Low-Carbon Insulating Geopolymer Binders: Thermal Properties

Abstract

1. Introduction

- High foaming (high porosity and low density);

- Improved insulating properties—thanks to additives with low thermal conductivity and the avoidance of heavy, inactive fillers;

- Maintaining adequate structural stability and durability;

- Compliance with sustainability principles.

2. Materials

2.1. Co-Forming Materials of Geopolymer Foams

2.2. Manufacture of Geopolymer Foams

3. Methods

3.1. Mechanical Properties of Geopolymer Foams

3.2. Thermal Properties of Geopolymer Foams

3.3. Morphology of Geopolymer Foams

4. Results

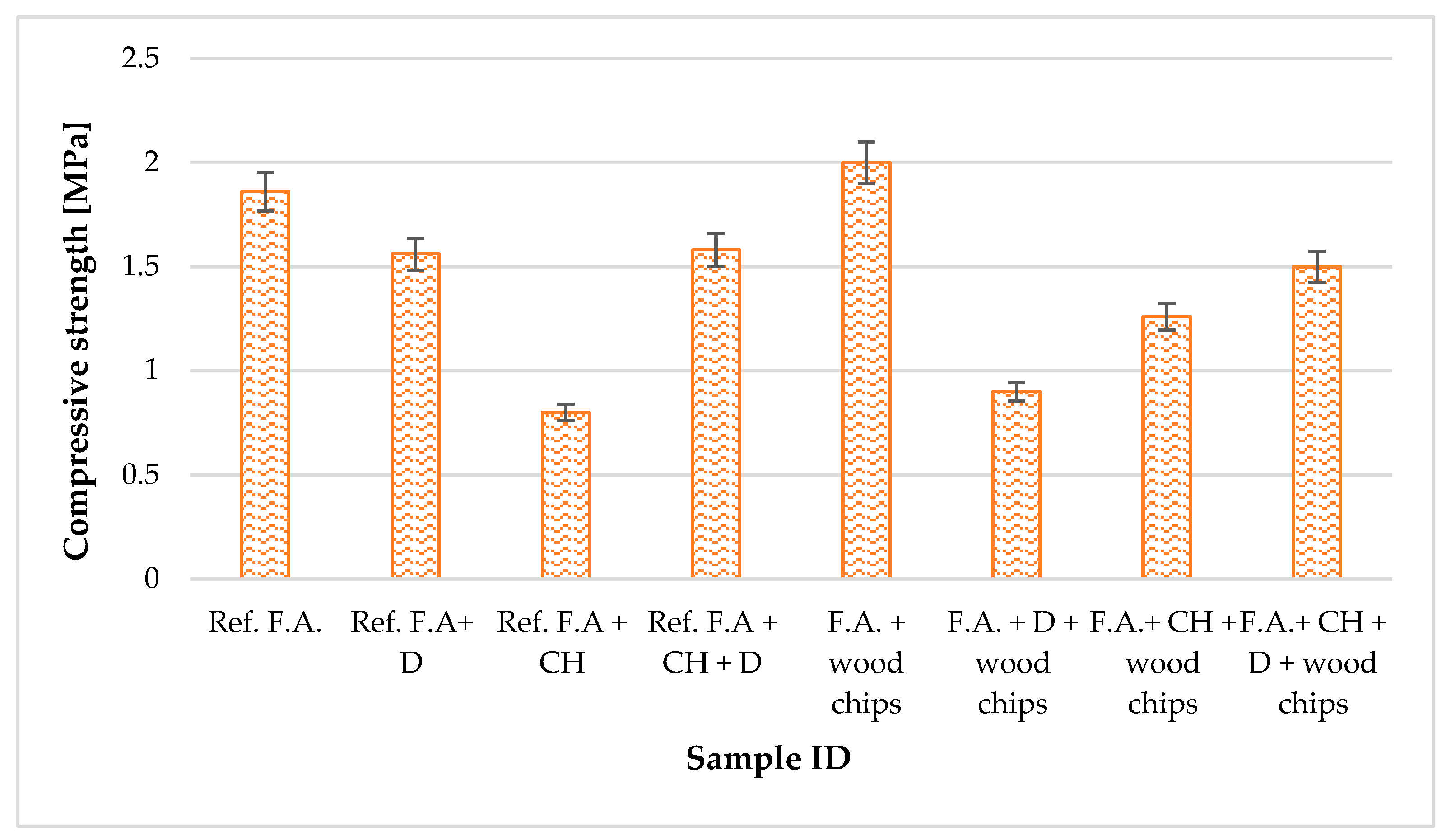

4.1. Mechanical Properties of Geopolymer Foams

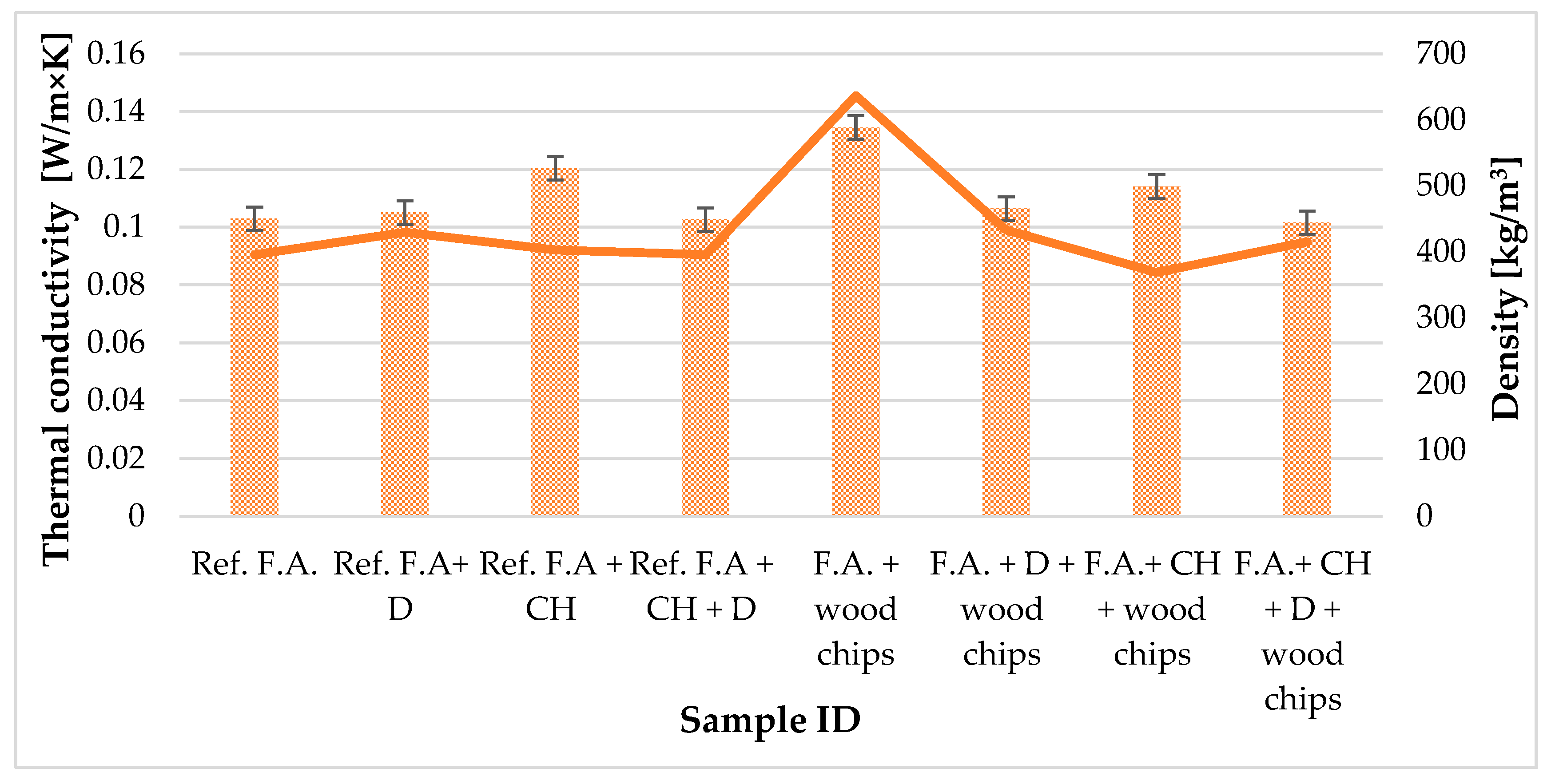

4.2. Thermal Properties of Geopolymer Foams

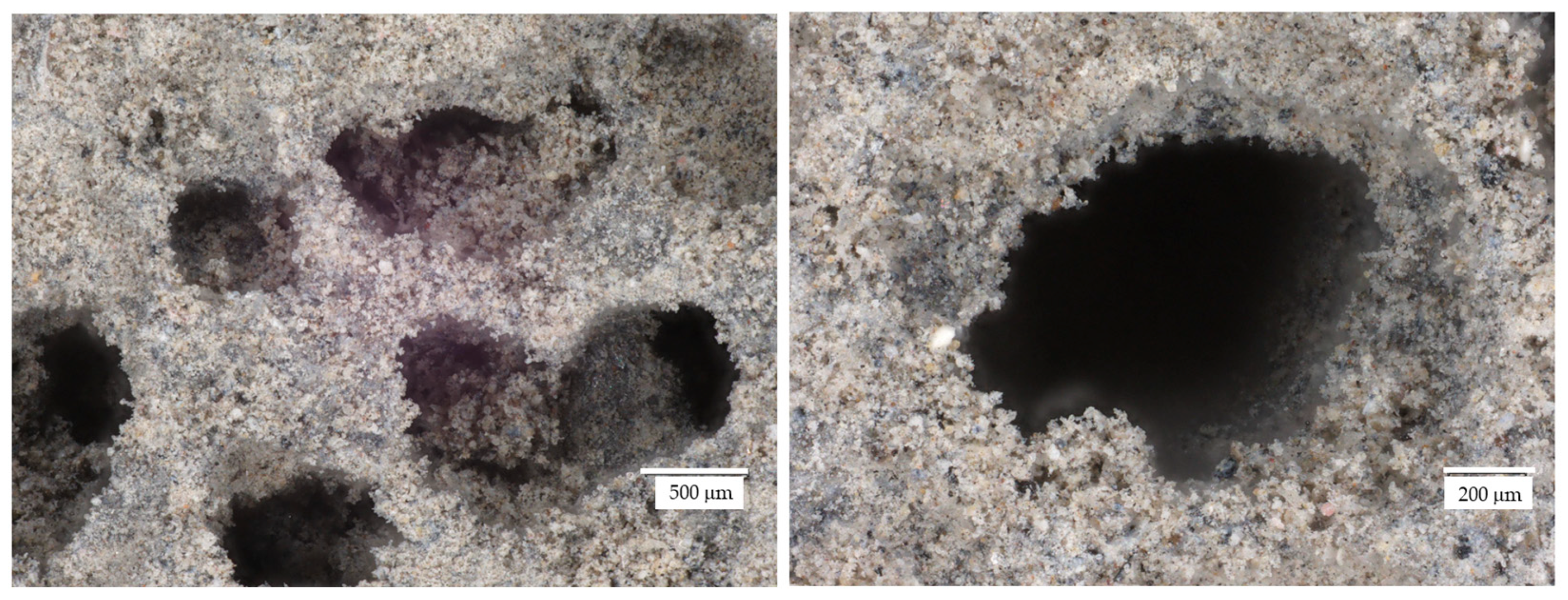

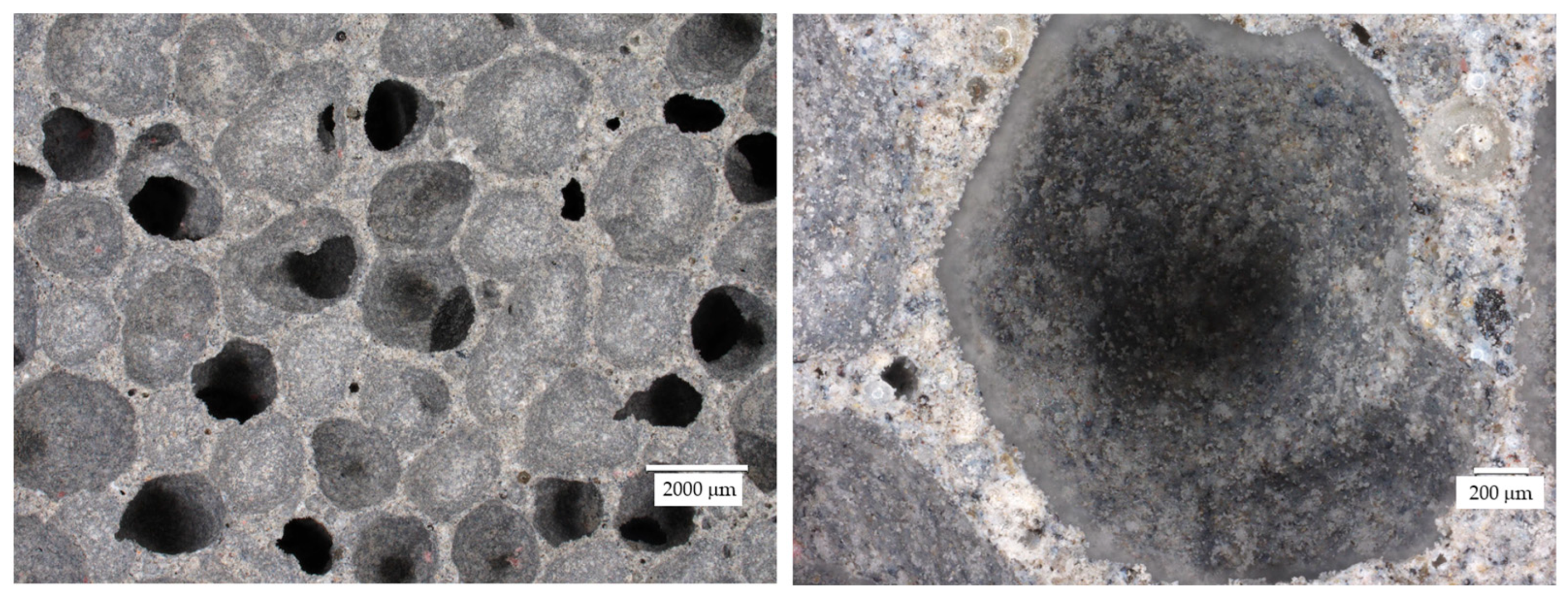

4.3. Morphology of Geopolymer Foams

5. Discussion

- −

- 0.90 kg CO2/kg for Portland cement (for comparison);

- −

- 0.85–0.95 kg CO2/kg for high alumina cement;

- −

- 0.10–0.15 kg CO2/kg for natural mineral additives (diatomite, chalcedonite);

- −

- ~0.02 kg CO2/kg for fly ash (as waste);

- −

- ~0.20–0.30 kg CO2/kg for microspheres (due to processing);

- −

- ~0.05–0.10 kg CO2/kg for organic additives (e.g., wood wool).

