1. Introduction

The integrity of the cement sheath is crucial for the long-term safe and efficient extraction of oil and gas wells [

1,

2,

3,

4,

5,

6]. However, complex downhole geological conditions and operational stresses during production frequently induce deterioration and cracking of the cement sheath, particularly at the annular interface [

4,

7,

8,

9]. Such damage compromises annular isolation, facilitates interlayer communication, diminishes hydrocarbon recovery efficiency, and significantly escalates operational expenditures (OPEX) in the latter stages of well life [

8,

10,

11,

12]. Consequently, developing effective strategies to proactively mitigate or repair micro-cracks resulting from cement sheath degradation has become a critical research focus within oil and gas engineering.

Traditional methods for repairing cracks in cement sheaths, such as secondary cementing operations and chemical grouting, have several drawbacks. Secondary cementing operations are often prohibitively expensive, technically challenging to execute, and frequently yield inadequate repair outcomes, particularly in achieving precise crack sealing. While chemical grouting can offer superior repair performance, it carries inherent environmental and safety risks [

8,

9,

11,

13,

14,

15,

16,

17,

18,

19]. In contrast, microbial self-healing technology leverages the principle of Microbial Induced Calcite Precipitation (MICP), where specific microbial metabolic processes produce calcite to fill and repair cracks in cement, thereby extending the service life of the cement structure. The microbial mineral deposition product exhibits excellent compatibility with cementitious matrices and is more environmentally friendly compared to synthetic polymers [

20,

21,

22,

23,

24,

25,

26,

27]. Therefore, it has been widely used to repair surface cracks and improve the durability of cementitious matrices.

Recent advancements have explored the application of microbial self-healing technology in downhole environments. Phillips et al. [

28,

29,

30,

31] employed conventional fluid injection techniques to deliver bacterial suspensions, urea, and calcium solutions into target formations, successfully reducing permeability by filling sandstone fractures and pores, repairing cement sheath cracks, and mitigating fluid channeling. Cunningham et al. [

32,

33,

34,

35,

36] utilized perforated completions to inject microbial fluids, blocking surrounding rock pores and forming a dense barrier layer, which effectively reduced CO

2 migration and mitigated CO

2 corrosion of the cement sheath and casing. Catherine et al. [

37] employed ultrasonic, acoustic, and temperature logging to evaluate MICP’s impact on cement sheath integrity, confirming its efficacy in reducing system permeability, repairing leakage channels, and improving water injection efficiency, even in the presence of hydrocarbons.

While injecting microbial solutions into annular fractures can effectively repair cement sheath micro-cracks and interface failures, this method often necessitates manual intervention. Furthermore, in formations with low fracture pressure, improper injection pressure may inadvertently propagate cracks. To circumvent these challenges, this study proposes the development of a self-healing cement slurry system. This system incorporates pre-embedded, environmentally responsive repair agents directly into the cement slurry matrix, aiming to achieve effective zonal isolation autonomously.

Previous studies have demonstrated that directly mixing microbial fluid with cement slurry often results in low microbial viability, which leads to suboptimal self-healing effects in the cement sheath [

23,

24,

38,

39]. Consequently, enhancing the viability of microorganisms within the cement slurry is crucial for the successful application of microbial self-healing technology. Various microbial protective carriers, such as polyurethane foam, diatomaceous earth, hydrogels, expanded clay particles, and microcapsules, have been incorporated into the cement-based materials to provide a porous structure for retaining moisture and nutrients, promoting microbial growth [

40,

41,

42,

43,

44]. However, many of these carriers exhibit poor compatibility with cementitious slurries, potentially compromising the overall material performance.

Therefore, this study proposes utilizing fly ash, a mineral additive known for its good compatibility with cement, as a microbial carrier. Concurrently, slow-release microcapsule technology is employed to encapsulate calcium sources and nutrients, thereby preventing premature interactions between these components and the microorganisms that could negatively affect cement slurry rheology. This paper systematically investigates microbial viability, optimizes suitable carrier materials and microbial loading rates, and assesses the compatibility of the microbial self-healing agent with cement slurry under simulated medium–deep well conditions. Furthermore, microscopic analysis, including CT scanning, was conducted to observe the characteristics within the internal micro-pores of the microbial well cement stone and elucidate the self-healing mechanism. The findings not only identify the optimal composition range for the microbial self-healing cement slurry for downhole applications but also present a promising strategy for maintaining the long-term integrity of oil and gas wells.

2. Materials and Methods

2.1. Main Components and Preparation of Microbial Self-Healing Agents

The strain used in this experiment was sourced from Sporosarcina pasteurii (ATCC11859, purchased from the China Microbial Culture Collection (CGMCC), Beijing, China), which has been domesticated and screened for high-temperature resistance under laboratory conditions. Compared to the original strain, it possesses higher adaptability, viability, germination rate, and mineralization efficiency in medium- to high-temperature environments. These enhanced characteristics are crucial for effectively repairing cement stone fractures during oil and gas extraction processes.

The main components of the microbial culture medium include urea (20 g/L), casein peptone (15 g/L), soy peptone (5 g/L), sodium chloride (5 g/L), and deionized water (1 L).

In this experiment, three common cement mineral additives, including ultra-fine fly ash (FA), blast furnace slag (BFS), and nano-silica (Nano-SiO

2), were used as microbial carriers due to the good compatibility between mineral crystals and cement components. All of the chemical reagents and experimental materials mentioned above were purchased from ChemicalBook (

www.labgogo.com).

