Strategic Human Resource Development for Industry 4.0 Readiness: A Sustainable Transformation Framework for Emerging Economies

Abstract

1. Introduction

2. Literature Review

2.1. Conceptual Foundations of Digital Transformation and Industry 4.0

2.2. Frameworks and Models for Assessing Industry 4.0 Readiness

| Maturity and Readiness Models | Focus | Gaps |

|---|---|---|

| IMPULS— Industrie 4.0 Readiness [49] |

|

|

| A maturity model for evaluating Industry 4.0 readiness and the maturity levels of manufacturing enterprises [1] |

|

|

| ACATECH— Industrie 4.0 Maturity Index [58] |

|

|

| VDMA—Guidelines for Industry 4.0 [59] |

|

|

| PWC—Readiness model [51] |

|

|

| Industry4WRD Readiness Assessment [60] |

|

|

| Singapore Smart Industry Readiness Index (SIRI) [61] |

|

|

| Thailand I4.0 Index [62] |

|

|

2.3. Strategic HRD in the Context of Industry 4.0

2.3.1. Organizational Preparedness for HRD in Industry 4.0

2.3.2. The Role of Leadership in Enabling Industry 4.0 Transformation

2.3.3. Strategic HRD Adaptation in Response to Business Pressures: Enhancing Industry 4.0 Preparedness

2.3.4. Technological Readiness as a Pillar of Industry 4.0 Adoption

2.4. A Dynamic Capability Framework for Strategic HRD and Industry 4.0 Readiness

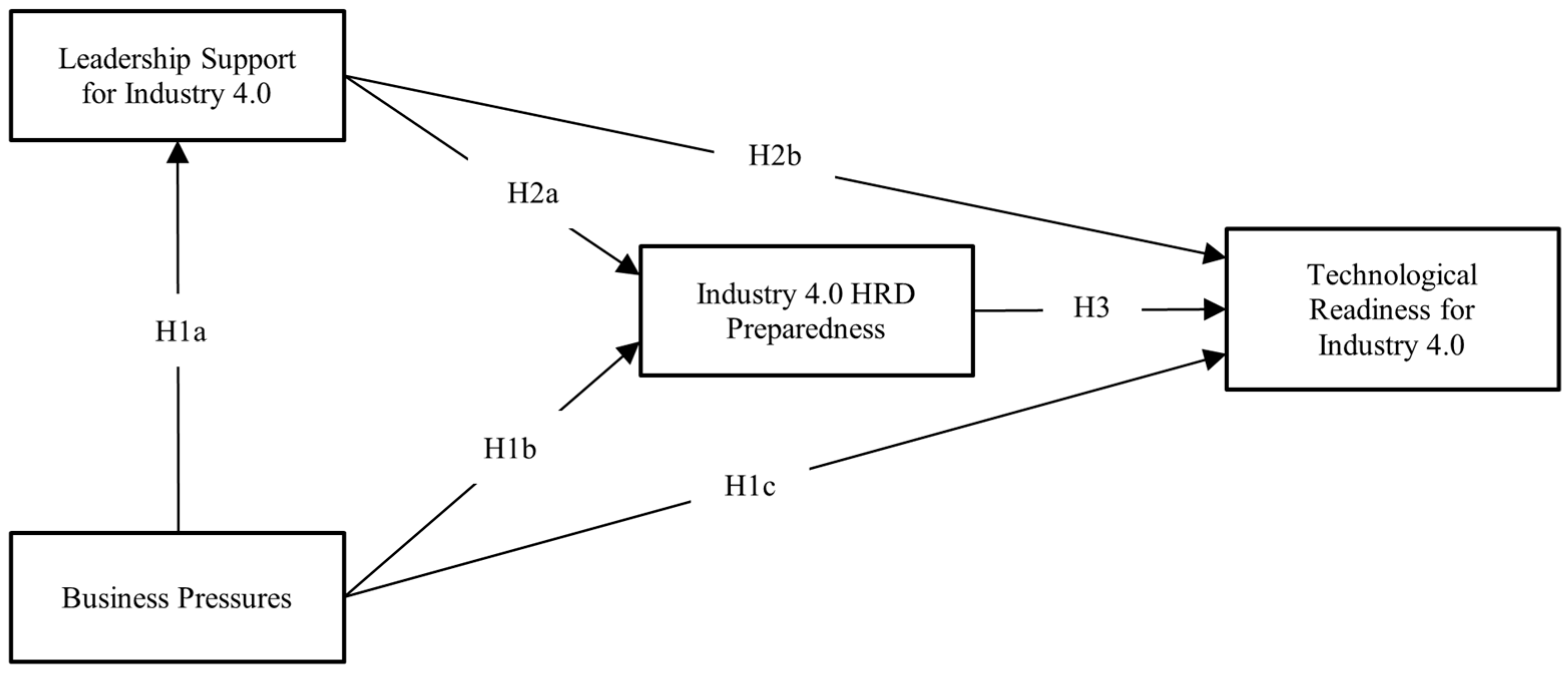

- Hypotheses

3. Research Methodology

3.1. Data Collection

3.1.1. Case Study Design and Qualitative Data Procedures

3.1.2. Survey Design and Quantitative Data Collection Procedures

3.2. Data Analysis

3.2.1. Thematic Analysis and Cross-Case Interpretation

3.2.2. Structural Equation Modeling for Industry 4.0 Readiness

3.2.3. Mixed-Method Integration Approach

4. Results

4.1. Qualitative Results

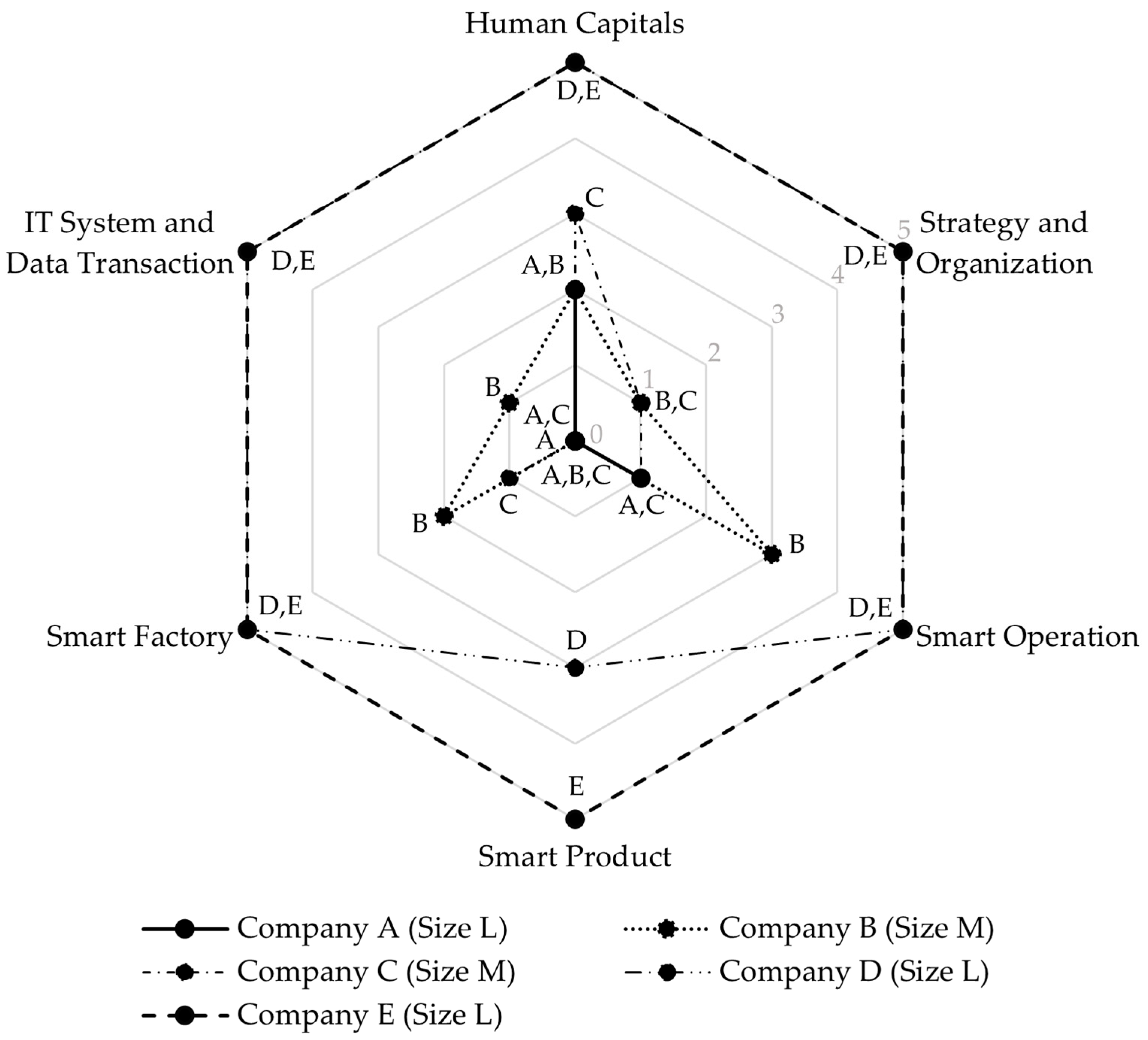

4.1.1. Firm-Level Case Study Insights on Industry 4.0 Readiness

4.1.2. Comparative Insights Across Industry 4.0 Case Studies

4.2. Quantitative Results

4.2.1. Descriptive Characteristics of Sampled Firms

4.2.2. Assessment of Common Method Variance

4.2.3. Measurement Reliability and Validity Assessment

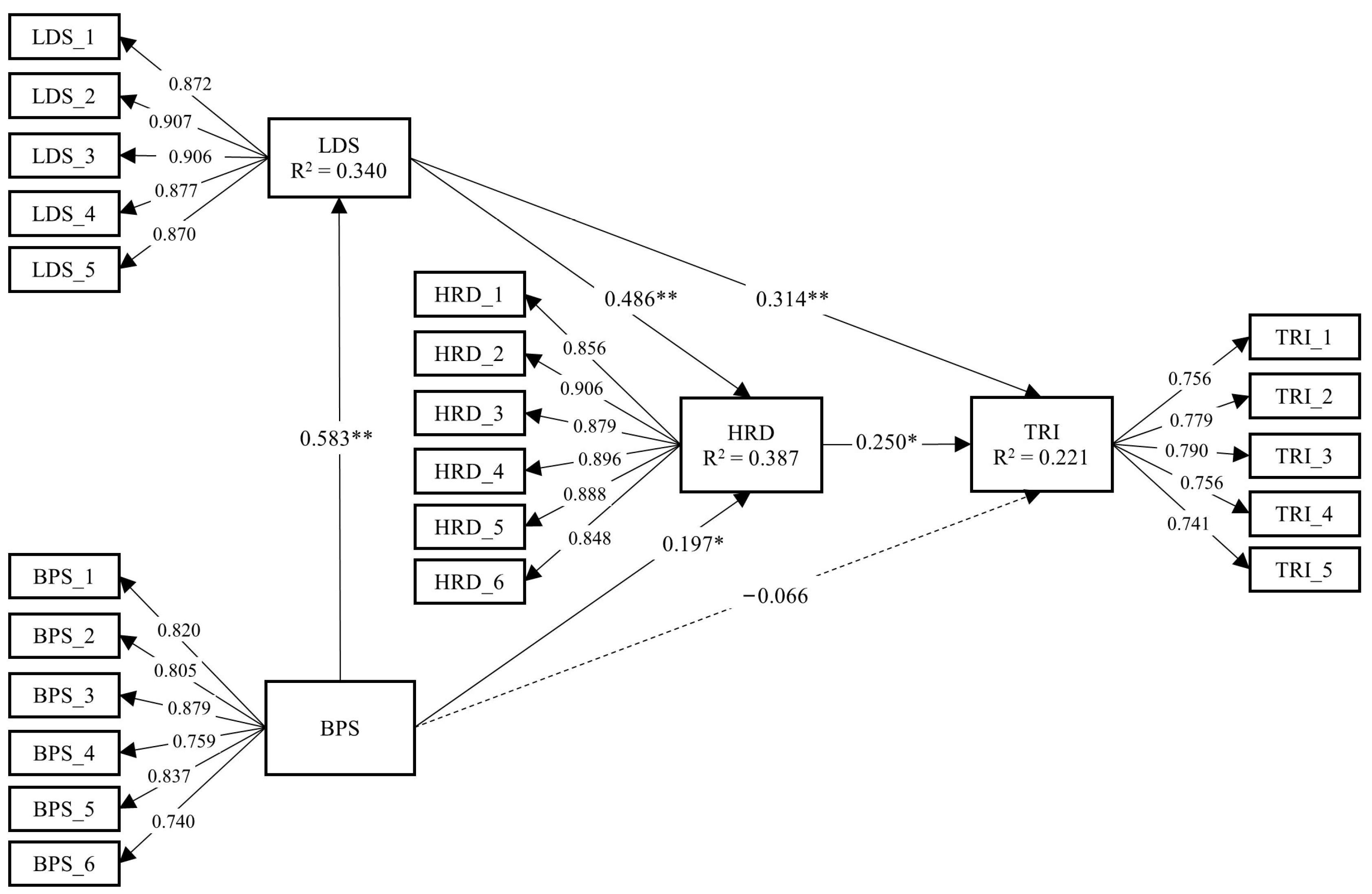