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rath, P.; Jindal, M.; Jindal, T. A review on economically-feasible and environmental-friendly technologies promising a sustainable environment. Clean. Eng. Technol. 2021, 5, 100318. [Google Scholar] [CrossRef]

- Zhong, Z.W. Processes for environmentally friendly and/or cost-effective manufacturing. Mater. Manuf. Process. 2021, 36, 987–1009. [Google Scholar] [CrossRef]

- Mariotti, N.; Bonomo, M.; Fagiolari, L.; Barbero, N.; Gerbaldi, C.; Bella, F.; Barolo, C. Recent advances in eco-friendly and cost-effective materials towards sustainable dye-sensitized solar cells. Green Chem. 2020, 22, 7168–7218. [Google Scholar] [CrossRef]

- Qureshi, F.; Yusuf, M.; Kamyab, H.; Vo, D.N.; Chelliapan, S.; Joo, S.; Vasseghian, Y. Latest eco-friendly avenues on hydrogen production towards a circular bioeconomy: Currents challenges, innovative insights, and future perspectives. Renew. Sustain. Energy Rev. 2022, 168, 112916. [Google Scholar] [CrossRef]

- Ncube, A.; Mtetwa, S.; Bukhari, M.; Fiorentino, G.; Passaro, R. Circular Economy and Green Chemistry: The Need for Radical Innovative Approaches in the Design for New Products. Energies 2023, 16, 1752. [Google Scholar] [CrossRef]

- Celerier, H.; Jouin, J.; Tessier-Doyen, N.; Rossignol, S. Influence of various metakaolin raw materials on the water and fire resistance of geopolymers prepared in phosphoric acid. J. Non-Cryst. Solids 2018, 500, 493–501. [Google Scholar] [CrossRef]

- Klima, K.; Schollbach, K.; Brouwers, H.; Yu, Q. Thermal and fire resistance of Class F fly ash based geopolymers—A review. Constr. Build. Mater. 2022, 323, 126529. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Z.; Zhou, J.; Du, R.; Yin, X.; Kang, S.; Zheng, Y.; Liu, Y. Thermal behavior and mechanism study of geopolymers prepared from ferronickel slag with high fire resistance. Constr. Build. Mater. 2024, 438, 137282. [Google Scholar] [CrossRef]

- Fan, F.; Liu, Z.; Xu, G.; Peng, H.; Cai, C. Mechanical and thermal properties of fly ash based geopolymers. Constr. Build. Mater. 2018, 160, 66–81. [Google Scholar] [CrossRef]

- Goryunova, K.; Gahramanli, Y.; Muradkhanli, V.; Nadirov, P. Phosphate-activated geopolymers: Advantages and application. RSC Adv. 2023, 13, 30329–30345. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Ruan, S.; Zeng, Q.; Liu, Y.; Zhang, M.; Tian, Y.; Yan, D. Pore structure of geopolymer materials and its correlations to engineering properties: A review. Constr. Build. Mater. 2022, 328, 127064. [Google Scholar] [CrossRef]

- Yalcinkaya, B.; Spirek, T.; Bousa, M.; Louda, P.; Růžek, V.; Rapiejko, C.; Buczkowska, K.E. Unlocking the Potential of Biomass Fly Ash: Exploring Its Application in Geopolymeric Materials and a Comparative Case Study of BFA-Based Geopolymeric Concrete against Conventional Concrete. Ceramics 2023, 6, 1682–1704. [Google Scholar] [CrossRef]

- Ji, Z.; Zhang, G.; Liu, R.; Qu, J.; Liu, H. Potential applications of solid waste-based geopolymer materials: In wastewater treatment and greenhouse gas emission reduction. J. Clean. Prod. 2024, 443, 141144. [Google Scholar] [CrossRef]

- Qin, Z.; Yuan, Y.; Chen, Z.; Li, Y.; Xia, Y. Combined preparation and application of geopolymer pavement materials from coal slurry-slag powder-fly ash mining solid waste: A case study. Constr. Build. Mater. 2024, 441, 137510. [Google Scholar] [CrossRef]

- Shakouri, S.; Bayer, Ö.; Erdoğan, S.T. Development of silica fume-based geopolymer foams. Constr. Build. Mater. 2020, 260, 120442. [Google Scholar] [CrossRef]

- Hajimohammadi, A.; Ngo, T.; Provis, J.L.; Kim, T.; Vongsvivut, J. High strength/density ratio in a syntactic foam made from one-part mix geopolymer and cenospheres. Compos. Part B Eng. 2019, 173, 106908. [Google Scholar] [CrossRef]

- Nodehi, M. A comparative review on foam-based versus lightweight aggregate-based alkali-activated materials and geopolymer. Innov. Infrastruct. Solut. 2021, 6, 231. [Google Scholar] [CrossRef]

- Liang, G.; Liu, T.; Li, H.; Dong, B.; Shi, T. A novel synthesis of lightweight and high-strength green geopolymer foamed material by rice husk ash and ground-granulated blast-furnace slag. Resour. Conserv. Recycl. 2021, 176, 105922. [Google Scholar] [CrossRef]

- Alnahhal, A.M.; Alengaram, U.J.; Yusoff, S.; Darvish, P.; Srinivas, K.; Sumesh, M. Engineering performance of sustainable geopolymer foamed and non-foamed concretes. Constr. Build. Mater. 2022, 316, 125601. [Google Scholar] [CrossRef]

- Ricciotti, L.; Occhicone, A.; Petrillo, A.; Ferone, C.; Cioffi, R.; Roviello, G. Geopolymer-based hybrid foams: Lightweight materials from a sustainable production process. J. Clean. Prod. 2020, 250, 119588. [Google Scholar] [CrossRef]

