M.R.; Brancheriau, L.; Napoli, A.; Trugilho, P.F. Factors Affecting the Mechanics of Carbonized Wood: Literature Review. Wood Sci. Technol. 2016, 50, 519–536. [Google Scholar] [CrossRef]

- Mencarelli, A.; Greco, R.; Grigolato, S. Can the Qualitative Characteristics of Commercial Charcoal-Based Products Affect Combustion Performance during Grilling? Biomass Convers. Biorefin. 2025. [Google Scholar] [CrossRef]

- Dufourny, A.; Van De Steene, L.; Humbert, G.; Guibal, D.; Martin, L.; Blin, J. Influence of Pyrolysis Conditions and the Nature of the Wood on the Quality of Charcoal as a Reducing Agent. J. Anal. Appl. Pyrolysis 2019, 137, 1–13. [Google Scholar] [CrossRef]

- Capareda, S.C. Comprehensive Biomass Characterization in Preparation for Conversion. In Sustainable Biochar for Water and Wastewater Treatment; Elsevier: Amsterdam, The Netherlands, 2022; pp. 1–37. ISBN 978-0-12-822225-6. [Google Scholar]

- Júnior, A.F.D.; Andrade, C.R.; Milan, M.; Brito, J.O.; de Andrade, A.M.; de Souza, N.D. Quality Function Deployment (QFD) Reveals Appropriate Quality of Charcoal Used in Barbecues. Sci. Agric. 2020, 77, e20190021. [Google Scholar] [CrossRef]

- Júnior, A.F.D.; Andrade, C.R.; Lana, A.Q.; da Silva, Á.M.; Brito, J.O.; Milan, M. Tips on the Variability of BBQ Charcoal Characteristics to Assist Consumers in Product Choice. Eur. J. Wood Wood Prod. 2021, 79, 1017–1026. [Google Scholar] [CrossRef]

- Demirbas, A.; Ahmad, W.; Alamoudi, R.; Sheikh, M. Sustainable Charcoal Production from Biomass. Energy Sources Part A Recovery Util. Environ. Eff. 2016, 38, 1882–1889. [Google Scholar] [CrossRef]

- EN 1860-2:2023; Appliances, Solid Fuels and Firelighters for Barbecuing—Part 2: Barbecue Charcoal and Barbecue Charcoal Briquettes—Requirements and Test Methods. British Standards Institution: London, UK, 2023.

- ISO 17225-1:2021; Solid Biofuels—Fuel Specifications and Classes—Part 1: General Requirements. International Organization for Standardization: Geneva, Switzerland, 2021.

- ASTM D2395-17R22; Standard Test Methods for Density and Specific Gravity (Relative Density) of Wood and Wood-Based Materials. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- Brzeziński, K.; Duda, A.; Styk, A.; Kowaluk, T. Photogrammetry-Based Volume Measurement Framework for the Particle Density Estimation of LECA. Materials 2022, 15, 5388. [Google Scholar] [CrossRef] [PubMed]

- Dos Santos, V.B.; Baraúna, E.E.P.; Colen, F.; Baldin, T.; Monteiro, T.C.; Arantes, M.D.C. Energy Characterization of Wood and Charcoal from Savannah Forest Species. BioResources 2023, 18, 1780–1787. [Google Scholar] [CrossRef]

- Pierdicca, R.; Balestra, M.; Micheletti, G.; Felicetti, A.; Toscano, G. Semi-Automatic Detection and Segmentation of Wooden Pellet Size Exploiting a Deep Learning Approach. Renew. Energy 2022, 197, 406–416. [Google Scholar] [CrossRef]

- Toscano, G.; Leoni, E.; De Francesco, C.; Ciccone, G.; Gasperini, T. The Application of Image Acquisition and Processing Techniques for the Determination of Wooden Pellet Length as an Alternative to ISO 17829. Resources 2023, 12, 125. [Google Scholar] [CrossRef]

- Igathinathane, C.; Davis, J.D.; Purswell, J.L.; Columbus, E.P. Application of 3D Scanned Imaging Methodology for Volume, Surface Area, and Envelope Density Evaluation of Densified Biomass. Bioresour. Technol. 2010, 101, 4220–4227. [Google Scholar] [CrossRef] [PubMed]

- Altgen, M.; Gedde, K.B.; Ross, L.; Larnøy, E. Physical and Chemical Characterization of Post-Consumer Wood Chips for Recycling. Waste Manag. 2025, 200, 114762. [Google Scholar] [CrossRef] [PubMed]

- Whiting, M.; Salley, S.W.; James, D.K.; Karl, J.W.; Brungard, C.W. Rapid Bulk Density Measurement Using Mobile Device Photogrammetry. Soil Sci. Soc. Am. J. 2020, 84, 811–817. [Google Scholar] [CrossRef]

- Fang, K.; Zhang, J.; Tang, H.; Hu, X.; Yuan, H.; Wang, X.; An, P.; Ding, B. A Quick and Low-Cost Smartphone Photogrammetry Method for Obtaining 3D Particle Size and Shape. Eng. Geol. 2023, 322, 107170. [Google Scholar] [CrossRef]

- Paixão, A.; Resende, R.; Fortunato, E. Photogrammetry for Digital Reconstruction of Railway Ballast Particles—A Cost-Efficient Method. Constr. Build. Mater. 2018, 191, 963–976. [Google Scholar] [CrossRef]

- ISO 18134-2:2024; Solid Biofuels—Determination of Moisture Content—Part 2: Simplified Method. International Organization for Standardization: Geneva, Switzerland, 2024.