4.2.4. Evaluation of Structural Relationships

4.3. Comparison of Qualitative and Quantitative Results

4.3.1. Summary of Qualitative Findings

4.3.2. Summary of Quantitative Findings

4.3.3. Integrative Analysis of Mixed-Method Findings

5. Discussion

5.1. Strategic HRD as a Catalyst for Industry 4.0 Readiness

5.2. Leadership Drivers of Digital Transformation

5.3. Business Environment as a Driver of HRD and Technology Adoption

5.4. Synergistic Effects of Technological and Human Readiness

5.5. Cross-Case Analysis: Firm-Level Differences in Industry 4.0 Readiness

5.6. Future Research Directions

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schumacher, A.; Erol, S.; Sihn, W. A maturity model for assessing industry 4.0 readiness and maturity of manufacturing enterprises. Procedia CIRP 2016, 52, 161–166. [Google Scholar] [CrossRef]

- Singh, K.A.; Patra, F.; Ghosh, T.; Mahnot, N.K.; Dutta, H.; Duary, R.K. Advancing food systems with industry 5.0: A systematic review of smart technologies, sustainability, and resource optimization. Sustain. Futures 2025, 9, 100694. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Müller, J.M.; Kiel, D.; Voigt, K.I. What drives the implementation of Industry 4.0? The role of opportunities and challenges in the context of sustainability. Sustainability 2018, 10, 247. [Google Scholar] [CrossRef]

- Rauch, E.; Linder, C.; Dallasega, P. Industry 4.0 as an enabler of proximity for construction supply chains: A systematic literature review. Comput. Ind. 2016, 82, 133–149. [Google Scholar] [CrossRef]

- Virmani, N.; Sharma, S.; Kumar, P.; Luthra, S.; Jain, V.; Jagtap, S. Navigating the landscape through digital human resource management: An initiative to achieve sustainable practices. Sustain. Futures 2025, 9, 100621. [Google Scholar] [CrossRef]