- Li, X.; Bai, C.; Qiao, Y.; Wang, X.; Yang, K.; Colombo, P. Preparation, properties and applications of fly ash-based porous geopolymers: A review. J. Clean. Prod. 2022, 359, 132043. [Google Scholar] [CrossRef]

- Hajimohammadi, A.; Ngo, T.; Kashani, A. Sustainable one-part geopolymer foams with glass fines versus sand as aggregates. Constr. Build. Mater. 2018, 171, 223–231. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, F.; Liu, M.; Hu, X. Novel sustainable geopolymer based syntactic foams: An eco-friendly alternative to polymer based syntactic foams. Chem. Eng. J. 2017, 313, 74–82. [Google Scholar] [CrossRef]

- Ibrahim, J.F.; Şahin, E.İ.; Kabatas, M.A.B.M.; Géber, R.; Kocserha, I. Sustainable fabrication of lightweight geopolymer foams from silica-fume and zeolite tuffs: Utilizing Al as foaming agent for thermal insulation. Case Stud. Constr. Mater. 2024, 21, e04024. [Google Scholar] [CrossRef]

- Łach, M. Geopolymer Foams—Will They Ever Become a Viable Alternative to Popular Insulation Materials?—A Critical Opinion. Materials 2021, 14, 3568. [Google Scholar] [CrossRef]

- Zawrah, M.; Sadek, H.; Ngida, R.E.; Sawan, S.; El-Kheshen, A. Effect of low-rate firing on physico-mechanical properties of unfoamed and foamed geopolymers prepared from waste clays. Ceram. Int. 2022, 48, 11330–11337. [Google Scholar] [CrossRef]

- Cavalieri, M.; Ferrara, P.L.; Finocchiaro, C.; Martorana, M.F. An Economic Analysis of the Use of Local Natural Waste: Volcanic Ash of Mt. Etna Volcano (Italy) for Geopolymer Production. Sustainability 2024, 16, 740. [Google Scholar] [CrossRef]

- Occhipinti, R.; Portale, S.; Lanzafame, G.; Gimeno, D.; Prašek, M.K.; Mazzoleni, P.; Barone, G. Alkali activated materials from Tajogaite volcanic ash (La Palma, Spain): A green recovery after the 2021 eruption. Volcanica 2024, 7, 421–980. [Google Scholar] [CrossRef]

- Yatsenko, E.A.; Goltsman, B.M.; Izvarin, A.I.; Kurdashov, V.M.; Ryabova, A.V. Influence of foaming additives on the porous structure and properties of lightweight geopolymers based on ash–slag waste. Constr. Build. Mater. 2024, 443, 137629. [Google Scholar] [CrossRef]

- Lori, A.R.; Novais, R.M.; Ascensão, G.; Fernandes, F.; Ranjbar, N.; Spangenberg, J. Chemically foamed geopolymers for 3D printing applications. Cem. Concr. Compos. 2025, 161, 106116. [Google Scholar] [CrossRef]

- Gadkar, A.; Subramaniam, K.V. Porosity and pore structure control in cellular geopolymer using rheology and surface tension modifiers. Constr. Build. Mater. 2022, 323, 126600. [Google Scholar] [CrossRef]

- Dos Santos, M.N.G.; Dos Santos, C.M.; De Souza, M.T.G.; De Vasconcelos, E.A.; Da Nóbrega, A.C.V.; Marinho, É.P. Use of sodium metasilicate as silica source and stabilizing agent in two-part metakaolin–H2O2 geopolymer foams. Constr. Build. Mater. 2023, 391, 131907. [Google Scholar] [CrossRef]

- Phavongkham, V.; Wattanasiriwech, S.; Cheng, T.; Wattanasiriwech, D. Effects of surfactant on thermo-mechanical behavior of geopolymer foam paste made with sodium perborate foaming agent. Constr. Build. Mater. 2020, 243, 118282. [Google Scholar] [CrossRef]

- Wattanasiriwech, D.; Yomthong, K.; Wattanasiriwech, S. Characterisation and properties of class C-fly ash based geopolymer foams: Effects of foaming agent content, aggregates, and surfactant. Constr. Build. Mater. 2021, 306, 124847. [Google Scholar] [CrossRef]

- Novais, R.M.; Pullar, R.; Labrincha, J.A. Geopolymer foams: An overview of recent advancements. Prog. Mater. Sci. 2020, 109, 100621. [Google Scholar] [CrossRef]

- Shao, N.; Dong, C.; Wei, X.; Su, Y.; Dong, Z.; Zhang, Z. Quantitative characterization and control mechanism of pore structure in geopolymer foams with addition of various surfactants. Cem. Concr. Compos. 2024, 149, 105522. [Google Scholar] [CrossRef]

- Gao, R.; Zhou, Z.; Chen, K.; Hu, X.; Jia, H.; Zhang, H.; Han, L. Mechanisms of the effect of surfactant types on the pore structure feature and properties of geopolymer foams. Constr. Build. Mater. 2025, 458, 139696. [Google Scholar] [CrossRef]

- Wang, X.; Wu, Y.; Li, X.; Li, Y.; Tang, W.; Dan, J.; Hong, C.; Wang, J.; Yang, X. Effect of Triterpenoid Saponins as Foaming Agent on Mechanical Properties of Geopolymer Foam Concrete. Materials 2024, 17, 3921. [Google Scholar] [CrossRef]