- Dias Júnior, A.F.; Esteves, R.P.; da Silva, Á.M.; Júnior, A.D.S.; Oliveira, M.P.; Brito, J.O.; Napoli, A.; Braga, B.M. Investigating the Pyrolysis Temperature to Define the Use of Charcoal. Eur. J. Wood Wood Prod. 2020, 78, 193–204. [Google Scholar] [CrossRef]

- Miroshnichenko, D.; Zhylina, M.; Shmeltser, K. Modern Use of Biochar in Various Technologies and Industries. A Review. Chem. Chem. Technol. 2024, 18, 232–243. [Google Scholar] [CrossRef]

- Antal, M.J.; Grønli, M. The Art, Science, and Technology of Charcoal Production. Ind. Eng. Chem. Res. 2003, 42, 1619–1640. [Google Scholar] [CrossRef]

- Mencarelli, A.; Greco, R.; Ippoliti, S.; Grigolato, S. Comparative assessment of lump charcoal density using photogrammetry as an alternative to Archimedes method according to ASTM D2395-17 standard. In Proceedings of the AIIA 2025 “Biosystems Engineering for the Green Transition”, Reggio Calabria, Italy, 21–24 September 2025. [Google Scholar]

| Sample Comparison | Negative Ranks | Positive Ranks | Test Statistics | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| n | Mean Rank | Sum of Ranks | n | Mean Rank | Sum of Ranks | Ties | Z | p | p-adj | |

| LC_01 | 0 | 0.0 | 0.0 | 6 | 3.5 | 21.0 | 0 | −2.306 | 0.021 | 0.106 n.s. |

| LC_02 | 3 | 3.3 | 10.0 | 3 | 3.7 | 11.0 | 0 | −0.210 | 0.834 | 0.834 n.s. |

| LC_03 | 3 | 4.0 | 12.0 | 3 | 3.0 | 9.0 | 0 | −0.419 | 0.675 | 0.834 n.s. |

| LC_04 | 2 | 5.0 | 10.0 | 4 | 2.75 | 11.0 | 0 | −0.210 | 0.834 | 0.834 n.s. |

| LC_05 | 6 | 3.5 | 21.0 | 0 | 0.0 | 0.0 | 0 | −2.306 | 0.021 | 0.106 n.s. |

| LC_06 | 3 | 4.7 | 14.0 | 3 | 2.3 | 7.0 | 0 | −0.839 | 0.402 | 0.670 n.s. |

| LC_07 | 3 | 5.0 | 15.0 | 3 | 2.0 | 6.0 | 0 | −1.048 | 0.295 | 0.552 n.s. |

| LC_08 | 4 | 2.5 | 10.0 | 2 | 5.5 | 11.0 | 0 | −0.210 | 0.834 | 0.834 n.s. |

| LC_09 | 6 | 3.5 | 21.0 | 0 | 0.0 | 0.0 | 0 | −2.306 | 0.021 | 0.106 n.s. |

| LC_10 | 2 | 2.5 | 5.0 | 4 | 4.0 | 16.0 | 0 | −1.238 | 0.208 | 0.521 n.s. |

| LC_11 | 2 | 3.0 | 6.0 | 4 | 3.75 | 15.0 | 0 | −1.048 | 0.295 | 0.552 n.s. |

| LC_12 | 4 | 2.75 | 11.0 | 2 | 5.0 | 10.0 | 0 | −0.210 | 0.834 | 0.834 n.s. |

| LC_13 | 3 | 3.7 | 11.0 | 3 | 3.3 | 10.0 | 0 | −0.210 | 0.834 | 0.834 n.s. |

| LC_14 | 1 | 3.0 | 3.0 | 5 | 3.6 | 18.0 | 0 | −1.677 | 0.093 | 0.351 n.s. |

| LC_15 | 4 | 4.0 | 16.0 | 2 | 2.5 | 5.0 | 0 | −1.258 | 0.208 | 0.521 n.s. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mencarelli, A.; Martini, M.; Greco, R.; Ippoliti, S.; Grigolato, S. Structure-from-Motion Photogrammetry for Density Determination of Lump Charcoal as a Reliable Alternative to Archimedes’ Method. Sustainability 2025, 17, 7991. https://doi.org/10.3390/su17177991

Mencarelli A, Martini M, Greco R, Ippoliti S, Grigolato S. Structure-from-Motion Photogrammetry for Density Determination of Lump Charcoal as a Reliable Alternative to Archimedes’ Method. Sustainability. 2025; 17(17):7991. https://doi.org/10.3390/su17177991

Chicago/Turabian StyleMencarelli, Alessio, Marco Martini, Rosa Greco, Stefano Ippoliti, and Stefano Grigolato. 2025. "Structure-from-Motion Photogrammetry for Density Determination of Lump Charcoal as a Reliable Alternative to Archimedes’ Method" Sustainability 17, no. 17: 7991. https://doi.org/10.3390/su17177991

APA StyleMencarelli, A., Martini, M., Greco, R., Ippoliti, S., & Grigolato, S. (2025). Structure-from-Motion Photogrammetry for Density Determination of Lump Charcoal as a Reliable Alternative to Archimedes’ Method. Sustainability, 17(17), 7991. https://doi.org/10.3390/su17177991