- Simetinger, F.; Basl, J. A pilot study: An assessment of manufacturing SMEs using a new Industry 4.0 Maturity Model for Manufacturing Small- and Middle-sized Enterprises (I4MMSME). Procedia Comput. Sci. 2022, 200, 1068–1077. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Industry 4.0, digitization, and opportunities for sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Warner, K.S.R.; Wäger, M. Building dynamic capabilities for digital transformation: An ongoing process of strategic renewal. Long Range Plan. 2019, 52, 326–349. [Google Scholar] [CrossRef]

- Madsen, D.Ø. The emergence and rise of Industry 4.0 viewed through the lens of management fashion theory. Adm. Sci. 2019, 9, 71. [Google Scholar] [CrossRef]

- Buck, C.; Clarke, J.; Torres de Oliveira, R.; Desouza, K.C.; Maroufkhani, P. Digital transformation in asset-intensive organisations: The light and the dark side. J. Innov. Knowl. 2023, 8, 100335. [Google Scholar] [CrossRef]

- Gimpel, H.; Hosseini, S.; Huber, R.; Probst, L.; Röglinger, M.; Faisst, U. Structuring digital transformation: A framework of action fields and its application at ZEISS. J. Inf. Technol. Theory Appl. 2018, 19, 31–54. [Google Scholar]

- Verhoef, P.C.; Broekhuizen, T.; Bart, Y.; Bhattacharya, A.; Dong, J.Q.; Fabian, N.; Haenlein, M. Digital transformation: A multidisciplinary reflection and research agenda. J. Bus. Res. 2021, 122, 889–901. [Google Scholar] [CrossRef]

- Li, S.; Gao, L.; Han, C.; Gupta, B.; Alhalabi, W.; Almakdi, S. Exploring the effect of digital transformation on Firms’ innovation performance. J. Innov. Knowl. 2023, 8, 100317. [Google Scholar] [CrossRef]

- Nyagadza, B. Sustainable digital transformation for ambidextrous digital firms: Systematic literature review, meta-analysis and agenda for future research directions. Sustain. Technol. Entrep. 2022, 1, 100020. [Google Scholar] [CrossRef]

- Hazée, S.; Zwienenberg, T.J.; Van Vaerenbergh, Y.; Faseur, T.; Vandenberghe, A.; Keutgens, O. Why customers and peer service providers do not participate in collaborative consumption. J. Serv. Manag. 2020, 31, 397–419. [Google Scholar] [CrossRef]

- Horváth, D.; Szabó, R.Z. Driving forces and barriers of Industry 4.0: Do multinational and small and medium-sized companies have equal opportunities? Technol. Forecast. Soc. Change 2019, 146, 119–132. [Google Scholar] [CrossRef]