- Yan, S.; Ren, X.; Wang, W.; He, C.; Xing, P. Preparation of eco-friendly porous ceramic with low thermal conductivity by high-temperature treatment of foamed solid waste based geopolymer with cenospheres. Constr. Build. Mater. 2023, 398, 131190. [Google Scholar] [CrossRef]

- Gadkar, A.; Subramaniam, K.V. Tailoring porosity and pore structure of cellular geopolymers for strength and thermal conductivity. Constr. Build. Mater. 2023, 393, 132150. [Google Scholar] [CrossRef]

- Soe, P.S.; Sornlar, W.; Wannagon, A.; Chaysuwan, D. Mechanical and thermal properties of bottom ash-based porous geopolymer as thermal insulation material for construction. J. Mater. Cycles Waste Manag. 2023, 25, 2964–2975. [Google Scholar] [CrossRef]

- Dong, C.; Shao, N.; Yan, F.; Ji, R.; Wei, X.; Zhang, Z. A novel integration strategy for the foaming and hydrophobization of geopolymer foams. Cem. Concr. Res. 2022, 160, 106919. [Google Scholar] [CrossRef]

- Li, Y.; Maimait, A.; Cheng, J.; Duan, Y.; Chen, Y.; Dong, H. Properties of Fiber-Reinforced Geopolymer Mortar Using Coal Gangue and Aeolian Sand. Materials 2024, 17, 3225. [Google Scholar] [CrossRef]

- Kotwa, A.; Ramiączek, P.; Bąk-Patyna, P.; Kowalik, R. Parameters of Concrete Modified with Micronized Chalcedonite. Materials 2023, 16, 3602. [Google Scholar] [CrossRef] [PubMed]

- Spychał, E.; Vyšvařil, M. Physico-Mechanical Properties and Hydration Processes of Cement Pastes Modified with Pumice, Trass and Waste Chalcedonite Powder. Materials 2024, 17, 236. [Google Scholar] [CrossRef] [PubMed]

- Walbrück, K.; Maeting, F.; Witzleben, S.; Stephan, D. Natural Fiber-Stabilized Geopolymer Foams—A Review. Materials 2020, 13, 3198. [Google Scholar] [CrossRef]

- Koh, C.H.; Luo, Y.; Gauvin, F.; Schollbach, K. Utilization of geopolymer in wood wool insulation boards: Design optimization, development and performance characteristics. Resour. Conserv. Recycl. 2024, 204, 107510. [Google Scholar] [CrossRef]

- Pavlík, Z.; Vyšvařil, M.; Pavlíková, M.; Žižlavský, T.; Záleská, M.; Pivák, A. Lightweight mortars with chalcedonite—Towards functional and durable Materials for repair of historical masonry. J. Build. Eng. 2023, 79, 107841. [Google Scholar] [CrossRef]

- Minelli, M.; Medri, V.; Papa, E.; Miccio, F.; Landi, E.; Doghieri, F. Geopolymers as solid adsorbent for CO2 capture. Chem. Eng. Sci. 2016, 148, 267–274. [Google Scholar] [CrossRef]

- Chen, H.; Dong, S.; Zhang, Y.; He, P. Robust structure regulation of geopolymer as novel efficient amine support to prepare high-efficiency CO2 capture solid sorbent. Chem. Eng. J. 2021, 427, 131577. [Google Scholar] [CrossRef]

- Minelli, M.; Papa, E.; Medri, V.; Miccio, F.; Benito, P.; Doghieri, F.; Landi, E. Characterization of novel geopolymer—Zeolite composites as solid adsorbents for CO2 capture. Chem. Eng. J. 2018, 341, 505–515. [Google Scholar] [CrossRef]

- Turner, L.K.; Collins, F.G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Al-Fakih, A.; Al-wajih, E.; Saleh, R.A.A.; Muhit, I.B. Ensemble machine learning models for predicting the CO2 footprint of GGBFS-based geopolymer concrete. J. Clean. Prod. 2024, 472, 143463. [Google Scholar] [CrossRef]

- Baziak, A.; Pławecka, K.; Hager, I.; Castel, A.; Korniejenko, K. Development and Characterization of Lightweight Geopolymer Composite Reinforced with Hybrid Carbon and Steel Fibers. Materials 2021, 14, 5741. [Google Scholar] [CrossRef] [PubMed]

- Crusil sp. z o.o. Available online: https://crusil.pl/o-chalcedonicie/ (accessed on 5 June 2025).

- Provis, J.L.; van Deventer, J.S.J. Geopolymers: Structures, Processing, Properties and Industrial Applications; Woodhead Publishing: Cambridge, UK, 2009. [Google Scholar]

- Bąk, A.; Pławecka, K.; Bazan, P.; Łach, M. Influence of the addition of phase change materials on thermal insulation properties of foamed geopolymer structures based on fly ash. Energy 2023, 278, 127624. [Google Scholar] [CrossRef]

- Przybek, A.; Łach, M. Insulating Innovative Geopolymer Foams with Natural Fibers and Phase-Change Materials—A Review of Solutions and Research Results. Materials 2024, 17, 4503. [Google Scholar] [CrossRef]

- PN-EN 196-1; Methods of Testing Cement—Part 1: Determination of Strength. Committee for Standardization: Warsaw, Poland, 2016.