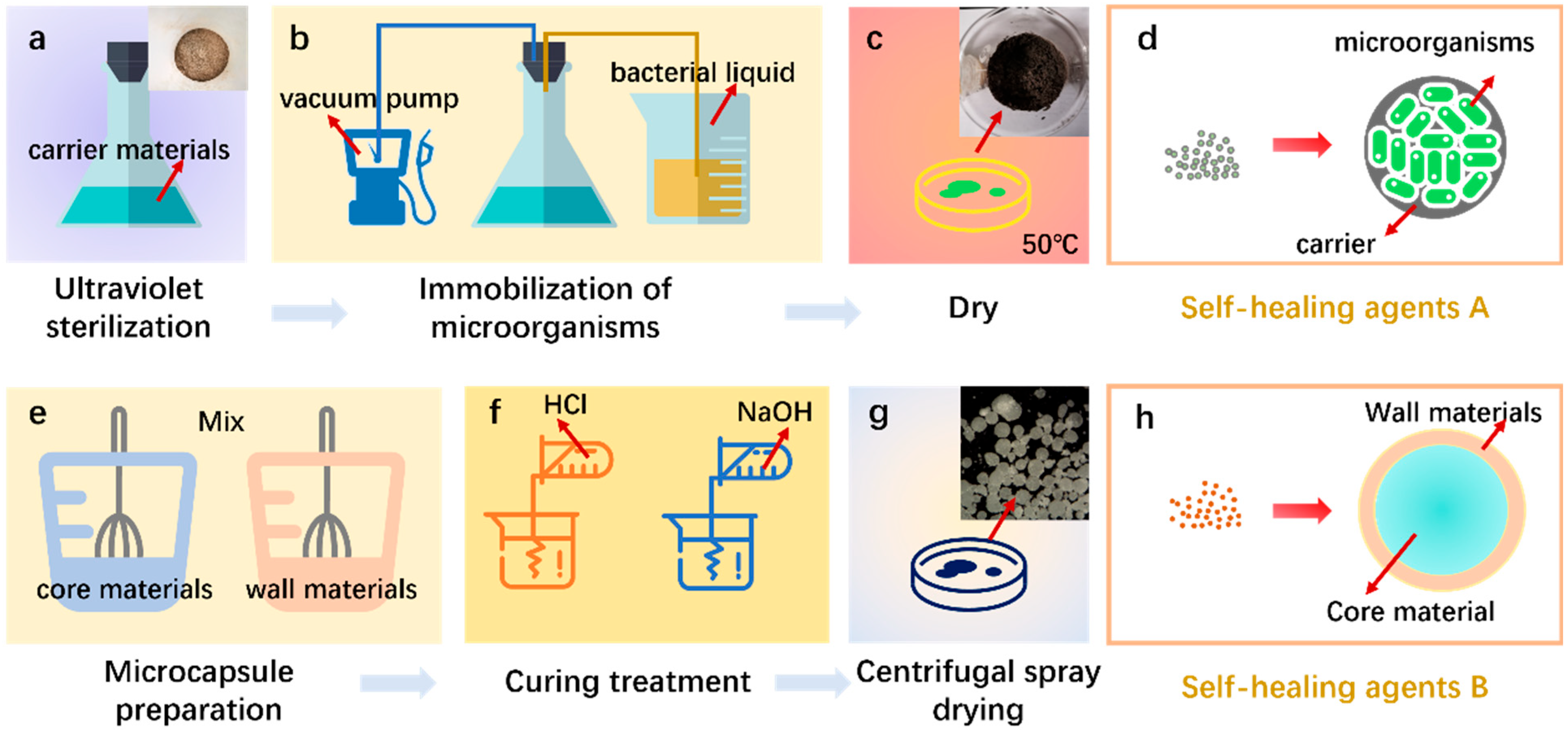

The microbial self-healing agent is comprised of microbial self-healing agent A and self-healing agent B, as shown in

Figure 1a–d. The carrier materials need to be sterilized under ultraviolet light and then placed in a vacuum filtration bottle before the experiment. A vacuum pump is used to achieve an internal vacuum of −0.06 MPa. The throttle valve is then opened to allow the culture solution of the domesticated mutant strain, which has been amplified and cultured for 48 h, to be absorbed into the vacuum filtration bottle under negative pressure. After 24 h of vacuum adsorption, the throttle valve is closed, and the filtration bottle is opened to obtain the complex of microorganisms and carrier materials. Subsequently, the composite material is placed in a 50 °C blast drying oven and dried to a constant weight, resulting in microorganism-loaded carriers, which were recorded as microbial self-healing agent A.

In this experiment, complex coacervation microcapsule technology was employed to encapsulate calcium chloride and nutrients as the core material within a wall material, forming sustained-release microcapsules and avoid the adverse effects of directly adding nutrients and calcium chloride to the cement slurry on its performance [

24]. The preparation process of the calcium chloride sustained-release microcapsules is illustrated in

Figure 1e–h.

Initially, 200 g of anhydrous calcium chloride powder, 45 g of solid powdered standard culture medium (containing casein peptone 15 g, soy peptone 5 g, sodium chloride 5 g, and urea 20 g), and 10 mL of Tween 80 were dissolved in 2 L of deionized water. The solution’s pH was adjusted to between 10 and 13.5. This high pH promotes the coacervation process. The solution was then placed in a high-pressure shear emulsifier and dispersed at 2000 rpm for 10 min to obtain a complex coacervation microcapsule core material containing calcium chloride and nutrients. Subsequently, the wall material was prepared by dissolving a mixture of polyvinyl alcohol (PVA), glutaraldehyde (GA), glycerin, and sodium dodecylbenzene sulfonate in 200 mL of deionized water. PVA was chosen for its film-forming ability and flexibility, while GA acts as a crosslinking agent to provide structural integrity. Glycerin serves as a plasticizer to enhance flexibility and prevent excessive brittleness. This mixture was heated and stirred in a 45 °C air bath constant temperature shaker until fully dissolved. The selection of these components and their ratios is crucial for achieving a wall that is robust enough to withstand the mixing process but brittle enough to fracture under the stress of a crack. Next, 100 g of the wall material solution was placed in a high-speed homogenizer and stirred at 2000 rpm for 10 min. The complex coacervation microcapsule core material solution was slowly added while increasing the speed to 10,000 rpm for dispersion processing, which facilitates the encapsulation of the core material within the wall material, influencing the uniformity and initial thickness of the wall. After 5 min, the mixed liquid was transferred to a high-pressure homogenizer for secondary mixing treatment under conditions of 30 MPa for 10 min and 49 MPa for 5 min, resulting in a uniformly dispersed microcapsule preparation liquid. These high pressures are essential for creating a uniform dispersion and ensuring the wall material fully coats the core, as well as keeping a balanced wall density and integrity without making it excessively thick or fragile. And then, the system was adjusted to a pH of about 4.5 using 1 mol/L HCl solution, which induces the coacervation and deposition of the wall material around the core. It was allowed to react for 10 min. The temperature was lowered to below 15 °C, and the pH was adjusted to 6.0 with 0.2 mol/L NaOH solution for curing treatment, promoting the crosslinking reaction (especially PVA with GA), solidifying the wall. And the prepared complex coacervation microcapsule dispersion was allowed to stand for 20 to 24 h to obtain wet microcapsules. Substantially, the wet microcapsules were spray-dried using a centrifugal spray dryer to remove the water and obtain the final complex coacervation microcapsules required for the experiment. The feed flow rate was 500 mL/h, and the inlet air temperature and outlet air temperature were set as 180 °C and 80 °C, respectively, ensuring rapid drying without degrading the core materials or causing excessive wall shrinkage and brittleness. After that, the calcium chloride sustained-release microcapsules were prepared, which were recorded as microbial self-healing agent B.

2.2. Preparation and Curing of Microbial Cement Slurry

This study simulates the well-cementing environment of the Chunguang Oilfield, located in Karamay City, Xinjiang Uyghur Autonomous Region. Structurally, the Chunguang Oilfield is situated in the eastern part of the Chepaizi uplift within the western uplift of the Junggar Basin, a secondary structural unit of the Junggar Basin. Field logging results indicate that oil extraction wells in this oilfield commonly experience cracking within the cement sheath and between the cement sheath and the formation. These cracks result in a loss of sealing capacity, leading to crossflow between the production oil layer and adjacent water layers. This issue severely impacts the timely production of new wells and the overall development capacity of the oilfield. The heavy oil layers in the Chunguang Oilfield are buried at depths ranging from 900 to 1100 m, with casing perforated completion methods employed. The average well depth is 1105 m, and bottomhole temperatures range from 50 to 55 °C, typical of medium-depth wells. The cement slurry formula used in Chunguang Oilfield includes G-grade oilwell cement, 35% quartz sand, 2.2% anti-channeling and water loss reducer W-99, 2.2% water loss reducer G303, 1.0% drag reducer USZ, 6.8% strength enhancer PZW-A, 2.0% toughening and anti-leakage agent F27A, and 0.8% expansion agent TW502.

During this experiment, three common cement mineral additives, including ultra-fine fly ash (FA), blast furnace slag (BFS), and nano-silica (Nano-SiO

2), were used as microbial carriers with a mass ratio of 1:1 to the bacterial solution. Furthermore, the viability of the microorganisms and the influence of different mass ratios (2:5, 3:5, 4:5, 1:1, 6:5) on the properties of the basic cement slurry were investigated to determine the optimal absorption amount of the bacterial solution in the carriers. After that, the effects of the microbial self-healing agent’s ratio on the properties of the cement slurry were explored, as shown in

Table 1. In this experiment, the water–cement ratio was 0.45, and the mixture was stirred at a specific rate for 30 s using a high-speed stirrer, and 0.6% defoamer was added. The mixture was then poured into standard steel molds with dimensions of 40 mm × 40 mm × 160 mm and cylindrical molds with dimensions of ∅25 mm × 100 mm. The molds were placed in a variable temperature and pressure curing vessel and cured at 55 °C and 15 MPa for 1 day, 3 days, 7 days, and 28 days, respectively.

2.3. Microbial Viability Test

During this test, the sample is serially diluted to ensure that the microorganisms are fully dispersed into individual cells. A specific volume of the diluted solution is then inoculated onto plates and evenly distributed across the medium in the petri dishes. After incubation, colonies form from each single cell. Each colony represents a single viable cell from the original sample. By considering the dilution factor and the inoculation volume, the number of viable bacteria in the sample can be calculated. Currently, Colony-Forming Units (CFUs) are commonly used to express the number of viable bacteria in a sample. The steps for performing plate colony counting are as follows:

- (1)

Prepare sterile solid media plates. Label nine plates: three each at dilutions of 10−4, 10−5, and 10−6.