- Kraus, S.; Durst, S.; Ferreira, J.J.; Veiga, P.; Kailer, N.; Weinmann, A. Digital transformation in business and management research: An overview of the current status quo. Int. J. Inf. Manag. 2022, 63, 102466. [Google Scholar] [CrossRef]

- Matt, C.; Hess, T.; Benlian, A. Digital Transformation Strategies. Bus. Inf. Syst. Eng. 2015, 57, 339–343. [Google Scholar] [CrossRef]

- Parviainen, P.; Tihinen, M.; Kääriäinen, J.; Teppola, S. Tackling the digitalization challenge: How to benefit from digitalization in practice. Int. J. Inf. Syst. Proj. Manag. 2017, 5, 63–77. [Google Scholar] [CrossRef]

- Gartner. Information Technology (IT)—Gartner Glossary. Available online: https://www.gartner.com/en/information-technology/glossary/it-information-technology (accessed on 7 January 2021).

- Wagner, T.; Herrmann, C.; Thiede, S. Industry 4.0 Impacts on Lean Production Systems. Procedia CIRP 2017, 63, 125–131. [Google Scholar] [CrossRef]

- Hess, T.; Matt, C.; Benlian, A.; Wiesböck, F. How German Media Companies Defined Their DigitalTransformation Strategies. MIS Q. Exec. 2016, 15, 103–119. [Google Scholar]

- Lai, K.H.; Wong, C.W.Y.; Cheng, T.C.E. Bundling digitized logistics activities and its performance implications. Ind. Mark. Manag. 2010, 39, 273–286. [Google Scholar] [CrossRef]

- Vendrell-Herrero, F.; Bustinza, O.F.; Parry, G.; Georgantzis, N. Servitization, digitization and supply chain interdependency. Ind. Mark. Manag. 2017, 60, 69–81. [Google Scholar] [CrossRef]

- Dougherty, D.; Dunne, D.D. Digital science and knowledge boundaries in complex innovation. Organ. Sci. 2012, 23, 1467–1484. [Google Scholar] [CrossRef]

- Pagani, M.; Pardo, C. The impact of digital technology on relationships in a business network. Ind. Mark. Manag. 2017, 67, 185–192. [Google Scholar] [CrossRef]

- McGrath, K.; Maiye, A. The role of institutions in ICT innovation: Learning from interventions in a Nigerian e-government initiative. Inf. Technol. Dev. 2010, 16, 260–278. [Google Scholar] [CrossRef]

- Teece, D.J. Business models, business strategy and innovation. Long Range Plan. 2010, 43, 172–194. [Google Scholar] [CrossRef]

- Heavin, C.; Power, D.J. Challenges for digital transformation–towards a conceptual decision support guide for managers. J. Decis. Syst. 2018, 27, 38–45. [Google Scholar] [CrossRef]

- Illa, P.K.; Padhi, N. Practical Guide to Smart Factory Transition Using IoT, Big Data and Edge Analytics. IEEE Access 2018, 6, 55162–55170. [Google Scholar] [CrossRef]

- Ramaswamy, V.; Ozcan, K. Brand value co-creation in a digitalized world: An integrative framework and research implications. Int. J. Res. Mark. 2016, 33, 93–106. [Google Scholar] [CrossRef]

- Grover, V.; Rajiv, K.; Ramanlal, P. Being mindful in digital initiatives. MIS Q. Exec. 2018, 17, 5. [Google Scholar]

- Kiel, D.; Müller, J.M.; Arnold, C.; Voigt, K.I. Sustainable Industrial Value Creation: Benefits and Challenges of Industry 4.0. Int. J. Innov. Manag. 2017, 21, 1740015. [Google Scholar] [CrossRef]

- Sebastian, I.M.; Moloney, K.G.; Ross, J.W.; Fonstad, N.O.; Beath, C.; Mocker, M. How big old companies navigate digital transformation. MIS Q. Exec. 2017, 16, 197–213. [Google Scholar] [CrossRef]

- Liao, Y.; Deschamps, F.; Loures, E.D.; Ramos, L.F. Past, present and future of Industry 4.0—A systematic literature review and research agenda proposal. Int. J. Prod. Res. 2017, 55, 3609–3629. [Google Scholar] [CrossRef]

- Schwab, K. The Fourth Industrial Revolution: What it means, how to respond. In Handbook of Research on Strategic Leadership in the Fourth Industrial Revolution, 1st ed.; Edward Elgar Publishing: Northampton, MA, USA, 2018. [Google Scholar]

- Thomson, S. Signs the Fourth Industrial Revolution Is Almost Here; World Economic Forum: New York, NY, USA, 2018. [Google Scholar]

- Danuso, A.; Giones, F.; Ribeiro da Silva, E. The digital transformation of industrial players. Bus. Horiz. 2022, 65, 341–349. [Google Scholar] [CrossRef]

- Ferreira, J.J.M.; Fernandes, C.I.; Ferreira, F.A.F. To be or not to be digital, that is the question: Firm innovation and performance. J. Bus. Res. 2019, 101, 583–590. [Google Scholar] [CrossRef]

- Jones, M.D.; Hutcheson, S.; Camba, J.D. Past, present, and future barriers to digital transformation in manufacturing: A review. J. Manuf. Syst. 2021, 60, 936–948. [Google Scholar] [CrossRef]

- Vogelsang, K.; Liere-Netheler, K.; Packmohr, S.; Hoppe, U. Success factors for fostering a digital transformation in manufacturing companies. J. Enterp. Transform. 2018, 8, 121–142. [Google Scholar] [CrossRef]

- Alcácer, V.; Cruz-Machado, V. Scanning the Industry 4.0: A Literature Review on Technologies for Manufacturing Systems. Eng. Sci. Technol. Int. J. 2019, 22, 899–919. [Google Scholar] [CrossRef]

- Grieco, A.; Caricato, P.; Gianfreda, D.; Pesce, M.; Rigon, V.; Tregnaghi, L.; Voglino, A. An Industry 4.0 Case Study in Fashion Manufacturing. Procedia Manuf. 2017, 11, 871–877. [Google Scholar] [CrossRef]