- ASTM C1784; Standard Test Method for Using a Heat Flow Meter Apparatus for Measuring Thermal Storage Properties of Phase Change Materials and Products. International American Society for Testing of Materials: West Conshohocken, PA, USA, 2020.

- ASTM C518; Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus. International American Society for Testing of Materials: West Conshohocken, PA, USA, 2021.

- ISO 8301; Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Heat Flow Meter Apparatus. International Standards Organization: London, UK, 1991.

- EN 12664; Thermal Performance of Building Materials and Products. Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods. Dry and Moist Products of Medium and Low Thermal Resistance. European Committee for Standardization: Brussels, Belgium, 2001.

- Yang, Y.; Chen, S. Thermal insulation solutions for opaque envelope of low-energy buildings: A systematic review of methods and applications. Renew. Sustain. Energy Rev. 2022, 167, 112738. [Google Scholar] [CrossRef]

- Giuma, A.S.; Abdul Khalil, H.P.; Yahya, E.B.; Sukeksi, L.; Alfatah, T.; Nurazzi, N.M.; Jaber, M.; Surya, I. Green thermal insulators: A review into the role of biopolymer-based aerogels in thermal insulation applications. Polym. Eng. Sci. 2024, 64, 4611–4629. [Google Scholar] [CrossRef]

- Wiprächtiger, M.; Haupt, M.; Heeren, N.; Waser, E.; Hellweg, S. A framework for sustainable and circular system design: Development and application on thermal insulation materials. Resour. Conserv. Recycl. 2020, 154, 104631. [Google Scholar] [CrossRef]

- Ali, A.; Issa, A.; Elshaer, A. A Comprehensive Review and Recent Trends in Thermal Insulation Materials for Energy Conservation in Buildings. Sustainability 2024, 16, 8782. [Google Scholar] [CrossRef]

- Przybek, A.; Łach, M.; Bogucki, R.; Ciemnicka, J.; Prałat, K.; Koper, A.; Korniejenko, K.; Masłoń, A. Energy-Efficient Geopolymer Composites Containing Phase-Change Materials—Comparison of Different Contents and Types. Materials 2024, 17, 4712. [Google Scholar] [CrossRef]

- Korniejenko, K.; Mikuła, J.; Brudny, K.; Aruova, L.; Zhakanov, A.; Jexembayeva, A.; Zhaksylykova, L. A Review of Industrial By-Product Utilization and Future Pathways of Circular Economy: Geopolymers as Modern Materials for Sustainable Building. Sustainability 2025, 17, 4536. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Palomo, A.; Criado, M. Microstructure development of alkali-activated fly ash cement: A descriptive model. Cem. Concr. Res. 2005, 35, 1204–1209. [Google Scholar] [CrossRef]

- Kamarudin, S.H.; Mohd Basri, M.S.; Rayung, M.; Abu, F.; Ahmad, S.B.; Norizan, M.N.; Abdullah, L.C. A review on natural fiber reinforced polymer composites (NFRPC) for sustainable industrial applications. Polymers 2022, 14, 3698. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Y.; Zhang, Y.; Bai, Y.; Dai, H. Effect of Quartz Powder on Mid-Strength Fly Ash Geopolymers at Short Curing Time and Low Curing Temperature. Constr. Build. Mater. 2022, 346, 128401. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Bayrak, B.; Zeyad, A.M.; Kaplan, G.; Öz, A.; Aydın, A.C. Effect of hybrid fibers and high temperatures on the properties of geopolymer composites based on slag, metakaolin, and natural zeolite. Constr. Build. Mater. 2024, 451, 138898. [Google Scholar] [CrossRef]

- Bayrak, B.; Mostafa, S.A.; Öz, A.; Tayeh, B.A.; Kaplan, G.; Aydın, A.C. The effect of clinker aggregate on acid resistance in prepacked geopolymers containing metakaolin and quartz powder in the presence of ground blast furnace slag. J. Build. Eng. 2023, 69, 106290. [Google Scholar] [CrossRef]

- Agustini, N.K.A.; Triwiyono, A.; Sulistyo, D.; Suyitno, S. Mechanical Properties and Thermal Conductivity of Fly Ash-Based Geopolymer Foams with Polypropylene Fibers. Appl. Sci. 2021, 11, 4886. [Google Scholar] [CrossRef]

- Hung Anh, L.D.; Pásztory, Z. An overview of factors influencing thermal conductivity of building insulation materials. J. Build. Eng. 2021, 44, 102604. [Google Scholar] [CrossRef]