- (2)

Prepare six test tubes containing 4.5 mL of sterile water each, labeled sequentially from 10−1 to 10−6.

- (3)

Using a 1 mL micropipette, accurately transfer 0.5 mL of the bacterial suspension into the 10−1 tube and mix thoroughly.

- (4)

Transfer 0.5 mL from the 10−1 tube into the 10−2 tube, mix well, and continue this process sequentially.

- (5)

From the 10−4, 10−5, and 10−6 dilutions, take 0.2 mL of the diluted bacterial suspension and inoculate the corresponding labeled sterile solid media plates.

- (6)

After inoculation, use a spreader to distribute the suspension evenly over the surface of the media.

- (7)

Incubate the plates upside down in the required environment as per experimental conditions.

- (8)

After the specified incubation period, remove the plates and use a plate colony counter to count the number of colonies on the solid media. For each dilution level, average the colony counts from the three plates.

- (9)

Calculate the number of viable bacteria in the original sample using Formula (1).

The viability of the microorganisms was subsequently determined using Formula (2), where

Nt is the number of viable microorganisms after a certain time, and

N0 is the initial number of microorganisms.

2.4. Sustained-Release Performance of Microcapsules

First, prepare 10 g of sustained-release microcapsules and add the microcapsules to 500 mL of a 1 mol/L sodium carbonate (Na2CO3) aqueous solution in a suitable reaction vessel. Start timing immediately upon addition of the microcapsules to the Na2CO3 solution. At regular intervals (e.g., every 10 min), withdraw a small aliquot (e.g., 10 mL) from the reaction mixture. Use the gravimetric method to measure the amount of calcium carbonate (CaCO3) precipitated in each aliquot. Record the mass of CaCO3 formed at each time point and plot a curve representing the mass of CaCO3 formed over time. Analyze the curve to determine the onset time of sustained release for the calcium chloride microcapsules. The onset time can be identified as the point where the mass of CaCO3 starts to increase significantly.

2.5. Morphology Test of Self-Healing Agents

Initially, the microcapsules were dispersed in an appropriate amount of deionized water to form a suspension. Following ultrasonic treatment for 30 s, the particle size of the microcapsules was measured using a Malvern Mastersizer 2000 laser particle size analyzer (manufactured by Malvern Panalytical, Malvern, UK). The surface morphology of both the carriers and the sustained-release microcapsules was observed with a Zeiss Stemi508 stereomicroscope (manufactured by Carl Zeiss AG, Oberkochen, Germany) and a FEI-HPLIPS3D scanning electron microscope (manufactured by FEI Company, Hillsboro, OR, USA). Additionally, the Nano-3000 X-ray CT produced by Tianjin Sanying Precision Instruments Co., Ltd. (Tianjin, China) was used to test the mineralization characteristics of products within the pores.

2.6. Performance Test of Cement Slurry

In the experiment, a densitometer (manufactured by Mettler Toledo, Columbus, OH, USA) was utilized to measure the density of the cement slurry. The initial and final setting times of the cement slurry were determined using a Vicat apparatus (model HY(RW)-300HB, manufactured by Shanghai Hengyi Precision Instruments Co., Ltd, Shanghai, China). Fluidity tests were conducted on the cement slurry using a conical cylinder mold. An 8040-model high-temperature and high-pressure thickening meter (manufactured by OFITE, Houston, TX, USA) was employed to determine the time required for the microbial cement slurry to reach consistencies of 30

Bc and 100

Bc, referred to as the thickening times

t30Bc and

t100Bc, respectively. The

API fluid loss of the cement slurry was tested using a high-temperature and high-pressure fluid loss apparatus (manufactured by Fann Instrument Company, Houston, TX, USA), with results recorded as

FL(API). The anti-channeling performance index, or

SPN value, was calculated according to Formula (3) to evaluate the gas channeling resistance performance of the cement slurry. The criteria for assessing gas channeling resistance were as follows: an SPN value between 0 and 3 indicated excellent gas channeling resistance; an

SPN value between 3 and 6 indicated moderate resistance; and an

SPN value greater than 6 indicated poor gas channeling resistance.

2.7. Mechanical and Permeability Testing of Cement Stone

The mechanical strength of the cement stones was tested by an automatic compression and flexural mechanical testing machine (model COMPTEST3000, manufactured by Jinan Testing Equipment IE Corporation, Jinan, China). During the test, a loading rate of 71.1 kN/min was set, whereas for samples with a strength lower than 3.5 MPa, the loading rate was adjusted to 17.9 kN/min. The permeability and porosity of the cement stone samples (with dimensions of ∅25 mm × 100 mm) were tested using a pore and permeability tester (model CUG-KSLC-1701, manufactured by China University of Geosciences (CUG), Wuhan, China), employing the constant flow method. This process involved passing nitrogen gas through the sample and measuring the pressure difference between the inlet and outlet ends to determine the permeability and porosity values. The flow rate of the test gas was maintained at 2 mL/min.