- Moshood, T.D.; Nawanir, G.; Lee, C.K.; Fauzi, M.A. Toward sustainability and resilience with Industry 4.0 and Industry 5.0. Sustain. Futures 2024, 8, 100349. [Google Scholar] [CrossRef]

- Baena, F.; Guarin, A.; Mora, J.; Sauza, J.; Retat, S. Learning Factory: The Path to Industry 4.0. Procedia Manuf. 2017, 9, 73–80. [Google Scholar] [CrossRef]

- Ji, W.; Wang, L. Big data analytics based fault prediction for shop floor scheduling. J. Manuf. Syst. 2017, 43, 187–194. [Google Scholar] [CrossRef]

- Lee, J.; Bagheri, B.; Kao, H.A. A Cyber-Physical Systems architecture for Industry 4.0-based manufacturing systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Lichtblau, K.; Stich, V.; Bertenrath, R.; Blum, M.; Bleider, M.; Millack, A.; Schmitt, K.; Schmitz, E.; Schröter, M. Industrie 4.0 Readiness; Aachen: Cologne, Germany, 2015. [Google Scholar]

- Ardito, L.; Petruzzelli, A.M.; Panniello, U.; Garavelli, A.C. Towards Industry 4.0: Mapping digital technologies for supply chain management-marketing integration. Bus. Process Manag. J. 2019, 25, 323–346. [Google Scholar] [CrossRef]

- Geissbauer, R.; Vedso, J.; Stefan, S. Industry 4.0: Building the Digital Enterprise—PWC 2016 Global Industry Survey. Available online: https://www.pwc.com/gx/en/industries/industries-4.0/landing-page/industry-4.0-building-your-digital-enterprise-april-2016.pdf (accessed on 6 August 2019).

- Westerman, G.; Tannou, M.; Bonnet, D.; Ferraris, P.; McAfee, A. The Digital Advantage: How Digital Leaders Outperform their Peers in Every Industry. MIT Sloan Manag. Rev. 2012, 2, 2–23. [Google Scholar]

- Kane, G.C.; Palmer, D.; Phillips, A.N.; Kiron, D.; Buckley, N. Coming of Age Digitally; MIT Sloan Management Review: Cambridge, MA, USA, 2018. [Google Scholar] [CrossRef]

- Teece, D.J. Explicating dynamic capabilities: The nature and micro-foundations of (sustainable) enterprise performance. Strateg. Manag. J. 2007, 28, 1319–1350. [Google Scholar] [CrossRef]

- Tripathi, S.; Gupta, M. A holistic model for Global Industry 4.0 readiness assessment. Benchmarking 2021, 28, 3006–3039. [Google Scholar] [CrossRef]

- Lucks, K. Industry 4.0 from An Entrepreneurial Transformation and Financing Perspective. Sci 2022, 4, 47. [Google Scholar] [CrossRef]

- Verma, A.; Venkatesan, M. HR factors for the successful implementation of Industry 4.0: A systematic literature review. J. Gen. Manag. 2022, 47, 73–85. [Google Scholar] [CrossRef]

- Schuh, G.; Anderl, R.; Gausemeier, J.; ten Hompel, M.; Wahlster, W. Industrie 4.0 Maturity Index. In Managing the Digital Transformation of Companies (Acatech Study); Utz Verlag: Munich, Germany, 2017. [Google Scholar]

- Anderl, R.; Picard, A.; Wang, Y.; Fleischer, J.; Dosch, S.; Klee, B.; Bauer, J. Guideline Industrie 4.0—Guiding Principles for the Implementation of Industrie 4.0 in Small and Medium Sized Businesses; VDMA Forum Industrie 4.0: Hannover, Germany, 2015; Available online: https://assomac.it/media/documents/vdma-guideline-industrie-40.pdf (accessed on 22 November 2024).

- MITI Malaysia. Industry 4WRD: National Policy on Industry 4.0; Ministry of International Trade and Industry: Kuala Lumpur, Malaysia, 2018. [Google Scholar]

- Singapore Economic Development Board (EDB). The Smart Industry Catalysing the Transformation of Manufacturing. 2020. Available online: https://www.edb.gov.sg/content/dam/edb-japan/key-activities/advanced-manufacturing/the-singapore-smart-industry-readiness-index/the-sg-smart-industry-readiness-index-whitepaper.pdf (accessed on 15 October 2024).

- National Science and Technology Development Agency (NSTDA); The Federation of Thai Industries (FTI). Thailand I4.0 Index. 2022. Available online: https://www.thindex.or.th/Content/assets/fileTemplate/ThailandIndex_Manual_20220609.pdf (accessed on 15 October 2024).

- Yim, D.S.; Kim, W.; Kang, S.; Kim, E.J. The Development Strategy for Indonesia Digital Center PIDI 4.0 toward Digital Transformation. In Proceedings of the PICMET 2023—Portland International Conference on Management of Engineering and Technology: Managing Technology, Engineering and Manufacturing for a Sustainable World, Monterrey, Mexico, 23–27 July 2023; pp. 1–7. [Google Scholar] [CrossRef]

- Shen, A.; Wang, R. Digital Transformation and Green Development Research: Microscopic Evidence from China’s Listed Construction Companies. Sustainability 2023, 15, 12481. [Google Scholar] [CrossRef]

- Alshebami, A.S.; College, A.; Arabia, S. Empowering Micro and Small Enterprises in Times of Crisis: How Human Resources Management Skills and Owned Funds Drive Self- Efficacy and Continuity Intention. Sustain. Futures 2025, 10, 100791. [Google Scholar] [CrossRef]

- Laguna, R.F.; Aguinaga, D.L.; Torres, D.E.; Cueto, B.A. Soft Skills and the Use of Industry 4.0 as Determinants of Professional Development in Engineering Graduates: A SEM Approach. Sustain. Futures 2025, 10, 100742. [Google Scholar] [CrossRef]