- Schiavoni, S.; D’Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

| Precursor | Oxide Composition (wt.%) | ||||||

|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | K2O | TiO2 | SO3 | |

| Fly ash | 59.27 | 30.35 | 3.68 | 2.24 | 2.57 | 0.66 | 0.33 |

| Diatomite | 78.99 | 15.90 | 2.62 | 0.28 | 1.38 | 0.35 | 0.40 |

| Chalcedonite | 94.35–99.54 | 0.40–3.69 | 0.12–0.49 | 0.01–0.10 | 0.06–0.42 | 0.06–0.42 | - |

| Sand | 98.99 | - | 0.18 | 0.17 | 0.33 | - | 0.13 |

| Cement | - | 82.86 | - | 17.08 | - | - | - |

| Microspheres | 55.59 | 38.05 | 2.41 | 0.80 | 2.15 | 0.78 | - |

| Sample ID | Sand [g] | Microspheres [g] | Fly Ash [g] | Chalcedonite/ Diatomite [g] | Cement [g] | Stabiliser [g] | Wood Wool [g] | H2O2 [mL] | Alkaline Activator [mL] |

|---|---|---|---|---|---|---|---|---|---|

| Ref. F.A. | 80 | 160 | 795 | - | 100 | 5 g | - | 25 | 350 |

| Ref. F.A + D | 80 | 160 | 681 | 114 | 100 | 5 g | - | 25 | 375 |

| Ref. F.A + CH | 80 | 160 | 681 | 114 | 100 | 5 g | - | 25 | 375 |

| Ref. F.A + CH + D | 80 | 160 | 681 | 57 CH + 57 D | 100 | 5 g | - | 25 | 375 |

| F.A. + WW | 80 | 160 | 795 | - | 100 | 5 g | 12 | 25 | 425 |

| F.A. + D + WW | 80 | 160 | 681 | 114 | 100 | 5 g | 12 | 25 | 425 |

| F.A. + CH + WW | 80 | 160 | 681 | 114 | 100 | 5 g | 12 | 25 | 375 |

| F.A. + CH + D + WW | 80 | 160 | 681 | 57 CH + 57 D | 100 | 5 g | 12 | 25 | 375 |

| Sample ID | Compressive Strength [MPa] |

|---|---|

| Ref. F.A. | 1.86 |

| Ref. F.A + D | 1.56 |

| Ref. F.A + CH | 0.80 |

| Ref. F.A + CH + D | 1.58 |

| F.A. + WW | 2.00 |

| F.A. + D + WW | 0.90 |

| F.A. + CH + WW | 1.26 |

| F.A. + CH + D + WW | 1.50 |

| Sample ID | Density [kg/m3] | Thermal Conductivity at 0–20 °C [W/m × K] | Thermal Resistance [m2 × K/W] | Specific Heat at 27.5–32.5 °C [kJ/kg × K] |

|---|---|---|---|---|

| Ref. F.A. | 395.700 | 0.10288 ± 0.02 | 0.2537 | 1.438 ± 0.07 |

| Ref. F.A + D | 429.628 | 0.10506 ± 0.01 | 0.2474 | 1.405 ± 0.04 |

| Ref. F.A + CH | 402.740 | 0.12043 ± 0.01 | 0.2203 | 1.839 ± 0.04 |

| Ref. F.A + CH + D | 395.606 | 0.10265 ± 0.03 | 0.2547 | 1.511 ± 0.06 |

| F.A. + WW | 636.274 | 0.13448 ± 0.02 | 0.1367 | 1.456 ± 0.03 |

| F.A. + D + WW | 433.024 | 0.10642 ± 0.02 | 0.2106 | 1.627 ± 0.04 |

| F.A. + CH + WW | 369.069 | 0.11412 ± 0.01 | 0.2352 | 1.968 ± 0.05 |

| F.A. + CH + D + WW | 415.139 | 0.10154 ± 0.03 | 0.2529 | 1.529 ± 0.03 |

| Component | Content in Mix [% wt.] | Emission Factor [kg CO2/kg] | Estimated CO2 Contribution [kg CO2/kg] |

|---|---|---|---|

| Fly ash (waste) | ~60% | ~0.02 (transport only) | 0.012 |

| Diatomite (natural) | ~7% | 0.10–0.15 | 0.009–0.011 |

| Chalcedonite | ~7% | ~0.10 | 0.007 |

| Wood wool | ~1% | 0.05–0.10 | 0.0005–0.001 |

| High alumina cement | ~8% | 0.85–0.95 | 0.068–0.076 |

| Microspheres | ~12% | 0.20–0.30 (incl. processing) | 0.024–0.036 |

| Sand | ~6% | 0.04–0.06 | 0.0025–0.0035 |

| Surfactant, others | ~<1% | 1.00 (small mass) | <0.005 |

| Total (estimate) | 100% | – | ~0.12–0.15 kg CO2/kg dry mix |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Przybek, A.; Piątkowski, J.; Romańska, P.; Łach, M.; Masłoń, A. Low-Carbon Insulating Geopolymer Binders: Thermal Properties. Sustainability 2025, 17, 6898. https://doi.org/10.3390/su17156898

Przybek A, Piątkowski J, Romańska P, Łach M, Masłoń A. Low-Carbon Insulating Geopolymer Binders: Thermal Properties. Sustainability. 2025; 17(15):6898. https://doi.org/10.3390/su17156898

Chicago/Turabian StylePrzybek, Agnieszka, Jakub Piątkowski, Paulina Romańska, Michał Łach, and Adam Masłoń. 2025. "Low-Carbon Insulating Geopolymer Binders: Thermal Properties" Sustainability 17, no. 15: 6898. https://doi.org/10.3390/su17156898

APA StylePrzybek, A., Piątkowski, J., Romańska, P., Łach, M., & Masłoń, A. (2025). Low-Carbon Insulating Geopolymer Binders: Thermal Properties. Sustainability, 17(15), 6898. https://doi.org/10.3390/su17156898