3. Results and Discussion

3.1. Differences of Microbial Viability in Various Carriers

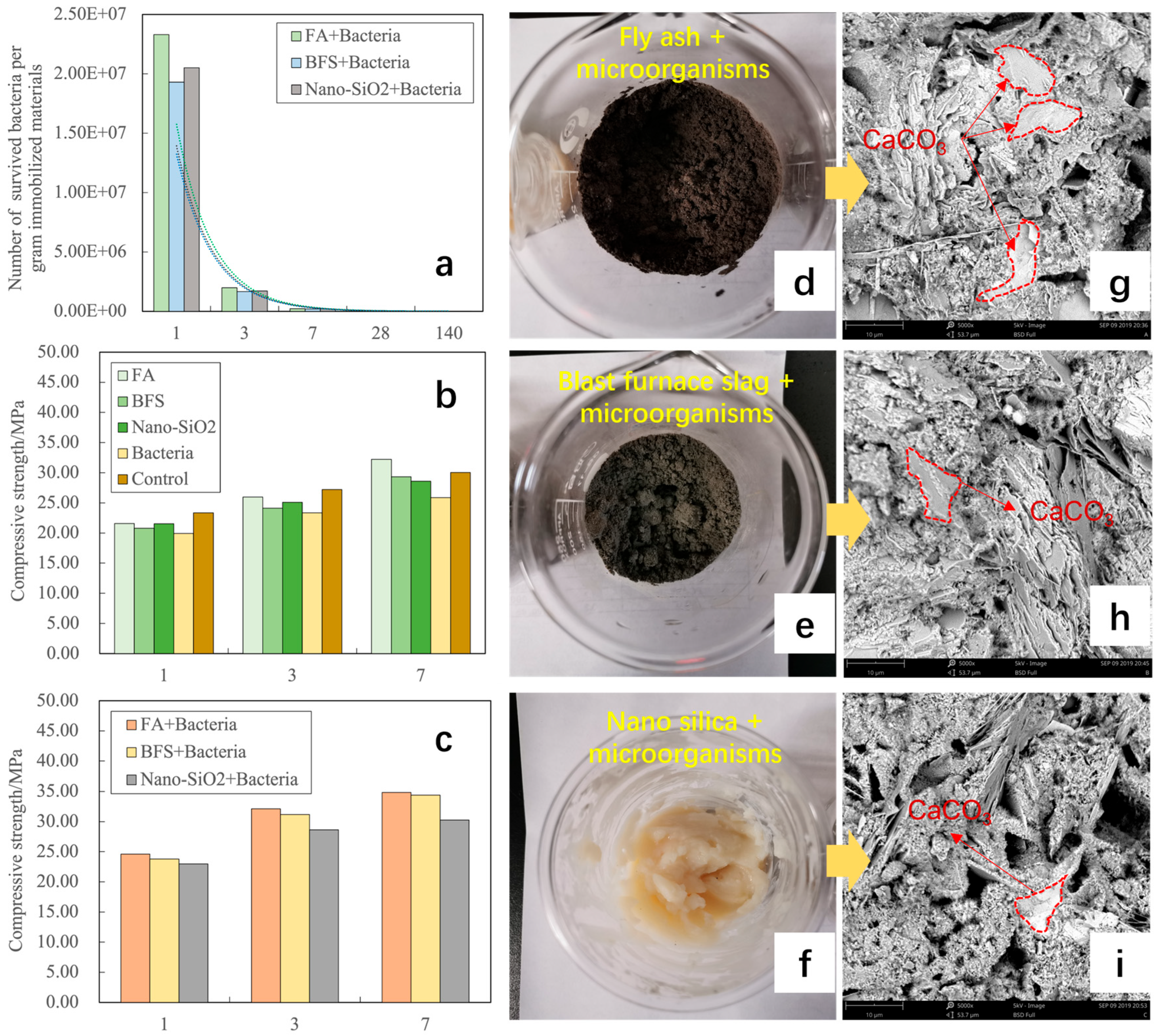

As shown in

Figure 2a, it can be observed that the number of viable microorganisms per unit mass of the carrier material decreases over time due to the lack of nutrient supplementation. Comparing the three carrier materials, the number of viable microorganisms in fly ash (FA) is significantly higher than that in blast furnace slag (BFS) and nano-silica (Nano-SiO

2), indicating that fly ash has a lesser impact on microbial viability. As seen in

Figure 2b, when the three microorganism-free carriers are added to the cement slurry at the same mass fraction, there is a decrease in the early compressive strength of the cement stone. Additionally, directly adding microbial broth to the cement slurry also results in a reduction in compressive strength. However, as illustrated in

Figure 2c, when microorganism-loaded carriers are added to the cement slurry, the cement stone exhibits a higher compressive strength compared to cement stone with microorganism-free carriers. Among these, the compressive strength of the cement stone with fly-ash-loaded microorganisms is the highest, indicating that fly-ash-loaded microorganisms have better compatibility with the cement slurry. Moreover, compared to directly adding microorganisms to the cement slurry, the cement stone formed by incorporating microorganism-loaded carrier materials shows a higher compressive strength, suggesting that the carriers provide protection for the microorganisms and are beneficial for improving microorganisms’ mineralization efficiency. Although the addition of microorganism-free carrier materials reduces the mechanical strength of the cement stone, this negative impact can be compensated for by microbial mineralization. It is evident that microbial mineralization plays a crucial role in enhancing the mechanical strength of the cement stone.

As depicted in

Figure 2d–f, it can be observed that under negative pressure, when the bacterial solution is mixed with fly ash (FA), the resulting sample is uniformly dispersed. However, when the bacterial solution is mixed with blast furnace slag (BFS), it tends to form clumps. Similarly, when mixed with nano-silica (Nano-SiO

2), the sample becomes damp and aggregates into lumps, which remain clumped and blocky even after drying. This non-uniform dispersion is not conducive to addition in the cement slurry and leads to issues with uneven microbial solid loading. Therefore, using fly ash as a carrier for microorganisms is more beneficial for achieving a uniform distribution within the carriers, which in turn helps to increase the number of microorganisms.

Figure 2g shows that the cement stone prepared with fly ash as the microbial carrier contains larger calcium carbonate crystal particles within the cement matrix. These large crystals fill the spaces between the cement hydration products and are wrapped in flake-like and flocculent materials, indicating good compatibility between the fly ash and the original cement slurry. In contrast,

Figure 2h reveals a reduction in flake-like crystals and the presence of a cluster of crystals within the cement stone. This clustering may be due to non-uniform microbial loading in the blast furnace slag, leading to locally higher concentrations of microorganisms and consequently, calcium carbonate crystal deposition in specific areas of the cement stone. In

Figure 2i, the surface of the calcium carbonate crystals is covered with numerous cement hydration products and nano-silica particles. Overall, the large specific surface area and porous nature of fly ash provide a suitable environment for microbial survival, which is conducive to microbial viability and calcium carbonate biomineralization.

3.2. Optimal Mass Ratio of Microorganisms in Fly Ash

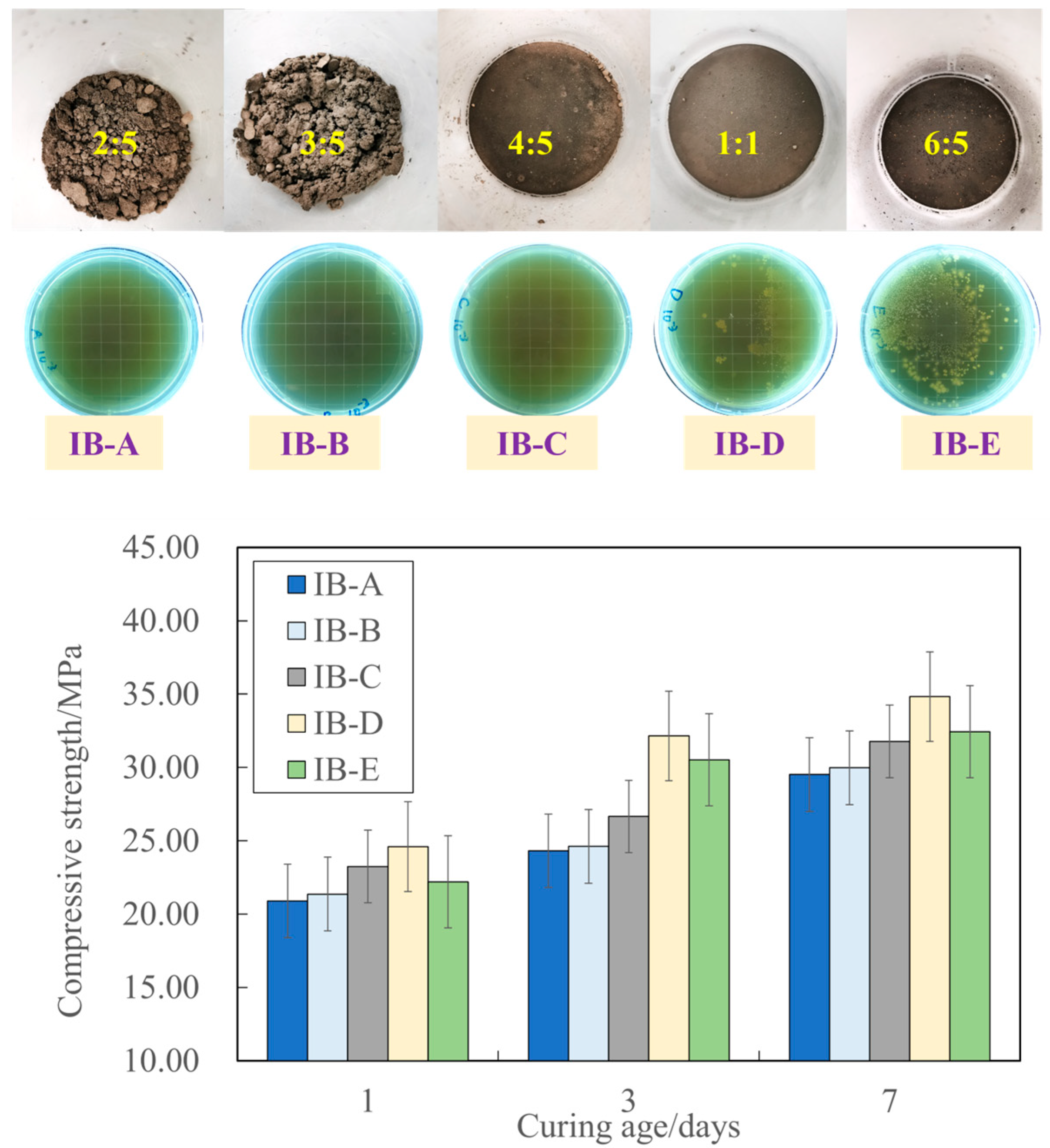

As shown in

Table 2, a higher concentration of bacterial solution in the carriers results in a greater number of viable microorganisms. However, a higher concentration of bacterial solution also increases the workload required for drying. As depicted in

Figure 3, when the mass ratio of bacterial solution to carrier is 0.4 and 0.6, fly ash is in excess and tends to form clumps. When the mass ratio is 1:1, the bacterial solution is close to saturation. When the mass ratio exceeds one, the microorganism-loaded carriers become uniform and dense, and the bacterial solution is slightly excessive.