- Takacs, J.M.; Pogatsnik, M. A systematic review of Human Aspects in Industry 4.0 and 5.0: Cybersecurity Awareness and Soft Skills. In Proceedings of the INES 2023—27th IEEE International Conference on Intelligent Engineering Systems 2023, Nairobi, Kenya, 2 May 2023; pp. 33–40. [Google Scholar] [CrossRef]

- Shigeno, H.; Ueki, Y.; Matsuzaki, T.; Tsuji, M.; Jeenanunt, C.; Abu Taher, S. Innovation Process of Small and Medium-sized Regional Firms before and during the COVID-19 Pandemic. In Proceedings of the 10th Multidisciplinary International Social Networks Conference (MISNC ’23), Phuket, Thailand, 4–6 September 2023; Association for Computing Machinery: Phuket, Thailand, 2023; pp. 143–150. [Google Scholar] [CrossRef]

- Tagscherer, F.; Carbon, C.C. Leadership for successful digitalization: A literature review on companies’ internal and external aspects of digitalization. Sustain. Technol. Entrep. 2023, 2, 100039. [Google Scholar] [CrossRef]

- Čirčová, V.; Blštáková, J. Reskilling and Upskilling of Managers: People Management in the Digital Era. In Proceedings of the EDAMBA 2022: Conference Proceedings 2023, Athens, Greece, 18–21 July 2022; pp. 87–96. [Google Scholar] [CrossRef]

- Fonseca, L.M. Industry 4.0 and the digital society: Concepts, dimensions and envisioned benefits. Proc. Int. Conf. Bus. Excell. 2018, 12, 386–397. [Google Scholar] [CrossRef]

- Trindade, D.N.; Duarte, L.G.; Perico, I.; Bandeira, G.L. Driving Change in the Oil and Gas Industry: A Digital Transformation Framework. In Proceedings of the Offshore Technology Conference Brasil, Rio de Janeiro, Brazil, 24–26 October 2023. [Google Scholar] [CrossRef]

- Raj, A.; Dwivedi, G.; Sharma, A.; Lopes de Sousa Jabbour, A.B.; Rajak, S. Barriers to the adoption of industry 4.0 technologies in the manufacturing sector: An inter-country comparative perspective. Int. J. Prod. Econ. 2020, 224, 107546. [Google Scholar] [CrossRef]

- Couto, C.A.; Exatas, E. Managing Enterprise Resource Systems (ERP) and Balanced Scorecard (BSC) in the Food Industry in Brazil—Food and Beverage Products—A Multiple Case Study. In Proceedings of the IFIP International Conference on Advances in Production Management Systems 2017, Hamburg, Germany, 3–7 September 2017. [Google Scholar] [CrossRef]

- Dong, J.; Mirza, Z. Supporting the production of pharmaceuticals in Africa. Bull. World Health Organ. 2016, 94, 71–72. [Google Scholar] [CrossRef]

- Tarique, I.; Schuler, R. A multi-level framework for understanding global talent management systems for high talent expatriates within and across subsidiaries of MNEs: Propositions for further research. J. Glob. Mobil. 2018, 6, 79–101. [Google Scholar] [CrossRef]

- Brettel, M.; Friederichsen, N.; Keller, M.; Rosenberg, M. How Virtualization, Decentralization and Network Building Change the Man-Ufacturing Landscape: An Industry 4.0 Perspective. Int. J. Mech. Ind. Sci. Eng. 2014, 8, 37–44. [Google Scholar]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital Twin in Industry: State-of-the-Art. IEEE Trans. Ind. Inform. 2019, 15, 2405–2415. [Google Scholar] [CrossRef]

- Tang, Q.; Wu, B.; Chen, W.; Yue, J. A Digital Twin-Assisted Collaborative Capability Optimization Model for Smart Manufacturing System Based on Elman-IVIF-TOPSIS. IEEE Access 2023, 11, 40540–40564. [Google Scholar] [CrossRef]

- Hofmann, E.; Rüsch, M. Industry 4.0 and the current status as well as future prospects on logistics. Comput. Ind. 2017, 89, 23–34. [Google Scholar] [CrossRef]

- Kouhizadeh, M.; Sarkis, J.; Zhu, Q. Blockchain technology and the sustainable supply chain: Theoretically exploring adoption barriers. Int. J. Prod. Econ. 2020, 231, 107831. [Google Scholar] [CrossRef]

- Kolberg, D.; Zühlke, D. Lean automation enabled by Industry 4.0 technologies. IFAC-Pap. 2015, 48, 1870–1875. [Google Scholar] [CrossRef]

- Gimenez, G.; Benedetto, S.; D’Angelo, M. Mixed Reality in Industry 4.0: Technologies, Applications, and Challenges. J. Manuf. Syst. 2021, 61, 143–156. [Google Scholar]

- Teece, D.J.; Pisano, G.; Shuen, A. Dynamic Capabilities and Strategic Management. Strateg. Manag. J. 1997, 18, 509–533. [Google Scholar] [CrossRef]

- Liu, D.; Son, S. Exploring the impact mechanism of collaborative robot on manufacturing firm performance: A dynamic capability perspective. Sustain. Futures 2024, 8, 100262. [Google Scholar] [CrossRef]

- Jain, N. Survey versus interviews: Comparing data collection tools for exploratory research. Qual. Rep. 2021, 26, 541–554. [Google Scholar] [CrossRef]

- Creswell, J.W.; Plano Clark, V.L. Designing and Conducting Mixed Methods Research, 3rd ed.; SAGE: Thousand Oaks, CA, USA, 2018. [Google Scholar]

- Braun, V.; Clarke, V. Reflecting on reflexive thematic analysis. Qual. Res. Sport Exerc. Health 2019, 11, 589–597. [Google Scholar] [CrossRef]

- Nowell, L.S.; Norris, J.M.; White, D.E.; Moules, N.J. Thematic Analysis: Striving to Meet the Trustworthiness Criteria. Int. J. Qual. Methods 2017, 16, 1609406917733847. [Google Scholar] [CrossRef]