Additionally, as shown in

Figure 3, after diluting the suspension of microorganism-loaded carriers and inoculating it onto a solid medium, it can be observed that as the mass ratio increases, the number of viable microbial colonies gradually increases. However, when the mass ratio is less than 1, virtually no colonies emerge after dilution and transfer to a solid medium. This indicates that at lower mass ratios, the number of viable microorganisms is smaller, and the microorganisms die more rapidly.

Furthermore, as shown in

Figure 3, with the extension of the curing age, the compressive strength of microbial cement stones with different mass ratios gradually increases. When the mass ratio is less than 1, the compressive strength of the cement stone increases with the increase in the mass ratio. However, when the mass ratio is too high, the excessive content of bacterial solution can adversely affect the compressive strength of the cement stone. Therefore, when the mass ratio is 1, it achieves a good loading effect while maintaining relatively high mechanical strength. An excessively high mass ratio is detrimental to the development of the mechanical strength of the cement stone.

3.3. Influence of Fly Ash Loaded with Microorganisms on the Properties of Cement Slurry

As

Table 3 indicates, the primary shortcoming of the basic cement slurry formulation is its high fluid loss, which compromises its resistance to gas and water channeling. Consequently, field applications have encountered issues with oil, gas, and water channeling. Furthermore, the simple addition of nutrients and urea to the basic cement slurry formulation leads to a significant prolongation of both setting and thickening times. This delay is detrimental to the development of cement stone strength. Moreover, fluid loss remains elevated, and the resistance to channeling does not improve; thus, the bonding quality at the secondary interface of well cementing is not enhanced.

The incorporation of alongside nutrients and urea into the well cement slurry results in a notable reduction in both setting and thickening times compared to the basic cement slurry formulation. Concurrently, this microbial mineralization action leads to decreased fluid loss and improved resistance to channeling. Furthermore, when fly ash, nutrients, and urea are simultaneously added to the basic well cement slurry formulation, the setting and thickening times are significantly shortened relative to the M-2 group. This observation suggests that the addition of fly ash accelerates the setting process, reduces fluid loss, and consequently enhances the slurry’s resistance to channeling.

A comparison between the M-5 and M-9 groups reveals a clear trend: as the concentration of microorganism-loaded carriers in the well cement slurry increases, both the setting and thickening times progressively decrease. Furthermore, an inverse relationship is observed between the concentration of microorganism-loaded carriers and the cement slurry’s resistance to channeling; higher concentrations yield stronger resistance. However, a potential drawback emerges when the concentration of microorganism-loaded carriers surpasses 4%. At this threshold, the setting time of the well cement slurry becomes excessively short, falling below 3 h, which is deemed impractical for field applications. Consequently, it is recommended that the concentration of microorganism-loaded carriers in the well cement slurry be maintained in the range of 2% to 4%.

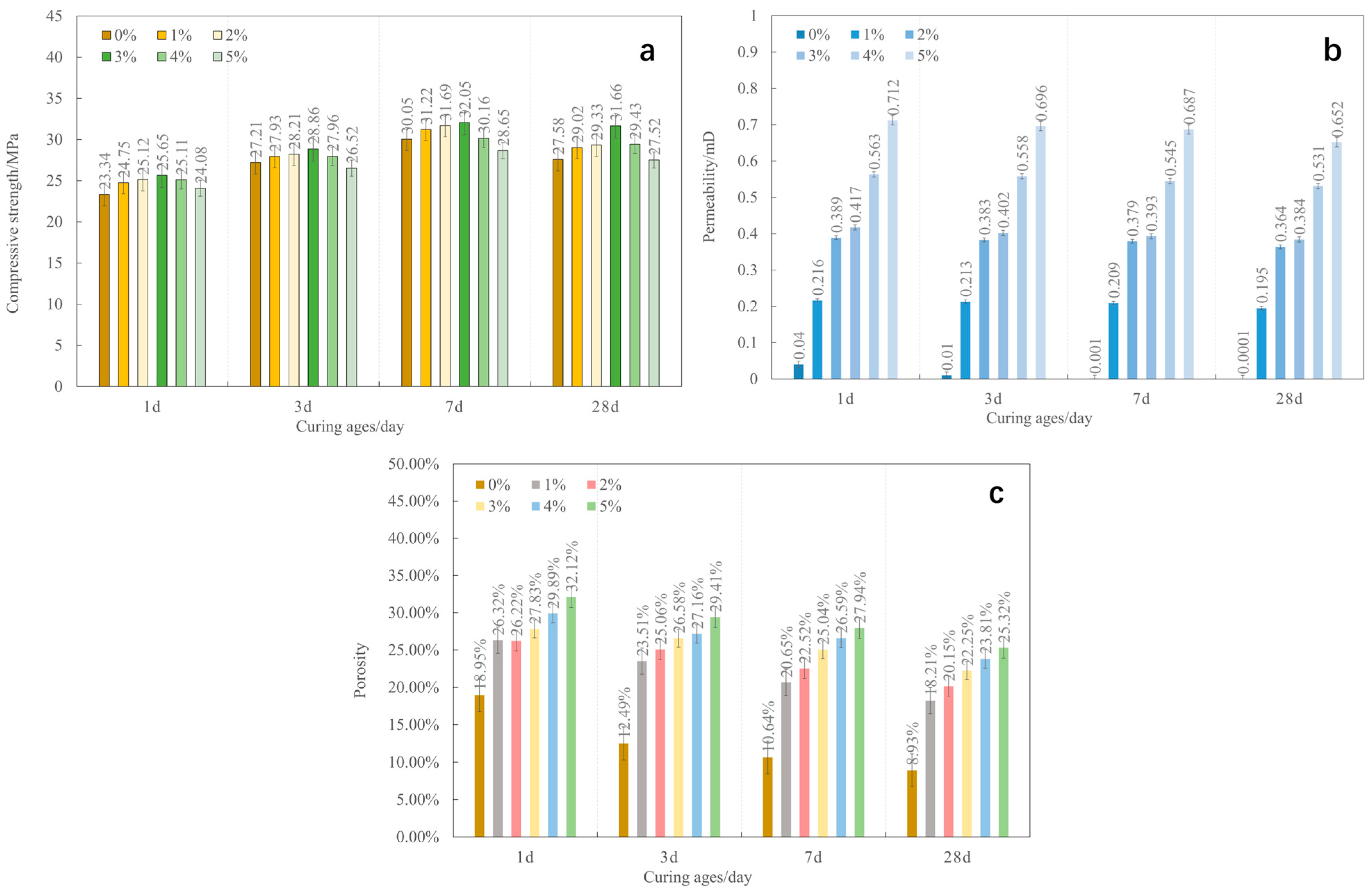

As

Figure 4a demonstrates, the mechanical strength of the well cement stone reaches its peak when the mass fraction of fly ash loaded with microorganisms in the well cement slurry is 3%. This optimal strength is achieved at the 7-day curing stage, although a subsequent decline is observed by the 28-day curing period, likely attributable to structural degradation occurring during the later stages of the curing process. Compared to the basic cement slurry group (M-1), the groups with microorganism-loaded carriers at concentrations ranging from 1% to 4% result in enhanced mechanical strength. However, exceeding a 1% concentration leads to an initial reduction in compressive strength compared to the basic cement slurry, indicating that an excessive introduction of microorganisms is detrimental to the early development of mechanical strength. Furthermore, the observed decrease in compressive strength is primarily attributed to the addition of nutrients and urea. Direct microbial addition to the well cement slurry also results in diminished mechanical strength, potentially because the microorganisms succumb rapidly during the cement slurry’s hydration process without the protective effect of carriers. Consequently, inefficient microbial mineralization occurs, and the deceased microorganisms negatively impact the strength development of the well cement slurry.