- Hair, J.F.; Tomas, G.; Hult, M.; Ringle, C.M.; Sarstedt, M. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM), 2nd ed.; SAGE: Los Angeles, CA, USA, 2017. [Google Scholar]

- Henseler, J.; Hubona, G.; Ray, P.A. Using PLS path modeling in new technology research: Updated guidelines. Ind. Manag. Data Syst. 2016, 116, 2–20. [Google Scholar] [CrossRef]

- Barclay, D.; Higgins, C.; Thompson, R. The Partial Least Squares (PLS) Approach to Causal Modeling: Personal Computer Adoption and Use as an Illustration. Technol. Stud. 1995, 2, 285–309. [Google Scholar]

- Hair, J.F.; Ringle, C.M.; Sarstedt, M. PLS-SEM: Indeed a silver bullet. J. Mark. Theory Pract. 2011, 19, 139–152. [Google Scholar] [CrossRef]

- Reinartz, W.; Haenlein, M.; Henseler, J. An empirical comparison of the efficacy of covariance-based and variance-based SEM. Int. J. Res. Mark. 2009, 26, 332–344. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; MacKenzie, S.B.; Lee, J.Y.; Podsakoff, N.P. Common Method Biases in Behavioral Research: A Critical Review of the Literature and Recommended Remedies. J. Appl. Psychol. 2003, 88, 879–903. [Google Scholar] [CrossRef]

- Kock, N. Common Method Bias in PLS-SEM: A Full Collinearity Assessment Approach. Int. J. E-Collab. (IJeC) 2015, 11, 1–10. [Google Scholar] [CrossRef]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E. Multivariate Data Analysis, 8th ed.; Cengage Learning, EMEA: Hampshire, UK, 2019. [Google Scholar] [CrossRef]

- Hair, J.F.; Sarstedt, M.; Ringle, C.M.; Gudergan, S.P. Advanced Issues in Partial Least Squares Structural Equation Modeling; SAGE Publications: Los Angeles, CA, USA, 2021. [Google Scholar]

- Dijkstra, T.K.; Henseler, J. Consistent partial least squares path modeling. MIS Q. Manag. Inf. Syst. 2015, 39, 297–316. [Google Scholar] [CrossRef]

- Hair, J.F.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM), 3rd ed.; SAGE: Los Angeles, CA, USA, 2022. [Google Scholar] [CrossRef]

- Fornell, C.; Larcker, D.F. Evaluating Structural Equation Models with Unobservable Variables and Measurement Error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Henseler, J.; Ringle, C.M.; Sarstedt, M. A new criterion for assessing discriminant validity in variance-based structural equation modeling. J. Acad. Mark. Sci. 2015, 43, 115–135. [Google Scholar] [CrossRef]

- Chin, W.W. The partial least squares approach to structural equation modeling. Mod. Methods Bus. Res. 1998, 295, 295–336. [Google Scholar]

- Picinin, C.T.; Pedroso, B.; Arnold, M.; Klafke, R.V.; Pinto, G.M.C. A Review of the Literature about Sustainability in the Work of the Future: An Overview of Industry 4.0 and Human Resources. Sustainability 2023, 15, 12564. [Google Scholar] [CrossRef]

- Pozzi, R.; Rossi, T.; Secchi, R. Industry 4.0 technologies: Critical success factors for implementation and improvements in manufacturing companies. Prod. Plan. Control 2021, 34, 139–158. [Google Scholar] [CrossRef]

- Ly, B. Leveraging leadership and digital transformation for sustainable development: Insights from Cambodia’s public sector. Sustain. Futures 2025, 9, 100545. [Google Scholar] [CrossRef]

- Tsuji, M.; Shigeno, H.; Ueki, Y.; Idota, H.; Bunno, T. Characterizing R&D and HRD in the innovation process of Japanese SMEs: Analysis based on field study. Asian J. Technol. Innov. 2017, 25, 367–385. [Google Scholar] [CrossRef]

| Company | Company 1 | Company 2 | Company 3 | Company 4 | Company 5 |

|---|---|---|---|---|---|

| Year of Establishment | 1990 | 1999 | 1987 | 1893 | 1916 |

| Number of Employees | 400 | 55 | 190 | 700 | 120,726 |

| Company Size | Large | Medium | Medium | Large | Large |

| Business Type | Manufacturing | Manufacturing | Manufacturing | Manufacturing | Manufacturing |

| Product | Finished yarn and fabric | Molded plastic parts | Plastic products, Plastic Bags | Sewing machines and components | Vehicles |

| Suppliers | Local | Local and International | Local and International | International | International |

| Customers | Multinational | Multinational | Multinational | International | Multinational |

| Supply Chain Type | Exporter | Multinational | Multinational | Multinational | Multinational |

| Company | Industry 4.0 Readiness Level | Company’s Practices |

|---|---|---|

| Company 1 | Level 0 |

|

| Company 2 | Level 1 |

|

| Company 3 | Level 1 |

|

| Company 4 | Level 5 |

|

| Company 5 | Level 5 |

|

| Company | Industry 4.0 Readiness Level | Company’s Practices |

|---|---|---|

| Company 1 | Level 0 |

|

| Company 2 | Level 2 |

|

| Company 3 | Level 1 |

|

| Company 4 | Level 5 |

|

| Company 5 | Level 5 |

|

| Company | Industry 4.0 Readiness Level | Company’s Practices |

|---|---|---|

| Company 1 | Level 1 |

|

| Company 2 | Level 3 |

|

| Company 3 | Level 1 |

|

| Company 4 | Level 5 |

|

| Company 5 | Level 5 |

|

| Company | Industry 4.0 Readiness Level | Company’s Practices |

|---|---|---|

| Company 1 | Level 0 |

|

| Company 2 | Level 0 |

|

| Company 3 | Level 0 |

|

| Company 4 | Level 3 |

|

| Company 5 | Level 5 |

|

| Company | Industry 4.0 Readiness Level | Company’s Practices |

|---|---|---|

| Company 1 | Level 0 |

|

| Company 2 | Level 1 |

|

| Company 3 | Level 0 |

|

| Company 4 | Level 5 |

|

| Company 5 | Level 5 |

|

| Company | Industry 4.0 Readiness Level | Company’s Practices |

|---|---|---|

| Company 1 | Level 2 |

|

| Company 2 | Level 2 |

|

| Company 3 | Level 3 |

|

| Company 4 | Level 5 |

|

| Company 5 | Level 5 |

|

| Demographic | Descriptive | n | Percent |

|---|---|---|---|

| The company’s size | Small (<50 employees) | 58 | 40.28% |

| Large (≥200 employees) | 51 | 35.42% | |

| Medium (50–199 employees) | 35 | 24.31% | |

| Main Business Activity | Other manufacturing | 34 | 23.61% |

| Automobile, auto parts | 25 | 17.36% | |

| Food, beverages, tobacco | 17 | 11.81% | |

| Plastic and rubber products | 11 | 7.64% | |

| Paper, paper products, printing | 8 | 5.56% | |

| Produce more than one main product | 8 | 5.56% | |

| Machinery, equipment, tools | 7 | 4.86% | |

| Textiles | 5 | 3.47% | |

| Wood, wood products | 4 | 2.78% | |

| Iron, steel | 4 | 2.78% | |

| Non-ferrous metals | 4 | 2.78% | |

| Other electronics and components | 4 | 2.78% | |

| Handicraft | 4 | 2.78% | |

| Chemicals, chemical products | 3 | 2.08% | |

| Coal, petroleum products | 2 | 1.39% | |

| Metal products | 2 | 1.39% | |

| Computers and computer parts | 2 | 1.39% | |

| The company’s capital structure | Thai-owned | 112 | 77.78% |

| Foreign-owned (MNC) | 15 | 10.42% | |

| Joint Venture (JV) | 17 | 11.81% |

| Constructs | Items | Item Loading | α | rho_A | CR | AVE |

|---|---|---|---|---|---|---|

| Business Pressures | BPS | 0.894 | 0.906 | 0.918 | 0.653 | |

| BPS_1 | 0.820 | ||||

| BPS_2 | 0.805 | ||||

| BPS_3 | 0.879 | ||||

| BPS_4 | 0.759 | ||||

| BPS_5 | 0.837 | ||||

| BPS_6 | 0.740 | ||||

| Industry 4.0 HRD Preparedness | HRD | 0.941 | 0.942 | 0.953 | 0.773 | |

| HRD_1 | 0.856 | ||||

| HRD_2 | 0.906 | ||||

| HRD_3 | 0.879 | ||||

| HRD_4 | 0.896 | ||||

| HRD_5 | 0.888 | ||||

| HRD_6 | 0.848 | ||||

| Leadership Support for Industry 4.0 | LDS | 0.932 | 0.932 | 0.948 | 0.786 | |

| LDS_1 | 0.872 | ||||

| LDS_2 | 0.907 | ||||

| LDS_3 | 0.906 | ||||

| LDS_4 | 0.877 | ||||

| LDS_5 | 0.870 | ||||

| Technological Readiness for Industry 4.0 | TRI | 0.823 | 0.827 | 0.876 | 0.585 | |

| TRI_1 | 0.756 | ||||

| TRI_2 | 0.779 | ||||

| TRI_3 | 0.790 | ||||

| TRI_4 | 0.756 | ||||

| TRI_5 | 0.741 |

| BPS | HRD | LDS | TRI | |

|---|---|---|---|---|

| BPS | 0.808 | |||

| HRD | 0.481 | 0.879 | ||

| LDS | 0.583 | 0.601 | 0.886 | |

| TRI | 0.238 | 0.408 | 0.427 | 0.765 |

| BPS | HRD | LDS | TRI | |

|---|---|---|---|---|

| BPS | ||||

| HRD | 0.513 | |||

| LDS | 0.628 | 0.640 | ||

| TRI | 0.281 | 0.461 | 0.480 |

| Hypothesis | β | p-Values | Assumption | |

|---|---|---|---|---|

| H1a | BPS > HRD | 0.197 * | 0.026 | Supported |

| H1b | BPS > LDS | 0.583 ** | 0.000 | Supported |

| H1c | BPS > TRI | −0.066 | 0.482 | Not Supported |

| H2a | LDS > HRD | 0.486 ** | 0.000 | Supported |

| H2b | LDS > TRI | 0.314 ** | 0.000 | Supported |

| H3 | HRD > TRI | 0.250 * | 0.002 | Supported |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vong, K.C.; Udomvitid, K.; Ueki, Y.; Intalar, N.; Pongsathornwiwat, A.; Pannakkong, W.; Komolavanij, S.; Jeenanunta, C. Strategic Human Resource Development for Industry 4.0 Readiness: A Sustainable Transformation Framework for Emerging Economies. Sustainability 2025, 17, 6988. https://doi.org/10.3390/su17156988

Vong KC, Udomvitid K, Ueki Y, Intalar N, Pongsathornwiwat A, Pannakkong W, Komolavanij S, Jeenanunta C. Strategic Human Resource Development for Industry 4.0 Readiness: A Sustainable Transformation Framework for Emerging Economies. Sustainability. 2025; 17(15):6988. https://doi.org/10.3390/su17156988

Chicago/Turabian StyleVong, Kwanchanok Chumnumporn, Kalaya Udomvitid, Yasushi Ueki, Nuchjarin Intalar, Akkaranan Pongsathornwiwat, Warut Pannakkong, Somrote Komolavanij, and Chawalit Jeenanunta. 2025. "Strategic Human Resource Development for Industry 4.0 Readiness: A Sustainable Transformation Framework for Emerging Economies" Sustainability 17, no. 15: 6988. https://doi.org/10.3390/su17156988

APA StyleVong, K. C., Udomvitid, K., Ueki, Y., Intalar, N., Pongsathornwiwat, A., Pannakkong, W., Komolavanij, S., & Jeenanunta, C. (2025). Strategic Human Resource Development for Industry 4.0 Readiness: A Sustainable Transformation Framework for Emerging Economies. Sustainability, 17(15), 6988. https://doi.org/10.3390/su17156988