As depicted in

Figure 4b, the permeability of the basic cement slurry is 0.038 mD after one day of curing, decreasing gradually as the curing age extends. The addition of nutrients, urea, and microorganisms to the basic well cement slurry significantly reduces the permeability of the cement stone. Notably, when microorganisms are adsorbed onto the carriers prior to addition, the impermeability of the well cement stone is enhanced. Specifically, as the concentration of microorganism-loaded carriers increases, the permeability of the microbial well cement stone first decreases, reaching its lowest value at an addition of 3%. At this concentration, after 1 day of curing, the permeability is 0.005 mD, decreasing further to 0.001 mD after 3 days. However, when the addition exceeds 3%, the permeability of the cement stone begins to increase again, suggesting that excessive microorganism-loaded carriers have an adverse effect on the cement stone’s permeability. This indicates a nuanced relationship: while moderate amounts improve impermeability, excessive amounts can lead to increased permeability, potentially compromising the long-term effectiveness of the well cement stone.

Figure 4c illustrates that the introduction of nutrients, urea, and microorganisms tends to increase porosity of the cement stone, likely contributing to a reduction in its mechanical strength. Conversely, incorporating a microorganism-loaded carrier into the well cement slurry notably decreases the porosity of the resulting cement stone, thereby enhancing its compressive strength. With an increase in the concentration of microorganism-loaded carriers, the porosity of the cement stone correspondingly decreases, remaining similar at 3% and 4% concentrations. However, further increases in the concentrations of these carriers result in increased porosity, which is consistent with the observations in

Figure 4a, where excessive microorganism-loaded carriers led to increased porosity and a corresponding decrease in compressive strength. We hypothesize that this adverse effect stems from two primary factors. Firstly, an overload of microorganism-loaded carriers may reduce the relative proportion of traditional cementitious components within the stone, thereby decreasing its overall compressive strength. Secondly, a higher microbial content can lead to an excessive amount of gas produced during microbial metabolism, resulting in more residual bubbles being trapped within the cement matrix and thus increasing the cement stone’s porosity.

Furthermore,

Figure 4d highlights the impact of delivery method on microbial viability. Direct addition of microorganisms to the well cement slurry results in the lowest count of viable microorganisms. In contrast, increasing the proportion of microorganism-loaded carriers leads to a higher number of viable microorganisms within the cement stone. However, while a higher concentration of carriers enhances microbial viability, they can negatively impact both the mechanical strength and permeability of the cement stone. Consequently, considering all relevant parameters and performance indicators, it is recommended that the optimal concentration of microorganism-loaded carriers in the cement slurry should be within the range of 3% to 4%.

3.4. Performance of Calcium Chloride Microcapsules and Influence on the Properties of Well Cement Slurry

As illustrated in

Figure 5c,d, the initial release time for the sustained-release microcapsules is 255 min [

24]. This characteristic ensures that during the preparation and subsequent injection of the cement slurry, the microcapsules remain intact. Consequently, their active contents commence release only after the initial setting phase of the cement slurry has been achieved. This temporal control is crucial for preventing potential degradation of the cement slurry’s properties and averting blockages within the annulus during the grouting process, thereby meeting essential requirements for effective on-site well-cementing operations.

Figure 5a,b depicts the morphological characteristics of the sustained-release microcapsules, which are predominantly spherical. Furthermore, as shown in

Figure 5e, the calcium chloride sustained-release microcapsules employed in this study demonstrate a particle size distribution primarily ranging from 50 to 200 μm.

As shown in

Table 4, the incorporation of calcium chloride sustained-release microcapsules significantly improves the performance of the well cement slurry compared to the basic cement slurry formulation. Specifically, this modification results in a reduction in density, setting time, and thickening time, accompanied by a substantial decrease in fluid loss. These changes notably enhance the cement slurry’s resistance to gas channeling. Furthermore, an increase in the mass fraction of these microcapsules leads to a further reduction in both setting and thickening times, while fluid loss continues to decrease. The observed decrease in the SPN value further corroborates the enhanced gas channeling resistance. This performance improvement is primarily attributed to the release of calcium chloride, which acts as an accelerator, promoting earlier setting of the cement slurry. Consequently, a higher concentration of calcium chloride microcapsules corresponds to a shorter setting time. Additionally, since the density of the calcium chloride sustained-release microcapsules is lower than that of dry cementitious materials, increasing their proportion in the slurry results in a corresponding reduction in the overall density of the well cement slurry.

As

Figure 6a demonstrates, the incorporation of calcium chloride sustained-release microcapsules generally facilitates the development of compressive strength in the well cement slurry. This enhancement is primarily attributed to the release of calcium chloride, which promotes the early strength development of the cement stone. However, the beneficial effect is concentration-dependent, exhibiting an optimal point. Specifically, a 3% addition yields the maximum compressive strength. Beyond this optimal concentration, excessive microcapsules can lead to a reduction in compressive strength. This phenomenon can be explained by two main factors. Firstly, the inherently lower density of the microcapsules themselves contributes to a decrease in the overall density of the cement slurry, which may negatively impact the mechanical strength of the resulting cement stone. Secondly, an excessive release of calcium chloride can potentially detrimentally affect the cement slurry’s properties, further compromising its performance. Therefore, while the addition of these microcapsules improves compressive strength up to a certain limit, exceeding this optimal level can result in adverse consequences.

Figure 6b indicates that an increase in the mass fraction of calcium chloride sustained-release microcapsules correlates with an increase in the permeability of the well cement stone. This observed phenomenon is largely attributed to the particle size characteristics of the microcapsules. In this study, the average particle size of the calcium chloride sustained-release microcapsules (50 to 200 μm) is significantly larger than that of the constituent oil well cement. Consequently, this size discrepancy hinders effective bonding between the microcapsules and the cement’s hydration products during the consolidation process, leading to the formation of a non-uniform cement matrix. This poor interfacial bonding and resultant heterogeneity contribute to increased permeability, particularly when these microcapsules are added in excessive amounts. Thus, it is crucial to control the concentration of calcium chloride sustained-release microcapsules to prevent compromised cement stone integrity and performance due to elevated permeability.

As shown in

Figure 6c, increasing the addition of sustained-release microcapsules also leads to an increase in the porosity of the well cement stone. Notably, when the mass fraction of calcium chloride sustained-release microcapsules is maintained between 2% and 5%, the change in porosity is relatively minor. However, compared to the basic cement slurry formula, the porosity of the cement stone still increases by 7.42% to 17.3%. This increase in porosity is likely a contributing factor to the observed reduction in the cement stone’s impermeability. Considering the multifaceted impact of sustained-release microcapsules on the well cement slurry’s properties—encompassing both beneficial effects on mechanical strength and detrimental effects on permeability and potentially porosity—it is recommended that the optimal addition of calcium chloride sustained-release microcapsules should be controlled within the range of 2% to 3%. This concentration range is proposed to achieve a balance, maximizing the benefits of enhanced compressive strength while minimizing potential adverse effects on permeability and overall cement stone performance.

3.5. Influence of Microbial Self-Healing Agents on the Properties of Well Cement Slurry

Following the optimization of the optimal addition ranges for microorganism-loaded carriers (self-healing agent A) and calcium chloride sustained-release microcapsules (self-healing agent B) within the well cement slurry, this study investigates the combined effect of both agents on various cement slurry properties. These properties include compressive strength, permeability, porosity, and the simulated bonding strength and interfacial permeability at the secondary interface during cementing. The objective is to identify the optimal formulation for a microbial well cement slurry suitable for medium- and high-temperature environments.

As presented in

Table 5, the microbial well cement slurry prepared by combining microorganism-loaded carriers and calcium chloride sustained-release microcapsules exhibits initial setting times ranging from 300 to 330 min, which meet the requirements for cementing operations. The slurry demonstrates excellent pumpability, with final setting times between 400 and 500 min. This indicates that the compounded microbial well cement slurry possesses favorable right-angle thickening characteristics, thereby enhancing its resistance to channeling. Furthermore, the water loss of the compounded slurry is effectively controlled within 30 mL, satisfying field requirements. All SPN values are below 3, confirming the superior anti-channeling properties of the compounded slurry. Among the four tested formulations, the combination incorporating 3% microorganism-loaded carriers and 3% calcium chloride sustained-release microcapsules into the basic well cement slurry yields the lowest water loss and the shortest setting and thickening times. This suggests that this specific ratio optimizes the cement slurry’s performance concerning both mechanical properties and practical application suitability.

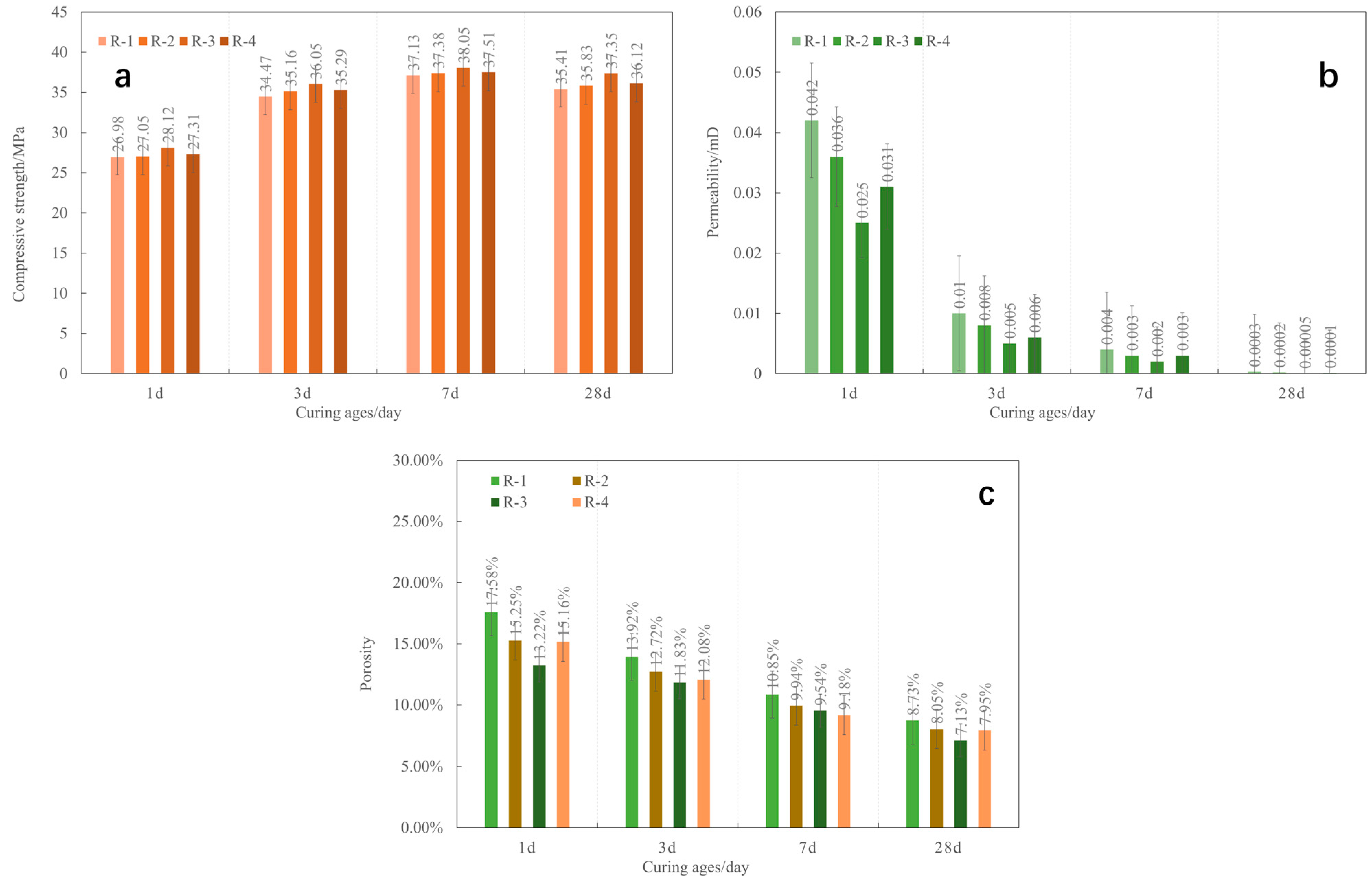

As shown in

Figure 7a, the mechanical strength of the compounded microbial well cement slurry exhibits a progressive increase with the extension of the curing age. Specifically, from 1 day to 3 days, the compressive strength of the cement stone increases by 7.49 MPa, 8.11 MPa, 7.93 MPa, and 7.98 MPa, respectively. Although the rate of strength gain decelerates between day three and day seven, with increments of 2.66 MPa, 2.22 MPa, 2.00 MPa, and 2.22 MPa, this further underscores the critical role of early-stage hydration in developing the primary mechanical framework. Our findings resonate with and significantly extend the pioneering work of Jonkers et al. [

45], who first established the potential for bacterial spores and nutrients to precipitate calcium carbonate crystals, thereby augmenting compressive strength.

Among the four tested formulations, the combination containing 3% microorganism-loaded carriers and 3% calcium chloride sustained-release microcapsules achieves the highest compressive strength, highlighting its superior structural integrity. Complementing the strength development, the cement stone’s permeability undergoes a marked reduction over time, with the most dramatic improvements occurring in the initial curing stages, as illustrated in

Figure 7b, which aligns with and surpass the reductions reported by Reinhardt et al. [

46] and Nguyen et al. [

47], who attributed permeability decline to calcium carbonate formation. Under identical curing conditions, the sample incorporating 3% microorganism-loaded carriers and 3% sustained-release microcapsules achieves the lowest permeability. This formulation’s permeability plummets from an initial 0.025 mD to an impressively low 0.002 mD after 7 days and further decreases to 5 × 10

−5 mD by day 28. This substantial decrease in permeability is directly linked to the enhanced sealing capability of the cement sheath, which is crucial for preventing fluid migration in oil and gas wells.

Furthermore, the porosity of the cement stone is effectively minimized as curing progresses. Initial porosity levels, ranging from 13% to 18% at day 1, are significantly lowered to 7% to 9% by day 28, as exhibited in

Figure 7c. This effective reduction in porosity, driven by both cement hydration and microbial mineralization processes, contributes synergistically to the observed decreases in permeability and the enhancement of compressive strength, which is similar to the results in the references [

48,

49,

50,

51]. Collectively, these data underscore the excellent characteristics of the developed microbial self-healing cement system, showing its potential to significantly improve the long-term integrity and performance of well cement sheaths by simultaneously enhancing mechanical strength, reducing permeability, and lowering porosity.

3.6. Characteristics of Internal Pore Morphology in Microbial Well Cement Stone

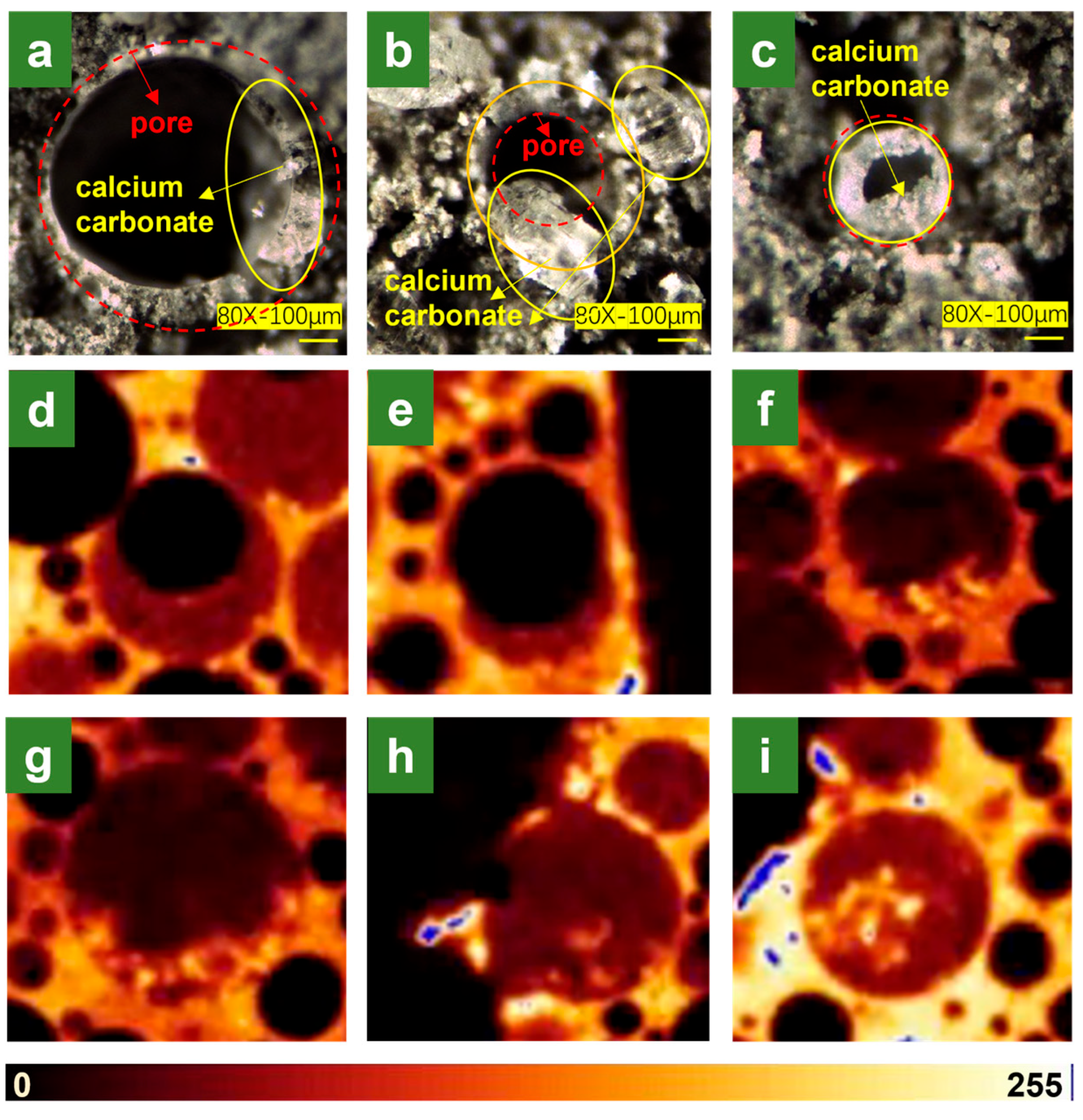

As depicted in

Figure 8a–c, mineralized products are observed within the internal pores of the microbial well cement stone. Larger crystals are embedded in the cement hydration products surrounding these pores. Furthermore, more prominent spherical sedimentary crystal structures with hollow interiors are evident, suggesting a propensity for microbial mineralization to favor spherical crystal formation. However, due to the small pore sizes in the original microbial well cement stone and the limited resolution of CT scans, direct observation of mineralization product distribution within the pores using CT alone is challenging. To overcome this limitation, a foaming agent was incorporated into the microbial well cement slurry in this study, resulting in a porous microbial well cement stone with artificially enlarged pore sizes. This modification facilitated the visualization of mineralization product growth within the pores under the achievable CT resolution.

Figure 8d–i illustrate the process: during the early stages of curing, external water penetrates the larger pores through interconnected pathways. Subsequently, a portion of this water migrates into the cement matrix and adjacent pores. Over time, precipitation commences within the pores, initiating at the base where initial crystal deposition occurs. The mineralization product crystals then grow upwards towards the pore centers, gradually filling the voids.

3.7. Self-Healing Mechanism of Micro-Pores in Microbial Well Cement Slurry

As illustrated in

Figure 9a, microorganisms within the cement stone contribute additional calcium sources and nutrients through their metabolic activities. Concurrently, upon contact with water, the sustained-release microcapsules release calcium chloride and nutrients. The carbonate ions generated by microbial metabolism within the cement matrix subsequently react with the released calcium ions to form calcium carbonate precipitates, thereby facilitating the autogenous healing of internal pores within the well cement stone.

Based on CT scan results, the deposition pattern of mineralized products within the internal pores of the cement stone can be inferred (

Figure 9a–g). Following water intrusion, a portion of the fluid flows through the pore throats, initiating pore filling. Due to gravitational forces, the fluid initially accumulates at the bottom of the pores and gradually fills the entire pore. Some of this fluid penetrates the cement matrix, triggering the sustained-release microcapsules within the microbial well cement stone to release more calcium chloride and nutrients. Simultaneously, provided sufficient nutrients and water are available, the microorganisms become activated, metabolize, and produce carbonate ions.

These carbonate ions then combine with the released calcium ions to precipitate calcium carbonate crystals, which occupy the pores and throats of the cement stone. Initially, these crystals adhere to the inner walls and bases of the pores. Given that crystal growth tends to occur in less obstructed regions, the calcium carbonate crystals gradually extend from the pore walls towards the central open spaces, ultimately filling the entire void. The formation of calcium carbonate crystals around the pores not only fills the pores but also exerts compressive forces on the surrounding cement hydration products, thereby enhancing the overall density of the cement stone.

4. Limitations and Prospects

This study introduces the utilization of fly ash as a carrier for microorganisms, aligning with the broader industrial trend towards the sustainable reuse of solid waste. This approach not only leverages microbial carbon fixation for potential carbon sequestration benefits but also lays a technical foundation for decarbonization efforts within the oil and gas sector. Moreover, the findings presented in this paper are anticipated to contribute significantly to mitigating the risk of annulus failure in critical well types, including deep wells, shale gas wells, and geothermal wells, thereby supporting the safe and efficient extraction of complex oil and gas resources.

While the compounding experiments have successfully identified an optimal range for the concentrations of the microbial self-healing agents, a more precise quantitative analysis of the impact of minor variations in component ratios on the overall cement slurry properties remains lacking. Future investigations could benefit from the application of advanced mathematical modeling techniques, such as Response Surface Methodology (RSM), to further refine the proportions of each constituent. This approach would likely yield a more finely tuned and balanced performance profile for the cement system. Additionally, although the current sustained-release microcapsule technology satisfies the fundamental timing requirements for field cementing applications, there is scope for improvement in the precision of release kinetics. Developing more sophisticated, intelligent, and precisely controlled sustained-release technologies could better synchronize the release of calcium sources and nutrients with the actual degradation rates of the cement sheath, thereby enhancing the overall effectiveness of the self-healing process. To deepen the mechanistic understanding of self-healing, multi-scale research incorporating in-situ characterization techniques, such as micro-CT and atomic force microscopy (AFM), is imperative. These advanced tools enable quantitative analysis of crystal growth kinetics and facilitate the development of cross-scale models linking pore-scale repair mechanisms to macroscopic mechanical property enhancements.

Future research should endeavor to broaden the scope of simulated geological environments to encompass a wider array of complex in-situ conditions, including variations in formation pressure, temperature gradients, and other pertinent environmental factors. Such an expansion would facilitate a more comprehensive assessment of the cement slurry system’s adaptability across diverse real-world scenarios. Furthermore, there is a clear need to enhance the monitoring protocols for microorganism survival rates and metabolic activity over extended durations within simulated subsurface environments to fully capture the long-term self-healing potential of the microbial system throughout the multi-year lifecycle of oil and gas extraction operations.